Page 1

1. Description

SAA8122A

Digital Still Camera Processor (ImagIC family)

Rev. 01 — 20 April 2000 Objective specification

The DSC SAA8122A is a high performance, low power, single-chip Million

Instructions Per Second (MIPS) based signal processor, part of the ImagIC family,

which is dedicated to image processing, compression, formatting and storage. The

DSC SAA8122A is optimized for use with Philips range of CCDs (e.g: FXA1022,

2 Mpixels CCD), V-driver (TDA9991), CDS/PGA/ADC (TDA9952), allowing easy

implementation of a complete system solution and fast development of high

performance consumer digital still cameras.

The SAA8122A is designed as a single-chip device, able to perform all treatments

and connections required for a wide range of Digital Still Cameras. Its embedded

RISC CPU, for which the development environment is available, enables shorter

development and validation cycles, as well as faster feature upgrade. Since one of

the main objectives of the SAA8122A is addressing a wide range of CCD sensors, a

DSP (with advanced embedded algorithm) forcamera signal processing is integrated

with a high level of programmability for pulses generation.

2. Features

The JPEG core is hardware based in order to allow high-speed image data

compression.

c

c

2.1 General

■ Supports a wide range of progressive CCDs (VGA, SVGA, QGA, XGA, EQGA),

■ Performs an advanced RGB to YUV conversion

■ Includes a smart measurement unit to speed up the control loop (focus,auto white

■ Supports a wide range of LCD and TV formats (both NTSC and PAL) with text

■ Includes an embedded JPEG encoder/decoder unit

■ Includes a MIPS PR3001 CPU, running at a frequency in a range from

■ PRISC compatible PI-bus architecture, interrupt, power management, clock and

■ Includes a dedicated video bus supporting SDRAM memory for picture storage

with RGB Bayer filters up to 2 Mpixels

balance, etc.)

insertion features

12 to 28 MHz

reset architectures

Page 2

Philips Semiconductors

■ Interface to ROM, DRAM, SRAM, flash and PC Card [Compact Flash and SSFDC

■ Integrated general purpose peripheral units like a UART, timers, an I2C-bus

■ Includes USB and RS-232C communication interfaces.

2.2 External interfaces

■ Two UART (RS-232) data ports with DMA capabilities (≤187.5 kbit/s) including

■ 32 general purpose, bidirectional I/O interface pins, the first 8 bits may also be

■ Two PWM outputs (8-bit resolution).

2.3 CPU related features

■ 32-bit PR3001 core

■ 1-kbyte data cache and 4-kbyte instruction cache

■ Programmable low-power mode, including wake-up on interrupt

■ Memory management unit [Translation Lookaside Buffer (TLB)]

■ Two built in 24-bit general purpose timers and one 24-bit watchdog timer

■ Real-time clock unit (active in sleep mode)

■ On-chip 8-kbyte SRAM for storing code which needs fast execution

■ Platform software based on real-time pSOS (plug-in Silicon Operating System).

SAA8122A

Digital Still Camera Processor (ImagIC family)

(SmartMedia)]

transceiver, ADC converters, RTC and I/O ports

hardware flow control RxD, TxD, RTS, CTS for modem support

used as interrupt inputs

2.4 DSP features

■ Advanced colour reconstruction

■ Programmable digital filters for noise reduction and contour enhancement

■ 16 programmable measurement windows allowing to perform the measurements

necessary for exposure, white balance and focus adjustment in a DSC system;

available measurement outputs for exposure, white balance and focus control.

2.5 Pulse pattern generator features

■ Programmable through dedicated PC-software, allowing to drive all CCDs

currently present in the market, as well as CDS/AGC/ADC chips: up to

8 × 8 kpixels.

2.6 JPEG

■ Fully ISO10918 compliant

■ Supports Tiff, Exif 2.1, DCF & DPOF

■ Quick compression (4 images/s for a 1.3 Mpixels resolution).

2.7 USB interface

■ Fully compatible with USB.

9397 750 07048

Objective specification Rev. 01 — 20 April 2000 2 of 26

© Philips Electronics N.V. 2000. All rights reserved.

Page 3

Philips Semiconductors

2.8 Card interfaces

■ Compatible with all SSFDC/CF cards on the market.

2.9 Bus

■ Bus structure allows for parallel processing depending on software

implementation, allowing easy system optimization.

2.10 SDRAM interface features

■ Supports up to 128 Mbyte of SDRAM and 16-bit wide addressses

■ Bus speed: 1 or 2 times CCD pixel clock

■ 32-bit bus width.

3. Quick reference data

Table 1: Quick reference data

Symbol Parameter Conditions Min Typ Max Unit

V

DDD

V

DDA

I

P

V

I

V

O

T

amb

f

clk

[1] The supplies considered as digital supply (V

[2] The supplies considered as analog supply (V

V

DDA(ADC)

[3] Including voltage on outputs in 3-state mode; only valid when supply voltage is present.

SAA8122A

Digital Still Camera Processor (ImagIC family)

DDD

DDA(SPLL)

, V

DDA(LCDG)

[1]

3 3.3 3.6 V

[2]

3 3.3 3.6 V

[3]

0 − 5.5 V

, V

DDD(RTC)

, V

DDA(PLL)

, V

DDA(LCDB)

.

, V

DDA(BG)

, V

DDA(DLL)

DDD

DDD

, V

.

V

V

DDA(PPG1)

digital supply voltage

analog supply current

total supply current f

=25MHz − 360 560 mA

clk

input voltage

general 0 − V

5 V tolerant cells only

output voltage output active 0 − V

ambient temperature 0 25 70 °C

clock frequency − 25 27 MHz

) are: V

DDD

) are: V

, V

DDA(OUTPUT1)

, V

DDA(OUTPUT2)

, V

DDA(LCDR)

DDA

,

4. Ordering information

Table 2: Ordering information

Type number Package

Name Description Version

SAA8122AEL LFBGA324 plastic low profile fine-pitch ball grid array package; 324 balls;

body 16 × 16 × 1.2 mm

9397 750 07048

Objective specification Rev. 01 — 20 April 2000 3 of 26

© Philips Electronics N.V. 2000. All rights reserved.

SOT571-1

Page 4

This text is here in white to force landscape pages to be rotated correctly when browsing through the pdf in the Acrobat reader.This text is here in

white to force landscape pages to be rotated correctly when browsing through the pdf in the Acrobat reader.This text is here inThis text is here in

white to force landscape pages to be rotated correctly when browsing through the pdf in the Acrobat reader. white to force landscape pages to be ...

9397 750 07048

Objective specification Rev. 01 — 20 April 2000 4 of 26

PC-CARD

CONTROLLER

DRAM

MEMORY

CONTROLLER

STATIC

MEMORY

CONTROLLER

PERIPHERAL

CONTROLLER

TCB

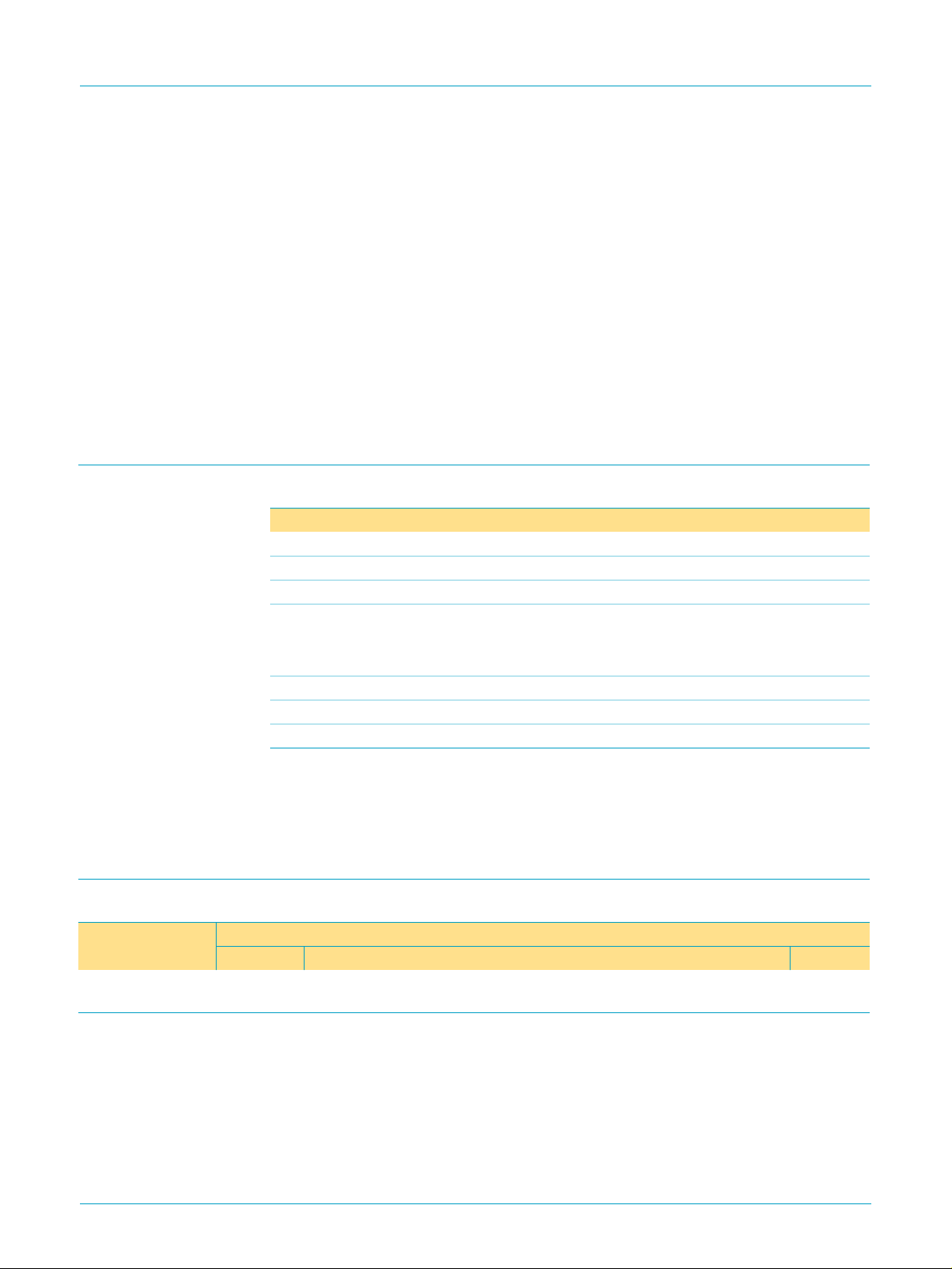

5. Block diagram

Philips Semiconductors

INTERUPT

CONTROLLER

UARTUSB

JPEG

CODEC

EBIU

PR3001

CPU

INTERUPT

CONTROLLER

PLL

CCD

PI

BCU

SAA8122A

SLAVE GROUP INTERFACE

VDO

CAMDSP

BCU

© Philips Electronics N.V. 2000. All rights reserved.

8K

SRAM

TIMER

TIMERTIMER

I2C

TRANSCIEVER

GPIO

+

INT

FOUR

GPIO

RTC

POWER

MANAGEMENT

CONTROLLER

ANALOG

DIGITAL

CONTROLLER

FCE686

Digital Still Camera Processor (ImagIC family)

SAA8122A

Fig 1. Block diagram.

Page 5

Philips Semiconductors

SAA8122A

Digital Still Camera Processor (ImagIC family)

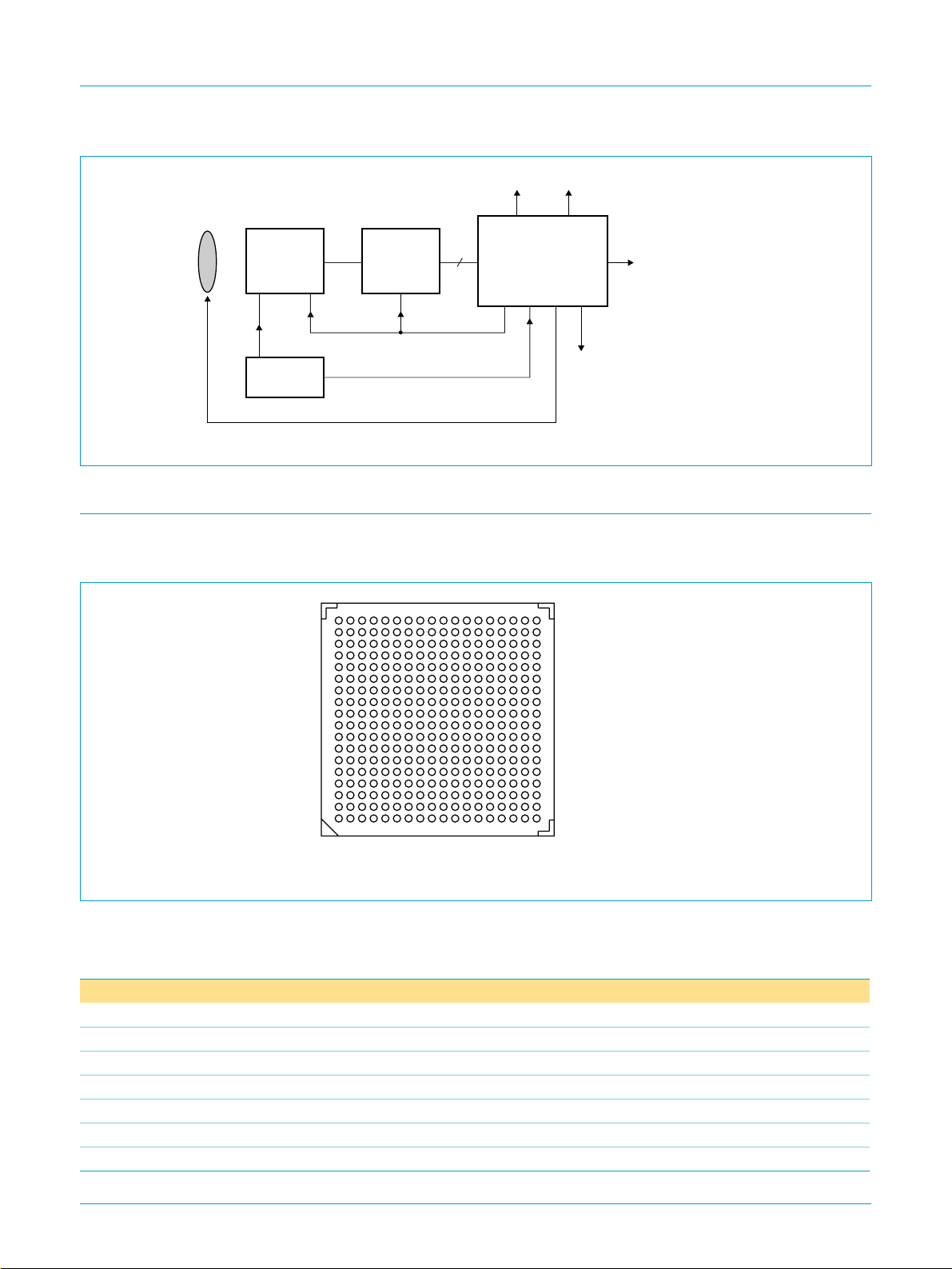

handbook, full pagewidth

lens

CCD

FXA1022

V-DRIVER

TDA9991

Fig 2. System block diagram.

6. Pinning information

6.1 Pinning

handbook, halfpage

V

U

T

R

P

N

M

L

K

J

H

G

F

E

D

C

B

A

to LCD to TV

TDA9952

2 4 6 8 1012141618

1 3 5 7 9 11 13 15 17

10

SAA8122A

to cards

(SSFDC, CF)

USB

IRDA

to PC

FCE687

SAA8122AEL

FCE677

Fig 3. Pin configuration (bottom view).

6.2 Pin description

Table 3: Pin description

Symbol Pin Type Description

V

DDD

V

SSA(DLL)

V

DDA(DLL)

DISP_VSYNC A4 O digital vertical synchronization signal

IO1/IRQ17 A5 I/O I/O port 0 bit 1 or interrupt request 17

V

DDA(LCDG)

V

DDA(OUTPUT2)

9397 750 07048

Objective specification Rev. 01 — 20 April 2000 5 of 26

A1 - digital supply voltage

A2 - analog ground for DLL of PPG

A3 - analog supply voltage for DLL of PPG

A6 P analog supply voltage for DAC component G

A7 P analog supply voltage for DAC video output 2

© Philips Electronics N.V. 2000. All rights reserved.

Page 6

Philips Semiconductors

SAA8122A

Digital Still Camera Processor (ImagIC family)

Table 3: Pin description

…continued

Symbol Pin Type Description

CREF_BG1 A8 - band-gap 1

V

SS(BG)

A9 P ground for BG of video DAC

SYSRSTIN A10 I system reset input/output; active LOW

V

SS(RTC)

A11 P ground for RTC

T0_CAP0 A12 I timer 0 capture input 0

CNT2 A13 I timer 2 count pulse input

CNT1 A14 I timer 1 count pulse input

PWM0 A15 O timer 0 PWM output

ADC0 A16 I analog input signal 0 for level measurement

ADC3 A17 I analog input signal 3 for level measurement

V

SS(ADC)

A18 P ground for ADC

ANPPG1 B1 O PPG analog signal 1

IO6/IRQ22 B4 I/O I/O port 0 bit 6 or interrupt request 22

IO3/IRQ19 B5 I/O I/O port 0 bit 3 or interrupt request 19

LCD_G B6 O analog green signal

VIDEO_OUT2 B7 O video output signal 2

V

SSA(ref)

B8 O analog reference ground

SC_TCK B9 I test clock input for surround scan chains

TCK B10 I test clock input

XTALCCDIN B11 - oscillator input from a specific CCD crystal

V

DDA(SPLL)

V

SS(PLL)

B12 P analog supply voltage for SPLL

B13 P ground for PLL

CNT0 B14 I timer 0 count pulse input

V

SSA(ref)(ADC)

B15 O analog reference ground for ADC

ADC2 B16 I analog input signal 2 for level measurement

V

DDA(ADC)

B17 P analog supply voltage for ADC

IO23 B18 I/O I/O port 2 bit 7

V

DDA(PPG1)

V

DDA(PPG0)

V

DDA(DLL)

C1 P analog supply voltage for PPG

C2 P analog supply voltage for PPG

C3 P analog supply voltage for DLL of PPG

IO7/IRQ23 C4 I/O I/O port 0 bit 7 or interrupt request 23

IO4/IRQ20 C5 I/O I/O port 0 bit 4 or interrupt request 20

LCD_R C6 O analog red signal

LCD_B C7 O analog blue signal

V

DDA(OUTPUT1)

V

DDA(BG)

C8 P analog supply voltage for DAC video output 1

C9 P analog supply voltage for BG of video DAC

TMS C10 I test mode select input

XTAL32KIN C11 - oscillator input from a 32 kHz crystal

XTAL10IN C12 - oscillator input from a 10 MHz crystal

GATE2 C13 I timer 2 gate input

V

DDA(PLL)

C14 P analog supply voltage for PLL

9397 750 07048

Objective specification Rev. 01 — 20 April 2000 6 of 26

© Philips Electronics N.V. 2000. All rights reserved.

Page 7

Philips Semiconductors

SAA8122A

Digital Still Camera Processor (ImagIC family)

Table 3: Pin description

…continued

Symbol Pin Type Description

PWM1 C15 O timer 1 PWM output

ADC1 C16 I analog input signal 1 for level measurement

IO22 C17 I/O I/O port 2 bit 6

IO16 C18 I/O I/O port 2 bit 0

ANPPG7 D1 O PPG analog signal 7

V

SSA(PPG1)

D2 P analog ground for PPG

DISP_HSYNC D3 O digital horizontal synchronization signal

IO5/IRQ21 D4 I/O I/O port 0 bit 5 or interrupt request 21

IO0/IRQ16 D5 I/O I/O port 0 bit 0 or interrupt request 16

V

SSA(LCD)

V

SS(OUTPUT)

D6 P analog ground for display RGB

D7 P ground for DAC video output

CREF_BG2 D8 - band-gap 2

TDO D9 O test data output

TDI D10 I test data input

XTAL32KOUT D11 - oscillator output from a 32 kHz crystal

XTAL10OUT D12 - oscillator output from a 10 MHz crystal

T0_CAP1 D13 I timer 0 capture input 1

GATE0 D14 I timer 0 gate input

PWM2 D15 O timer 2 PWM output

IO17 D16 I/O I/O port 2 bit 1

IO15 D17 I/O I/O port 1 bit 7

IO11 D18 I/O I/O port 1 bit 3

PPG1 E1 O PPG digital signal 0

PPG2 E2 O PPG digital signal 1

ANPPG8 E3 O PPG analog signal 8

V

DDA(PPG0)

E4 P analog supply voltage for PPG

IO2/IRQ18 E5 I/O I/O port 0 bit 2 or interrupt request 18

V

DDA(LCDR)

V

DDA(LCDB)

E6 P analog supply voltage for DAC component R

E7 P analog supply voltage for DAC component B

VIDEO_OUT1 E8 O video output signal 1

SYSRST E9 O system reset output; active LOW

TRST E10 I test reset input

V

DDD(RTC)

E11 P digital supply voltage for RTC

XTALCCDOUT E12 - oscillator output from a specific CCD crystal

GATE1 E14 I timer 1 gate input

IO18 E15 I/O I/O port 2 bit 2

IO10 E16 I/O I/O port 1 bit 2

IO9 E17 I/O I/O port 1 bit 1

UA_CLK E18 I UART external clock

PPG5 F1 O PPG digital signal 4

PPG6 F2 O PPG digital signal 5

9397 750 07048

Objective specification Rev. 01 — 20 April 2000 7 of 26

© Philips Electronics N.V. 2000. All rights reserved.

Page 8

Philips Semiconductors

SAA8122A

Digital Still Camera Processor (ImagIC family)

Table 3: Pin description

…continued

Symbol Pin Type Description

PPG3 F3 O PPG digital signal 2

ANPPG5 F4 O PPG analog signal 5

ANPPG3 F5 O PPG analog signal 3

V

SS

V

SS

V

DD

V

DD

V

DD

V

DD

V

DD

F6 - ground

F7 - ground

F8 - supply voltage

F9 - supply voltage

F10 - supply voltage

F11 - supply voltage

F12 - supply voltage

IO20 F13 I/O I/O port 2 bit 4

IO19 F14 I/O I/O port 2 bit 3

IO12 F15 I/O I/O port 1 bit 4

CTS F16 I UART clear to send

RXD F17 I UART receive input

TXD F18 O UART transmit output

PPG10 G1 O PPG digital signal 17

PPG12 G2 O PPG digital control signal 1

PPG8 G3 O PPG digital signal 8

PPG4 G4 O PPG digital signal 3

ANPPG6 G5 O PPG analog signal 6

ANPPG2 G6 O PPG analog signal 2

V

DD

V

SS

V

SS

V

SS

V

SS

V

DD

G7 - supply voltage

G8 - ground

G9 - ground

G10 - ground

G11 - ground

G12 - supply voltage

IO21 G13 I/O I/O port 2 bit 5

IO13 G14 I/O I/O port 1 bit 5

RTS G15 O UART request to send

2

SDA G16 I/O I

SCL G17 I/O I

C-bus data

2

C-bus clock

n.c. G18 - not connected

HDHREF H1 I/O PPG horizontal synchronization signal

VDVS H2 I/O PPG vertical synchronization signal

PPG13 H3 O PPG digital control signal 2

PPG7 H4 O PPG digital control signal 6

PPG14 H5 O PPG digital control signal 3

ANPPG4 H6 O PPG analog signal 4

V

DD

H7 - supply voltage

9397 750 07048

Objective specification Rev. 01 — 20 April 2000 8 of 26

© Philips Electronics N.V. 2000. All rights reserved.

Page 9

Philips Semiconductors

SAA8122A

Digital Still Camera Processor (ImagIC family)

Table 3: Pin description

…continued

Symbol Pin Type Description

V

SS

V

SS

V

SS

V

SS

V

DD

H8 - ground

H9 - ground

H10 - ground

H11 - ground

H12 - supply voltage

IO14 H13 I/O I/O port 1 bit 6

RXVPI H14 I USB

n.c. H15 - not connected

RXVMI H16 I/O USB

TXVPO H17 O USB

RXDATA H18 I USB

CCD_IM2 J1 I digital image signal 2

CCD_IM3 J2 I digital image signal 3

CCD_IM4 J3 I digital image signal 4

PPG11 J4 O PPG digital signal 18

PPG9 J5 O PPG digital signal 8

V

DD

V

DD

V

SS

V

SS

V

SS

V

SS

V

DD

J6 - supply voltage

J7 - supply voltage

J8 - ground

J9 - ground

J10 - ground

J11 - ground

J12 - supply voltage

IO8 J13 I/O I/O port 1 bit 0

SUSPEND J14 O USB

TXOE J15 O USB

D2 J16 I/O EBIU D2

D3 J17 I/O EBIU D3

D0 J18 I/O EBIU D0

CCD_IM10 K1 I digital image signal 10

CCD_IM9 K2 I digital image signal 9

CCD_IM8 K3 I digital image signal 8

CCD_IM1 K4 I digital image signal 1

CCD_IM0 K5 I digital image signal 0

V

DD

V

DD

V

SS

V

SS

V

SS

V

SS

V

DD

K6 - supply voltage

K7 - supply voltage

K8 - ground

K9 - ground

K10 - ground

K11 - ground

K12 - supply voltage

9397 750 07048

Objective specification Rev. 01 — 20 April 2000 9 of 26

© Philips Electronics N.V. 2000. All rights reserved.

Page 10

Philips Semiconductors

SAA8122A

Digital Still Camera Processor (ImagIC family)

Table 3: Pin description

…continued

Symbol Pin Type Description

TXVMO K13 O USB

D1 K14 I/O EBIU D1

D4 K15 I/O EBIU D4

D6 K16 I/O EBIU D6

D7 K17 I/O EBIU D7

D8 K18 I/O EBIU D8

SD_A[0] L1 O SDRAM controller address bus bit 0

SD_A[3] L2 O SDRAM controller address bus bit 3

SD_A[2] L3 O SDRAM controller address bus bit 2

CCD_IM6 L4 I digital image signal 6

CCD_IM7 L5 I digital image signal 7

CCD_IM5 L6 I digital image signal 5

V

DD

V

SS

V

SS

V

SS

V

SS

V

DD

L7 - supply voltage

L8 - ground

L9 - ground

L10 - ground

L11 - ground

L12 - supply voltage

D5 L13 I/O EBIU D5

D9 L14 I/O EBIU D9

D11 L15 I/O EBIU D11

D14 L16 I/O EBIU D14

D13 L17 I/O EBIU D13

D12 L18 I/O EBIU D12

SD_A[7] M1 O SDRAM controller address bus bit 7

SD_A[8] M2 O SDRAM controller address bus bit 8

SD_A[9] M3 O SDRAM controller address bus bit 9

SD_A[4] M4 O SDRAM controller address bus bit 4

SD_A[1] M5 O SDRAM controller address bus bit 1

CCD_IM11 M6 I digital image signal 11

V

DD

V

SS

V

SS

V

SS

V

SS

V

DD

M7 - supply voltage

M8 - ground

M9 - ground

M10 - ground

M11 - ground

M12 - supply voltage

D10 M13 I/O EBIU D10

SC_SE M14 O EBIU controller SE signal for SSFDC card; active LOW

D15 M15 I/O EBIU D15

PC_WAIT2 M16 I EBIU controller WAIT signal for PC card 2; active LOW

SC_CE M17 O EBIU controller CE signal for SSFDC card; active LOW

9397 750 07048

Objective specification Rev. 01 — 20 April 2000 10 of 26

© Philips Electronics N.V. 2000. All rights reserved.

Page 11

Philips Semiconductors

SAA8122A

Digital Still Camera Processor (ImagIC family)

Table 3: Pin description

…continued

Symbol Pin Type Description

SC_CLE M18 O EBIU controller CLE signal for SSFDC card

SD_A[12] N1 O SDRAM controller address bus bit 12

SD_A[13] N2 O SDRAM controller address bus bit 13

SD_A[14] N3 O SDRAM controller address bus bit 14

SD_A[10] N4 O SDRAM controller address bus bit 10

SD_A[6] N5 O SDRAM controller address bus bit 6

SD_A[5] N6 O SDRAM controller address bus bit 5

V

DD

V

DD

V

DD

V

DD

V

DD

N7 - supply voltage

N8 - supply voltage

N9 - supply voltage

N10 - supply voltage

N11 - supply voltage

SC_ALE N12 O EBIU controller ALE signal for SSFDC card

PC2_CE1 N13 O EBIU controller CE1 signal for PC card 2; active LOW

PC2_CE2 N14 O EBIU controller CE2 signal for PC card 2; active LOW

PC_REG N15 O EBIU controller REG signal for PC cards; active LOW

PC_WAIT1 N16 O EBIU controller WAIT signal for PC card 1; active LOW

IOWR_WE N17 O EBIU controller IORD signal for PC cards; active LOW

IORD_RE N18 O EBIU controller IORD signal for PC cards; active LOW

SD_CLKOUT P1 O SDRAM controller clock output

SD_CLKIN P2 I SDRAM controller clock input

SD_CS2 P3 O SDRAM controller chip select for memory 2; active LOW

SD_CLKEN P4 O SDRAM controller clock enable

SD_A[11] P5 O SDRAM controller address bus bit 11

V

DD

P6 - supply voltage

SD_D[7] P7 I/O SDRAM controller data bus bit 7

IO25 P8 I/O I/O port 3 bit 1

IO38 P9 I/O I/O port 4 bit 6

A25 P10 I/O EBIU A25 (Strapin[0] during boot sequence)

A21 P11 I/O EBIU A21 (Strapin[4] during boot sequence)

V

DD

P12 - supply voltage

A14 P13 I/O EBIU A14

SCLK P14 O EBIU controller clock signal for external peripherals

A9 P15 I/O EBIU A9

CAS0 P16 O EBIU controller CAS signal for DRAM memory for lower byte; used as data

strobe signal for lower byte for general chip select; active LOW

PC1_CE1 P17 O EBIU controller CE1 signal for PC card 1; active LOW

PC1_CE2 P18 O EBIU controller CE2 signal for PC card 1; active LOW

SD_CS0 R1 O SDRAM controller chip select for memory 0; active LOW

SD_CS1 R2 O SDRAM controller chip select for memory 1; active LOW

SD_CS3 R3 O SDRAM controller chip select for memory 3; active LOW

9397 750 07048

Objective specification Rev. 01 — 20 April 2000 11 of 26

© Philips Electronics N.V. 2000. All rights reserved.

Page 12

Philips Semiconductors

SAA8122A

Digital Still Camera Processor (ImagIC family)

Table 3: Pin description

Symbol Pin Type Description

SD_D[4] R4 I/O SDRAM controller data bus bit 4

SD_RAS R5 O SDRAM controller row address strobe; active LOW

SD_D[6] R6 I/O SDRAM controller data bus bit 6

SD_D[13] R7 I/O SDRAM controller data bus bit 13

IO30 R8 I/O I/O port 3 bit 6

IO37 R9 I/O I/O port 4 bit 5

A24 R10 I/O EBIU A24 (Strapin[1] during boot sequence)

A19 R11 I/O EBIU A19 (Strapin[6] and Strapin[9] during boot sequence)

A18 R12 I/O EBIU A18 (Strapin[10] during boot sequence)

A13 R13 I/O EBIU A13

A5 R14 O EBIU A5

CS6 R15 O EBIU controller chip select 6; active LOW

CAS1 R16 O EBIU controller CAS signal for DRAM memory for upper byte; used as data

OE R17 O EBIU controller output enable signal; active LOW

RAS R18 O EBIU controller RAS signal for DRAM memory; active LOW

SD_CAS T1 O SDRAM controller column address strobe; active LOW

SD_WE T2 O SDRAM controller write enable; active LOW

SD_D[3] T3 I/O SDRAM controller data bus bit 3

SD_D[8] T4 I/O SDRAM controller data bus bit 8

SD_D[10] T5 I/O SDRAM controller data bus bit 10

SD_D[14] T6 I/O SDRAM controller data bus bit 14

IO26 T7 I/O I/O port 3 bit 2

IO29 T8 I/O I/O port 3 bit 5

IO33 T9 I/O I/O port 4 bit 1

IO36 T10 I/O I/O port 4 bit 4

A23 T11 I/O EBIU A23 (Strapin[2] during boot sequence)

A16 T12 I/O EBIU A16

A12 T13 I/O EBIU A12

A3 T14 O EBIU A3

CS7 T15 O EBIU controller chip select 7; active LOW

CS4 T16 O EBIU controller chip select 4; active LOW

WE T17 O EBIU controller write enable signal; active LOW

CS_WAIT T18 O EBIU controller wait signal for chip selects; active LOW

SD_DQM0 U1 O SDRAM controller DQ mask enable for byte 0; active LOW

SD_DQM1 U2 O SDRAM controller DQ mask enable for byte 1; active LOW

SD_D[2] U3 I/O SDRAM controller data bus bit 2

SD_D[9] U4 I/O SDRAM controller data bus bit 9

SD_D[11] U5 I/O SDRAM controller data bus bit 11

SD_D[15] U6 I/O SDRAM controller data bus bit 15

IO27 U7 I/O I/O port 3 bit 3

…continued

strobe signal for upper byte for general chip select; active LOW

9397 750 07048

Objective specification Rev. 01 — 20 April 2000 12 of 26

© Philips Electronics N.V. 2000. All rights reserved.

Page 13

Philips Semiconductors

SAA8122A

Digital Still Camera Processor (ImagIC family)

Table 3: Pin description

Symbol Pin Type Description

IO32 U8 I/O I/O port 4 bit 0

IO34 U9 I/O I/O port 4 bit 2

A22 U10 I/O EBIU A22 (Strapin[3] during boot sequence)

A17 U11 I/O EBIU A17 (Strapin[11] during boot sequence)

A11 U12 I/O EBIU A11

A8 U13 I/O EBIU A8

A4 U14 O EBIU A4

A2 U15 O EBIU A2

CS5 U16 O EBIU controller chip select 5; active LOW

CS3 U17 O EBIU controller chip select 3; active LOW

CS0 U18 O EBIU controller chip select 0; active LOW

SD_D[0] V1 I/O SDRAM controller data bus bit 0

SD_D[1] V2 I/O SDRAM controller data bus bit 1

SD_D[5] V3 I/O SDRAM controller data bus bit 5

SD_D[12] V4 I/O SDRAM controller data bus bit 12

IO24 V5 I/O I/O port 3 bit 0

IO28 V6 I/O I/O port 3 bit 4

IO31 V7 I/O I/O port 3 bit 7

IO35 V8 I/O I/O port 4 bit 3

IO39 V9 I/O I/O port 4 bit 7

A20 V10 I/O EBIU A20 (Strapin[5] and Strapin[8] during boot sequence)

A15 V11 I/O EBIU A15

A10 V12 I/O EBIU A10

A7 V13 I/O EBIU A7

A6 V14 I/O EBIU A6

A1 V15 O EBIU A1

A0 V16 O EBIU A0

CS2 V17 O EBIU controller chip select 2; active LOW

CS1 V18 O EBIU controller chip select 1; active LOW

…continued

9397 750 07048

Objective specification Rev. 01 — 20 April 2000 13 of 26

© Philips Electronics N.V. 2000. All rights reserved.

Page 14

Philips Semiconductors

7. Limiting values

Table 4: Limiting values

In accordance with the Absolute Maximum Rating System (IEC 60134).

Symbol Parameter Conditions Min Max Unit

V

V

V

I

DD

I

SS

T

[1] Value may not exceed 4 V.

[2] Including voltage on outputs in 3-state mode.

[3] Only valid when supply voltage is present.

[4] The peak current is limited to 10 times the corresponding maximum current.

[5] Dependent of package and not yet determined.

DDD

DDA

I

stg

SAA8122A

Digital Still Camera Processor (ImagIC family)

digital supply voltage −0.5 4 V

analog supply voltage −0.5 4 V

DC input voltage general

5 V tolerant

cells only

DC supply current per

supply pin

DC ground current per

ground pin

storage temperature

[1]

−0.5 VDD+ 0.5 V

[2]

[2]

−0.5 −0.5 V

[3]

[4]

− 60 mA

[4]

− 60 mA

[5]

0 125 °C

8. Characteristics

Table 5: General supply characteristics

Symbol Parameter Conditions Min Typ Max Unit

V

DDD

V

DDA(DLL)

V

DDA(LCDR)

V

DDA(LCDG)

V

DDA(LCDB)

V

DDA(OUTPUT1)

V

DDA(OUTPUT2)

V

DDA(ADC)

V

DDA(PPG1)

V

DDA(PPG0)

V

DDA(BG)

V

DDA(PLL)

V

DDA(SPLL)

V

DDD(RTC)

[1] V

DDD(RTC)

digital supply voltage 3.0 3.3 3.6 V

analog supply voltage for DLL 3.0 3.3 3.6 V

analog supply voltage for LCDR output of DAC 3.0 3.3 3.6 V

analog supply voltage for LCDG output of DAC 3.0 3.3 3.6 V

analog supply voltage for LCDB 3.0 3.3 3.6 V

analog supply voltage for video output 1 of DAC 3.0 3.3 3.6 V

analog supply voltage for video output 2 of DAC 3.0 3.3 3.6 V

analog supply voltage for ADC 3.0 3.3 3.6 V

analog supply voltage for PPG 3.0 3.3 3.6 V

analog supply voltage for PPG 3.0 3.3 3.6 V

analog supply voltage for bandgap 3.0 3.3 3.6 V

analog supply voltage for PLL 3.0 3.3 3.6 V

analog supply voltage for SPLL 3.0 3.3 3.6 V

digital supply voltage for RTC

is the single supply which may be on when the others are off. In this case the I/Os of the SAA8122A have to be at 0 V.

[1]

3.0 3.3 3.6 V

9397 750 07048

Objective specification Rev. 01 — 20 April 2000 14 of 26

© Philips Electronics N.V. 2000. All rights reserved.

Page 15

Philips Semiconductors

SAA8122A

Digital Still Camera Processor (ImagIC family)

Table 6: Operating characteristics

Symbol Parameter Conditions Min Typ Max Unit

V

DDA(LCDR)

analog supply voltage for LCDR

output of DAC

V

DDA(LCDG)

analog supply voltage for LCDG

output of DAC

V

DDA(LCDB)

analog supply voltage for LCDB

output of DAC

V

DDA(OUTPUT1)

analog supply voltage for video

output 1 of DAC

V

DDA(OUTPUT2)

analog supply voltage for video

output 2 of DAC

V

DDA(BG)

V

BG

V

OL

V

OH

analog supply voltage for bandgap 3.0 3.3 3.6 V

bandgap reference voltage (4σ) 1.18 1.22 1.26 V

LOW-level output voltage code 0 - 0.225 - V

HIGH-level output voltage code 511 - 1.625 - V

LCD channels (1 kΩ buffer)

R

L

C

L

load resistance - 1 - kΩ

load capacitance - - 5 pF

RES resolution - 8 - bit

LCD channels (75 Ω mode)

R

L

C

L

load resistance - 75 - Ω

load capacitance - 5 100 pF

RES resolution - 9 - bit

VIDEO_OUT channels (1 kΩ buffer)

R

L

C

L

load resistance - 1 - kΩ

load capacitance - - 5 pF

RES resolution - 8 - bit

VIDEO_OUT channels (1 kΩ mode)

R

L

C

L

load resistance - 1 - kΩ

load capacitance - - 5 pF

RES resolution - 9 - bit

ADC

V

DDA(ADC)

analog supply voltage for analog

ADC

∆V

DD

supply voltage difference between

and V

V

DDA

DDA(ADC)

RES resolution 8 - 10 bit

C

i

V

i

f

sample

input capacitance - 2 - pF

input voltage 0 - 3.3 V

sample frequency 8-bit 0 - 100 kHz

PLL

V

DDA(PLL)

analog supply voltage for analog

PLL

3.0 3.3 3.6 V

3.0 3.3 3.6 V

3.0 3.3 3.6 V

3.0 3.3 3.6 V

3.0 3.3 3.6 V

3.0 3.3 3.6 V

- - 0.2 V

3.0 3.3 3.6 V

9397 750 07048

Objective specification Rev. 01 — 20 April 2000 15 of 26

© Philips Electronics N.V. 2000. All rights reserved.

Page 16

Philips Semiconductors

SAA8122A

Digital Still Camera Processor (ImagIC family)

Table 6: Operating characteristics

…continued

Symbol Parameter Conditions Min Typ Max Unit

∆V

f

clk

DD

supply voltage difference between

and V

V

DDA

DDA(PLL)

- - 0.2 V

clock frequency - 96 - MHz

SPLL

V

DDA(SPLL)

analog supply voltage for analog

3.0 3.3 3.6 V

SPLL

∆V

DD

supply voltage difference between

and V

V

DDA

DDA(SPLL)

- - 0.2 V

Power-on reset

V

trip

t

HIGH

trip level of power-on reset 1.5 2.07 2.65 V

time that V

has to be above

DDA

--2µs

2.65 V beforeinternalreset signal is

asserted

t

LOW

time that V

has to be above

DDA

--8µs

2.65 V beforeinternalreset signal is

de-asserted

Analog PPG

V

DDA(DLL)

analog supply voltage for analog

3.0 3.3 3.6 V

DLL

∆V

DD-DDA(DLL)

V

DDA(PPG1)

V

DDA(PPG0)

∆V

DD-DDA(PPG)

I/Os (V

DDD=VDDA, Tamb

supply voltage difference between

and V

V

DDA

;

analog supply voltage for analog

DDA(DLL)

PPG

supply voltage difference between

V

DDA

and V

DDA(PPG1)

or V

= 0 to 60 °C)

- - 0.2 V

3.0 3.3 3.6 V

- - 0.2 V

DDA(PPG0)

Data and control inputs

SD_CLKIN

V

IL

V

IH

C

i

I

IL

I

IH

I

lu(I/O)

LOW-level digital input voltage 0 - 0.3V

HIGH-level digital input voltage 0.7V

DDD

-V

DDD

DDD

V

V

input capacitance - 1.14 - pF

LOW-level input current VI=0V --1µA

HIGH-level input current VI=V

DDD

I/O latch-up current −0.5<V

+ 0.5 100 - - mA

DDD

--1µA

CS_WAIT, PC_WAIT1, PC_WAIT2, SC_TCK, TCK, TDI, TMS, TRST, CCD_IM0 to CCD_IM11, CNT0 to CNT2,

GATE0 to GATE2, T0_CAP0, T0_CAP1, CTS, RXD, UA_CLK, RXDATA, RXVMI, RXVPI

V

IL

V

IH

C

i

I

IL

I

IH

I

lu(I/O)

LOW-level digital input voltage 0 - 0.8 V

HIGH-level digital input voltage 2.0 - 5.5 V

input capacitance - 1.2 - pF

LOW-level input current VI=0V --1µA

HIGH-level input current VI=V

DDD

I/O latch-up current −0.5<V

< 5.5 100 - - mA

DDD

--1µA

SYSRSTIN

V

IL

LOW-level digital input voltage 0 - 0.8 V

9397 750 07048

Objective specification Rev. 01 — 20 April 2000 16 of 26

© Philips Electronics N.V. 2000. All rights reserved.

Page 17

Philips Semiconductors

SAA8122A

Digital Still Camera Processor (ImagIC family)

Table 6: Operating characteristics

…continued

Symbol Parameter Conditions Min Typ Max Unit

V

IH

V

hys

C

i

I

IL

I

IH

I

lu(I/O)

HIGH-level digital input voltage 2.0 - 5.5 V

hysteresis voltage 0.4 - - V

input capacitance - 1.2 - pF

LOW-level input current VI=0V --1µA

HIGH-level input current VI=V

DDD

I/O latch-up current −0.5<V

< 5.5 100 - - mA

DDD

--1µA

Data and control outputs

ANPPG1 to ANPPG8

V

OL

V

OH

C

o(L)(max)

I

OL

I

OH

LOW-level digital output voltage IOL= 4 mA 0 - 0.4 V

HIGH-level digital output voltage IOH= 4 mA V

maximum output load capacitance

[1]

LOW-level output current VOL= 0.4 V;

V

OH=VDDA

HIGH-level output current VOH=V

− 0.4

− 0.4 −4--mA

DDA

− 0.4 - V

DDA

DDA

- - 100 pF

4--mA

V

SCLK, SD_A[0] to SD_A[14], SD_CAS, SD_CLKEN, SD_CLKOUT, SD_CS0 to SD_CS3, SD_DQM0 to SD_DQM1,

SD_RAS, SD_WE

V

OL

V

OH

C

i

C

o(L)(max)

I

OL

I

OH

I

OZ

LOW-level digital output voltage IOL= 4 mA 0 - 0.4 V

HIGH-level digital output voltage IOH= −4mA V

− 0.4 V

DDD

DDD

V

input capacitance - - 1 - pF

maximum output load capacitance -

[1]

- - 100 pF

LOW-level output current VOL= 0.4 V - - - µA

HIGH-level output current VOH=V

3-state output leakage current VO=0;

V

O=VDDD

− 0.4 −4--mA

DDD

--1µA

TDO, SYSRST, PWM0 to PWM2, RTS, TXD, SUSPEND, TXOE, TXVMO, TXVPO, DISP_HSYNC, DISP_VSYNC

V

OL

V

OH

C

i

C

o(L)(max)

I

OL

I

OH

I

OZ

LOW-level digital output voltage IOL= 2 mA 0 - 0.4 V

HIGH-level digital output voltage IOH= −2mA V

− 0.4 - V

DDD

DDD

V

input capacitance - - 2.2 - pF

maximum output load capacitance LOW-level output current VOL= 0.4 V;

V

OH=VDDD

HIGH-level output current VOH=V

DDD

3-state output leakage current VO=0;

V

O=VDD

− 0.4

− 0.4 −2--mA

[1]

--30pF

2--mA

--1µA

CAS0, CAS1, CS0 to CS7, IORD_RE, IOWR_WE, OE, PC_REG, PC1_CE1, PC1_CE2, RAS, SC_ALE, SC_SE, WE,

PPG1 to PPG14

V

OL

V

OH

C

i

C

o(L)(max)

I

OL

I

OH

LOW-level digital output voltage IOL= 4 mA 0 - 0.4 V

HIGH-level digital output voltage IOH= −4mA V

− 0.4 - V

DDD

DDD

V

input capacitance - - 2.4 - pF

maximum output load capacitance LOW-level output current VOL= 0.4 V;

V

OH=VDDD

HIGH-level output current VOH=V

DDD

− 0.4

− 0.4 −4--mA

[1]

--30pF

4--mA

9397 750 07048

Objective specification Rev. 01 — 20 April 2000 17 of 26

© Philips Electronics N.V. 2000. All rights reserved.

Page 18

Philips Semiconductors

SAA8122A

Digital Still Camera Processor (ImagIC family)

Table 6: Operating characteristics

…continued

Symbol Parameter Conditions Min Typ Max Unit

I

OZ

3-state output leakage current VO=0;

V

O=VDDD

--1µA

Data and control I/Os

SD_D[0] to SD_D[15]

V

IL

V

IH

V

OL

V

OH

C

i

C

o(L)(max)

I

OL

I

OH

I

OZ

I

IL

I

IH

LOW-level digital input voltage - 0 - 0.3V

HIGH-level digital input voltage - 0.7V

DDD

-V

DDD

DDD

V

V

LOW-level digital output voltage IOL= 4 mA 0 - 0.4 V

HIGH-level digital output voltage IOH= −4mA V

− 0.4 - V

DDD

DDD

V

input capacitance - - 1.2 - pF

maximum output load capacitance LOW-level output current VOL= 0.4 V;

V

OH=VDDD

HIGH-level output current VOH=V

DDD

3-state output leakage current VO=0;

V

O=VDDD

− 0.4

− 0.4 −4--mA

[1]

- - 100 pF

4--mA

--1µA

LOW-level input current VI=0 --1µA

HIGH-level input current VI=V

DDD

--1µA

A0 to A15, IO8 to IO15, HDHREF, VDVS

V

IL

V

IH

V

OL

V

OH

C

i

C

o(L)(max)

I

OL

I

OH

I

OZ

I

IL

I

IH

LOW-level digital input voltage - 0 - 0.6V

HIGH-level digital input voltage - 0.7V

DDD

-V

DDD

DDD

V

V

LOW-level digital output voltage IOL= 4 mA 0 - 0.4 V

HIGH-level digital output voltage IOH= −4mA V

− 0.4 - V

DDD

DDD

V

input capacitance - - 2.5 - pF

maximum output load capacitance LOW-level output current VOL= 0.4 V;

V

OH=VDDD

HIGH-level output current VOH=V

DDD

3-state output leakage current VO=0;

V

O=VDDD

− 0.4

− 0.4 −4--mA

[1]

--30pF

4--mA

--1µA

LOW-level input current VI=0 --1µA

HIGH-level input current VI=V

DDD

--1µA

IO16 to IO23, IO0/IRQ16, IO1/IRQ17, IO2/IRQ18, IO3/IRQ19, IO4/IRQ20, IO5/IRQ21, IO6/IRQ22, IO7/IRQ23

V

IL

V

IH

V

OL

V

OH

C

i

C

o(L)(max)

I

OL

I

OH

LOW-level digital input voltage - 0 - 0.3V

HIGH-level digital input voltage - 0.7V

DDD

-V

DDD

DDD

V

V

LOW-level digital output voltage IOL= 2 mA 0 - 0.4 V

HIGH-level digital output voltage IOH= −2mA V

− 0.4 - - V

DDD

input capacitance - - 2.3 - pF

maximum output load capacitance - - - 30 pF

LOW-level output current VOL= 0.4 V;

V

OH=VDDD

HIGH-level output current VOH=V

DDD

− 0.4

− 0.4 −2--mA

2--mA

9397 750 07048

Objective specification Rev. 01 — 20 April 2000 18 of 26

© Philips Electronics N.V. 2000. All rights reserved.

Page 19

Philips Semiconductors

SAA8122A

Digital Still Camera Processor (ImagIC family)

Table 6: Operating characteristics

…continued

Symbol Parameter Conditions Min Typ Max Unit

I

OZ

I

IL

I

IH

3-state output leakage current VO=0;

V

O=VDDD

--1µA

LOW-level input current VI=0 --1µA

HIGH-level input current VI=V

DDD

--1µA

IO4 to IO31

V

IL

V

IH

V

OL

V

OH

C

i

C

o(L)(max)

I

OL

I

OH

I

OZ

I

IL

I

IH

LOW-level digital input voltage - 0 - 0.8 V

HIGH-level digital input voltage - 2.0 - 5.5 V

LOW-level digital output voltage IOL= 2 mA - - 0.4 V

HIGH-level digital output voltage IOH= −2mA V

− 0.4 - V

DDD

DDD

V

input capacitance - - 1.5 - pF

maximum output load capacitance - - - 30 pF

LOW-level output current VOL= 0.4 V;

V

OH=VDDD

HIGH-level output current VOH=V

DDD

3-state output leakage current VO=0;

V

O=VDDD

− 0.4

− 0.4 −2--mA

2--mA

--1µA

LOW-level input current VI=0 --1µA

HIGH-level input current VI=V

DDD

--1µA

IO32 to IO39

V

IL

V

IH

V

OL

V

OH

C

i

C

o(L)(max)

I

OL

I

OH

I

OZ

I

IL

I

IH

2

C-bus I/Os

I

LOW-level digital input voltage - 0 - 0.8 V

HIGH-level digital input voltage - 2.0 - 5.5 V

LOW-level digital output voltage IOL= 1 mA 0 - 0.4 V

HIGH-level digital output voltage IOH= −1mA V

− 0.4 - V

DDD

DDD

V

input capacitance - - 1.4 - pF

maximum output load capacitance - - - 30 pF

LOW-level output current VOL= 0.4 V;

V

OH=VDDD

HIGH-level output current VOH=V

DDD

3-state output leakage current VO=0;

V

O=VDDD

− 0.4

− 0.4 −1--mA

1--mA

--1µA

LOW-level input current VI=0 --1µA

HIGH-level input current VI=V

DDD

--1µA

SCL and SDA

V

IL

V

IH

V

hys

V

OL

C

i

C

o(L)(max)

LOW-level digital input voltage - 0 - 0.3V

HIGH-level digital input voltage - 0 - 0.3V

hysteresis voltage - 0.005V

--V

DDD

DDD

DDD

V

V

LOW-level digital output voltage IOL= 3 mA - - 0.4 V

input capacitance - - 3.2 - pF

maximum output load capacitance -

[1]

- - 400 pF

9397 750 07048

Objective specification Rev. 01 — 20 April 2000 19 of 26

© Philips Electronics N.V. 2000. All rights reserved.

Page 20

Philips Semiconductors

SAA8122A

Digital Still Camera Processor (ImagIC family)

Table 6: Operating characteristics

…continued

Symbol Parameter Conditions Min Typ Max Unit

I

OZ

I

IL

I

IH

[1] The maximum capacitance value given does not take into account the signal frequency. For critical signals the maximum capacitance

has to be weighted according to the signal frequency and external devices constraints.

3-state output leakage VO=0;

V

O=VDDD

--1µA

LOW-level input current VI=0 --1µA

HIGH-level input current VI=V

DDD

--1µA

9397 750 07048

Objective specification Rev. 01 — 20 April 2000 20 of 26

© Philips Electronics N.V. 2000. All rights reserved.

Page 21

Philips Semiconductors

9. Package outline

SAA8122A

Digital Still Camera Processor (ImagIC family)

LFBGA324: plastic low profile fine-pitch ball grid array package; 324 balls; body 16 x 16 x 1.2 mm

A

B

E

M

vB

vA

e

E

1

A

2

A

A

1

detail X

C

y

C

M

1

y

X

ball A1

index area

D

D

1

e

V

U

T

R

P

N

M

L

K

J

H

G

F

E

D

C

B

A

2 4 6 8 1012141618

1 3 5 7 9 11 13 15 17

b

∅ w

M

SOT571-1

5 10 mm

scale

0.8

0.15v0.1

w

ye

y

0.12 0.10

1

EUROPEAN

PROJECTION

ISSUE DATE

00-01-20

DIMENSIONS (mm are the original dimensions)

A

UNIT

mm

OUTLINE

VERSION

SOT571-1 MO-205

max.

1.70

A

1bA2

0.45

0.35

D

D

1.35

1.05

16.1

0.55

15.9

0.45

IEC JEDEC EIAJ

1

16.1

15.9

0

E

E

1

13.613.6

REFERENCES

Fig 4. SOT571-1.

9397 750 07048

Objective specification Rev. 01 — 20 April 2000 21 of 26

© Philips Electronics N.V. 2000. All rights reserved.

Page 22

Philips Semiconductors

10. Soldering

10.1 Introduction to soldering surface mount packages

This text gives a very brief insight to a complex technology. A more in-depth account

of soldering ICs can be found in our

Packages

There is no soldering method that is ideal for all surface mount IC packages. Wave

soldering is not always suitable for surface mount ICs, or for printed-circuit boards

with high population densities. In these situations reflow soldering is often used.

10.2 Reflow soldering

Reflow soldering requires solder paste (a suspension of fine solder particles, flux and

binding agent) to be applied to the printed-circuit board by screen printing, stencilling

or pressure-syringe dispensing before package placement.

Several methods exist for reflowing; for example, infrared/convection heating in a

conveyor type oven. Throughput times (preheating, soldering and cooling) vary

between 100 and 200 seconds depending on heating method.

SAA8122A

Digital Still Camera Processor (ImagIC family)

Data Handbook IC26; Integrated Circuit

(document order number 9398 652 90011).

Typical reflow peak temperatures range from 215 to 250 °C. The top-surface

temperature of the packages should preferable be kept below 230 °C.

10.3 Wave soldering

Conventional single wave soldering is not recommended for surface mount devices

(SMDs) or printed-circuit boards with a high component density, as solder bridging

and non-wetting can present major problems.

To overcome these problems the double-wave soldering method was specifically

developed.

If wave soldering is used the following conditions must be observed for optimal

results:

Use a double-wave soldering method comprising a turbulent wave with high

•

upward pressure followed by a smooth laminar wave.

For packages with leads on two sides and a pitch (e):

•

– larger than or equal to 1.27 mm, the footprint longitudinal axis is preferred to be

parallel to the transport direction of the printed-circuit board;

– smaller than 1.27 mm, the footprint longitudinal axis must be parallel to the

transport direction of the printed-circuit board.

The footprint must incorporate solder thieves at the downstream end.

For packages with leads on four sides, the footprint must be placed at a 45° angle

•

to the transport direction of the printed-circuit board. The footprint must

incorporate solder thieves downstream and at the side corners.

9397 750 07048

Objective specification Rev. 01 — 20 April 2000 22 of 26

© Philips Electronics N.V. 2000. All rights reserved.

Page 23

Philips Semiconductors

During placement and before soldering, the package must be fixed with a droplet of

adhesive. The adhesive can be applied by screen printing, pin transfer or syringe

dispensing. The package can be soldered after the adhesive is cured.

Typical dwell time is 4 seconds at 250 °C. A mildly-activated flux will eliminate the

need for removal of corrosive residues in most applications.

10.4 Manual soldering

Fix the component by first soldering two diagonally-opposite end leads. Use a low

voltage (24 V or less) soldering iron applied to the flat part of the lead. Contact time

must be limited to 10 seconds at up to 300 °C.

When using a dedicated tool, all other leads can be soldered in one operation within

2 to 5 seconds between 270 and 320 °C.

10.5 Package related soldering information

Table 7: Suitability of surface mount IC packages for wave and reflow soldering

Package Soldering method

BGA, LFBGA, SQFP, TFBGA not suitable suitable

HBCC, HLQFP, HSQFP, HSOP, HTQFP,

HTSSOP, SMS

PLCC

LQFP, QFP, TQFP not recommended

SSOP, TSSOP, VSO not recommended

SAA8122A

Digital Still Camera Processor (ImagIC family)

methods

Wave Reflow

not suitable

[3]

, SO, SOJ suitable suitable

[2]

[3][4]

[5]

suitable

suitable

suitable

[1]

[1] All surface mount (SMD) packages are moisture sensitive. Depending upon the moisture content, the

maximum temperature (with respect to time) and body size of the package, there is a risk that internal

or external package cracks may occur due to vaporization of the moisture in them (the so called

popcorn effect). For details, refer to the Drypack information in the

Circuit Packages; Section: Packing Methods

[2] These packages are not suitable for wavesoldering as a solder joint between the printed-circuit board

and heatsink (at bottom version) can not be achieved,and as solder may stick to the heatsink (on top

version).

[3] If wave soldering is considered, then the package must be placed at a 45° angle to the solder wave

direction. The package footprint must incorporate solder thieves downstream and at the side corners.

[4] Wave soldering is only suitable for LQFP, QFP and TQFP packages with a pitch (e) equal to or larger

than 0.8 mm; it is definitely not suitable for packages with a pitch (e) equal to or smaller than 0.65 mm.

[5] Wave soldering is only suitable for SSOP and TSSOP packages with a pitch (e) equal to or larger than

0.65 mm; it is definitely not suitable for packages with a pitch (e) equal to or smaller than 0.5 mm.

.

Data Handbook IC26; Integrated

11. Revision history

Table 8: Revision history

Rev Date CPCN Description

01 20000420 - Objective specification; initial version

9397 750 07048

Objective specification Rev. 01 — 20 April 2000 23 of 26

© Philips Electronics N.V. 2000. All rights reserved.

Page 24

Philips Semiconductors

12. Data sheet status

SAA8122A

Digital Still Camera Processor (ImagIC family)

Datasheet status Product status Definition

Objective specification Development This data sheet contains the design target or goal specifications for product development. Specification may

change in any manner without notice.

Preliminary specification Qualification This data sheet contains preliminary data, and supplementary data will be published at a later date. Philips

Semiconductors reserves the right to make changes at any time without notice in order to improve design and

supply the best possible product.

Product specification Production This data sheet contains final specifications. Philips Semiconductors reserves the right to make changes at any

time without notice in order to improve design and supply the best possible product.

[1] Please consult the most recently issued data sheet before initiating or completing a design.

13. Definitions

Short-form specification — The data in a short-form specification is

extracted from a full data sheet with the same type number and title. For

detailed information see the relevant data sheet or data handbook.

Limiting values definition — Limiting values given are in accordance with

the Absolute Maximum Rating System (IEC 60134). Stress above one or

more of the limiting values may cause permanent damage to the device.

These are stress ratings only and operation of the device at these or at any

other conditions above those given in the Characteristics sections of the

specification is not implied. Exposure to limiting values for extended periods

may affect device reliability.

Application information — Applications that are described herein for any

of these products are for illustrative purposes only. Philips Semiconductors

make no representation or warranty that such applications will be suitable for

the specified use without further testing or modification.

14. Disclaimers

Life support — These products are not designed for use in life support

appliances, devices, or systems where malfunction of these products can

reasonably be expected to result in personal injury. Philips Semiconductors

[1]

customers using or selling these products for use in such applications do so

at their own risk and agree to fully indemnify Philips Semiconductors for any

damages resulting from such application.

Right to make changes — Philips Semiconductors reserves the right to

make changes, without notice, in the products, including circuits, standard

cells, and/or software, described or contained herein in order to improve

design and/or performance. Philips Semiconductors assumes no

responsibility or liability for the use of any of these products, conveys no

licence or title under any patent, copyright, or mask work right to these

products, and makes no representations or warranties that these products

are free from patent, copyright, or mask work right infringement, unless

otherwise specified.

15. Licenses

Purchase of Philips I2C components

2

Purchase of Philips I

under the Philips’ I

2

I

C system provided the system conforms to the I2C

specification defined by Philips. This specification can be

ordered using the code 9398 393 40011.

C components conveys a license

2

C patent to use the components in the

9397 750 07048

© Philips Electronics N.V. 2000 All rights reserved.

Objective specification Rev. 01 — 20 April 2000 24 of 26

Page 25

Philips Semiconductors

SAA8122A

Digital Still Camera Processor (ImagIC family)

Philips Semiconductors - a worldwide company

Argentina: see South America

Australia: Tel. +61 2 9704 8141, Fax. +61 2 9704 8139

Austria: Tel. +43 160 101, Fax. +43 160 101 1210

Belarus: Tel. +375 17 220 0733, Fax. +375 17 220 0773

Belgium: see The Netherlands

Brazil: see South America

Bulgaria: Tel. +359 268 9211, Fax. +359 268 9102

Canada: Tel. +1 800 234 7381

China/Hong Kong: Tel. +852 2 319 7888, Fax. +852 2 319 7700

Colombia: see South America

Czech Republic: see Austria

Denmark: Tel. +45 3 288 2636, Fax. +45 3 157 0044

Finland: Tel. +358 961 5800, Fax. +358 96 158 0920

France: Tel. +33 14 099 6161, Fax. +33 14 099 6427

Germany: Tel. +49 40 23 5360, Fax. +49 402 353 6300

Hungary: see Austria

India: Tel. +91 22 493 8541, Fax. +91 22 493 8722

Indonesia: see Singapore

Ireland: Tel. +353 17 64 0000, Fax. +353 17 64 0200

Israel: Tel. +972 36 45 0444, Fax. +972 36 49 1007

Italy: Tel. +39 039 203 6838, Fax +39 039 203 6800

Japan: Tel. +81 33 740 5130, Fax. +81 3 3740 5057

Korea: Tel. +82 27 09 1412, Fax. +82 27 09 1415

Malaysia: Tel. +60 37 50 5214, Fax. +60 37 57 4880

Mexico: Tel. +9-5 800 234 7381

Middle East: see Italy

Netherlands: Tel. +31 40 278 2785, Fax. +31 40 278 8399

New Zealand: Tel. +64 98 49 4160, Fax. +64 98 49 7811

Norway: Tel. +47 22 74 8000, Fax. +47 22 74 8341

Philippines: Tel. +63 28 16 6380, Fax. +63 28 17 3474

Poland: Tel. +48 22 5710 000, Fax. +48 22 5710 001

Portugal: see Spain

Romania: see Italy

Russia: Tel. +7 095 755 6918, Fax. +7 095 755 6919

Singapore: Tel. +65 350 2538, Fax. +65 251 6500

Slovakia: see Austria

Slovenia: see Italy

South Africa: Tel. +27 11 471 5401, Fax. +27 11 471 5398

South America: Tel. +55 11 821 2333, Fax. +55 11 829 1849

Spain: Tel. +34 33 01 6312, Fax. +34 33 01 4107

Sweden: Tel. +46 86 32 2000, Fax. +46 86 32 2745

Switzerland: Tel. +41 14 88 2686, Fax. +41 14 81 7730

Taiwan: Tel. +886 22 134 2865, Fax. +886 22 134 2874

Thailand: Tel. +66 27 45 4090, Fax. +66 23 98 0793

Turkey: Tel. +90 216 522 1500, Fax. +90 216 522 1813

Ukraine: Tel. +380 44 264 2776, Fax. +380 44 268 0461

United Kingdom: Tel. +44 208 730 5000, Fax. +44 208 754 8421

United States: Tel. +1 800 234 7381

Uruguay: see South America

Vietnam: see Singapore

Yugoslavia: Tel. +381 11 3341 299, Fax. +381 11 3342 553

For all other countries apply to: Philips Semiconductors,

International Marketing & Sales Communications,

Building BE, P.O. Box 218, 5600 MD EINDHOVEN,

The Netherlands, Fax. +31 40 272 4825

Internet: http://www.semiconductors.philips.com

(SCA69)

9397 750 07048

Objective specification Rev. 01 — 20 April 2000 25 of 26

© Philips Electronics N.V. 2000. All rights reserved.

Page 26

Philips Semiconductors

Contents

1 Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

2 Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

2.1 General. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

2.2 External interfaces . . . . . . . . . . . . . . . . . . . . . . 2

2.3 CPU related features . . . . . . . . . . . . . . . . . . . . 2

2.4 DSP features . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2.5 Pulse pattern generator features . . . . . . . . . . . 2

2.6 JPEG . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2.7 USB interface . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2.8 Card interfaces . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.9 Bus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.10 SDRAM interface features . . . . . . . . . . . . . . . . 3

3 Quick reference data . . . . . . . . . . . . . . . . . . . . . 3

4 Ordering information. . . . . . . . . . . . . . . . . . . . . 3

5 Block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . 4

6 Pinning information. . . . . . . . . . . . . . . . . . . . . . 5

6.1 Pinning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

6.2 Pin description . . . . . . . . . . . . . . . . . . . . . . . . . 5

7 Limiting values. . . . . . . . . . . . . . . . . . . . . . . . . 14

8 Characteristics. . . . . . . . . . . . . . . . . . . . . . . . . 14

9 Package outline . . . . . . . . . . . . . . . . . . . . . . . . 21

10 Soldering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

10.1 Introduction to soldering surface mount

packages . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

10.2 Reflow soldering. . . . . . . . . . . . . . . . . . . . . . . 22

10.3 Wave soldering. . . . . . . . . . . . . . . . . . . . . . . . 22

10.4 Manual soldering . . . . . . . . . . . . . . . . . . . . . . 23

10.5 Package related soldering information . . . . . . 23

11 Revision history. . . . . . . . . . . . . . . . . . . . . . . . 23

12 Data sheet status . . . . . . . . . . . . . . . . . . . . . . . 24

13 Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

14 Disclaimers. . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

15 Licenses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

SAA8122A

Digital Still Camera Processor (ImagIC family)

© Philips Electronics N.V. 2000. Printed in The Netherlands

All rights are reserved. Reproduction in whole or in part is prohibited without the prior

written consent of the copyright owner.

The information presented in this document does not form part of any quotation or

contract, is believed to be accurate and reliable and may be changed without notice. No

liability will be accepted by the publisher for any consequence of its use. Publication

thereof does not convey nor imply any license under patent- or other industrial or

intellectual property rights.

Date of release: 20 April 2000 Document order number: 9397 750 07048

Loading...

Loading...