Page 1

12-V Voice Coil Motor Driver

FEATURES

D 1.8-A H-Bridge Output

D Class B Linear Operation

D Externally Programmable Gain and

Bandwidth

DESCRIPTION

The Si9961 is a linear actuator (voice coil motor) driver suitable

for use in disk drive head positioning systems. The Si9961

contains all of the power and control circuitry necessary to

drive the VCM that is typically found in 3

drives and optical disk drives. The driver is capable of

delivering 1.8 A at a nominal supply of 12 V.

The Si9961 provides all necessary functions including a motor

current sense amplifier, a loop compensation amplifier and a

power amplifier featuring four complementary MOSFETs in a

H-bridge configuration. The output crossover protection

ensures no cross-conducting current and true Class B

D Undervoltage Head Retract

D Programmable Retract Current

D Low Standby Current

1

/2-inch hard disk

Si9961

Vishay Siliconix

D Rail-to-Rail Output Swing

D Single 12-V Supply

D System Voltage Monitor with Fault Output

operation during linear tracking. Externally programmable

gain switch at the input summing junction increases the

resolution and dynamic range for a given DAC. The head

retract circuitry can be activated by either an undervoltage

condition or an external command. An external resistor is

required to set the VCM current during retract.

The Si9961 is constructed on a self-isolated BiC/DMOS power

IC process. The IC is available in 24-pin SO package for

operation over the commercial, C suffix (0 to 70_C)

temperature range.

FUNCTIONAL BLOCK DIAGRAM

V

CC

IA2–

I

RET

OA2

4

5

23

V

R

9

6

11

22

10

A2

–

+

Acceleration Error

V

FAULT

RETRACT

Enable

GAIN

SELECT

R

EXT

V

REFVREF–

V

8 R

+

–

Retract

Control

–

+

7 R

A3

R

A4

A5

–

+

V+

818712

Voltage

Monitor

R

V

R

R

Q1

Q2

V

DD

Q3

17

OUTPUT

A

OUTPUT

19

Q4

B

Document Number: 70014

S-20883—Rev. G, 24-Jun-02

R

INHRINL

20161415211332421

I

R

FB

SENSE

OUT

I

SENSE

IN+

I

SENSE

IN–

GND

SA SB

www.vishay.com

1

Page 2

Si9961

Vishay Siliconix

ABSOLUTE MAXIMUM RATINGS

Voltages Referenced to Common Pin

V+ Supply Range –0.3 V to 16 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Pin (FAULT

) –0.3 V to VCC + 0.3 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Pin (Output A & B, Source A & B) –0.3 V to V

Pin (All Others) –0.3 V to V+ + 0.3 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maximum Clamp Current

Output A, Output B (Pulsed 10 ms at 10% duty cycle) "1.8 A. . . . . . . . . . . .

Pin (All Others) "20 mA. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Storage Temperature –65 to 150_C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DD

+ 0.3 V. . . . . . . . . . . . . . . .

Operating Temperature 0 to 70_C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Junction Temperature (T

Power Dissipation (Package)

24-Pin SOIC

b

Thermal Impedance (

24-Pin SOIC 40_C/W. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Notes

a. Device mounted with all leads soldered or welded to PC board.

b. Derate 25 mW/_C above 25_C.

) 150_C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

J

a

a

)

JA

3.125 W. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

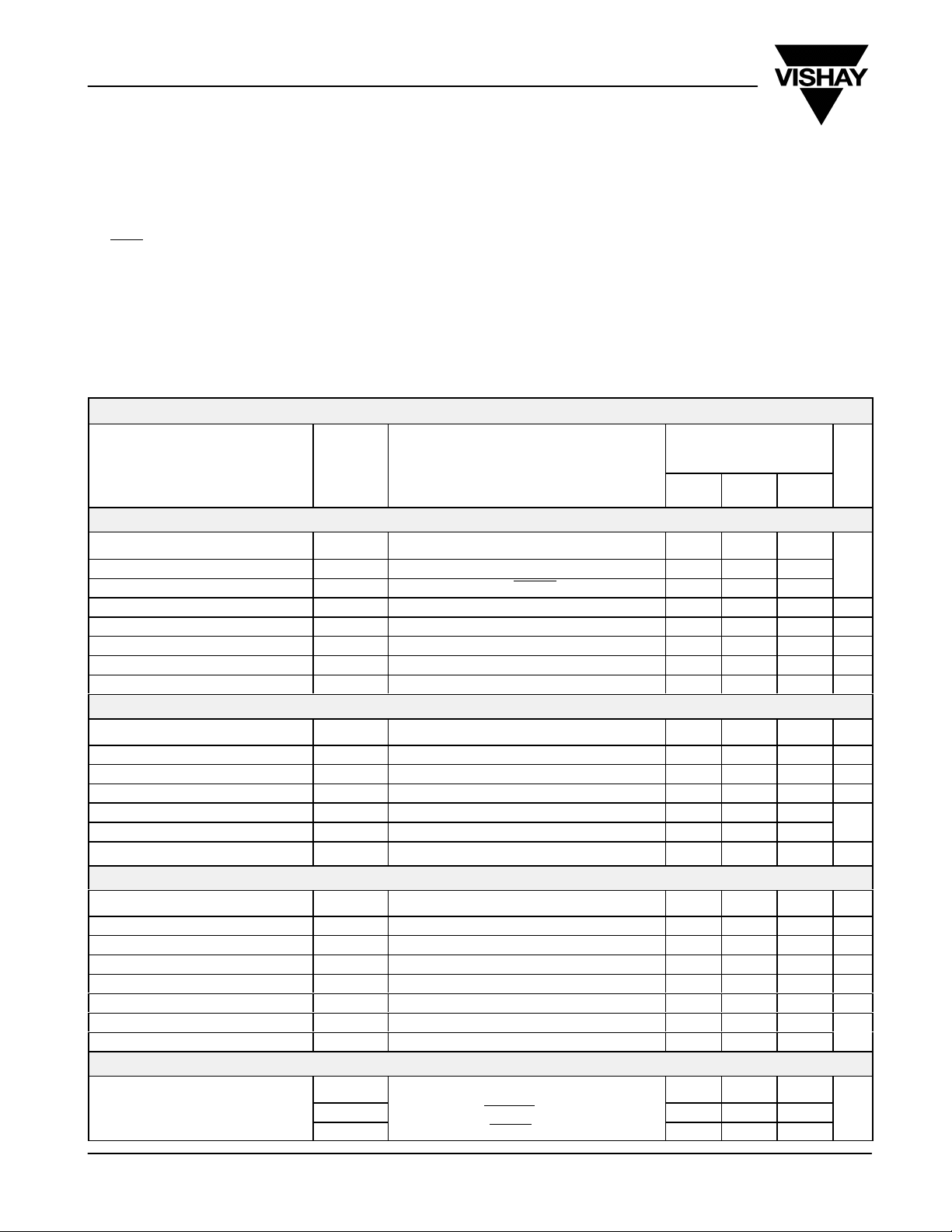

SPECIFICATIONS

T est Conditions

Unless Otherwise Specified

V+ = 12 V "10%, VDD = 11.6 V "10%

V

Parameter Symbol

= 5 V "10%, V

CC

V

REF

= GND = 0 V

REF–

= 5 V "5%

Min

Bridge Outputs (A4, A5)

High Level Output Voltage V

Low Level Output Voltage V

Clamp Diode Voltage V

OH

OL

CL

Amplifier Gain Output V

Dynamic Crossover Current Measured at V

Slew Rate SR 1 V/S

Small Signal Bandwidth (–3 dB) 0.2 MHz

Input Deadband –60 60 mV

IOH = 1.0 A, VDD = 10.2 V, OA2= V

IOL = –1.0 A, OA2 = V

REF

"1 V 8.0 9.1

REF

"1 V 0.6 1.1

IF = 1.0 A, ENABLE = High 2.5

= V

RANGE

"2 V 12 16 18 V/V

REF

DD

A2, Loop Compensation Amplifier

Input Offset Voltage V

Input Bias Current I

Unity Gain Bandwidth R

Slew Rate SR 1 V/s

Power Supply Rejection Ratio PSRR @ 10 kHz 50

Open Loop Voltage Gain A

Output Voltage Swing V

OS

B

VOL

Gain Select = High, IA

= 10 k, C

LOAD

O

R

LOAD

LOAD

= 10 k to V

–

= 5 V –50 50 nA

2

= 100 pF to V

REF

REF

V

REF

A3, Current Sense Amplifier

Input Offset Voltage V

Input Impedance R

Small Signal Bandwidth (–3 dB) R

Common Mode Rejection Ratio CMRR @ 5 kHz 50 dB

Slew Rate SR 2 V/s

Gain 3.9 4 4.1 V/V

Input Common-Mode Voltage Range V

Output Voltage Swing V

OS

CM

I

IN

LOAD

IN+ to I

SENSE

= 10 k, C

LOAD

IN– 5 k

SENSE

= 100 pF to V

REF

T o GND –0.3 2

R

O

LOAD

= 10 k, C

= 100 pF to V

LOAD

REF

V

REF

Supply

I

CC Static, No Load

Supply Current (Normal)

I

V+

I

DD

RETRACT = High 2 5

ENABLE = Low

Limits

C Suffix 0 to 70_C

b

TypaMaxbUnit

10 mA

–8 8 mV

1 MHz

80

–2 V

–5 5 mV

1 MHz

–2 V

5 13

REF

REF

0.01

+2 V

+2

V

dB

V

mA

www.vishay.com

2

Document Number: 70014

S-20883—Rev. G, 24-Jun-02

Page 3

Si9961

Vishay Siliconix

SPECIFICATIONS

T est Conditions

T est Conditions

Unless Otherwise Specified

Unless Otherwise Specified

V+ = 12 V "10%, VDD = 11.6 V "10%

V+ = 12 V "10%, VDD = 11.6 V "10%

V

V

= 5 V "10%, V

= 5 V "10%, V

CC

Parameter UnitMax

Symbol

CC

V

V

REF

REF

= GND = 0 V

= GND = 0 V

REF–

REF–

= 5 V "5%

= 5 V "5%

Min

Supply

I

CC Static, No Load

Supply Current (Standby)

VDD Range V

VCC Range V

V+ Range V+ 10.8 12 13.2

I

V+

I

DD

DD

CC

RETRACT = High 0.2 0.4

ENABLE = High

Normal Mode 10.2 11.6 13.2

Retract Mode 2.0 14

Gain Select Switch

RFB Switch Resistance 108 240

R

Switch Resistance

INH

R

Switch Resistance 810 1800

INL

V

(EXT)

REF

Input Current I

External Voltage Range V

REF

REF

IA2– = 5 V

OA2 = V

REF

Power Supply Monitor

VCC Undervoltage Threshold V

Hysteresis 40 mV

V+ Undervoltage Threshold V

Hysteresis 100 mV

= 5.0 V 3.82 4.12 4.42 V

REF

= 5.0 V 9.1 9.8 10.6 V

REF

Gain Select, RETRACT, ENABLE Input

Input High V oltage V

Input Low Voltage V

Input High Current I

Input Low Current I

IH

IL

IH

IL

VIN = 5 V –1 1

VIN = 0 V –1 1

FAULT Output

Output High Voltage V

Output Low Voltage V

Output High Sourcing Current I

OH

OL

OHS

IOH = –100 A

IOL = 1.6 mA 0.25 0.50

V

= 0 V 400 1100 A

OUT

RETRACT Current Control (RETRACT = Low, Output Current from A to B)

I

Bias Voltage V(I

RET

Retract Output Pull-Up Voltage V

Retract Output Pull-Down Current I

Maximum Emergency Retract Current I

Retract Current VDD Supply Rejection Ratio VDD = 2 V to 14 V, R

Retract Current Temperature Coefficient VDD = 10 V, R

Notes

a. Typical values are for DESIGN AID ONLY, not guaranteed nor subject to production testing.

b. The algebraic convention whereby the most negative value is a minimum and the most positive a maximum.

) VDD = 10 V, R

RET

OUT A

OUTB

(Max) VDD = 2 V, V

OUTB

VDD = 10 V, V

RET

VDD = 2.5 V to 14 V, I

= 5 V R

OUTB

R

= 0.5 , TA = 25_C

SB

= 0.7 V R

OUTB

RET

RET

= 3.74 k 0.66

= 30 mA VDD –1

OUTA

= 3.74 k

RET

= < 10 , RSB = 0.5 , 40

= 3.74 k 3.0 %/V

RET

= 3.74 k –0.3 %/_C

Limits

C Suffix 0 to 70_C

b

4.5 5 5.5

0.15 0.40 0.65 mA

4.75 5 5.25 V

3.5

V

CC

–0.8

22 30 38

a

Typ

0.8 1.6

135 300

V

CC

–0.33

b

0.01

1.5

mA

V

V

A

V

V

mA

mA

Document Number: 70014

S-20883—Rev. G, 24-Jun-02

www.vishay.com

3

Page 4

Si9961

Vishay Siliconix

PIN CONFIGURATION

24-Pin SOIC

(Wide Body)

APPLICATIONS

Introduction

R

1

INH

R

2

INL

OUT OA2

I

SENSE

FAULT

EXT V

RETRACT GND

GAIN SELECT SOURCE A

ENABLE GND

V

3

4

V

5

CC

I

RET

6

7

REF

V+ OUTPUT A

8

9

10

11

12

REF–

Top View

24

23

22

21

20

19

18

17

16

15

14

13

R

FB

IA2–

I

(IN)–

SENSE

SOURCE B

OUTPUT B

(Spindle Supply)

V

DD

I

(IN)

SENSE

User-Programmable Gains

Order Number: Si9961ACY

+

The Si9961 Voice Coil Motor (VCM) driver integrates the active

feedback and drive components of a head-positioning servo

loop for high-performance hard-disk applications. The Si9961

operates from a 12-V ("10%) power supply and delivers 1 A

of steady-state output current. This device is made possible by

a power IC process which combines bipolar, CMOS and

complimentary DMOS technologies. CMOS logic and linear

components minimize power consumption, bipolar front-ends

on critical amplifiers provide necessary accuracy, and

complimentary (p- and n-channel) DMOS devices allow the

transconductance output amplifier to operate from ground to

. Two user-programmable, current feedback/input voltage

V

DD

ratios may be digitally selected to optimize gain for both seek

and track following modes, to maximize system accuracy for

a given DAC resolution. An undervoltage lockout circuit

monitors the V+ supply and generates a fault signal to trigger

an orderly head-retract sequence at a voltage level sufficient

to allow the spindle motor’s back EMF-generated voltage to

supply the necessary head parking energy. Head retract can

also be commanded via a separate RETRACT input. VCM

current during retract can be user programmed with a single

external resistor. External components are limited to R/C filter

components for loop compensation and the resistors that are

required to program gain, retract current, and the load current

sense.

www.vishay.com

4

During linear operation, the transconductance amplifiers’

gains (input voltage at V

by external resistors R

gain input. After selecting a value for R

vs. VCM current, in Figure 1) are set

IN

R5, RSA, and RSB and selected by

3

and RSB that will yield

SA

the desired VCM current level, the High and Low feedback

gain ratios may be determined by the following:

R

1

High Gain +

Low Gain +

5

ǒ

Ǔ

R

3

R

5

ǒ

Ǔ

R

4

Where RS = RSA = R

4R

1

4R

SB

(GAIN SELECT Input = High)

S

(GAIN SELECT Input = Low)

S

Input offset current may then be calculated as:

I

OS

1

+

4R

S

ǒ

ǒ

ǒ

Where RIN = R3 or R

RS) R

4

Ǔ

IN

V

) 5V

Ǔ

OSA2

R

IN

Ǔ

IAS3

Document Number: 70014

S-20883—Rev. G, 24-Jun-02

Page 5

Si9961

Vishay Siliconix

mP

mP

12 V

System

Supply

R

RET

GAIN

SELECT

5 V

5-V Ref

818712

V+

FAULT

4

5

V

CC

23

IA2–

–

C

L

R

L

9

6

11

22

10

+

V

R

RETRACT

I

RET

ENABLE

OA2

R

INHRINL

Voltage

Monitor

A2

Acceleration Error

V

R

EXT

V

REF

8 R

R

+

–

V

R

Retract

Control

–

+

R

7 R

R

I

FB

A3

SENSE

OUT

A4

A5

V

REF–

V

R

–

+

I

I

SENSE

SENSE

IN+

IN–

V

DD

Q1

Q2

GND

AB

Back EMF Supply

Q3

Q4

20161415211332421

17

OUTPUT

A

19

OUTPUT

B

C2

I

OUT

VCM

R2

R3 R4 R5

V

IN

FIGURE 1. Si9961 Typical Application

Head Retract

A low on the RETRACT

input pin turns output devices Q1 and

Q4 on, and output devices Q2 and Q3 off. Maximum VCM

current can be set during head retract by adding an external

resistor between the IRET pin and ground. Maximum retract

current may be calculated as:

I

OUT

+ 175 x I

ret

+ 175 x

0.66 V

R

ret

Head retract can be initiated automatically by an undervoltage

condition (either the 12-V or 5-V supplies on the Si9961) by

connecting the FAULT output to the RETRACT input.

A high ENABLE

high-impedance state. The ENABLE

input puts both driver outputs in a

function can be used to

R

SA

R

SB

eliminate quiescent output current when power is applied but

the head has been parked, such as a sleep mode. A

sleep-mode power down sequence should be preceded by a

retract signal since a power failure during this state may not

provide adequate spindle-motor back EMF to permit head

retraction.

Transconductance Amplifier Compensation

The Si9961CY features an integrated transconductance

amplifier to drive the voice coil motor (VCM). To ensure proper

operation, this amplifier must be compensated specifically for

the VCM being driven. As a first approximation, the torque

constant and inertia of the VCM may be ignored, although they

will have some influence on the final results, especially if large

values are involved. (See Figure 1.)

Document Number: 70014

S-20883—Rev. G, 24-Jun-02

www.vishay.com

5

Page 6

Si9961

Vishay Siliconix

Frequency Compensation:

The VCM transconductance (in siemens) of this simplified

case may be expressed in the s (Laplace) plane as:

1

L

g

v

v

+

s )

R

v

L

v

Where Rv = VCM resistance in ohms

= VCM inductance in henrys

L

V

s is the Laplace operator

In this case, the transconductance pole is at –Rv/Lv. It is

desirable to cancel this pole in the interest of stability. To do

this, a compensation amplifier is cascaded with the VCM and

its driver. The transfer function of this amplifier is:

1

RL C

s

Ǔ

L

Hc+ A

ǒ

s )

Where RL= Compensation amplifier feedback

resistor in ohms

CL= Compensation amplifier feedback

capacitor in farads

A = Compensation amplifier and driver

voltage gain at high frequency

If R

x CL is set equal to Lv/Rv, then the combined open loop

L

transconductance in siemens becomes:

+

A

s L

v

g

to

In this case, the transconductance has a single pole at the

origin. If this open loop transfer is closed with a

transimpedance amplifier having a gain of B ohms, the

resultant closed loop transconducatance stage has the

transfer function (in siemens) of:

A

L

s )

v

A B

L

v

g

+

tc

Where B = Current feedback transimpedence amplifier gain in

ohms.

The entire transconductance now contains only a single pole

at –A*B/Lv. A and B are chosen to be considerably higher than

the servo bandwidth, to avoid undue phase margin reduction.

A = 16 x R

C

=Lv/(Rv x RL) = 100 x 10–6/RL farads

L

/10000

L

Gain Optimization:

There are three things to consider when optimizing the gain (A)

above. The first is servo bandwidth. The main criterion here is

to avoid having the transconductance amplifier cause an

undue loss of phase margin in the overall servo (mechanical

+ electrical + firmware) loop. The second is to avoid confirguing

a bandwidth that is more than required in view of noise and

stability considerations. The third is to keep the voltage output

waveform overshoot to a level that will not cause

cross-conduction of the output FETs.

The first two problems can be considered together. Let us

assume a disk drive with a spindle RPM of 4400 and with

50 servo sectors per track. The sample rate is therefore:

fs + 50

440

60

This is a sample frequency of 3667 Hz

As a rule of thumb, the open loop unity gain crossover

frequency of the entire servo (mechanical + electrical +

firmware) loop should be less than 1/10 of the sample

frequency. In this example, the servo open loop unity gain

crossover frequency would be less than 367 Hz. If we allow

only a 10_ degradation in phase margin due to the

transconductance amplifier, then a phase lag of 10_ at 367 Hz

is acceptable. This results in a 3-dB point in the

transconductance at :

+

367

tan(10

)

f

3db

or a 3-dB point in the transconductance at 2081 Hz.

The pole in the closed loop transconductance (–A * B / Lv)

should then be 2081 * 2 * = 13075. This means that A = 9.8.

From the above equation for A, RL = 6.2 k. This sets the

minimum gain limit governed by the servo bandwidth

requirements. The gain should not be much greater than this,

since increased noise will degrade the servo response.

The third problem, keeping the transconductance amplifier

voltage output wave form overshoot to a level that will not

cause the wrong output FETs to conduct, can be evaluated by

deriving the voltage transfer function of the closed loop

transconductance amplifier from input voltage to output

voltage (Vin to output A and B on the reference schematic).

As a typical example, in the referenced schematic, assume

that Rsa and Rsb = 0.5 , R5= R3 = 10 k, VCM inductance

(Lv) = 1.5 mH, VCM resistance (Rv) = 15 . Hence:

= 15

R

v

= 1.5 mH

L

v

B=2

www.vishay.com

6

This is :

Hto+ A

s ) p

s ) x

Where p = 1/RL x CL) or Rv/Lv Comp amplifier

zero/VCM pole

x = A x B/Lv closed loop pole

Document Number: 70014

S-20883—Rev. G, 24-Jun-02

Page 7

Si9961

Vishay Siliconix

If a unit step voltage is applied to the above transfer function

and the inverse Laplace transform is taken, the output result is:

VO+ A

p )(x * p)xe

*x t

x

Where t = time

As we can see, if x = p (i.e. if the VCM pole and compensation

amplifier zero = the transconductance closed loop pole), then

Vo reduces to A. In other words, a step input results in a step

output without overshoot. If x < p then a step input results in an

increased rise time output and no overshoot. If x > p, a step

input results in a step output with an overshoot.

If this overshoot is large enough, there may be a

cross-conduction condition in the output FETs.

Let us look at the above equation at t = 0 and t >> 0, expressed

in terms of the open loop high frequency voltage gain, A.

VO+ A

V

+

O

p L

B

v

At t = 0

At t uu 0

In the example shown above, p = 10,000 and A = 9.8. This

means that there is some overshoot. At t = 0, the output voltage

is 9.8 V per volt of input. At some later time, it has dropped to

7.5 V per volt of input. An overshoot of 31 % is thus produced.

The maximum overshoot voltage requires careful

consideration, since it constitutes a potentially catastrophic

problem area. If we had decided to optimize for no overshoot,

A would equal 7.5, and hence the closed loop pole (A * B / Lv)

would be 10,000, which is a frequency of 1.592 kHz. This

would have resulted in a phase margin degradation of 13_ at

the 367-Hz frequency desired. This may or may not be

acceptable. One must weigh the servo bandwidth, phase

margin degradation, and maximum voltage at the VCM for

each individual case.

Result:

In the example for the 2081-Hz roll-off case with 31%

overshoot and proper pole cancellation, the compensation

values are:

R

= 6.2 k

L

C

= 0.016 F

L

In the example for the 1592-Hz roll-off case with no overshoot

and proper pole cancellation, the compensation values are:

= 4.7 k

R

L

= 0.022 F

C

L

The linearity of the transconductance amplifier (around a

center value of 500 mA/volt) is shown in Figure 2. In this case,

the output current sense resistors (R

tolerance, 0.5

. Any mismatch between R

and RSB) were "5%

SA

and R

SA

SB

contribute directly to mismatch between the positive and

negative “full-scale”. Including the external resistor mismatch,

the overall loop nonlinearity is approximately 1% maximum

over a "250-mV input voltage range.

5

4

3

2

1

0

VDD = 12 V

–1

R

= RSB = 0.5 ”5%

SA

–2

R

= 52

m

G

= 500 mA/V

m

–3

Error in Percent of Full Scale

–4

–5

–300 –200 –100 0 100 200 300

VIN in mV

FIGURE 2. Si9961 Transconductance

End Point Non-Linearity

Document Number: 70014

S-20883—Rev. G, 24-Jun-02

www.vishay.com

7

Page 8

Si9961

Vishay Siliconix

V

IN

Gain+

V

S

6.2 k

RL

0.016 F

CL

8 R

V

R

IN

10 k

V

V

S

V

IN

R5

10 k

–

+

R

A3

(4 x Gain)

A2

R

V

R

A4

–

+

Cross-Over

Protection

A5

–

R

V

R

+

Cross-Over

Protection

7 R

–

+

R

0.5

V

R

DD

I

OUT

V

DD

SA

R

0.5

VCM

1.5 mH

15

SB

FIGURE 3. Transconductance Amplifier

–5

–8

–11

–14

GAIN (in dB)

–17

–20

1 10 100 1000 10000

www.vishay.com

8

= 6.2 k , CL = 0.016 F

R

L

Frequency (Hz)

FIGURE 4. FIGURE 5.

= 6.2 k , CL = 0.016 F

R

L

0

–20

–40

PHASE (in degrees)

–60

–80

1 10 100 1000 10000

Frequency (Hz)

S-20883—Rev. G, 24-Jun-02

Document Number: 70014

Loading...

Loading...