Page 1

DATA SH EET

Preliminary specification

File under Integrated Circuits, IC01

2000 Mar 21

INTEGRATED CIRCUITS

SAA7392

Channel encoder/decoder CDR60

Page 2

2000 Mar 21 2

Philips Semiconductors Preliminary specification

Channel encoder/decoder CDR60 SAA7392

CONTENTS

1 FEATURES

2 GENERAL DESCRIPTION

3 QUICK REFERENCE DATA

4 ORDERING INFORMATION

5 BLOCK DIAGRAM

6 PINNING INFORMATION

6.1 Pinning

6.2 Pin description

7 FUNCTIONAL DESCRIPTION

7.1 Microprocessor interfaces

7.2 Register map

7.3 System clocks

7.4 HF analog front-end

7.5 Bit recovery

7.6 Decoder function

7.7 Subcode interface

7.8 Digital output

7.9 Serial output interface

7.10 Motor control

7.11 The serial in function

7.12 The subcode insert function

7.13 The data encoder block

7.14 Encode control block

7.15 The EFM modulator

7.16 The EFM clock generator

7.17 The Wobble processor

8 LIMITING VALUES

9 OPERATING CHARACTERISTICS

9.1 ADC and AGC parameters

10 APPLICATION INFORMATION

10.1 Write startcontrol of encoder in CD-ROM mode

10.2 Write start control of encoder in Audio mode

10.3 Start-up of encode in flow-control operation

10.4 Start-up of encoder in synchronous stream

mode

10.5 Operating CDR60 in CAV mode, flow control

on input stream

10.6 Operating in CLV Mode, Flow Control on Input

Stream

10.7 Operating in CLV Mode, Synchronous Stream

Operation

11 PACKAGE OUTLINE

12 SOLDERING

12.1 Introduction to soldering surface mount

packages

12.2 Reflow soldering

12.3 Wave soldering

12.4 Manual soldering

12.5 Suitability of surface mount IC packages for

wave and reflow soldering methods

13 DEFINITIONS

14 LIFE SUPPORT APPLICATIONS

15 PURCHASE OF PHILIPS I2C COMPONENTS

Page 3

2000 Mar 21 3

Philips Semiconductors Preliminary specification

Channel encoder/decoder CDR60 SAA7392

1 FEATURES

• Very high speed Compact Disc (CD) compatible

decoding and encoding device

• On-chip Analog-to-Digital Converter (ADC) and

Automatic Gain Control (AGC) for HF data capture

• Eight-to-Fourteen Modulation (EFM)

• Advanced motor control loop to allow CAV, CLV and

pseudo-CLV playback

• Integrated FIFO for de-coupling of mechanism speed

and application speed

• Versatile output interface allowing different I2S-bus and

Electronic Industries Association of Japan (EIAJ)

formats

• Device is fully compatible with ELM, PLUM and Sanyo

CD-ROM block decoders

• Quad-pass CIRC correction for CD mode

(C1-C2-C1-C2)

• Subcode/header processing for CD format

• Frequency multiplier allows use of a 8 MHz crystal.

2 GENERAL DESCRIPTION

CDR60 is a channel encoder/decoder for

CD/CD-R/CD-RW/CD Audio Recorder systems. It

incorporates all logic and RAM required for the complete

encoding and decoding processes.

There aretwo main datapathsthrough the CDR60 device.

The decode datapath captures the incoming EFM data

stream via the HF ADC and AGC functions.

The bit detector recovers the individual bits from the

incoming signal, correcting asymmetry, performing noise

filtering and equalisation, and recovering the channel bit

clock using a digital PLL. The demodulator converts the

EFM bits to byte-wide data symbols, before passing them

onto the decoder for subcode extraction, de-interleaving

and error correction. The decoded data is then made

available via the multi-function serial output interface.

The encode datapath takes data symbols from the block

encoder/decoder via the serial data and subcode input

functions, encoding them via the encoder block. The

encoded data stream is passed to the EFM modulator,

which generates the required EFM signal, output as a

digital bitstream. Theencode process iscontrolled viathe

Wobble processor, encode control and EFM clock

generator functions.

As well as these two data processing sections, three

further blocks support overall device operation. The

system clockgenerator provides all digitalclocks required

by the CDR60. The motor servo allows the CDR60 to

control the spindle motor and is controlled by the

microprocessor interface. This interface can be accessed

either via a parallel (80C51) or a serial (I2C-bus) interface.

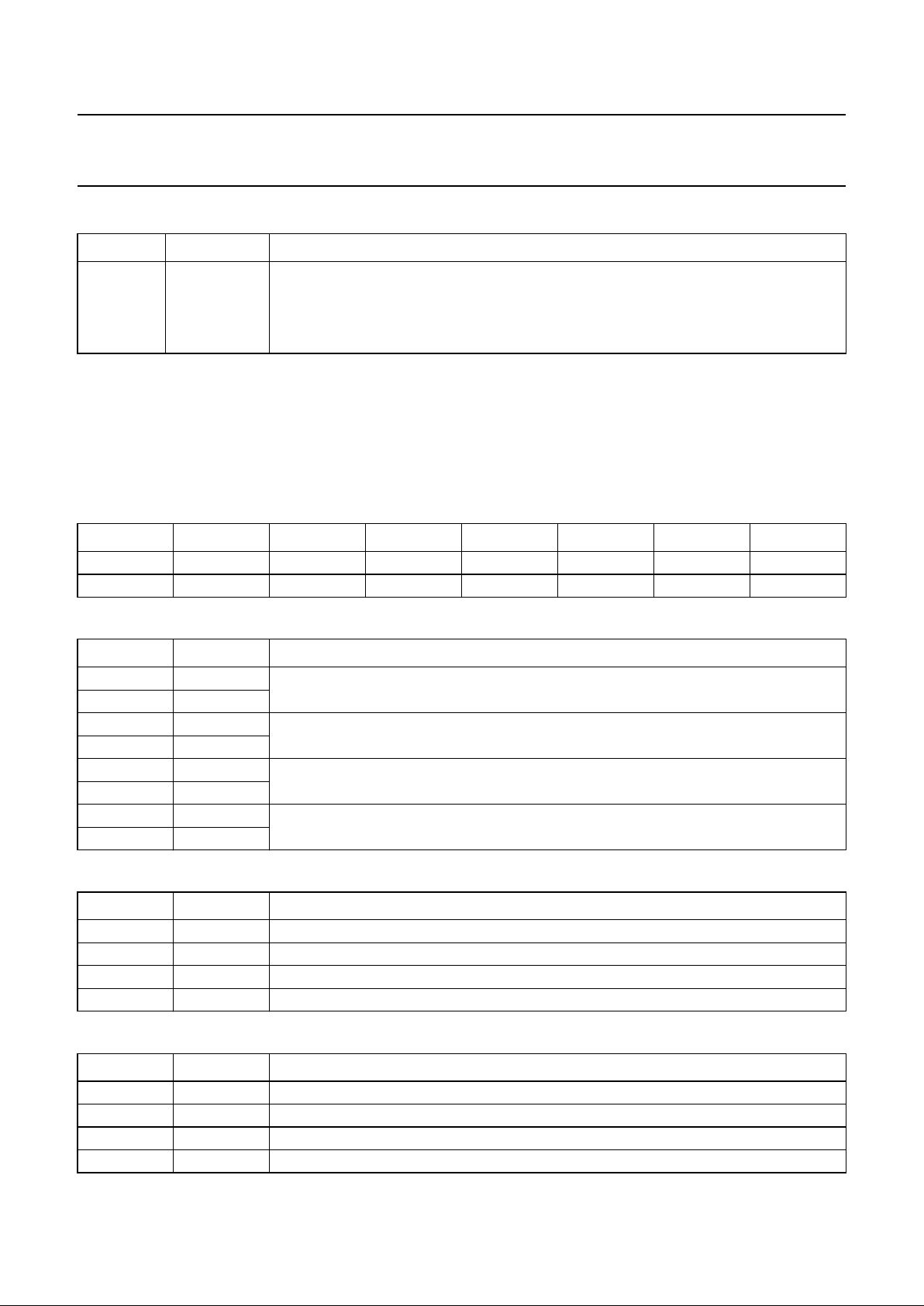

3 QUICK REFERENCE DATA

4 ORDERING INFORMATION

SYMBOL PARAMETER MIN. TYP. MAX. UNIT

V

DDD

supply voltage (core and pad ring) 3.0 3.3 3.6 V

V

DDA

supply voltage (analog) 3.0 3.3 3.6 V

V

DDE

supply voltage (output drivers) 3.0 3.3 3.6 V

I

DD

supply current − 200 − mA

f

xtal

crystal frequency 8 8.4672 33 MHz

T

amb

operating ambient temperature 0 − 70 °C

T

stg

storage temperature −55 − +125 °C

TYPE

NUMBER

PACKAGE

NAME DESCRIPTION VERSION

SAA7392HL LQFP80 plastic low profile quad flat package; 80 leads; body 12 × 12 × 1.4 mm SOT315-1

Page 4

2000 Mar 21 4

Philips Semiconductors Preliminary specification

Channel encoder/decoder CDR60 SAA7392

This text is here in white to force landscape pages to be rotated correctly when browsing through the pdf in the Acrobat reader.This text is here in

_white to forcelandscape pages to be rotated correctly when browsing through the pdf in the Acrobat reader.This text is here inThistext is here in

white to force landscape pagesto be rotated correctly when browsingthrough the pdf in theAcrobatreader. white to force landscapepagesto be ...

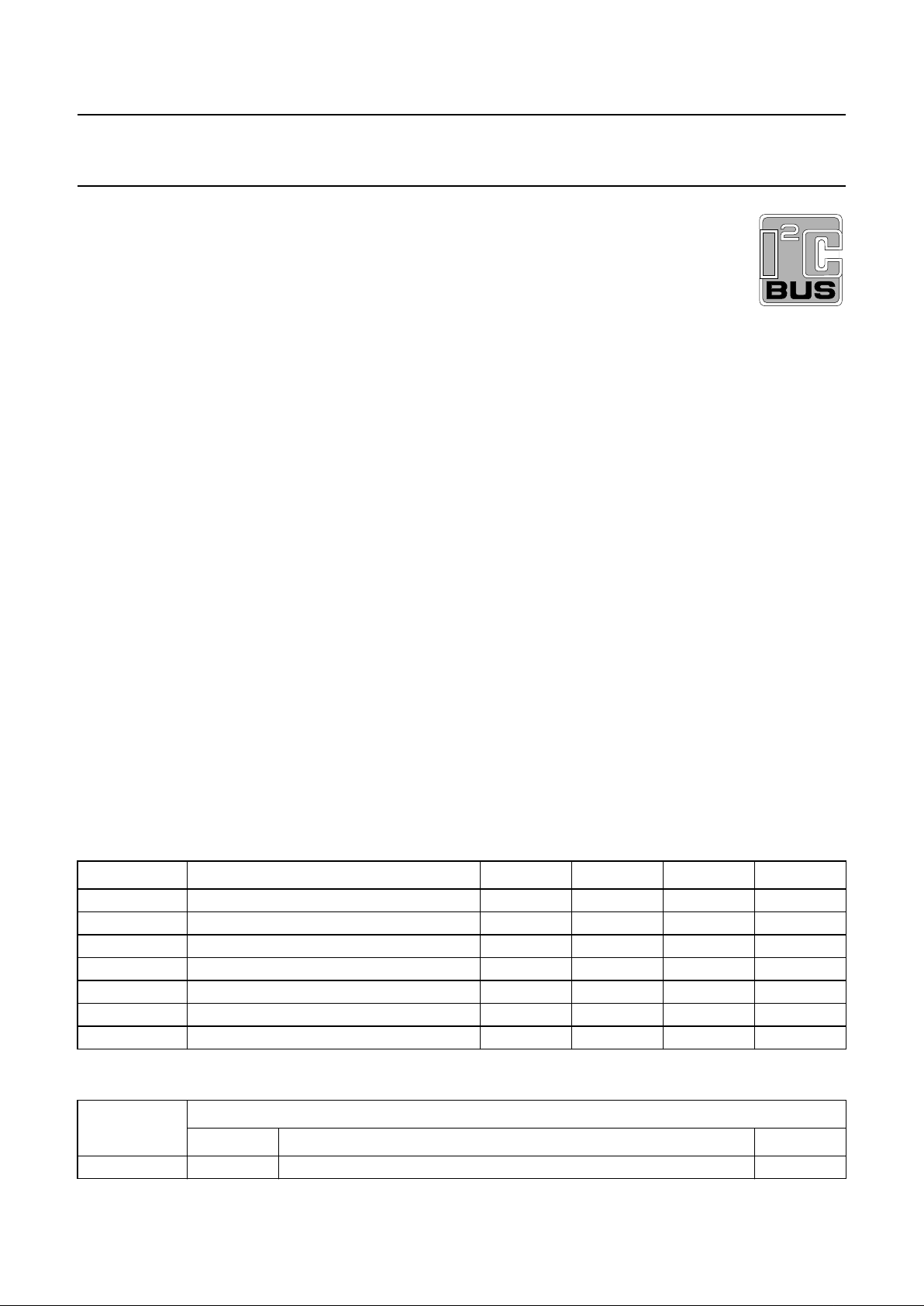

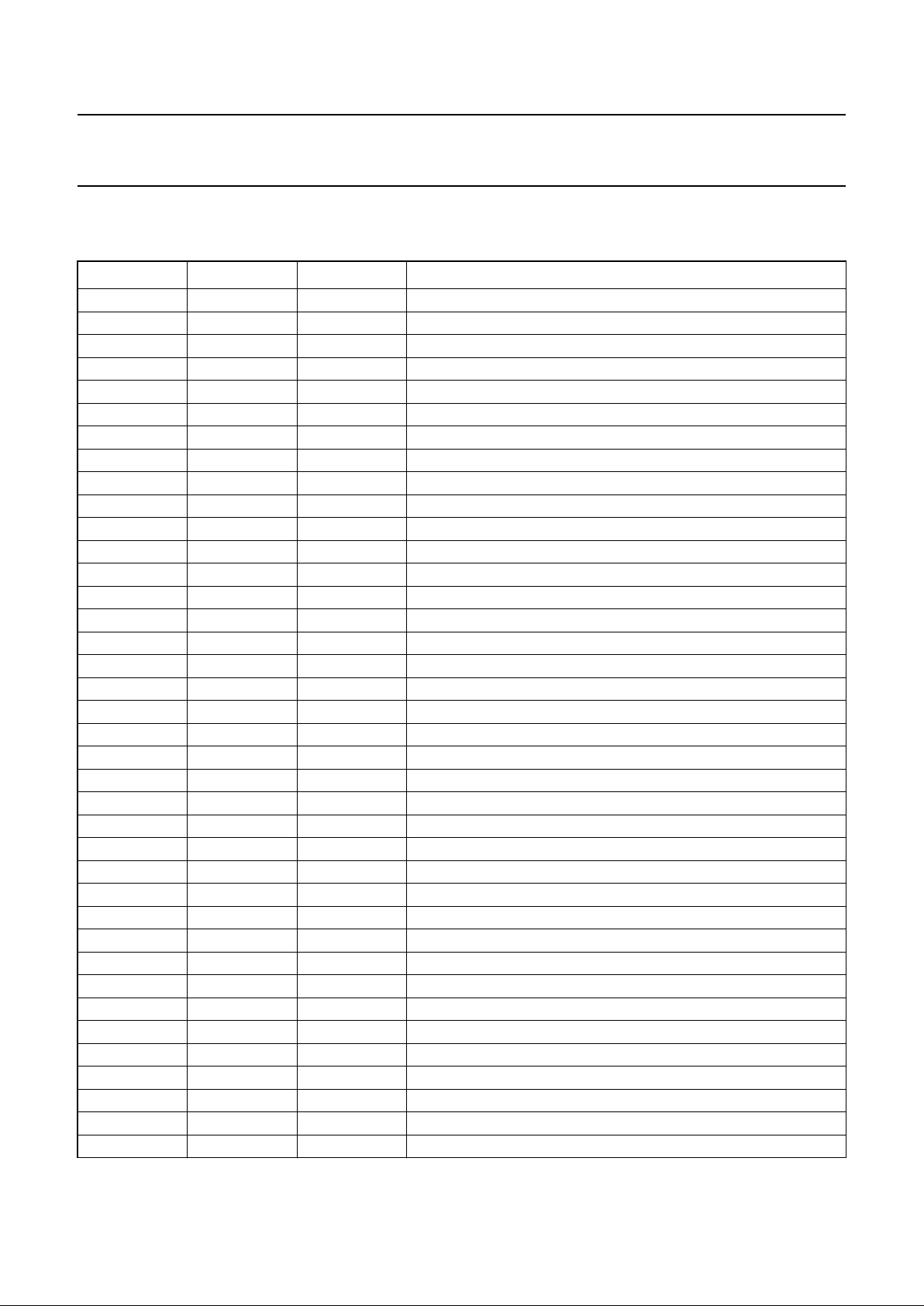

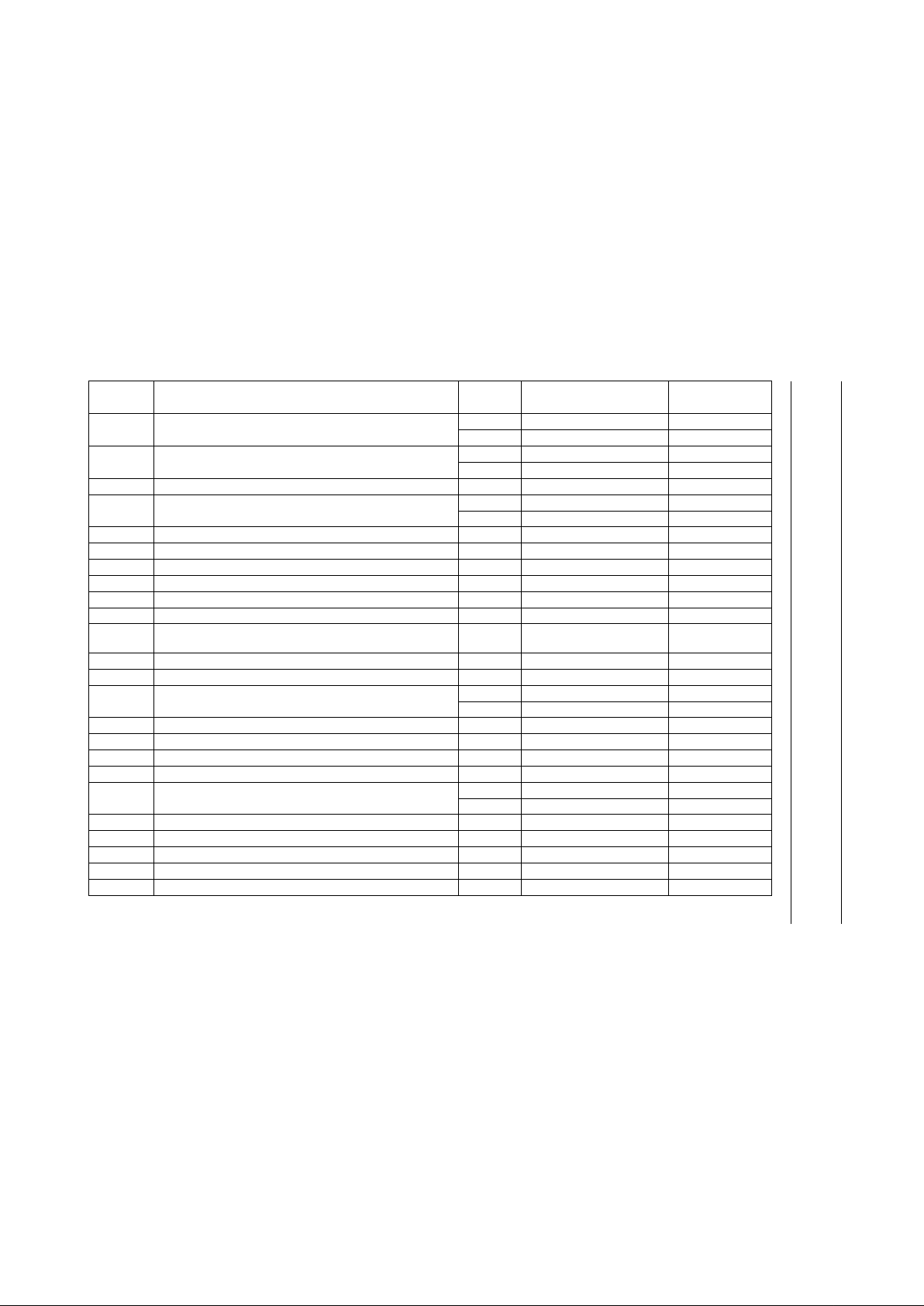

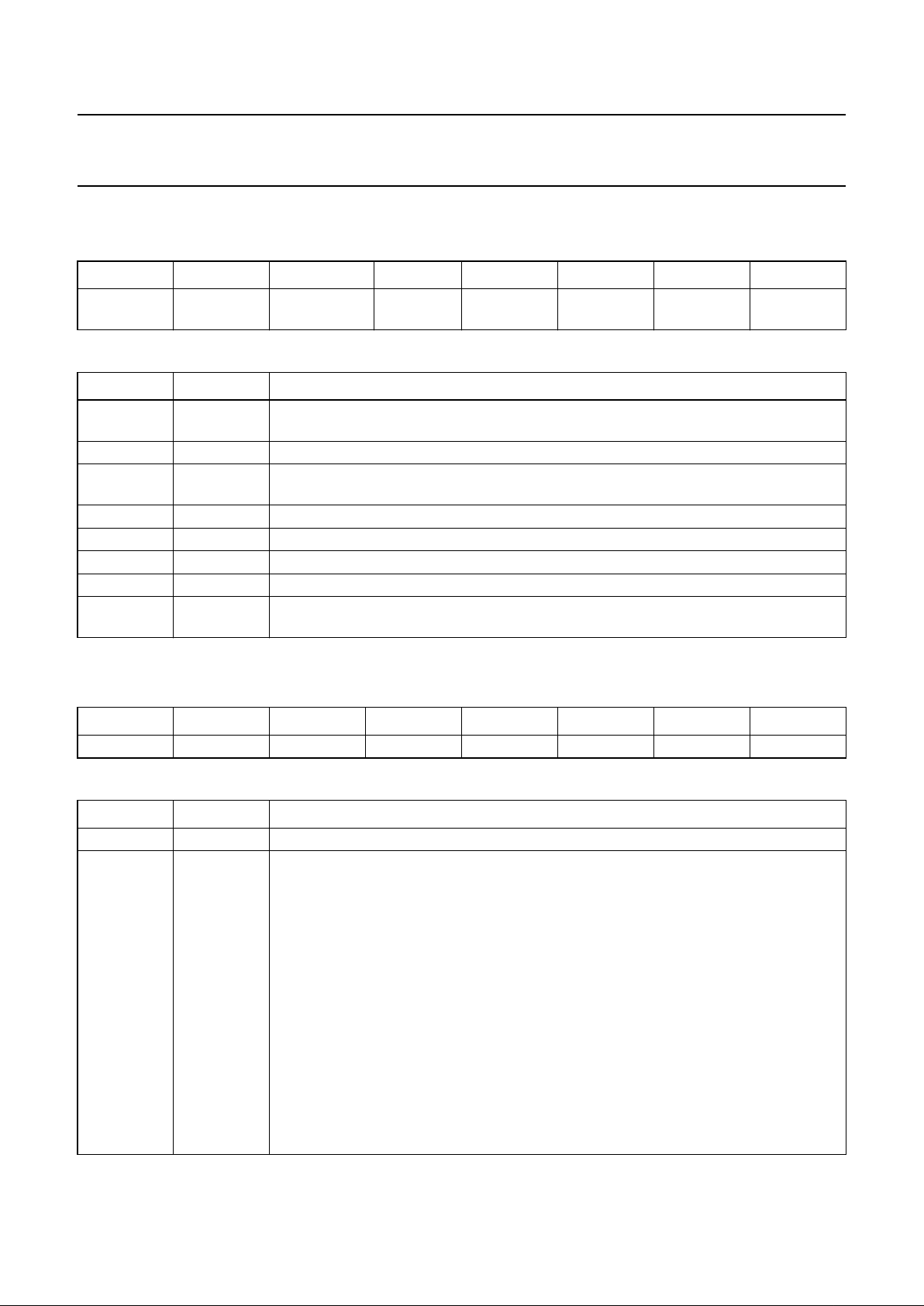

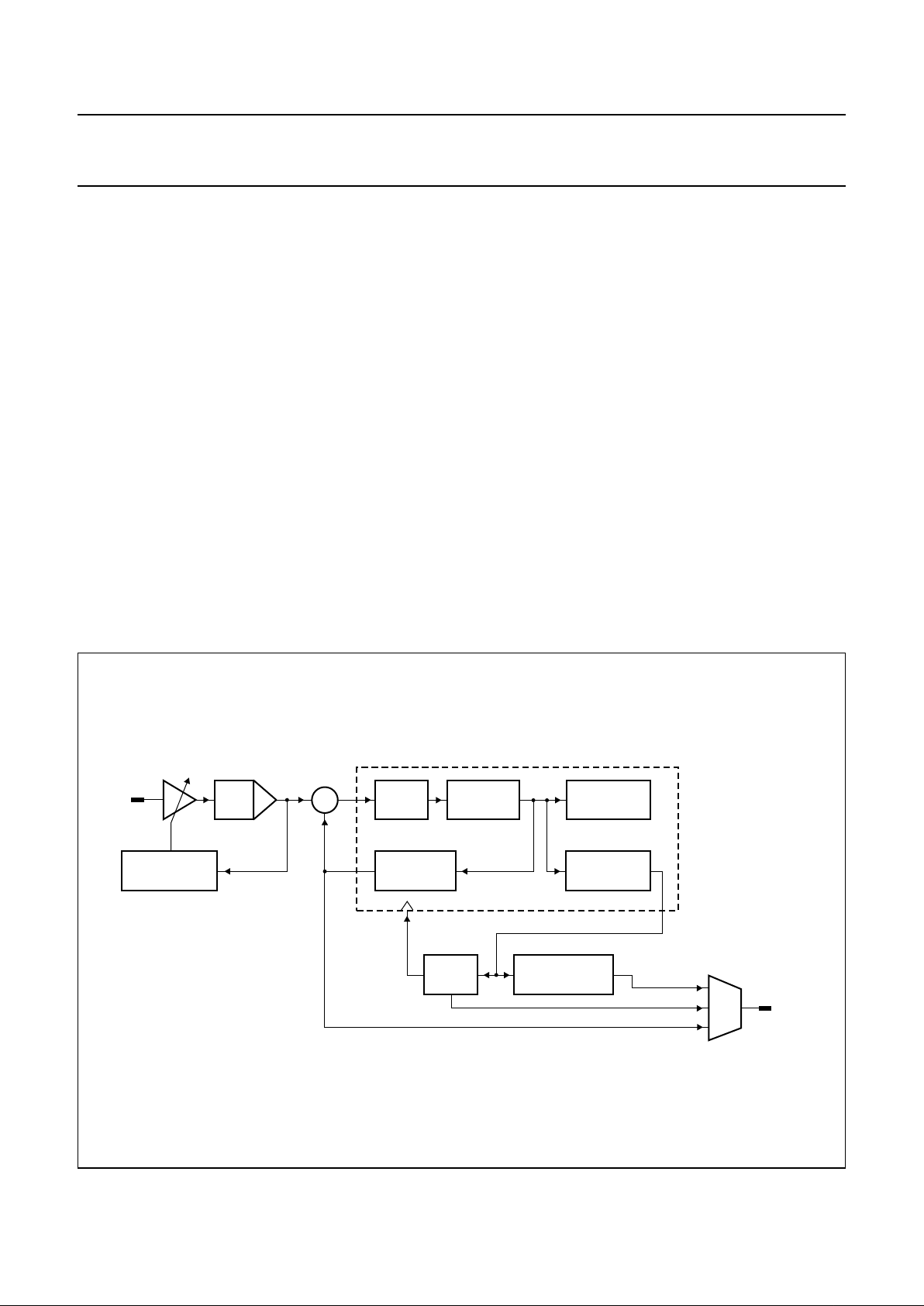

5 BLOCK DIAGRAM

d

book, full pagewidth

SAA7392

MGR791

SUB-CPU INTERFACE

SERIAL OUT

51

PCAin

58

FLAG

54

STOPCK

59

DATAO

56

EBUOUT

55

V4

57

SYNC

61

BCLK

SERIAL IN

SUBCODE

INSERT

60

WCLK

64

DATAI

66

RCK

67

SFSY

65

SUB

34

INT

33

SDA

32

SCL

50

CSi

45

WRi

46

RDi

47

ALE

68

CFLG

35

to

42

DA7

to

DA0

ENCODE

CONTROL

27

PANIC

77

LASERON

EFM

MODULATOR

79

EFMDATA

IREF

GENERATOR

EFM CLOCK

GENERATOR

78

XEFM

WOBBLE

PROCESSOR

MOTOR/TACHO

INTERFACE

ERROR CORRECTOR

AND

MEMORY PROCESSOR

25

W441

26

ATIPSYC

6

WIN

2

WREFHI

3

WREFMID

1

8

WREFLO

RESET

28

PORE

TEST

CONTROL

17

TEST1

18

TEST2

SYSTEM CLOCK

GENERATOR

BIT DETECTOR DE-MODULATOR

21

XTLI

22

XTLO

24

MUXSWI

80

MEAS1

29

CL1

HF DATA

CAPTURE

12

AGCREF

13

HIN

10

HREFHI

14

HREFMID

11

HREFLO

IREF

7

VREF

23

OTD

4

5

15

16

30, 49, 53, 76

19, 31, 43, 48,

52, 62, 71, 75

20, 44, 63, 72

70

T1

69

T2

73

MOTO2/T3

74

MOTO1

V

SSA1

V

DDA1

V

DDA2

V

SSA2

V

SSD

V

DDD

V

DDE

Fig.1 Block diagram.

Page 5

2000 Mar 21 5

Philips Semiconductors Preliminary specification

Channel encoder/decoder CDR60 SAA7392

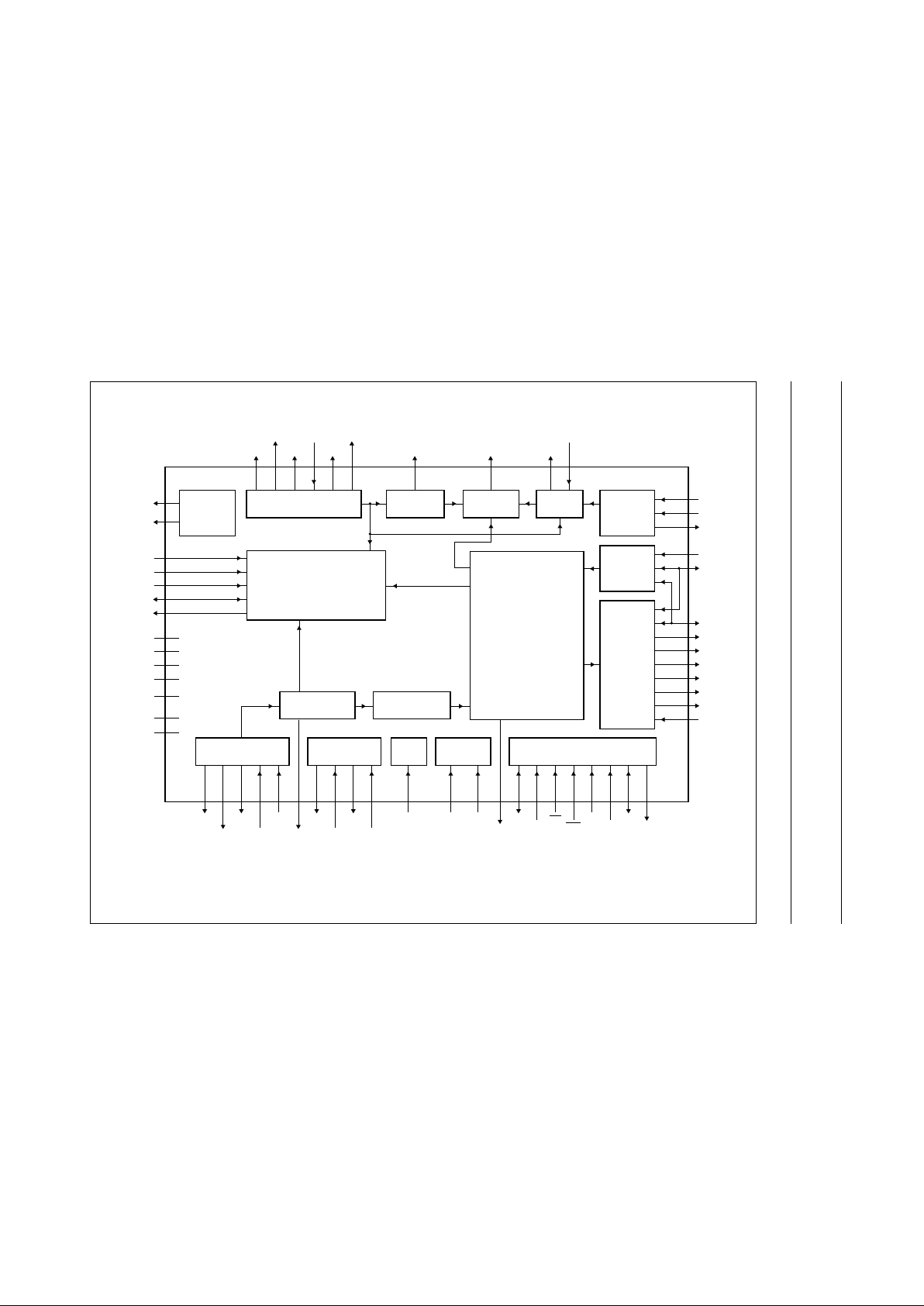

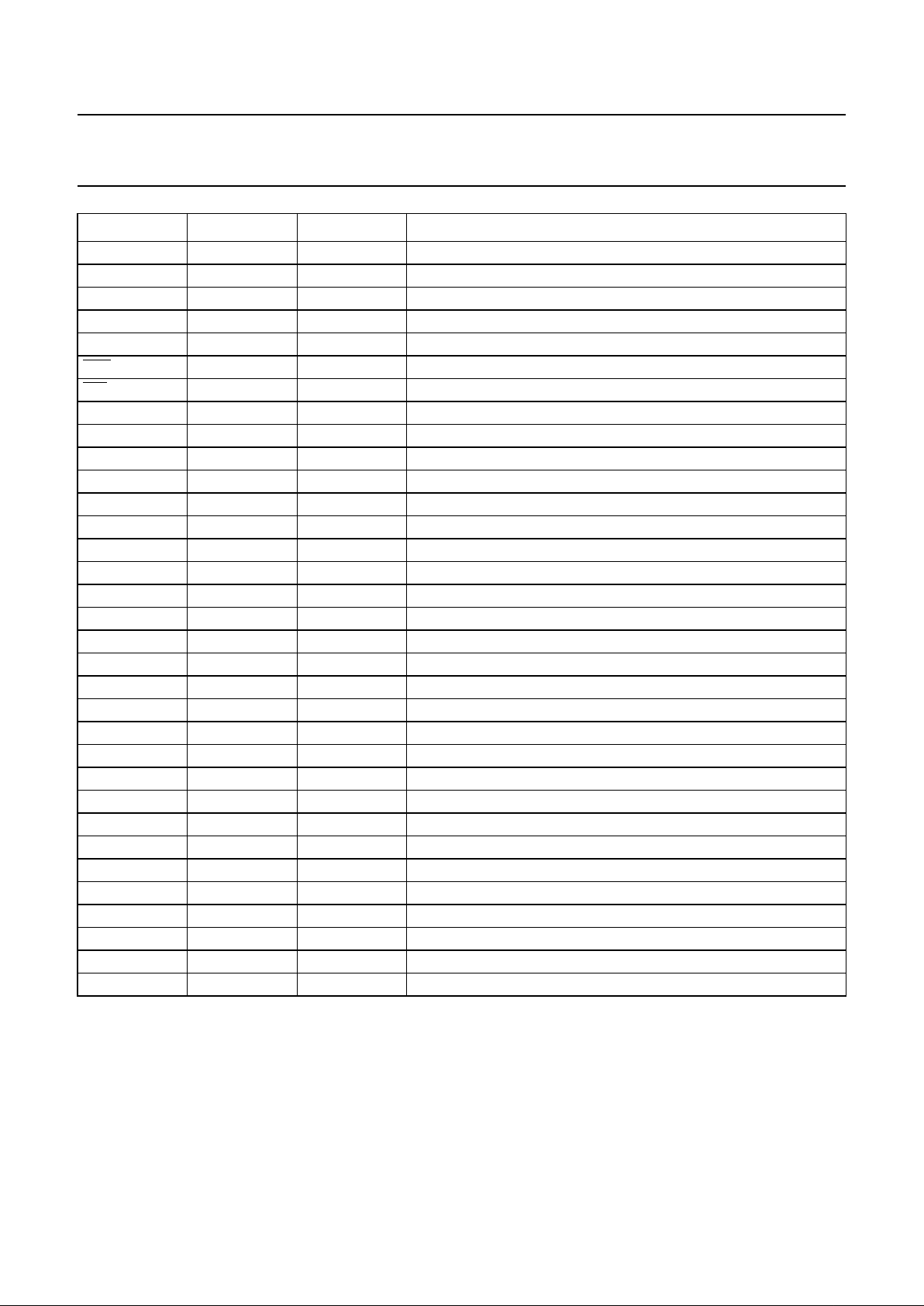

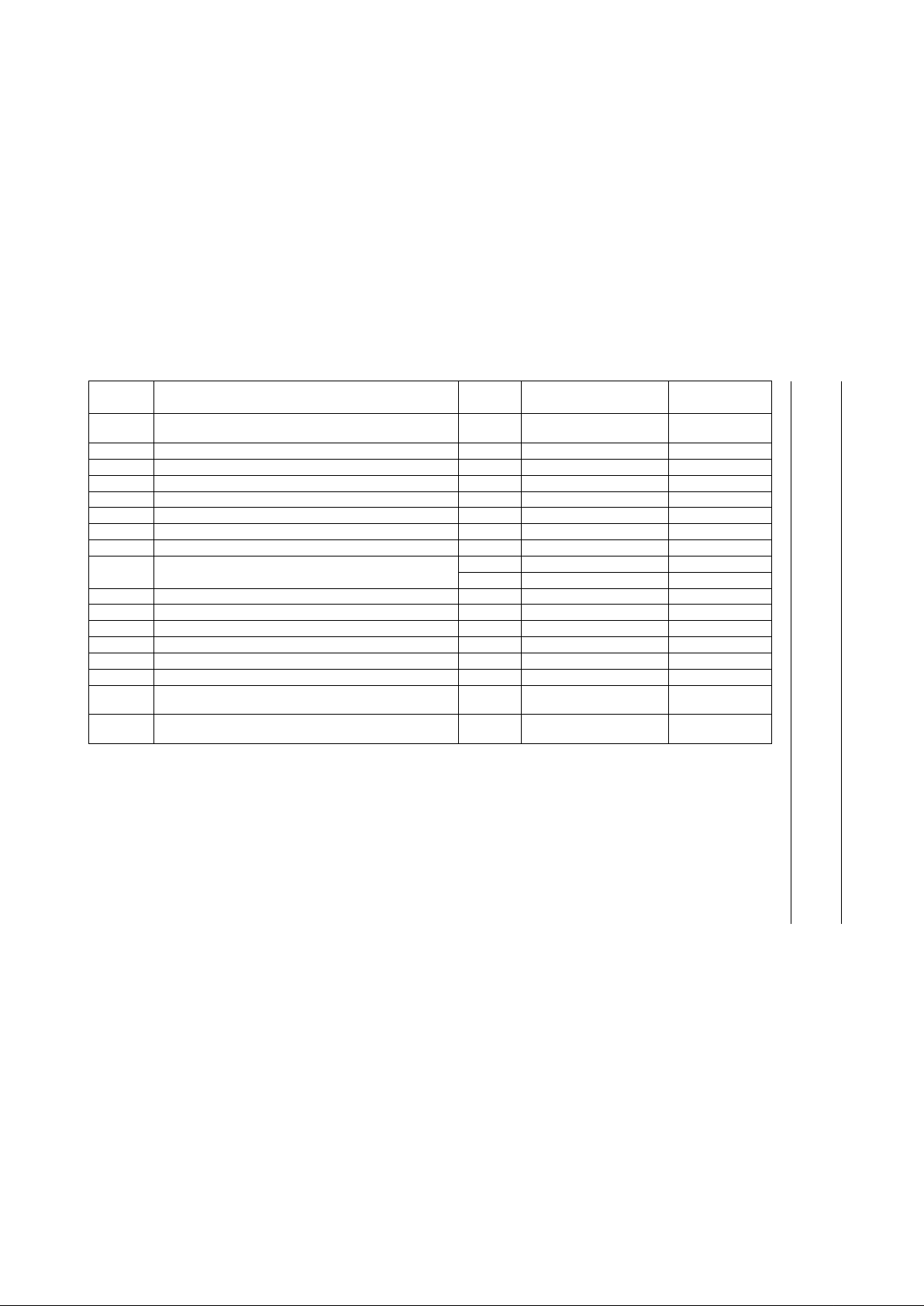

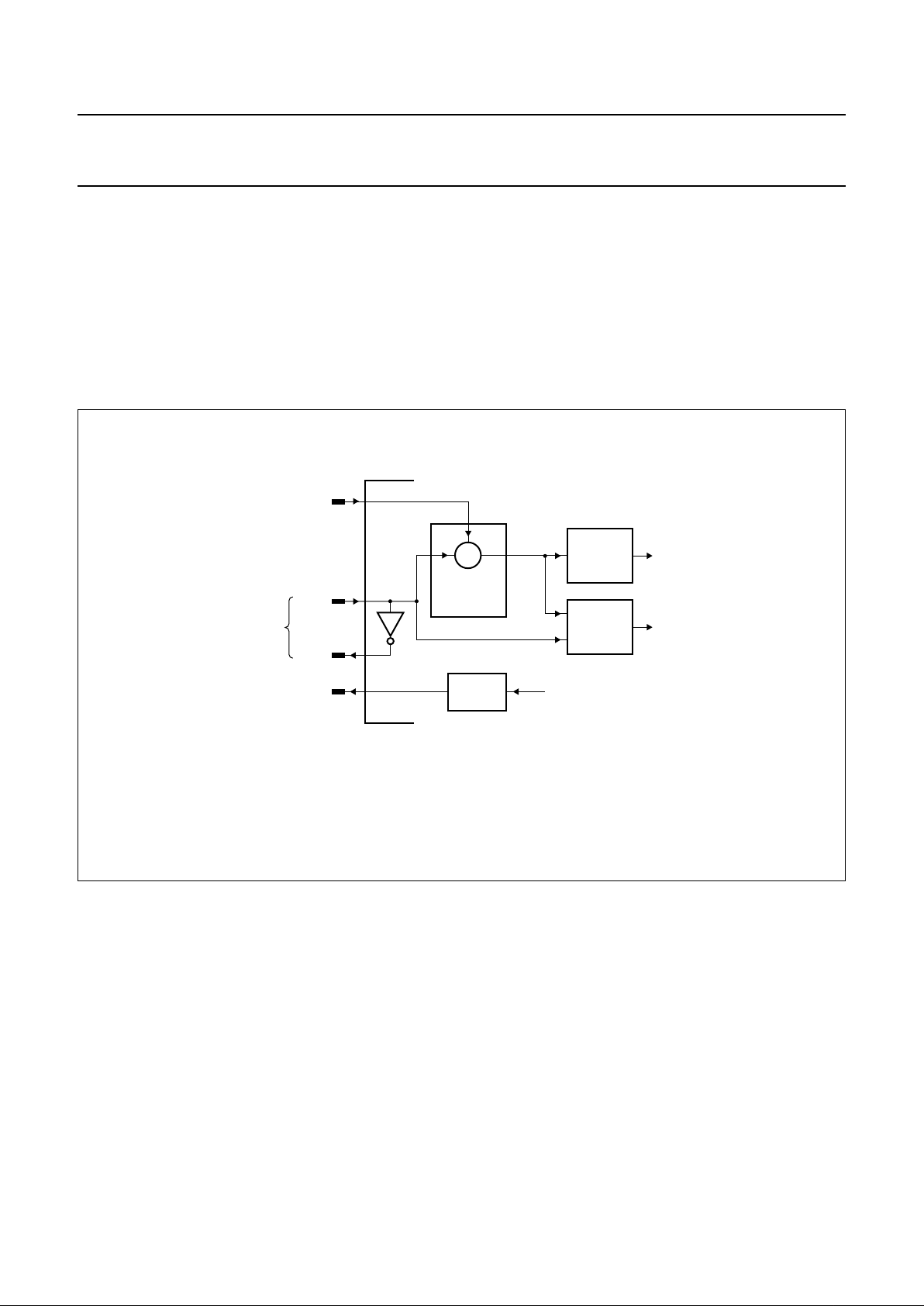

6 PINNING INFORMATION

6.1 Pinning

Fig.2 Pin configuration.

handbook, full pagewidth

SAA7392

MGR792

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

WREFLO

WREFHI

WREFMID

V

SSA1

V

DDA1

WIN

VREF

IREF

n.c.

HREFHI

HREFLO

AGCREF

HIN

HREFMID

V

DDA2

V

SSA2

TEST1

TEST2

V

SSD

V

DDE

20

60

59

58

57

56

55

54

53

52

51

50

49

48

47

46

45

44

43

42

41

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

80

79

78

77

76

75

74

73

72

71

70

69

68

67

66

65

64

63

62

61

MEAS1

EFMDATA

XEFM

LASERON

V

DDDVSSD

MOTO1

MOTO2/T3

V

DDEVSSD

T1

T2

CFLG

SFSY

RCK

SUB

DATAI

V

DDEVSSD

BCLK

XTLI

XTLO

OTD

MUXSWI

W441

ATIPSYC

PANIC

PORE

CL1

V

DDD

V

SSD

SCL

SDA

INT

DA7

DA6

DA5

DA4

DA3

DA2

WCLK

DATAO

FLAG

SYNC

EBUOUT

V4

STOPCK

V

DDD

V

SSD

PCAin

CSi

V

DDD

V

SSD

ALE

RDi

WRi

V

DDE

V

SSD

DA0

DA1

Page 6

2000 Mar 21 6

Philips Semiconductors Preliminary specification

Channel encoder/decoder CDR60 SAA7392

6.2 Pin description

Table 1 LQFP80 package; note 1

SYMBOL PIN TYPE DESCRIPTION

WREFLO 1 O wobble ADC analog reference voltage

WREFHI 2 O wobble ADC analog reference voltage

WREFMID 3 O wobble ADC analog reference voltage

V

SSA1

4 supply analog ground

V

DDA1

5 supply 3 V analog supply voltage 1; note 2

WIN 6 I wobble analog input

VREF 7 O analog voltage reference

IREF 8 O analog current reference

n.c. 9 − not connected

HREFHI 10 O HFADC analog reference voltage

HREFLO 11 O HF ADC analog reference voltage

AGCREF 12 I AGC analog reference voltage

HIN 13 I HF analog data input

HREFMID 14 O HFADC analog reference voltage

V

DDA2

15 supply 3 V analog supply voltage 2; note 2

V

SSA2

16 supply analog ground

TEST1 17 I test input 1

TEST2 18 I test input 2

V

SSD

19, 43, 62, 71 supply output driver ground

V

DDE

20 supply output driver 3 V supply voltage

XTLI 21 I crystal oscillator input

XTLO 22 O crystal oscillator output

OTD 23 I off track detect input

MUXSWI 24 I clock multiplier enable

W441 25 O wobble 44.1 kHz clock output

ATIPSYC 26 O ATIPSync output

PANIC 27 I laser low power (LLP)

PORE 28 I power-on reset

CL1 29 O divided clock output

V

DDD

30, 49, 53, 76 supply core and pad ring 3 V supply voltage; note 2

V

SSD

31, 48, 52, 75 supply core and pad ring ground

SCL 32 I sub-CPU clock

SDA 33 I/O bidirectional sub-CPU data

INT 34 O sub-CPU interrupt

DA7 35 I/O bidirectional sub-CPU parallel data bus

DA6 36 I/O bidirectional sub-CPU parallel data bus

DA5 37 I/O bidirectional sub-CPU parallel data bus

DA4 38 I/O bidirectional sub-CPU parallel data bus

Page 7

2000 Mar 21 7

Philips Semiconductors Preliminary specification

Channel encoder/decoder CDR60 SAA7392

Notes

1. No signal may be applied to this device when it is not powered.

2. The analog and digital supply pins (V

DDA

and V

DDD

) must be connected to the same external supply.

DA3 39 I/O bidirectional sub-CPU parallel data bus

DA2 40 I/O bidirectional sub-CPU parallel data bus

DA1 41 I/O bidirectional sub-CPU parallel data bus

DA0 42 I/O bidirectional sub-CPU parallel data bus

V

DDE

44 supply output driver 3 V supply voltage

WRi 45 I sub-CPU write enable; active LOW

RDi 46 I sub-CPU read enable; active LOW

ALE 47 I sub-CPU address latch enable

CSi 50 I sub-CPU chip select

PCAin 51 I PCA input

STOPCK 54 O stop clock output

V4 55 O serial subcode output

EBUOUT 56 O digital output

SYNC 57 O I

2

S sector sync output

FLAG 58 O I

2

S correction flag

DATAO 59 O I

2

S data output

WCLK 60 I/O bidirectional I

2

S word clock

BCLK 61 I/O bidirectional I

2

S bit clock

V

DDE

63 supply output driver 3 V supply voltage

DATAI 64 I I

2

S data input

SUB 65 I EIAJ subcode data

RCK 66 O EIAJ subcode clock

SFSY 67 I EIAJ subcode sync

CFLG 68 O correction statistics; open-drain

T2 69 I tacho control input 2

T1 70 I tacho control input 1

V

DDE

72 supply output driver 3 V supply voltage

MOTO2/T3 73 I/O motor output 2/tacho input 3

MOTO1 74 O motor control output 1

LASERON 77 O laser write control

XEFM 78 O EFM clock output

EFMDATA 79 O EFM data output

MEAS1 80 O front end telemetry; open-drain

SYMBOL PIN TYPE DESCRIPTION

Page 8

2000 Mar 21 8

Philips Semiconductors Preliminary specification

Channel encoder/decoder CDR60 SAA7392

7 FUNCTIONAL DESCRIPTION

7.1 Microprocessor interfaces

The SAA7392 is programmed via two independent

microprocessor interfaces:

• Serial I2C-bus

– SDA=I2C-bus data

– SCL = I2C-bus clock

–I2C-bus write address = 3EH

–I2C-bus read address = 3FH.

• Parallel 80C51 compatible

– DA(7:0) = address/data bus

– ALE = address latch enable; latches the address

information on the bus

– WRi = active LOW write signal; write to SAA7392

– RDi = active LOW read signal; read from SAA7392

– CSi = chip select signal; gates the RDi and WRi

signals.

7.1.1 S

ERIAL I

2

C-BUS INTERFACE

Data is transferred over the interface in single bytes, via

write data or read data commands.

The sequence for a write data command is as follows:

1. Send START condition

2. Send address 3EH (write)

3. Write register address byte

4. Write data byte

5. Send STOP condition.

The sequence for a read data command is as follows:

1. Send START condition

2. Send address 3EH (write)

3. Write status register address byte

4. Send STOP condition

5. Send address 3FH (read)

6. Read data byte

7. Send STOP condition.

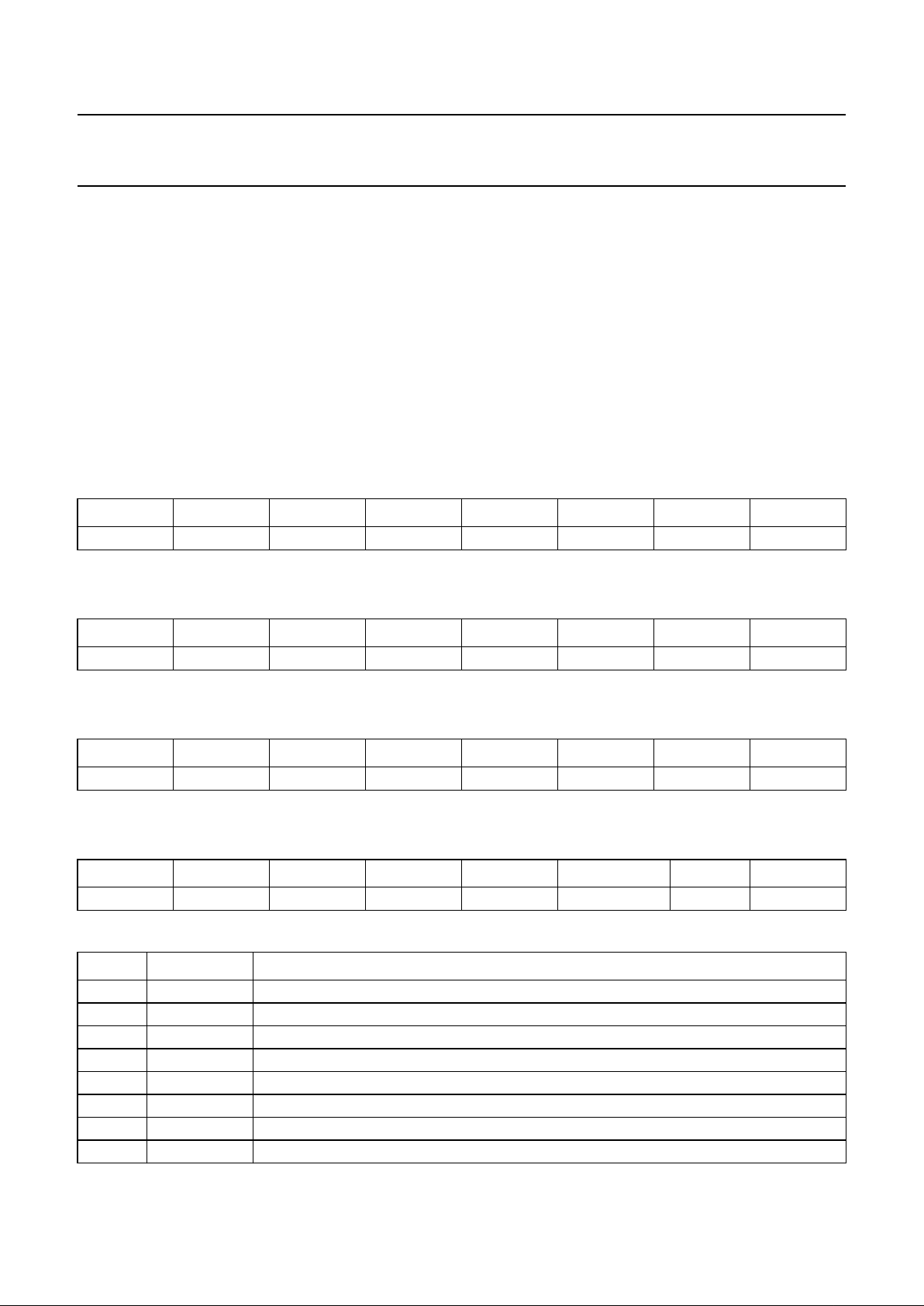

7.1.2 P

ARALLEL INTERFACE

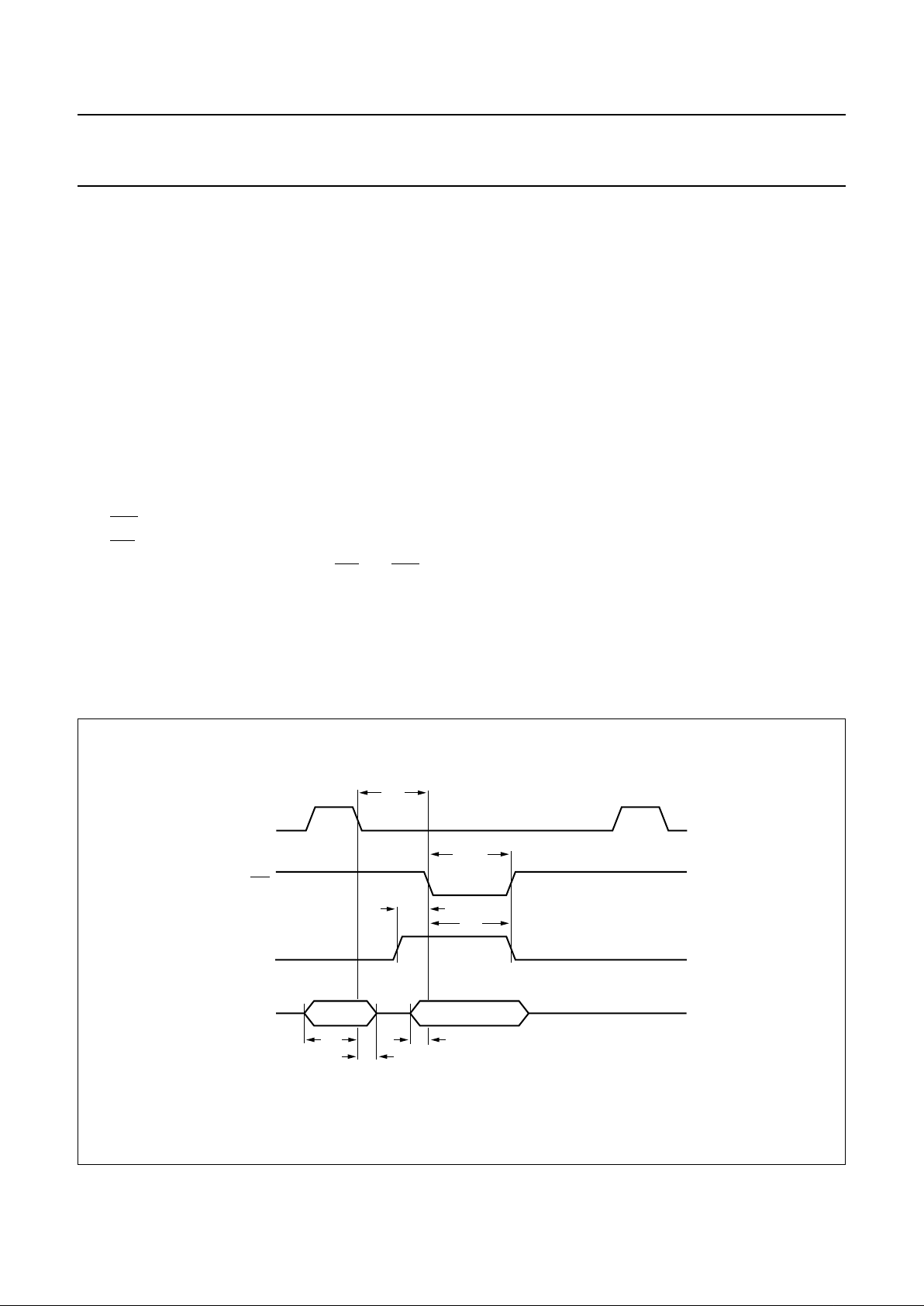

The parallelinterface hasa multiplexed address/databus.

Information can be written to or read from the SAA7392

using the protocols shown inFigs 3 and 4; specific timings

are shownin Table 2. Notethat only thelower six address

bits are decoded; so writing to address 40H would have

the same effect as writing to address 00H.

handbook, full pagewidth

MGR793

ALE

WRi

CSi

DA0 to DA7

address (0:7)

IN

data (0:7)

IN

t

d1

t

WRiL

t

h1

t

d2

t

su2

t

su1

t

h2

Fig.3 Microprocessor write protocol.

Page 9

2000 Mar 21 9

Philips Semiconductors Preliminary specification

Channel encoder/decoder CDR60 SAA7392

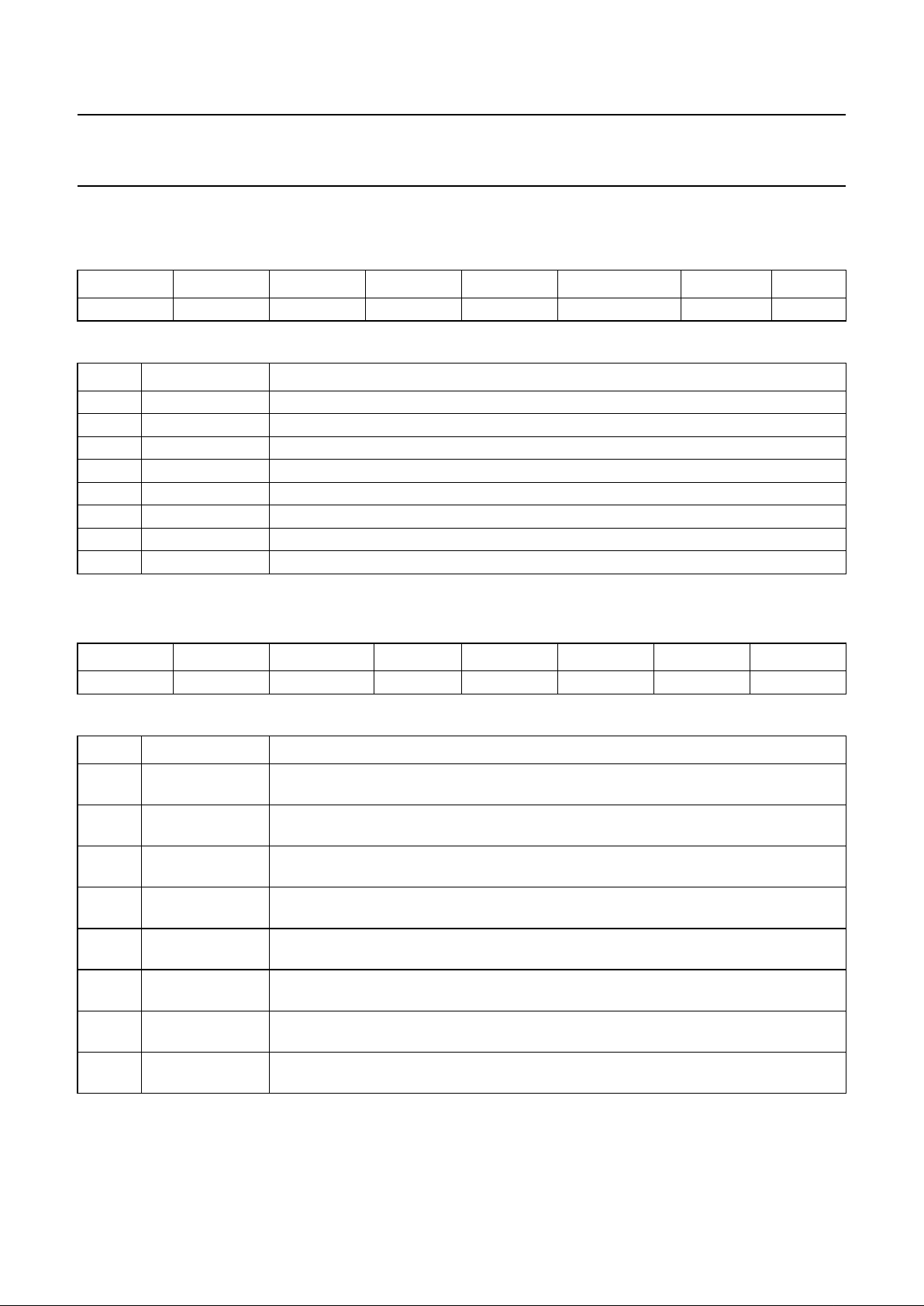

handbook, full pagewidth

MGR794

ALE

RDi

CSi

DA0 to DA7

address (0:7)

IN

data (0:7)

OUT

t

d1

RDi

L

t

h1

t

d2

t

su1

t

h2

Fig.4 Microprocessor read protocol.

Table 2 Parallel interface timing

Note

1. T

clk

is the system clock period.

SYMBOL DESCRIPTION MIN.

(1)

MAX.

(1)

UNIT

t

d1

Delay ALE falling to RDi/WRi falling. 17 − ns

t

d2

Delay CSi rising to RDi/WRi falling. 17 − ns

t

h1

CSi hold time after RDi/WRi falling. 2T

clk

+17 − ns

t

su1

Address setup time before ALE falling. 17 − ns

t

h2

Address hold time after ALE falling. 17 − ns

t

su2

Data setup time before WRi falling. 0 − ns

t

h3

Data hold time after WRi falling. 2T

clk

+17 − ns

t

WRiL

WRi LOW time. 1T

clk

+17 − ns

t

h4

ALE LOW hold time after WRi LOW. 3T

clk

+17 − ns

t

d3

Delay data valid after RDi LOW. − 3T

clk

+17 ns

t

d4

Delay RDi HIGH to data out high-impedance. − 17 ns

t

RDiL

RDi LOW time. 3T

clk

+ 128 − ns

Page 10

2000 Mar 21 10

Philips Semiconductors Preliminary specification

Channel encoder/decoder CDR60 SAA7392

This text is here in white to force landscape pages to be rotated correctly when browsing through the pdf in the Acrobat reader.This text is here in

_white to forcelandscape pages to be rotated correctly when browsing through the pdf in the Acrobatreader.This text is here inThis text is here in

white to force landscape pagesto berotated correctlywhen browsing throughthe pdfin theAcrobat reader. whiteto forcelandscape pagesto be ...

7.2 Register map

Table 3 Register map

ADDRESS

(HEX)

REGISTER NAME TYPE FUNCTION

BLOCK

RESPONSIBLE

00 PLL Lock Select Register (PLLLock) Write PLL lock select bit detector

Read 8-bit PLL frequency bit detector

01 PLL Bandwidth Select Register (PLLSet) Write PLL bandwidth select bit detector

Read 8-bit asymmetry signal bit detector

02 PLL Frequency Preset Register (PLLFreq) Write PLL frequency preset bit detector

Read 8-bit jitter signal bit detector

03 PLL Equalizer Preset Register (PLLEqu) Write PLL equalizer preset bit detector

Read Observe internal lock flags bit detector

04 PLL Lock Aid2 Preset Register (PLLFMeas) Write PLL lock aid 2 preset bit detector

05 I2S Output Register 1 (Output1) Write I2S output 1 serial out

06 I

2

S Output Register 2 (Output2) Write I2S output 2 serial out

07 I

2

S Output Register 3 (Output3) Write I2S output 3 serial out

08 Semaphore Register 1 (Sema1) Write/Read Inter-microprocessor

communication

sub-CPU

09 Semaphore Register 2 (Sema2) Write/Read Inter-microprocessor

communication

sub-CPU

0A Semaphore Register 3 (Sema3) Write/Read Inter-microprocessor

communication

sub-CPU

0B Interrupt Enable Register (IntEn) Write Enable interrupts sub-CPU

0B Status Register (Status) Read Interrupt status sub-CPU

0C Motor Control Register1 (Motor1) Write Frequency set-point motor/tacho

Read 8-bit slicer compensation

value

bit detector

0D Motor Mode Select Register2 (Motor2) Write Motor coefficient preset motor/tacho

Read Opening of eye pattern bit detector

0E Motor Control Register 3 (Motor3) Write Motor integrator preset motor/tacho

Read Read back of motor frequency motor/tacho

0F Motor Control Register 4 (Motor4) Write Motor control motor/tacho

10 Motor Control Register 5 (Motor5) Read/Write Motor integrator value motor/tacho

11 Motor Control Register 6 (Motor6) Read/Write Motor integrator value motor/tacho

Page 11

2000 Mar 21 11

Philips Semiconductors Preliminary specification

Channel encoder/decoder CDR60 SAA7392

This text is here in white to force landscape pages to be rotated correctly when browsing through the pdf in the Acrobat reader.This text is here in

_white to forcelandscape pages to be rotated correctly when browsing through the pdf in the Acrobatreader.This text is here inThis text is here in

white to force landscape pagesto berotated correctlywhen browsing throughthe pdfin theAcrobat reader. whiteto forcelandscape pagesto be ...

12 Clock Preset Register (ClockPre) Write Clock control clock generator

Read Status of Q-channel subcode encoder/decoder

13 Decoder Mode Select Register (DecoMode) Write Decoder mode select encoder/decoder

Read Q-channel subcode data encoder/decoder

14 Subcode Read End Register (SubReadEnd) Read Subcode data read finished encoder/decoder

15 Analog Settings Register 1 (AnaSet1) Write Analog control analog

Read C1 frames in FIFO + offset encoder/decoder

16 Viterbi Detector Settings Register (VitSet) Write Viterbi detector control bit detector

17 Tacho Gain Setting Register (Tacho1) Write Tacho gain setting motor/tacho

18 Tacho Trip Setting Register (Tacho2) Write Tacho trip setting motor/tacho

19 Tacho Control Register (Tacho3) Write Tacho control settings motor/tacho

1B Soft Reset Register (SoftReset) Write Sub-block reset sub-CPU

1D Motor Control Register7 (Motor7) Write Control coefficients select motor/tacho

1E Input Configuration Register (InputConfig) Write EBU clock frequency and

input format

serial input

20 Status Register 2 (Status2) Read/Write Interrupt status sub-CPU

21 Interrupt Enable Register 2 (IntEn2) Write Enable interrupts sub-CPU

22 Subcode Preset Count Register (SubPresetCount) Write Preset count field subcode insert

Read Current count field subcode insert

23 Subcode Configuration Register 1 (SubConfig1) Write Subcode control subcode insert

24 Subcode Configuration Register 2 (SubConfig2) Read/Write Subcode control subcode insert

25 Subcode Start Data Register (SubStartData) Write Subcode control subcode insert

26 Subcode Data Register (SubData) Read/Write Subcode data subcode insert

27 Wobble Configuration Register1 (WobbleConfig1) Integrator and loop bandwidth Wobble processor

Window width ATIP syncs Wobble processor

28 Wobble Configuration Register2 (WobbleConfig2) Write Wobble PLL control Wobble processor

29 ATIP Status Register (ATIPStatus) Read ATIP status Wobble processor

2A Wobble Frequency Register 1 (WobbleFreq1) Read/Write 8 MSBs of PLL frequency Wobble processor

2B Wobble Frequency Register 2 (WobbleFreq2) Read/Write 8 LSBs of PLL frequency Wobble processor

2C ATIP Data Register (ATIPData) Read ATIP data Wobble processor

ADDRESS

(HEX)

REGISTER NAME TYPE FUNCTION

BLOCK

RESPONSIBLE

Page 12

2000 Mar 21 12

Philips Semiconductors Preliminary specification

Channel encoder/decoder CDR60 SAA7392

This text is here in white to force landscape pages to be rotated correctly when browsing through the pdf in the Acrobat reader.This text is here in

_white to forcelandscape pages to be rotated correctly when browsing through the pdf in the Acrobatreader.This text is here inThis text is here in

white to force landscape pagesto berotated correctlywhen browsing throughthe pdfin theAcrobat reader. whiteto forcelandscape pagesto be ...

2D ATIP Data End Register (ATIPDataEnd) Read Least significant byte ATIP

data

Wobble processor

2E Wobble Peak Status Register (WobbleStatus) Read Peak value of wobble signal Wobble processor

30 Encode WriteOn Control Register (EncodeWContr) Read/Write Laser and data flow control encode control

31 Encode Start Offset Register (EncodeStartOffset) Write Start WriteOn flags delay encode control

32 Encode Stop Offset Register (EncodeStopOffset) Write Stop WriteOn flags delay encode control

33 Encode Offset Register (EncodeXOffset) Write 10-bit value for Xoffset encode control

34 EFM Clock Configuration Register 1 (EFMClockConf1) Write EFM clock control EFM clock generator

35 EFM Clock Configuration Register 2 (EFMClockConf2) Write EFM clock control EFM clock generator

36 EFM Clock Configuration Register 3 (EFMClockConf3) Write EFM clock control EFM clock generator

Read Integrator value EFM clock generator

37 EFM PLL Frequency Register (EFMPLLFreq) Read EFM PLL frequency EFM clock generator

37 EFM Clock Configuration Register 4 (EFMClockConf4) Write EFM clock control EFM clock generator

38 ATIP Error Register (ATER) Read Counter for ATIP CRC errors sub-CPU

39 C1 Block Error Register (C1BLER) Read Counter for C1 errors sub-CPU

3A C2 Block Error Register (C2BLER) Read Counter for C2 errors sub-CPU

3C EFM Preset Count Register (EFMPresetCount) Write EFM frame position for output EFM modulator

3D EFM Modulator Configuration Register (EFMModConfig) Write XEFM control and output data

format

EFM modulator

3E EFM Modulator Configuration Register 2 (EFMModConfig2) Write XEFM control and output data

format

EFM modulator

ADDRESS

(HEX)

REGISTER NAME TYPE FUNCTION

BLOCK

RESPONSIBLE

Page 13

2000 Mar 21 13

Philips Semiconductors Preliminary specification

Channel encoder/decoder CDR60 SAA7392

7.2.1 INTERRUPT PIN

The interrupt pin (INT) is the AND-OR-INVERT of the Status and Interrupt Enable Registers, i.e. INT will become active

when corresponding bits are set at the same time in the Status and Interrupt Enable Registers.

7.2.2 THE SEMAPHORE REGISTERS (SEMA1, SEMA2 AND SEMA3)

The Semaphore Registers are intended for inter-microprocessor communications. For example, microcontroller 1 can

writedata tomicrocontroller 2 viaSema1 andmicrocontroller 2 can writedata tomicrocontroller 1 viaSema2. TheStatus

Register ofthe SAA7392offers a mechanismso that both microcontrollers cansee when newdata hasbeen written and

whenit hasbeen readby lookingat thecontents ofthe Semaphore Registers. Version M3of theCDR60 canbe identified

by writingand reading register Sema3. In version M3,bit 1 of Sema3is always read as logic 0, whereas inother CDR60

versions this bit reads the same value as what was written to it before.

7.2.2.1 Semaphore Register 1 (Sema1)

Table 4 Semaphore Register 1 (address 08H) - READ/WRITE

7.2.2.2 Semaphore Register 2 (Sema2)

Table 5 Semaphore Register 2 (address 09H) - READ/WRITE

7.2.2.3 Semaphore Register 3 (Sema3)

Table 6 Semaphore Register 3 (address 0AH) - READ/WRITE

7.2.3 S

TATUS REGISTER (STATUS)

Table 7 Status Register (address 0BH) - READ

Table 8 Description of Status bits

76543210

Sema1.7 Sema1.6 Sema1.5 Sema1.4 Sema1.3 Sema1.2 Sema1.1 Sema1.0

76543210

Sema2.7 Sema2.6 Sema2.5 Sema2.4 Sema2.3 Sema2.2 Sema2.1 Sema2.0

76543210

Sema3.7 Sema3.6 Sema3.5 Sema3.4 Sema3.3 Sema3.2 Sema3.1 Sema3.0

76543 210

Sema1 Sema2 Sema3 LockIn HeaderVal MotorOverflow FIFOOv −

BIT SYMBOL DESCRIPTION

7 Sema1 If Sema1 = 1, change in register Sema1 has been detected. Reset if register Sema1 read.

6 Sema2 If Sema2 = 1, change in register Sema2 has been detected. Reset if register Sema2 read.

5 Sema3 If Sema3 = 1, change in register Sema3 has been detected. Reset if register Sema3 read.

4 LockIn If LockIn = 1, then channel data PLL in lock (not latched).

3 HeaderVal HeaderVal is set when new header/subcode is available; reset on reading SubReadEnd.

2 MotorOverflow If MotorOverflow = 1, then a motor overflow is occurring (not latched).

1 FIFOOv If FIFOOv = 1, then the FIFO has overflowed.

0 − This bit is reserved.

Page 14

2000 Mar 21 14

Philips Semiconductors Preliminary specification

Channel encoder/decoder CDR60 SAA7392

7.2.4 INTERRUPT ENABLE REGISTER (INTEN)

Table 9 Interrupt Enable Register (address 0BH) - WRITE

Table 10 Description of IntEn bits

7.2.5 S

TATUS REGISTER 2(STATUS2)

Table 11 Status Register 2 (address 20H) - READ/WRITE

Table 12 Description of Status2 bits

76543 2 10

Sema1En Sema2En Sema3En LockInEn HeaderValen MotorOverflowEn FIFOOvEn −

BIT SYMBOL DESCRIPTION

7 Sema1En If Sema1En = 1, then Semaphore Register 1 interrupt is enabled.

6 Sema2En If Sema2En = 1, then Semaphore Register 2 interrupt is enabled.

5 Sema3En If Sema3En = 1, then Semaphore Register 3 interrupt is enabled.

4 LockInEn If LockinEn = 1, then channel data PLL in lock interrupt is enabled.

3 HeaderValEn If HeaderValEn = 1, then new header/subcode available interrupt is enabled.

2 MotorOverflowEn If MotorOverflowEn = 1, then motor overflow interrupt is enabled.

1 FIFOOvEn If FIFOOvEn = 1, then FIFO overflow interrupt is enabled.

0 − This bit is reserved.

76 543210

BankSwitch SyncError DataNotValid QSync ATIPSync LaserOn LaserOff XErrorLarge

BIT SYMBOL DESCRIPTION

7 BankSwitch When set a ‘Bank switch’in the subcode insert blockhas occurred; reset when a logic 1

is written to this bit.

6 SyncError When set synchronisation with PLUM on subcode transfer has failed; reset when a

logic 1 is written to this bit.

5 DataNotValid When set an under-run on subcode transfer with PLUM has occurred; reset when a

logic 1 is written to this bit.

4 QSync When set a Q-channel subcode sync has been written to disc; reset when a logic 1 is

written to this bit.

3 ATIPSync When set sync has been found in the ATIP channel; reset when a logic 1 is written to

this bit.

2 LaserOn When set a rising edge of the internal LaserOn signal has occurred; reset when a

logic 1 is written to this bit.

1 LaserOff When set a falling edge of the internal LaserOn signal has occurred; reset when a

logic 1 is written to this bit.

0 XErrorLarge When set the offset between QSync and ATIPSync is more than 2 EFM frames different

from the programmed value.

Page 15

2000 Mar 21 15

Philips Semiconductors Preliminary specification

Channel encoder/decoder CDR60 SAA7392

7.2.6 INTERRUPT ENABLE REGISTER 2(INTEN2)

Table 13 Interrupt Enable Register 2 (address 21H) - WRITE

Table 14 Description of IntEn2 bits

7.2.7 S

OFT RESET REGISTER (SOFTRESET)

Table 15 Soft Reset Register (address 1BH) - WRITE

Table 16 Description of SoftReset bits

76 543210

BankSwitchEnSyncErrorEn DataNotValidEnQSyncEn ATIPSyncEn LaserOnEn LaserOffEn XErrorLarge

En

BIT SYMBOL DESCRIPTION

7 BankSwitchEnIf BankSwitchEn = 1, then BankSwitch interrupt is enabled.

6 SyncErrorEn If SyncErrorEn = 1, then SyncError interrupt is enabled.

5 DataNotVali

dEn

If DataNotValidEn= 1, then DataNotValid interrupt is enabled.

4 QSyncEn If QSyncEn = 1, then QSync interrupt is enabled.

3 ATIPSyncEn If ATIPSyncEn = 1, then ATIPSync interrupt is enabled.

2 LaserOnEn If LaserOnEn = 1, then LaserOn interrupt is enabled.

1 LaserOffEn If LaserOffEn = 1, then LaserOff interrupt is enabled.

0 XErrorLargeEnIf XerrorLarge = 1, then XErrorLarge interrupt is enabled.

76543210

−−−−−−−SReset1

BIT SYMBOL DESCRIPTION

7to1 − These 7 bits are reserved.

0 SReset1 When set, synchronisation with PLUM on subcode transfer has failed; reset when

a logic 1 is written to this bit (Status2).

This bit is an active HIGH reset to the following blocks: Encoder/decoder, EFM

modulator, Encode control block, Serial input/output block and Encode subcode insert

block. The clock control, EFM PLL, tacho, motor interface and wobble interface remain

running.

Soft reset will reset the following registers: EFMPresetCount, EFMModulateConfig,

EFMModulateConfig2, EncodeXOffset, EncodeWriteControl, EncodeStartOffset,

EncodeStopOffset, SubPresetCount, SubConfig1, Subconfig2,SubStartData, SubData,

InputConfig, DecoMode, Output1, Output2 and Output3.

A soft reset is mandatory in the following cases:

1. After programming the BCLK clock

2. When switching from encode to decode

3. When switching from decode to encode.

Page 16

2000 Mar 21 16

Philips Semiconductors Preliminary specification

Channel encoder/decoder CDR60 SAA7392

7.3 System clocks

The principleclocks used inthe SAA7392 are derived from the crystaloscillator input pinXTLI (alternatively, anexternal

clock can be connected to this pin). These clocks are the system clock (also used as the ADC clock) and the I2S output

bit clock (BCLK).

The system clock (f

clk

) defines the maximumoperational channel rate for the device. The maximum EFM channel clock

is twice the system clock, for CD it is equivalent tosystem clock/(4.3 × 106) which is approximately 11.5 × CDROM for a

25 MHz system clock.

The other clock in the system is the channel data clock, this is recovered by the front-end bit recovery PLL.

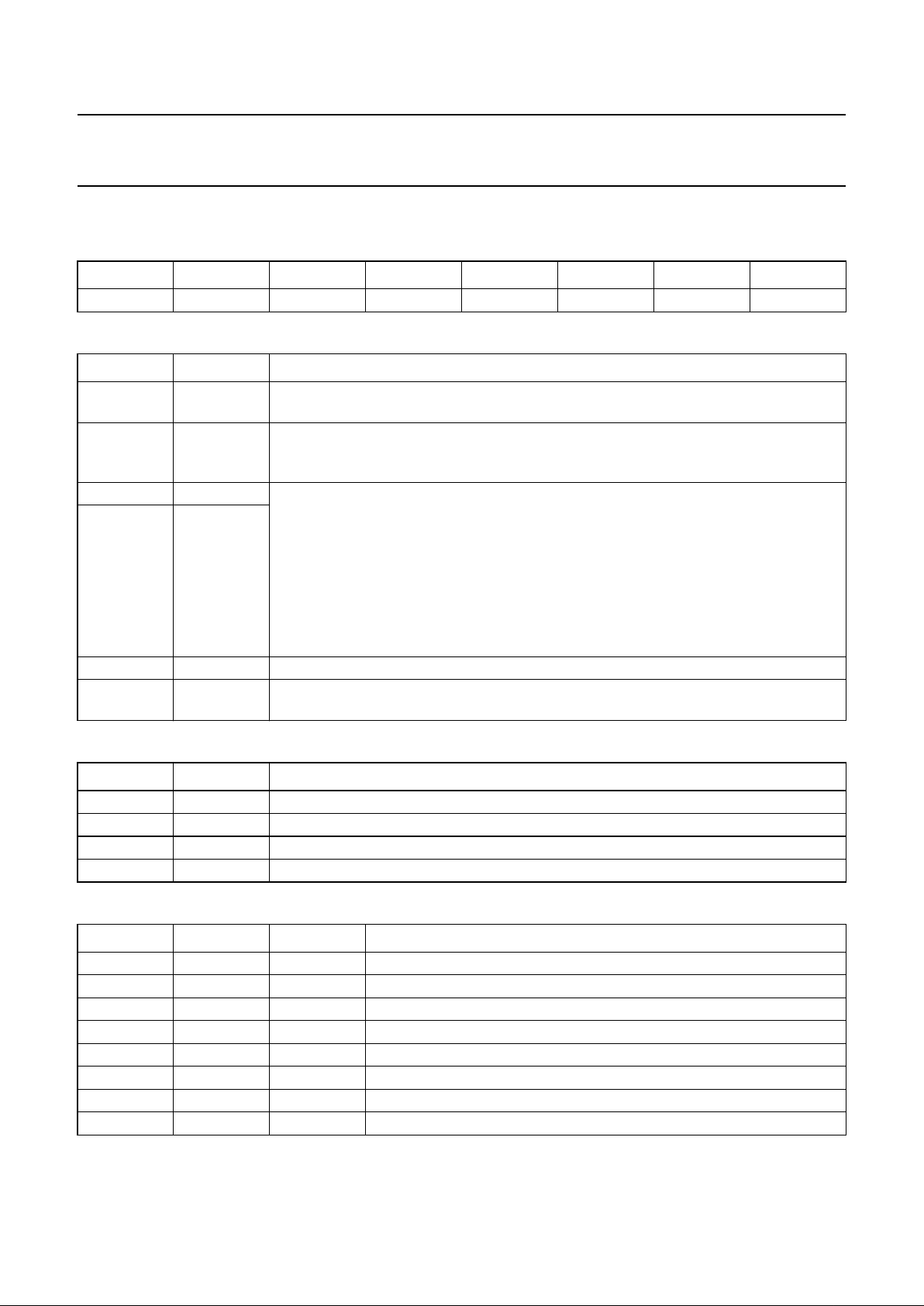

Fig.5 System clock generator.

handbook, full pagewidth

MGR795

MUXSWI

XTLI

XTLO

CL1

system clock

SYSTEM

CLOCK

DIVIDER

BCLK

XTLI

M × XTLI

BIT

CLOCK

DIVIDER

system clock

CL1

DIVIDER

CLOCK

(1)

MULTIPLIER

×

crystal

oscillator

(1) M = 1 if MUXSWI is LOW; M = 8 if MUXSWI is HIGH.

Page 17

2000 Mar 21 17

Philips Semiconductors Preliminary specification

Channel encoder/decoder CDR60 SAA7392

7.3.1 CLOCK PRESET REGISTER (CLOCKPRE)

Table 17 Clock Preset Register (address 12H) - WRITE

Table 18 Description of ClockPre bits

Table 19 Selection of system clock frequency

Table 20 Selection of BCLK frequency

76543210

CL1Div GateBClk Div.1 Div.0 Mux2 Div2.2 Div2.1 Div2.0

BIT SYMBOL DESCRIPTION

7 CL1Div If CL1Div = 0, then CL1 output frequency is

1

⁄3f

clk

. If CL1Div = 1, then CL1 output

frequency is1⁄2f

clk

.

6 GateBClk If GateBClk = 0, then I

2

S output bit clock gating is disabled. If GateBClk = 1, then I2S

output bit clock gating enabled, BCLK is output, clock is automatically stopped if FIFO

underflows (this is known as Flow control mode).

5 Div.1 These 2 bits select the system clock frequency (f

clk

); see Table 19. This frequency

should be programmed for the expected disc channel rate (e.g. 4.33 MHz for 1 × CD)

within the following constraints:

In this clock range, reliable bit detection is possible. All data found will be written to the

FIFO. It is the responsibility of the user to select system clock values so that the FIFO

performance is controlled.

4 Div.0

3 Mux2 If Mux2 = 0, then N (bit clock divider pre-scaler) = 1. If Mux2 = 1, then N = M.

2 to 0 Div2<2:0> These 3 bits select the BCLK frequency (f

BCLK

); see Table 20. It is the responsibility of

the user to select BCLK values so that the FIFO performance is controlled.

Div.1 Div.0 SYSTEM CLOCK FREQUENCY (f

clk

)

00M×f

XTLI

0 1 0.5 × M × f

XTLI

1 0 0.25 × M × f

XTLI

1 1 0.125 × M × f

XTLI

Div2.1 Div2.1 Div2.0 BCLK FREQUENCY (f

BCLK

)

000N×f

XTLI

001N×f

XTLI

010

1

/

2

(N × f

XTLI

)

011

1

/

3

(N × f

XTLI

)

100

1

/

4

(N × f

XTLI

)

101

1

/

6

(N × f

XTLI

)

110

1

/

8

(N × f

XTLI

)

111

1

/

12

(N × f

XTLI

)

Channel rate

2

----------------------------------

f

clk

4 Channel rate×<<

Page 18

2000 Mar 21 18

Philips Semiconductors Preliminary specification

Channel encoder/decoder CDR60 SAA7392

7.4 HF analog front-end

The HF ADC in the SAA7392 encodes the EFM high

frequency signal from the disc light pen assembly. These

signals are pre-processed, externally to the SAA7392, by

either AEGER-2 or a DALAS equivalent. The dynamic

range of the ADC is optimized by the inclusion of an

AC coupled AGC function under digital control.

In order to make use of the whole digital front-end

resolution, the output of the gain control amplifier should

constantly deliver 1.4 V

(p-p)

output signal. The gain range

ofthe ADC isapproximately14 dB, with32 steps. Thegain

control for the variable gain amplifier is controlled by an

on-chip digital gaincontrol block (AGC). This blockallows

for both automatic and microprocessor gain control. The

gain control block will detect ADC extreme conditions

(00H or FFH outputs); on these values the gain control

block will decrement the gain. If no extreme codes occur

the gain is incremented.

7.4.1 FIXED GAIN

Control of the gain is as follows:

1. Writing XX1X XXXX to the Anaset1 register

(address 15H) increases the AGC gain by 1.1 dB

2. Writing XX0X XXXX to the AnaSet1 register

(address 15H) decreases the AGC gain by 1.1 dB

3. Instructions to increment/decrement gain are ignored

when the AGC gain limits of −4/+12 dB are reached.

7.4.2 AUTOMATIC GAIN CONTROL (AGC)

The gain of theAGC cellis adjusteduntil the analog signal

at the ADC input extends over the complete range of

the ADC.Detection ofthis conditionis in thedigital domain

where the maximum and minimum ADC codes are

measured. The dynamics of the AGC system are as

follows.

1. If the ADC output codes are not full scale (i.e.

000 0000 and 111 11111) the AGC gain is

incremented in 1.1 dB steps with a time constant of

1000/n µs, where n is the over-speed factor i.e. n = 1

for basic audio CD.

2. When full scale is detected at the output of the ADC

the AGC gain is fixed provided that full scale is

maintained and clipping does not occur for greater

than 20% of the time.

3. If clipping occurs for more than 20% of the time, then

the AGC gain is reduced in 1.1 dB steps with a time

constant of 60/n µs.

The ADC and AGC electrical characteristics are specified

in Chapter 9.

7.4.3 ANALOG SETTINGS REGISTER 1(ANASET1)

Table 21 Analog Settings Register 1 (address 15H) - WRITE

Table 22 Description of AnaSet1 bits

76543210

GainControl MaxGain StepUp StepDown PowerDown −−−

BIT SYMBOL DESCRIPTION

7 GainControl If GainControl = 0, then gain control is in Hold mode. If GainControl = 1, then automatic

gain control is on.

6 MaxGain If MaxGain = 0, then there is no gain limit. If MaxGain = 1, then the maximum gain is

7.66 dB.

5 StepUp If StepUp = 1, then step up gain by one LSB.

4 StepDown If StepDown = 1, then step down gain by one LSB.

3 PowerDown If PowerDown = 0, then analog blocks are powered up. If PowerDown = 1, then analog

blocks are powered down.

2to0 − These 3 bits are reserved and must be set to a logic 0s.

Page 19

2000 Mar 21 19

Philips Semiconductors Preliminary specification

Channel encoder/decoder CDR60 SAA7392

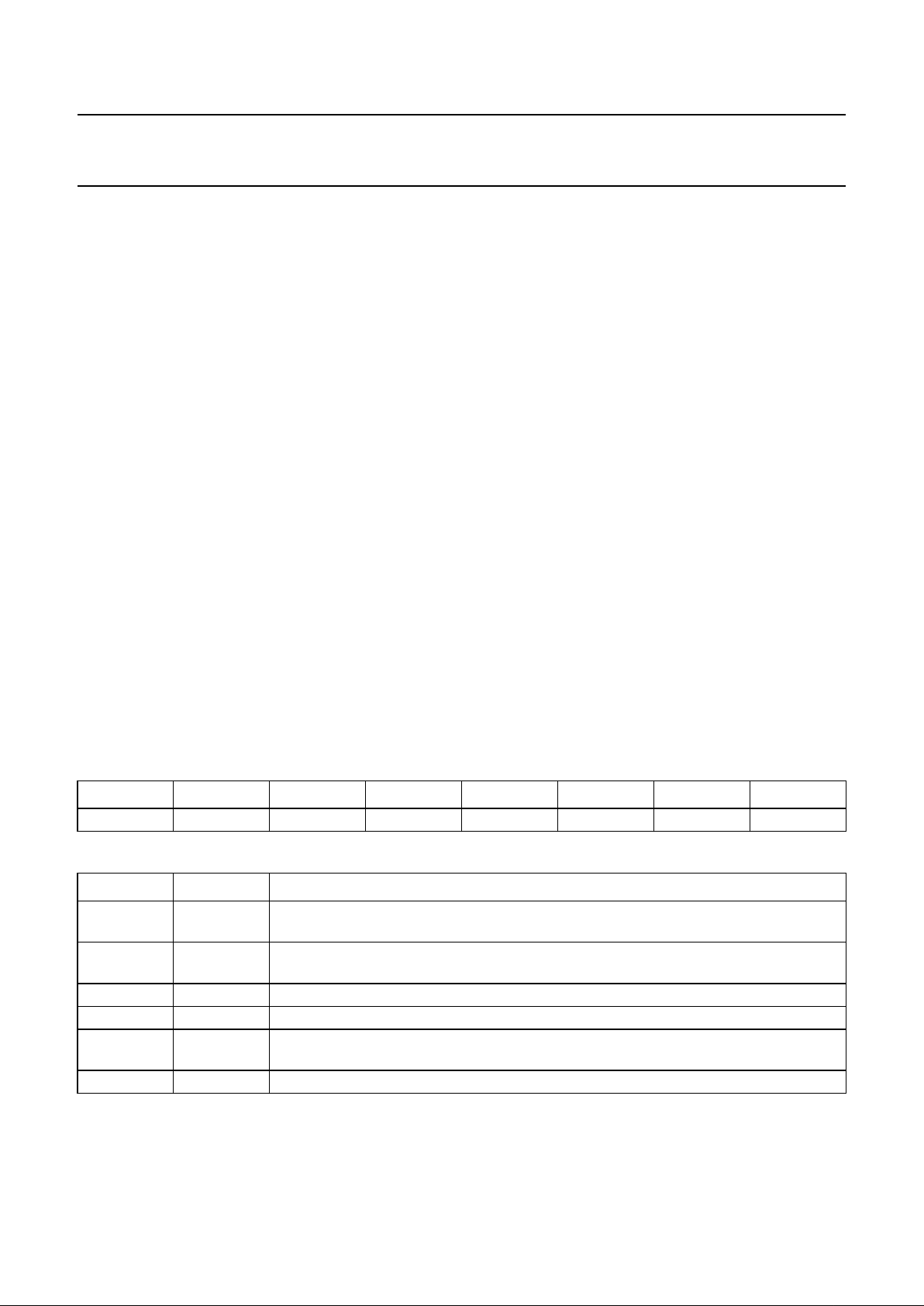

7.5 Bit recovery

The bit recovery block (shown in Fig.6) contains the slice

levelcircuitry, anoise filtertolimit theHF-EFMsignal noise

contribution, an adaptive slicer circuit and a digital PLL.

These blocks can be controlled via the microprocessor.

The channel rate should always obey the following

constraints:

• It should be less than 2 × the system clock

• It should be greater than 0.25 × the system clock.

In this clock range reliable bit clock detection is possible.

All data found will be written to the FIFO. It is the

responsibility ofthe user toselect BCLK and system clock

values so that the FIFO operation is controlled.

The digital noise filter runs on the PLL bit clock and limits

the bandwidthof the incomingsignal to 0.25 ofthe PLL bit

clock frequency. The characteristics of the filter are:

• Passband: 0 to 0.22 f

b

• Stopband: 0.28 fb to (f

clk

− 0.28 fb)

• Rejection: −28 dB.

The slice level determination circuit compensates the

incoming signalasymmetry component. Thebandwidth of

this circuit is programmable via register PLLSet.

A programmable (one tap presetable, asymmetrical)

equaliser is used in the bit detection circuit. The first and

last tap settings are different. Possible tap values are

settable via register PLLEqu.

The advanced detector has two extra detection circuits

(adaptive slicer and run length 2 push-back) which are

controlled via the VitSet register, that allow improved

margin in the bit detector.

The adaptive slicer does a second stage slice operation;

thebandwidth ishigherthan thefirst slicer. Itcan beturned

on/off via the VitSet register.

If the advanced detector is switched on all run length 2

symbols are pushed back to run length 3. The circuit will

determine thetransition that was most likely to bein error,

and shift the transition on that edge.

Fig.6 Block diagram of bit recovery block.

handbook, full pagewidth

MGR796

+

−

GAIN CONTROLLED

AMPLIFIER

+

MEAS1

clocked on PLL clock

MULTIPLEXER

jitter value

PLL frequency

slice level

RMS JITTER

MEASUREMENT

VITERBI

DETECTOR

DIGITAL

EQUALIZER

NOISE

FILTER

ADC

ZERO TRANS

DETECTOR

SLICE LEVEL

DETERMINE

GAIN CONTROL

BLOCK

DIGITAL

PLL

HIN

Page 20

2000 Mar 21 20

Philips Semiconductors Preliminary specification

Channel encoder/decoder CDR60 SAA7392

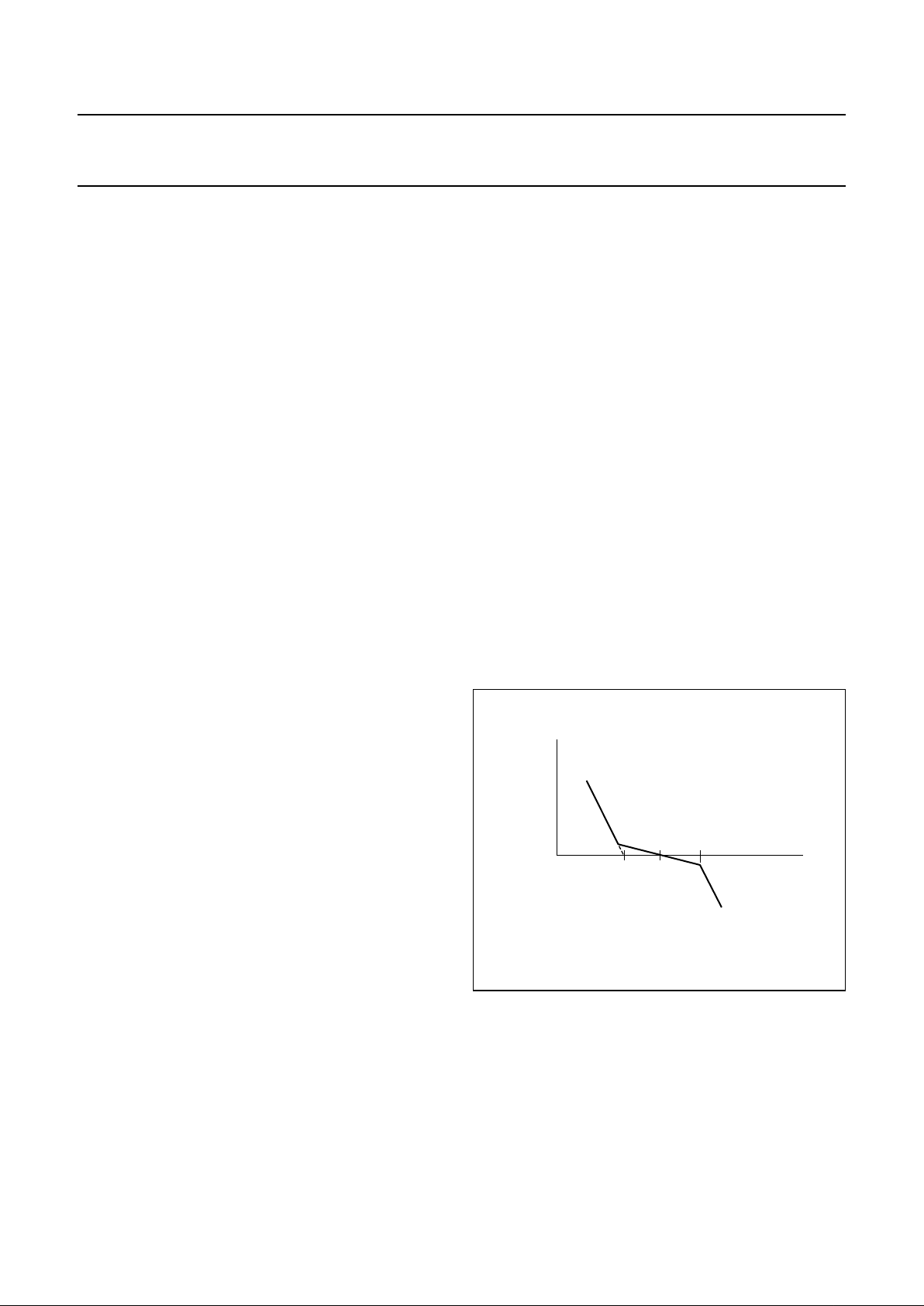

7.5.1 DIGITAL PLL

The digital PLL will recover the channel bit clock. As the

capturerange ofthe PLLitselfis limited,lockdetectors and

2 capture aids are present. In total three different PLL

operation modes exist: In-lock, Inner-lock aid and

Outer-lock aid.

The PLL behaviour during in-lock (the normal on-track

situation) can be best explained in the frequency domain.

The PLL operation is completely linear during in-lock

situations. The open-loop response of the PLL is given in

Fig.7. The three frequencies, f0(integrator cross-over

frequency), f1(PLL bandwidth) and f2(low-pass

bandwidth) are programmable via register PLLSet.

To extend the PLL capture range two lock aids are used:

• Inner lock aid: has a capture range of ±10% and will

bring the PLL frequency to the lock point

• Outer lock range: has no limitation on capture range,

and will bring the PLL within the range of the inner lock

range.

Two outer lock aids can be used:

• Run length 3 deviation detector: this circuit is known to

be sensitive to systematic over/under equalization; this

over/under equalizationcan becounter-acted by writing

a non-zero phase offset value to register PLLLock.

• Frequency measurement detector: this circuit regulates

the PLL frequency so that the average number of EFM

transitions is a fixed fraction of the PLL bit clock; the

transition frequency is settable via register PLLFMeas.

Programmability/observability is built into the PLL. Its

operation can be influenced in two ways:

• It is possible to select the state the PLL is in (in-lock,

near-lock, outer-lock) via register PLLLock

• It is possible to preset the PLL frequency to a certain

value via registers PLLEqu and PLLFreq.

The operation of the bit detector can be monitored by the

microprocessor and via the MEAS1 pin. Four signals are

available for measurement:

• PLL frequency signal: the most significant 8 bits are

available via register PLLLock

• Asymmetry signal: the 8-bit signal in 2’s complement

form is available via register PLLSet

• Jitter signal: the most significant 8 bits are available via

register PLLFreq. This gives an impression of the

detection jitter after all processing is done.

jitter<9:0> = average ((jitter individual

transition)2× 8192)

To obtain the jitter in the bit clocks the jitter<9:0> value

must be divided by 8192 and square routed. Note that

the jitter<9:0> overestimates thejitter (byapproximately

rms jitter increase of 0.03 bit clock), because the

quantization of the zero transitions is in 4 intervals.

Note the jitter is measured before the bit detection and

contains contributions due to various imperfections in

the complete signal path; i.e. disc, preamplifier, ADC,

limited bitwidths, PLL performance, internal filter noise,

asymmetry compensation, equalizer.

• Internal lock flags: The internally generated inner-lock

signal (f_lock_in), lock signal (lock_in) and flag that

indicates when a run length 14 is detected

(long_symbol) are available via register PLLEqu.

Fig.7 PLL bode diagram.

MGR797

handbook, halfpage

frequency (Hz)

amplitude

(dB)

f

0f1

f

2

Page 21

2000 Mar 21 21

Philips Semiconductors Preliminary specification

Channel encoder/decoder CDR60 SAA7392

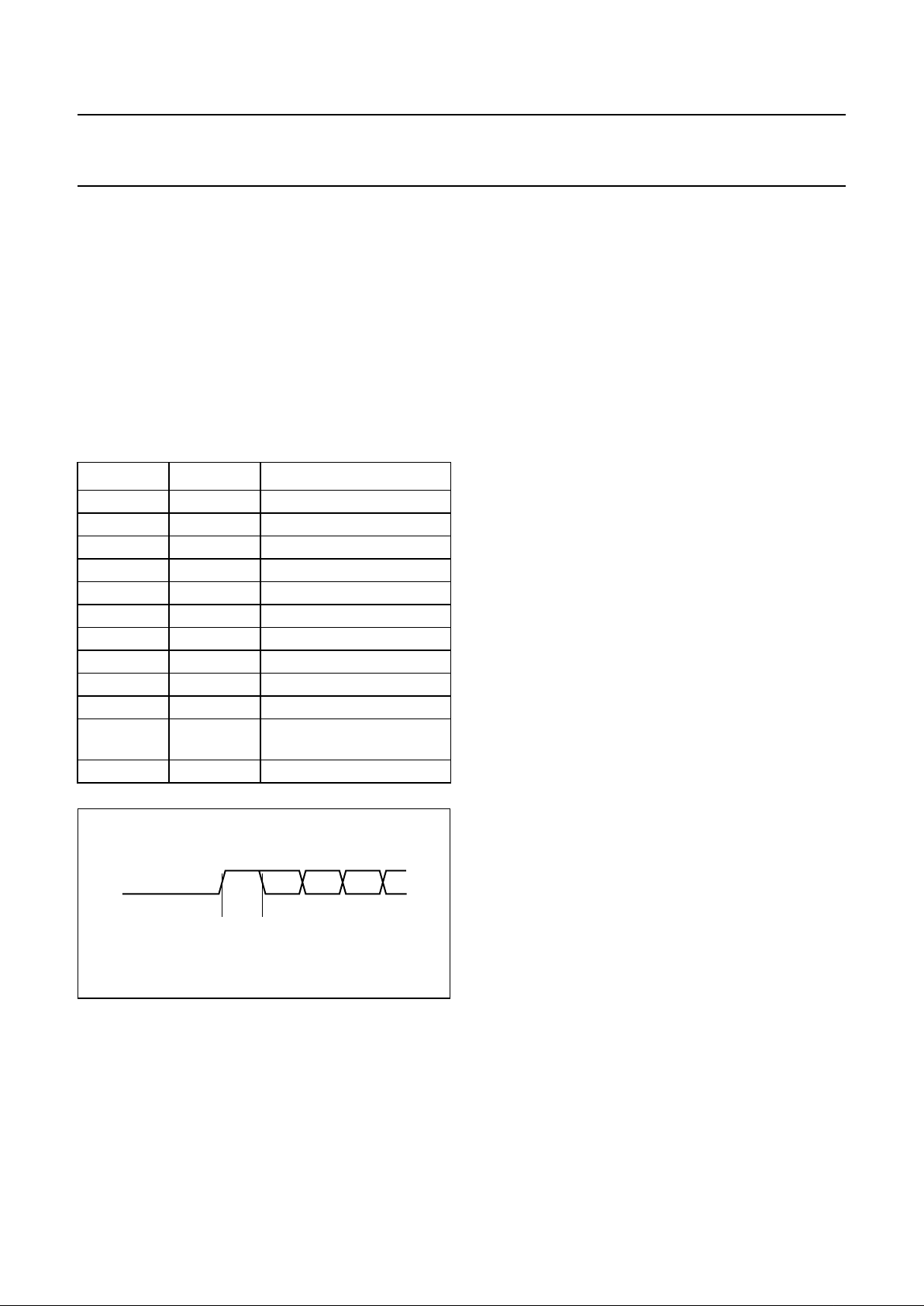

7.5.2 MEAS1 PIN

The MEAS1 pin carries the 3 measurement signals: jitter

(sampled twice), PLL frequency, and asymmetry. Each

frame consists of 64 bits (each 4 system clock periods

long), beginning with a start bit, then data bits then pause

bits (see Fig.8). The start bit is always preceded by

17 pause bits; and the intermediate start bits at

locations 12, 24 and 36 guarantee that no other ‘1’ bit is

preceded by 17 ‘0’ bits, making the start detection easy.

The structure of the frame is described in Table 23 and

shown in Fig.8.

Table 23 Frame structure

BIT VALUE FUNCTION

0 logic 1 start bit

1 to 10 jitter<9:0> jitter word

11 logic 0

12 logic 1 intermediate start bit

13 to 22 pllfreq<9:0> PLL frequency word

23 logic 0

24 logic 1 intermediate start bit

25 to 32 assym<7:0> asymmetry word

33 logic 0

34 logic 1 intermediate start bit

37 to 46 jitter<9:0> second sample of jitter

word

47 to 63 logic 0 pause

Fig.8 Format on MEAS1 pin.

MGR798

handbook, halfpage

bit 0 bit 1

start

bit

pause data bits

bit 2 bit 3

Page 22

2000 Mar 21 22

Philips Semiconductors Preliminary specification

Channel encoder/decoder CDR60 SAA7392

7.5.3 PLL LOCK SELECT REGISTER (PLLLOCK)

The behaviour of this register is dependent upon whether its being read or written. The behaviour for the write operation

is described in Tables 24 to 27. When read the 8 MSBs of the PLL frequency counter are returned; this is described in

Tables 24 and 28.

Table 24 PLL Lock Select Register (address 00H) - WRITE/READ

Table 25 Description of PLLLock bits for write operation

Table 26 Selection of phase override setting

Table 27 Selection of PLL lock

76543210

LockOride PhaOset.2 PhaOset.1 PhaOset.0 PLLForceL.3 PLLForceL.2 PLLForceL.1 PLLForceL.0

PLLFreq.7 PLLFreq.6 PLLFreq.5 PLLFreq.4 PLLFreq.3 PLLFreq.2 PLLFreq.1 PLLFreq.0

BIT SYMBOL DESCRIPTION

7 LockOride When LockOride = 0, then automatic lock behaviourselected, PLLForceL<3:0>must be

set to ‘0000’. When LockOride = 1, then PLL manual override, PLLForceL<3:0> must

also be programmed.

6 PhaOset.2 These 3 bits are used to select the phase override settings; see Table 26.

5 PhaOset.1

4 PhaOset.0

3 PLLForceL.3 These 4 bits are used to select the PLL lock; see Table 27.

2 PLLForceL.2

1 PLLForceL.1

0 PLLForceL.0

PhaOset.2 PhaOset.1 PhaOset.0 PHASE OVERRIDE

0 0 0 reserved

001

3

/

8

×PLL clock over-equalized T3

010

2

/

8

×PLL clock over-equalized T3

011

1

/

8

×PLL clock over-equalized T3

1 0 0 correct equalisation

101

1

/

8

×PLL clock under-equalized T3

110

2

/

8

×PLL clock under-equalized T3

111

3

/

8

×PLL clock under-equalized T3

PLLForceL.3 PLLForceL.2 PLLForceL.1 PLLForceL.0 PLL LOCK

0000automatic lock behaviour

0001force PLL in-lock

0100force PLL into outer-lock

0110force PLL into inner-lock

1000force PLL into Hold mode (PLL frequency can be

forced using preset value in register PLLFreq)

XXXXall other combinations are reserved

Page 23

2000 Mar 21 23

Philips Semiconductors Preliminary specification

Channel encoder/decoder CDR60 SAA7392

Table 28 Description of PLLock bits for read operation

7.5.4 PLL B

ANDWIDTH SELECT REGISTER (PLLSET)

The function of this register is dependent upon whether its being read or written. The function for the write operation is

described in Tables 29 to 34. Note the measurement conditions are: system clock = 2.15 MHz, bit clock = 4.3 MHz,

bandwidth is proportional to the system clock.

When read this register returns the 8-bit PLL asymmetry value, see Table 29.

Table 29 PLL Bandwidth Select Register (address 01H) - WRITE/READ

Table 30 Description of PLLSet bits for write operation

Table 31 Selection of Slicer bandwidth

Table 32 Selection of integrator crossover frequency

BIT SYMBOL DESCRIPTION

7 to 0 PLLFreq<7:0> This register holds the 8 MSBs of the PLL frequency counter. The PLL frequency is

calculated as shown below:

76543210

SliceBW.1 SliceBW.0 IntegF0.1 IntegF0.0 PLLBWF1.1 PLLBWF1.0 LPBWF2.1 LPBWF2.0

PLLAsym.7 PLLAsym.6 PLLAsym.5 PLLAsym.4 PLLAsym.3 PLLAsym.2 PLLAsym.1 PLLAsym.0

BIT SYMBOL DESCRIPTION

7 SliceBW.1 These 2 bits select the Slicer bandwidth; see Table 31.

6 SliceBW.0

5 IntegF0.1 These 2 bits select the integrator crossover frequency; see Table 32.

4 IntegF0.0

3 PLLBWF1.1 These 2 bits select the PLL bandwidth; see Table 33.

2 PLLBWF1.0

1 LPBWF2.1 These 2 bits select the low-pass bandwidth; see Table 34.

0 LPBWF2.0

SliceBW.1 SliceBW.0 SLICER BANDWIDTH

0 0 12 Hz

0 1 50 Hz

1 0 200 Hz

1 1 This value is reserved.

IntegFO.1 IntegFO.0 INTEGRATOR CROSSOVER FREQUENCY

0 0 3780 Hz

0 1 1890 Hz

1 0 945 Hz

1 1 This value is reserved.

f

PLL

(Hz)

PLLFreq<7:0> ADC clock (Hz)×()

128

------------------------------------------------------------------------------------------

=

Page 24

2000 Mar 21 24

Philips Semiconductors Preliminary specification

Channel encoder/decoder CDR60 SAA7392

Table 33 Selection of PLL bandwidth

Table 34 Selection of low-pass bandwidth

7.5.5 PLL FREQUENCY PRESET REGISTER (PLLFREQ)

The function of this register is dependent upon whether its being read or written. Tables 35 and 36 define the register

function for the write operation. Tables 35 and 37 define the register function for the read operation.

Table 35 PLL Frequency Preset Register (address 02H) - WRITE/READ

Table 36 Description of PLLFreq bits for write operation

Table 37 Description of PLLFreq bits for read operation

PLLBWF1.1 PLLBWF1.0 PLL BANDWIDTH

0 0 21000 Hz

0 1 10528 Hz

1 0 5264 Hz

1 1 2632 Hz

LPBWF2.1 LPBWF2.0 LOW-PASS BANDWIDTH

0 0 42100 Hz

0 1 21000 Hz

1 0 10528 Hz

1 1 This value is reserved.

76543210

PLLFreq.9 PLLFreq.8 PLLFreq.7 PLLFreq.6 PLLFreq.5 PLLFreq.4 PLLFreq.3 PLLFreq.2

JV.7 JV.6 JV.5 JV.4 JV.3 JV.2 JV.1 JV.0

BIT SYMBOL DESCRIPTION

7 to 0 PLLFreq<9:2> These are the 8 MSBs of the 10-bit code used to set the PLL frequency. The 2 LSBs

reside in the PLLEqu register; these 2 bits should be written to first. The PLL frequency

can be set using the following equation:

BIT SYMBOL DESCRIPTION

7 to 0 JV.7 to JV.0 Jitter value. These 8 bits determine the PLL clock jitter value (jitter values below 7%

cannot be measuredwith this register). The absoluteclock jitter value can be calculated

as follows:

f

PLL

PLLFreq<9:0>

512

--------------------------------------

2

5–

+

f

clk

×=

PLL clock recovery jitter %

JV<7:0> 6.5–

2048

------------------------------------ 10 0×=

Page 25

2000 Mar 21 25

Philips Semiconductors Preliminary specification

Channel encoder/decoder CDR60 SAA7392

7.5.6 PLL EQUALIZER PRESET REGISTER (PLLEQU)

The functionof thisregister is dependent upon whetherits being read or written.Tables 38, 39and 40 definethe register

function for the write operation. Tables 38 and 41 define the register function for the read operation.

Table 38 PLL Equalizer Preset Register (address 03H) - WRITE/READ

Table 39 Description of PLLEqu bits for write operation

Table 40 Selection of equalizer tap settings: a1 and a2

Table 41 Description of PLLEqu bits for read operation

76543210

PLLFreq.1 PLLFreq.0 Tap a1.2 Tap a1.1 Tap a1.0 Tap a2.2 Tap a2.1 Tap a2.0

−−−−−LongSymb FLock InLock

BIT SYMBOL DESCRIPTION

7 PLLFreq.1 These 2 bits are the 2 LSBs of the 10-bit PLL frequency code; see Section 7.5.5.

6 PLLFreq.0

5 Tapa1.2 These 3 bits select the equalizer tap setting a1; see Table 40.

4 Tapa1.1

3 Tapa1.0

2 Tapa2.2 These 3 bits select the equalizer tap setting a2; see Table 40.

1 Tapa2.1

0 Tapa2.0

Tap a1.2 Tap a1.1 Tap a1.0

a1 OR a2 EQUALIZER TAP SETTINGS

Tap a2.2 Tap a2.1 Tap a2.0

0000

001−0.0625

010−0.125

011−0.1875

100−0.25

101−0.3125

X X X All other settings are reserved.

BIT SYMBOL DESCRIPTION

7to3 − These 5 bits are reserved.

2 LongSymb If LongSymb = 1, then a run length of 14 has been detected.

1 FLock If FLock = 1, then PLL is in inner-lock range.

0 InLock If Inlock = 1, then PLL is in lock.

Page 26

2000 Mar 21 26

Philips Semiconductors Preliminary specification

Channel encoder/decoder CDR60 SAA7392

7.5.7 PLL LOCK AID2PRESET REGISTER (PLLFMEAS)

The PLL setting point for the EFM counting locking strategy is controlled by setting the PLL frequency such that, there

are, on average, a fixed number of EFM transitions per PLL clock period:

PLL Locking Frequency/EFM Transition Frequency = (EFM_Count + 32)/16 = 4.75 in a typical application.

Thisvalue (4.75) isdependent ondisc andmechanical variations,improvements maybe achievedby adjusting the value

slightly.

Table 42 PLL Lock Aid2 Preset Register (address 04H) - WRITE

Table 43 Description of PLLFMeas bits

7.5.8 MOTOR CONTROL REGISTER 2(MOTOR2)

This is a dual-function register. When read Motor2 gives an indication of the EYE opening of the equalised HF.

Table 44 Eye Open Register (address 0DH) - READ

76543210

RL3_En − EFMns.5 EFMns.4 EFMns.3 EFMns.2 EFMns.1 EFMns.0

BIT SYMBOL DESCRIPTION

7 RL3_En If RL3_En = 0, then EFM transition counting outer PLL lock strategy. If RL3_En = 1,

then RL3 detection PLL outer lock strategy.

6 − This bit is reserved.

5 to 0 EFMns<5:0> These 6 bits select the EFM nominal setting. The default nominal setting should be set

to ‘101110’.

76543210

EOV.7 EOV.6 EOV.5 EOV.4 EOV.3 EOV.2 EOV.1 EOV.0

Page 27

2000 Mar 21 27

Philips Semiconductors Preliminary specification

Channel encoder/decoder CDR60 SAA7392

7.5.9 VITERBI DETECTOR SETTING REGISTER (VITSET)

Thisregister controlsanadvanced dataslicerfor improved

bit detector performance.

• An adaptive slicer performs a second slice operation.

This has a higher bandwidth than the first slicer.

• Ifswitched on,the runlength 2push-back circuitpushes

allrun lengthtwo symbolsto run length 3.The circuitwill

determine which transition was most likely in error and

shift transition on that edge.

To avoid advanced detector hang-up, caused by a

detection level that is too high and is not brought down, a

Watchdog counter on the slicer level is installed.

The Watchdog counter is a counter that counts on the

front-end PLL clock.

• If rl1 or a rl2 received: count + stepsize

• Elsif no transition: count + 1

• Elsif transition on a valid runlength: count − 8

• Elsif (count > maxcount): reset count.

Stepsize and maxcountcan be set by writing to the VitSet

register. On a reset of the counter the slice level is also

reset.

Table 45 Viterbi Detector Setting Register (address 16H) - WRITE

Table 46 Description of VitSet bits

Table 47 Selection of Watchdog count step

7.5.10 M

OTOR CONTROL REGISTER 1(MOTOR1)

When read this register holds the 8-bit advanced slicer compensation value.

76 543210

AdSliceON AdDetON FEndAutoSON RL2PB WDog MaxCnt WDogCnt.1 WDogCnt.0

BIT SYMBOL DESCRIPTION

7 AdSliceON If AdSliceON = 0, then slicer reset (to logic 0). If AdSliceON = 1, then slicer active.

6 AdDetON If AdDetON = 0, then advanced bit detector off. If AdDetON = 1, then advanced bit

detector on.

5 FEndAutoSON If FEndAutoSON = 0, then auto-scaling in front-end Hold mode. If FEndAutoSON = 1,

then auto-scaling in front-end on.

4 RL2PB If RL2PB = 0, then run length 2 push-back off. If RL2PB = 1, then run length 2

push-back on.

3 WDog If WDog = 0, then slicer Watchdog is off. If WDog = 1, then slicer Watchdog is on.

2 MaxCnt If MaxCnt = 0, then maxcount is 1024. If MaxCnt = 1, then maxcount is 2048.

1 WDogCnt.1 These 2 bits select the Watchdog count step; see Table 47.

0 WDogCnt.0

WDogCnt.1 WDogCnt.0 WATCHDOG COUNT STEP

00 32

01 64

1 0 128

1 1 256

Page 28

2000 Mar 21 28

Philips Semiconductors Preliminary specification

Channel encoder/decoder CDR60 SAA7392

Table 48 Motor Control Register 1 (address 0CH) - READ

76543210

ASCV.7 ASCV.6 ASCV.5 ASCV.4 ASCV.3 ASCV.2 ASCV.1 ASCV.0

7.6 Decoder function

7.6.1 DEMODULATOR

The demodulator block includes sync extraction,

interpolation and protection circuits, and converts the

14-bit EFM data and subcode words into 8-bit symbols.

Two counters are used to detect frame synchronisation.

The coincidence counter detects the coincidence of

successive syncs (i.e. 2 syncs are within

588 ± 1 EFM clock). The main counter partitions the EFM

signal into 16 or 17-bit bytes; and is reset when a sync

coincidence is found or the sync pulse is within ±6 EFM

clock pulses. The sync coincidence signal generates the

‘lock’ signal which goes active HIGH when one sync

coincidence is found, and goes inactive when no sync

coincidence is found within 61 consecutive EFM frames.

The frame sync detection circuit extracts the frame sync

and will guard against mis-detection; up to 7 consecutive

corrupted syncs will not disturb the sync detection.

After data demodulation the sector sync is extracted; a

doublelock counteris used.Themain counterinterpolates

the sector syncs, and a coincidence counter resets the

main counter.

7.6.2 ERROR CORRECTOR

The error corrector can correct up to 2 errors on the

C1 level and up to 4 errors on the C2 level. The error

corrector also contains a flag processor. Flags are

assigned to symbols when the error corrector cannot

ascertain if the symbols are definitely good.C1 generates

output flags that are used by C2. The C2 output flags are

output via the FLAG signal along with the I2S, and can be

used by the interpolator for concealment of uncorrectable

errors for audio output.

• Muting of data. Data output via the serial interface

and/or the EBU can be set to zero using register

Output3.

• Concealment of audio errors. A simple 1 sample

linear interpolator can be selected via register Output3.

If selected the interpolator becomes active if a single

sample is flagged as erroneous; left and right channels

have independent interpolators.

7.6.2.1 CFLG pin

The error corrector outputs status information in serial

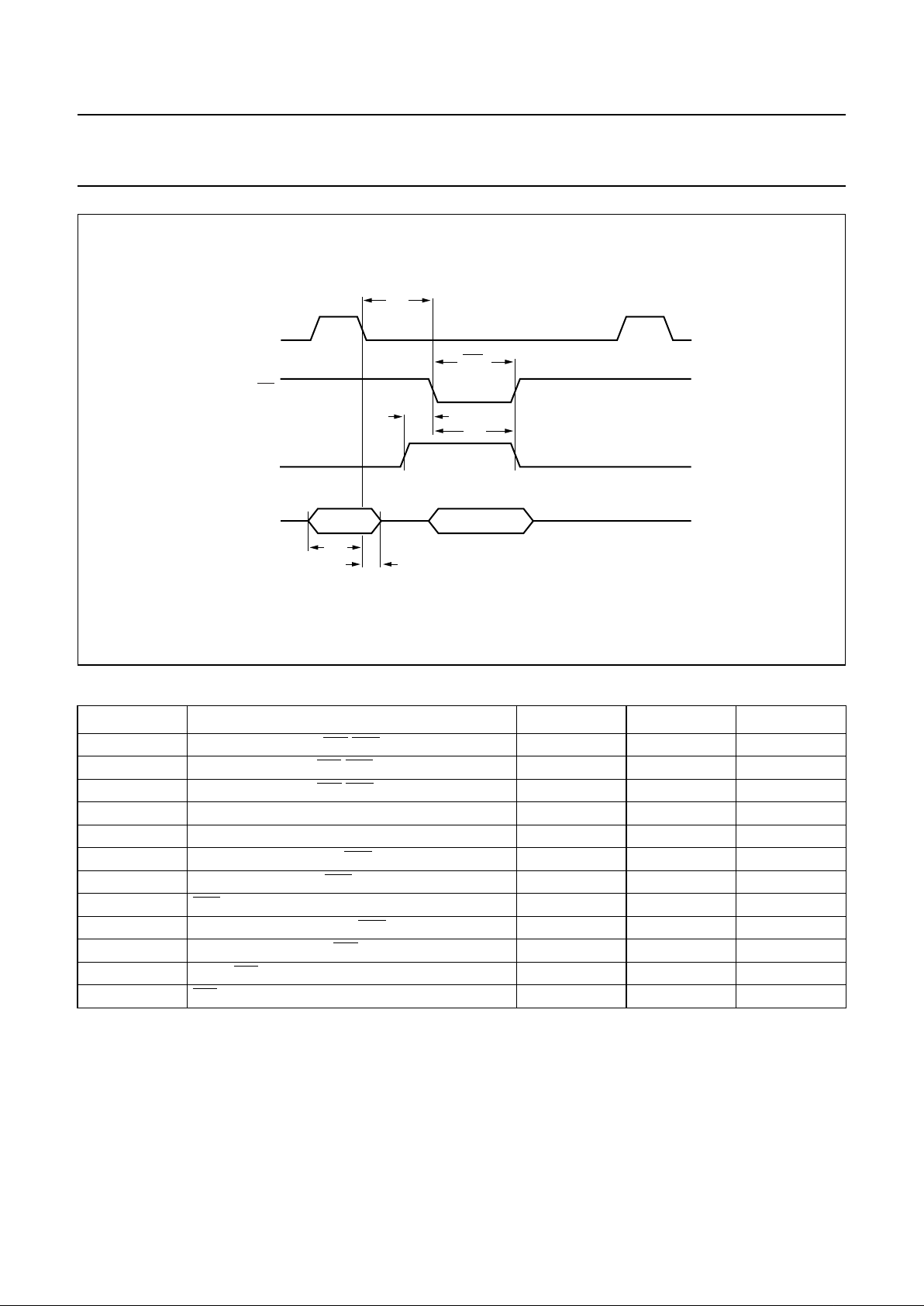

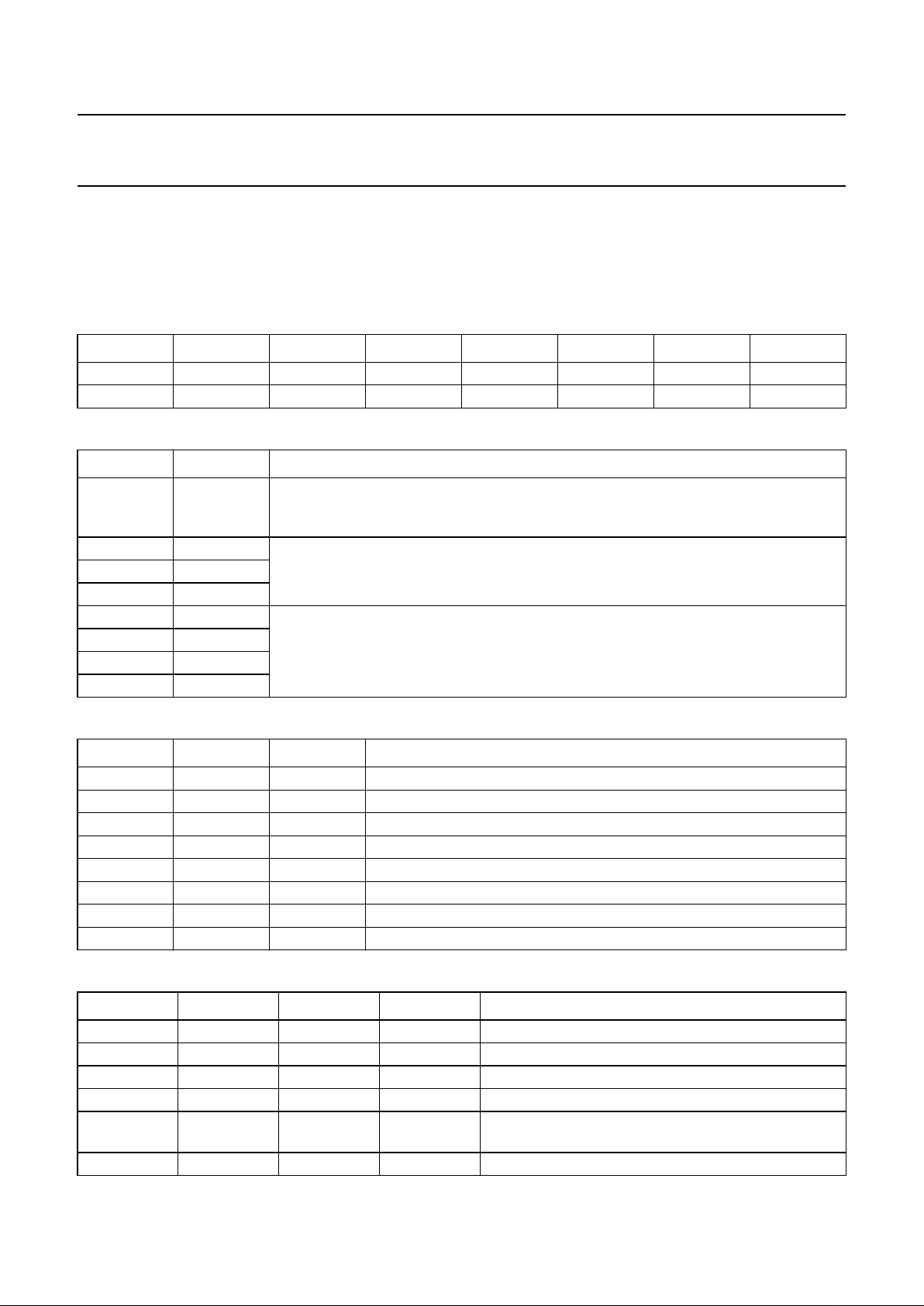

format on the CFLG pin. Each frame consists of 11 bits

(each 7 system clock periods long), beginning with a start

bit, then data bits then pause bit (see Fig.9). The repetition

rate of CFLGis notfixed; itdepends onthe discspeed and

output interface speed. There is always at least one pause

bit. The structure of the frame is shown in Table 49.

Table 49 Frame structure

BIT VALUE COMMENT

0 logic 1 start bit

1 to 3 cormode<2:0> 000 = C1 correction

011 = C2 correction

100 = corrector not active

all other codes not used

4 corfail failure flag set because

correction impossible

5 flagfail failure flag set because

correction too risky

6 to 9 rootcount<3:0> number of errors corrected,

after Euclidean algorithm

10 logic 0 pause bit

Fig.9 Format on CFLG pin.

MGR798

handbook, halfpage

bit 0 bit 1

start

bit

pause data bits

bit 2 bit 3

Page 29

2000 Mar 21 29

Philips Semiconductors Preliminary specification

Channel encoder/decoder CDR60 SAA7392

7.6.3 DECODER MODE SELECT REGISTER (DECOMODE)

Table 50 Decoder Mode Select Register (address 13H) - WRITE

Table 51 Description of DecoMode bits

Table 52 Selection of Decoder mode

7.6.4 F

RAME ERROR STATUS REGISTERS (C1BLER AND C2BLER)

These two registers are non-buffered counters. Each time a C1 frame with errors is found the register C1BLER is

incremented. In the same way C2BLER increments on all C2 frames with errors. When the value of either register

reaches 255, it will hold. When read, the register value is reset.

7.6.4.1 C1 Block Error Register (C1BLER)

Table 53 C1 Block Error Register (address 39H) - READ

7.6.4.2 C2 Block Error Register (C2BLER)

Table 54 C2 Block Error Register (address 3AH) - READ

76543210

Mode.6 Mode.5 Mode.4 Mode.3 Mode.2 Mode.1 Mode.0 LWCon

BIT SYMBOL DESCRIPTION

7 to 1 Mode<6:0> These 7 bits select the Decoder mode; see Table 52.

0 LWCon When a logic 0, LaserOn and WriteOn2 signals operate normally. When a logic 1,

LaserOn and WriteOn2 signals are reset.

MODE

DECODER MODE

6543210

0000000Flush mode. Deinterleaver table is emptied and all data is discarded.

0100000Normal play. Uses the Quad-pass error correction mode used for disc speeds up

to 75% of maximum defined by ADCCLK. Note the data integrity should be

checked using the CRC as the FLAG pin is not fully defined in this mode.

0101000Fast play. Used for audio play or fast CDROM mode (25 to 100% of maximum

defined by ADCCLK), this reduces the error correction performance, but also

halves the throughput time of error corrector (only dual pass error correction

algorithm used).

0110000Hold mode. Data into output FIFO is stopped (header/subheader decoding

remains operative).

0101010Encode mode.

X X X X X X X All other combinations reserved.

76543210

C1BLER.7 C1BLER.6 C1BLER.5 C1BLER.4 C1BLER.3 C1BLER.2 C1BLER.1 C1BLER.0

76543210

C2BLER.7 C2BLER.6 C2BLER.5 C2BLER.4 C2BLER.3 C2BLER.2 C2BLER.1 C2BLER.0

Page 30

2000 Mar 21 30

Philips Semiconductors Preliminary specification

Channel encoder/decoder CDR60 SAA7392

7.6.5 DATA FIFO

Thedecoder blockcan beviewed as aFIFO, demodulated

data is written in while the output interface reads from it.

The way in which the FIFO is filled depends on the

decoder mode set via register DecoMode. The decoder

modes that effect the filling of the FIFO are described in

Sections 7.6.5.1 to 7.6.5.3.

Data is read out via the output interface and is only

possible if enough data is present in the FIFO. The

minimumamount ofdata is110 C1 frames (C1 frame = 24

user bytes).

7.6.5.1 Flush mode

The FIFO contentis thrown away; no read-out possible. It

is necessary to flush the FIFO every time a context switch

is made; when data written to the FIFO is not subsequent

with data already present in the FIFO.

7.6.5.2 Hold mode

Writing to the FIFO is stopped; read-out possible if FIFO

wasfilled. Thismodeis intendedtoavoid FIFOoverflowby

implementing a ‘stop write - jump back’ action in the

microprocessor. When the microprocessor switches to

hold mode the switch-over is synchronised internally with

the next subcode block start, allowing the microprocessor

to know exactly where the writing will stop or start. This

mode is also intended to avoid overflow in the block

decoder; on imminent overflow the microprocessor can

switch to hold mode. When it jumps back one track and

switches off hold mode on the samesubcode address the

SAA7392 will make a seamless link.

7.6.5.3 Play mode

The FIFO is filled; read-out possible when FIFO filling big

enough.

7.6.5.4 Data FIFO monitoring

The state of the internal data FIFO may be monitored by

reading the AnaSet1 register. This gives the number of

C1 frames present in the FIFO including those frames in

the outer corrector (i.e. 110 in CD fast and 220 in

CD normal). One C1 frame equates to 24 user bytes in

CD mode).

7.7 Subcode interface

Q-channel subcode data can be read using the ClockPre

and DecoMode registers. The ClockPre register must be

read first; this contains the status of the Q-channel

subcode that maybe read. Reading the ClockPreregister

with Ready = 1 will block the subcode interface for data

read; no new subcode will overwrite the current subcode,

and the microprocessor may retrieve as many bytes (up

to 12) as required by issuing reads to register DecoMode.

After finishing the subcode read the microprocessor must

release the interface by issuing a read to the dummy

register SubReadEnd (no data can be read from it); this

allows the SAA7392 to capture new subcode frames.

The serial Q to W subcode is output on the V4 pin as

illustrated in Fig.10. The subcode sync word is formed by

a pause of

200

/nµs minimum; where n = the disc speed.

Each subcode word starts with a logic 1followed by 7 bits

(Q to W); the bit time is 0.5 of the period of the WCLK

signal, (

11.3

/nµs). The gap between the words is between

11.3

/n and90/nµs. Note that the subcode data cannot be

guaranteed at a rate higher than 0.5 × the maximum data

rate programmed.

The subcode data is also available in the EBU output

(EBUOUT).

Fig.10 Subcode format and timing on V4 pin.

handbook, full pagewidth

MGR799

W96

200/n µs min 11.3/n µs

11.3/n µs min

90/n µs max

1 Q1 R1 S1 T U1 V W1 1 Q2

n = disc speed

Page 31

2000 Mar 21 31

Philips Semiconductors Preliminary specification

Channel encoder/decoder CDR60 SAA7392

7.7.1 CLOCK PRESET REGISTER (CLOCKPRE)

This is a dual-function register. When read the status of the Q-channel is returned.

Table 55 Clock Preset Register (address 12H) - READ

Table 56 Description of ClockPre bits

7.7.2 D

ECODER MODE SELECT REGISTER (DECOMODE)

This is a dual-function register. When read this register holds the Q-channel subcode data.

Table 57 Decoder Mode Select Register (address 13H) - READ

7.7.3 S

UBCODE READ END REGISTER (SUBREADEND)

After finishing a subcode read, the microprocessor must release the interface to allow the SAA7392 to capture new

subcode frames. This is done by issuing a read to SubReadEnd. No data can be read from this register; only the side

effect is important.

Table 58 Subcode Read End Register (address 14H) - READ

76543210

Ready Busy CRC OK −−−−−

BIT SYMBOL DESCRIPTION

7 Ready If Ready = 0, then buffer filling. If Ready = 1, then valid Q subcode frame available.

6 Busy If Busy = 0, then buffer filling. If Busy = 1, then buffer held (set after reading this register

with Ready = 1).

5 CRC OK If CRC OK = 0, then CRC not checked or not OK. If CRC OK = 1, then CRC of

Q-channel checks OK, only valid if Ready = 1.

4to0 − These 5 bits are reserved.

76543210

SubD.7 SubD.6 SubD.5 SubD.4 SubD.3 SubD.2 SubD.1 SubD.0

76543210

−−−−−−−−

Page 32

2000 Mar 21 32

Philips Semiconductors Preliminary specification

Channel encoder/decoder CDR60 SAA7392

7.8 Digital output

The AES/EBU signal is available on pin EBUOUT,

according to the format defined by the

“IEC958

specification”

. This signal is only available in the CLV

modes of the decoder (not in QCLV). Three different

modes can be selected:

• EBU off

• EBU data all zero

• EBU data valid.

The EBU interface uses a clock derived from XTLI for

timing generation. For correct operation of the EBU

interface, BCLKmust be non-gated and the selected EBU

clock and BCLK must fulfil the following constraint:

WCLK is BCLK divided by 16, 24 or 32 depending on the

chosen output format.

EBU clock WCLK 64×=

7.8.1 INPUT CONFIGURATION REGISTER (INPUTCONFIG)

Table 59 Input Configuration Register (address 1EH) - WRITE

Table 60 Description of InputConfig bits

76543210

EBUClkSelect −−−−ScramOn InputFmt.1 InputFmt.0

BIT SYMBOL DESCRIPTION

7 EBUClkSelect If EBUClkSelect = 0, then the EBU clock frequency is

1

/3f

XTLI

. If

EBUClkSelect = 1, then the EBU clock frequency is2/3f

XTLI

(input

MUXSWI must be a logic 1 for this setting).

6to3 − These 4 bits are reserved.

2 ScramOn See Section 7.11.1.

1 InputFmt1

0 InputFmt0

Page 33

2000 Mar 21 33

Philips Semiconductors Preliminary specification

Channel encoder/decoder CDR60 SAA7392

7.8.2 FORMAT

The digital audio output consists of 32-bit words (subframes) transmitted in biphasemark code (two transitions for a

logic 1 and one transition for a logic 0). Words are transmitted in blocks of 384.

Table 61 Digital audio output subframe format

Table 62 Channel status bit assignment

BIT FIELD NAME DESCRIPTION

0 to 3 sync The sync word is formed by violation of the biphase rule and therefore does not

contain any data. Its length is equivalent to 4 data bits. The 3 different sync patterns

indicate the following situations:

• Sync B: Start of a block (384 words), word contains left sample

• Sync M: Word contains left sample (no block start)

• Sync W: Word contains right sample.

4 to 7 auxiliary These bits are not used; normally zero.

8 to 27 audio sample Left and right samples are transmitted alternately. The first 4 bits not used (always

zero); 2’s compliment; LSB = bit 12 and MSB = bit 27.

28 validity flag If validity flag = 1, audio samples are flagged if an error has been detected but was

uncorrectable. This flag remains the same even if data is taken after concealment.

29 user data Subcode bits Q until W from the subcode section are transmitted via the user data

bit. This data is asynchronous with the block rate.

30 channel status The channel status bit is the same for left and right words. Therefore, a block of

384 words contains 192 channel status bits. The category code is always CD. The bit

assignment is shown in Table 62.

31 parity bit Even parity for bits 4 to 30.

BIT FIELD NAME DESCRIPTION

0 to 4 control Bits 1 to 4 copied from register Output2. Bit 2 is logic 1 when copy permitted. Bit 3 is

logic 1 when recording has pre-emphasis

5 to 7 reserved mode always zero

8 to 15 category code CD: bit 8 = logic 1, all other bits = logic 0

28 to 29 clock accuracy set by register Output2:

10 = level I

00 = level II

01 = level III

16 to 27, remaining always zero

30 to 191

Page 34

2000 Mar 21 34

Philips Semiconductors Preliminary specification

Channel encoder/decoder CDR60 SAA7392

7.9 Serial output interface

The serial data output interface consists of three signals:

WCLK (word select), BCLK (serial clock), DATAO (serial

data). The polarity of WCLK and the data can be inverted.

The FLAG signal is used to identify if there are errors in

either the LSB or MSB of the 16-bit data word. The

interfacecan beused asamaster orslaveinterface (BCLK

and WCLK are then inputs), selectable by register

Output1.

The serial datainterface can be switched into two modes:

PhilipsI2Sand theEIAJformat (theprotocol can useeither

16, 24 or 32 BCLK clocks for each 16-bit output,

selectable by Output1register). The formats are shownin

Figs 11 to 16.

The BCLK frequency can be selected by register

ClockPre, or input externally. If the data out rate does not

correspond with the disc speed and the bit clock data, the

FIFO will either fill or empty. FIFO underflow (STOPCK

output goes HIGH indicating absence of data) must be

avoided. If BCLK is an input, it should be stopped and

restarted again when STOPCK goes LOW. If BCLK is

output, it is automatically stopped if BCLK gate enable is

set(via registerClockPre);if itisnot setthenunpredictable

operation will result.

Fig.11 Format 1: 16 clocks/word I2S format.

handbook, full pagewidth

MGR800

D15

DATA

FLAG FLAG - MSB (1 is unreliable) FLAG - LSB

WCLK

SYNC

BCLK

D14 D13 D12 D11 D10 D9 D8 D7 D6 D5 D4 D3 D2 D1 D0D1 D0 D15 D14

left

right

Fig.12 Format 2: 16 clocks/word ‘S’ format (WCLK inverted).

handbook, full pagewidth

MGR801

D15

DATA

FLAG FLAG - MSB (1 is unreliable) FLAG - LSB

WCLK

SYNC

BCLK

D14 D13 D12 D11 D10 D9 D8 D7 D6 D5 D4 D3 D2 D1 D0D1 D0 D15 D14

right

left

Page 35

2000 Mar 21 35

Philips Semiconductors Preliminary specification

Channel encoder/decoder CDR60 SAA7392

Fig.13 Format 3: 24 clocks/word I2S format.

handbook, full pagewidth

MGR802

D15

DATA

FLAG FLAG - MSB (1 is unreliable) FLAG - LSB

WCLK

SYNC

BCLK

D14 D13 D12 D11 D10 D9 D8 D7 D6 D5 D4 D3 D2 D1 D0 D15 D14

left

right

Fig.14 Format 4: 24 clocks/word ‘S’ format (WCLK inverted).

handbook, full pagewidth

MGR803

D15

DATA

FLAG FLAG - MSB (1 is unreliable) FLAG - LSB

WCLK

SYNC

BCLK

D14 D13 D12 D11 D10 D9 D8 D7 D6 D5 D4 D3 D2 D1 D0D1 D0

right

left

Page 36

2000 Mar 21 36

Philips Semiconductors Preliminary specification

Channel encoder/decoder CDR60 SAA7392

This text is here in white to force landscape pages to be rotated correctly when browsing through the pdf in the Acrobat reader.This text is here in

_white to forcelandscape pages to be rotated correctly when browsing through the pdf in the Acrobatreader.This text is here inThis text is here in

white to force landscape pagesto berotated correctlywhen browsing throughthe pdfin theAcrobat reader. whiteto forcelandscape pagesto be ...

MGR804

D15

DATA

FLAG FLAG - MSB (1 is unreliable) FLAG - LSB

WCLK

SYNC

BCLK

D14 D13 D12 D11 D10 D9 D8 D7 D6 D5 D4 D3 D2 D1 D0 D15 D14

left

right

Fig.15 Format 5: 32 clocks/word I2S format.

MGR805

D15

DATA

FLAG FLAG - MSB (1 is unreliable) FLAG - LSB

WCLK

SYNC

BCLK

D14 D13 D12 D11 D10 D9 D8 D7 D6 D5 D4 D3 D2 D1 D0D1 D0

right

left

Fig.16 Format 6: 32 clocks/word ‘S’ format (WCLK inverted).

Page 37

2000 Mar 21 37

Philips Semiconductors Preliminary specification

Channel encoder/decoder CDR60 SAA7392

7.9.1 I2SOUTPUT REGISTER (OUTPUT1)

Table 63 I

2

S Output Register 1 (address 05H) - WRITE

Table 64 Description of Output1 bits

Table 65 Format selection

7.9.2 I

2

SOUTPUT REGISTER 2(OUTPUT2)

Table 66 I

2

S Output Register 2 (address 06H) - WRITE

Table 67 Description of Output2 bits

76543210