Page 1

查询ST24E64EB1TR供应商

SERIALEXTENDED ADDRESSING COMPATIBLE

COMPATIBLEwith I2C EXTENDED

ADDRESSING

TWO WIRE SERIAL INTERFACE,

SUPPORTS400kHz PROTOCOL

1 MILLION ERASE/WRITECYCLES, OVER

the FULL SUPPLYVOLTAGERANGE

40 YEARSDATA RETENTION

SINGLESUPPLYVOLTAGE

– 4.5V to 5.5V for ST24E64 version

– 2.5V to 5.5V for ST25E64 version

WRITECONTROLFEATURE

BYTEand PAGEWRITE (up to 32 BYTES)

BYTE, RANDOM and SEQUENTIALREAD

MODES

SELFTIMED PROGRAMINGCYCLE

AUTOMATIC ADDRESS INCREMENTING

ENHANCEDESD/LATCHUP

PERFORMANCES

WITH I

ST24E64

ST25E64

2

C BUS 64K (8K x 8) EEPROM

PRELIMINARYDATA

8

1

PSDIP8 (B)

0.25mm Frame

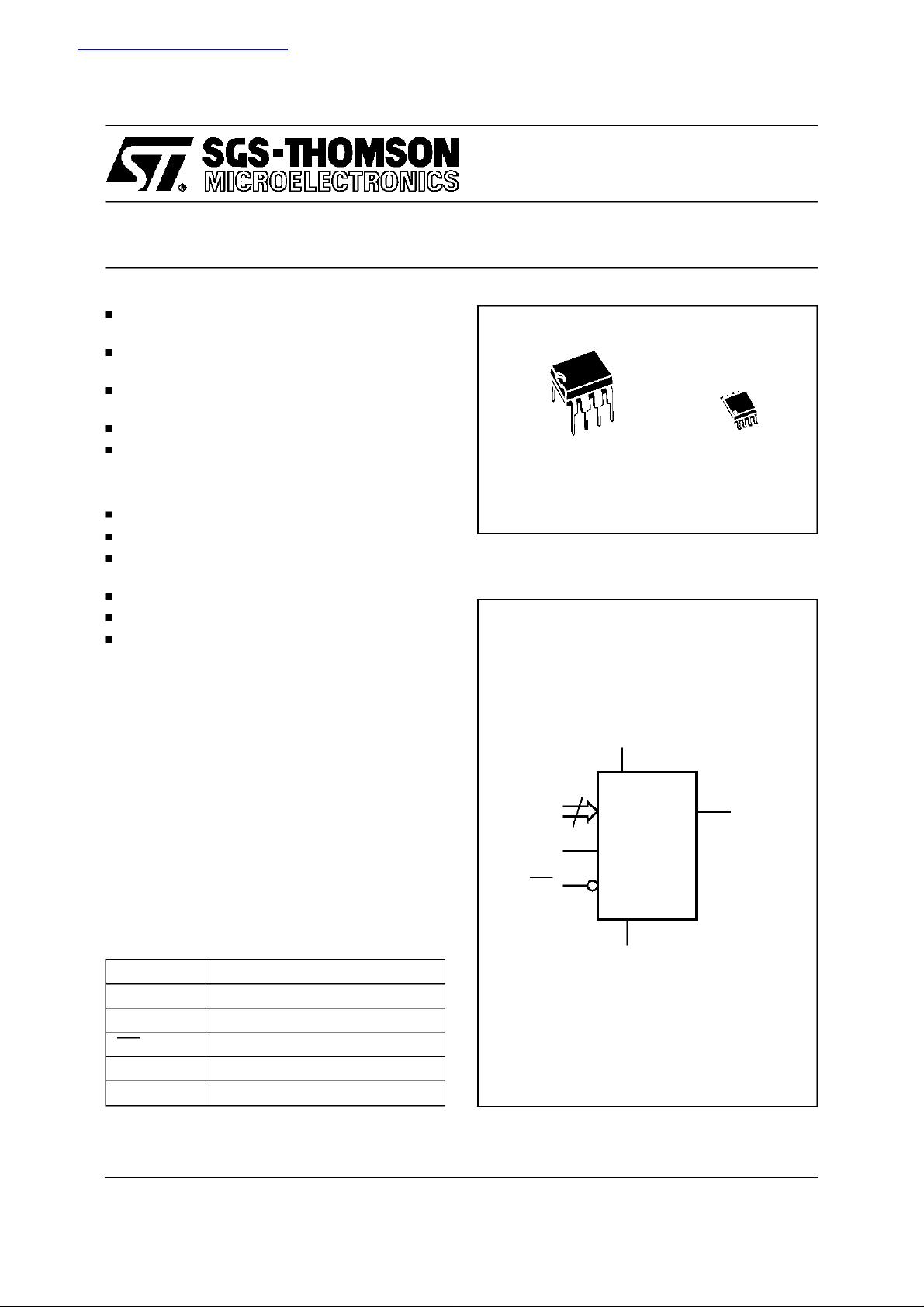

Figure 1. Logic Diagram

8

1

SO8 (M)

200mil Width

V

CC

DESCRIPTION

The ST24/25E64 are 64K bit electrically erasable

programmable memories (EEPROM), organized

as8 blocksof 1024x 8bits.TheST25E64operates

with a power supply value as low as 2.5V. Both

PlasticDual-in-LineandPlasticSmallOutlinepack-

E0-E2 SDA

SCL

3

ST24E64

ST25E64

ages are available.

WC

Table 1. Signal Names

V

E0 - E2 Chip Enable Inputs

SDA Serial Data Address Input/Output

SCL Serial Clock

WC Write Control

V

CC

V

SS

November 1996 1/16

This is preliminary information on a newproduct now in development or undergoing evaluation.Details are subject to change without notice.

Supply Voltage

Ground

SS

AI01204B

Page 2

ST24E64, ST25E64

Figure2A. DIP Pin Connections

ST24E64

ST25E64

E0 V

1

2

E2

3

4

SS

Table2. Absolute MaximumRatings

Symbol Parameter Value Unit

T

A

T

STG

Ambient Operating Temperature –40 to 125 °C

Storage Temperature –65 to 150 °C

8

7

6

5

AI01205B

CC

WCE1

SCL

SDAV

(1)

Figure2B. SO Pin Connections

ST24E64

ST25E64

E0 V

1

2

E2

SS

3

4

8

7

6

5 SDAV

AI01206C

CC

WCE1

SCL

T

LEAD

V

IO

V

CC

V

ESD

Notes: 1. Except for the rating ”Operating Temperature Range”, stresses above those listed in the Table”Absolute Maximum Ratings”

may cause permanent damage to the device. Theseare stress ratings only and operation of the device atthese or any other

conditions above thoseindicated in the Operating sections of this specification is not implied. Exposure to Absolute Maximum

Rating conditions for extended periods may affectdevice reliability. Refer also to the SGS-THOMSON SURE Program and

other relevantquality documents.

2. 100pF through 1500Ω; MIL-STD-883C, 3015.7

3. 200pF through 0Ω; EIAJ IC-121 (condition C)

Lead Temperature, Soldering (SO8)

Input or Output Voltages –0.6 to 6.5 V

Supply Voltage –0.3 to 6.5 V

Electrostatic Discharge Voltage (Human Body model)

Electrostatic Discharge Voltage (Machine model)

(PSDIP8)

(3)

DESCRIPTION (cont’d) slave devices in the I

2

Each memory is compatible with the I

Cextended

addressing standard, two wire serial interface

which uses a bi-directional data bus and serial

clock.TheST24/25E64carrya built-in4bit, unique

deviceidentification code(1010) correspondingto

2

C bus definition.The ST24/25E64behaveas

the I

operationssynchronizedby the serial clock. Read

and write operations are initiated by a START

conditiongeneratedbythebusmaster.TheSTART

conditionis followed by a stream of 4 bits(identification code 1010), 3 bit Chip Enable input to form

a 7 bit DeviceSelect, plus one read/write bit and

terminatedby an acknowledgebit.

40 sec

10 sec

(2)

2

C protocol with all memory

215

260

4000 V

500 V

°C

2/16

Page 3

ST24E64, ST25E64

Table 3. Device Select Code

Device Code Chip Enable RW

Bit b7 b6 b5 b4 b3 b2 b1 b0

Device Select 1 0 1 0 E2 E1 E0 RW

Note: The MSB b7 is sent first.

Table 4. OperatingModes

Mode RW bit Bytes Initial Sequence

Current Address Read ’1’ 1 START,Device Select, RW = ’1’

Random Address Read

Sequential Read ’1’ 1 to 8192 As CURRENT or RANDOM Mode

Byte Write ’0’ 1 START,Device Select, RW = ’0’

Page Write ’0’ 32 START, Device Select, RW = ’0’

’0’

’1’ reSTART, Device Select, RW = ’1’

1

Whenwritingdata tothememoryit respondsto the

8 bits received by asserting an acknowledge bit

during the 9th bit time. When data is read by the

busmaster,itacknowledgesthereceiptof the data

bytes in the same way.

Data transfers are terminated with a STOP condition. In this way, up to 8 ST24/25E64 may be

connectedto the same I

2

C bus and selected individually, allowing a total addressing field of 512

Kbit.

Power On Reset: V

lock out write protect. In

CC

order to prevent data corruption and inadvertent

write operations during power up, a Power On

Reset(POR) circuit is implemented.Untill the V

CC

voltagehas reachedthe POR thresholdvalue,the

internal reset is active:all operationsare disabled

and the device will not respondto any command.

In the same way, when V

drops down from the

CC

operating voltage to below the POR threshold

value, all operations are disabled and the device

will not respond to any command. A stable V

CC

mustbe appliedbefore applying any logic signal.

START, Device Select, RW = ’0’, Address,

resistorcan be connected fromtheSCLlineto V

to act as a pull up (see Figure 3)

Serial Data (SDA). The SDA pin is bi-directional

and isusedtotransferdatain oroutof the memory.

It is an opendrain output that may be wire-OR’ed

with other open drain or open collector signals on

the bus.AresistormustbeconnectedfromtheSDA

bus line to V

to act as pull up (seeFigure 3).

CC

Chip Enable (E0 - E2). These chip enableinputs

are used to set the 3 least significant bits of the 7

bit deviceselectcode.Theymaybedrivendynamically or tied to V

selectcode. Note that theV

or VSSto establish the device

CC

IL

inputs are CMOS, not TTL compatible.

Write Control (WC). The Write Control feature

WC isuseful to protectthe contentsof the memory

from any erroneous erase/write cycle. The Write

Control signal is used to enable (WC at V

disable (WC at V

) the internal write protection.

IL

When pin WC is unconnected, the WC input is

internallyread as V

(seeTable 5).

IL

When WC = ’1’, Device Select and Addressbytes

are acknowledged; Data bytes are not acknow-

SIGNALSDESCRIPTION

Serial Clock (SCL). The SCLinput pin is used to

synchronize all data in and out of the memory. A

ledged.

Refer to the AN404 ApplicationNote for morede-

tailed information about WriteControl feature.

CC

and VIHlevelsfor the

)or

IH

3/16

Page 4

ST24E64, ST25E64

Figure3. Maximum RLValueversusBus Capacitance(C

20

16

12

max (kΩ)

L

R

8

4

0

VCC=5V

25 50 75 100

C

(pF)

BUS

) foran I2C Bus, fC= 400kHz

BUS

V

CC

R

L

SDA

MASTER

SCL

C

BUS

R

L

C

BUS

AI01115

DEVICE OPERATION

2

I

C Bus Background

TheST24/25E64supportthe extendedaddressing

2

I

C protocol.This protocol defines any devicethat

sends data onto the bus as a transmitterand any

devicethatreadsthedataas areceiver. Thedevice

that controls the data transfer is known as the

masterand the other as the slave. The masterwill

always initiate a data transfer and will provide the

serial clock for synchronisation. The ST24/25E64

arealways slavedevices in allcommunications.

Start Condition. STARTis identified by a high to

low transition of the SDA line while the clock SCL

isstable in the high state. ASTARTcondition must

precede any command for data transfer. Except

duringa programmingcycle,the ST24/25E64continuously monitor the SDA and SCL signals for a

START conditionand will not respond unless one

isgiven.

StopCondition. STOPisidentifiedbyalowtohigh

transition of the SDA line while the clock SCL is

stable in the high state. A STOP condition terminates communication between the ST24/25E64

and the bus master.A STOP condition at the end

of a Read command forces the standby state. A

STOP condition at the end of a Write command

triggersthe internalEEPROM write cycle.

Acknowledge Bit (ACK). Anacknowledgesignal

is used to indicate a successfuldata transfer.The

bustransmitter, eithermasteror slave,will release

theSDAbusaftersending8 bits of data.Duringthe

9th clock pulse the receiverpulls the SDAbus low

to acknowledgethe receiptof the 8 bitsofdata.

Data Input. During data input the ST24/25E64

sample the SDA bus signal on the rising edge of

the clock SCL. For correct device operation the

SDAsignal must be stable during the clock low to

high transition and the data must change ONLY

when the SCL lineis low.

Device Selection. To start communication between the bus master and the slave ST24/25E64,

the master must initiate a STARTcondition.The 8

bitssent after a STARTcondition aremadeup ofa

deviceselectof4bitsthatidentifiesthedevicetype,

3 Chip Enable bits and one bit for a READ (RW =

1) or WRITE (RW = 0) operation. There are two

modesboth for read andwrite. Theseare summarisedinTable4 anddescribedhereafter.Acommunicationbetweenthemasterandtheslaveis ended

witha STOP condition.

4/16

Page 5

ST24E64, ST25E64

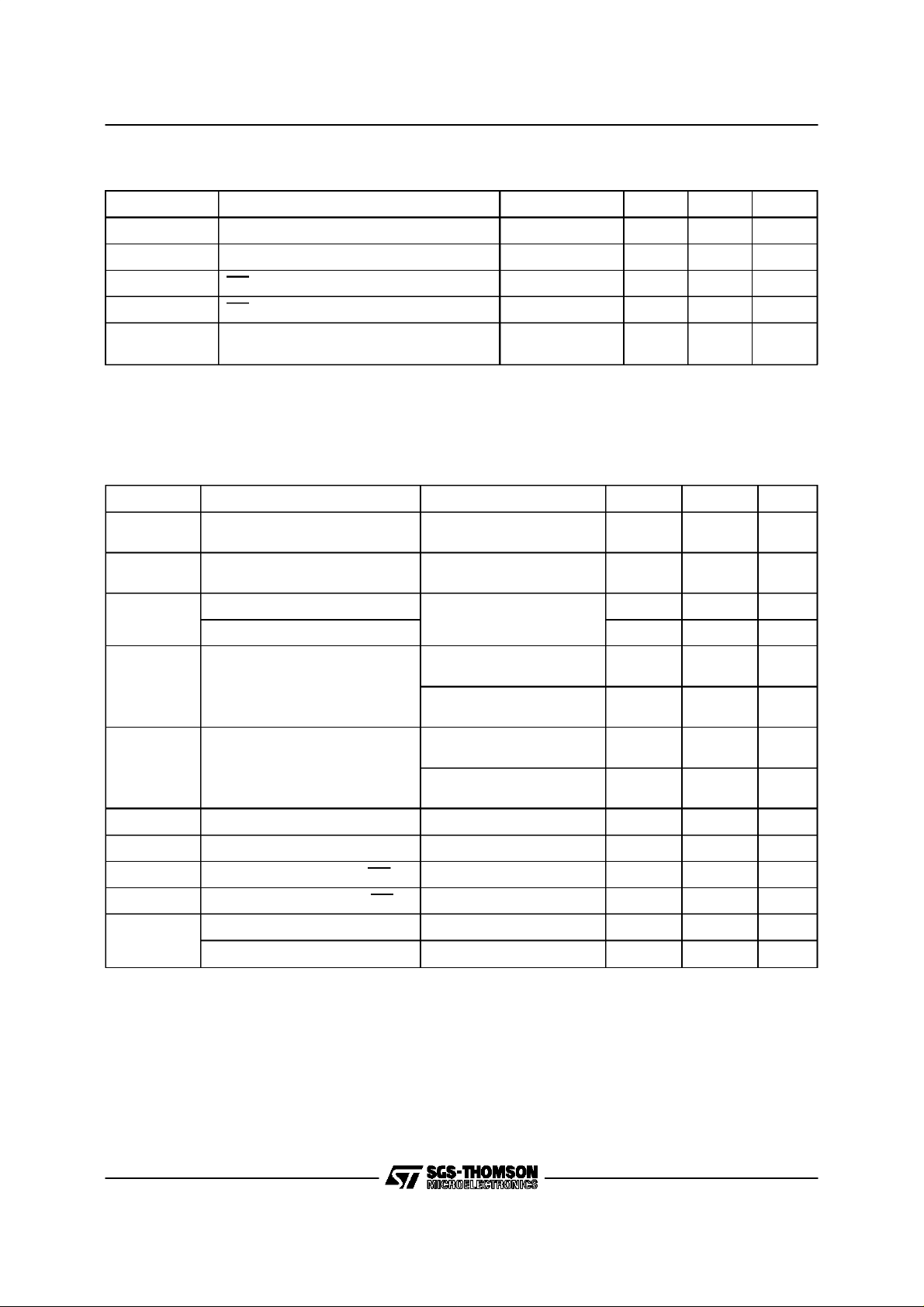

Table5. InputParameters

(1)

(TA=25°C, f =400 kHz )

Symbol Parameter Test Condition Min Max Unit

C

IN

C

IN

Z

WCL

Z

WCH

t

LP

Note: 1. Sampled only,not 100% tested.

Input Capacitance (SDA) 8 pF

Input Capacitance (other pins) 6 pF

WC Input Impedance VIN≤ 0.3 V

WC Input Impedance VIN≥ 0.7 V

Low-pass filter input time constant

(SDAand SCL)

CC

CC

520kΩ

500 kΩ

100 ns

Table 6. DC Characteristics

= –40 to 85°C or 0to 70 °C; VCC=4.5V to 5.5Vor 2.5V to 5.5V)

(T

A

Symbol Parameter Test Condition Min Max Unit

I

LI

I

LO

I

CC

Input Leakage Current

(SCL, SDA, E0-E2)

Output LeakageCurrent

Supply Current (ST24 series)

Supply Current (ST25 series) 1 mA

0V ≤ V

0V ≤ V

IN

OUT

≤ V

≤ V

CC

CC

SDAin Hi-Z

f

= 400kHz

C

(Rise/Fall time < 30ns)

±2 µA

±2 µA

2mA

I

I

V

V

V

CC1

CC2

V

V

OL

V

IN=VSS

Supply Current (Standby)

(ST24 series)

V

IN=VSS

V

=5V,fC= 400kHz

CC

V

IN=VSS

Supply Current (Standby)

(ST25 series)

IL

IH

IL

IH

Input Low Voltage (SCL, SDA) –0.3 0.3 V

Input High Voltage (SCL, SDA) 0.7 V

Input Low Voltage (E0-E2, WC) –0.3 0.5 V

Input High Voltage (E0-E2, WC) VCC– 0.5 VCC+1 V

V

IN=VSS

V

= 2.5V,fC= 400kHz

CC

or VCC,

V

=5V

CC

or VCC,

or VCC,

V

= 2.5V

CC

or VCC,

CC

100 µA

300 µA

5 µA

50 µA

CC

V

VCC+1 V

Output Low Voltage IOL= 3mA, VCC= 5V 0.4 V

Output Low Voltage (ST25 series) I

= 2.1mA, VCC= 2.5V 0.4 V

OL

5/16

Page 6

ST24E64, ST25E64

Table 7. AC Characteristics

(T

= –40 to 85 °C or0 to 70 °C; VCC= 4.5V to 5.5V or 2.5V to 5.5V)

A

Symbol Alt Parameter Min Max Unit

t

CH1CH2

t

CL1CL2

(1)

t

DH1DH2

(1)

t

DL1DL1

(2)

t

CHDX

t

CHCL

t

DLCL

t

CLDX

t

CLCH

t

DXCX

t

CHDH

t

DHDL

(3)

t

CLQV

t

CLQX

f

C

t

W

Notes: 1. Sampled only, not 100% tested.

2. For a reSTART condition, or following a write cycle.

3. The minimum value delays the falling/rising edge of SDAaway from SCL = 1 in order to avoidunwanted STARTand/or STOP

conditions.

t

t

t

t

t

SU:STA

t

HIGH

t

HD:STA

t

HD:DAT

t

LOW

t

SU:DAT

t

SU:STO

t

BUF

t

AA

t

DH

f

SCL

t

WR

R

F

R

F

Clock Rise Time 300 ns

Clock Fall Time 300 ns

SDA Rise Time 20 300 ns

SDA Fall Time 20 300 ns

Clock High to InputTransition 600 ns

Clock Pulse Width High 600 ns

Input Low to Clock Low (START) 600 ns

Clock Low to Input Transition 0 µs

Clock Pulse Width Low 1.3 µs

Input Transition to Clock Transition 100 ns

Clock High to Input High (STOP) 600 ns

Input High to Input Low (Bus Free) 1.3 µs

Clock Low to Next Data Out Valid 200 1000 ns

Data Out Hold Time 200 ns

Clock Frequency 400 kHz

Write Time 10 ms

AC MEASUREMENT CONDITIONS

Input Rise and Fall Times ≤ 50ns

Input Pulse Voltages 0.2V

Input and Output Timing Ref. Voltages 0.3VCCto 0.7V

CC

to 0.8V

CC

CC

Figure4. AC TestingInput Output Waveforms

0.8V

6/16

0.2V

CC

CC

0.7V

0.3V

AI00825

CC

CC

DEVICEOPERATION(cont’d)

MemoryAddressing. A data byte in the memory

is addressed through 2 bytes of addressinformation. The MostSignificant Byte is sent first andthe

Leastsignificant Byte is sent after. The Least Significant Byte addresses a block of 256 bytes, bits

b12,b11,b10,b9,b8 of the Most Significant Byte

selectoneblock among 32 blocks(one blockis 256

bytes).

MostSignificant Byte

X X X b12 b11 b10 b9 b8

X = Don’t Care.

Least SignificantByte

b7 b6 b5 b4 b3 b2 b1 b0

Page 7

Figure5. ACWaveforms

ST24E64, ST25E64

SCL

SDA IN

SCL

SDA OUT

SCL

tCHCL

tDLCL

tCHDX

START

CONDITION

tCLQV tCLQX

tDHDL

tCLDX

SDA

INPUT

DATA VALID

DATA OUTPUT

SDA

CHANGE

tW

tCLCH

tDXCX

tCHDH

tDHDL

STOP &

BUS FREE

SDA IN

tCHDH

STOP

CONDITION

WRITE CYCLE

tCHDX

START

CONDITION

AI00795

7/16

Page 8

ST24E64, ST25E64

Figure6. I2C Bus Protocol

SCL

SDA

SCL

SDA

SCL

SDA

START

CONDITION

START

CONDITION

SDA

INPUT

123 789

MSB

123 789

MSB ACK

SDA

CHANGE

CONDITION

ACK

STOP

STOP

CONDITION

Write Operations

Following a STARTcondition the master sends a

deviceselect code withthe RW bit reset to ’0’. The

ST24/25E64 acknowledge this and waits for 2

bytes of address. These 2 address bytes (8 bits

each)provideaccesstoanyof the 32 blocksof 256

bytes each. Writing in the ST24/25E64 may be

inhibitedif input pin WC is takenhigh.

For the ST24/25E64versions, any writecommand

with WC = ’1’ (during a period of time from the

START condition untill the end of the 2 Bytes

Address) will not modify data and will NOT be

acknowledgedon data bytes, as in Figure 9.

Byte Write. In the Byte Write mode the master

sendsonedatabyte,whichisacknowledgedby the

8/16

AI00792

ST24/25E64. The master then terminates the

transfer by generatinga STOPcondition.

PageWrite. The Page Writemode allows up to 32

bytesto be written in a single write cycle,provided

thattheyare all locatedinthe samerowof 32bytes

in the memory, that is the same Address bits (b12

tob5).Themastersendsone upto32 bytesofdata,

whichareeachacknowledgedby the ST24/25E64.

After each byte is transfered, the internal byte

address counter (5 Least Significant Bits only) is

incremented. The transfer is terminated by the

mastergeneratingaSTOPcondition.Caremustbe

taken to avoid address counter ’roll-over’ which

couldresult in data being overwritten.Notethat for

anywritemode,thegenerationbythemasterofthe

STOP condition starts the internal memory pro-

Page 9

ST24E64, ST25E64

gram cycle. This STOP condition will trigger an

internal memory program cycle only if the STOP

conditionis internally decoded right after the ACK

bit; any STOP condition decoded out of this ”10th

bit” time slot will not trigger the internal programmingcycle.Allinputsaredisableduntilthecompletion of this cycle and the ST24/25E64 will not

respondto any request.

Minimizing System Delay by Polling On ACK.

During the internal Write cycle, the ST24/25E64

disableitself from the bus in order to copy the data

fromthe internal latches to thememory cells. The

maximumvalue oftheWritetime(t

) isgiveninthe

W

AC Characteristics table, this timingvalue maybe

reducedbyan ACKpollingsequenceissuedby the

master.

Figure7. WriteCycle Polling using ACK

WRITE

Cycle

in Progress

START Condition

The sequenceis:

– Initialcondition:a Write is in progress (see Fig-

ure 7).

– Step 1: the Masterissues a STARTcondition

followed by a Device Selectbyte. (1st byte of

the newinstruction)

– Step 2: if the ST24/25E64are internallywrit-

ing, no ACK will be returned.The Master goes

back to Step1.If the ST24/25E64have terminated the internalwriting, it will issue an ACK.

The ST24/25E64are ready to receive the second partof the instruction(the first byte of this

instructionwas already sentduring Step1).

First byte of

with RW = 0

decoded by ST24xxx

instruction

already

ReSTART

STOP

DEVICE SELECT

with RW = 0

ACK

NO

Returned

YES

Next

Operation is

Addressing the

Memory

WRITE Operation

YESNO

Proceed

Send

Byte Address

Proceed

Random

Address

READ Operation

AI01099B

9/16

Page 10

ST24E64, ST25E64

Figure8. Write Modes Sequence with Write Control = 0

WC

ACK

BYTE WRITE DEV SEL BYTE ADDR BYTE ADDR DATA IN

R/W

START

WC

ACK ACK ACK ACK

PAGE WRITE DEV SEL BYTE ADDR BYTE ADDR DATA IN 1

R/W

START

WC (cont’d)

ACKACK

PAGE WRITE

(cont’d)

DATA IN N

ACK ACK ACK

STOP

DATA IN 2

STOP

Read Operations

On delivery,the memory content is set at all ”1’s”

(or FFh).

Current Address Read. The ST24/25E64 have

an internal 13 bits address counter. Each time a

byte is read, this counter is incremented.For the

Current Address Read mode, following a START

condition, the master sends a Device Select with

theRWbit setto’1’.TheST24/25E64acknowledge

thisand outputs thebyte addressedby the internal

addresscounter.Thiscounteris then incremented.

The master does NOT acknowledge the byte output, but terminates the transfer with a STOPcondition.

10/16

AI01106

Random Address Read. A dummy write is performed to load the address into the address

counter,see Figure 10. Thisis followed byanother

START condition from the master and the byte

address repeated with the RW bit set to ’1’. The

ST24/25E64 acknowledge this and outputs the

byte addressed. The master does NOT acknowledge the byte output, but terminates the transfer

witha STOP condition.

SequentialRead. This mode can be initiatedwith

either a Current Address Read or a Random Address Read. However, in this case the master

DOES acknowledge the data byte output and the

ST24/25E64 continue to output the next byte in

Page 11

Figure9. WriteModes Sequence with Write Control = 1

WC

ACK ACK ACK NO ACK

BYTE WRITE DEV SEL BYTE ADDR BYTE ADDR DATA IN

ST24E64, ST25E64

R/W

START

WC

ACK ACK ACK NO ACK

PAGE WRITE DEV SEL BYTE ADDR BYTE ADDR DATA IN 1

R/W

START

WC (cont’d)

NO ACK NO ACK

PAGE WRITE

(cont’d)

DATA IN N

STOP

STOP

DATA IN 2

AI01120

sequence. To terminate the stream of bytes, the

master must NOT acknowledgethe last byte output, but MUST generate a STOP condition. The

output data is from consecutive byte addresses,

with the internal byte address counter automatically incremented after each byte output. After a

count of the last memory address, the address

counterwill’roll-over’ andthe memorywillcontinue

to output data.

Acknowledge in Read Mode. In all read modes

the ST24/25E64 wait for an acknowledge during

the 9th bittime. If the masterdoes notpull the SDA

linelowduringthistime,theST24/25E64terminate

the data transferand switch to a standbystate.

11/16

Page 12

ST24E64, ST25E64

Figure10. Read Modes Sequence

CURRENT

ADDRESS

READ

RANDOM

ADDRESS

READ

SEQUENTIAL

CURRENT

READ

SEQUENTIAL

RANDOM

READ

ACK

DEV SEL DATA OUT

R/W

START

ACK

DEV SEL * BYTE ADDR BYTE ADDR

R/W

START

ACK ACK ACK NO ACK

DEV SEL DATA OUT 1

R/W

START

ACK ACK ACK

DEV SEL * BYTE ADDR BYTE ADDR

NO ACK

STOP

ACK ACK ACK

DEV SEL * DATA OUT

R/W

START

DATA OUT N

STOP

ACK ACK

DEV SEL * DATA OUT 1

NO ACK

STOP

R/W

START

ACK NO ACK

DATA OUT N

STOP

Note: * The 7 Most Significantbits of DEV SEL bytes of a Random Read (1st byte and 4th byte)must be identical.

START

R/W

AI01105B

12/16

Page 13

ORDERING INFORMATIONSCHEME

Example: ST24E64 M 1 TR

ST24E64, ST25E64

Operating Voltage

24 4.5V to 5.5V

25 2.5V to 5.5V

Note: 3 * Temperature Range on special request only.

Range

E Extended

Addressing

Package

B PSDIP8

0.25mm Frame

M SO8

200mil Width

Temperature Range

1 0 to 70 °C

6 –40 to 85 °C

3 * –40 to 125 °C

Option

TR Tape& Reel

Packing

Parts are shipped with the memorycontent set at all ”1’s” (FFh).

For a list of available options (Operating Voltage,Range, Package, etc...) refer to the current Memory

Shortformcatalogue.

For further information on any aspect of this device, please contact the SGS-THOMSON Sales Office

nearestto you.

13/16

Page 14

ST24E64, ST25E64

PSDIP8 - 8 pin Plastic Skinny DIP,0.25mm lead frame

Symb

Typ Min Max Typ Min Max

A 3.90 5.90 0.154 0.232

A1 0.49 – 0.019 –

A2 3.30 5.30 0.130 0.209

B 0.36 0.56 0.014 0.022

B1 1.15 1.65 0.045 0.065

C 0.20 0.36 0.008 0.014

D 9.20 9.90 0.362 0.390

E 7.62 – – 0.300 – –

E1 6.00 6.70 0.236 0.264

e1 2.54 – – 0.100 – –

eA 7.80 – 0.307 –

eB 10.00 0.394

L 3.00 3.80 0.118 0.150

N8 8

PSDIP8

mm inches

Drawing is not o scale

14/16

A2A1A

L

B

e1

B1

D

N

C

eA

eB

E1 E

1

PSDIP-a

Page 15

ST24E64, ST25E64

SO8 - 8 lead Plastic Small Outline, 200 mils body width

Symb

Typ Min Max Typ Min Max

A 2.03 0.080

A1 0.10 0.25 0.004 0.010

A2 1.78 0.070

B 0.35 0.45 0.014 0.018

C 0.20 – – 0.008 – –

D 5.15 5.35 0.203 0.211

E 5.20 5.40 0.205 0.213

e 1.27 – – 0.050 – –

H 7.70 8.10 0.303 0.319

L 0.50 0.80 0.020 0.031

α 0° 10° 0° 10°

N8 8

CP 0.10 0.004

SO8b

mm inches

Drawing is notto scale

A2

A

C

B

e

CP

D

N

E

H

1

LA1 α

SO-b

15/16

Page 16

ST24E64, ST25E64

Information furnished is believed to be accurate and reliable.However, SGS-THOMSON Microelectronics assumes no responsibility for the

consequences of use of such information nor for any infringementof patents or other rights of third parties which may result from its use. No

license is granted by implication or otherwise under any patentor patent rights ofSGS-THOMSON Microelectronics. Specificationsmentioned

in this publication are subject to change without notice. This publication supersedes and replaces all information previously supplied.

SGS-THOMSON Microelectronics products are not authorized for useascritical components inlife supportdevices or systems without express

written approval of SGS-THOMSON Microelectronics.

1996 SGS-THOMSON Microelectronics - AllRights Reserved

Purchase of I

2

I

C Patent.Rights to use these components in an I2C system, is granted provided that the system conformsto

Australia - Brazil -Canada - China- France - Germany - Hong Kong - Italy - Japan - Korea- Malaysia - Malta - Morocco - The Netherlands -

2

C Components by SGS-THOMSON Microelectronics, conveys a license under the Philips

2

the I

C Standard Specifications as defined by Philips.

SGS-THOMSON Microelectronics GROUP OF COMPANIES

Singapore- Spain - Sweden - Switzerland - Taiwan- Thailand - United Kingdom- U.S.A.

16/16

Loading...

Loading...