Page 1

Ordering number: EN 5227A

Thick Film Hybrid IC

STK672-040

Microstep Operation-Supported

4-Phase Stepping Motor Driver (I

= 1.5A)

O

Overview

The STK672-040 is a unipolar constant-current choppertype externally-excited 4-phase stepping motor driver

hybrid IC which uses MOSFET power devices. It has a

microstep operation-supported 4-phase distributed controller built-in to realize a high torque, low vibration, low

noise stepping motor driver using a simple control circuit.

Applications

• Printer, copier, and X-Y plotter stepping motor drivers

Features

• Microstep sine-wave driver operation using only an

external clock input (0.33 Ω current detection resistor

built-in)

• Microstep drive using only an external reference v oltage

setting resistor

• 2, 1-2, W1-2, 2W1-2, 4W1-2 phase excitation selectable

using external pins

• Selectable vector locus (perfect circle mode, inside 1

mode, outside 2 modes) to match motor characteristics

in microstep drive state

• Phase hold function during excitation switching

• Schmitt trigger inputs with built-in pull-up resistor

(20k Ω )

• Monitor output pin enabling real-time confirmation of

IC excitation

• The CLK and RETURN inputs provide an internal

noise elimination circuit as well as CMOS Schmitt circuit to prevent malfunction due to impulse noise.

• 4-phase distribution switch timing selected externally to

either CLK rising-edge only detection mode or both rising-edge and falling-edge detection mode

• ENABLE pin for excitation current cutoff, thereby

reducing system current drain when driver is stopped

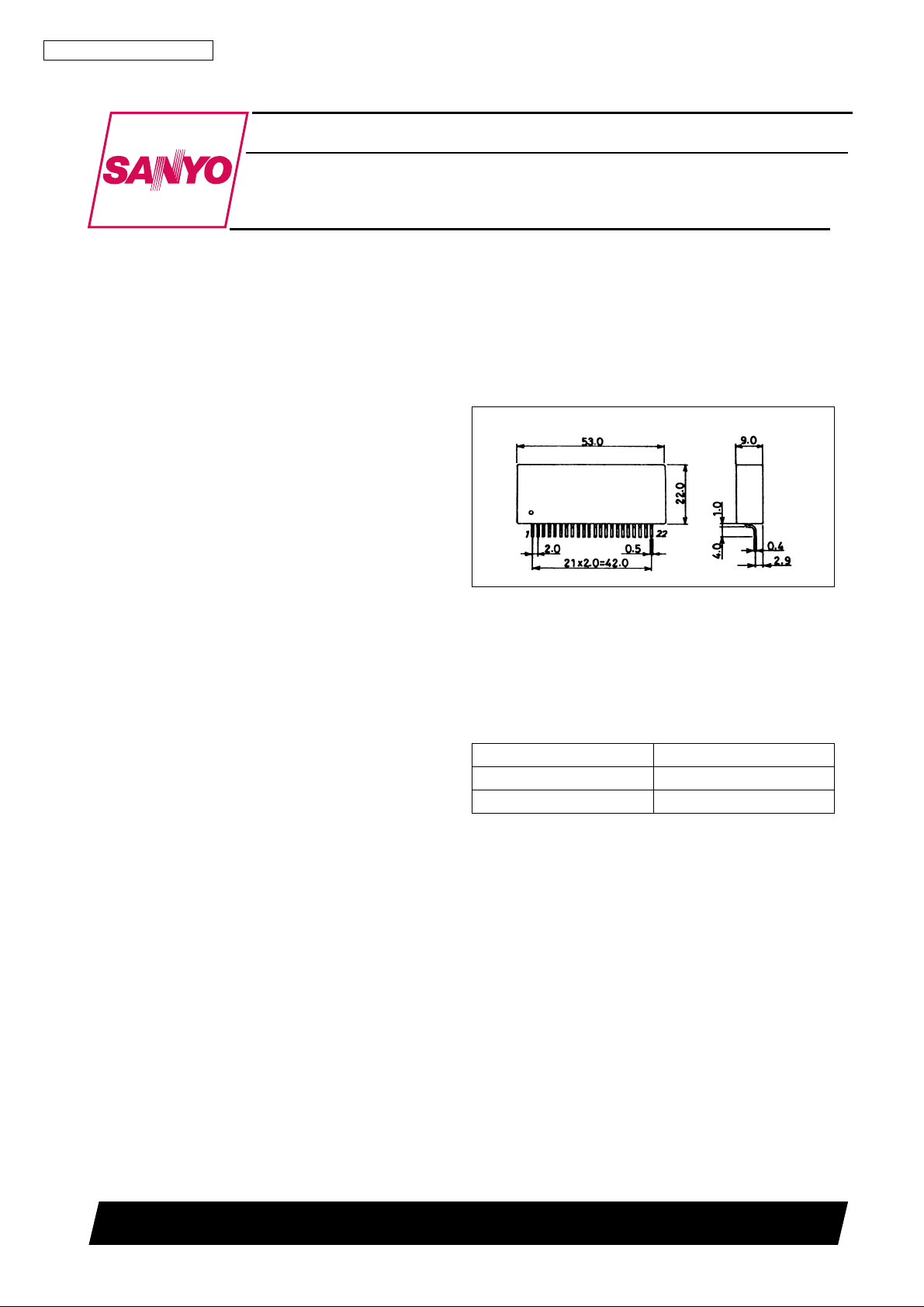

Package Dimensions

unit: mm

4161

[STK672-040]

Series Organization

The following devices form a series with differing output

capacity.

Type No. Output current (A)

STK672-040 1.5

STK672-050 3.0

SANYO Electric Co., Ltd. Semiconductor Business Headquarters

TOKYO OFFICE Tokyo Bldg., 1-10, 1 Chome, Ueno, Taito-ku, TOKYO, 110 JAPAN

10997HA(ID) / 110896HA(ID) No. 5227—1/11

Page 2

Specifications

−

−

°

°

−

° C

Ω

µ

µ A

µ A

STK672-040

Maximum Ratings

at Ta = 25 ° C

Parameter Symbol Conditions Ratings Unit

Maximum supply voltage 1

Maximum supply voltage 2 V

Input voltage V

Phase output current I

V

1 max No signal 52 V

CC

2 max No signal

CC

max Logic input block

IN

One 0.5s pulse, V

max

OH

Load/phase: R = 5 Ω , L = 10mH

1 applied,

CC

0.3 to +7.0 V

0.3 to +7.0 V

2.2 A

Repetitive avalanche handling capability Ear max 38 mJ

Maximum output dissipation Pd max θ c–a = 0 12 W

Operating substrate temperature Tc max 105

Junction temperature Tj max 150

Storage temperature Tstg

Allowable Operating Ranges

at Ta = 25 ° C

40 to +125

Parameter Symbol Conditions Ratings Unit

Supply voltage 1 V

Supply voltage 2 V

Input voltage V

Phase driver withstand voltage V

Phase current I

1 With signal 10 to 45 V

CC

2 With signal 5.0 ± 5% V

CC

0 to V

IH

Tr1, 2, 3, 4 (A, A

DSS

max 50% duty 1.5 (max) A

OH

, B, B outputs) 100 (min) V

2V

CC

C

C

Electrical Characteristics

at Tc = 25 ° C, V

1 = 24V, V

CC

CC

2 = 5V

Parameter Symbol Conditions min typ max Unit

Control supply current I

Output saturation voltage Vsat R

Average output current Io ave

Pin 7 input, ENABLE = low – 4.5 15 mA

CC

= 15 Ω (I = 1.5A) – 1.4 1.9 V

L

Vref = 1V,

Load/phase: R = 3.5

, L = 3.8mH

0.465 0.517 0.569 A

FET diode forward voltage Vdf If = 1.0A – 1.2 1.8 V

[Control inputs]

V

Excluding Vref pin 4.0 – – V

Input voltage

Input current

IH

V

Excluding Vref pin – – 1.0 V

IL

I

Excluding Vref pin 0 1 10

IH

I

Excluding Vref pin 125 250 510

IL

[Vref input]

Input voltage V

Input current I

Pin 8 0 – 2.5 V

I

Pin 8 – 1 –

I

[Control outputs]

V

I = − 3mA (MoI, Mo1, Mo2 pins) 2.4 – – V

Output voltage

OH

V

I = +3mA (MoI, Mo1, Mo2 pins) – – 0.4 V

OL

PWM frequency fc 37 47 57 kHz

[Current division ratio (A/B)]

2W1-2, W1-2, 1-2 Vref θ = 1/8 100 %

2W1-2, W1-2 Vref θ = 2/8 92 %

2W1-2 Vref θ = 3/8 83 %

2W1-2, W1-2, 1-2 Vref θ = 4/8 71 %

A

No. 5227—2/11

Page 3

STK672-040

2W1-2 Vref θ = 5/8 55 %

2W1-2, W1-2 Vref θ = 6/8 40 %

2W1-2 Vref θ = 7/8 20 %

2 Vref 100 %

Note: All tests are made using a constant-voltage supply.

The current division ratio shows the design value.

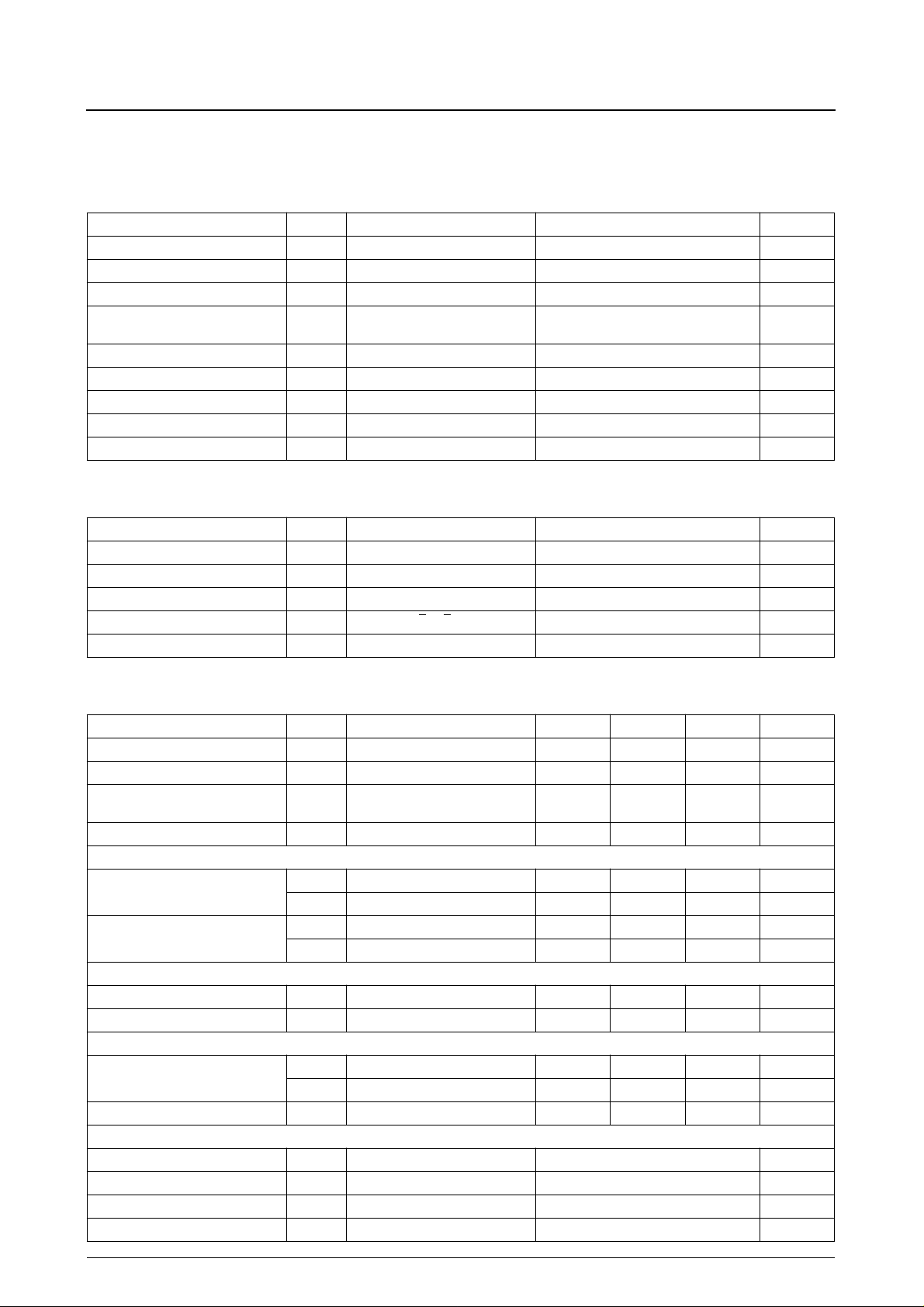

Equivalent Block Diagram

Sample Application Circuit

2W1-2 phase excitation (microstep operation)

No. 5227—3/11

Page 4

STK672-040

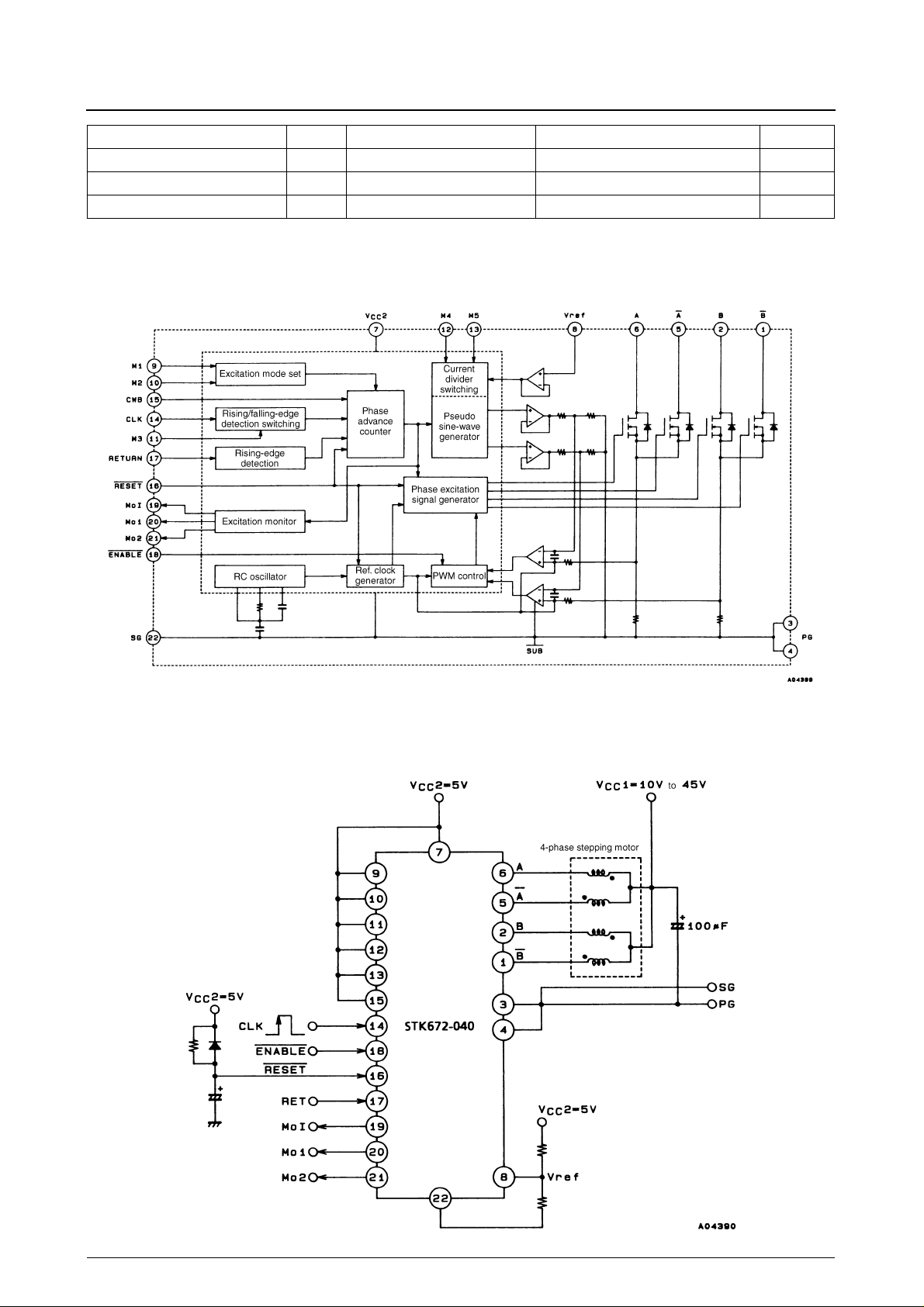

Motor Current Calculation

The motor current I

age on pin 8 (Vref). The relationship between I

Vref is given by the following equation.

1

OH

---

Vref Rs ⁄×

=

3

I

is determined by the reference volt-

OH

OH

Motor current waveform

Function T ables

M1 M2 M3 Excitation Phase switching CLK edge timing

0 0 0 Phase 1-2

0 1 0 Phase 2W1-2

1 0 0 Phase W1-2

1 1 0 Phase 4W1-2

0 0 1 Phase 2

0 1 1 Phase W1-2

1 0 1 Phase 1-2

1 1 1 Phase 2W1-2

Rising and falling edge

Rising edge only

and

where Rs is the built-in current detection resistance

(0.33 Ω ± 3%).

The motor current ranges from the current due to the frequency duty set by the oscillator (0.05 to 0.1A) to the

allowable operating range maximum of I

Input Active level

ENABLE

RESET Low

Mo1 Mo2 Output

00A

01B

10A

11B

= 1.5A.

OH

Low

CWB Direction

0 Forward

1 Reverse

No. 5227—4/11

Page 5

Design material

1. Explanation of input pins

Pin No. Name Function Pin format

14 CLK Phase switching phase CMOS Schmitt configuration with pull-down resistor

■

■

■

■

15 CWB Setting of rotation direction (CW/CCW) CMOS Schmitt configuration with pull-down resistor

17 RETURN Phase origin forced return CMOS Schmitt configuration with pull-down resistor

18 ENABLE

9, 10, 11 M1, M2, M3 Setting of exciting mode CMOS Schmitt configuration with pull-down resistor

12, 13 M4, M5 Setting of vector locus CMOS Schmitt configuration with pull-down resistor

16 RESET System reset CMOS Schmitt configuration with pull-down resistor

8 Vref Setting of current value CMOS Schmitt configuration with pull-down resistor

2. Functions and timing of input signals

2-1. CLK (Phase switching clock)

1. Input frequency range ■ DC to 50 kHz

2. Minimum pulse width ■ 10 µ s

3. Duty

4. Pin format

5. Noise eliminating circuit with multiple stages is contained.

6. Functions

a. When the signal M3 is set to 1 or it is opened.

b. When the signal M3 is set to 0

Output cut-off CMOS Schmitt configuration with pull-down resistor

40 to 60%

CMOS Schmitt containing pull-up resistor (20 k Ω typical value)

The exciting phase moves at each step at the leading edge of the clock.

The exciting phase moves at each step at the leading and trailing edges of the clock.

STK672-040

2-2. CWB (Setting of rotation direction)

1. Pin format

CMOS Schmitt configuration containing pull-up resistor

(20k Ω , typical value)

2. Function

a. When the signal CWB is set to 1

It rotates clockwise.

b. When the signal CWB is set to 0

It rotates counterclockwise.

3. Note

When the signal M3 is set to 0, the CWB input signal must not be changed

at the leading edge and trailing edge of the clock input for the period of 5 µ s.

No. 5227—5/11

Page 6

STK672-040

2-3. RETURN (It forcibly returns the phase to the origin of current exciting phase.)

1. Pin format

CMOS Schmitt configuration containing pull-up resistor

(20k Ω , typical value)

2. Noise eliminating circuit is contained.

3. Function

2-4. ENABLE

(ON/OFF control of exciting drive output A, A, B, and B and selection of

Forces to moves to the origin of current exciting phase by

setting the RETURN signal to high state.

■

■

■

■

■

operation/hold state in HI-IC)

1. Pin format

CMOS Schmitt configuration containing pull-up resistor

(20 k Ω , typical value)

2. Function

a. When the ENABLE signal is set to a high state or it is opened.

It is usually placed in the operation status.

b. When the ENABLE signal is set to a low state

The H-IC is placed into the hold state, forcing the exciting drive output to be turned off.

At this time, the system clock of the HC stops, the H-IC is not affected if the input pin other

than the reset input changes.

2-5. M1, M2, and M3 (Selection of exciting modes and clock input edge timing)

1. Pin format

CMOS Schmitt configuration containing the pull-up resistor

(20 k Ω typical value)

2. Functions

M20011

M1

M3

1 2 phase exciting 1-2 phase exciting W1-2 phase exciting 2W1-2 phase exciting Only the leading edge

0 1-2 phase exciting W1-2 phase exciting 2W1-2 phase exciting 4W1-2 phase exciting Leading edge and trailing edge

0101

Phase switching clock edge timing

3. Valid timing of mode setting

The mode must not be changed within 5 µ s from the leading edge and

trailing edge of the clock.

No. 5227—6/11

Page 7

STK672-040

2-6. M4 and M5 (Setting of rotation vector locus at micro-step)

M4 1 0 1 0

M5 1 0 0 1

Mode Real circle

For the current division ratio, see Section 4.3.

■

➀➁➂

■

■

■

■

■

■

■

2-7. RESET

1. Pin format

(Reset of entire system)

CMOS Schmitt configuration containing the pull-up resistor

(20 k Ω typical value)

2. Function

All circuit states are set to the initial values by setting the RESET signal to the

low state (pulse width of 10 µ s or more). At this time, for all modes including

the exciting mode, the A and B phases are set to the origin.

2-8. Vref(Setting of the current value used as the reference of constant current detection)

1. Pin format

2. Function

Analog input configuration

By applying the voltage of 2.5 V or less of the control system power source

Vcc2, the constant current control can be performed over the exciting current of

the motor at the 100% of the rated current value.

The constant current can be controlled in proportional to the Vref voltage with

this value specified as a high limit.

3. Explanation of output pins

Pin No. Name Function Pin format

19 MoI Phase exciting origin monitor CMOS standard configuration

20, 21 Mo1, Mo2 Phase exciting state monitor CMOS standard configuration

4. Functions and timing of output signals

4-1. A, A

4-2. MO1, MO2, and MOI (Monitor of exciting state)

, B, and B (Output for phase exciting use of motor)

1. Function

In four phase two exciting mode, the interval of 3.75 µ s (typical value)

is set when the output signals of the phases A and A, B and B change.

1. Pin format

2. Function

CMOS standard configuration

Outputs the state of the current phase exciting output.

Phase coordinate A phase B phase A

Mo1 1 0 0 1

Mo2 0 1 0 1

For the MOI, 0 is output at the origin of each phase.

At other points, 1 is output.

phase B phase

No. 5227—7/11

Page 8

STK672-040

4-3. Current division ratio based on M3, M4, and M5 . . . . . . . . . . . . . . . . . . . Reference values

Mode Real circle ➀➁➂

Setting M3 = 0 M3 = 1

2W1-2 20 25 23 19 1 / 8 2 / 16

2W1-2 40 44 42 39 2 / 8 4 / 16

2W1-2 55 62 57 54 3 / 8 6 / 16

4W1–2

Current division ratio

2W1-2 71 77 71 69 4 / 8 8 / 16

2W1-2 83 88 85 82 5 / 8 10 / 16

2W1-2 92 95 95 92 6 / 8 12 / 16

2W1-2 100 100 100 100 7 / 8 14 / 16

M4 = 1 M4 = 0 M4 = 1 M4 = 0

M5 =1 M5 = 0 M5 =1 M5 = 0

14 15 15 13

31 34 33 28 3 / 16

48 51 49 45 5 / 16

65 69 65 62 7 / 16

77 82 77 74 9 / 16

88 92 89 85 11 / 16

97 98 98 94 13 / 16

Unit Number of steps

%

1 / 16

[Load conditions]

Vccl = 24V, Vcc2 = 5V, R / L = 3.5 Ω / 3.8mH

No. 5227—8/11

Page 9

STK672-040

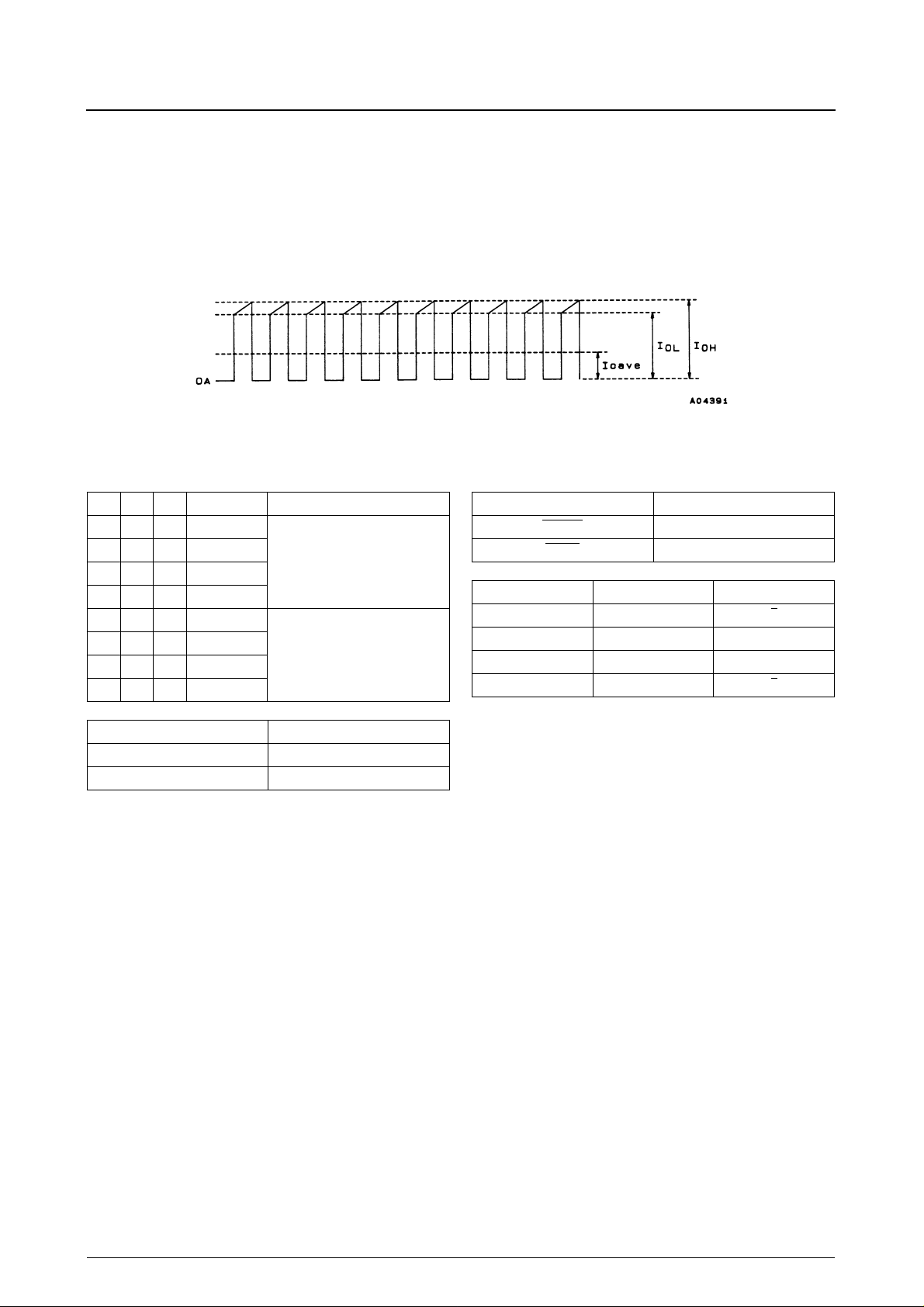

5. Phase exciting and timing chart

5-1. Leading edge operation of clock

• 2 phase exciting • 1-2 phase exciting

• W1-2 phase exciting • 2W-2 phase exciting

No. 5227—9/11

Page 10

STK672-040

5-2. Leading edge and trailing edge operation of clock

• 2 phase exciting • 1-2 phase exciting

• W1-2 phase exciting • 2W-2 phase exciting

No. 5227—10/11

Page 11

STK672-040

■

No products described or contained herein are intended for use in surgical implants, life-support systems, aerospace equipment, nuclear

power control systems, vehicles, disaster/crime-pre v ention equipment and the lik e, the failure of which may directly or indirectly cause injury,

death or property loss.

■

Anyone purchasing any products described or contained herein for an above-mentioned use shall:

➀

Accept full responsibility and indemnify and defend SANYO ELECTRIC CO., LTD., its affiliates, subsidiaries and distributors and all their

officers and employees, jointly and severally, against any and all claims and litigation and all damages, cost and expenses associated

with such use:

➁

Not impose any responsibility for any fault or negligence which may be cited in any such claim or litigation on SANYO ELECTRIC CO.,

LTD., its affiliates, subsidiaries and distributors or any of their officers and employees, jointly or severally.

■

Information (including circuit diagrams and circuit parameters) herein is for e xample only; it is not guaranteed for volume production. SANYO

believes information herein is accurate and reliable, but no guarantees are made or implied regarding its use or any infringements of

intellectual property rights or other rights of third parties.

This catalog provides information as of January, 1997. Specifications and information herein are subject to change without notice.

No. 5227—11/11

Loading...

Loading...