Page 1

with User-Defined Block Write Protection

1 MILLION ERASE/WRITE CYCLES with

40 YEARS DAT A RE TENTION

SINGLE SUPPLY VOLTAGE:

– 3V to 5.5V for ST24x04 versions

– 2.5V to 5.5V for ST25x04 versions

HARDWARE WRITE CONT ROL VERSIONS:

ST24W04 and ST25W04

PROGRAMMABLE WRITE PROTECTION

TWO WIRE SERIAL INTERFACE, FULLY I2C

BUS COMPATIBLE

BYTE and MULTIBYTE WRITE (up to 4

BYTES)

PAGE WRITE (up to 8 BYTES)

BYTE, RANDOM and SEQUENTIAL READ

MODES

SELF TIMED PROGRAMMING CYCLE

AUTOMATIC ADDRESS INCREME NTING

ENHANCE D ESD/LATCH UP

PERFORMANCES

ST24C04, ST25C04

ST24W04, ST25W04

4 Kbit Serial I2C Bus EEPROM

8

1

PSDIP8 (B)

0.25mm Frame

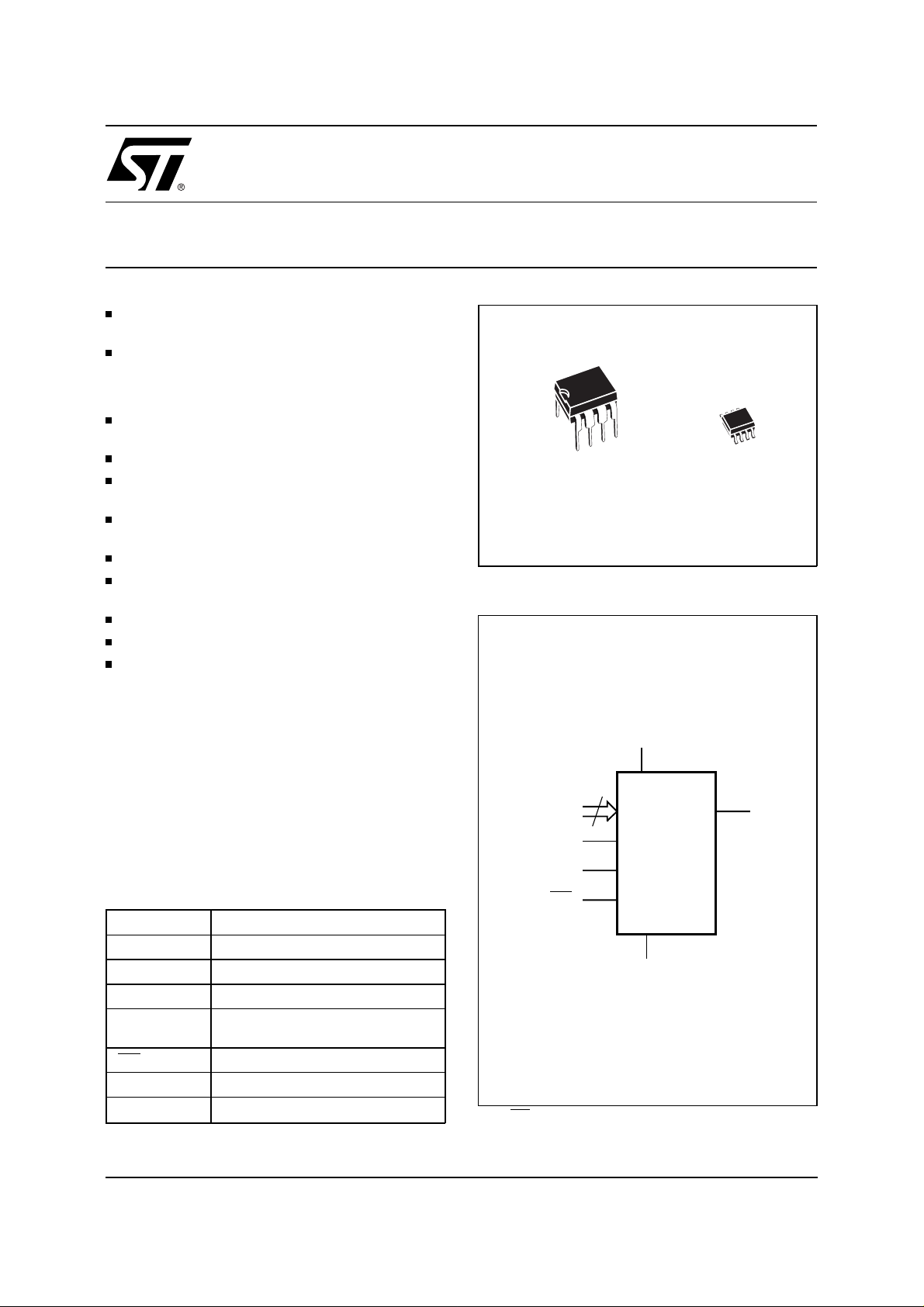

Figure 1. Logic Diagram

8

1

SO8 (M)

150mil Width

V

CC

DESCRIPTION

2

This specification covers a range of 4 Kbits I

EEPROM products, the ST24/25C04 and the

ST24/25W04. In the text, products are referred to

as ST24/25x04, where "x" is: "C" for Standard

version and "W" for hardware Write Control version.

T ab le 1. Signal Names

PRE Write Protect Enable

E1-E2 Chip Enable Inputs

SDA Serial Data Address Input/Output

SCL Serial Clock

MODE

WC Write Control (W version)

V

CC

V

SS

February 1999 1/16

Multibyte/Page Write Mode

(C version)

Supply Voltage

Ground

C bus

2

E1-E2 SDA

PRE

SCL

MODE/WC*

Note:

WC signal is only available for ST24/25W04 products.

ST24x04

ST25x04

V

SS

AI00851E

Page 2

ST24/25C04, ST24/25W04

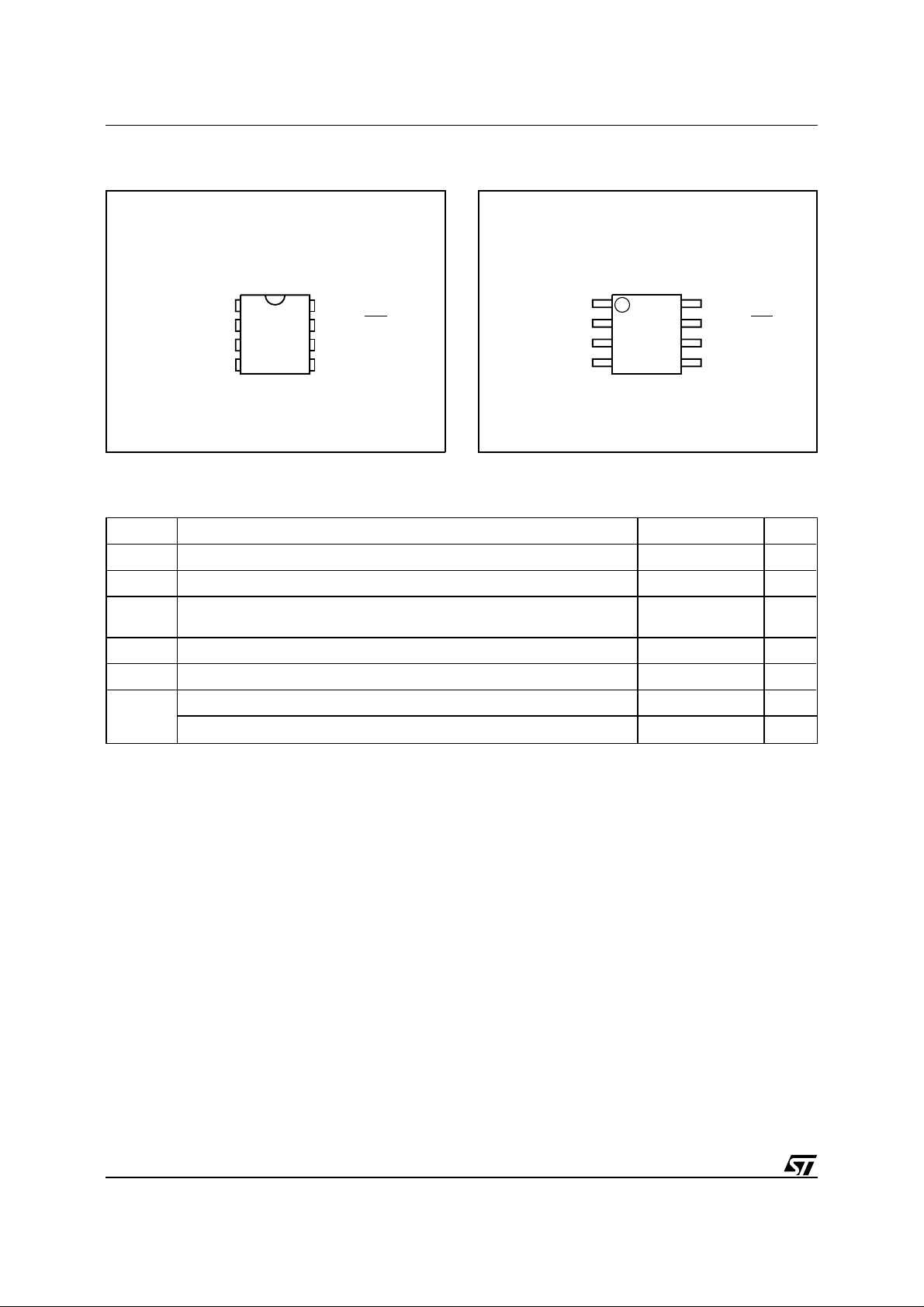

Figure 2A. DIP Pin Connections

ST24x04

ST25x04

1

PRE V

2

3

E2

4

SS

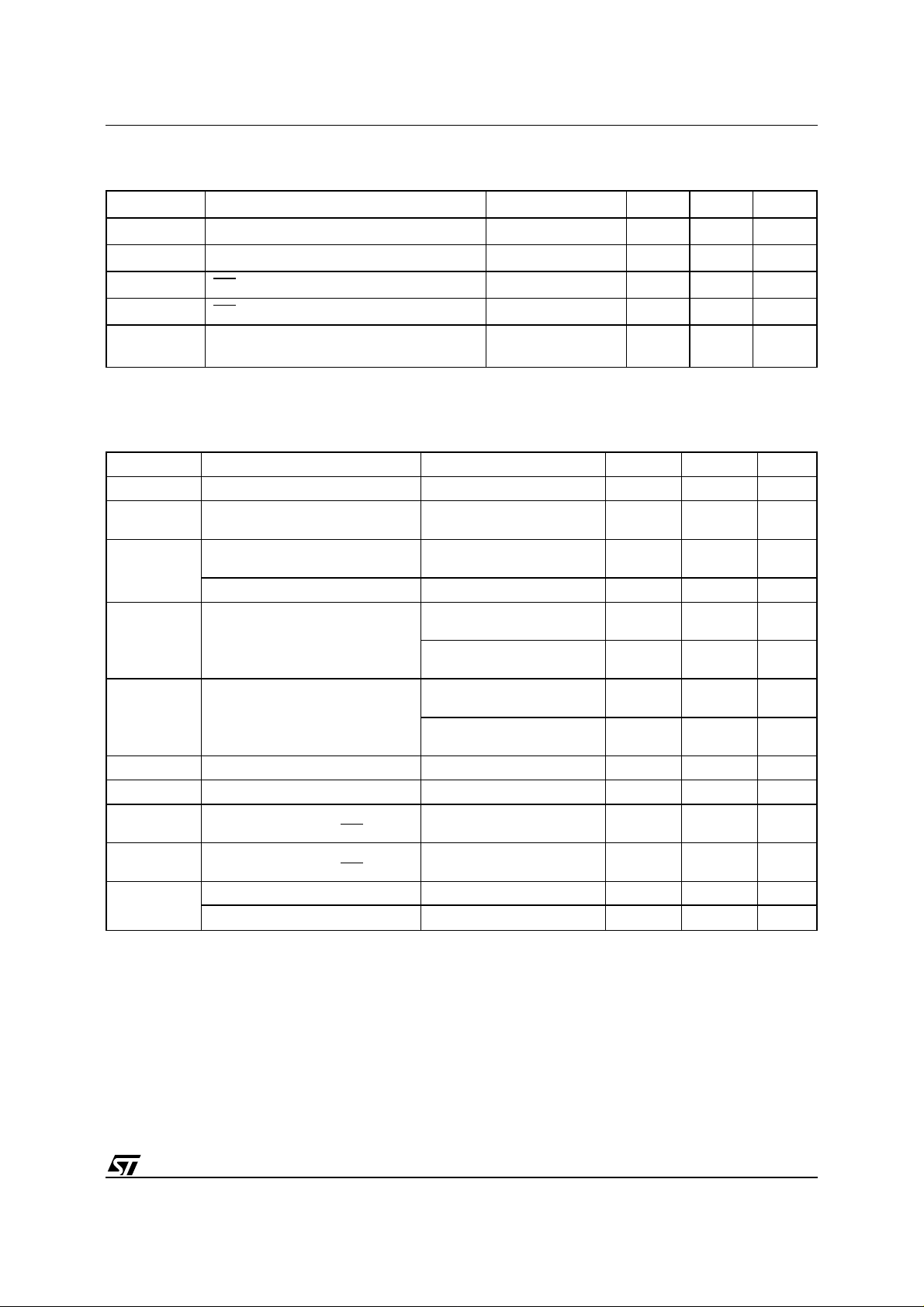

T ab le 2. Absolute Maximum Ratings

Symbol Parameter Value Unit

T

T

V

Notes:

T

STG

LEAD

V

V

ESD

Ambient Operating Temperature –40 to 125

A

Storage Temperature –65 to 150

Lead Temperature, Soldering (SO8 package)

Input or Output Voltages –0.6 to 6.5 V

IO

Supply Voltage –0.3 to 6.5 V

CC

Electrostatic Discharge Voltage (Human Body model)

Electrostatic Discharge Voltage (Machine model)

1. Except for the rating "Operating Temperature Range", stresses above those listed in the Table "Absolute Maximum Ratings"

may cause permanent damage to the device. These are stress rating s only and operation of the device at these or any other

conditions above those indicated in the Operating sections of this specification is not implied. Exposure to Absolute Maximum

Rating conditions for extended periods may affect device reliability. Refer also to the STMicroelectronics SURE Program and other

relevant quality documents.

2. MIL-STD-883C, 3015.7 (100pF, 1500 Ω).

3. EIAJ IC-121 (Condition C) (200pF, 0 Ω).

8

7

6

5

AI00852E

CC

MODE/WCE1

SCL

SDAV

(1)

(PSDIP8 package)

Figure 2B. SO Pin Connections

ST24x04

ST25x04

PRE V

1

2

E2

SS

40 sec

10 sec

(2)

(3)

3

4

8

7

6

5

AI01107E

215

260

4000 V

500 V

CC

MODE/WCE1

SCL

SDAV

C

°

C

°

C

°

DESCRIPTION (cont’d)

The ST24/25x04 are 4 Kbit electrically erasable

programmable memories (EEPROM), organized

as 2 blocks of 256 x8 bits. They are manufactured

in STMicroelectronics’s Hi-Endurance Advanced

CMOS technology which guarantees an endurance of one million erase/write cycles with a data

retention of 40 years.

Both Plastic Dual-in-Line and Plastic Small Out line

packages are available.

2

The memories are compatible with the I

C standard, two wire serial interface which uses a bi-directional data bus and serial clock. The memories

2/16

carry a built-in 4 bit, unique device identification

code (1010) corresponding to the I

2

C bus definition. This is used together with 2 chip enable inputs

(E2, E1) so that up to 4 x 4K devices may be

attached to the I

The memories behave as a slave device in the I

2

C bus and selected individually.

2

protocol with all memory operations synchronized

by the serial clock. Read and write operations ar e

initiated by a START condition generated by the

bus master. The START condition is followed by a

stream of 7 bits (identification code 1010), plus one

read/write bit and terminated by an acknowledge

bit.

C

Page 3

T ab le 3. Device Select Code

ST24/25C04, ST24/25W04

Device Code Chip Enable

Bit b7 b6 b5 b4 b3 b2 b1 b0

Device Select 1 0 1 0 E2 E1 A8 R

Note:

The MSB b7 is sent first.

T ab le 4. Operating Modes

Mode RW bit MODE Bytes Initial Sequence

Current Address Read ’ 1’ X 1 STAR T, Device Select, R

Random Address Read

Sequential Read ’1’ X 1 to 512 Similar to Current or Random Mode

Byte Write ’0’ X 1 START, Device Select, R

IH

or V

(2)

IL

Multibyte Write

Page Write ’0’ V

Notes:

1. X = V

2. Multibyte Write not available in ST24/25W04 versions.

(1)

’0’

’1’ reSTART, Device Select, R

’0’ V

X1

IH

IL

4 START, Device Select, RW = ’0’

8 START, Device Select, RW = ’0’

START, Device Select, R

Block

Select

W = ’1’

W = ’0’, Address,

W = ’1’

W = ’0’

RW

W

When writing data to the memory it responds to the

8 bits received by asserting an acknowledge bit

during the 9th bit time. When data is read by the

bus master, it acknowledges the receipt of the data

bytes in the same way. Data transfers are terminated with a STOP condition.

Power On Reset: V

lock out write protect . In

CC

order to prevent data corruption and inadvertent

write operations during power up, a Power On

Reset (POR) circuit is implemented. Until the V

CC

voltage has reached the POR threshold value, the

internal reset is active, all operations are disabled

and the device will not respond to any c ommand.

In the same way, when V

drops down from the

CC

operating voltage to below the POR threshold

value, all operations are disabled and the device

will not respond to any command. A stable V

CC

must be applied before applying any logic signal.

SIGNAL DESCRIPTIONS

Serial Clock (SCL). The SCL input pin is used to

synchronize all data in and out of the memory. A

resistor can be connected from the SCL line to V

CC

to act as a pull up (see Figure 3).

Serial Data (SDA). The SDA pin is bi-directional

and is used to transfer data in or out of the memory.

It is an open drain output that may be wire-OR’ed

with other open drain or open collector signals on

the bus. A resistor must be connected from the SDA

bus line to V

to act as pull up (see Figure 3).

CC

Chip Enable (E1 - E2). These chip enable inputs

are used to set the 2 least significant bits (b2, b3)

of the 7 bit device select code. These inputs may

be driven dynamically or tied to V

or VSS to

CC

establish the device select code.

Protect Enable (PRE). The PRE input pin, in ad-

dition to the status of the Block Address Pointer bit

(b2, location 1FFh as in Figure 7), sets the PRE

write protection active.

Mode (M ODE). The MO DE input is available on pin

7 (see also

cally. It must be at V

mode, V

WC feature) and may be driven dynami-

or VIH for the Byte Write

for Multibyte Write mode or VIL for Page

IH

IL

Write mode. When unconnected, the MODE input

is internally read as V

Write Control (

feature (

WC) is offered only for ST24W04 and

WC) . An hardware Write Control

(Multibyte Write mode).

IH

ST25W04 versions on pin 7. This feature is usefull

to protect the contents of the memory from any

erroneous erase/write cycle. The Write Control signal is used to enable (

) the internal write protection. When uncon-

V

IL

nected, the

WC input is internally read as VIL and

WC = VIH) or disable (WC =

the memory area is not write protected.

3/16

Page 4

ST24/25C04, ST24/25W04

SIGNAL DESCRIPTIONS (cont’d)

The devices with this Write Control feature no

longer support the Multibyte Write mode of operation, however all other write modes are fully supported.

Refer to the AN404 Application Note for more detailed information about Write Control feature.

DEVICE O PERATION

2

C Bus Background

I

The ST24/25x04 support the I

2

C protocol. This

protocol defines any device that sends data onto

the bus as a transmitter and any device that reads

the data as a receiver. The devic e that controls the

data transfer is known as the master and the other

as the slave. The master will always initiate a data

transfer and will provide the serial clock for synchronisation. The ST24/25x04 are always slave

devices in all communications.

Start Condition . START is identified by a high to

low transition of the SDA line while the clock SCL

is stable in the high state. A ST AR T condition must

precede any command for data transfer. Except

during a programming cycle, the ST24/25x04 continuously monitor the SDA and SCL signals for a

START condition and will not respond unless one

is given.

Stop Condition. STOP is identified by a low to high

transition of the SDA line while the clock SCL is

stable in the high state. A STOP condition terminates communication between the ST24/25x04

and the bus master. A STOP condition at the end

of a Read command, after and only after a No

Acknowledge, forces the standby state. A STOP

condition at the end of a Write command triggers

the internal EEPROM write cycle.

Acknowledge B it ( ACK). An acknowledge signal

is used to indicate a successfull data transfer. The

bus transmitter, eit her master or s lave, will release

the SDA bus after sending 8 bits of data. During the

9th clock pulse period the receiver pulls t he SDA

bus low to acknowledge the receipt of the 8 bits of

data.

Data Input. During data input the ST24/25x04

sample the SDA bus signal on the rising edge of

the clock SCL. Note that for correct device operation the SDA signal must be stable during the clock

low to high transition and the data must change

ONLY when the SCL line is low.

Memory Addressing. To start communication between the bus master and the slave ST24/25x04,

the master must initiate a ST ART condition. Following this, the master sends onto the SDA bus line 8

bits (MSB first) corresponding to the device select

code (7 bits) and a READ or WRITE bit.

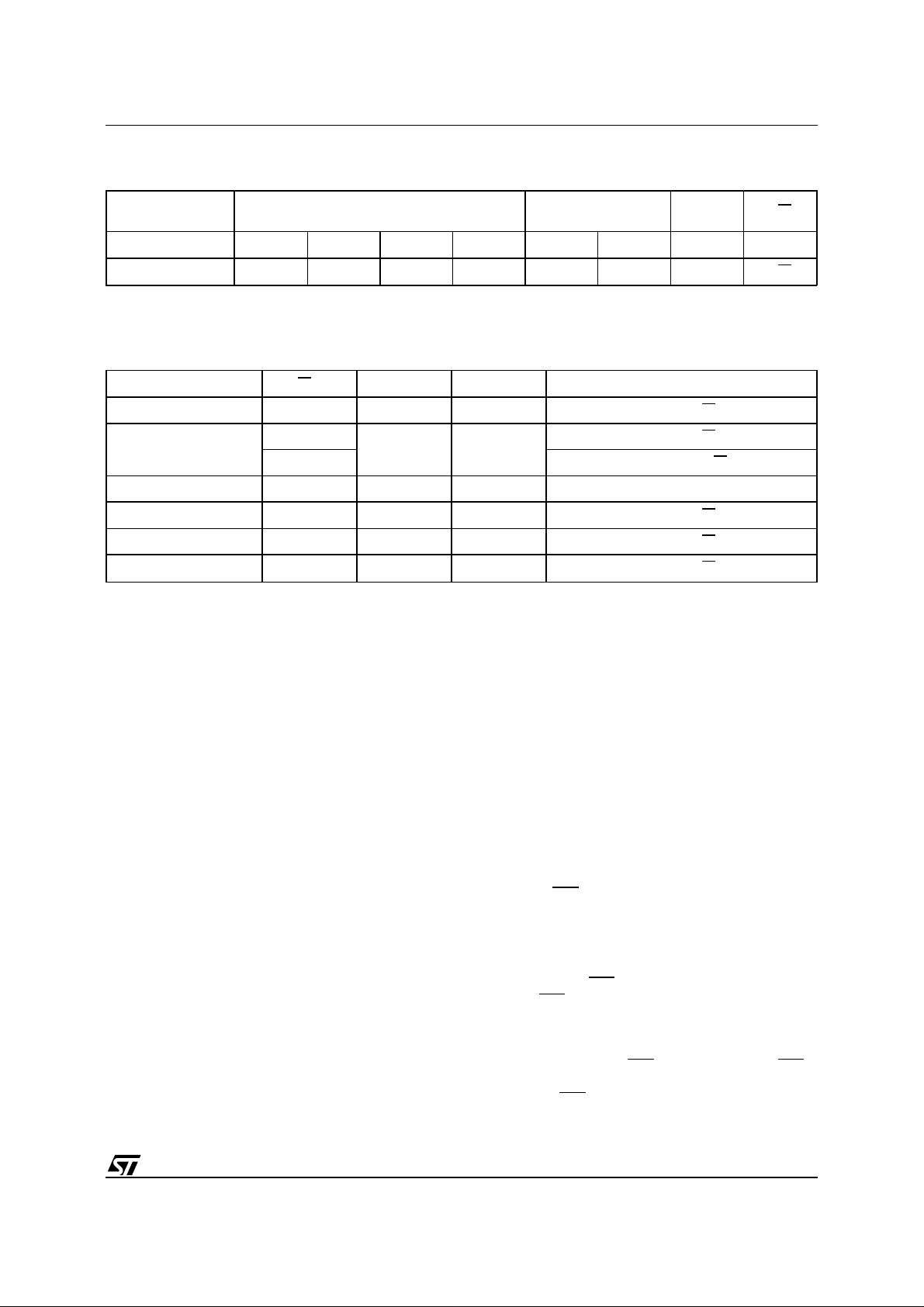

Figure 3. Maximum RL Value versus Bus Capacitance (C

20

16

12

max (kΩ)

L

R

8

4

0

VCC = 5V

100 200 300 400

C

(pF)

BUS

) for an I2C Bus

BUS

V

CC

MASTER

SDA

SCL

R

R

BUS

L

C

BUS

AI01100

L

C

4/16

Page 5

ST24/25C04, ST24/25W04

T able 5. Input Parameters

(1)

(TA = 25 °C, f = 100 kHz )

Symbol Parameter Test Condition Min Max Unit

C

IN

C

IN

Z

WCL

Z

WCH

t

LP

Note:

1. Sampled only, not 100% tested.

Input Capacitance (SDA) 8 pF

Input Capacitance (other pins) 6 pF

WC Input Impedance (ST24/25W04) VIN ≤ 0.3 V

WC Input Impedance (ST24/25W04) VIN ≥ 0.7 V

Low-pass filter input time constant

(SDA and SCL)

CC

CC

520k

500 k

100 ns

T ab le 6. DC Characteristics

(T

= 0 to 70°C, –20 to 85°C or –40 to 85°C; VCC = 3V to 5.5V or 2.5V to 5.5V)

A

Symbol Parameter Test Condition Min Max Unit

I

I

V

V

V

I

LI

I

LO

I

CC

CC1

CC2

V

V

OL

IL

IH

IL

IH

Input Leakage Current 0V ≤ VIN ≤ V

Output Leakage Current

Supply Current (ST24 series)

Supply Current (ST25 series) V

Supply Current (Standby)

(ST24 series)

Supply Current (Standby)

(ST25 series)

0V ≤ V

SDA in Hi-Z

V

= 5V, fC = 100kHz

CC

(Rise/Fall time < 10ns)

= 2.5V, fC = 100kHz 1 mA

CC

V

= VSS or VCC,

IN

V

CC

V

= VSS or VCC,

IN

= 5V, fC = 100kHz

V

CC

V

= VSS or VCC,

IN

V

CC

V

= VSS or VCC,

IN

= 2.5V, fC = 100kHz

V

CC

≤ VCC

OUT

= 5V

= 2.5V

CC

Input Low Voltage (SCL, SDA) –0.3 0.3 V

Input High Voltage (SCL, SDA) 0.7 V

Input Low Voltage

(E1-E2, PRE, MODE,

WC)

Input High Voltage

(E1-E2, PRE, MODE,

WC)

CC

–0.3 0.5 V

V

– 0.5 VCC + 1 V

CC

2

±

2

±

2mA

100

300

5

50

CC

VCC + 1 V

Output Low Voltage (ST24 series) IOL = 3mA, VCC = 5V 0.4 V

Output Low Voltage (ST25 series) I

= 2.1mA, VCC = 2.5V 0.4 V

OL

Ω

Ω

A

µ

A

µ

A

µ

A

µ

A

µ

A

µ

V

5/16

Page 6

ST24/25C04, ST24/25W04

T ab le 7. AC Characteristics

(T

= 0 to 70°C, –20 to 85°C or –40 to 85°C; VCC = 3V to 5.5V or 2.5V to 5.5V)

A

Symbol Alt Parameter Min Max Unit

t

CH1CH2

t

CL1CL2

t

DH1DH2

t

DL1DL1

(1)

t

CHDX

t

CHCL

t

DLCL

t

CLDX

t

CLCH

t

DXCX

t

CHDH

t

DHDL

(2)

t

CLQV

t

CLQX

f

C

(3)

t

W

Notes:

1. For a reSTART condition, or following a write cycle.

2. The minimum value delays the falling/rising edge of SDA away from SCL = 1 in order to avoid unwanted START and/or STOP

conditions.

3. In the Multibyte Write mode only, if accessed bytes are on two consecutive 8 bytes rows (6 address MSB are not constant) the

maximum programming time is doubled to 20ms.

t

R

t

F

t

R

t

F

t

SU:STA

t

HIGH

t

HD:STA

t

HD:DAT

t

LOW

t

SU:DAT

t

SU:STO

t

BUF

t

AA

t

DH

f

SCL

t

WR

Clock Rise Time 1

Clock Fall Time 300 ns

Input Rise Time 1

Input Fall Time 300 ns

Clock High to Input Transition 4.7

Clock Pulse Width High 4

Input Low to Clock Low (START) 4

Clock Low to Input Transition 0

Clock Pulse Width Low 4.7

Input Transition to Clock Transition 250 ns

Clock High to Input High (STOP) 4.7

Input High to Input Low (Bus Free) 4.7

Clock Low to Next Data Out Valid 0.3 3.5

Data Out Hold Time 300 ns

Clock Frequency 100 kHz

Write Time 10 ms

s

µ

s

µ

s

µ

s

µ

s

µ

s

µ

s

µ

s

µ

s

µ

s

µ

AC MEASUREMENT CONDITIONS

Input Rise and Fall Times

Input Pulse Voltages 0.2V

Input and Output Timing Ref. Voltages 0.3VCC to 0.7V

50ns

≤

to 0.8V

CC

CC

CC

Figure 4. AC Testing Input Output Waveforms

0.8V

6/16

0.2V

CC

CC

0.7V

0.3V

AI00825

CC

CC

DEVICE OPERATION (cont’d)

The 4 most significant bits of the device select code

are the device type identifier, corresponding to the

2

C bus definition. For these memories the 4 bits

I

are fixed as 1010b. The following 2 bits identify the

specific memory on the bus. They are matched to

the chip enable signals E2, E1. Thus up to 4 x 4K

memories can be connected on the same bus

giving a memory capacity total of 16 Kbits. After a

ST AR T condition any memory on the bus will identify the device code and compare the following 2

bits to its chip enable inputs E2, E1.

The 7th bit sent is th e block number (one block =

256 bytes). The 8th bit sent is the read or write bit

W), this bit is set to ’1’ for read and ’0’ for write

(R

operations. If a match is found, the corresponding

memory will acknowledge the identification on the

SDA bus during the 9th bit time.

Page 7

Figure 5. AC Waveforms

ST24/25C04, ST24/25W04

SCL

SDA IN

SCL

SDA OUT

SCL

tCHCL

tDLCL

tCHDX

START

CONDITION

tCLQV tCLQX

tCLDX

SDA

INPUT

DATA VALID

DATA OUTPUT

SDA

CHANGE

tW

tCLCH

tDXCX

tCHDH

tDHDL

STOP &

BUS FREE

SDA IN

tCHDH

STOP

CONDITION

Write Operations

The Multibyte Write mode (only available on the

ST24/25C04 versions) is selected when the MODE

pin is at V

pin is at V

and the Page Write mode when MODE

IH

. The MODE pin may be driven dynami-

IL

cally with CMOS input levels.

Following a START condition the master sends a

device select code with the R

W bit reset to ’0’. The

memory acknowledges this and waits for a byte

address. The byte address of 8 bits provides access to one block of 256 bytes of the memory . After

receipt of the byte address the device again responds with an acknowledge.

tCHDX

WRITE CYCLE

START

CONDITION

AI00795B

For the ST24/25W04 versions, any write command

WC = 1 will not modify the memory content.

with

Byte Write. In the Byte Write mode the master

sends one data byte, which is acknowledged by the

memory. The master then terminates the transfer

by generating a STOP condition. The Write mode

is independant of the state of the MODE pin whic h

could be left floating if only this mode was to be

used. However it is not a recommended operating

mode, as this pin has to be connected to either V

or VIL, to minimize the stand-by current.

IH

7/16

Page 8

ST24/25C04, ST24/25W04

Figure 6. I2C Bus Protocol

SCL

SDA

SCL

SDA

SCL

SDA

START

CONDITION

START

CONDITION

SDA

INPUT

1 23 789

MSB

1 23 789

MSB ACK

SDA

CHANGE

CONDITION

ACK

STOP

STOP

CONDITION

AI00792

Multibyte Write. For the Multibyte Write mode, the

MODE pin must be at V

. The Multibyte Write

IH

mode can be started from any address in the

memory . The master sends from one up to 4 bytes

of data, which are each acknowledged by the memory. The transfer is terminat ed by the master generating a STOP condition. The duration of the write

cycle is t

= 10ms maximum except when bytes

W

are accessed on 2 rows (that is have different

values for the 6 most significant addr ess bits A7A2), the programming time is then doubled to a

maximum of 20ms. Writing more than 4 bytes in the

8/16

Multibyte Write mode may modify data bytes in an

adjacent row (one row is 8 bytes long). However,

the Multibyte Write can properly write up to 8

consecutive bytes as soon as the first address of

these 8 bytes is the first address of the row, the 7

following bytes being written in the 7 following bytes

of this same row.

Page Write. For the Page Write mode, the MODE

pin must be at V

. The Page Write mode allows up

IL

to 8 bytes to be written in a single write cycle,

provided that they are all located in the same ’row’

in the memory: that is the 5 most significant mem-

Page 9

ST24/25C04, ST24/25W04

ory address bits (A7-A3) are the same inside one

block. The master sends from one up to 8 by tes of

data, which are each acknowledged by the memory. After each byte is transfered, the internal byte

address counter (3 least significant bits only) is

incremented. The transfer is terminated by the

master generating a STOP condition. Care must be

taken to avoid address counter ’roll-over’ which

could result in data being overwritten. Note that, for

any write mode, the generation by the master of the

STOP condition starts the internal memory program cycle. All inputs are disabled until the completion of this cycle and t he m emory will not respond

to any request.

Minimizing System Delays by Polling On ACK.

During the internal write cycle, the memory disconnects itself from the bus in order to copy the data

from the internal latches to the m emory cells. The

maximum value of the write time (t

) is given in the

W

AC Characteristics table, since the t ypical time is

shorter, the time seen by the system may be reduced by an ACK polling sequence issued by the

master.

Figure 8. Write Cycle Polling using ACK

Figure 7. Memory Protection

Protect Location

8 byte

boundary

address

b7 b3 b2

1FFh

100h

Protect Flag

Enable = 0

Disable = 1

XX

Block 1

Block 0

AI00855B

First byte of instruction

with RW = 0 already

decoded by ST24xxx

ReSTART

STOP

WRITE Cycle

in Progress

START Condition

DEVICE SELECT

with RW = 0

ACK

NO

Returned

YES

Next

Operation is

Addressing the

Memory

WRITE Operation

YESNO

Proceed

Send

Byte Address

Proceed

Random Address

READ Operation

AI01099B

9/16

Page 10

ST24/25C04, ST24/25W04

Figure 9. Write Modes Sequence (ST24/25C04)

BYTE WRITE DEV SEL BYTE ADDR DATA IN

ACK ACK ACK

MULTIBYTE

AND

PAGE WRITE

R/W

START

ACK ACK ACK

DEV SEL BYTE ADDR

R/W

START

ACK ACK

DATA IN N

DATA IN 1 DATA IN 2

STOP

STOP

AI00793

DEVICE O PERATION (cont’d) ’0’. This Address Pointer can therefore address a

boundary in steps of 8 bytes.

The sequence is as follows:

– Initial condition: a Write is in progress (see Figure

8).

– Step 1: the Master issues a START condition

followed by a Device Select byte (1st byte of the

new instruction).

– Step 2: if the memory is busy with the internal

write cycle, no ACK will be returned and the

master goes back to Step 1. If the memory has

terminated the internal write cycle, it will respond with an ACK, indicating that the memory

is ready to receive the second part of t he next

instruction (the first byte of this instruction was

already sent during Step 1).

Write Protecti on. Data in the upper block of 256

bytes of the memory may be write protected. The

memory is write protected between a boundary

address and the top of memory (address 1FFh)

when the PRE input pin is taken high and when the

Protect Flag (bit b2 in location 1FFh) is set to ’0’.

The boundary address is user defined by writing it

in the Block Address Pointer. The Block Address

Pointer is an 8 bit EEPROM regis ter located at the

address 1FFh. It is composed by 5 MSB s Addr ess

Pointer, which defines the bottom boundary address, and 3 LSBs which must be programmed at

The sequence to use the Write Protected feature

is:

– write the data to be protected into the top of the

memory , up to, but not including, loc ation 1FFh;

– set the protection by writing the c orrect bottom

boundary address in the Address Pointer (5

MSBs of location 1FFh) with bit b2 (Protect flag)

set to ’0’. Note that for a correct fonctionality of

the memory , all the 3 LSBs of the Block Address

Pointer must also be programmed at ’0’.

The area will now be protected when the PRE input

pin is taken High. While the PRE input pin is read

at ’0’ by the memory , the location 1FFh can be used

as a normal EEPROM byte.

Caution:

Special attention must be used when

using the protect mode together with the Multibyte

Write mode (MODE input pin High). If the Multibyte

Write starts at the location right below the first byte

of the Write Protected area, then the instruction will

write over the first 3 bytes of the Write Protected

area. The area protected is therefore smaller than

the content defined in the location 1FF h, by 3 bytes.

This does not apply to the Page Write mode as the

address counter ’roll-over’ and thus cannot go

above the 8 bytes lower boundary of the protected

area.

10/16

Page 11

ST24/25C04, ST24/25W04

Figure 10. Write Modes Sequence with Write Control = 1 (ST24/25W04)

WC

ACK ACK ACK

BYTE WRITE DEV SEL BYTE ADDR DATA IN

R/W

START

WC

ACK ACK ACK

PAGE WRITE DEV SEL BYTE ADDR

R/W

START

WC (cont'd)

ACK ACK

PAGE WRITE

(cont'd)

DATA IN N

STOP

DATA IN 1

STOP

DATA IN 2

AI01101B

Read Operations

Read operations are independent of the state of the

MODE pin. On delivery , the mem ory content is set

at all "1’s" (or FFh).

Current Address Read. The memory has an internal byte address counter . Each time a byte is read,

this counter is incremented. For the Current Address Read mode, following a START condition,

the master sends a memory address with the R

W

bit set to ’1’. The memory acknowledges this and

outputs the byte addressed by the internal byte

address counter. This counter is then incremented.

The master does NOT acknowledge the byte output, but terminates the tr ansfer with a STOP condition.

Random Address Read. A dummy write is performed to load the address into the address

counter, see Figure 1 1. This is followed by another

START condition from the master and the byte

address is repeated with the R

W bit set to ’1’. The

memory acknowledges this and outputs the byte

addressed. The master have to NOT acknowledge

the byte output, but terminates the transfer with a

STOP condition.

Sequential Read. This mode can be initiated with

either a Current Address Read or a Random Address Read. However, in this case the master

DOES acknowledge the data byte output and the

memory continues to output the next byte in s equence. To terminate the stream of bytes, the

master must NOT acknowledge the last byte out-

11/16

Page 12

ST24/25C04, ST24/25W04

DEVICE O PERATION (cont’d)

put, but MUST generate a STOP condition. The

output data is from consecutive byte addresses,

with the internal byte address counter automatically incremented after each byte output. After a

count of the last memory address, the address

Figure 11. Read Modes Sequence

ACK

CURRENT

ADDRESS

READ

RANDOM

ADDRESS

READ

DEV SEL DATA OUT

R/W

START

ACK

DEV SEL * BYTE ADDR

counter will ’roll- over’ and the memory will continue

to output data.

Acknowledge in Read Mode. In all re ad modes

the ST24/25x04 wait for an acknowledge during the

9th bit time. If the master does not pull the SDA line

low during this time, the ST24/25x04 terminate the

data transfer and switches to a standby state.

NO ACK

STOP

ACK ACK

DEV SEL * DATA OUT

NO ACK

SEQUENTIAL

CURRENT

READ

SEQUENTIAL

RANDOM

READ

R/W

START

ACK ACK ACK NO ACK

DEV SEL DATA OUT 1

R/W

START

ACK ACK

DEV SEL * BYTE ADDR

R/W

START

ACK NO ACK

DATA OUT N

STOP

R/W

START

DATA OUT N

ACK ACK

DEV SEL * DATA OUT 1

R/W

START

STOP

STOP

AI00794C

Note:

* The 7 Most Significant bits of DEV SEL bytes of a Random Read (1st byte and 3rd byte) must be identical.

12/16

Page 13

ORDERING INFORMATION SCHEME

Example: ST24C04 M 1 TR

ST24/25C04, ST24/25W04

Operating Voltage

ST24C04 3V to 5.5V

ST24W04 3V to 5.5V

ST25C04 2.5V to 5.5V

ST25W04 2.5V to 5.5V

Notes:

3 * Temperature range on special request only.

Range

Standard

Hardware Write Control

Standard

Hardware Write Control

Package

B PSDIP8

0.25mm Frame

M SO8 150mil Width

Temperature Range

1 0 to 70 °C

5 –20 to 85 °C

6 –40 to 85 °C

3 * –40 to 125 °C

Option

TR Tape & Reel

Packing

Parts are shipped with the memory content set at all "1’s" (FFh).

For a list of available options (Operating Voltage, Range, Package, etc...) or for further information on any

aspect of this device, please contact the STMicroelectronics Sales Office nearest to you.

13/16

Page 14

ST24/25C04, ST24/25W04

PSDIP8 - 8 pin Plastic S ki nny DIP, 0.25mm lead frame

Symb

Typ Min Max Typ Min Max

A 3.90 5.90 0.154 0.232

A1 0.49 – 0.019 –

A2 3.30 5.30 0.130 0.209

B 0.36 0.56 0.014 0.022

B1 1.15 1.65 0.045 0.065

C 0.20 0.36 0.008 0.014

D 9.20 9.90 0.362 0.390

E 7.62 – – 0.300 – –

E1 6.00 6.70 0.236 0.264

e1 2.54 – – 0.100 – –

eA 7.80 – 0.307 –

eB – 10.00 – 0.394

L 3.00 3.80 0.118 0.150

N8 8

mm inches

Drawing is not to scale

14/16

A2

A1AL

B

e1

B1

D

N

C

eA

eB

E1 E

1

PSDIP-a

Page 15

ST24/25C04, ST24/25W04

SO8 - 8 lead Plastic Small Outline, 150 mils body width

Symb

Typ Min Max Typ Min Max

A 1.35 1.75 0.053 0.069

A1 0.10 0.25 0.004 0.010

B 0.33 0.51 0.013 0.020

C 0.19 0.25 0.007 0.010

D 4.80 5.00 0.189 0.197

E 3.80 4.00 0.150 0.157

e1.27– –0.050– –

H 5.80 6.20 0.228 0.244

h 0.25 0.50 0.010 0.020

L 0.40 0.90 0.016 0.035

α

N8 8

CP 0.10 0.004

mm inches

0

°

8

°

0

°

8

°

Drawing is not to scale

B

SO-a

h x 45˚

A

C

e

CP

D

N

E

H

1

LA1 α

15/16

Page 16

ST24/25C04, ST24/25W04

Information furnished is believ ed to be accura te a nd rel i abl e. However, STMicroelec tronics assumes no responsibility for the consequences

of use of such information nor for any infringement of patents or other rights of third parties which may result from its use. No license is granted

by implication or otherwise under any patent or patent rights of STMicroelectronics. Specifications mentioned in this publication are subject to

change without notice. This publication supersedes and repl aces all information previously supplied. STMicroelectron ics products are not

authorized for use as critical components in life support devices or systems without express written approval of STMicroelectronics.

The ST logo is a registered trademark of STMicroelect roni cs

© 1999 STMicroelectronics - All Rights Reserved

Australia - Brazil - Canada - China - France - Germany - Italy - Japan - Korea - Malaysia - Malta - Mexico - Morocco - The Netherlands -

Singapore - Spain - Sweden - Switzerland - Taiwan - Thailand - United Kingdom - U.S.A.

STMicroelectronics GROUP OF COMPANIES

http://www.st.com

16/16

Loading...

Loading...