Page 1

INTEGRATED CURCUITS

DATA SH EET

SC4000

Universal Timeslot Interchange

Preliminary specification

File under Integrated Curcuits

2000 Sep 07

Page 2

Philips Semiconductors Preliminary specification

Universal Timeslot Interchange SC4000

Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Logic Pin Organization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

SC4000 100-Pin TQFP (top view) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

SC4000 Physical Dimensions (all dimensions in millimeters) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Pin Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Device Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Function Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Switching . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

PLL Timing and Clock Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Interrupts Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

CLKFAIL Timing and Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Message Channel Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Operation Mode and Configuration Register Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Register Access Schemes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Microprocessor Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

I/O Address Map . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Busy (D_0) (Read Only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Read (D_1) (Write only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Write (D_2) (Write only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Terminate (D_3) (Read/Write) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Channel Bank Select Register [1:0] (D_[5:4]) (Read/Write) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Channel Bank Select Register Enable (D_6) (Write only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Reset (D_7) (Read/Write) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Channel Specific Registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Time-Slot Select [6:0] (Read/write) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Port Select [3:0] (Read/Write) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Parallel Access Enable (Read/Write) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Switch Output Enable (Read/Write) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Time-Slot/Channel Select [6:0] (Read/Write) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Port Select [3:0] (Read/Write) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Local Connect Enable (Read/Write) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Switch Output Enable (Read/Write) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Parallel Access . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Serial Data [1:8] (Read/Write) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Source Parallel Access . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Serial Data [1:8] (Read Only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

2000 Sep 07 2

Page 3

Philips Semiconductors Preliminary specification

Universal Timeslot Interchange SC4000

Configuration Registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

SCbus Clock Master (C_0) (Read/Write) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

SCbus Clock Master Arm (C_1) (Read/Write) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

SCbus Primary/Alternate Select (C_2) (Read/Write) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Diagnostic Mode Enable (C_3) (Read/Write) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

SCbus Framing Mode [1:0](C_[5:4]) (Read/Write) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Local bus Framing Mode [1:0](C_[7:6]) (Read/Write) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Master Clock Input Frequency Select [2:0] (C_[10:8]) (Read/Write) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Direct R/W to Parallel Access Registers Enable (C_11) (Read/Write) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Message Channel Registered TXD Enable (C_12) (Read/Write) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Message Channel TXD_0 or TXD_1 Select (C_13) (Read/Write) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Message Channel Clock Duty Cycle Select (C_14) (Read/Write) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Message Channel Output Disable (W/ loopback) (C_15) (Read/Write) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

SCbus SD Sample Position (C_16) (Read/Write) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Local Bus SI Sample Position (C_17) (Read/Write) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

SCbus SD Output Delay Enable (C_18) (Read/Write) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Local bus SO Output Delay Enable (C_19) (Read/Write) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

SCbus FSYNCN Sample Position (C_20) (Read/Write) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

SCbus FSYNCN Rate (C_21) (Read/Write) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

SCbus SCLKX2N, SCLKX2NA Output Disable(C_22) (Read/Write) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

SCbus Alternate (“A”) Signals Output Enable (C_23) (Read/Write) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Local bus L_CLK Polarity (C_24) (Read/Write) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Local bus L_FS Polarity (C_25) (Read/Write) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Local bus L_FS Position (C_[27:26]) (Read/Write) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Local bus L_CLK & L_FS Rate (C_28) (Read/Write) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Local bus L_CLK DPLL Enable (C_29) (Read/Write) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Local bus L_CLK 8.192 MHz 62.5% Duty Cycle (C_30) (Read/Write) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Version/Revision Status (C_[39:32]) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Master PLL Reference Select [2:0] (C_[42:40]) (Read/Write) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Internal/External Master PLL Select (C_43) (Read/Write) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

SCbus SREF_8K Source Select [1:0] (C_[45:44]) (Read/Write) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

SCbus SREF_8K Output Enable (C_46) (Read/Write) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

SCbus SCLK 8.192 MHz 62.5% Duty Cycle (C_47) (Read/Write) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Clock Watchdog Enable (C_48) (Read/Write) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Microprocessor Watchdog Enable (C_49) (Read/Write) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

SCbus CLKFAIL Latch Set Polarity Select (C_50) (Read/Write) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

SCbus CLKFAIL Latch Debounce Enable (C_51) (Read/Write) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Frame Boundary Latch Set Delay Enable (C_52) (Read/Write) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

INT_0 Mask_N (C_53) (Read/Write) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

INT_0 Output Polarity (C_54) (Read/Write) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

INT_0 Output Driver (C_55) (Read/Write) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

SCbus CLKFAIL Latch (C_56) (Read Only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Frame Boundary Latch (C_57) (Read only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

2000 Sep 07 3

Page 4

Philips Semiconductors Preliminary specification

Universal Timeslot Interchange SC4000

Internal Master PLL Error Latch (C_58) (Read Only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

SCbus Error Indicator (C_59) (Read Only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

SCbus CLKFAIL Latch Clear_N (C_60) (Read/Write) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Frame Boundary Latch Clear_N (C_61) (Read/Write) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Internal Master PLL Error Latch Clear_N (C_62) (Read/Write) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

SCbus SCLKX2N Error Latch (C_64) (Read Only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

SCbus SCLKX2NA Error Latch (C_65) (Read only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

SCbus SCLK Error Latch (C_66) (Read only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

SCbus SCLKA Error Latch (C_67) (Read only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

SCbus SCLKX2N Error Latch Clear_N (C_68) (Read/Write) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

SCbus SCLKX2NA Error Latch Clear_N (C_69) (Read/Write) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

SCbus SCLK Error Latch Clear_N (C_70) (Read/Write) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

SCbus SCLKA Error Latch Clear_N(C_71) (Read/Write) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

SCbus FSYNCN Error Latch (C_72) (Read Only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

SCbus FSYNCNA Error Latch (C_73) (Read Only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

SCbus Clock Master Error Latch (C_74) (Read Only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

SCbus FSYNCN Error Latch Clear_N (C_76) (Read/Write) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

SCbus FSYNCNA Error Latch Clear_N (C_77) (Read/Write) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

SCbus Clock Master Error Latch Clear_N (C_78) (Read/Write) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

SCbus SREF_8K NE SREF_8KA Error Latch (C_80) (Read only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

SCbus CLKFAIL NE CLKFAILA Error Latch (C_81) (Read only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

SCbus MC NE MCA Error Latch (C_82) (Read only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

SCbus SD Error Indicator (C_83) (Read only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

SCbus SREF_8K NE SREF_8KA Error Latch Clear_N (C_84) (Read/Write) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

SCbus CLKFAIL NE CLKFAILA Error Latch Clear_N (C_85) (Read/write) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

SCbus MC NE MCA Error Latch Clear_N (C_86) (Read/Write) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

SCbus SD Error Latch Clear_N (C_87) (Read/Write) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

SCbus SD_[15:0] Error Latch (C_[103:88]) (Read only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Summary of SC4000 Configuration Registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Miscellaneous . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Master Clock/PLL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

SCbus (MVIP Bus) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Local Bus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Message Channel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Watchdog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Interrupt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Reserved Bit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Typical Internal Register Access . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Typical Write Internal Register Access . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Typical Read Internal Register Access . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

Electrical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

AC Electrical Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

2000 Sep 07 4

Page 5

Philips Semiconductors Preliminary specification

Universal Timeslot Interchange SC4000

Table 1. Configuration Register Setup for SCbus Clock Slave . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Table 2. Configuration Register Setup for SCbus Clock Master. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Table 3. Configuration Register Setup for SCbus Armed Clock Master. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Table 4. Configuration Register Setup for MVIP Clock Master . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Table 5. Configuration Register Setup for MVIP Clock Slave. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Table 6. SCbus/MVIP Signals Cross Reference. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Table 7. Microprocessor Interface Timing - Intel Bus Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Table 8. Microprocessor Interface Timing - Intel Bus Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Table 9. Microprocessor Interface Timing - Multiplexed Address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Table 10. Local Bus Timing, 1X L_CLK Mode (C_28=0) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Table 11. Local Bus Timing, 2X L_CLK Mode (C_28=1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Table 12. SCbus Timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

Table 13. SCbus Clock Master Timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Table 14. SCbus Clock Fail Timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Table 15. REF_8K_[3:0] and SREF_8K Timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

2000 Sep 07 5

Page 6

Philips Semiconductors Preliminary specification

Universal Timeslot Interchange SC4000

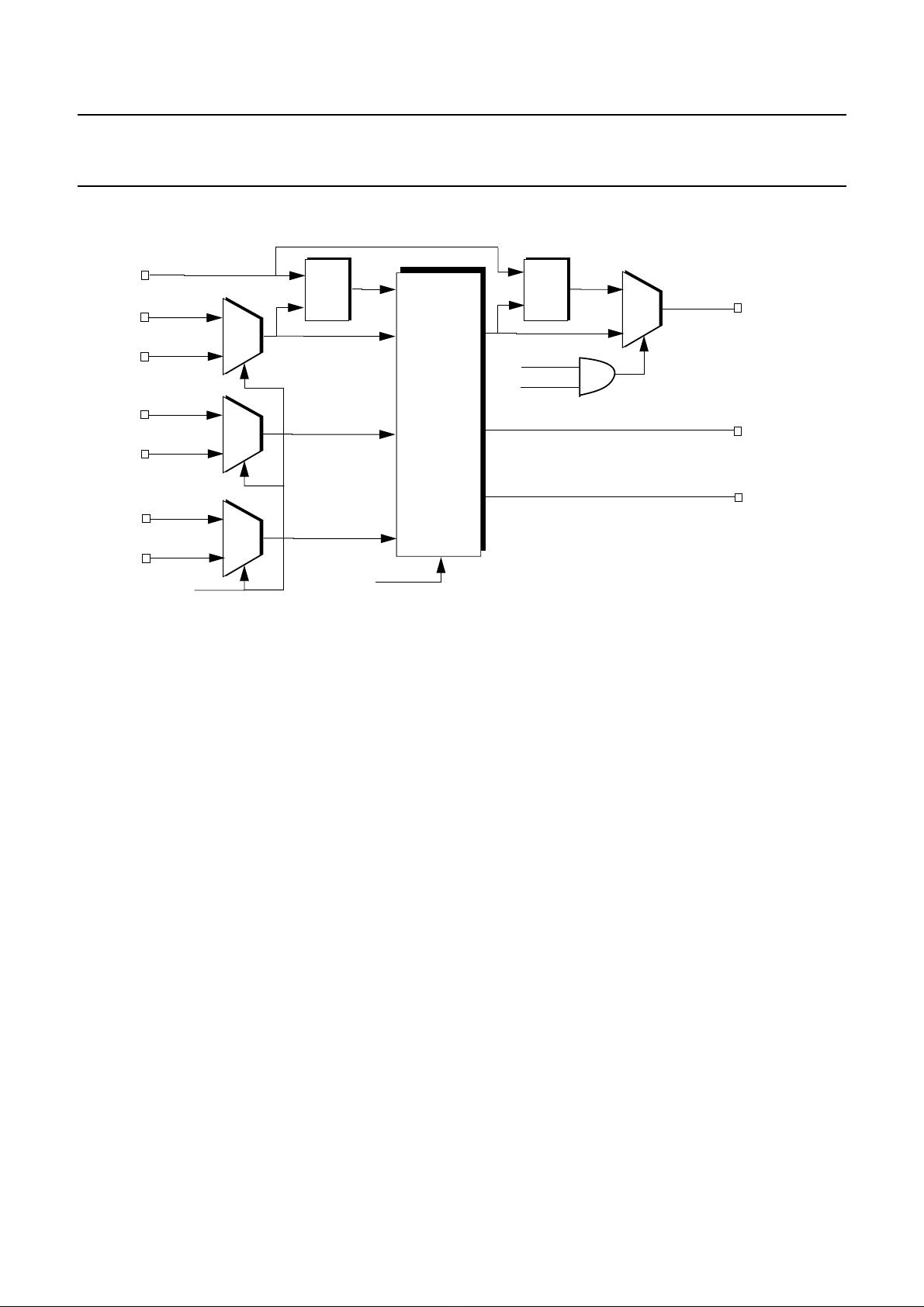

Figure 1.

Figure 2. Internal Master PLL (C_43 = 0) Function Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Figure 3.

Figure 4. Internal PLL and Local Bus PLL Timing Function Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Figure 5.

Figure 6.

Figure 7.

Figure 8.

Figure 9.

Figure 10.

Figure 11.

Figure 12.

Figure 13.

Figure 14.

Figure 15.

Destination and Source Switch Function Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

External Master PLL (C_43 = 1) Function Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Using Two Pins A_[1:0] for Address Bus Interface Scheme (C_11 = 0) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Using Nine Pins A_[8:0] for Address Bus Interface Scheme (C_11 = 1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Microprocessor Interface Timing - Intel Bus Mode (Pin I_N = 0), Non-Multiplexed Address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

Microprocessor Interface Timing - Motorola Bus Mode (Pin I_N = 1), Non-multiplexed Address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

Microprocessor Interface Timing - Multiplexed Address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

Local Bus Timing, 1XL_CLK Mode (C_28=0) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

Local Bus Timing, 2X L_CLK Mode (C_28=1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

SCbus Timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

SCbus Clock Master Timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

SCbus Clock Fail Timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

REF_8K_[3:0] and SREF_8K input mode Timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

2000 Sep 07 6

Page 7

Philips Semiconductors Preliminary specification

Universal Timeslot Interchange SC4000

FEATURES

• Timeslot interchange between local

and expansion buses

• Architecture optimized for call processing environments: SCbus™,

MVIP® and ST-BUS Compatible

• Full switching between any of:

– 128 local bus input SI timeslots

– 128 local bus output SO timeslots

– up to 2048 expansion bus SD

timeslots

• Multiple local bus speeds and

formats:

– 2.048, 4.096 or 8.192 Mb/s

– PEB®, STbus or GCI

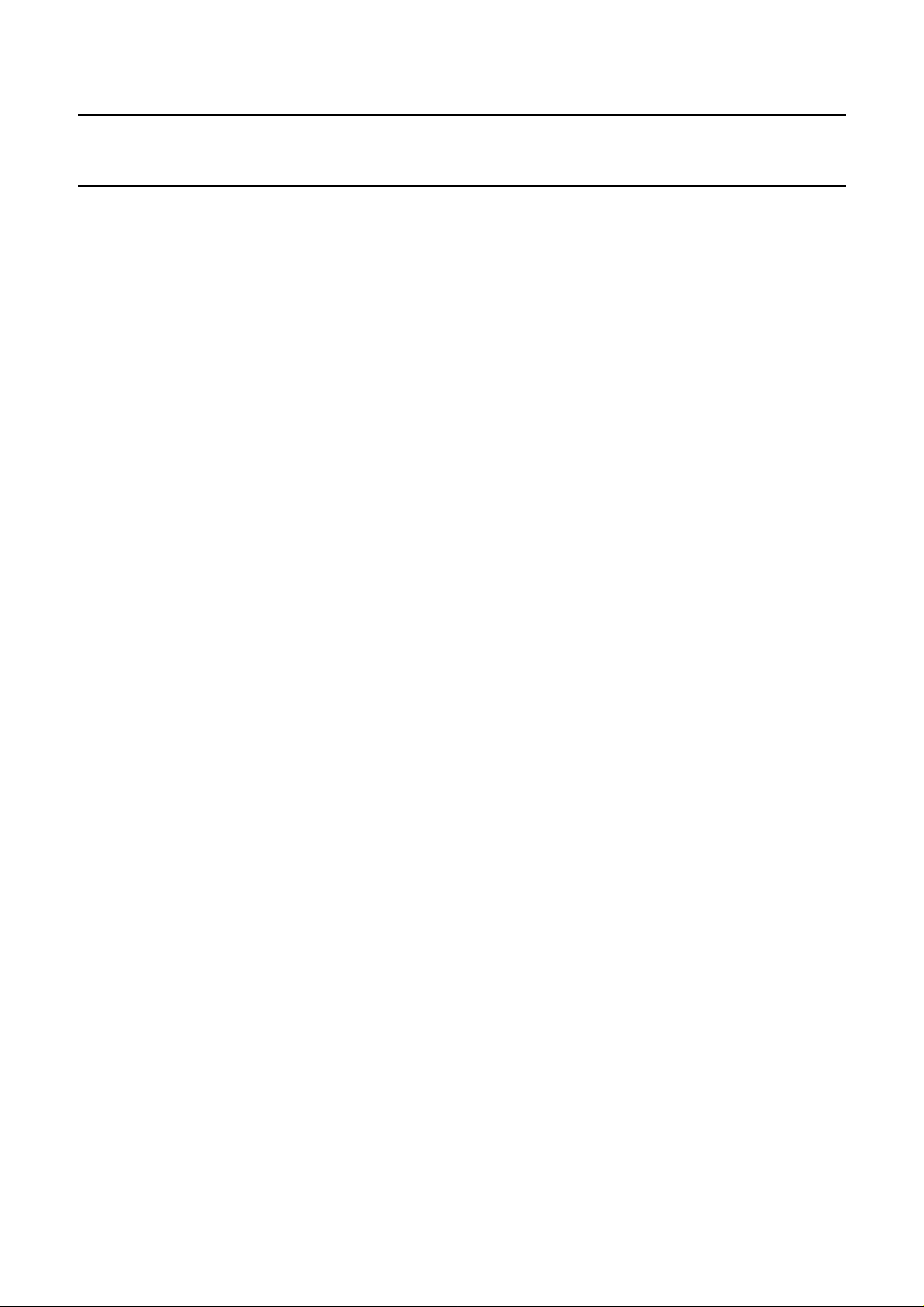

Logic Pin Organization

• Supports both Intel® and Motorola®

processor interfaces

• Serial or parallel access to expansion

bus

• Enhanced input hysteresis threshold

• Internal phased lock loop

• Fast response and support for SCbus

clock fallback

• Flexible local frame sync interface

• Supports hyper channel capability

(bundling)

• SCbus message bus interface and local

loopback control

• High availability and self-diagnostic

features

44

D_7

43

D_6

42

D_5

40

D_4

39

D_3

38

D_2

36

D_1

35

D_0

34

A_8

32

A_7

31

A_6

30

A_5

28

A_4

27

A_3

26

A_2

25

A_1

24

A_0

22

ALE

17

CS_1_N

16

CS_0_N

19

RD_N(STRB_N)

20

WR_N(R/W_N)

21

DACK_N

96

RESET

12

I_N(M)

2

X_IN

1

X_OUT

7

REF_8K_3(REF_8K_OUT)

6

REF_8K_2(CLK_IN)

5

REF_8K_1

4

REF_8K_0

95

SI_3

94

SI_2

92

SI_1

91

SI_0

9

TXD_0

98

TEST

(TEST_OUT_0)DRQ_R

(TEST_OUT_1)DRQ_T

SC4000

INT_1

INT_0

SCLKX2N

SCLKX2NA

SCLK

SCLKA

SREF_8K

SREF_8KA

FSYNCN

FSYNCNA

CLKFAIL

CLKFAILA

SD_0

SD_1

SD_2

SD_3

SD_4

SD_5

SD_6

SD_7

SD_8

SD_9

SD_10

SD_11

SD_12

SD_13

SD_14

SD_15

MC

MCA

L_CLK

L_FS

SO_3

SO_2

SO_1

SO_0

MC_CLK

RXD

• 5V CMOS technology

• 100-pin TQFP package

APPLICATIONS

• PC-based switching

• Small to medium size digital switch

matrices

• SCbus/MVIP interface functions

• Digital centralized voice processing

system

• Voice/Data multiplexer and exchange

• Computer telephony interface

15

14

99

100

46

47

49

50

51

52

54

55

56

58

59

60

62

63

64

66

67

68

70

71

72

74

75

76

77

79

80

81

83

84

90

88

87

86

11

10

2000 Sep 07 7

Page 8

Philips Semiconductors Preliminary specification

Universal Timeslot Interchange SC4000

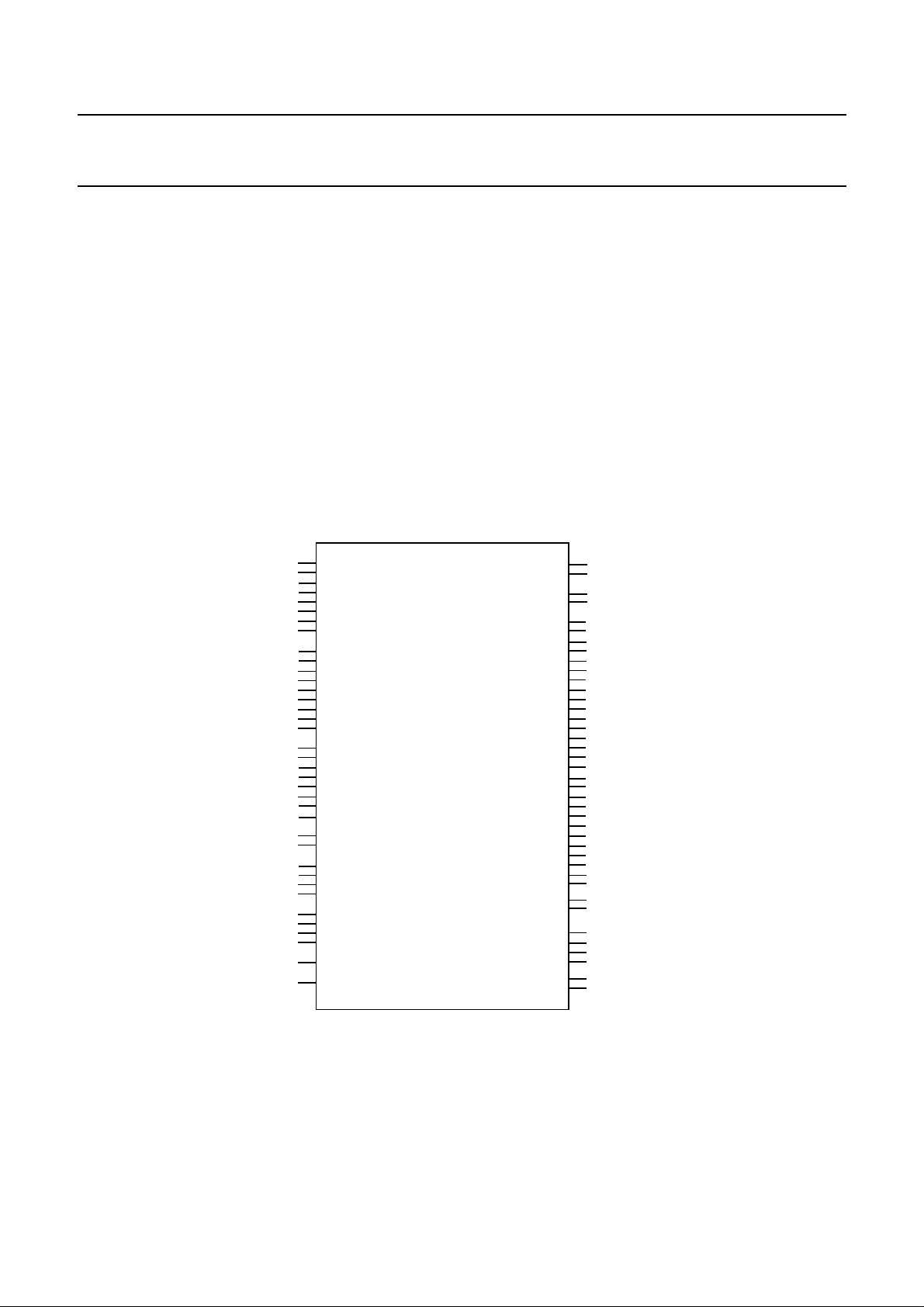

Block Diagram

SI_[3:0]

SO_[3:0]

Local Bus Timing

CLK_IN

REF_8K_[3:0]

A_[8:0]

D_[7:0]

Control

SC4000 100-Pin TQFP (top view)

Micro

Processor

Interface

SD_12

SD_11

VSS

SD_10

SD_9

Control

Bus

SD_8

VSS

SD_7

SD_6

SD_5

Timing

DPLL

VDD

SD_4

SD_3

SD_2

VDD

SD_1

SD_0

128 x 2048

Destination

Switch

128 x 2176

Source

Switch

CLKFAILA

VSS

CLKFAIL

FSYNCNA

FSYNCN

VSS

SREF_8KA

SD_[15:0]

Local

Connect

SCbus Timing

SERF_8K

SD_13

SD_14

VDD

SD_15

MC

MCA

VSS

L_CLK

L_FS

VDD

SO_0

SO_1

SO_2

VDD

SO_3

SI_0

SI_1

VSS

SI_2

SI_3

RESET

VSS

TEST

DRQ_R

DRQ_T

75747372717069686766656463626160595857565554535251

76

77

78

79

80

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

97

98

99

100

1 2 3 4 5 6 7 8 9 10 11121314 15 16 17 1819 202122 23 24 25

VSS

X_IN

X_OUT

REF_8K_0

REF_8K_1

SC4000

100-PIN TQFP

(TOP VIEW)

I_N

VDD

RXD

VDD

INT_0

REF_8K_2

REF_8K_3

TXD_0

MC_CLK

INT_1

CS_0_N

VSS

SC_1_N

RD_N

WR_N

DACK_N

ALE

VSS

A_0

A_1

SCLKA

50

49

SCLK

48

VDD

SCLKX2NA

47

46

SCLKX2N

45

VSS

D_7

44

D_6

43

42

D_5

41

VSS

40

D_4

D_3

39

D_2

38

37

VDD

36

D_1

D_0

35

A_8

34

33

VSS

32

A_7

A_6

31

A_5

30

29

VDD

A_4

28

27

A_3

26

A_2

2000 Sep 07 8

Page 9

Philips Semiconductors Preliminary specification

Universal Timeslot Interchange SC4000

SC4000 Physical Dimensions (all dimensions in millimeters)

+

_

16.00 0.40

+

_

14.00 0.20

16.00 0.40

14.00 0.20

+

_

+

_

+

_

1.40 0.05

0.15

MAX

0.50

Typ

+

_

0.22 0.05

o

12 REF

o

12 REF

0.20

1.00 REF

0.14

0.25

00-

0.60

MIN

+

_

0.04

0

10

+

_

0.15

2000 Sep 07 9

Page 10

Philips Semiconductors Preliminary specification

Universal Timeslot Interchange SC4000

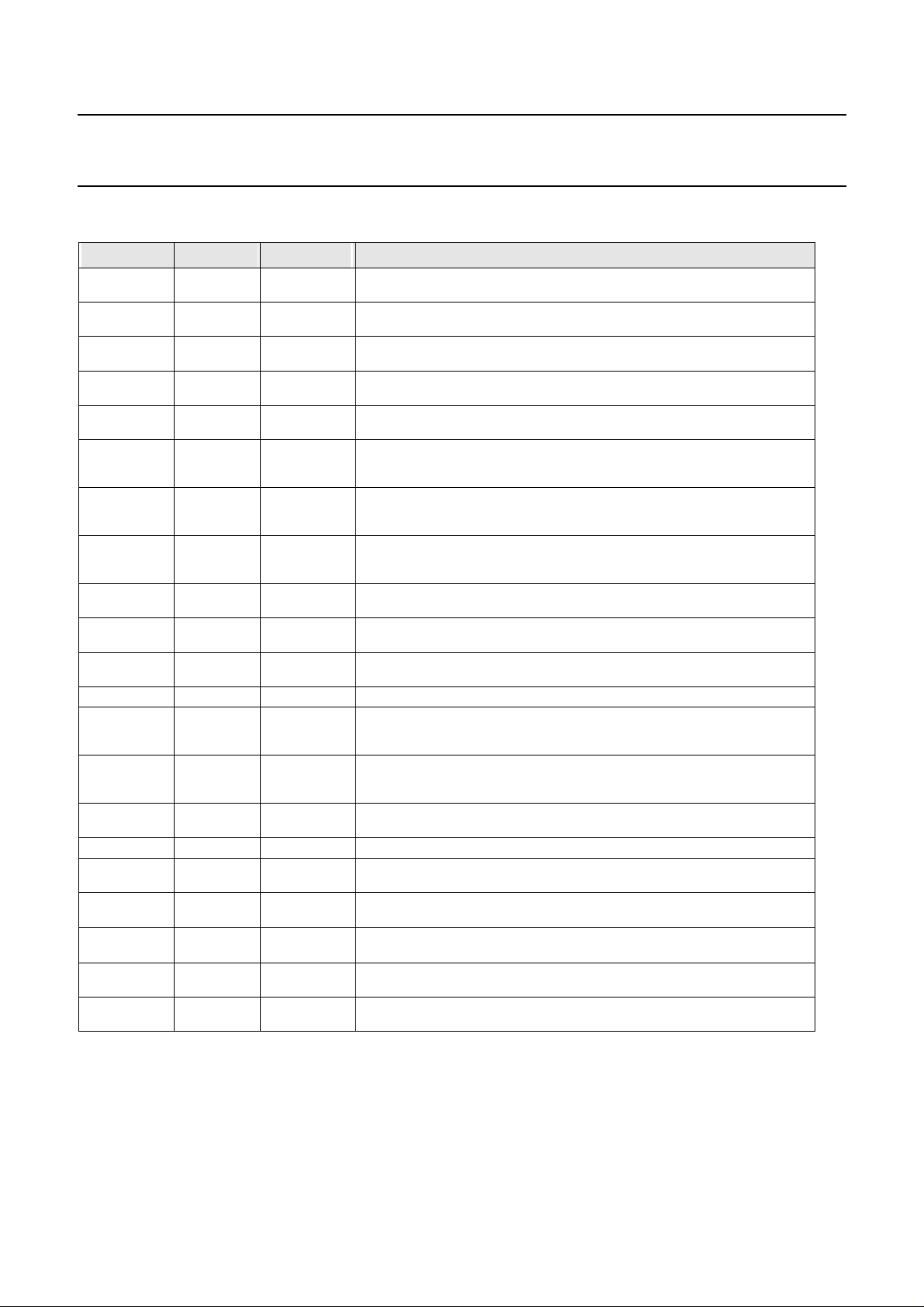

PIN DESCRIPTION

Pin Name Input/Output Pin Number Pin Description

D_[7:0] I/O 44,43,42,40,

A_[8:0] I 34,32,31,30,

ALE I 22 (TTL Input) Address Latch Enable. This input pin is tied to high in non-multiplexed mode. Otherwise, in multi-

CS_1_N I 17 (TTL Input) Chip Select 1. Reserved for future internal HDLC controller. If unused, this pin should be connected to

CS_0_N I 16 (TTL Input) Chip Select 0. This active low signal selects the SC4000

I_N

or

M

RD_N

or

STRB_N

WR_N

or

R/W_N

DACK_N I 21 (TTL Input, Pull up) DMA Acknowledge Reserved for future internal HDLC controller. If unused, this pin should be

RESET I 96 (TTL Input) Reset. This active high signal initializes the microprocessor interface, configuration, routing and paral-

X_IN I 2 (CMOS Input) Crystal Clock Input. This pin is a CMOS level input of either 2.048, 4.096, 8.192, 16.384, 32.768 or

X_OUT O 1 (CMOS Output) Crystal Clock Output.

REF_8K_3

or

REF_8K_OUT

REF_8K_2

or

CLK_IN

REF_8K_1 I 5 (TTL Input) Local 8 KHz Reference 1 Input.

I 12 (TTL Input) Microprocessor Bus Interface Mode Select.

I 19 (TTL Input) In Intel Bus Mode (RD_N), this active low input operates with CS_0_N to configure the data bus lines

I 20 (TTL Input) In Intel Bus Mode (WR_N), when CS_0_N is active, the rising edge of WR_N is used to latch an inter-

I

O

I 6 (TTL Input) Internal Master PLL (REF_8K_2). If configuration register bit C_43=0, this pin is a Local 8 KHz Refer-

39,38,36,35

28,27,26,25,24

7 (TTL Bi-Directional) Internal Master PLL (REF_8K_3). If configuration register bit C_43=0, this pin is a Local 8

(TTL Bi-directional) Microprocessor Data Bus. These bi-directional, tri-state lines allow the microprocessor to

access SC4000 internal registers as well as the source/destination routing memory and parallel access registers.

(TTL Input) Microprocessor Address Bus. These inputs select the internal registers used by a read or write operation. Normally these inputs are connected to Microprocessor address lines A[8:0].

plexed mode, the Microprocessor Address Bus is latched internally on the falling edge of this signal.

high.

for a microprocessor read or write operation.

When this input is low, Intel Bus Mode (I_N) is selected.

When this input is high, Motorola Bus (M) Mode is selected.

D_[7:0] as output. In Motorola Bus Mode (STRB_N), this active low input operates with CS_0_N to enable a read

or write operation.

nal data register with data provided via the data bus lines D_[7:0]. In Motorola Bus Mode (R/W_N), this R/W_N

input is used to distinguish between read or write during a microprocessor access.

left unconnected

lel access registers.

65.536 MHz. A crystal of 16.384 MHz from X_IN to X_OUT may also be used.

KHz Reference 3 Input.

External Master PLL (REF_8K_OUT). If configuration register bit C_43=1, this pin is an 8 KHz Reference Output.

ence 2 Input.

External Master PLL (CLK_IN). If configuration register bit C_43=1, this is a clock input from external master PLL.

REF_8K_0 I 4 (TTL Input) Local 8 KHz Reference 0 Input.

SI_[3:0] I 95,94,92,91 (TTL Input, Pull Up) Local Bus Serial Input Data Streams. This pin can be programmed to 2.048, 4.096 or 8.192

TXD_0 I 9 (TTL Input, Pull Up) Message Channel Transmit Data. This pin is for the SCbus Message channel transmit data

TEST I 98

INT_1 I/O 15 (TTL Bi-directional) Interrupt Request 1. Reserved for future internal HDLC controller. If unused, this pin should be

INT_0 I/O 14 (TTL Bi-directional) Interrupt Request 0. This pin will be asserted (controlled by C_[55:53]) if either SCbus Error,

Mb/s data rates.

input line.

(TTL Input) NAND Gate Test Mode Enable. When in test mode (TEST=1) each pin except VDD/VSS/X_OUT is

nanded with the preceding pin and output at both DRQ_R and DRQ_T pins.

left unconnected.

SCbus CLKFAIL, Frame Boundary or Internal Master PLL Error and INT_0 unmasked (C_53 = 1).

2000 Sep 07 10

Page 11

Philips Semiconductors Preliminary specification

Universal Timeslot Interchange SC4000

Pin Description (continued)

Pin Name Input/Output Pin Number Pin Description

DRQ_R

or

TEST_OUT_0

DRQ_T

or

TEST_OUT_1

SCLKX2N I/O 46 (SCbus Bi-directional) SCbus System clock x 2.

SCLKX2NA I/O 47 (SCbus Bi-directional) SCbus Alternate System clock x 2.

SCLK I/O 49 (SCbus Bi-directional) SCbus System clock. This can be programmed to either 2.048, 4.096 or 8.192 MHz.

SCLKA I/O 50 (SCbus Bi-directional) SCbus Alternate System clock.

SREF_8K I/O 51 (SCbus Bi-directional) SCbus 8 KHz Reference.

SREF_8KA I/O 52 (SCbus Bi-directional) SCbus 8 KHz Alternate Reference.

FSYNCN I/O 54 (SCbus Bi-directional) SCbus 8 KHz Frame Synchronization signal.

FSYNCNA I/O 55 (SCbus Bi-directional) SCbus 8 KHz Alternate Frame Synchronization signal.

CLKFAIL I/O 56 (SCbus Bi-directional) SCbus System Clock Fail signal.

CLKFAILA I/O 58 (SCbus Bi-directional) SCbus Alternate System Clock Fail signal.

O 99 (TTL Output) Receive DMA Request. This pin is reserved for a future internal HDLC controller. Otherwise, in Test

Mode (TEST=1), this is a NANDed gate test chain 0 output.

O 100 (TTL Output) Transmit DMA Request. This pin is reserved for a future internal HDLC controller. Otherwise, in Test

Mode (TEST=1), this is a NANDed gate test chain 1 output.

Set C_0 = 1 to enable the SCLK output driver as master mode.

Set C_0 = 0 to disable the SCLK output driver as slave mode.

If C_46 = 1, the SREF_8K output is enabled at SCbus

If C_46 = 0, the SREF_8K output is disabled at SCbus

Set C_0 = 1 to enable the FSYNCN output driver as master mode.

Set C_0 = 0 to disable the FSYNCN output driver as slave mode.

SD_[0:15] I/O 59,60,62,63,

64,66,67,68,

70,71,72,74,

75,76,77,79

MC I/O 80 (SCbus Bi-directional Open Collector) SCbus Message Channel.

MCA I/O 81 (SCbus Bi-directional Open Collector) SCbus Alternate Message Channel.

L_CLK I/O 83 (TTL Bi-directional) Local bus Clock Output. It can be programmed to: 2.048, 4.096 or 8.192 MHz if set C_28 = 0.

L_FS I/O 84 (TTL Bi-directional) Local bus 8 KHz Frame Synchronization Output.

S0_[3:0] I/O 90,88,87,86 (TTL Bi-directional) Local Bus Serial Output Data Streams. It can be programmed to 2.048, 4.096 or 8.192 Mb/s

MC_CLK I/O 11 (TTL Bi-directional) Message Channel Data Clock. This pin is a 2.048 MHz output. The clock duty cycle can be

RXD I/O 10 (TTL Bi-directional) Message Channel Receive Data. This pin is for the SCbus message channel receive data output

VDD Power 8,13,29,37,48,

61,65,78,85,89

VSS Power 3,18,23,33,41,

45,53,57,69,73,

82,93,97

Note: In Test mode (TEST=1), every pin except VDD/VSS/X_OUT/DRQ_R/DRQ_T is configured as input.

(SCbus Bi-directional) These are SCbus Serial Data Streams can be programmed to 2.048, 4.096 or 8.192 Mb/s

data rates.

4.096, 8.192 or 16.384 MHz if set C_28 = 1.

data rates.

programmed by C_14 bit.

line.

+5 Volt Power Supply.

Ground.

2000 Sep 07 11

Page 12

Philips Semiconductors Preliminary specification

Universal Timeslot Interchange SC4000

DEVICE OVERVIEW

The SC4000 Universal Timeslot Interchange is designed to provide the hardware interface to the SCbus. Its primary

function is exchanging digital data between the Local bus serial port and the

SCbus serial port. A microprocessor

interface allows the host controller to

specify the timeslots and serial lines for

this exchange. Both the SCbus and the

Local bus can be programmed to operate at either 2.048 Mb/s, 4.096 Mb/s or

8.192 Mb/s.

Local Bus Channels to Serial Ports SI and SO Time Slot Assignments

Framing mode SI_0 and SO_0 SI_1 and SO_1 SI_2 and SO_2 SI_3 and SO_3

2.048 Mb/s

4.096Mb/s ch[0:63] -> ts[0:63] ch[64:127] -> ts[0:63]

8.192 Mb/s ch[0:127] -> ts[0:127]

ch[0:31] -> ts[0:31] ch[32:63] -> ts[0:31] ch[64:95] -> ts[0:31] ch[96:127] -> ts[0:31]

As shown in Figure 1 , the destination

routing memory defines the Local Bus to

SCbus switch connection. There are 128

destination routing memory locations

— one for each Local Bus input channel.

The data stored in the destination routing memory selects the timeslot and

SCbus serial port connection for the

Local Bus input channel. The source

routing memory defines the SCbus to

Local Bus switch connection. There are

128 source routing memory locations —

one for each Local Bus output channel.

The data stored in the source routing

memory selects the time slot and SCbus

serial port connection for the Local Bus

output channel.

2000 Sep 07 12

Page 13

Philips Semiconductors Preliminary specification

Universal Timeslot Interchange SC4000

Writing to the routing memory is synchronized with SCbus timing. So routing information can be changed only on

time slot boundaries. All input data is

buffered in holding registers. The entire

holding register is transferred to the output registers on a frame boundary basis.

All frame-bounded time slots incur a

one frame delay as they pass through the

switch. Switching data in this fashion

supports time slot bundling.

The SO outputs are tri-state controlled

on time slot boundaries by the Source

Routing Memory Switch Output Enable

Bit. This allows SO outputs from multiple devices to be connected to a common line. The data sample position of

both the SCbus and the Local bus can be

selected for either 50% or 75% of the bit

cell.

In addition to switching local bus serial

data to and from the SCbus, the SC4000

provides a means of switching parallel

data through the microprocessor interface to the SCbus. A frame boundary interrupt helps control the timing of

parallel data accesses. Direct reading and

writing of parallel access register contents makes for an efficient data transfer.

When using direct access, the controlling processor places the address of the

target channel on the address bus. In

this way, data can be read or written in a

single cycle. To avoid data corruption,

the application should not access the

channel for a time period defined as four

clocks before and four clocks after the

frame boundary.

The Source Routing Memory Local

Connect Enable mode allows the switching of any destination channel to

Figure 1. Destination and Source Switch Function Block

1 OF 128 DESTINATION SWITCH

SI_[3:0]

D_[7:0]

W/R_N

INPUT

HOLDING

REGISTER

PARALLEL

ACCESS

REGISTER

O

I

PARALLEL

ACCESS

ENABLE

OUTPUT

HOLDING REGISTER

any source channel without SCbus

intervention. This mode accommodates

either serial or parallel data transfer.

Since data passes through the switch

twice in this mode, there is a two-frame

delay from input to output.

Diagnostic mode electrically disconnects

the SC4000 from the SCbus but allows

access through the local bus. This mode

is particularly useful for running board

diagnostics without upsetting the

SCbus. A Master Clock source is

required to run this mode.

The SC4000 pinout anticipates a future

version of the chip that includes an internal HDLC controller for the message

channel. To remain compatible with this

and other subsequent versions of the

SC4000, applications must write 0 to

all “Reserved (read only)” configuration

registers.

SD_[15:0]

TIMESLOT & PORT

OUTPUT ENABLE

LOCAL CONNECT BUS

DESTINATION

ROUTING MEMORY

1 OF 128 SOURCE SWITCH

OUTPUT

HOLDING

REGISTER

HOLDING

REGISTER

SO_[3:0]

SOURCE

ROUTING MEMORY

INTERNAL PARALLEL

ACCESS

READ

OUTPUT

ENABLE

2000 Sep 07 13

INPUT

TIMESLOT,

PORT AND LOCAL

CONNECT ENABLE

Page 14

Philips Semiconductors Preliminary specification

Universal Timeslot Interchange SC4000

FUNCTION DESCRIPTION

Switching

The SC4000 allows data switching

through the microprocessor interface in

any of the following three directions:

• From any local bus serial channel (SI)

or parallel data bus D_[7:0] input to

any SCbus channel (SD) output

• From any SCbus channel (SD) input

to any output of the local bus serial

channel (SO) or parallel data bus

D_[7:0]

• From any of local bus serial channel

(SI) or parallel data bus D_[7:0] input

directly through an internal local

connect bus to any local bus serial

channel (SO) output

As shown in Figure 1, each input SI and

output SO channel is mapped to one of

128 unique locations in the destination

routing memory and source routing

memory, respectively. So data stored in

the destination or source routing memory selects the timeslot and serial port of

the SCbus. All data is buffered through

the input holding register, output holding register or parallel access register for

a switching matrix with one frame delay.

PLL Timing and Clock Control

The SC4000 provides the option of using the internal master PLL (C_43 = 0)

or an external master PLL (C_43 = 1).

As shown in Figure 2, the internal

master PLL generates a clock that is frequency-locked to an 8 KHz reference input of either SREF_8K or REF_8K[3:0].

When the SC4000 is enabled as SCbus

master (C_0 =1), a state machine inside

the SC4000 uses this clock to generate

Figure 2. Internal Master PLL (C_43 = 0) Function Block

EXTERNAL

CRYSTAL or OSC

REF_8K_[3:0]

4, 5, 6, 7

C_[42:40]

X_OUT

1

Master PLL

Reference

8 K Select

X_IN

2

65.536 MHz

SCbus

Clock

Master PLL

C_2

C_[10:8], C_[5:4]

Programmable

Divider

SCLK, SCLKX2N and a “free-running”

FSYNCN signal based on the speed of

the SCbus and the clock frequency. The

internal master PLL runs free when:

• Put into free run mode (ignoring

reference input changes) by control

C_[42:40]

• The 8 KHz reference input is static

“1” or “0”

• The input of X_IN is less than 65.536

MHz.

The internal master PLL can also generate an interrupt if it cannot lock the

selected 8 KHz reference input.

C_0, C_3, C_[23:22]

SCLKX2N

SCLKX2NA

46, 47

FSYNCN

FSYNCNA

54, 55

SCLK

SCLKA

49, 50

To Internal Watchdogs and

SCbus Error Detectors

Primary

or

Alternate

C_[45:44]

SCbus

SREF_8K

Source

Select

Select

C_3, C_23, C_46

2000 Sep 07 14

SREF_8K

SREF_8KA

51, 52

Page 15

Philips Semiconductors Preliminary specification

Universal Timeslot Interchange SC4000

Figure 3 shows an external master PLL

implementation. The SC4000 provides

the 8 KHz reference output signal

REF_8K_OUT (pin 7) to the external

PLL. This 8 KHz reference signal is

sourced from either REF_8K[1:0] or

SREF_8K. The output of the external

PLL is then routed back to the SC4000

via CLK_IN (pin 6). The master clock

input (CLK_IN) frequency select at

C_[10:8] would then be programmed

for the external PLL frequency.

As shown in Figure 4, the SC4000 also

provides an internal clock PLL and local

bus PLL timing control circuitry for

both SCbus master and slave operations.

The internal clock PLL is used to create

the 4.096 or 8.192 MHz timing slaved to

the SCbus when the local bus is running

faster than the SCbus (i.e., 2.048 MHz at

SCbus, 8.096 MHz at local bus). If the

SCbus is faster or equal to the local bus,

then the SCbus clocks serve as the internal clock and use to create the local bus

clocks as well as message channel clock.

The local bus clock PLL is used to create

a 2.048 MHz L_CLK when:

• Local bus framing mode C_[7:6] is set

to 2.048 Mb/s

• A 65.536 MHz clock is supplied on

X_IN

• The C_29 bit is set to one.

If SCLK stops transitionally such as

during a clock fail condition (CLKFAIL

= 1), then the local bus clock PLL runs

free to generate L_CLK clock. In addition, the local bus SO lines are tri-stated

so that the network interface can continue to run.

Interrupts Control

The SC4000 can interrupt the host CPU

with the interrupt request signal INT_0

Figure 3. External Master PLL (C_43 = 1) Function Block

REF_8K_OUT

External

PLL

7

REF_8K_[1:0]

4, 5

C_[42:40]

Master PLL

Reference

8 K Select

(pin 14). This signal is configured and

unmasked by configuration register bits

C_55, C_54 and C_53. The interrupt

sources are:

• C_56 SCbus CLKFAIL

• C_57 Frame Boundary

• C_58 Internal Master PLL Error

• C_59 SCbus Error Indicator (logical

“OR” of C_[67:64], C_[74:72], and

C_[83:80])

The interrupts are structured this way to

improve performance by allowing a single read operation (of configuration register byte 7) to determine whether the

SC4000 is the source of the interrupt.

Each of the SC4000 interrupt sources

can be individually masked.

C_0, C_3, C_[23:22]

SCLKX2N

SCLKX2NA

46, 47

FSYNCN

FSYNCNA

54, 55

SCLK

SCLKA

49, 50

C_2

C_[10:8], C_[5:4]

Programmable

Divider

To Internal Watchdogs and

SCbus Error Detectors

CLK_IN

6

Primary

or

Alternate

C_[45:44]

SCbus

SREF_8K

Source

Select

Select

C_3, C_23, C_46

2000 Sep 07 15

SREF_8K

SREF_8KA

51, 52

Page 16

Philips Semiconductors Preliminary specification

Universal Timeslot Interchange SC4000

Figure 4. Internal PLL and Local Bus PLL Timing Function Block

X_IN

2

SCLK

49

SCLKA

50

SCLKX2N

46

SCLKX2NA

47

FSYNCN

54

FSYNCNA

55

65.536 MHz

C_2

Primary

or

Alternate

Select

Primary

or

Alternate

Select

Primary

or

Alternate

Select

Internal

Clock

PLL

Internal

Timing

Control

State

Machine

C_[7:6], C_[5:4]

Local

Bus

Clock

PLL

C_[7:6]=0X (2.048 Mb/s)

C_29=1

2.048 MHz

1

0

L_CLK

83

L_FS

84

MC_CLK

11

2000 Sep 07 16

Page 17

Philips Semiconductors Preliminary specification

Universal Timeslot Interchange SC4000

CLKFAIL Timing and Control

When an SC4000 is enabled to be clock

master (C_0 = 1), the chip drives clock

and frame sync signals to the SCbus and

pulls the CLKFAIL line low. If the

SC4000 is then disabled as clock master,

the internal state machine waits for the

next frame boundary and then stops

driving clock and frame sync signals.

Instead, it drives the CLKFAIL line high

for one clock before tri-stating it (CLKFAIL is pulled up with 4.7K on every

board). An “armed” clock master (C_1

= 1) contains logic that monitors the

CLKFAIL line (C_51 must be set). If

CLKFAIL is sampled high for two consecutive clock periods, then the C_0 bit

is automatically set; the armed master

then begins driving clock and frame

sync signals and pulls CLKFAIL low.

Since the internal state machine was

using the clock and frame sync signals

driven by the previous master, the new

master takes over without any framing

error. It is as if one clock period had

been stretched, as shown in Figure 14.

Message Channel Interface

The SC4000 is designed for use with an

HDLC controller to implement the message channel interface. The interface between an HDLC controller and SC4000

consists of the 2.048 MHz MC_CLK

(pin 11), TXD_0 (pin 9) and RXD (pin

10) lines. Data read from the SCbus MC

(pin 80) line is passed straight through

the SC4000 to the RXD output. Data

read from TXD_0 can be passed straight

through the SC4000 to the MC output,

or be buffered internally through a

clocked register. Buffering output data is

controlled by C_12. When the Message

Table 1. Configuration Register Setup for SCbus Clock Slave

Operation Mode Conguration Register Bits Setup Function Description

SCbus Slave C_0 = 0 SCbus clock master disabled (Default)

C_1 = 0 SCbus clock master disarmed (Default)

C_2 SCbus Primary or Alternate Select

C_3 = 0 Diagnostic mode disabled (Note)

C_[5:4] SCbus Framing mode to select one of the following rate:

C_[7:6] Local bus Framing mode to select one of the following rate:

Note: Default of all configuration register bits except C_3 are 0

0: Primary SCbus signals selected (Default)

1: Alternate SCbus signals selected

0X = 2.048 Mb/s, 256 Bits/Frame, 32 Timeslots/Frame (Default)

10 = 4.096 Mb/s, 512 Bits/Frame, 64 Timeslots/Frame

11 = 8.192 Mb/s, 1024 Bits/Frame, 128 Timeslots/Frame

0X = 2.048 Mb/s, 256 Bits/Frame, 32 Timeslots/Frame (Default)

10 = 4.096 Mb/s, 512 Bits/Frame, 64 Timeslots/Frame

11 = 8.192 Mb/s, 1024 Bits/Frame, 128 Timeslots/Frame

Channel is Disabled (C_15 = 1), TXD_0

is looped back to the RXD to allow

diagnostics to be run on the HDLC

controller.

Operation Mode and Configuration Register Setup

The SC4000 can be configured to function in five different modes shown in the

tables below:

• SCbus Clock Slave (Table 1)

• SCbus Clock Master (Table 2)

• SCbus Armed Clock Master (Table 3)

• MVIP Clock Master (Table 4)

• MVIP Clock Slave (Table 5)

Table 6 shows signals that are cross

referenced by SCbus and MVIP.

2000 Sep 07 17

Page 18

Philips Semiconductors Preliminary specification

Universal Timeslot Interchange SC4000

Table 2. Configuration Register Setup for SCbus Clock Master

Operation Mode Conguration Register Bits Setup Function Description

SCbus Master C_0 = 1 SCbus clock master enabled

C_1 = 0 SCbus clock master disarmed (Default)

C_2 SCbus Primary or Alternate Select

C_3 = 0 Diagnostic mode disabled

C_[5:4] SCbus Framing mode to select one of the following rate:

C_[7:6] Local bus Framing mode to select one of the following rate:

C_[10:8] Master clock input frequency select:

C_21 = 0 SCbus FSYNCN rate to select one SCLK period (Default)

C_22 SCbus SCLKX2N and SCLKX2NA output enable control

C_23 SCbus Alternate signals output enable control

C_[43:40] (Internal/External

Master PLL reference 8K select)

0: Primary SCbus signals selected (Default)

1: Alternate SCbus signals selected

0X = 2.048 Mb/s, 256 Bits/Frame, 32 Timeslots/Frame (Default)

10 = 4.096 Mb/s, 512 Bits/Frame, 64 Timeslots/Frame

11 = 8.192 Mb/s, 1024 Bits/Frame, 128 Timeslots/Frame

0X = 2.048 Mb/s, 256 Bits/Frame, 32 Timeslots/Frame (Default)

10 = 4.096 Mb/s, 512 Bits/Frame, 64 Timeslots/Frame

11 = 8.192 Mb/s, 1024 Bits/Frame, 128 Timeslots/Frame

000 = 2.048 MHz (Default), 001 = 4.096 MHz, 010 = 8.192 MHz,

011 = 16.384 MHz, 100 = 32.768 MHz, 101= 65.536 MHz,

11X =Reserved

0: SCbus SCLKX2N and SCLKX2NA output enabled (Default)

1: SCbus SCLKX2N and SCLKX2NA output disabled

0: SCbus Alternate signals output disabled (Default)

1: SCbus Alternate signals output enabled

Internal/External Master PLL reference select:

If C_43 = 0 select the reference for the internal master PLL from C_[42:40]: 000 = Free-run (Default),

001/010 = Free-run,

011 = SREF_8K/SREF_8KA, 100 = REF_8K_0, 101 = REF_8K_1,

110 = REF_8K_2, 111 = REF_8K_3

(see Figure 2)

If C_43 = 1 select the reference for the external master PLL (output on REF_8K_OUT pin 7) from

C_[42:40]: 000 = Free-run (driven high) (Default), 001/010 = Free-run (driven high), 011 =

SREF_8K/SREF_8KA,

100 = REF_8K_0, 101 = REF_8K_1, 110/111 = Tri-state (Z)

(see Figure 3)

C_51 = 1 SCbus CLKFAIL latch debounce enabled

2000 Sep 07 18

Page 19

Philips Semiconductors Preliminary specification

Universal Timeslot Interchange SC4000

Table 3. Configuration Register Setup for SCbus Armed Clock Master

Operation Mode Conguration Register Bits Setup Function Description

SCbus Armed Master C_0 = 0 SCbus clock master disabled initially

C_1 = 1 SCbus clock master armed. When CLKFAIL goes high, C_0 bit will be automatically set and SC4000

C_2 SCbus Primary or Alternate Select

C_3 = 0 Diagnostic mode disabled

C_[5:4] SCbus Framing mode to select one of the following rate:

C_[7:6] Local bus Framing mode to select one of the following rate:

C_[10:8] Master clock input frequency select:

C_21 = 0 SCbus FSYNCN rate to select one SCLK period (Default)

C_22 SCbus SCLKX2N and SCLKX2NA output enable control

C_23 SCbus Alternate signals output enable control

C_[43:40] (Internal/External

Master PLL reference 8K select)

becomes clock master

0: Primary SCbus signals selected (Default)

1: Alternate SCbus signals selected

0X = 2.048 Mb/s, 256 Bits/Frame, 32 Timeslots/Frame (Default)

10 = 4.096 Mb/s, 512 Bits/Frame, 64 Timeslots/Frame

11 = 8.192 Mb/s, 1024 Bits/Frame, 128 Timeslots/Frame

0X = 2.048 Mb/s, 256 Bits/Frame, 32 Timeslots/Frame (Default)

10 = 4.096 Mb/s, 512 Bits/Frame, 64 Timeslots/Frame

11 = 8.192 Mb/s, 1024 Bits/Frame, 128 Timeslots/Frame

000 = 2.048 MHz (Default), 001 = 4.096 MHz, 010 = 8.192 MHz,

011 = 16.384 MHz, 100 = 32.768 MHz, 101= 65.536 MHz,

11X =Reserved

0: SCbus SCLKX2N and SCLKX2NA output enabled (Default)

1: SCbus SCLKX2N and SCLKX2NA output disabled

0: SCbus Alternate signals output disabled (Default)

1: SCbus Alternate signals output enabled

Internal/External Master PLL reference select:

If C_43 = 0 select the reference for the internal master PLL from C_[42:40]: 000 = Free-run (Default),

001/010 = Free-run,

011 = SREF_8K/SREF_8KA, 100 = REF_8K_0, 101 = REF_8K_1,

110 = REF_8K_2, 111 = REF_8K_3

(see Figure 2)

If C_43 = 1 select the reference for the external master PLL (output on REF_8K_OUT pin 7) from

C_[42:40]: 000 = Free-run (driven high) (Default), 001/010 = Free-run (driven high), 011 =

SREF_8K/SREF_8KA,

100 = REF_8K_0, 101 = REF_8K_1, 110/111 = Tri-state (Z)

(see Figure 3)

C_51 = 1 SCbus CLKFAIL latch debounce enabled

2000 Sep 07 19

Page 20

Philips Semiconductors Preliminary specification

Universal Timeslot Interchange SC4000

Table 4. Configuration Register Setup for MVIP Clock Master

Operation Mode Conguration Register Bits Setup Function Description

MVIP Master C_0 = 1 MVIP clock master enabled

C_1 = 0 MVIP clock master disarmed (Default)

C_2 = 0 Primary SCbus signals selected (Default)

C_3 = 0 Diagnostic mode disabled (Note 1)

C_[5:4] =00 MVIP Framing mode to select only one rate:

C_[7:6] Local bus Framing mode to select one of the following rate:

C_[10:8] Master clock input frequency select:

C_21 = 1 MVIP F0/ rate to select one C4/ period

C_22 = 0 MVIP C4/ output enabled (Default)

C_23 =0 SCbus Alternate signals output disabled (Default)

C_[43:40] (Internal/External

Master PLL reference 8K select)

0X = 2.048 Mb/s, 256 Bits/Frame, 32 Timeslots/Frame (Default)

0X = 2.048 Mb/s, 256 Bits/Frame, 32 Timeslots/Frame (Default)

10 = 4.096 Mb/s, 512 Bits/Frame, 64 Timeslots/Frame

11 = 8.192 Mb/s, 1024 Bits/Frame, 128 Timeslots/Frame

000 = 2.048 MHz (Default), 001 = 4.096 MHz, 010 = 8.192 MHz,

011 = 16.384 MHz, 100 = 32.768 MHz, 101= 65.536 MHz,

11X =Reserved

Internal/External Master PLL reference select:

If C_43 = 0 select the reference for the internal master PLL from C_[42:40]: 000 = Free-run (Default),

001/010 = Free-run,

011 = SEC_8K, 100 = REF_8K_0, 101 = REF_8K_1,

110 = REF_8K_2, 111 = REF_8K_3

(see Figure 2)

If C_43 = 1 select the reference for the external master PLL (output on REF_8K_OUT pin 7) from

C_[42:40]: 000 = Free-run (driven high) (Default), 001/010 = Free-run (driven high), 011 = SEC_8K,

100 = REF_8K_0, 101 = REF_8K_1, 110/111 = Tri-state (Z)

(see Figure 3)

Table 5. Configuration Register Setup for MVIP Clock Slave

Operation Mode Conguration Register Bits Setup Function Description

MVIP Slave C_0 = 0 MVIP clock master disabled (Default)

C_1 = 0 MVIP clock master disarmed (Default)

C_2 = 0 Primary SCbus signals selected (Default)

C_3 = 0 Diagnostic mode disabled

C_[5:4] = 00 MVIP Framing mode to select only one rate:

C_[7:6] Local bus Framing mode to select one of the following rate:

0X = 2.048 Mb/s, 256 Bits/Frame, 32 Timeslots/Frame (Default)

0X = 2.048 Mb/s, 256 Bits/Frame, 32 Timeslots/Frame (Default)

10 = 4.096 Mb/s, 512 Bits/Frame, 64 Timeslots/Frame

11 = 8.192 Mb/s, 1024 Bits/Frame, 128 Timeslots/Frame

2000 Sep 07 20

Page 21

Philips Semiconductors Preliminary specification

Universal Timeslot Interchange SC4000

Table 6. SCbus/MVIP Signals Cross Reference

SCbus 26-Pin Connector SCbus Signal MVIP Signal MVIP 40-Pin Connector

1 SCLKX2N C4/ 31

2 GND GND 30, 32

3 SCLK C2 35

4 SREF_8K SEC_8K 37

5 FSYNCN F0/ 33

6 CLKFAIL N/A N/A

7 SD_0 DSi0 8

8 GND GND 34

9 SD_1 DSo0 7

10 SD_2 DSi1 10

11 SD_3 DSo1 9

12 SD_4 DSi2 12

13 SD_5 DSo2 11

14 SD_6 DSi3 14

15 GND GND 36

16 SD_7 DSo3 13

17 SD_8 DSi4 16

18 SD_9 DSo4 15

19 SD_10 DSi5 18

20 SD_11 DSo5 17

21 GND GND 38

22 SD_12 DSi6 20

23 SD_13 DSo6 19

24 SD_14 DSi7 22

25 SD_15 DSo7 21

26 MC N/A N/A

2000 Sep 07 21

Page 22

Philips Semiconductors Preliminary specification

Universal Timeslot Interchange SC4000

Register Access Schemes

The SC4000 features two address access

schemes. One is an indirect access

scheme (C_11 = 0) to reduce the number of pins required for the micropro-

cessor address bus interface from nine to

two (A_[1:0]), as shown in Figure 5. The

other is a combination of both indirect

and direct parallel access schemes (C_11

= 1). Using the combination requires

Figure 5. Using Two Pins A_[1:0] for Address Bus Interface Scheme (C_11 = 0)

Address Data

03h High Byte Data Register (HBDR)

02h Low Byte Data Register (LBDR)

01h Internal Address Register (IAR)

00h Command/Status Register (CSR)

A_[1:0] D_[7:0]

FFh - E0h Source Parallel Access (31 - 0)

DFh - C0h Destination Parallel Access (31 - 0)

BFh - A0h Source Routing Memory (31 - 0)

9Fh - 80h Destination Routing Memory (31 - 0)

7Fh - 0Dh Reserved

0Ch - 00h Configuration Register (12 - 0)

Note: See bit 5 and 4 of CSR to select

the bank of channels

Microprocessor

Figure 6. Using Nine Pins A_[8:0] for Address Bus Interface Scheme (C_11 = 1)

Address Data

1FFh - 180h Source Parallel Access (127 - 0)

17Fh - 100h Destination Parallel Access (127 - 0)

FFh - 04h Reserved

03h High Byte Data Register (HBDR)

02h Low Byte Data Register (LBDR)

01h Internal Address Register (IAR)

00h Command/Status Register (CSR)

A_[8:0] D_[7:0]

FF - E0 Source Parallel Access (31 - 0)

DF - C0 Destination Parallel Access (31 - 0)

BF - A0 Source Routing Memory (31 - 0)

9F - 80 Destination Routing Memory (31 - 0)

7F - 0D Reserved

0C - 00 Configuration Register (12 - 0)

Note: See bit 5 and 4 of CSR to select

the bank of channels

that all nine microprocessor address

pins (A_[8:0]) be used, as shown in

Figure 6.

Microprocessor

2000 Sep 07 22

Page 23

Philips Semiconductors Preliminary specification

Universal Timeslot Interchange SC4000

MICROPROCESSOR INTERFACE

I/O Address Map

With Direct R/W to Parallel Access

Registers Disabled (C_11=0) (default)

A_[1:0] REGISTER

3h High Byte Data Register (HBDR)

2h Low Byte Data Register (LBDR)

1h Internal Address Register (IAR)

0h Command / Status Register

With direct R/W to Parallel Access

Register Enable (C_11=1)

A_[8:0] REGISTER

1FFh:180h Source Parallel Access Register

Ch. 127:0

17Fh:100h Destination Parallel Access Register

Ch. 127:0

0FFh:004h Reserved

003h High Byte Data Register (HBDR)

002h Low Byte Data Register (LBDR)

001h Internal Address Register (IAR)

000h Command / Status Register

Command / Status Register (Address = 0h)

D_[7:0] Definition

0 Busy (Read only)

1 Read Command (Write only)

2 Write Command (Write only)

3 Terminate Command (Read/Write)

[5:4] Channel Bank Select Register [1:0]

(Read/Write)

6 Channel Bank Select Register Enable

(Write only)

7 Reset (Read/Write)

Note: Setting more than one command

(Read, Write, Terminate or Reset) during an access to the Command/Status

register is not recommended.

Busy (D_0) (Read Only)

This bit is set (“1”) when a command

that requires synchronization with the

SC4000’s internal state machine has

been initiated. This bit clears (“0”)

when the command is completed.

The following commands require

synchronization:

• Destination Routing Memory

Write command

• Source Routing Memory Write

command

• Indirect Parallel Access Destination

Write command

• Indirect Parallel Access Source

Read command

Read (D_1) (Write only)

Setting this bit (“1”) initiates a read of

the register pointed to by the Internal

Address Register. When the Busy bit is

clear (“0”), the contents of the register

to be read are available by reading the

Low byte & HighByte Data register. It is

not necessary to clear (“0”) this bit after

it has been set (“1”).

Note: Set this bit for an Indirect Parallel

Access Source Read (this is the only

“READ” requiring synchronization).

For reads which do not require synchronization, the data registers can be read

immediately after writing the internal

address register.

Write (D_2) (Write only)

Setting this bit (“1”) initiates a write

to the register selected by the Internal

Address Register. When the Busy bit is

clear (“0”), the contents of the target

register have been updated using the

data stored in the Low Byte & High Byte

Data Register. It is not necessary to clear

(“0”) this bit after it has been set (“1”).

Terminate (D_3) (Read/Write)

Setting this bit (“1”) terminates a command that requires synchronization

with the SC4000’s internal state machine. This is necessary to complete a

command when the SC4000’s internal

state machine has stopped running (no

SCLK). The command in process is

completed asynchronously and the

Busy bit is cleared. It is necessary to clear

(“0”) this bit after it has been set (“1”).

Note: A new command (Read or Write)

should not be issued until after the

Terminate bit is cleared (“0”).

Channel Bank Select Register

[1:0] (D_[5:4]) (Read/Write)

This field determines the bank of channels that a command will affect. The

Channel Bank Select Register field is

combined with the Internal

Address Register to provide access to the

channel specific registers (routing and

parallel access). D_[5:4]) selects the

bank of channels to be accessed. This

field is cleared (“00”) on reset.

D_[5:4] = 00 -> Ch. 0 - 31

D_[5:4] = 01 -> Ch.32 - 63

D_[5:4] = 10 -> Ch.64 - 95

D_[5:4] = 11 -> Ch.96 - 127

Channel Bank Select Register Enable

(D_6) (Write only)

Writing to the command register with

this bit set (“1”) enables the Channel

bank select field to be changed. Writing

to the command register with this bit

cleared (“0”) causes the Channel Bank

Select Register field to retain its previous

value.

Note 1: The Channel Bank Select Register may be changed during a write cycle

which also initiates a Read or Write

command. The Read or Write command affects the register pointed to by

the new value written into the Channel

Bank Select Register.

Note 2: The Channel Bank Select Register should not be changed if the microprocessor interface is busy.

Note 3: The Channel Bank Select Register should not be changed during a write

cycle that either sets (0->1) or clears

(1->0) the Terminate command.

2000 Sep 07 23

Page 24

Philips Semiconductors Preliminary specification

Reset (D_7) (Read/Write)

Internal Address Register Map Low Byte Data Register (Address = 02h)

Universal Timeslot Interchange SC4000

Setting this bit (“1”) puts the SC4000 in

reset and initializes the Configuration,

Routing and Parallel Access Registers.

This command is analogous to the function of the RESET pin. Clearing this bit

(“0”) returns the SC4000 to normal operation, ready for configuration.

Internal Address Registerr (Address = 01h)

D_[7:0] Definition

7:0 Internal Address Register (IAR_[7:0])

IAR_

[7:0]

FFh:80h Channel Spe-

7Fh:0Dh Reserved

0Ch:00h Configuration

Register IAR_

[7:0]

FFh:E0h Source

cific Registers

DFh:C0h Destination

BFh:A0h Source

9Fh:80h Destination

Registers

Register

Parallel

Access

Parallel

Access

Routing

Memory

Routing

Memory

D_[7:0] Definition

7:0 Low byte Data Register (LBDR_[7:0])

High Byte Data Register (Address = 03h)

D_[7:0] Definition

7:0 High byte Data Register (HBDR_[7:0])

2000 Sep 07 24

Page 25

Philips Semiconductors Preliminary specification

Universal Timeslot Interchange SC4000

Channel Specific Registers

The Channel Specific Registers are

divided into four groups. A group is selected by bits 5 through 7 of theinternal

address register.

Channel Specific Registers Map

IAR[7:0] CBSR_[1:0] = 00 CBSR_[1:0] = 01 CBSR_[1:0] = 10 CBSR_[1:0] = 11

IAR_[7:5]

FFh - E0h

Source

Parallel

Access

IAR_[7:5]

DFh - C0h

Destination

Parallel

Access

IAR_[7:5]

BFh - A0h

Source

Routing

Memory

IAR_[7:5]

9Fh - 80h

Destination

Routing

Memory

IAR_[4:0] = 1Fh Ch. 31 Ch. 63 Ch. 95 Ch. 127

IAR_[4:0] = 1Eh Ch. 30 Ch. 62 Ch. 94 Ch. 126

. . . . .

. . . . .

IAR_[4:0] = 01h Ch. 1 Ch. 33 Ch. 65 Ch. 97

IAR_[4:0] = 00h Ch. 0 Ch. 32 Ch. 64 Ch. 96

IAR_[4:0] = 1Fh Ch. 31 Ch. 63 Ch. 95 Ch. 127

IAR_[4:0] = 1Eh Ch. 30 Ch. 62 Ch. 94 Ch. 126

. . . . .

. . . . .