Page 1

8 Kbit Serial SPI EEPROM with Positive Clock Strobe

1 MILLION ERASE/WRITE CYCLES

40 YEARS DA TA RETE NT ION

SINGLE 3V to 5.5V SUPPLY VOLTAGE

SPI BUS COMPATIBLE SERIAL INTERFACE

2 MHz CLOCK RA TE MAX

BLOCK WRITE PROTECTION

STATUS REGISTER

16 BYTE PAGE MODE

WRITE PROTECT

SELF-TIMED PROGRAMMING CY CLE

E.S.D.PROTECTION GREATER than 4000V

SUPPO RTS POSITIVE CLOCK SPI MODES

8

1

PSDIP8 (B)

0.25mm Frame

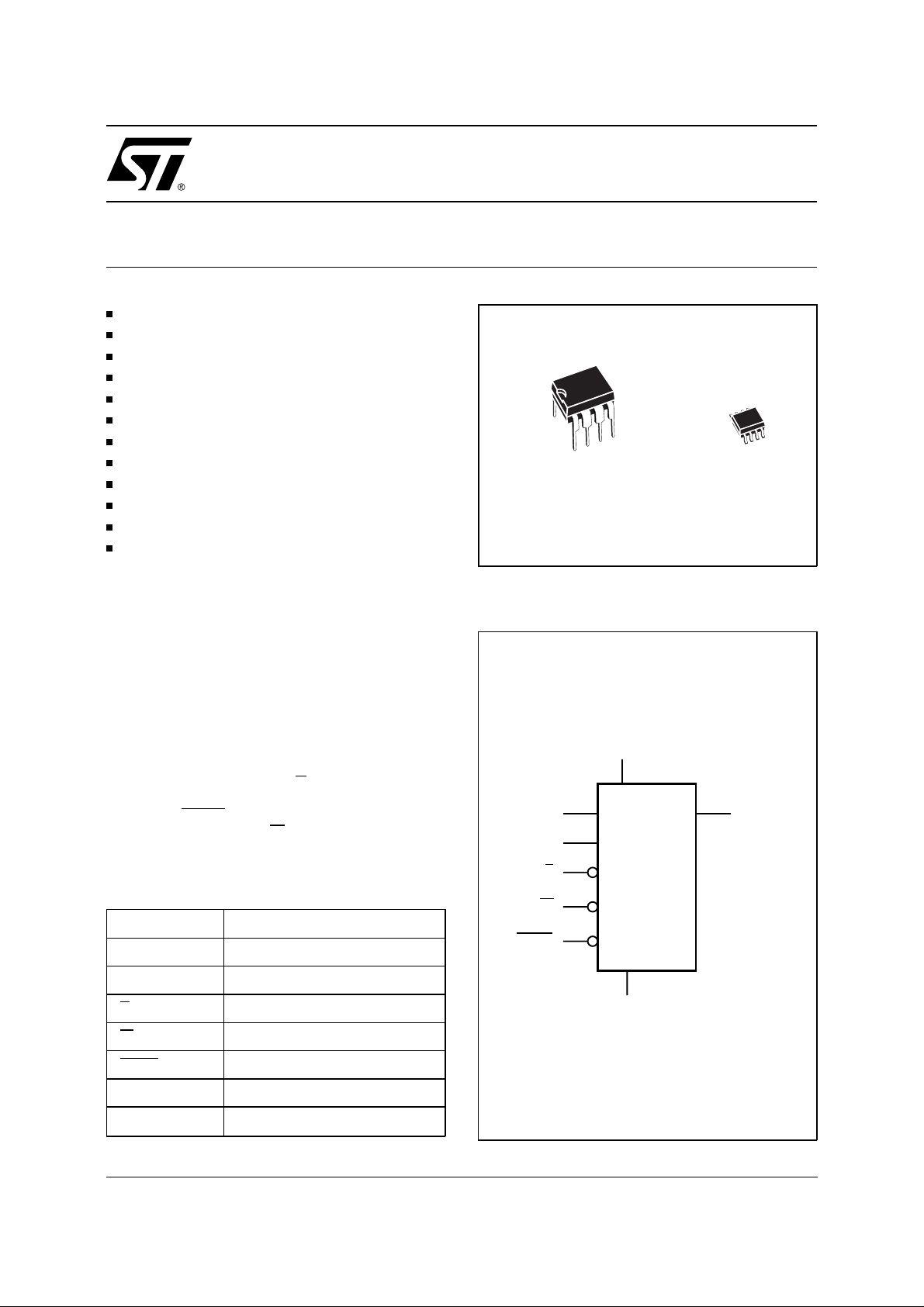

ST95P08

8

1

SO8 (M)

150mil Width

DESCRIPTION

The ST95P08 is an 8 Kbit Electrically Erasable

Programmable Memory (EEPROM) fabricated with

STMicroelectronics’s High Endurance Single

Polysilicon CMOS technology. The 8 Kbit memory

is organised as 64 pages of 16 by tes. The memory

is accessed by a simple SPI bus c ompatible serial

interface. The bus signals are a serial clock input

(C), a serial data input (D) and a serial data output

(Q). The device connected to t he bus is selected

when the chip select input (

S) goes low. Communications with the chip can be interrupted with a

hold input (

by a write protect input (

HOLD). The write operation is disabled

W).

T ab le 1. Signal Names

C Serial Clock

D Serial Data Input

Q Serial Data Output

S Chip Select

W Write Protect

Figure 1. Logic Diagram

V

CC

D

C

S

W

HOLD

ST95P08

V

SS

Q

AI01315

HOLD Hold

V

CC

V

SS

February 1999 1/16

Supply Voltage

Ground

Page 2

ST95P08

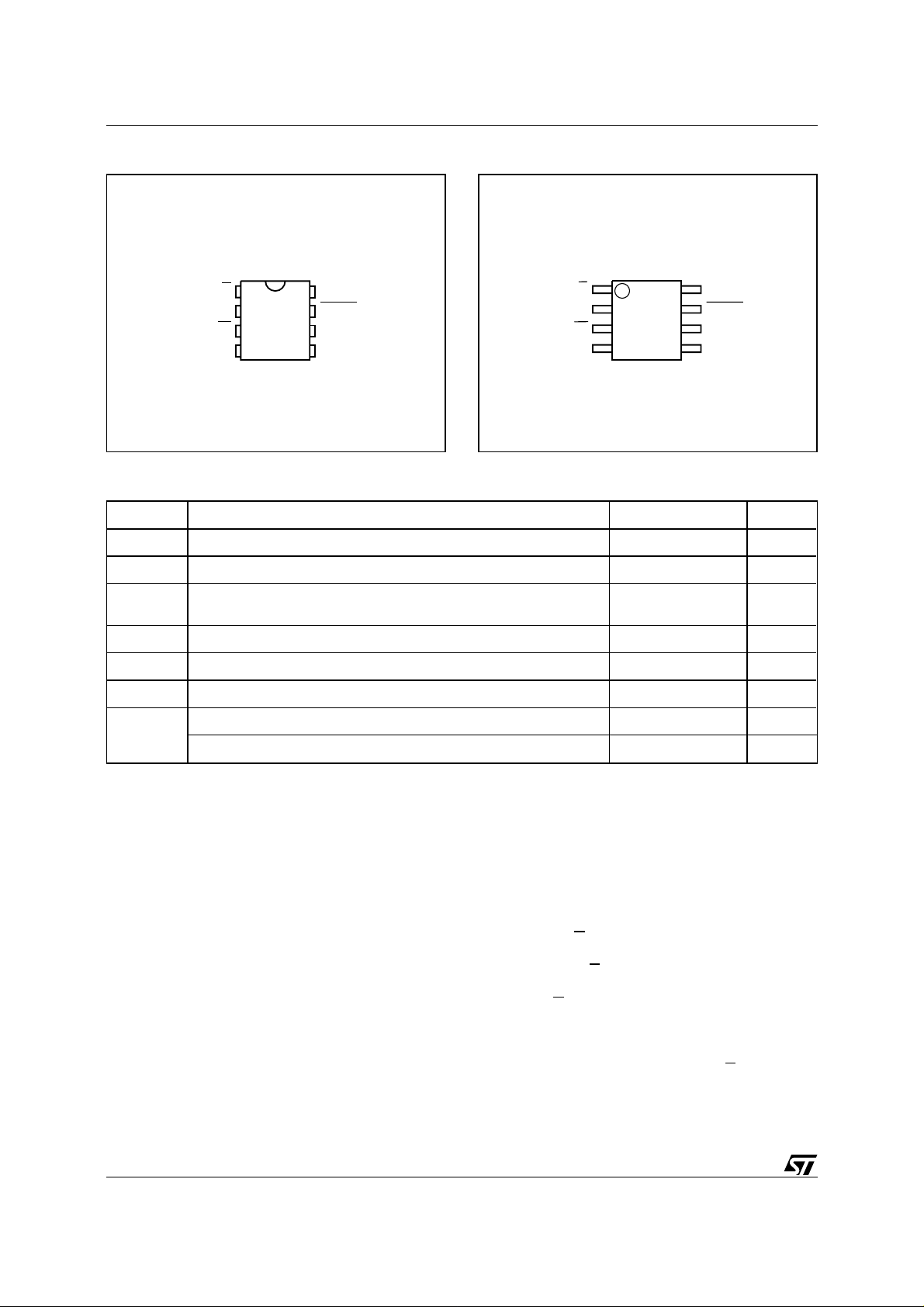

Figure 2A. DIP Pin Connections

ST95P08

1

SV

2

3

W

4

SS

T ab le 2. Absolute Maximum Ratings

Symbol Parameter Value Unit

T

T

T

A

STG

LEAD

Ambient Operating Temperature

Storage Temperature –65 to 150 °C

Lead Temperature, Soldering (SO8 package) 40 sec

8

7

6

5

AI01316

CC

HOLDQ

C

DV

(1)

(2)

(PSDIP8 package) 10 sec

Figure 2B. SO Pin Connections

ST95P08

1

SV

2

3

W

SS

4

8

7

6

5

AI01317B

–40 to 85 °C

215

260

CC

HOLDQ

C

DV

°C

V

O

V

V

CC

V

ESD

Notes:

1. Except for the rating "Operating T emperature Range", stresses above those listed in the Table "Absolute Maximum Ratings"

2. Depends on range.

3. MIL-STD-883C, 3015.7 (100pF, 1500Ω)

4. EIAJ IC-121 (Condition C) (200pF , 0Ω)

SIGNALS DESCRIPTION

Serial Output (Q ).

fer data serially out of the ST95P08. Data is shifted

out on the falling edge of the serial clock.

Serial Input (D) .

data serially into the device. It receives instructions,

addresses, and data to be written. Input is latched

on the rising edge of the serial clock.

Serial Clock (C).

timing of the serial interface. Instructions, addresses, or data present at the input pin are latched

Output Voltage –0.3 to VCC +0.6 V

Input Voltage –0.3 to 6.5 V

I

Supply Voltage –0.3 to 6.5 V

Electrostatic Discharge Voltage (Human Body model)

Electrostatic Discharge Voltage (Machine model)

may cause permanent damage to the device. These are stress rating s only and operation of the device at these or any other

conditions above those indicated in the Operating sections of this specification is not implied. Exposure to Absolute Maximum

Rating conditions for extended periods may affect device reliability. Refer also to the STMicroelectronics SURE Program and

other relevant quality documents.

(3)

(4)

4000 V

500 V

the Q pin changes after the falling edge of the clock

The output pin is used to trans-

input.

Chip Select (

S).

This input is used to select the

ST95P08. The chip is selected by a high to low

The input pin is used to transfer

transition on the

time, the chip is deselected by a low t o high t ransition on the

S pin when C is at ’0’ state. At any

S pin when C is at ’0’ state. As soon as

the chip is deselected, the Q pin is at high impedance state. This pin allows multiple ST95P08 to

The serial clock provides the

share the same SPI bus. After power up, the chip

is at the deselect state. T r ansition of

when C is at ’1’ state.

on the rising edge of the clock input, while data on

S are ignored

2/16

Page 3

Figure 3. Block Diagram

ST95P08

HOLD

W

S

C

D

Q

Control Logic

I/O Shift Register

Address Register

and Counter

Y Decoder

High Voltage

Generator

Data

Register

Status

Block

Protect

16 Bytes

X Decoder

AI01272

3/16

Page 4

ST95P08

T able 3. AC Measurement Conditions

Figure 4. AC Testing Input Output Waveforms

Input Rise and Fall Times ≤ 50ns

0.8V

0.2V

CC

CC

Input Pulse Voltages 0.2V

Input and Output Timing

Reference Voltages

Note that Output Hi-Z is defined as the point where data is no

longer driven.

T able 4. Input Parameters

(1)

(TA = 25 °C, f = 1 MHz )

0.3V

to 0.8V

CC

to 0.7V

CC

CC

CC

Symbol Parameter Min Max Unit

C

IN

C

IN

t

LPF

Note:

1. Sampled only, not 100% tested.

Input Capacitance (D) 8 pF

Input Capacitance (other pins) 6 pF

Input Signal Pulse Width 10 ns

Tabl e 5. DC Characteristics

(T

= 0 to 70°C or –40 to 85°C; VCC = 3V to 5.5V)

A

0.7V

0.3V

AI00825

CC

CC

Symbol Parameter Test Condition Min Max Unit

I

LI

I

LO

I

CC

I

CC1

V

IL

V

IH

V

OL

V

OH

Input Leakage Current 2 µA

Output Leakage Current ±2 µA

VCC Supply Current (Active)

C = 0.1 V

@ 2 MHz, Q = Open

S = VCC, VIN = VSS or VCC,

VCC Supply Current (Standby)

S = VCC, VIN = VSS or VCC,

Input Low Voltage – 0.3 0.3 V

Input High Voltage 0.7 V

Output Low Voltage IOL = 2mA 0.2 V

Output High Voltage IOH = –2mA 0.8 V

V

V

= 5.5V

CC

CC

/0.9 VCC ,

CC

= 3V

CC

CC

2mA

50 µA

10 µA

CC

V

VCC + 1 V

CC

V

V

4/16

Page 5

ST95P08

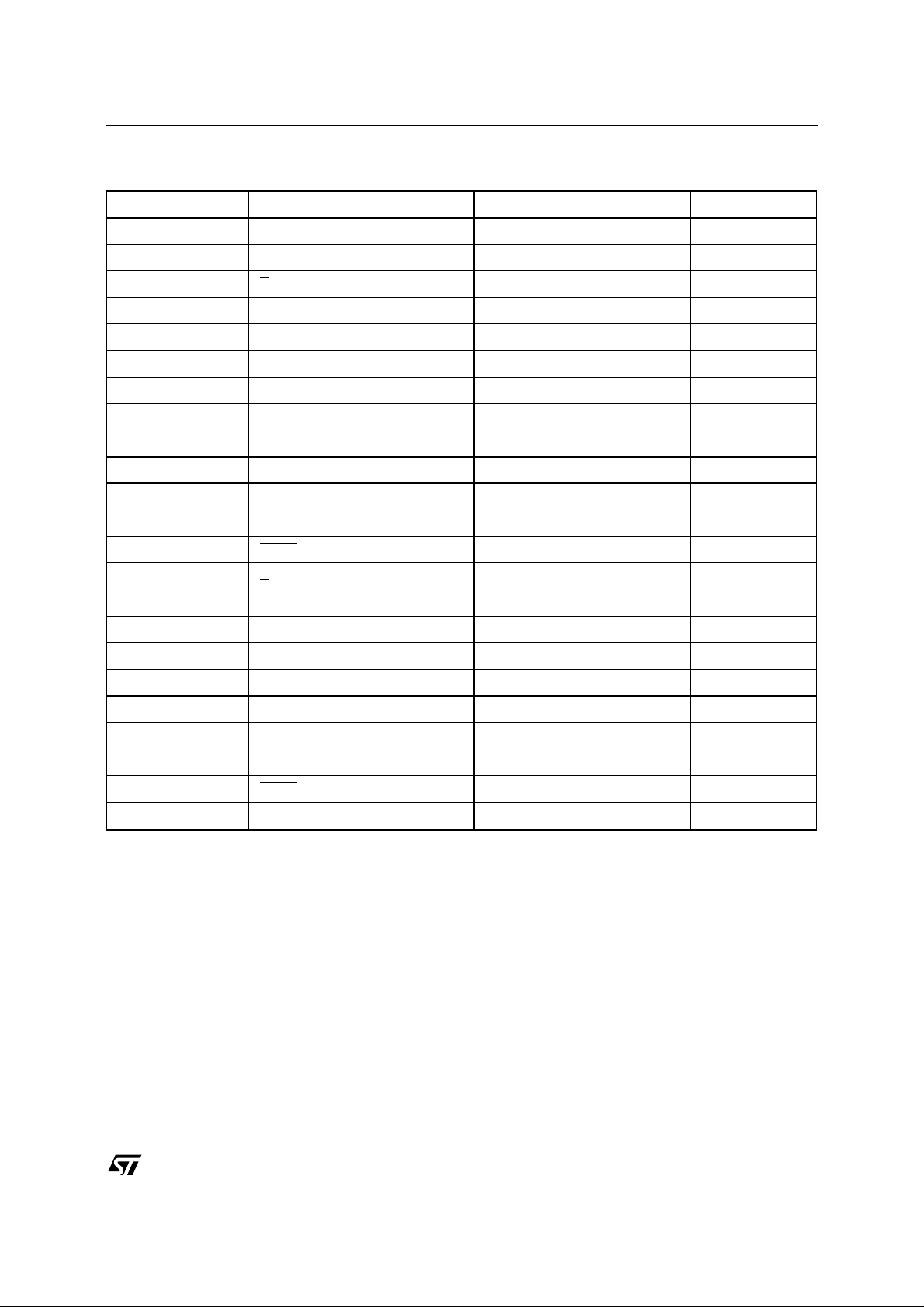

Table 6. AC Characteristics

(T

= 0 to 70°C or –40 to 85°C; VCC = 3V to 5.5V)

A

Symbol Alt Parameter Test Condition Min Max Unit

f

C

t

SLCH

t

CLSH

t

CH

t

CL

t

CLCH

t

CHCL

t

DVCH

t

CHDX

t

DLDH

t

DHDL

t

HXCH

t

CLHX

t

SHSL

t

SHQZ

t

QVCL

t

CLQX

t

QLQH

t

QHQL

t

HHQX

t

HLQZ

(1)

t

W

Note:

1. Not enough characterisation data were availa ble on this parameter at the time of issue this Data Sheet. The typical value is well

below 5ms, the maximum value will be reviewed and lowered when sufficient data is available.

t

t

t

t

t

t

t

DSU

t

t

t

HSU

t

t

t

t

t

t

t

t

f

SU

SH

WH

WL

RC

FC

DH

t

HH

CS

DIS

t

HO

RO

FO

HZ

t

C

Clock Frequency D.C. 2 MHz

S Setup Time 50 ns

S Hold Time 50 ns

Clock High Time 200 ns

Clock Low Time 300 ns

Clock Rise Time 1 µs

Clock Fall Time 1 µs

Data In Setup Time 50 ns

Data In Hold Time 50 ns

RI

FI

Data In Rise Time 1 µs

Data In Fall Time 1 µs

HOLD Setup Time 50 ns

HOLD Hold Time 50 ns

S Deselect Time

4.5V < V

3V < V

< 5.5V 200 ns

CC

< 4.5V 250 ns

CC

Output Disable Time 150 ns

V

Clock Low to Output Valid 300 ns

Output Hold Time 0 ns

Output Rise Time 100 ns

Output Fall Time 100 ns

LZ

HOLD High to Output Low-Z 150 ns

HOLD Low to Output High-Z 150 ns

W

Write Cycle Time 10 ms

5/16

Page 6

ST95P08

Figure 5. Output Timing

S

C

tCLQX

tQVCL

tCH

tCL

tSHQZ

Q

D

ADDR.LSB IN

MSB OUT MSB-1 OUT LSB OUT

Figure 6. Serial Input Timing

S

C

tDVCH

tSLCH

tCHDX

tQLQH

tQHQL

AI01070B

tSHSL

tCLSH

tCHCL

tCLCH

6/16

D

Q

MSB IN

HIGH IMPEDANCE

tDLDH

tDHDL

LSB IN

AI01071

Page 7

Figure 7. Hold Timing

S

C

Q

D

HOLD

tCLHX

ST95P08

tHXCH

tHXCH

tCLHX

tHHQXtHLQZ

AI01072B

Write Protect (

protect. When

W).

This pin is for hardware write

W is low, non-volatile writes to the

ST95P08 are disabled but any other operation

stays enabled. When

including non-volatile writes are available.

W is high, all operations

W going

low at any time before the last bit D0 of the data

stream will reset the write enable latch and prevent

programming. No action on

W or on the write

enable latch can interrupt a write cycle which has

commenced.

HOLD ).

Hold (

HOLD pin is used to pause

The

serial communications with a ST95P08 without

resetting the serial sequence. To take the Hold

condition into account, the product must be selected (

a high to low transition on

resume the communications,

S = 0). Then the Hold state is validated by

HOLD when C is low. To

HOLD is brought high

when C is low. During Hold condition D, Q, and C

are at a high impedance state.

When the ST95P08 is under Hold condition, it is

possible to deselect it. However, the serial communications will remain paused after a reselect, and

the chip will be reset.

OPERATIONS

All instructions, addresses and data are shifted in

and out of the chip MSB first. Data input (D) is

sampled on the first rising edge of clock (C) after

the chip select (

S) goes low. Prior to any operation,

a one-byte instruction code must be entered in the

chip. This code is entered via the data input (D),

and latched on the rising edge of the clock input

(C). To enter an instruction code, the product must

have been previously selected (

S = low). Table 7

shows the instruction set and format for device

operation. When an invalid instruction is sent (one

not contained in Table 7), the chip is automatically

deselected. For operations that read or write data

in the memory array, bit 3 of the instruction is the

MSB of the address, otherwise, it is a don’t care.

Write Enable (WREN) and Wri te Disable (WRDI)

The ST95P08 contains a write enable latch. This

latch must be set prior to every WRITE or WRSR

operation. The WREN instruction will set the latch

and the WRDI instruction will reset the latch. The

latch is reset under all the following conditions:

W pin is low

–

– Power on

– WRDI instruction executed

– WRSR instruction executed

– WRITE instruction executed

As soon as the WREN or WRDI instruction is

received by the ST95P08, the circuit executes the

instruction and enters a wait mode until it is deselected.

7/16

Page 8

ST95P08

Read Status Register (RDSR)

The RDSR instruction provides access to the status

register. The status register may be read at any

time, even during a non-volatile write. As soon as

the 8th bit of the status register is read out, the

ST95P08 enters a wait mode (data on D are not

decoded, Q is in Hi-Z) until it is deselected.

The status register format is as follows:

b7 b0

1 1 1 1 BP1 BP0 WEL WIP

BP1, BP0: Read and write bits

WEL, WIP: Read only bits.

During a non-volatile write to the memory array, all

bits BP1, BP0, WEL, WIP are valid and can be read.

During a non volatile write t o the status register , the

only bits WEL and WIP are valid and can be read.

The values of BP1 and BP0 read at that time

correspond to the previous contents of the status

register.

The Write-In-Process (WIP) read only bit indic ates

whether the ST95P08 is busy with a write operation. When set to a ’1’ a write is in progress, when

set to a ’0’ no write is in progress.

The Write Enable Latch (WEL) read only bit indicates the status of the write enable latch. When set

to a ’1’ the latch is s et, when set to a ’0’ t he latch is

reset.

The Block Protect (BP0 and BP1) bits indicate the

extent of the protection employed. These bits are

set by the user issuing the WRSR instruction.

These bits are non-volatile.

Write Status Register (WRSR)

The WRSR instruction allows the user to select the

size of protected memory . The ST95P08 is div ided

into four 2048 bit blo cks. The user may read the

blocks but will be unable to write within the selected

blocks.

The blocks and respective WRSR control bit s are

shown in Table 6.

When the WRSR instruction and the 8 bits of the

Status Register are latched-in, the internal write

cycle is then triggered by the rising edge of

rising edge of

S must appear after the 8th bit of the

S. This

Status Register content (it must not appear a 17th

clock pulse before the rising edge of

S), otherwise

the internal write sequence is not performed.

Read Operation

The chip is first selected by putting

S low. The serial

one byte read instruction is followed by a one byte

address (A7-A0), each bit being latched-in during

the rising edge of the clock (C). Bit 3 and 4 of the

read instruction contain address bits A9 and A8

(most significant address bits). These bits ar e used

to select the first or second page of the device.

Then, the data stored in the m emory at the selected

address is shifted out on the Q output pin; each bit

being shifted out during the falling edge of the clock

(C). The data stored in the memory at the next

address can be read in s equence by continuing to

provide clock pulses. The byte address is automat-

T ab le 7. Array Addresses P rotect

Status Register Bits

BP1 BP0

0 0 none

0 1 300h - 3FFh

1 0 200h - 3FFh

1 1 000h - 3FFh

Array Addresses

Protected

T ab le 8. Instruction Set

Instruction Description Instruction Format

WREN Set Write Enable Latch 000X X110

WRDI Reset Write Enable Latch 000X X100

RDSR Read Status Register 000X X101

WRSR Write Status Register 000X X001

READ Read Data from Memory Array 000A A011

WRITE Write Data to Memory Array 000A A 010

Notes:

A = 1, Upper page selected

A = 0, Lower page selected

X = Don’t care

8/16

Page 9

ST95P08

ically incremented to the next higher address after

each byte of data is shifted out. When the highest

address is reached (1FFh), the address counter

rolls over to 0h allowing the read cycle to be continued indefinitely. The read operation is terminated

by deselecting the chip. The chip can be deselected

at any time during data output. Any read attempt

during a non-volatile write cycle will be rejected and

will deselect the chip.

Byte Write Operation

Prior to any write attempt, the write enable lat ch

must have been set by issuing the WREN instruction. First, the device is selected (

S = low) and a

serial WREN instruction byte is issued. Then, the

product is deselected by taking

S high. After the

WREN instruction byte is sent, the ST95P08 will

set the write enable latch and then remain in

standby until it is deselected. Then, the write state

is entered by selecting the chip, issuing a one byte

address (A7-A0), and one byte of data. Bits 3 and

4 of the write instruction contain address bits A9

and A8 (most significant address bits).

S must

remain low for the entire duration of the operation.

The product must be deselected just after the eigth

bit of data has been latched in. If not, the write

process is cancelled. As soon as the product is

deselected, the self-timed write cycle is initiated.

While the write is in pr ogress, the status register

may be read to check BP1, BP0, WEL and WIP.

WIP is high during the s elf-timed write cycle. When

the cycle is close to completion, the write enable

latch is reset.

Page Write Operation

A maximum of 16 bytes of data may be written

during one non-volatile write cycle. All 16 bytes

must reside on the same page. The page write

mode is the same as the byte write mode except

that instead of deselecting after the first byte of

data, up to 15 additional bytes can be shifted in

prior to deselecting the chip. A page address begins

with address xxxx 0000 and ends with xxxx 1111.

If the address counter reaches xxxx 1111 and the

clock continues, the counter will roll over to the first

address of the page (xxxx 0000) and overwrite any

previous written data. The progr amming cycle will

only start if the

S transition does occur at the clock

low pulse just after the eigth bit of data of a word is

received.

Figure 8. Read Operation Sequence

S

21 345678910111213141516171819

0

C

INSTRUCTION BYTE ADDRESS

D

HIGH IMPEDANCE

Q

A7

20 21 22 23

A6 A5 A4 A3 A2 A1 A0A9 A8

DATA OUT

7 65432 0

1

AI01318

9/16

Page 10

ST95P08

Figure 9. Write Enable Latch Sequence

S

C

D

Q

21 34567

0

HIGH IMPEDANCE

AI01430

Figure 10. Write Operation Sequence

S

21 345678910111213141516171819

0

C

INSTRUCTION BYTE ADDRESS

D

HIGH IMPEDANCE

Q

A7

20 21 22 23

DATA BYTE

A6 A5 A4 A3 A2 A1 A0A9 A8

7 65432 0

1

AI01319

10/16

Page 11

Figure 11. Page Write Operation Sequence

S

21 345678910111213141516171819

0

C

ST95P08

20 21 22 23

INSTRUCTION BYTE ADDRESS

A7

D

S

2625 27 28 29 30 31

C

DATA BYTE 2

D

7 6 321054

A6 A5 A4 A3 A2 A1 A0A9 A8

8+8N

9+8N

DATA BYTE N

7

6 3210247 65432

5 4

Figure 12. RDSR: Read Status Register Sequence

10+8N

11+8N

12+8N

13+8N

DATA BYTE 1

7 65432 0

14+8N

15+8N

136

137

138

139

DATA BYTE 16

140

141

1

1

142

7

143

0

AI01320

S

21 3456789101112131415

0

C

INSTRUCTION

D

Q

HIGH IMPEDANCE

STATUS REG. OUT

7 6543210

MSB

AI01431

11/16

Page 12

ST95P08

Figure 13. WRSR: Write Status Register Sequence

S

21 3456789101112131415

0

C

INSTRUCTION STATUS REG.

D

HIGH IMPEDANCE

Q

AI01432

POWER ON STATE

After a Power up the ST95P08 is in the following

state:

– The device is in the low power standby state.

– The chip is deselected.

– The chip is not in hold condition.

– The write enable latch is reset.

– BP1 and BP0 are unc hanged (non-volatile bits).

DATA PROTECTION AND PROTOCOL SAFETY

– All inputs are protected against noise, see T able

3.

– Non valid

S and HOLD transitions are not taken

into account.

S must come high at the proper clock count in

–

order to start a non-volatile write cycle (in the

memory array or in the c ycle status register). The

Chip Select

S must rise during the clock pulse

following the introduction of a multiple of 8 bits.

– Access to the memory array during non-volatile

programming cycle is cancelled and the chip is

automatically deselected; however, the programming cycle continues.

– After either of the following operations (WREN,

WRDI, RDSR) is completed, the chip enters a

wait state and waits for a deselect.

– The write enable latch is reset upon power-up.

– The write enable latch is reset when

W is brought

low.

INITIAL DELIVERY STATE

The device is delivered with the memory array in a

fully erased state (all data set at all "1’s" or FFh).

The block protect bits are initialized to 00.

12/16

Page 13

ORDERING INFORMATION SCHEME

Example: ST95P08 M 6 TR

ST95P08

Data Strobe

(1)

P

D Q

Notes:

1. Data In strobed on rising edge of the clock (C) and Data Out synchronized from the falling edge of the clock.

2. Temperature range on request only, 5V ± 10% only.

Package

B PSDIP8

0.25 mm Frame

M SO8

150mil Width

Temperature Range

1 0 to 70 °C

6 –40 to 85 °C

(2)

3

–40 to 125 °C

Option

TR Tape & Reel

Packing

Devices are shipped from the factory with the memory content set at all "1’s" (FFh).

For a list of available options (Package, etc...) or for further information on any aspect of this device, please

contact the STMicroelectronics Sales Office nearest to you.

13/16

Page 14

ST95P08

PSDIP8 - 8 pin Plastic S k i nny DIP, 0.25mm lead f r ame

Symb

Typ Min Max Typ Min Max

A 3.90 5.90 0.154 0.232

A1 0.49 – 0.019 –

A2 3.30 5.30 0.130 0.209

B 0.36 0.56 0.014 0.022

B1 1.15 1.65 0.045 0.065

C 0.20 0.36 0.008 0.014

D 9.20 9.90 0.362 0.390

E 7.62 – – 0.300 – –

E1 6.00 6.70 0.236 0.264

e1 2.54 – – 0.100 – –

eA 7.80 – 0.307 –

eB 10.00 0.394

L 3.00 3.80 0.118 0.150

N8 8

CP 0.10 0.004

PSDIP8

mm inches

Drawing is not to scale.

14/16

A2

A1AL

B

e1

B1

D

N

C

eA

eB

E1 E

1

PSDIP-a

Page 15

SO8 - 8 lead Plastic Small Outline, 150 mils body width

ST95P08

Symb

Typ Min Max Typ Min Max

A 1.35 1.75 0.053 0.069

A1 0.10 0.25 0.004 0.010

B 0.33 0.51 0.013 0.020

C 0.19 0.25 0.007 0.010

D 4.80 5.00 0.189 0.197

E 3.80 4.00 0.150 0.157

e 1.27 – – 0.050 – –

H 5.80 6.20 0.228 0.244

h 0.25 0.50 0.010 0.020

L 0.40 0.90 0.016 0.035

α 0° 8° 0° 8°

N8 8

CP 0.10 0.004

mm inches

Drawing is not to scale.

B

SO-a

h x 45˚

A

C

e

CP

D

N

E

H

1

LA1 α

15/16

Page 16

ST95P08

Information furnished is believ ed to be accurate and reliable. How ever, STMicroelectronic s assumes no responsi bility for the consequences

of use of such information nor for any infringement of patents or other rights of third parties which may result from its use. No license is granted

by implication or otherwise under any patent or patent rights of STMicroelectronics. Specifications mentioned in this publication are subject to

change without notice. This publication supersedes and repl aces all information previous ly supplied. STMicroelect ronics products are not

authorized for use as critical components in life support devices or systems without express written approval of STMicroelectronics.

The ST logo is a registered trademark of STMicroelectronics

© 1999 STMicroelectronics - All Rights Reserved

All other names are the property of their respective owners

Australia - Brazil - Canada - China - France - Germany - Italy - Japan - Korea - Malaysia - Malta - Mexico - Morocco - The Netherlands -

Singapore - Spain - Sweden - Switzerland - Taiwan - Thailand - United Kingdom - U.S.A.

STMicroelectronics GROUP OF COMPANIES

http://www.st.com

16/16

Loading...

Loading...