Page 1

Rev. 1.4

January 2000 1/71

ST72411R

8-BIT MCU WITH SMARTCARD INTERFACE, LCD DRIVER,

8-BIT TIMER, SAFE RESET AND SUPPLY MONITORING

PRODUCT PREVIEW

■ Memories

– 4K Program memory

(ROM/FLASH) with read-out protection

– In-Situ Programming (remote ISP) for FLASH

devices using Smartcard orstandard I/O lines

– 256-bytes RAM

■ Clock, Reset and Supply Management

– Power-on supply at Smartcard insertion

– Low supply voltage detection for battery

monitoring

– Smart Card withdrawal detection

– On-chip main clock source

– 3 Power saving modes

– Clock-out capability for synchronous and

asynchronous Smartcards

■ Smartcard Interface

– Smart Card Supply Supervisor with: 3V or 5V

voltage regulator and current overload protec-

tion

■ 15 I/O Ports

– 15 multifunctional bidirectional I/O lines with:

external interrupt capability (2 vectors), 2 al-

ternate function lines, 5 I/Os for ISO7816-3

Smartcard interface, 1 I/O for Smartcard with-

drawal detection

■ Display Driver

– LCD driver with 32 segment outputs and 4

backplane outputs able to drive up to 32x4

LCD displays

■ Timer

– One 8-bit timer with: 9-bit prescaler, selecta-

ble input frequency with external clock input

option and event output signal generation ca-

pability

■ Instruction Set

– 8-bit Data Manipulation

– 63 Basic Instructions

– 17 main Addressing Modes

– 8 x 8 Unsigned Multiply Instruction

– True Bit Manipulation

■ Development Tools

– Full hardware/software development package

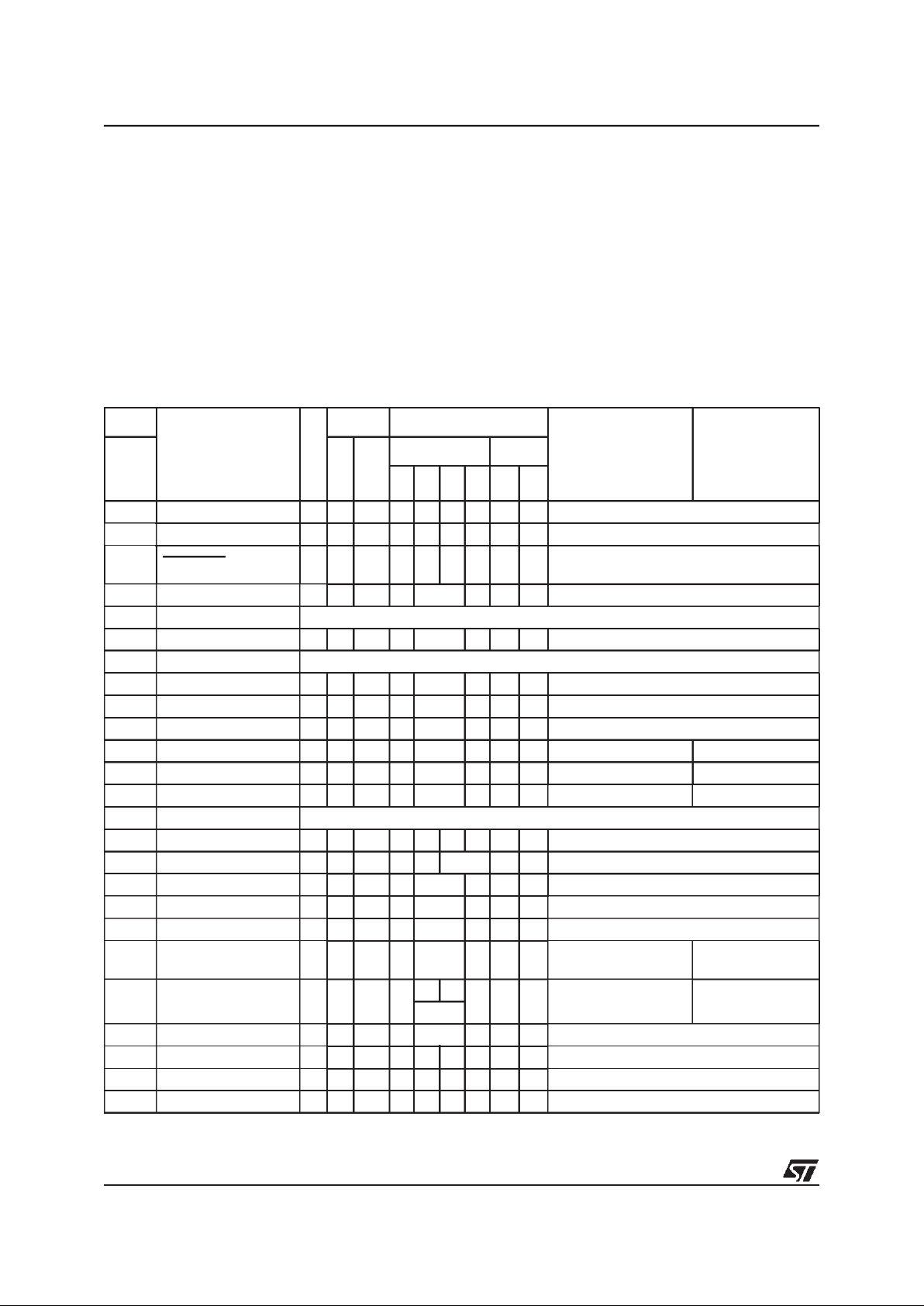

Device Summary

TQFP64

14 x 14

Features ST72411R

Program memory - bytes 4K

RAM (stack) - bytes 256 (64)

Peripherals Smart Card supply interface, LCD Driver, 8-bit Timer

Operating Supply 4V to 6.6V (5.5V min. for 5V Smartcard power supply output)

CPU Frequency 3.58 MHz (7.16 MHz internal oscillator)

Temperature Range 0°C to +70°C

Packages TQFP64 or Die Form

Development device ST72C411R

1

Page 2

Table of Contents

71

2/71

2

1 GENERAL DESCRIPTION . . . . . . ................................................ 4

1.1 INTRODUCTION . . . . . .. . . . . . ............................................. 4

1.2 PIN DESCRIPTION . . ..................................................... 5

1.3 REGISTER & MEMORY MAP . . . ............................................ 8

1.4 FLASH PROGRAM MEMORY . . . . . . . . . . . . .................................. 10

1.4.1 Introduction . . . .................................................... 10

1.4.2 Main features . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1.4.3 Structural organisation . . . . . . . . . . . . . . ................................. 10

1.4.4 In-Situ Programming(ISP) modes . . . . . . . . . . . . . . . . . . .................... 10

1.5 PROGRAM MEMORY READ-OUT PROTECTION . . . . . . . . . . . . . . . . . . . ...........11

2 CENTRAL PROCESSING UNIT . . ............................................... 12

2.1 INTRODUCTION . . . . . .. . . . . . ............................................12

2.2 MAIN FEATURES . . . . . . . . . . . . . . . . . . . . . . . . . .............................. 12

2.3 CPU REGISTERS . . . .................................................... 12

3 SUPPLY, RESET AND CLOCK MANAGEMENT . . . . ................................ 15

3.1 LOW VOLTAGE DETECTOR AND SUPERVISOR (LVDS) . . . . . . . . . . . . . . . . . . . . . . . 15

3.1.1 Low Voltage Detector . . . . . ........................................... 15

3.1.2 Open Power Supply Detection (OPSD) . ................................. 15

3.1.3 Power Supply Supervisor (PSS) . . . .................................... 15

3.2 RESET SEQUENCE MANAGER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

3.3 MAIN CLOCK CONTROLLER SYSTEM (MCC) . . . ............................. 21

4 INTERRUPTS . . ............................................................. 22

4.1 NON MASKABLE SOFTWARE INTERRUPT .................................. 22

4.2 EXTERNAL INTERRUPTS . . . . . . . . . . .. . . . . . ............................... 22

4.3 PERIPHERAL INTERRUPTS ............................................... 22

4.4 POWER SAVING MODES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ........ 25

4.4.1 Introduction . . . .................................................... 25

4.4.2 Slow Mode . . . . . . . . . . . . . . . . . . . . . . . ................................. 25

4.4.3 Wait Mode . . . . . . . . . . . . . . . . ........................................ 25

4.4.4 Halt Mode . . . . . .................................................... 26

5 ON-CHIP PERIPHERALS . . . . . . . . . . . ...........................................27

5.1 I/O PORTS . . . . . . . . . . . . . . . . . . ...........................................27

5.1.1 Introduction . . . .................................................... 27

5.1.2 Functional Description . . . . ........................................... 27

5.1.3 I/O Port Implementation . . . . . . . . . . . . . . . . . . . ........................... 29

5.1.4 Register Description . . . . . . ........................................... 30

5.2 MISCELLANEOUS REGISTER . . . . . . . . . . . .................................. 32

5.2.1 I/O Port Interrupt Sensitivity Description . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . 32

5.2.2 Slow modeand VDD Supply Monitoring .................................32

5.3 8-BIT TIMER (TIM8) . . . . . . . . . . . . . . . . . . . . . ................................. 34

5.3.1 Introduction . . . .................................................... 34

5.3.2 Main Features . . . . . . ...............................................34

5.3.3 Counter/Prescaler Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ........ 35

5.3.4 Functional description . . . . . . . . . . . . . . . . . . . . ........................... 36

5.3.5 Register Description . . . . . . ........................................... 38

Page 3

Table of Contents

3/71

3

5.4 32 X 4 LCD DRIVER . . . . . . . . . . ........................................... 40

5.4.1 Introduction . . . .................................................... 40

5.4.2 Segment and Common signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ........ 41

5.4.3 Reference Voltages . . . . . . . . . . . . . . . . ................................. 41

5.4.4 Display Example . . . . . . . . . . . ........................................ 41

5.4.5 Clock generation . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . 43

5.4.6 Register Description . . . . . . ........................................... 44

5.4.7 LCD RAM Description . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

5.5 SMARTCARD SUPPLY SUPERVISOR (SSS) ................................. 46

5.5.1 Introduction . . . .................................................... 46

5.5.2 Main Features . . . . . . ...............................................46

5.5.3 General description . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

5.5.4 Functional Description . . . . ........................................... 47

5.5.5 Register Description . . . . . . ........................................... 48

6 INSTRUCTION SET . . . . . . . . . . . . . . . . . . ........................................ 50

6.1 ST7 ADDRESSING MODES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

6.1.1 Inherent . . . . . . . . . . . ...............................................51

6.1.2 Immediate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

6.1.3 Direct . ........................................................... 51

6.1.4 Indexed (No Offset, Short, Long) . . . . . . . . . . . . ........................... 51

6.1.5 Indirect (Short, Long) . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

6.1.6 Indirect Indexed (Short, Long) . ........................................ 52

6.1.7 Relative mode (Direct, Indirect) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

6.2 INSTRUCTION GROUPS . . . . . . . . . . . . . . . . .................................53

7 ELECTRICAL CHARACTERISTICS . . . . . . . . . . . . . . . . .............................. 56

7.1 ABSOLUTE MAXIMUM RATINGS . . . ........................................ 56

7.2 RECOMMENDED OPERATING CONDITIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

7.3 SUPPLY, RESET AND CLOCK CHARACTERISTICS . . . . . .. . . . . . . . . . . . . . . . . .... 60

7.4 TIMING CHARACTERISTICS . . ...........................................60

7.5 MEMORY CHARACTERISTICS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

7.5.1 RAM and Hardware Registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ........ 61

7.5.2 FLASH Program Memory . ...........................................61

7.6 LCD ELECTRICAL CHARACTERISTICS . . . . . . . . . . . . . . . . . . . . . . ............... 61

7.7 SMARTCARD SUPPLY SUPERVISOR ELECTRICAL CHARACTERISTICS . . . . . . . . . . 62

8 DEVICE CONFIGURATION . . . . . ............................................... 64

8.1 OPTION BYTE . . . . . . . ................................................... 64

9 GENERAL INFORMATION . . . . . . . . . . ...........................................65

9.1 PACKAGE MECHANICAL DATA . . . . . . .. . . . . . . . . . ........................... 65

9.2 ADAPTOR / SOCKET PROPOSAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ........ 66

9.3 DEVELOPMENT TOOLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ........ 67

9.4 ST7 APPLICATION NOTES . . . . . . . ........................................ 68

9.5 TO GET MORE INFORMATION . . . . . . . . .................................... 68

10 SUMMARY OF CHANGES . ................................................... 69

10.1DEVICE CONFIGURATION AND ORDERING INFORMATION . . . . . ............... 70

10.1.1Transfer Of Customer Code . . . . . . . ....................................70

Page 4

ST72411R

4/71

1 GENERAL DESCRIPTION

1.1 INTRODUCTION

The ST72411R devices are members of the ST7

microcontroller family. They are designed for

Smartcard reader applications.

All ST72411R family devices are based on a common industry-standard 8-bit core, featuring an enhanced instruction set.

The ST72C411R devices feature single-voltage

FLASH memory with byte-by-byte In-Situ Programming (ISP) capability.

Under software control, all devices can be placed

in WAIT, SLOW, or HALT mode, reducing power

consumption when the application is in idle or

standby state.

The enhanced instruction set and addressing

modes of the ST7 offer both power and flexibilityto

software developers, enabling the design ofhighly

efficient andcompact application code.In addition

to standard 8-bit data management, all ST7 microcontrollers feature true bit manipulation, 8x8 unsigned multiplication and indirect addressing

modes.

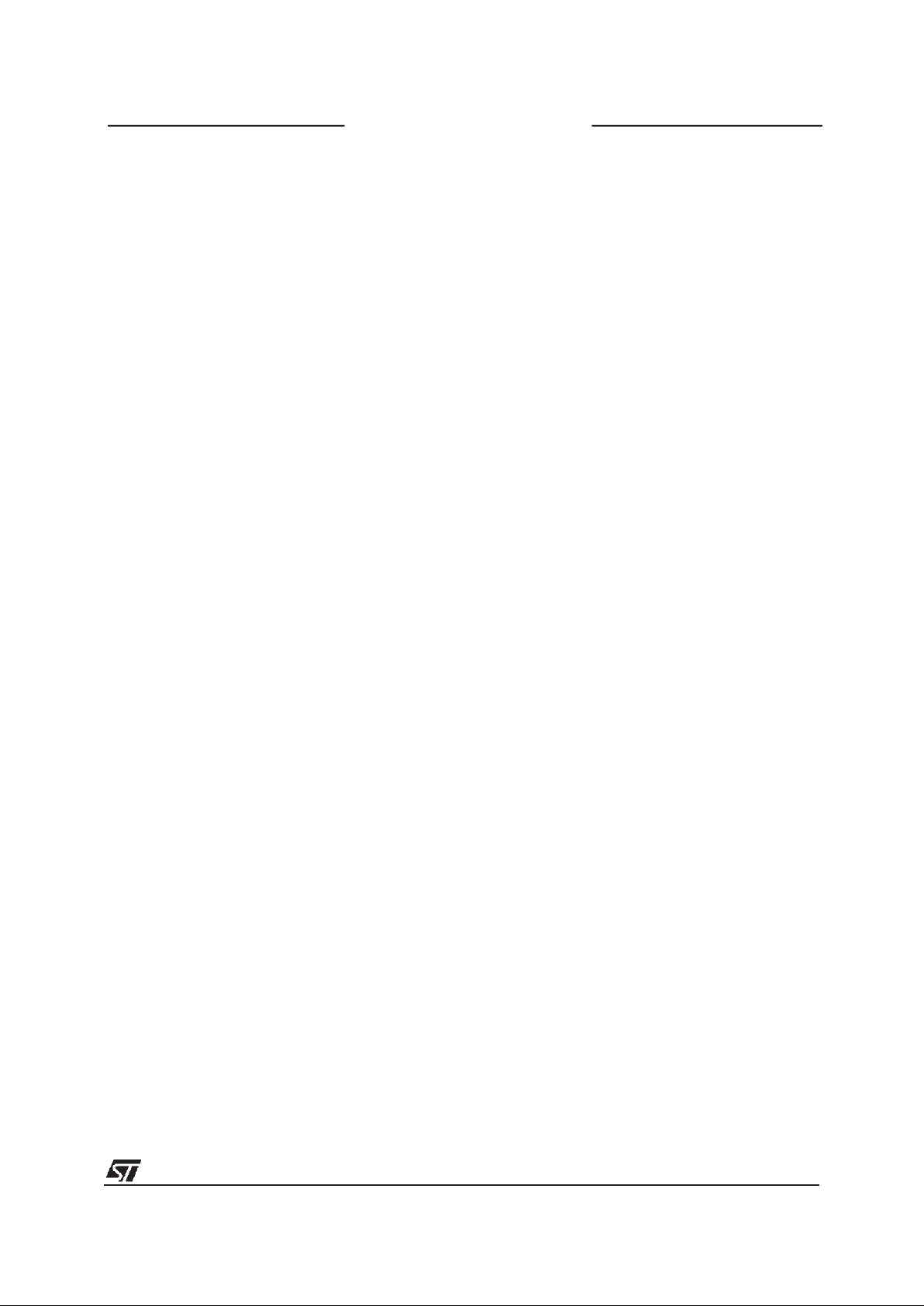

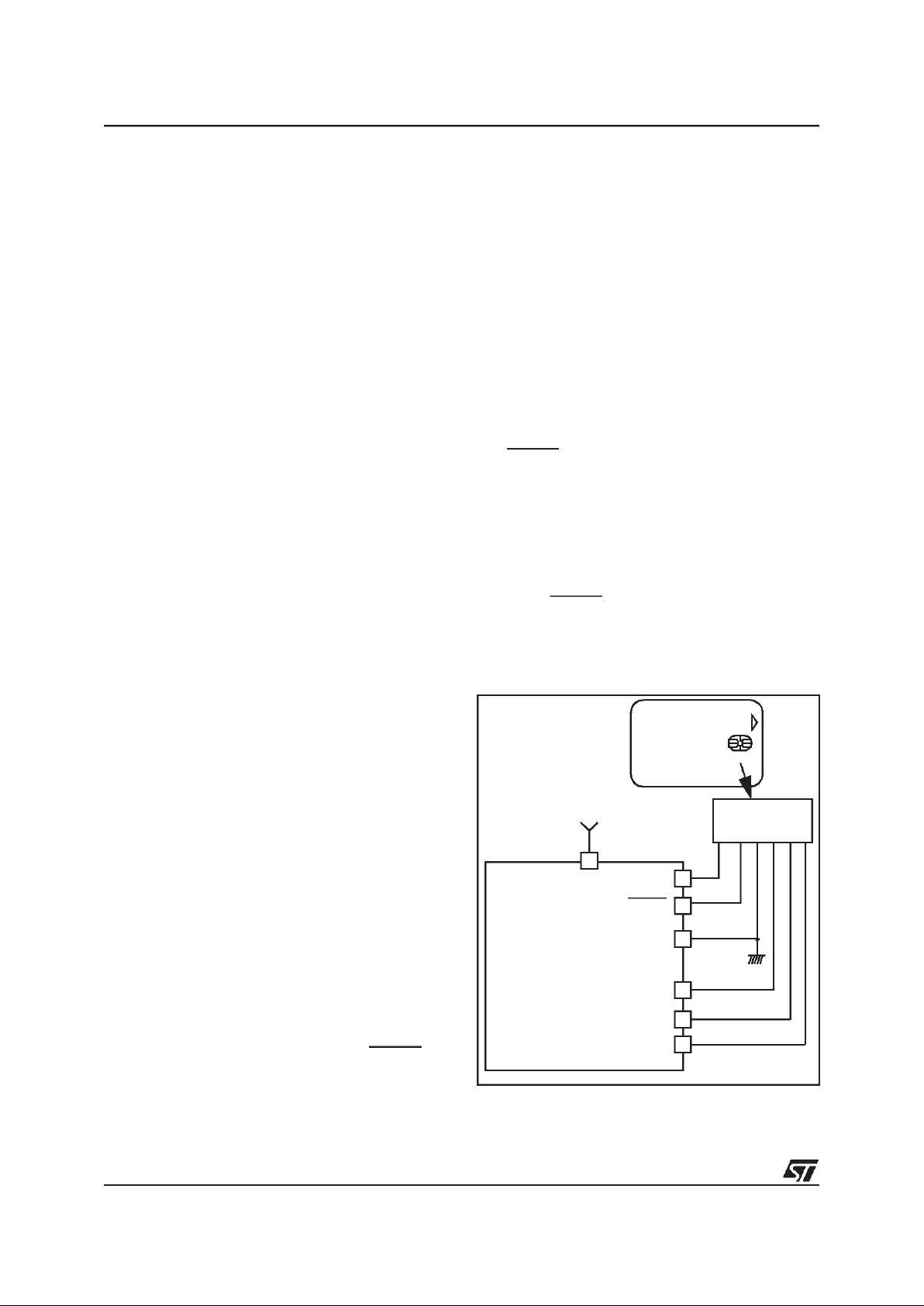

Figure 1. Device Block Diagram

8-BIT CORE

ALU

ADDRESS AND DATA BUS

OSC_SEL

CONTROL

PROGRAM

(4K Bytes)

V

SS

RESET

RAM

(256 Bytes)

PORT A

PA7:0

(8 bits)

8-BIT TIMER

PORT B

PB6:0

(7 bits)

V

DD

OSCIN

INTEGRATED

LVDS

MEMORY

7.16 MHZ

OSCILLATOR

SC SUPPLY

SUPERVISOR

SC_PWR

LCD DRIVER

+

LCD RAM (32x4)

SEG31:0

(32 segments)

COM3:0

(4 coms)

V

REF

(SSS)

4

Page 5

ST72411R

5/71

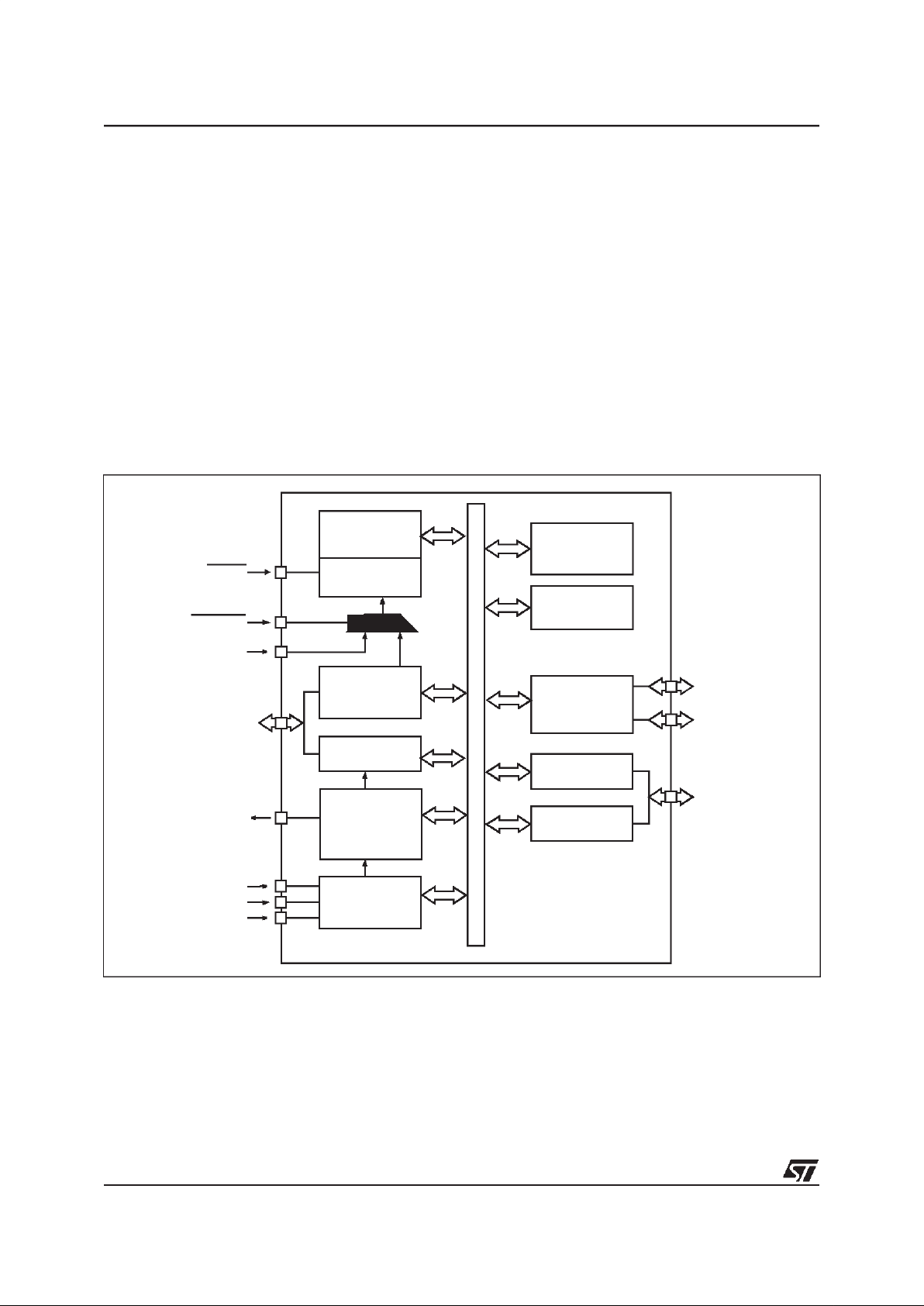

1.2 PIN DESCRIPTION

Figure 2. 64-Pin TQFP Package Pinout

(SC) PB4

(SC) PB3

ISPCLK1 / (SC_CK) PB2

ISPDATA1 / (SC_DATA) PB1

(SC_RESET) PB0

SC_PWR

V

DDA

V

DD

V

SSA

V

SS

OSCIN

NC

NC

V

REF

PB6

PB5

64 63 62 61 60 59 58 57 56 55 54 53 52 51 50 49

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

17 18 19 20 21 22 23 24 29 30 31 3225 26 27 28

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

EI0

RESET

ISP_SEL / OSC_SEL

PA7

NC

PA6

NC

PA5

PA4

PA3

ISPCLK2 / PA2

ISPDATA2 / PA1

TIMIO / PA0

SEG28

SEG29

SEG30

SEG31

SEG7

SEG6

SEG5

SEG4

SEG3

SEG2

SEG1

SEG0

COM3

COM2

COM1

COM0

SEG11

SEG10

SEG9

SEG8

SEG23

SEG22

SEG21

SEG20

SEG19

SEG18

SEG17

SEG16

SEG15

SEG14

SEG13

SEG12

SEG27

SEG26

SEG25

SEG24

EI1

EI0

EI0

5

Page 6

ST72411R

6/71

PIN DESCRIPTION (Cont’d)

Legend / Abbreviations:

Type: I = input, O = output, S = supply

Output level: SC = powered by V

SC_PWR

smartcard power, HS = high sink (on N-buffer only)

Input level: C = CMOS : 0.3VDD/0.7VDD, SC = CMOS : 0.3V

SC_PWR

/ 0.7V

SC_PWR

Port configuration capabilities:

– Input:float = floating, wpu = weak pull-up, int = interrupt, wpd = weak pull-down

– Output: OD = open drain, T = true open drain, PP = push-pull

Note: Reset configuration of each pin is bold.

Table 1. Device Pin Description

Pin n°

Pin Name

Type

Level Port

Main

function

(after

reset)

Alternate function

TQFP64

Input

Output

Input Output

float

wpu

int

wpd

OD

PP

1 ... 4 S28 ... S31 O LCD Segment outputs

5 RESET I/O Top priority non maskable interrupt.

6 OSC_SEL / ISP_SEL I

This pin acts as the Remote ISP mode and

oscillator selection.

7 PA7 I/O C X EI0 X X Port A7

8 NC Not Connected

9 PA6 I/O C X EI0 X X Port A6

10 NC Not Connected

11 PA5 I/O C X EI0 X X Port A5

12 PA4 I/O C X EI0 X X Port A4

13 PA3 I/O C X EI0 X X Port A3

14 PA2 / ISPCLK2 I/O C X EI0 X X Port A2 ISP Clock line 2

15 PA1 / ISPDATA2 I/O C X EI0 X X Port A1 ISP Data line 2

16 PA0 / TIMIO I/O C X EI0 X X Port A0 8-bit Timer I/O

17 NC Not Connected

18 V

REF

1)

I Analog input for battery power monitoring

19 PB6 I/O C X EI1 X X Port B6

20 PB5 I/O C X EI1 X X Port B5

21 PB4(SC) I/O SC SC X EI1 X X Port B4 (Smartcard)

22 PB3(SC) I/O SC SC X EI1 X X Port B3 (Smartcard)

23

PB2(SC_CK) /

ISPCLK1

I/O SC SC X EI1 X X

Port B2 (Smartcard

clock)

ISP Clock line 1

24

PB1(SC_DATA) /

ISPDATA1

I/O SC SC

X

XX

Port B1 (Smartcard

Data)

ISP Data line 1

EI1

25 PB0(SC) I/O SC SC X EI1 X X Port B0 (Smartcard)

26 SC_PWR O Smartcard Regulated Supply Output

27 V

DDA

S Analog Power Supply Voltage

28 V

DD

S Digital Main Supply Voltage

Page 7

ST72411R

7/71

Note:

1) There is no protection diode referenced to VDDon the V

REF

pad. If the microcontroller is not poweredon atthe main VDDsupply, it is possible tohave nopower consumption (other thanleakage currents -see

electrical parameters), while applying power to V

REF

.

29 V

SSA

S Analog Ground Voltage

30 V

SS

S Digital Ground Voltage

31 OSCIN I External main clock source

32 NC Not Connected

33 ... 36 COM0 ... COM3 O LCD Common outputs

37 ... 64 SEG0 ... SEG27 O LCD Segment outputs

Pin n°

Pin Name

Type

Level Port

Main

function

(after

reset)

Alternate function

TQFP64

Input

Output

Input Output

float

wpu

int

wpd

OD

PP

Page 8

ST72411R

8/71

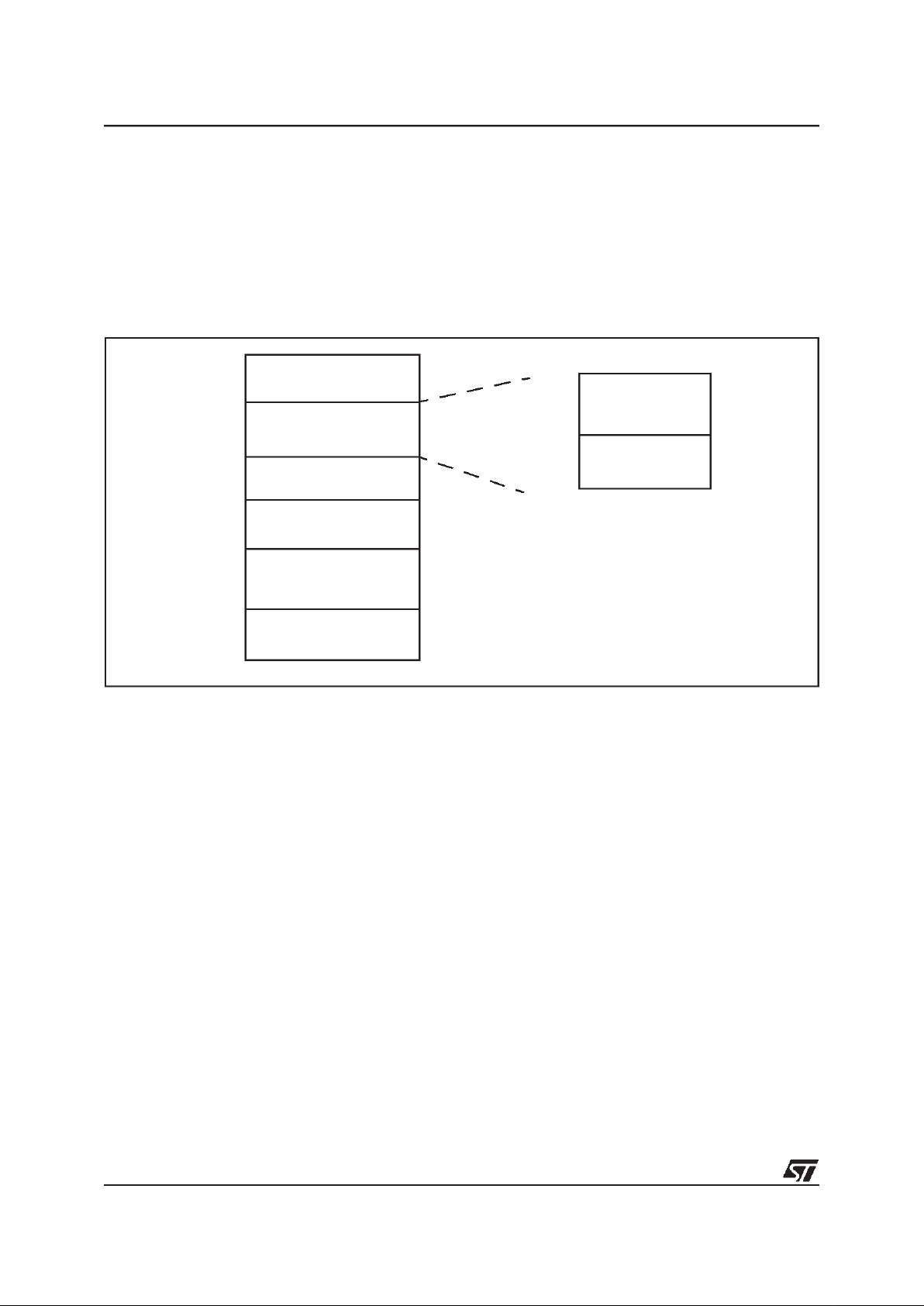

1.3 REGISTER & MEMORY MAP

As shown in Figure 3, the MCU is capable of

adressing 64K bytes of memories and I/O registers.

The available memory locations consist of 64

bytes of register locations, up to 256 bytes of

RAM, 16 bytes of LCD RAM and 4Kbytes of user

program memory. The RAM space includes up to

64 bytes for the stack from 0100h to 013Fh.

The highest address bytes contain the user reset

and interrupt vectors.

Figure 3. Memory Map

0000h

RAM

Program Memory

(4K = 4096 Bytes)

Interrupt & Reset Vectors

HW Registers

014Fh

0040h

003Fh

0150h

EFFFh

Reserved

(see Table 2)

F000h

FFDFh

FFE0h

FFFFh

(see Table 4)

0140h

LCD RAM (16 Bytes)

013Fh

Short Addressing

RAM (zero page)

Stack

(64 Bytes)

0100h

013Fh

0040h

00FFh

(256 Bytes)

Page 9

ST72411R

9/71

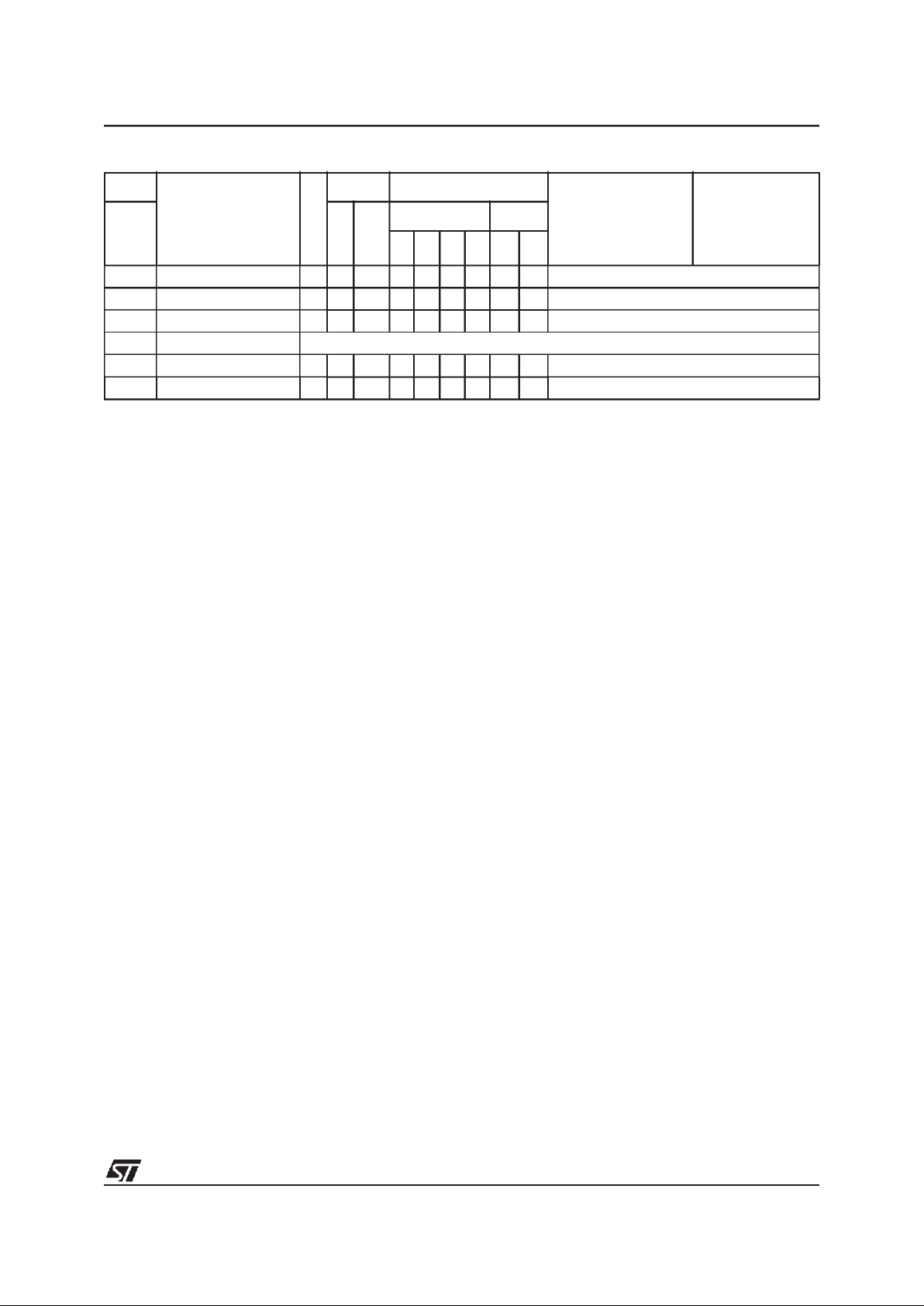

Table 2. Hardware Register Map

Address Block

Register

Label

Register Name

Reset

Status

Remarks

0000h

0001h

0002h

Port A

PADR

PADDR

PAOR

Port A Data Register

Port A Data Direction Register

Port A Option Register

00h

00h

00h

R/W

R/W

R/W

0003h Reserved Area (1 Byte)

0004h

0005h

0006h

Port B

PBDR

PBDDR

PBOR

Port B Data Register

Port B Data Direction Register

Port B Option Register

00h

00h

00h

R/W

R/W

R/W

0007h

to

001Fh

Reserved Area (25 Bytes)

0020h MISCR Miscellaneous Register x0h R/W

0021h

0022h

0023h

Reserved Area (3 Bytes)

0024h LCD LCDCR LCD Control Register 00h R/W

0025h SSS SSSCR

Smartcard Supply Supervisor Control Status

Register

00h R/W

0026h

to

0030h

Reserved Area (11 Bytes)

0031h

0032h

0033h

TIMER

PSCR

TCR

TSCR

Timer Prescaler register

Timer Counter Register

Timer Status Register

FFh

FFh

50h

Read Only

R/W

R/W

0034h

to

003Fh

Reserved Area (12 Bytes)

Page 10

ST72411R

10/71

1.4 FLASH PROGRAM MEMORY

1.4.1 Introduction

Flash devices have a single voltage non-volatile

FLASH memory that may be programmed in-situ

(or plugged in a programming tool) on a byte-bybyte basis.

1.4.2 Main features

■ Remote In-Situ Programming (ISP) mode

■ Up to 16 bytes programmedin the same cycle

■ MTP memory (Multiple Time Programmable)

■ Read-out memory protection against piracy

1.4.3 Structural organisation

The FLASH program memory is organised in a

single 8-bit wide memory block which can be used

for storing both code and data constants.

The FLASH program memory is mappedin the upper part of the ST7 addressing space (F000hFFFFh) and includes the reset and interrupt user

vector area.

1.4.4 In-Situ Programming (ISP) modes

The FLASH program memory canbe programmed

using two Remote ISP modes. These ISP modes

allow the contents of the ST7 program memory to

be updated using a standard ST7 programming

tool after the device is mounted on the application

board. This feature can be implemented with a

minimum numberof addedcomponents and board

area impact.

Examples of Remote ISP hardware interfaces to

the standard ST7 programming tool are described

below. For more details on ISP programming,refer

to the ST7 Programming Specification.

Remote ISP Overview

The Remote ISP modes are initiated by a specific

sequence on the dedicated ISPSEL pin.

The Remote ISP is performedin three steps:

– Selection of the RAM execution mode

– Download of Remote ISP code in RAM

– Execution ofRemote ISP code in RAM to pro-

gram the user program into the FLASH

Remote ISP hardware configuration

Remote ISP mode works using either the internal

oscillator (no external clock is necessary), or an

external square wave clock. The selection of the

oscillator (internal or external) depends on the

ISP_SEL pin during the rising edge of RESET pin

(see “MAIN CLOCK CONTROLLER SYSTEM

(MCC)” on page 21).

Two ISP modes exist:

■ ISP1: ISP signals mapped onsmartcard I/O pins

■ ISP2: ISP signal mapped on general purpose

I/O pins

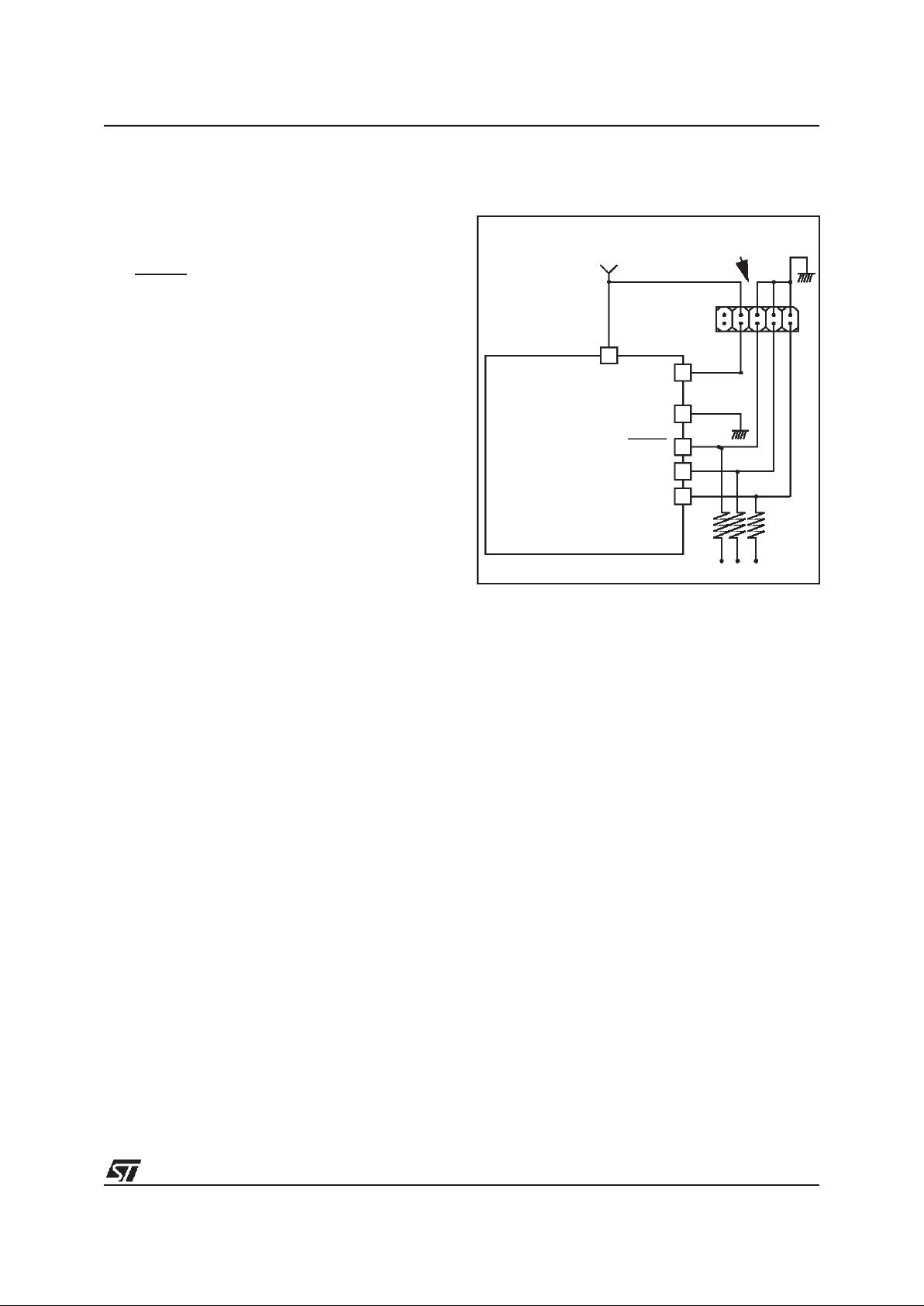

ISP1 Mode

In ISP1 mode, it is possible to re-program the microcontroller using a ISO7816 smartcard connector as shown in Figure 3.

This mode requires five signals (plus the SC_PWR

signal if necessary) to be connected to the programming tool. These signals are:

– RESET: device reset

–VSS: device ground power supply

– ISPCLK1: ISP output serial clock pin

– ISPDATA1: ISP input serial data pin

– ISPSEL: Remote ISP modeselection. Thispin

has an internal pulldown and mustbe left high

impedance if the internal oscillator is selected.

Otherwise an appropriate pull-up is needed

(see Electrical Characteristics).

Note: The RESET and ISPSEL pins are not part of

the ISO7816 interface. Consequently, two additional contacts on the smartcard connector are

necessary.

Table 3. ISP1 (Smartcard) interface

ISPSEL

V

SS

RESET

ISPCLK1

ISPDATA1

ST72411

SMARTCARD

FOR ISP

SMARTCARD

CONNECTOR

SC_PWR

V

DD

ISO7816

Page 11

ST72411R

11/71

FLASH PROGRAM MEMORY (Cont’d)

ISP2 Mode

This mode requires five signals (plus the VDDsignal if necessary) to be connected to the programming tool. These signals are:

– RESET: device reset

–VSS: device groundpower supply

– ISPCLK2: ISP output serial clock pin

– ISPDATA2: ISP input serial data pin

– ISPSEL: Remote ISP mode selection. Thispin

must be left high impedance (internal pull

down on pin ISPSEL) if the internal oscillator

is selected. Otherwise an appropriate pull-up

is needed (see Electrical Characteristics).

If anyof these pins are used for other purposes on

the application, a serial resistor has to be implemented toavoid a conflict if the otherdevice forces

the signal level.

Figure 4 shows a typical hardware interface to a

standard ST7 programming tool. For more details

on the pin locations, refer to the device pinout description.

Figure 4. Typical Remote ISP2 Interface

1.5 Program Memory Read-out Protection

The read-out protection is enabled through an option bit.

For FLASH devices, when this option is selected,

the program and data stored in the FLASH memory are protected against read-out piracy (including

a re-write protection). When this protection option

is removed the entire FLASH program memory is

automatically erased.

ISPSEL

V

SS

RESET

ISPCLK2

ISPDATA2

V

DD

ST7

HE10 CONNECTOR TYPE

TO PROGRAMMING TOOL

APPLICATION

4.7kΩ

1

Page 12

ST72411R

12/71

2 CENTRAL PROCESSING UNIT

2.1 INTRODUCTION

This CPU has a full 8-bit architecture and contains

six internal registers allowing efficient 8-bit data

manipulation.

2.2 MAIN FEATURES

■ 63 basic instructions

■ Fast 8-bit by 8-bit multiply

■ 17 main addressing modes

■ Two 8-bit index registers

■ 16-bit stack pointer

■ Low power modes

■ Maskable hardware interrupts

■ Non-maskable software interrupt

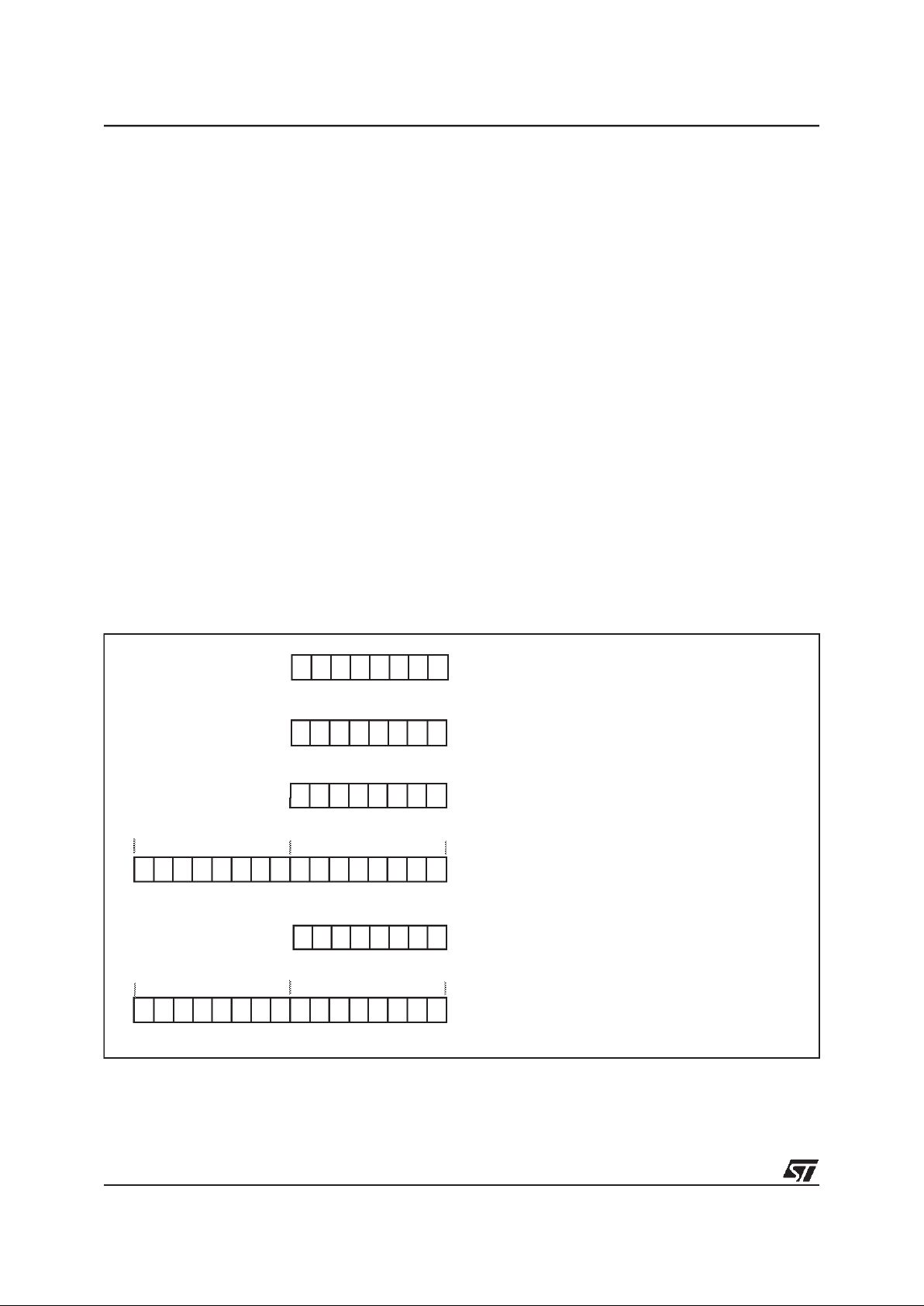

2.3 CPU REGISTERS

The 6 CPU registers shown in Figure 13 are not

present in the memory mapping andare accessed

by specific instructions.

Accumulator (A)

The Accumulator is an 8-bit general purpose register used to hold operands and the results of the

arithmetic and logic calculations and to manipulate

data.

Index Registers (X and Y)

In indexed addressing modes, these 8-bit registers

are used to create either effective addresses or

temporary storage areas for data manipulation.

(The Cross-Assembler generates a precede instruction (PRE) to indicate that the following instruction refers to the Y register.)

The Y registeris not affected by the interrupt automatic procedures (notpushed to and popped from

the stack).

Program Counter (PC)

The program counter is a 16-bit register containing

the address of the next instruction to be executed

by the CPU. It is made of two 8-bit registers PCL

(Program Counter Low which is the LSB) and PCH

(Program CounterHigh which is the MSB).

Figure 5. CPU Registers

ACCUMULATOR

X INDEX REGISTER

Y INDEX REGISTER

STACK POINTER

CONDITION CODE REGISTER

PROGRAM COUNTER

70

1C11HI NZ

RESET VALUE = RESET VECTOR @ FFFEh-FFFFh

70

70

70

0

7

15 8

PCH

PCL

15

87 0

RESET VALUE = STACKHIGHER ADDRESS

RESET VALUE =

1X11X1XX

RESET VALUE = XXh

RESET VALUE = XXh

RESET VALUE = XXh

X = Undefined Value

Page 13

ST72411R

13/71

CPU REGISTERS (Cont’d)

CONDITION CODE REGISTER (CC)

Read/Write

Reset Value: 111x1xxx

The 8-bit Condition Code register contains the interrupt mask and four flags representative of the

result ofthe instruction just executed. Thisregister

can also be handled by the PUSH and POP instructions.

These bits can be individually tested and/or controlled by specific instructions.

Bit 4 = H

Half carry

.

This bit is set by hardware whena carry occurs between bits 3 and 4 of the ALU during an ADD or

ADC instruction. It is reset by hardware during the

same instructions.

0: No half carry has occurred.

1: A half carry has occurred.

This bit is tested using the JRH or JRNH instruction. The H bit is useful in BCD arithmetic subroutines.

Bit 3 = I

Interrupt mask

.

This bit is set by hardware when entering in interrupt or by software to disable all interrupts except

the TRAP software interrupt. This bit is cleared by

software.

0: Interrupts are enabled.

1: Interrupts are disabled.

This bit is controlledby the RIM, SIM and IRET instructions and is tested by the JRM and JRNM instructions.

Note: Interrupts requested while I is set are

latched and can be processed when I is cleared.

By default an interrupt routine is not interruptable

because the I bit is set by hardware when you en-

ter it and reset by the IRET instruction at the end of

the interrupt routine. If the I bit is cleared by software in the interrupt routine, pending interrupts are

serviced regardless of the priority level of the current interrupt routine.

Bit 2 = N

Negative

.

This bit is set and cleared by hardware. It is representative of the result sign of the last arithmetic,

logical or data manipulation. It is a copy of the 7

th

bit of the result.

0:Theresultof the lastoperationis positive or null.

1: The result of the last operation is negative

(i.e. the most significant bit is a logic 1).

This bit isaccessed by the JRMI andJRPL instructions.

Bit 1 = Z

Zero

.

This bit is set and cleared by hardware. This bit indicates thatthe result of the last arithmetic, logical

or data manipulation is zero.

0: The result of the last operation is different from

zero.

1: The result of the last operation is zero.

This bit is accessed by the JREQ and JRNE test

instructions.

Bit 0 = C

Carry/borrow.

This bit is set and cleared by hardware and software. It indicates an overflow or an underflow has

occurred during the last arithmetic operation.

0: No overflow or underflow has occurred.

1: An overflow or underflow hasoccurred.

This bit is driven by the SCF and RCF instructions

and tested by the JRC and JRNC instructions. It is

also affected by the “bit test and branch”, shift and

rotate instructions.

70

111HINZC

Page 14

ST72411R

14/71

CENTRAL PROCESSING UNIT (Cont’d)

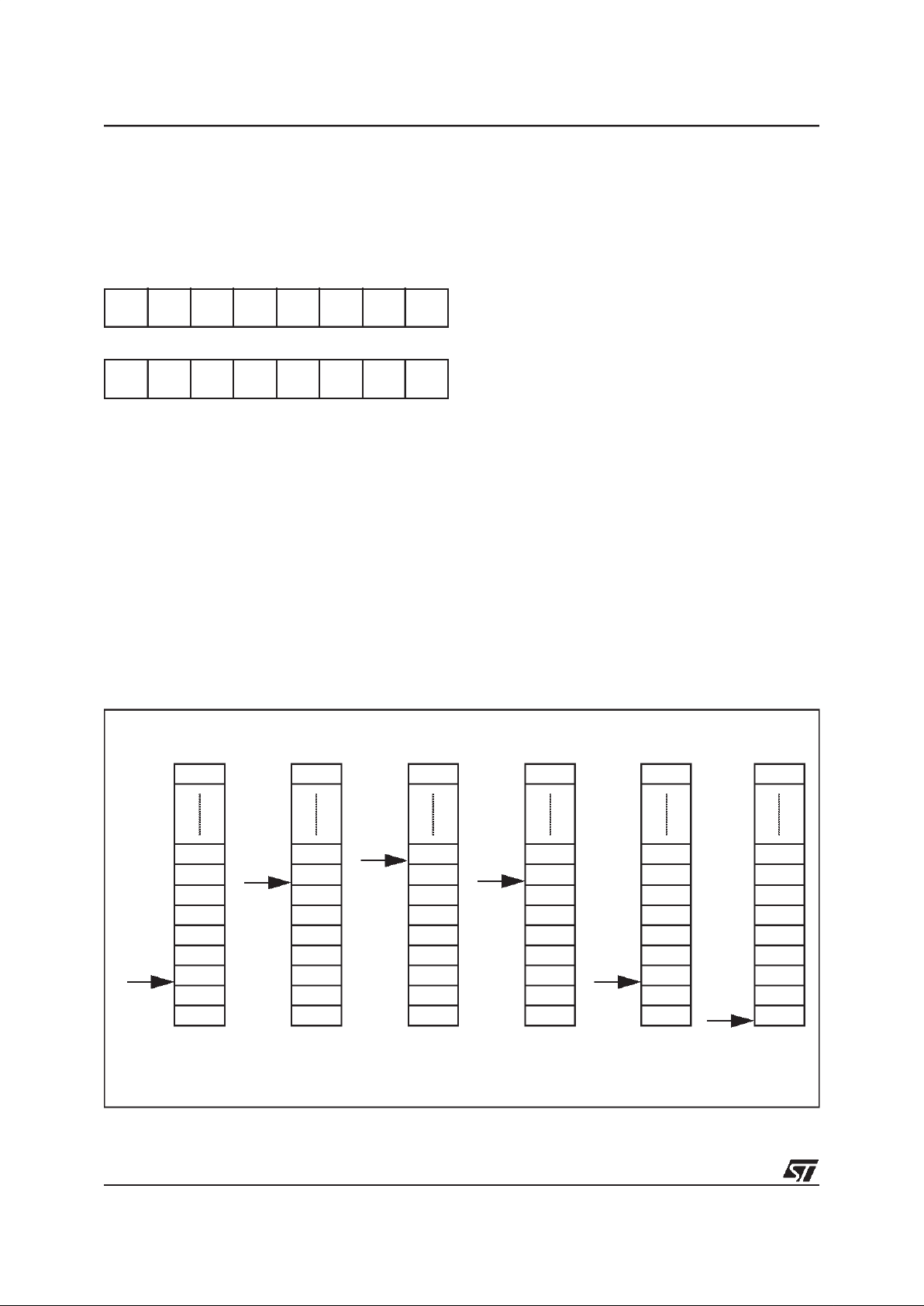

STACK POINTER (SP)

Read/Write

Reset Value: 013Fh

The Stack Pointer is a 16-bit register which is always pointingto the next free location in the stack.

It isthen decremented after data has been pushed

onto the stack and incremented before data is

popped from the stack (see Figure 6).

Since the stack is 64 bytes deep, the 10 most significant bits are forced by hardware. Following an

MCU Reset, orafter a Reset Stack Pointer instruction (RSP),the Stack Pointer contains its resetvalue (the SP5 to SP0 bitsare set) whichis the stack

higher address.

The least significant byte of the Stack Pointer

(called S) can be directly accessed by a LD instruction.

Note: When the lower limit is exceeded, the Stack

Pointer wraps around to the stackupper limit, without indicating the stack overflow. The previously

stored information is then overwritten and therefore lost. The stack also wrapsin caseof anunderflow.

The stack is used to save the return address during a subroutine call and the CPU context during

an interrupt. The user may also directly manipulate

the stack by meansof the PUSH and POP instructions. In the case of an interrupt, the PCL is stored

at the first location pointed to by the SP. Then the

other registers are stored in the next locations as

shown in Figure 6.

– When an interrupt is received, the SP is decre-

mented and the context is pushed on the stack.

– On return from interrupt, the SP is incremented

and the context is popped from thestack.

A subroutine call occupies twolocations and an interrupt five locations in the stack area.

Figure 6. Stack Manipulation Example

15 8

00000001

70

0 0 SP5 SP4 SP3 SP2 SP1 SP0

PCH

PCL

SP

PCH

PCL

SP

PCL

PCH

X

A

CC

PCH

PCL

SP

PCL

PCH

X

A

CC

PCH

PCL

SP

PCL

PCH

X

A

CC

PCH

PCL

SP

SP

Y

CALL

Subroutine

Interrupt

Event

PUSH Y POP Y IRET

RET

or RSP

@ 013Fh

@ 0100h

Stack Higher Address = 013Fh

Stack Lower Address =

0100h

Page 15

ST72411R

15/71

3 SUPPLY, RESET AND CLOCK MANAGEMENT

The ST72411 microcontroller includes a range of

utility features for securing the application in critical situations (for example in case of a power

brown-out), and reducing the number of external

components.

Main Features

■ V

DD

Low Voltage Detection and Supervisor

(LVDS)

■ Reset Sequence Manager

■ Main Clock Controller System (MCC)

3.1 LOW VOLTAGE DETECTOR AND

SUPERVISOR (LVDS)

The LVDS consists of three main blocks:

– Low Voltage Detector (LVD)

– Open Power Supply Detection (OPSD)

– Power Supply Supervisor (PSS)

If the internal oscillator is selected (OSC_SEL pin

is tied to VSS), the LVDS, OPSD and PSS functions are always enabled.

If an external clock is selected (OSC_SEL tied to

VDD), the LVDS, OPSD and PSS are disabled

while the external RESET is low and during the

first 260 clock cycles (f

CPU

). They become enabled after this period. Refer to Figure 13. This

means an external reset circuit must be provided.

However, afterthis periodthe LVDS may generate

a reset if a power voltage drop occurs.

3.1.1 Low Voltage Detector

To allow the integration of power management

features in the application, the Low Voltage Detector function (LVD) generates a static reset when

the VDDsupply voltage is below a V

IT+

reference

value (positive-going input thresholdvoltage). This

means that it secures the power-up as well as the

power-down by keeping the ST7 in reset state.

The V

IT-

reference value (negative-going input

threshold voltage) for a voltage drop is lower than

the V

IT+

reference value for power-on in order to

avoid a parasitic reset when the MCU starts running and sinks current on the supply(hysteresis).

The LVD Reset circuitry generates a reset when

VDDis below:

–V

IT+

when VDDis rising

–V

IT-

when VDDis falling

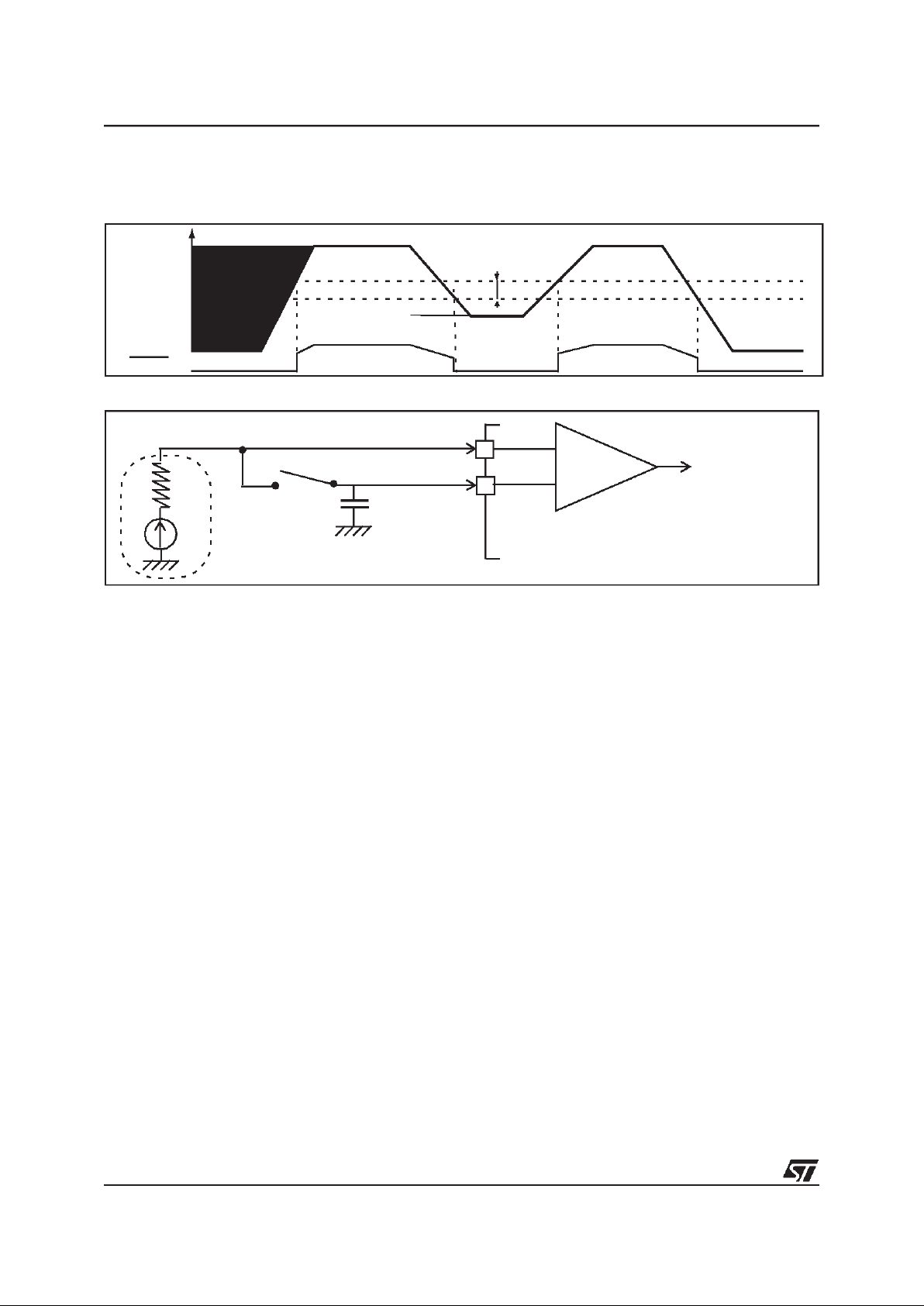

The LVD function is illustrated in Figure 7.

Provided the minimum VDDvalue (guaranteed for

the oscillator frequency) is below V

IT-

, the MCU

can only be in one of two modes:

– Under full software control

– In static safe reset

In this condition, secure operation is always ensured for the application without the need for external reset hardware.

The LVD filters spikes on VDDlarger than t

g(VDD)

to

avoid parasitic resets.

3.1.2 Open Power Supply Detection (OPSD)

The purpose of the Open Power Supply Detection

function is to detect if the VDDpower circuit is

open.

It detects if the microcontroller is about to be powered down, to allow software to shutdown the application properly before the Power Down Reset

generate by the LVDS.

The system is based on a comparison between

V

REF

andVDD.V

REF

is an analog input which is intended to be directly connected to the power

source (see Figure 8).

The detection is not dependent on the MCU consumption (not dependent on the voltage drop due

to the internal resistor of the power source).

To avoid spurious setting of the Power Down Flag

due to possible noise (PDF bit in the MISCR register), a margin M is factored into the comparison.

The detectionis done if:

(V

REF-VDD

)>M

The PDF flag can be used to monitor the main

supply supervisor function as shown in Figure 9.

When (V

REF-VDD

) > M, the PDFflag is set and an

interrupt is generated if the PDIE bit in the MISCR

register is set. This feature allows the user program to detect and manage the VDDdrop according to the application before the reset generated

by the LVDS (See Figure 9).

See the Miscellaneous register chapter for more

details on the PDF and PDIE bits.

3.1.3 Power Supply Supervisor (PSS)

The Power Supply Supervisor function compares

the Power Supply to a fixed analog reference voltage (V

PSS

) (see Figure 10). The output of this

comparator is directly connected to the PSSF bitin

the MISCR register (read only bit).

This feature can be used to monitor the power

supply.

Page 16

ST72411R

16/71

LOW VOLTAGE DETECTOR AND SUPERVISOR (Cont’d)

Figure 7. Low Voltage Detector vs Reset

Figure 8. Open Power Supply Detection: V

REF

Connections

V

DD

V

IT+

RESET

V

IT-

HYSTERESIS

V

hys

V

DD

V

REF

R

S

Power

V

E

+

-

C

Power Down Flag

Source

(PDF)generation

SW1

if (V

REF-VDD

)>M

Page 17

ST72411R

17/71

LOW VOLTAGE DETECTOR AND SUPERVISOR (Cont’d)

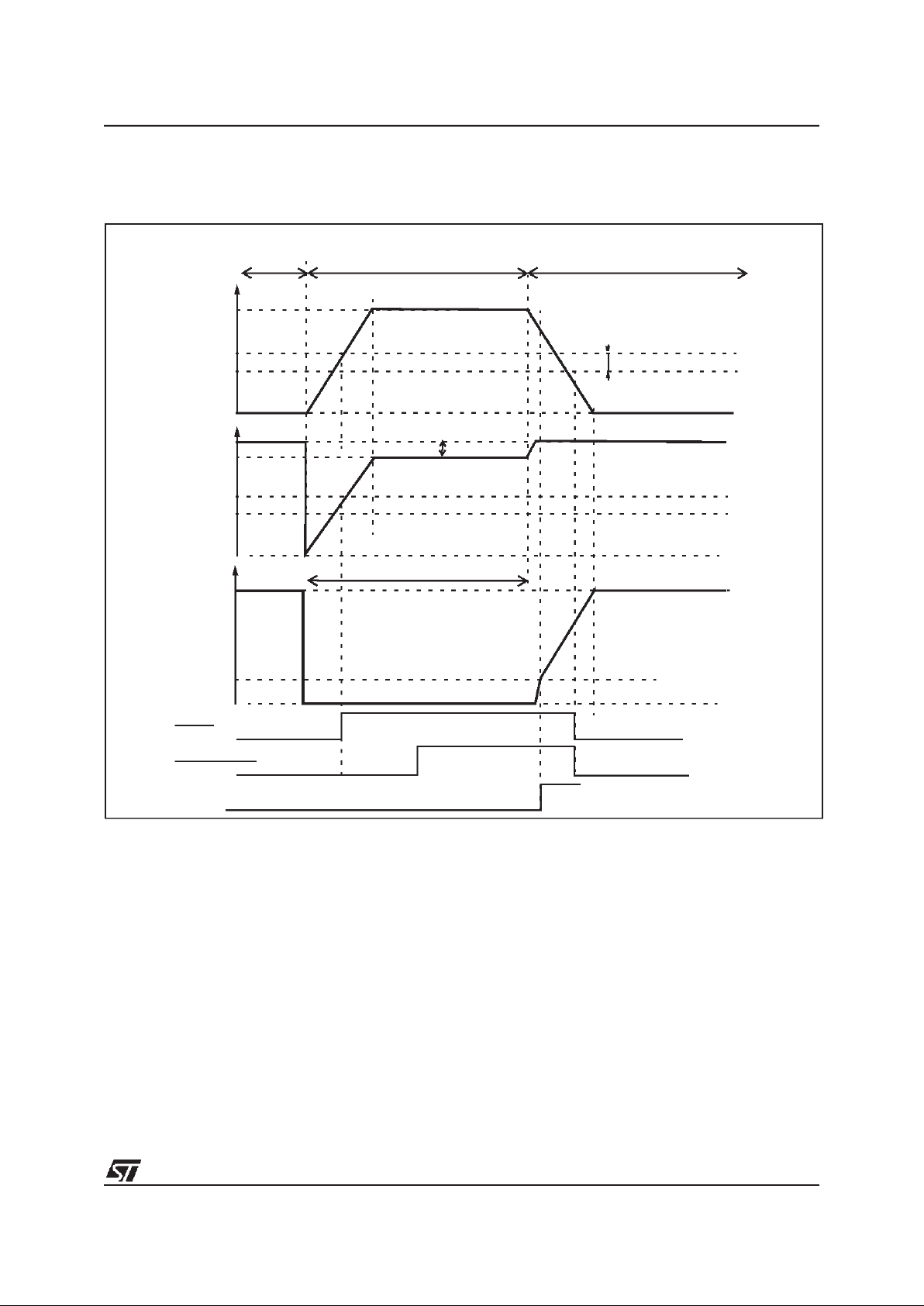

Figure 9. Open Power Supply Detection (OPSD)

Figure 10. Power Supply Supervisor system (PSS)

V

’’

RESET

V

IT+

V

IT-

HYSTERESIS

V

hys

PDF

Internal RESET

RUN

Open V

DD

detection

V

5()

V

5()

V

’’

DV = RS.I

RUN

V

E

V

DDRUN

V

DDRUN

0V

+V

E

RESET

SW1 OPEN SW1 CLOSED SW1 OPEN

0V

0V

V

5( )

V

’’

M

(CAPACITOR

DISCHARGED)

Page 18

ST72411R

18/71

3.2 RESET SEQUENCE MANAGER

The RESET sequence manager includes two reset sources as shown in Figure 11:

■ External RESET source pulse

■ Internal LVDS RESET (Low Voltage Detection)

These sources act on the RESET PIN and it is always kept low during the delay phase.

The RESET service routine vector is fixed at addresses FFFEh-FFFFh in the ST7 memory map.

A 4096 CPUclock cycle delay allows the oscillator

to stabilise and to ensure that recovery has taken

place from the Reset state.

The RESET vector fetch phase duration is 2 clock

cycles.

Figure 11. Reset Block Diagram

f

CPU

COUNTER

RESET

R

ON

V

DD

LVD RESET

INTERNAL

RESET

Page 19

ST72411R

19/71

RESET MANAGER (Cont’d)

([WHUQD O 5(6( 7 SLQ

The RESETpin is both an input andan open-drain

output with integrated RONweak pull-up resistor

(see Figure11). This pull-up has nofixed value but

varies in accordance with the input voltage. It can

be pulled low by external circuitry to reset the device.

A RESET signal coming from an external source

must have a duration of at least t

PULSE

in order to

be recognized. Two RESET sequences can be associated with this RESET source as shown in Figure 12.

When the RESET is generated by an internal

source, during the two first phases of the RESET

sequence, the device RESET pin acts as an output that is pulled low.

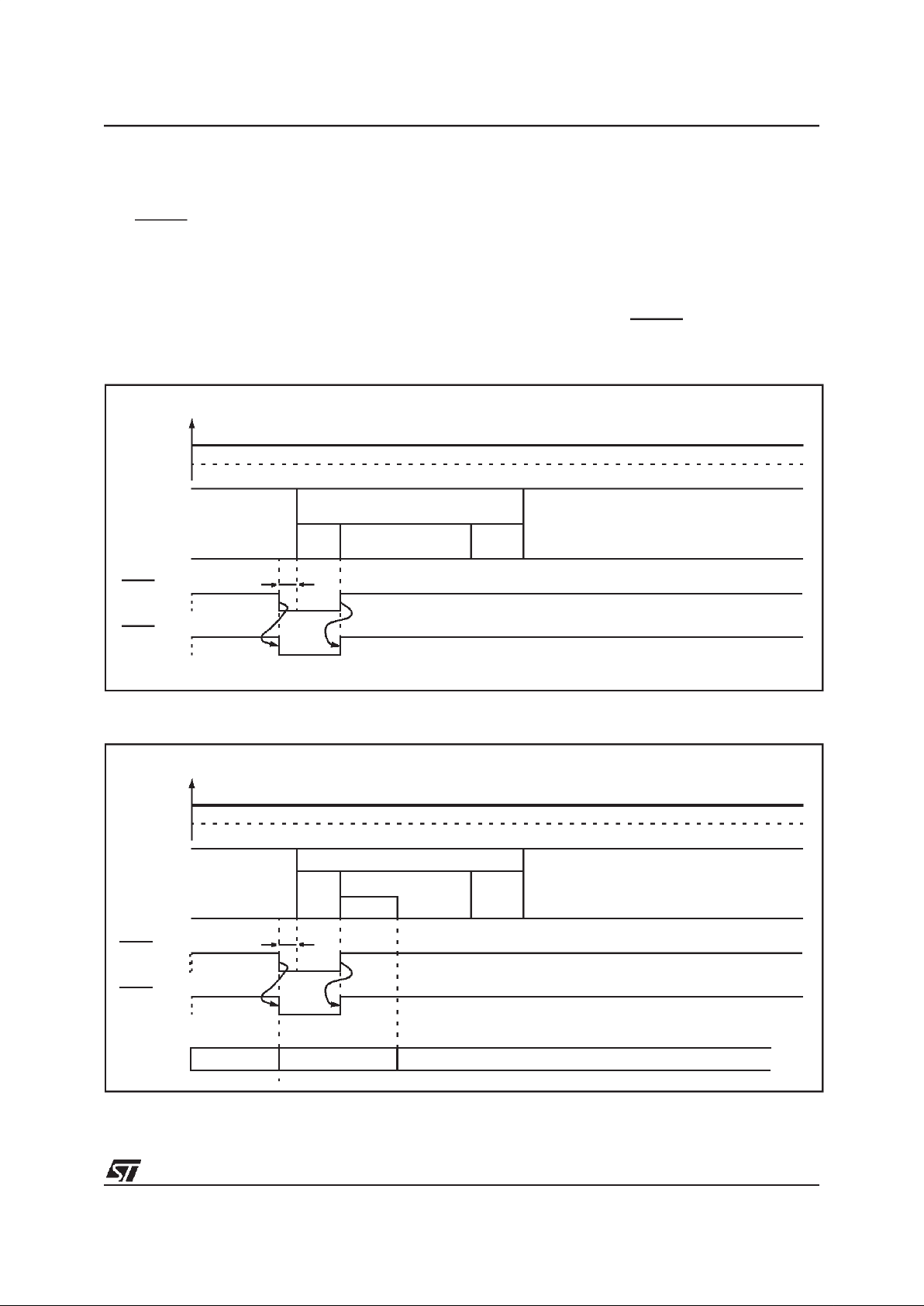

Figure 12. External RESET Sequence with internal Clock Selected (OSC_SEL pin tied to VSS)

Figure 13. External RESET Sequence with External Clock Selected (OSC_SEL pin tied to VDD)

5(6(7

581

INTERNAL RESET

4096 CLOCK CYCLES

FETCH

VECTOR

581

t

PULSE

9

’’

V

IT+

V

DD nominal

DELAY

RESET PIN

EXTERNAL

RESET SOURCE

5(6(7

581

INTERNAL RESET

260 CLOCK

FETCH

VECTOR

581

t

PULSE

9

’’

V

IT+

V

DD nominal

DELAY

LVDS,

ONOFF

OPSD,

PSS

4096 CLOCK CYCLES

CYCLES

ON

RESET PIN

EXTERNAL

RESET SOURCE

Page 20

ST72411R

20/71

RESET MANAGER (Cont’d)

,QWHUQD O /RZ 9ROWDJ H ’HWHFWL RQ 5 ( 6 ( 7

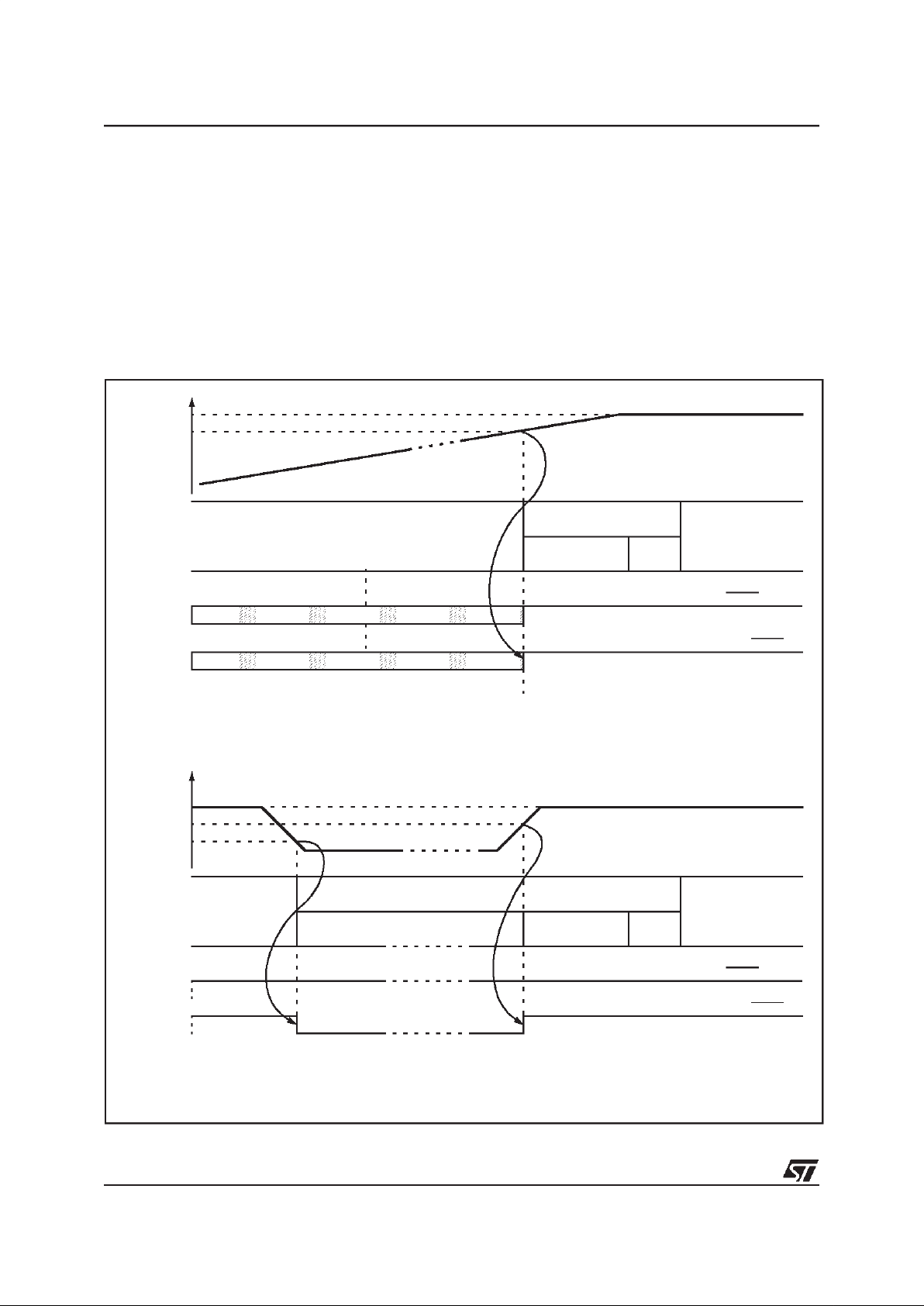

Two different RESET sequences caused bythe internal LVD circuitry can be distinguished:

- LVD Power-On RESET

- Voltage Drop RESET

In the second sequence, a “delay” phase is used

to keep the device in RESET state until VDDrises

up to V

IT+

(see Figure 14).

Important: if OSC_SEL pin is HIGH (external

clock selected), the LVD Power-On and the Voltage Drop featuresare disabled during the first 260

clock cycles (f

CPU

) after reset. This means that an

external reset circuitry must be provided to reset

the microcontroller.

Figure 14. LVD RESET Sequences when the OSC_SEL pin is tied to GND

5( 6( 7

581

INTERNAL RESET

4096 CLOCK CYCLES

FETCH

VECTOR

32 : ( 5

RESET PIN

EXTERNAL RESET SOURCE

5(6(7

581

INTERNAL RESET

4096 CLOCK CYCLES

FETCH

VECTOR

581

RESET PIN

EXTERNAL RESET SOURCE

9

’’

V

DDnominal

DELAY

V

IT+

V

IT-

9

’’

V

DDnominal

V

IT+

/

9

’

3

2

:

(

5

2

1

5

(

6

(

7

9

2

/

7

$

*

(

’

5

2

3

5

(

6

(

7

2))

7KH 2 6 &B6( / SLQ LV WLHG WR 9

66

LQWHU QD O FORFN VHOHFWHG / 9 ’ 6 D OZD\V DFWLYDWHG

7KH 2 6&B6( / SLQ LV WLHG WR * 1 ’

LQWHU QDO FORFN

V

HOHFWHG / 9 ’ 6 DOZD\V DFWLYDWHG

Page 21

ST72411R

21/71

3.3 MAIN CLOCK CONTROLLER SYSTEM (MCC)

The MCC block supplies the clock for the ST7

CPU and its internal peripherals. It allows to manage the SLOW power saving mode acting on the

SMS bit of the Miscellaneous register (MISCR)

and the Main clock-out capability acting on the

CKD and CKAFOEN bits of the Smartcard Supply

Supervisor ControlRegister (SSSCR).

The main clock of the ST7 can be generated by

two different sources (see Figure 17):

■ an external source

■ an internal RC oscillator

The device is normally operated using anintegrated 7.16MHz oscillator, meaning 3.58MHz operating frequency. However, an external clock can be

applied, up to 8MHz (4MHz operating frequency).

The clock source is selected through the

OSC_SEL pin status.

([WHUQD O &ORFN 6RXUFH

The OSC_SEL pin status selects the External

Clock capability when it is tied to VDD. In this

mode, a clock signal with ~50% duty cycle has to

drive the OSCIN pin (see Figure 15).

,QWHUQD O 5& 2VFLOODWRU 6RXUFH

The OSC_SEL pin status selects the Internal RC

clock source capability when it is tied to VSS(see

Figure 16).

Note that OSC_SEL pin contains a pull-down

which allows to leave OSC_SEL in high impedance in the applicationwhen the internal oscillator

is selected. This is mandatory for using the Remote In Situ Programming feature.

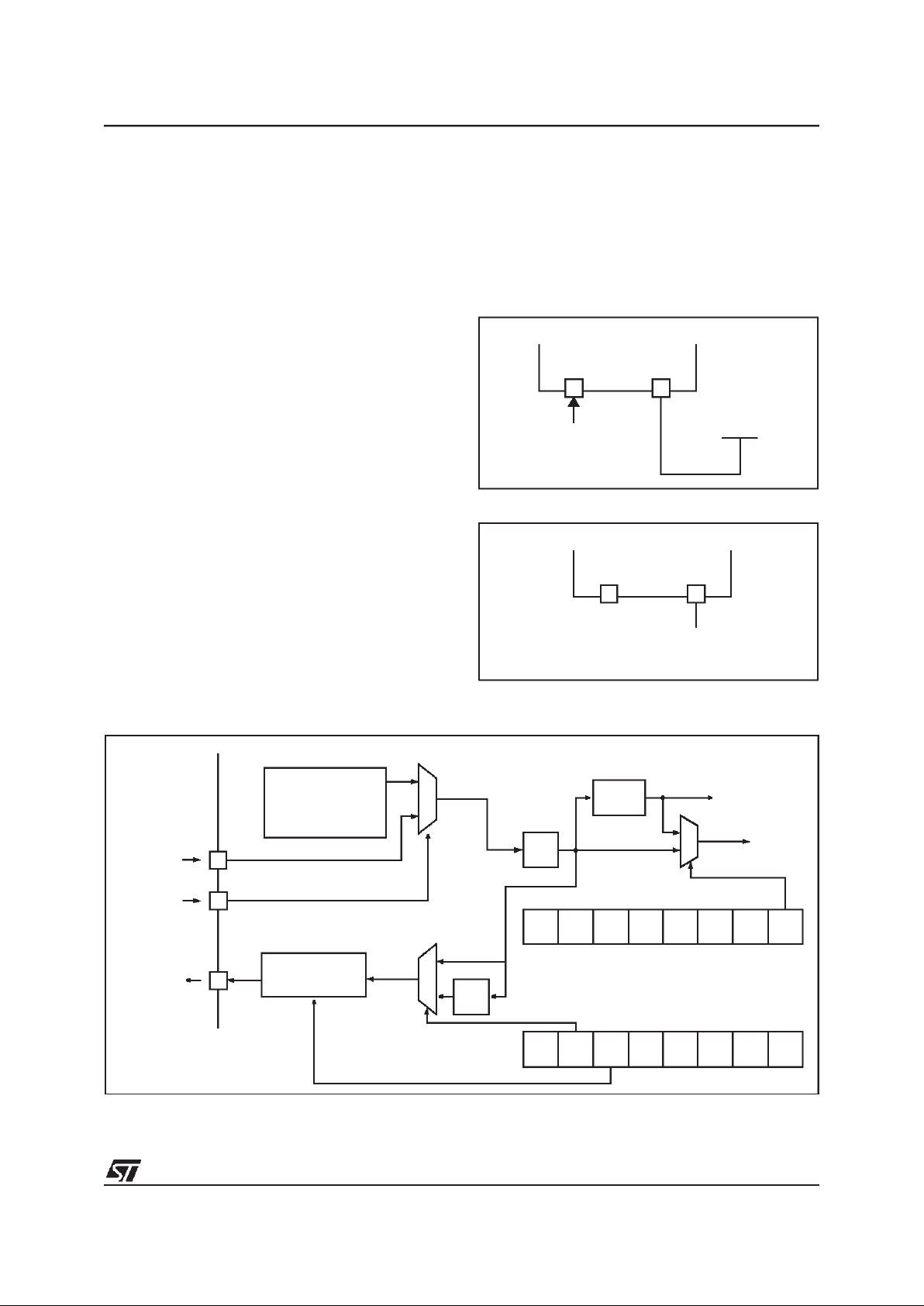

Figure 15. External Clock

Figure 16. Internal RC Oscillator

Figure 17. Main Clock Controller (MCC) Block Diagram

OSCIN OSC_SEL

EXTERNAL

ST7

SOURCE

V

DD

OSCIN OSC_SEL

ST7

highZ

(internal pulldown is present)

DIV 2

SMS--

MISCR

f

OSC

f

CPU

OSCIN

-----

INTERNAL

RC OSCILLATOR

7.16 MHz

OSC_SEL

DIV 16

SMARTCARD

interface

LCD and TIMER

---

SSSR

CK_A

--CKD-

FOEN

DIV 2

I/O ALTERNATE

FUNCTION

SC_CK

Page 22

ST72411R

22/71

4 INTERRUPTS

The ST7 core may be interruptedby one of two different methods: maskable hardware interrupts as

listed in the Interrupt Mapping Table and a nonmaskable software interrupt (TRAP). The Interrupt

processing flowchart is shown in Figure 1.

The maskableinterrupts must be enabled clearing

the I bit in order to be serviced. However, disabled

interrupts may be latched and processed when

they are enabled (see external interrupts subsection).

When an interrupt has to be serviced:

– Normal processing is suspended at the end of

the current instruction execution.

– The PC, X, A and CC registers are saved onto

the stack.

– The I bit of the CC register is set to prevent addi-

tional interrupts.

– ThePC is then loaded withtheinterrupt vector of

the interruptto service and the first instruction of

the interrupt service routine is fetched (refer to

the Interrupt Mapping Table for vector addresses).

The interrupt service routine should finish with the

IRET instruction which causes the contents of the

saved registers to be recovered from thestack.

Note: As a consequence of the IRET instruction,

the I bit will be cleared and the main program will

resume.

Priority management

By default, a servicing interrupt cannot be interrupted because the I bit is set by hardware entering in interrupt routine.

In the case when several interrupts are simultaneously pending, an hardware priority defines which

one will be serviced first (see the Interrupt Mapping Table).

Interrupts and Low power mode

All interrupts allow the processor to leave the

WAIT low power mode. Only external and specifically mentioned interrupts allow the processor to

leave the HALT low power mode (refer to the “Exit

from HALT“ column in the Interrupt Mapping Table).

4.1 NON MASKABLE SOFTWARE INTERRUPT

This interrupt is entered when the TRAP instruction is executed regardless of the state of the I bit.

It will be serviced according to the flowchart on

Figure 1.

4.2 EXTERNAL INTERRUPTS

External interrupt vectors can be loaded into the

PC register if the corresponding external interrupt

occurred and if the I bit is cleared.These interrupts

allow the processor to leave the Halt low power

mode.

The external interrupt polarity is selected through

the miscellaneous register or interrupt register (if

available).

An external interrupt triggered on edge will be

latched and the interrupt request automatically

cleared upon entering the interrupt serviceroutine.

If several input pins, connected to the same interrupt vector, are configured as interrupts, their signals are logically ANDed before entering the edge/

level detection block.

Caution:The type of sensitivity defined inthe Miscellaneous or Interrupt register (if available) applies to the ei source. In case of an ANDedsource

(as described on the I/O ports section), a lowlevel

on an I/O pin configured as input with interrupt,

masks the interrupt requesteven in case of risingedge sensitivity.

4.3 PERIPHERAL INTERRUPTS

Different peripheral interrupt flags in the status

register are able to cause an interrupt when they

are active if both:

– The I bit of the CC register is cleared.

– Thecorrespondingenablebit isset in the control

register.

If any of these two conditions is false, the interrupt

is latched and thus remains pending.

Clearing an interrupt request is done by:

– Writing “0”to the corresponding bit in the status

register or

– Access tothe status registerwhile the flag is set

followed by a read or write of an associated register.

Note: the clearing sequence resets the internal

latch. A pending interrupt (i.e. waiting for being enabled) will therefore be lost ifthe clear sequence is

executed.

Page 23

ST72411R

23/71

INTERRUPTS (Cont’d)

Figure 18. Interrupt Processing Flowchart

I BIT SET?

Y

N

IRET?

Y

N

FROM RESET

LOAD PC FROM INTERRUPT VECTOR

STACK PC, X, A, CC

SET I BIT

FETCH NEXT INSTRUCTION

EXECUTE INSTRUCTION

THIS CLEARS I BIT BY DEFAULT

RESTORE PC, X, A, CC FROM STACK

INTERRUPT

Y

N

PENDING?

Page 24

ST72411R

24/71

INTERRUPTS (Cont’d)

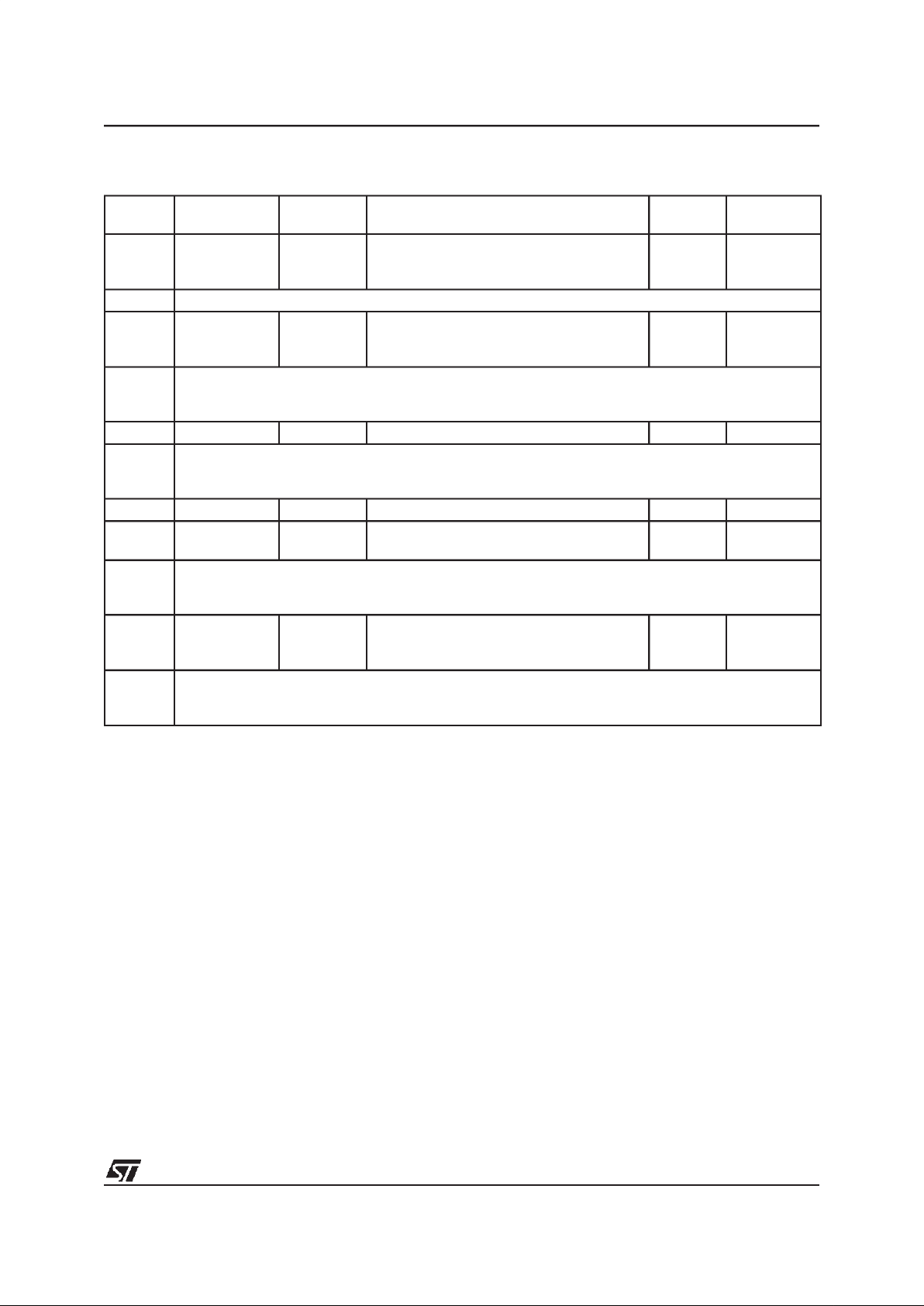

Table 4. Interrupt Mapping

N°

Source

Block

Description

Register

Label

Priority

Order

Exit

from

HALT

Address

Vector

RESET Reset

N/A

Highest

Priority

Lowest

Priority

yes FFFEh-FFFFh

TRAP Software Interrupt no FFFCh-FFFDh

0 Not used

-

FFFAh-FFFBh

1 Not used FFF8h-FFF9h

2 EI0 External Interrupt Port A7..0

N/A yes

FFF6h-FFF7h

3 EI1 External Interrupt Port B6..0 FFF4h-FFF5h

4 Not used

-

FFF2h-FFF3h

5 Not used FFF0h-FFF1h

6 Not used FFEEh-FFEFh

7 Not used FFECh-FFEDh

8 TIMER Timer Underflow Interrupt TSCR yes FFEAh-FFEBh

9 Not used FFE8h-FFE9h

10 Not used FFE6h-FFE7h

11 Not used FFE4h-FFE5h

12 SSS Smartcard Current Overload Interrupt SSSR no FFE2h-FFE3h

13 LVDS Power Down Interrupt MISCR no FFE0h-FFE1h

Page 25

ST72411R

25/71

4.4 POWER SAVING MODES

4.4.1 Introduction

There are three Power Saving modes. Slow Mode

is selected by setting the relevant bits in the Miscellaneous register. Wait and Halt modes may be

entered using the WFI and HALT instructions.

Table 5. Power Saving Modes

1

Except with external timer clock.

2

If the LVD bit in the MISCR register is reset

Note: To reduce power consumption (in Run or

Wait modes), the smartcard supply supervisor

(SSS) and the LCD can be disabled by software.

4.4.2 Slow Mode

In Slow mode, the oscillator frequency can be divided by a value defined in the Miscellaneous

Register. The CPU and peripherals are clocked at

this lower frequency except theLCD driver and the

8-bit Timerwhich have a fixed clock. Slow modeis

used to reduce power consumption, and enables

the user to adapt the clock frequency to the available supply voltage.

4.4.3 Wait Mode

Wait mode places the MCU in a low power consumption mode by stopping the CPU. The peripherals remain active. During Wait mode, the I bit

(CC Register) is cleared, so as to enable all interrupts. All other registers and memory remain unchanged. The MCU will remain in Wait mode until

an Interruptor Resetoccurs, the Program Counter

then branches to the starting address of the Interrupt or Reset Service Routine.

The MCUwill remainin Wait mode until aReset or

an Interrupt occurs, causing it to wake up.

Refer to Figure 19.

Figure 19. Wait Mode Flow Chart

Mode f

CPU

CPU

Peripherals

switched off.

Wake up

Slow f

OSC

/32 ON None -

Wait

f

OSC

/2

or

f

OSC

/32

OFF None

- External I/O

- Timer

- LVDS (PDF Flag).

- Reset

Halt OFF OFF

- SSS

- TIMER

1

- LVDS

2

- LCD

- External I/O

- Timer

- Reset

WFI INSTRUCTION

RESET

INTERRUPT

Y

N

N

Y

CPU CLOCK

OSCILLATOR

PERIPH. CLOCK

I-BIT

ON

ON

CLEARED

OFF

CPU CLOCK

OSCILLATOR

PERIPH. CLOCK

I-BIT

ON

ON

SET

ON

FETCH RESET VECTOR

OR SERVICE INTERRUPT

4096 CPU CLOCK

CYCLES DELAY

IF RESET

Note: Before servicing an interrupt, the CC register is

pushed on the stack. The I-Bit is set during the interrupt routine and cleared when the CC register is

popped.

Page 26

ST72411R

26/71

POWER SAVING MODES (Cont’d)

4.4.4 Halt Mode

The Halt mode is the lowest power consumption

mode of the MCU. Halt modeis entered byexecuting the HALT instruction. The internal oscillator is

then turned off, causing all internal processing to

be stopped, including the operation of the on-chip

peripherals.

When entering Halt mode, the I bit in the CC Register is cleared so as to enable External Interrupts.

If an interrupt occurs, the CPU becomes active.

The MCU can exit Halt modeon reception of an interrupt or a reset. Refer to the Interrupt Mapping

Table. The oscillator is then turned onand a stabilization time is provided before releasing CPU operation. The stabilization time is 4096 CPU clock

cycles.

After the start up delay, the CPU continues operation by servicing the interrupt which wakes it up

or by fetching the reset vector if a reset wakes it

up.

Note: If the LVD bit in the MISCR register is set,

the LVDS is not disabled when entering Halt

mode.

Figure 20. HALT Flow Chart

N

N

EXTERNAL

INTERRUPT*

RESET

HALT INSTRUCTION

4096 CPU CLOCK

FETCH RESET VECTOR

OR SERVICE INTERRUPT

CYCLES DELAY

CPU CLOCK

OSCILLATOR

PERIPH. CLOCK

I-BIT

ON

ON

SET

ON

CPU CLOCK

OSCILLATOR

PERIPH. CLOCK

I-BIT

OFF

OFF

CLEARED

OFF

Y

Y

* or some specific interrupts

Note: Before servicing an interrupt, the CC register is

pushed on the stack. The I-Bit is set during the interrupt routine and cleared when the CC register is

popped.

Page 27

ST72411R

27/71

5 ON-CHIP PERIPHERALS

5.1 I/O PORTS

5.1.1 Introduction

The I/O ports offer different functional modes:

– transferof data through digitalinputs and outputs

and for specific pins:

– external interrupt generation

– alternate signal input/output for the on-chip pe-

ripherals.

An I/O port contains up to 8 pins. Each pin can be

programmed independently as digital input (with or

without interrupt generation)or digital output.

5.1.2 Functional Description

Each port is associated to 2 main registers:

– Data Register (DR)

– Data Direction Register (DDR)

and one optional register:

– Option Register (OR)

Each I/Opin may beprogrammed using the corre-

sponding registerbits in DDR and ORregisters: bit

X corresponding to pinX of the port. The samecorrespondence is used for the DR register.

The following description takes into account the

OR register, for specific port which do not provide

this register refer to the I/O Port Implementation

section. The generic I/O block diagram is shown

on Figure 21.

Input Modes

The input configuration is selected by clearing the

corresponding DDR register bit.

In this case, reading the DR register returns the

digital value applied to the external I/O pin.

Different input modes can beselected by software

through the OR register.

Note1: Writing the DR register modifies the latch

value but does not affect the pin status.

Note2: When switching from input to output mode,

the DR register has to be written first to drive the

correct levelon the pinas soon as the ports is configured as an output.

External interrupt function

When an I/O is configured in Input with Interrupt,

an event on this I/O can generate an external Interrupt request to the CPU.

Each pin can independently generate an Interrupt

request. The interrupt sensitivity is given independently according to the description mentioned

in the Miscellaneous register.

Each external interrupt vector is linked to a dedicated group of I/O port pins (see Interrupt section).

If more than one input pins are selected simultaneously as interrupt source, these are logically ANDed. For this reason if one of the interrupt pins is

tied low, it masks the other ones.

In case of a floating input with interrupt configuration, special cares mentioned in the IO port implementation section have to betaken.

Output Mode

The output configuration is selected by setting the

corresponding DDR register bit.

In this case, writing the DR register applies this

digital value to the I/O pin through the latch. Then

reading the DR register returns the previously

stored value.

Two different output modes can be selected by

software through the OR register: Output push-pull

and open-drain.

DR register value and output pin status:

Note: In this mode, interrupt function is disabled.

Alternate function

When an on-chip peripheral is configured to use a

pin, the alternate function is automatically selected. This alternate function takes priority over the

standard I/O programming.

When the signal is coming froman on-chip peripheral, the I/O pin is automatically configured in output mode (push-pull or open drain according to the

peripheral).

When the signal is going to an on-chip peripheral,

the I/O pin has to be configured in input mode. In

this case, the pin’s state is also digitally readable

by addressing the DR register.

Note: Input pull-up configuration can cause unexpected value atthe input of the alternate peripheral

input. Whenan on chip peripheral use a pin as input and output, this pin has to be configured in input floating mode.

WARNING: The alternate function mustnot be activated as long as the pin is configured as input

with interrupt,in order toavoid generating spurious

interrupts.

DR Push-pull Open-drain

0V

SS

Vss

1V

DD

or V

SC_PWR

Floating

Page 28

ST72411R

28/71

I/O PORTS (Cont’d)

Smartcard versus Standard I/Os

The SmartcardI/O ports differfrom thestandard I/

O ports in that they have a different power supply:

the output buffers and the input Schmitt trigger are

supplied by V

SC_PWR

for the Smartcard I/Os and

by VDDfor the Standard I/Os.For Smartcard I/Os,

the Schmitttrigger is designed to guarantee output

levels compatible with VDDfor V

SC_PWR

=5V or

3V.

Caution: When the SSS regulator is deactivated

(bit SSSEN=0), the Smartcard I/O ports cannot be

used correctly (VSC_PWR=VSS). In this case,

special care is required when manipulating external interrupts: As Smartcard I/Os are always tied

to ground, they may mask interrupts on other I/O

lines of the same port.

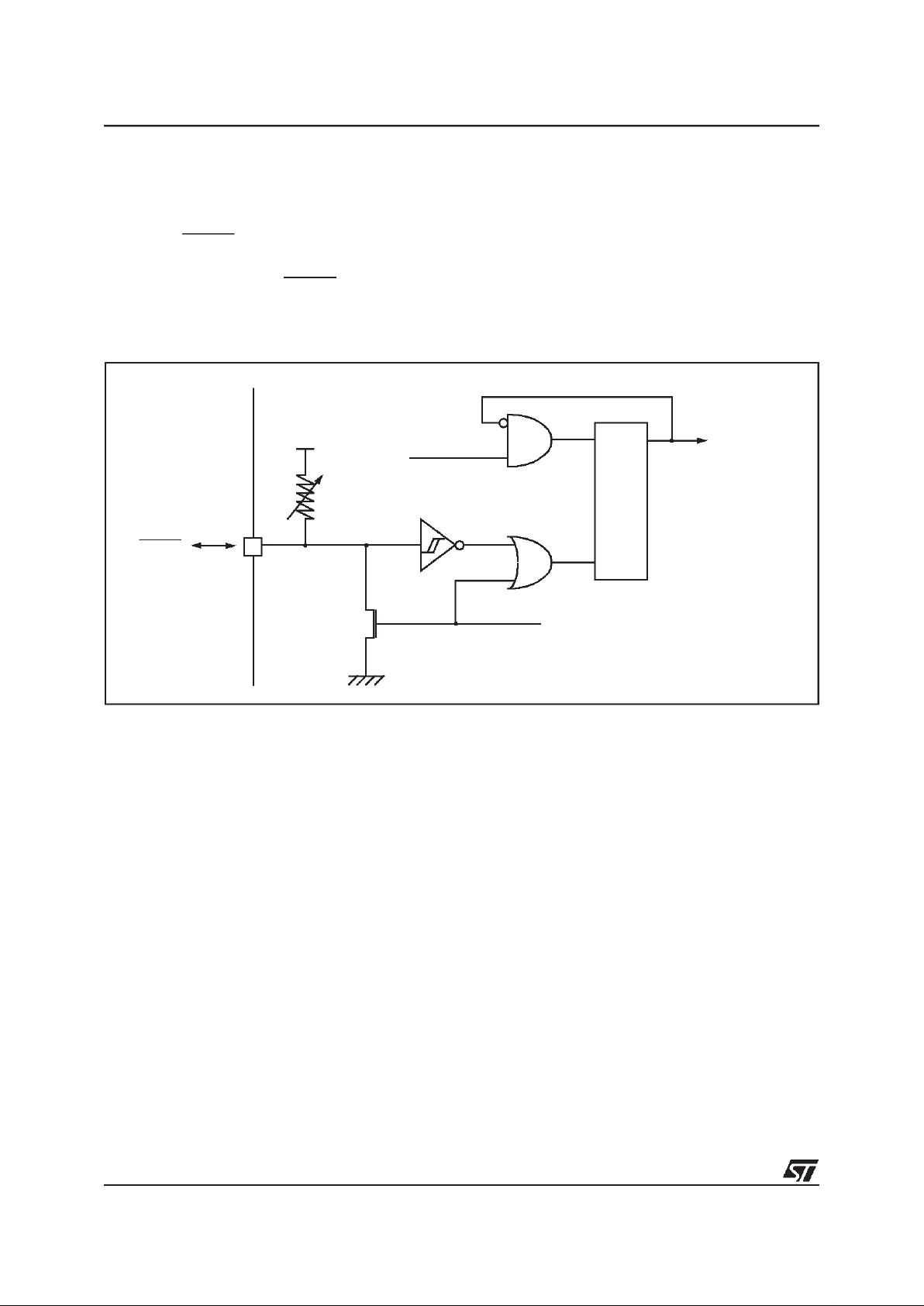

Figure 21. I/O Block Diagram

Table 6. Port Mode Options

NI - not implemented

Off - implemented not activated

On - implemented and activated

DR

DDR

OR

DATA BUS

PAD

V

DD

or V

SC_PWR

ALTERNATE

ENABLE

ALTERNATE

OUTPUT

1

0

OR SEL

DDR SEL

DR SEL

INTERRUPT

PULL-UP

CONDITION

P-BUFFER

(OPTION*)

N-BUFFER

PULL-UP

(OPTION*)

1

0

* SEE TABLE BELOW

ANALOG

INPUT

If implemented

ALTERNATE

INPUT

V

DD

or V

SC_PWR

DIODES

(OPTION*)

V

DD

or V

SC_PWR

PULL-DOWN

CONDITION

Configuration Mode Pull-Up P-Buffer Diodes

Input

Floating Off

Off

On

Pull-up with Interrupt On

Output

Push-pull

Off

On

Open Drain (logic level) Off

Push-pull with pull-up

On

On

Open Drain (logic level) with pull-up Off

True Open Drain NI

Page 29

ST72411R

29/71

I/O PORTS (Cont’d)

5.1.3 I/O Port Implementation

The I/O port register configurations are summarised as follows.

Standard Ports

PA0:7, PB5 (supplied by VDD)

PB6 (supplied by VDD)

PB0, 2, 3, 4 (supplied by V

SC_PWR

)

PB1 (Smartcard Data supplied by V

SC_PWR

)

Switching these I/O ports from one state to another should be done in a sequence that prevents unwanted side effects. Recommended safe transitions are illustrated in Figure 22 Other transitions

are potentially risky and should be avoided, since

they are likely to present unwanted side-effects

such as spurious interrupt generation.

Figure 22. Interrupt I/O Port State Transition

Table 7. Port Configuration

* Note: Smartcard I/Os supplied by V

SC_PWR

.

MODE DDR OR

floating input 0 0

pull-up input with interrupt 0 1

open drain output 1 0

push-pull output 1 1

MODE DDR OR

floating input 0 0

pull-down input with interrupt 0 1

open drain output 1 0

push-pull output 1 1

MODE DDR OR

floating input 0 0

pull-up input with interrupt 0 1

open drain output 1 0

push-pull output 1 1

MODE DDR OR

pull-up input 0 0

pull-up input with interrupt 0 1

open drain output with pull-up 1 0

push-pull output with pull-up 1 1

01

pull-up

interrupt

INPUT

00

floating

(reset state)

INPUT

10

open-drain

OUTPUT

11

push-pull

OUTPUT

XX

= DDR, OR

Port Pin name

Input Output

OR = 0 OR = 1 OR = 0 OR = 1

Port A PA7:0 floating pull-up interrupt open drain push-pull

Port B

PB6 floating pull-down interrupt open drain push-pull

PB5 floating pull-up interrupt open drain push-pull

PB4:2 (SC*) floating pull-up interrupt open drain push-pull

PB1 (SC*) pull-up pull-up interrupt pull-up open drain pull-up push-pull

PB0 (SC*) floating pull-up interrupt open drain push-pull

Page 30

ST72411R

30/71

I/O PORTS (Cont’d)

5.1.4 Register Description

’ $7$ 5(*,67(5 ’ 5

Port x Data Register

PxDR with x = A or B.

Note: In Port B, PB[7] is unused.

Read/Write

Reset Value: 0000 0000 (00h)

Bit 7:0 = D[7:0]

Data register 8 bits.

The DR register has a specific behaviour according to the selectedinput/output configuration. Writing the DR register is always taken into account

even ifthe pin is configuredas aninput; this allows

to always have the expected level on the pin when

toggling to output mode. Reading the DR register

returns either the DR register latch content (pin

configured asoutput) or the digitalvalue applied to

the I/O pin (pin configured as input).

DATA DIRECTION REGISTER (DDR)

Port x Data Direction Register

PxDDR with x = A or B.

Read/Write

Reset Value: 0000 0000 (00h)

Bit 7:0 = DD[7:0]

Data direction register 8 bits.

The DDR register gives the input/output direction

configuration of the pins. Each bits is set and

cleared by software.

0: Input mode

1: Output mode

237,2 1 5(*,67(5 25

Port x Option Register

PxOR with x = A or B.

Read/Write

Reset Value: 0000 0000 (00h)

Bit 7:0 = OR[7:0]

Option register 8 bits.

For specific I/O pins, this register is not implemented. In this case the DDR register is enough to select the I/O pin configuration.

The OR register allows to distinguish: in input

mode if the pull-up (or pull-down for PB6) with interrupt capability or the floating (pull-up for PB1)

configuration is selected, in output mode if the

push-pull or open drain configuration is selected.

Each bit is set and cleared by software.

70

D7 D6 D5 D4 D3 D2 D1 D0

70

DD7 DD6 DD5 DD4 DD3 DD2 DD1 DD0

70

O7 O6 O5 O4 O3 O2 O1 O0

Page 31

ST72411R

31/71

I/O PORTS (Cont’d)

Table 8. I/O Port Register Map and Reset Values

Address

(Hex.)

Register

Label

76543210

Reset Value

of all IO port registers

00000000

0000h PADR

MSB LSB0001h PADDR

0002h PAOR

0004h PBDR

- MSB LSB0005h PBDDR

0006h PBOR

Page 32

ST72411R

32/71

5.2 MISCELLANEOUS REGISTER

The miscellaneous register allows control over

several features such as the external interrupts or

the I/O alternate functions.

5.2.1 I/O Port Interrupt Sensitivity Description

The external interrupt sensitivity is controlled by

the IPBand IS[1:0]bits ofthe Miscellaneous register (Figure 23). Up to 2 fully independent external

interrupt source sensitivities are allowed.

Each external interrupt source can be triggered by

four different events on the pin:

■ Falling edge

■ Rising edge

■ Falling and rising edge

■ Falling edge and low level

To guarantee the functionality, a modification of

the sensitivity in the MISC register can be done

only when the I bit of the CC register is set to 1 (interrupt masked). See I/O port register and Miscellaneous register descriptions for more details on

programming.

Caution: Take care when changing the value of

the IPB bit as, in some cases, an interrupt will be

generated by the edge resulting from the change.

5.2.2 Slowmode and VDDSupply Monitoring

The MISCRregister manages SLOW mode selection and the LVDSVDDmonitoring interrupt. Refer

to the register description.

Figure 23. External Interrupt Sources vs MISCR

EI1

INTERRUPT

SOURCE

EI0

INTERRUPT

SOURCE

IS0IS1

MISCR

SENSITIVITY

CONTROL

PB6

IPB

PB0

SOURCES

PA7

PA0

SOURCES

Page 33

ST72411R

33/71

MISCELLANEOUS REGISTER (Cont’d)

0,6&(//$1(286 5(*,67(5 0 ,6&5

Read/Write

Reset Value: x000 0000 (x0h)

(for bit 7, the reset value depends on VDD)

Bit 7 = PSSF

Power Supply Supervisor Flag

This bit is set and cleared by hardware.

0: VDDis greater than V

PSS

.

1: VDDis less than V

PSS

.

Bit 6= LVD

LVD ON during HALT mode

This bit is set and cleared by software.

This bit is used to keep the LVD active during

HALT mode.

0: LVD switched off in HALT mode (reset state).

1: LVD active in HALT mode.

Bit 5 = IPB

Interrupt polarity for port B

This bit is used to reverse the external interrupt

sensitivity polarity of the port B[6:0] pins. It is set

and cleared by software.

0: Standard sensitivity polarity

1: Reversed sensitivity polarity

Note: See IS[1:0] bit description for more details.

This bit canbe written onlywhen the I bit of theCC

register is set to 1(if interrupts are masked).

Bit 4:3 = IS[1:0]

EI0 and EI1 sensitivity

These bits are used to program the interrupt sensitivity of the following external interrupts:

- EI1 (port B[6:0])

- EI0 (port A[7:0])

These 2 bits can be written only when the I bit of

the CC register is set to 1 (interrupt masked).

Bit 2 = PDIE

Power Down Interrupt Enable

This bit is set andcleared by software.

0: Power down interrupt disabled

1: Power down interrupt enabled

Bit 1 = PDF

Power Down Flag

This bit is set and cleared by software or set by

hardware if(V

REF-VDD

) > M. If the PDIEbit is set,

an interrupt is generated when PDF is set (sensitivity is high level). It can be cleared only by software writing zero. It can also be set by software,

generating an interrupt if PDIE is enabled.

0: (V

REF-VDD

) < M: No open VDDcircuit detected

1: (V

REF-VDD

) > M : Open VDDcircuit detected.

Bit 0 = SMS

Slow mode select

This bit is set andcleared by software.

0: Normal mode. f

CPU

= f

OSC

/2

1: Slow mode. f

CPU

= f

OSC

/32

See low power mode and MCC chapters for more

details.

76543210

PSSF LVD IPB IS1 IS0 PDIE PDF SMS

IS1 IS0

External Interrupt Sensitivity

MISCR.IPB=0 MISCR.IPB=1

00

Falling edge &

low level

Rising edge

& high level

0 1 Rising edge only Falling edge only

1 0 Falling edge only Rising edge only

1 1 Rising and falling edge

IS1 IS0 External Interrupt Sensitivity

0 0 Falling edge & low level

0 1 Rising edge only

1 0 Falling edge only

1 1 Rising and falling edge

Page 34

ST72411R

34/71

5.3 8-BIT TIMER (TIM8)

5.3.1 Introduction

The 8-Bit Timer on-chip peripheral (TIM8) is a free

running downcounter based on an 8-bit downcounter with a 9-bit programmable prescaler.

5.3.2 Main Features

■ Timeout downcounting mode with up to 16-bit

accuracy

■ External counter clock source (valid also in

HALT mode)

■ Interrupt capability on counter underflow

■ Output signal generation

■ External pulse length measurement

■ Time base interrupt

The timer can be used in WAIT and HALT modes

and to wake upthe MCU.

Figure 24. Timer Block Diagram

f

TIMER

/8

f

TIMER

/64

f

TIMER

/512

UDF INTERRUPT

OEN TOUT DOUT UDF ETI PSE PS1 PS0

TSCR

PROGRAMMABLE PRESCALER

PSCR7 PSCR6 PSCR5 PSCR4 PSCR3 PSCR2 PSCR1 PSCR0

PSCR

0

PSCR8

852

70

TCR7 TCR6 TCR5 TCR4 TCR3 TCR2 TCR1 TCR0

TCR

70

UNDERFLOW

RELOAD

8-BIT COUNTER

ALTERNATE

FUNCTION

TIMIO

f

TIMER

f

TIMER

f

COUNTER

f

EXT

DIV16

DIV2

f

CPU

f

OSC

LATCH

Page 35

ST72411R

35/71

8-BIT TIMER (Cont’d)

5.3.3 Counter/Prescaler Description

Counter

The free running 8-bit downcounter is fed by the

output of the programmable prescaler, and is decremented on every rising edge of the f

COUNTER

clock signal.

It is possible to read or write the contents of the

counter on the fly, by reading or writing the timer

counter register (TCR).

When a counter underflow occurs, the counter is

automatically reloaded with the value FFh.

Counter clock and prescaler

The counter clock frequency is given by:

f

COUNTER=fTIMER

/8

PS[1:0]

where f

TIMER

can be:

–f

CPU

/16

–f

EXT

(input on TIMIO pin)

–f

CPU

/16 gated by TIMIO pin

Table 13 lists the values that f

COUNTER

can take if

f

TIMER

is f

CPU

/16.

Table 9. f

counter

values for a f

cpu

=3.58MHz

The timer input clock (f

TIMER

) feeds the 9-bit programmable prescaler. The prescaler output can be

programmed by selecting one of the 4 available

prescaler taps using the PS[1:0] bits in the Status/

Control Register (TSCR). Thus the division factor

of the prescaler can be set to 8n(where nequals 0,

1, 2 or 3). See Figure 38.

The clock input is enabled by the PSE (Prescaler

Enable) bit in the TSCR register. When PSE is reset, the counter is frozen andthe prescaler is loaded with the value 1FFh. When PSE is set, the

prescaler and thecounter run at the rate of the selected clock source.

Counter and Prescaler Initialization

After RESET, the counterand theprescaler are initialized to FFh and 1FFh respectively.

The 9-bit prescaler can be initialized separately to

1FFh by clearing the PSE bit. Direct write access

to the prescaler is not possible.

The 8-bit counter can be initialized separately by

writing to the TCR register.

f

counter

PS0 PS1

224 kHz 0 0

28 kHz 1 0

3.5 kHz 0 1

437 Hz 1 1

Page 36

ST72411R

36/71

8-BIT TIMER (Cont’d)

5.3.4 Functional description

5.3.4.1 8-bit counting and interrupt capability

on counter underflow

Whatever the division factor defined for the prescaler, the Timer Counter works as an 8-bit downcounter. The inputclock frequency is user selectable using the PS0 and PS1 bits.

When the downcounter underflows (transition from

00h to FFh), the UDF (Timer Underflow) bit in the

TSCR is set. If the ETI (Enable Timer Interrupt) bit

in the TSCR is also set, an interrupt request is

generated.

The Timer interrupt can be used to exit the MCU

from WAIT or HALT mode.

The TCR can be written at any time by softwareto

define a time period endingwith a UDF event, and

therefore manage delay or timer functions.

UDF is set when the counter underflows (clock

pulse creating the transition from 00h to FFh);

however, it may also be set by setting bit 4 of the

TSCR register. The UDF bit must be cleared by

user software when servicing the timer interrupt to

avoid undesired interrupts when leaving the interrupt service routine. After reset, the 8-bit counter

register is loaded with 0FFh, while the 9-bit prescaler is loaded with 1FFh, and the TSCR register

is loaded with 050h. This means that the Timer is

stopped (PSE=“0”) and the timer interrupt is disabled.

Note: A write to the TCR register will predominate

over the 8-bit counter decrement to 00h function,

i.e. if a write and a TCR register decrement to 00h

occur simultaneously, the write will take precedence, and the UDF bit is not set until the 8-bit

counter underflows again.

Application Notes

– Atimebase interrupt can becreated by using the

UDF interrupt to generate interrupts at regular

time intervals.

With the maximum prescaler ratio set, the maximum period between two UDF flags is:

512/f

TIMER

If we consider the previous example:

(f

TIMER=fCPU

/16)

we have

(512*16) / f

CPU

(2.3 ms for a f

CPU

of 3.58MHz).

With the minimum prescaler ratio set, the minimum step of the 8-bit downcounter, i.e the res-

olution, is 1/f

TIMER

, that means16 / f

CPU

(4.5 µs

for a f

CPU

=3.58MHz)

.

– When the maximum divisionfactor (512) is set,

the input clock tothe 8-bit downcounter is the9th

and last bit of the prescaler. This means, the 9bit prescaler and the 8-bit counter are serialized

and canbe considered as a 16-bit counterwith a

frequency of f

TIMER

/512.

5.3.4.2 Gated mode

(TOUT = “0”, DOUT = “1”)

Figure 25. f

TIMER

Clock in Gated Mode

In this mode, the prescaler is decremented by the

Timer clock input, but only when the signal on the

TIMIO pin is held high (f

CPU

/16 gated by TIMIO).

See Figure 39 and Figure 40.

This mode is selected by clearing the TOUT bit in

the TSCR register (i.e. as input) and setting the

DOUT bit.

Figure 26. .Gated Mode Operation

f

TIMER

TIMIO

f

CPU

/16

f

EXT

xx1

1

Counter Value

TIMIO Pin

Timer Clock

Value 1

Value 2

Pulse Length

xx2

Page 37

ST72411R

37/71

8-BIT TIMER (Cont’d)

5.3.4.3 Event counter mode

(TOUT = “0”, DOUT = “0”)

Figure 27. f

TIMER

Clock in Event Counter Mode

In this mode, theTIMIO pin is the input clockof the

Timer prescaler which is decremented on every

rising edge of the input clock (allowing event

count). See Figure 41 and Figure 42.

This mode is selected by clearing the TOUT bit in

the TSCR register (i.e. as input) and clearing the

DOUT bit.

Figure 28. Event Counter Mode Operation

5.3.4.4 Output mode

(TOUT = “1”, DOUT = “data out”)

Figure 29. Output Mode Control

In Output mode, theTIMIO pin is connected to the

DOUT latch, hence the Timer prescaler isclocked

by the prescaler clock input (f

CPU

/16). See Figure

43.

The user can select the desired prescaler division

ratio through the PS1 and PS0 bits of the TSCR

register. When the TCR count underflows, it sets

the UDF bit in the TSCR. TheUDF bit can be tested under program control to perform a timer function whenever it goes high and has to be cleared

by the user. The low-to-high UDF bit transition is

used to latch the DOUT bit ofthe TSCR and, if the

OEN bit is set, DOUT is transferred to the TIMIO

pin. This operating mode allows external signal

generation on the TIMIO pin. See Figure 44.

This mode is selected by setting the TOUT bit in

the TSCR register (i.e. as output) and setting the

DOUT bit to output a high level or clearing the

DOUT bit to output a low level

Figure 30. Output Mode Operation

f

TIMER

TIMIO

xx1

Counter Value

TIMIO Pin

Value 1

Value 2

xx2

TIMIO

OEN DOUT UDF

LATCH

ALTERNATE

FUNCTION

TOUT DOUT

Timer

Function

Application

00

Event Counter

(input)

External counter clock

source

01