Page 1

DATA SH EET

Product specification

File under Integrated Circuits, IC02

January 1990

INTEGRATED CIRCUITS

SAA1101

Universal sync generator (USG)

Page 2

January 1990 2

Philips Semiconductors Product specification

Universal sync generator (USG) SAA1101

FEATURES

• Programmable to seven standards

• Additional outputs to simplify signal processing

• Can be synchronized to an external sync. signal

• Option to select the 524/624 line mode instead of the 525/625 line mode

• Lock from subcarrier to line frequency

GENERAL DESCRIPTION

The SAA1101 is a Universal Sync Generator (USG) and is designed for application in video sources such as cameras,

film scanners, video generators and associated apparatus. The circuit can be considered as a successor to the SAA1043

sync generator and the SAA1044 subcarrier coupling IC.

QUICK REFERENCE DATA

ORDERING AND PACKAGE INFORMATION

Notes

1. SOT117-1; 1996 December 02.

2. SOT136-1; 1996 December 02.

SYMBOL PARAMETER MIN. MAX. UNIT

V

DD

supply voltage range (pin 28) 4.5 5.5 V

I

DD

quiescent supply current − 10 µA

f

OSC

clock oscillator frequency − 24 MHz

EXTENDED

TYPE NUMBER

PACKAGE

PINS PIN POSITION MATERIAL CODE

SAA1101P 28 DIL plastic SOT117

(1)

SAA1101T 28 SO28 plastic SOT136A

(2)

Page 3

January 1990 3

Philips Semiconductors Product specification

Universal sync generator (USG) SAA1101

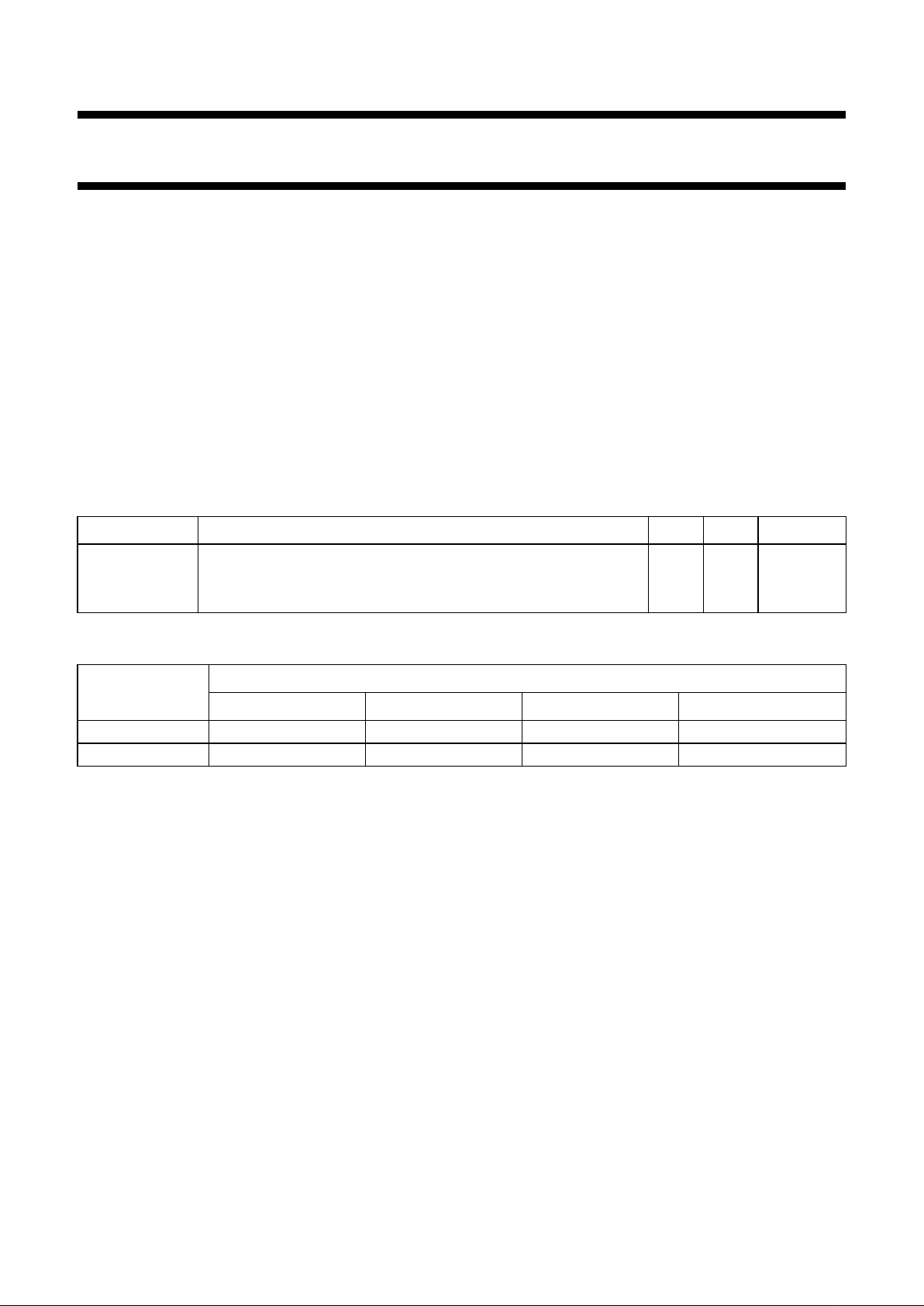

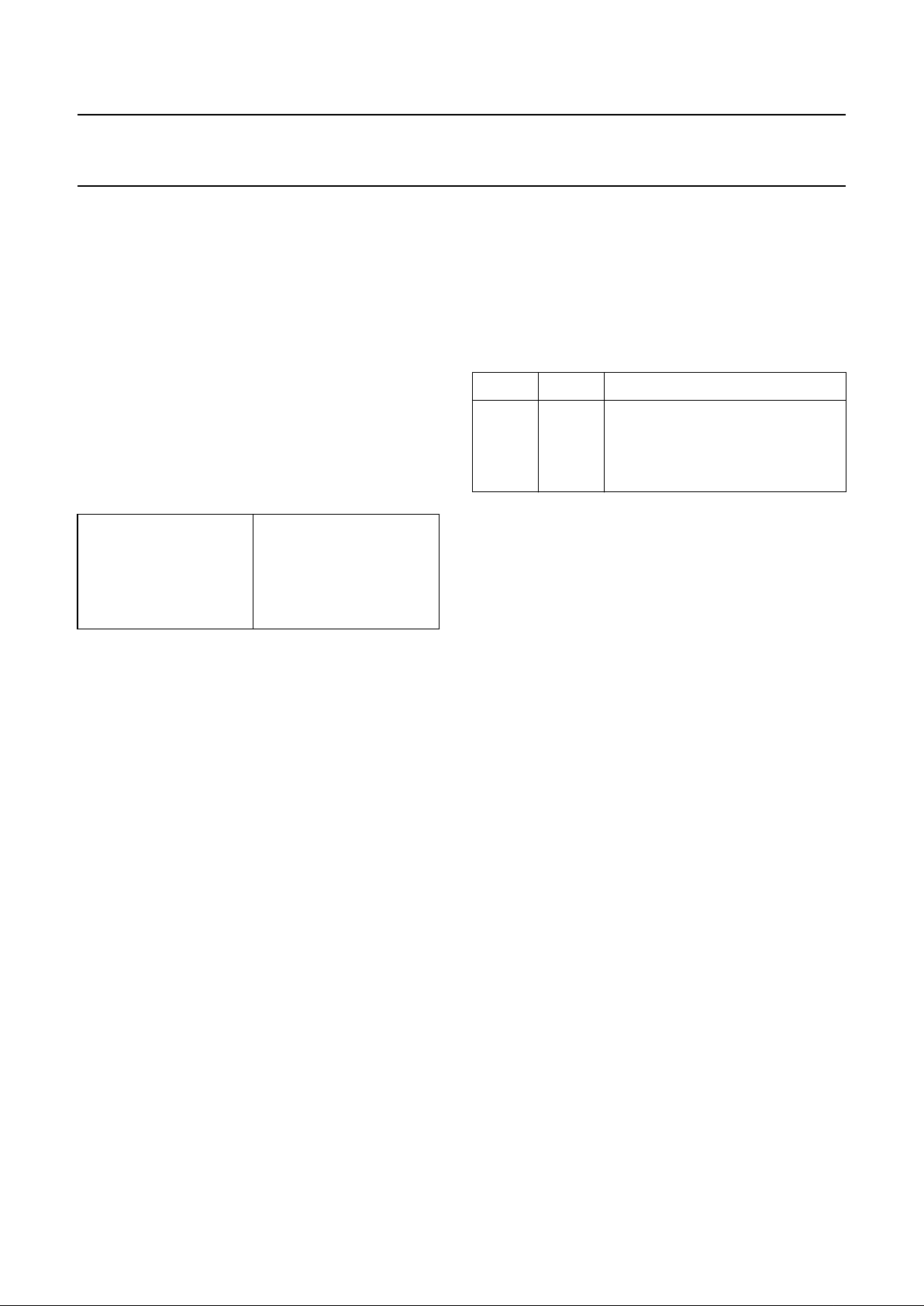

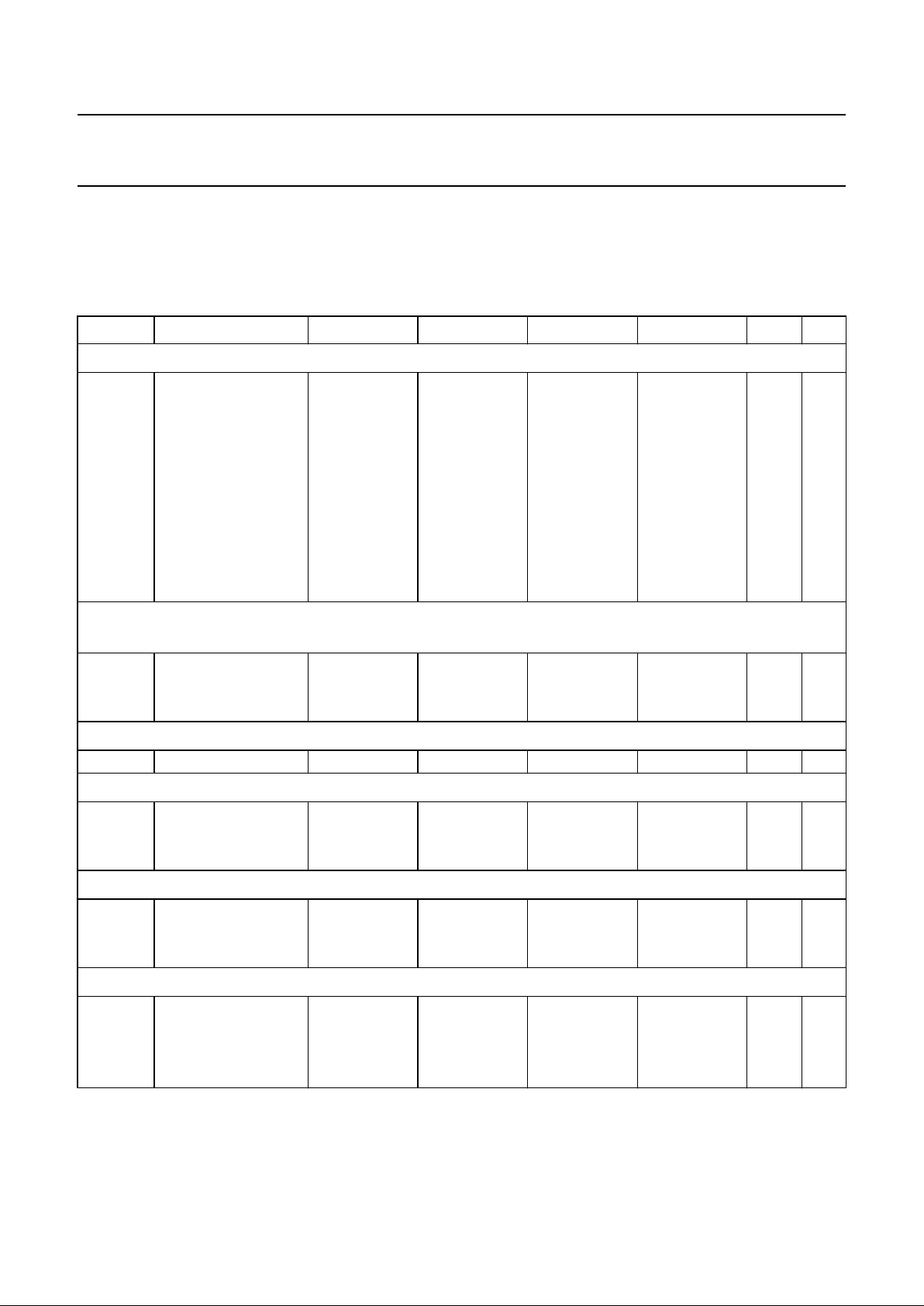

, full pagewidth

MGH191

COMBINING

LOGIC

VERTICAL

DIVIDER

RESET

PULSE

SHAPER

ADDITION/

SUPPRESSION

LOGIC

STANDARD

PROGRAMMED

DIVIDER

LINE

DIVIDER

HORIZONTAL

DETECTION

VERTICAL

DETECTION

VERTICAL

LOCK

SUBCARRIER

DIVIDER

SUBCARRIER

SUBTRACTION

LOCK MODE

SELECTION

PHASE

DETECTION

18171615222120

19

CSCBBKIDHDVDWMP

CLP12RR

7

VLE11ECS

f

s

− ∆f

f

s

∆f

f

H

H

ref

40f

H

HRI

f

H

2f

H

160f

H

PRESCALER

SAA1101

81428 910

PH LM1 LM0

NORM SI

13232434

CS1 CLOCS0

V

SS

V

DD

X

Y

Z

FSO

FSI

OSCO

OSCI

252627

2

1

6

5

Fig.1 Block diagram.

Page 4

January 1990 4

Philips Semiconductors Product specification

Universal sync generator (USG) SAA1101

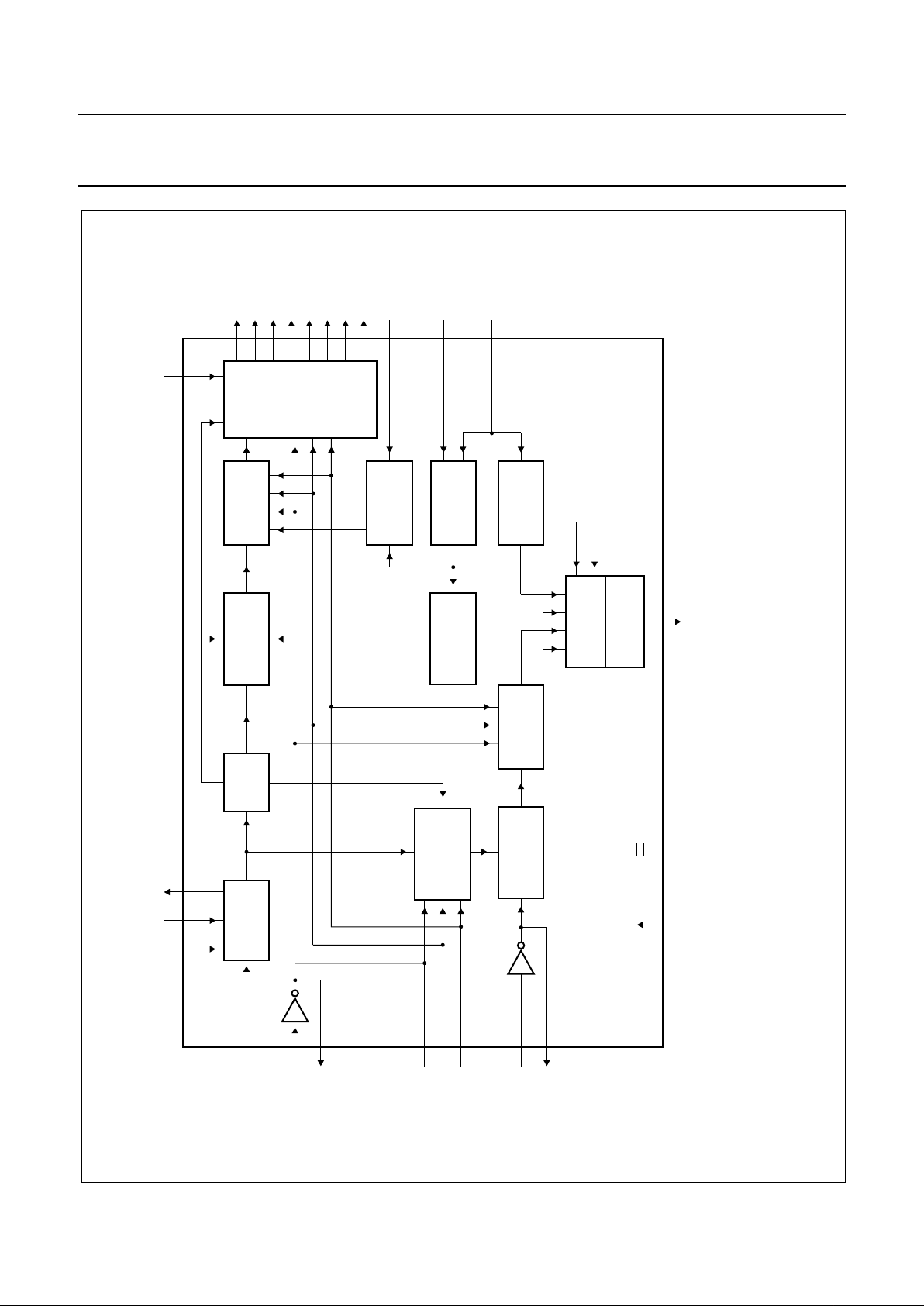

FUNCTIONAL DESCRIPTION

Generation of pulses

Generation of standard pulses such

as sync, blanking and burst for TV

systems: PAL B/G, PALN, PALM,

SECAM and NTSC. In addition a

number of non-standard pulses have

been supplied to simplify signal

processing. These signals include horizontal drive, vertical drive, clamp

pulse, identification etc. It is possible

to select the 524/624 line mode

instead of the 525/625 line mode for

all the above TV systems for

applications such as robotics, games

and computers.

Fig.2 Pinning configuration;

SOT117.

page

FSI

FSO

CS1

CS0

OSCI

OSCO

VLE

PH

LM1

LM0

ECS

RR

SI

V

SS

V

DD

Z

Y

X

NORM

HD

CLO

VD

WMP

CLP

CS

CB

BK

ID

1

2

3

4

5

6

7

8

9

10

11

12

13

28

27

26

25

24

23

22

21

20

19

18

17

16

1514

SAA1101

MGH190

PINNING

SYMBOL PIN DESCRIPTION

FSI 1 subcarrier oscillator input, where f

max

= 5 MHz

FSO 2 subcarrier oscillator output

CS1 3 clock frequency selection - CMOS input

CS0 4 clock frequency selection - CMOS input

OSCI 5 clock oscillator input, where f

max

= 24 MHz

OSCO 6 clock oscillator output

VLE 7 vertical in-lock enable - CMOS input

PH 8 phase detector output - 3-state output

LM1 9 lock mode selection - CMOS input

LM0 10 lock mode selection - CMOS input

ECS 11 external composite sync. signal - CMOS Schmitt-trigger

input

RR 12 frame reset - CMOS Schmitt-trigger input

SI 13 set identification, used to set the correct field sequence in

P AL-mode. The correction (inversion of fH2) is done at the

left-hand slope of the SI-pulse. Minimum pulse width is

800 ns. CMOS Schmitt-trigger input.

V

SS

14 ground

ID 15 identification - push-pull output

BK 16 burst key (PAL/NTSC), chroma-blanking (SECAM) -

push-pull output

CB 17 composite blanking - push-pull output

CS 18 composite sync. - push-pull output

CLP 19 clamp pulse - push-pull output

WMP 20 white measurement pulse-3-state output

VD 21 vertical drive pulse - push-pull output

HD 22 horizontal drive pulse - push-pull output

NORM 23 used with X, Y and Z to select TV system; NORM = 0,

625/525 line mode (standard);

NORM = 1, 624/524 line mode - CMOS input

CLO 24 clock output - push-pull output

X 25 TV system selection input - CMOS input

Y 26 TV system selection input - CMOS input

Z 27 TV system selection input - CMOS input

V

DD

28 voltage supply

Page 5

January 1990 5

Philips Semiconductors Product specification

Universal sync generator (USG) SAA1101

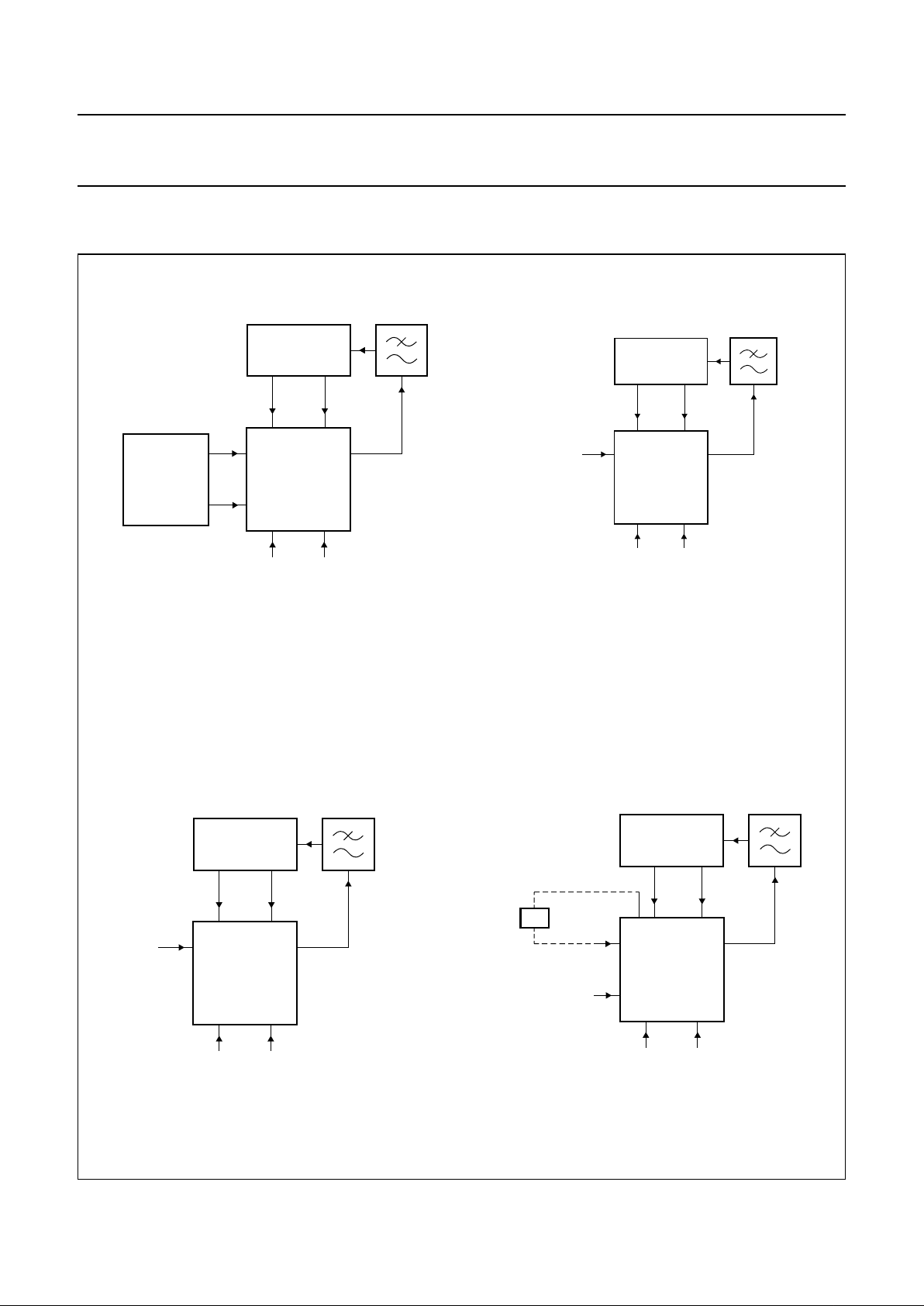

Lock modes

The USG offers four lock modes:

• Lock from the subcarrier

• Slow sync. lock, external H

ref

• Slow sync. lock, internal H

ref

• Fast sync. lock, internal H

ref

LOCK FROM SUBCARRIER

Lock from subcarrier to the line frequency for the above

mentioned TV systems is given below; the horizontal

frequency (fH) = 15.625 kHz for 625 line systems and

15.734264 kHz for 525 line systems.

These relationships are obtained by the use of a phase

locked loop and the internal programmed divider chain,

see Fig.3(a).

LOCK TO AN EXTERNAL SIGNAL SOURCE

The following methods can be used to lock to an external

signal source:

1. Sync. lock slow; the line frequency is locked to an

external signal. The line and frame information are

extracted from the external sync. signal and used

separately in the lock system. The line information is

used in a phase-locked loop where external and

internal line frequencies are compared by the same

phase detector as is used for the subcarrier lock. The

external frame information is compared with the

internal frame in a slow lock system; mismatch of

internal and external frames will result in the addition

or suppression of one line depending on the direction

of the fault. The maximum lock time for frame lock is

6.25 s, see Fig.3(b).

2. Sync. lock fast. A fast lock of frames is possible with a

frame reset which is extracted out of the incoming

external sync. signal, see Fig.3(c).

3. Sync. lock with external reference. Lock of an external

sync. signal to the line frequency with an external line

reference to make possible a shifted lock. The

SECAM (1 and 2) 282f

H

PALN 229.2516f

H

NTSC (1 and 2) 227.5f

H

PALM 227.25f

H

PAL B/G 283.7516f

H

subcarrier input is, in this case, used as an external

input for the horizontal reference, see Fig.3(d).

SELECTION OF LOCK MODE

Lock mode is selected using the inputs LM0 and LM1 as

illustrated in the Table below.

LM0 LM1 SELECTION

0 0 lock to subcarrier

0 1 slow sync. lock external H

ref

1 0 slow sync. lock internal H

ref

1 1 fast sync. lock internal H

ref

Page 6

January 1990 6

Philips Semiconductors Product specification

Universal sync generator (USG) SAA1101

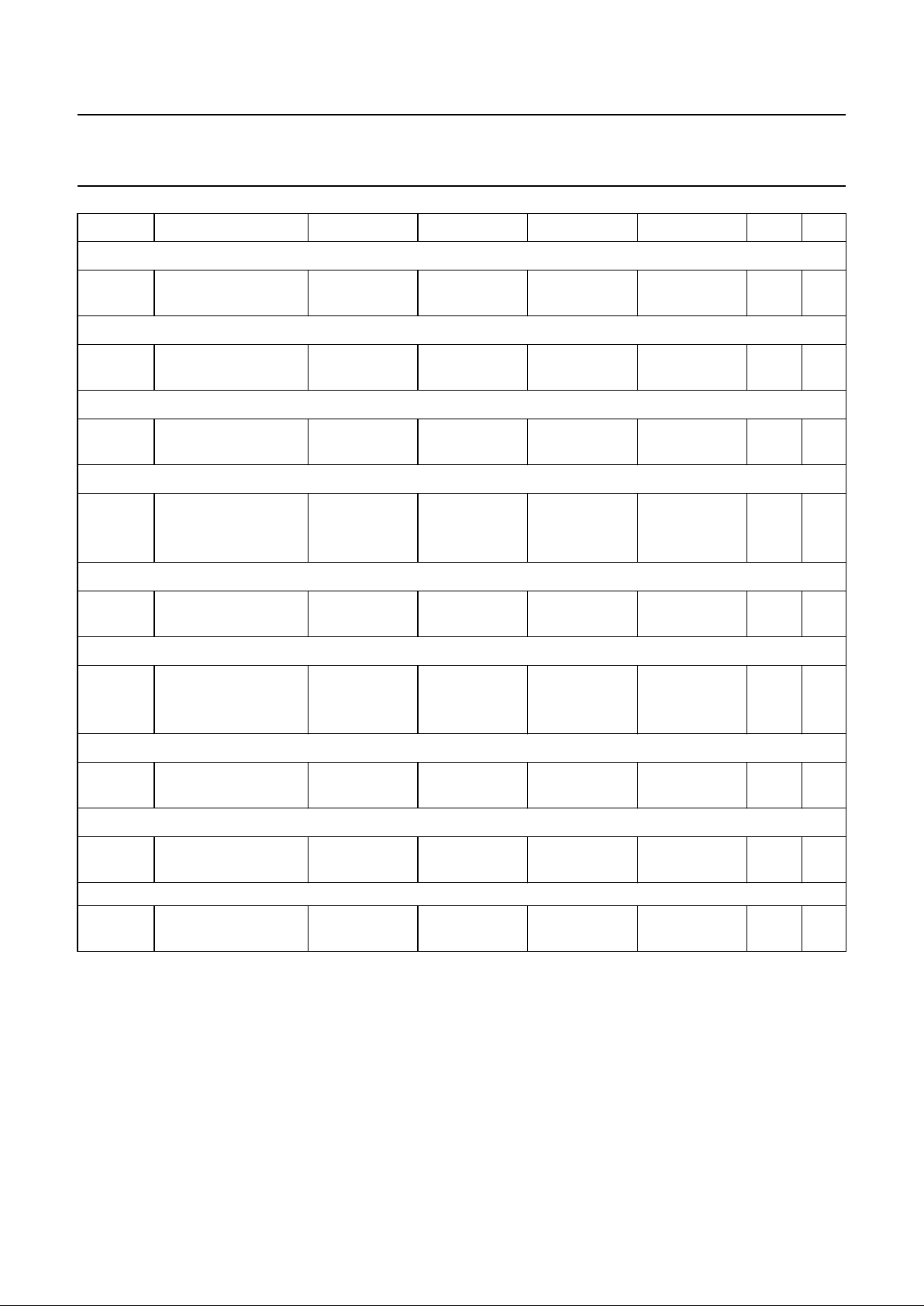

The different lock modes are illustrated by the following figures:

Fig.3 (a) Lock to subcarrier.

Fig.3 (b) Slow sync lock, internal H

ref

Fig.3 (c) Fast sync lock, internal H

ref

Fig.3 (d) Slow sync lock, external H

ref

handbook, halfpage

MGH193

n × f

H

LINE

OSCILLATOR

FSO

FSI

OSCO OSCI

SAA1101

SUB-

CARRIER

OSCILLATOR

PH

LM1LM0

logic 0 logic 1

10

65

8

2

1

9

handbook, halfpage

MGH194

n × f

H

LINE

OSCILLATOR

ECS

OSCO OSCI

SAA1101

PH

LM1LM0

logic 0 logic 1

10

65

8

11

9

handbook, halfpage

MGH195

n × f

H

LINE

OSCILLATOR

ECS

OSCO OSCI

SAA1101

PH

LM1LM0

logic 1 logic 1

10

65

8

11

9

handbook, halfpage

MGH192

n × f

H

LINE

OSCILLATOR

τ

H

ref

ECS

FSI

H

D OSCO OSCI

SAA1101

PH

LM1LM0

logic 0 logic 1

10

65

8

22

11

1

9

Page 7

January 1990 7

Philips Semiconductors Product specification

Universal sync generator (USG) SAA1101

LOCK WITH HORIZONTAL AND VERTICAL SIGNALS

(slow lock modes only)

It is possible to use horizontal and vertical signals instead of composite sync signals. The connections in this situation

are: the external horizontal signal is connected to the ECS input (pin 11) and the vertical signal to the RR input (pin 12).

The HIGH time of the horizontal pulse must be less than 14.4 µs, otherwise it will be detected as being a vertical pulse

and will corrupt the vertical slow lock system.

Selection of Clock Frequency

The clock frequency is selected using the CS0 and CS1 inputs as illustrated below.

Where the horizontal frequency, f

H

= 15.625 kHz for 625 lines and 15.734264 kHz for 525 lines.

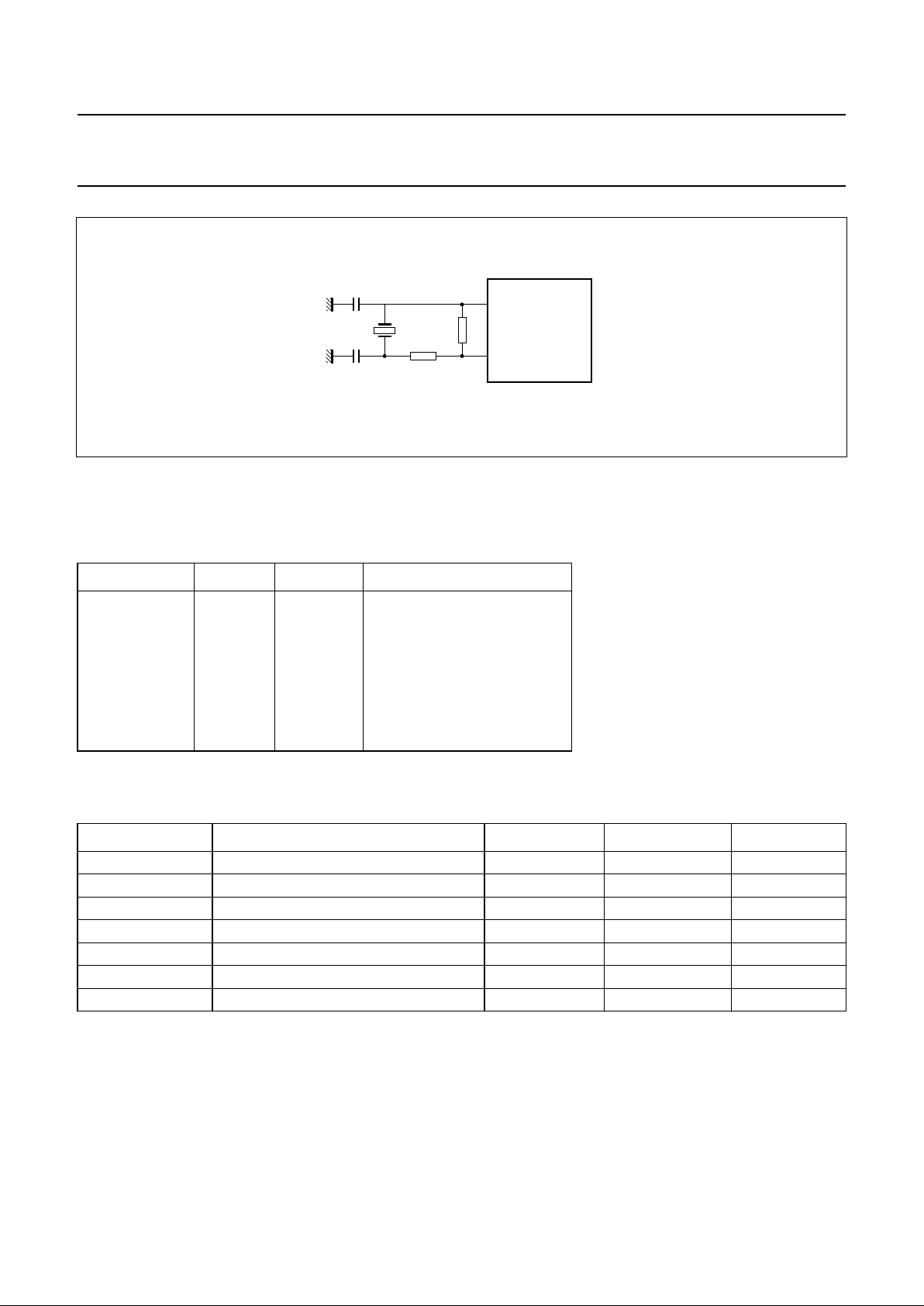

Oscillators

The subcarrier oscillator has FSI as its input and FSO as its output. It is always used as a crystal oscillator with a series

resonance crystal with parallel load capacitor. The maximum frequency, f

max

= 5 MHz and the load capacitor,

CL=10<CL<35 pF.

The clock oscillator has OSCI as its input and OSCO as its output. It can be used with an LC oscillator or a series

resonance crystal with parallel load capacitor (Fig.4). The maximum frequency, f

max

= 24 MHz and the load capacitor,

CL = 10 < CL< 35 pF.

Selection of 625/525 (standard; interlaced mode) or 624/524 lines (non-interlaced mode)

Selection is achieved using the NORM input. When NORM = 0, 625/525 (standard) lines are selected;

when NORM = 1, 624/524 line are selected.

Output Dimensions

All push-pull outputs: standard output 2 mA.

White measurement pulse, WMP: 3-state output 2 mA.

Phase detector, PH: 3-state output 2 mA.

CS0 CS1 FREQUENCY 625 LINES 525 LINES UNITS

0 0 160f

H

2.5 2.517482 MHz

0 1 160f

H

5 5.034964 MHz

1 0 960f

H

15 15.104893 MHz

1 1 1440f

H

22.5 22.657340 MHz

Page 8

January 1990 8

Philips Semiconductors Product specification

Universal sync generator (USG) SAA1101

Selection of TV System

Selection of the required TV system is achieved by the X, Y and Z inputs as illustrated by the following Table.

LIMITING VALUES

Limiting values in accordance with the Absolute Maximum System (IEC 134)

Note

1. Input voltage should not exceed 7 V.

SYSTEM

XY Z

SECAM1 0 0 0

PALN 0 0 1

NTSC1 0 1 0

PALM 0 1 1

SECAM2 1 0 0 (with identifier)

PAL B/G 1 0 1

NTSC2 1 1 0 (short blanking)

SYMBOL PARAMETER MIN. MAX. UNIT

V

DD

supply voltage −0.5 +7V

V

I

input voltage −0.5 VDD+ 0.5

(1)

V

I

I

maximum input current −±10 mA

I

O

maximum output current −±10 mA

I

DD

maximum supply current in V

DD

− 25 mA

P

tot

maximum power dissipation − 400 mW

T

stg

storage temperature range −55 +150 °C

Fig.4 Crystal oscillator circuit.

handbook, halfpage

MGH196

SAA1101

6

5

500 kΩ

1 kΩ

39 pF

39 pF

15 MHz

OSCI

OSCO

Page 9

January 1990 9

Philips Semiconductors Product specification

Universal sync generator (USG) SAA1101

CHARACTERISTICS

V

DD

= 4.5 to 5.5 V; T

amb

= −25 to +70 °C unless otherwise specified

SYMBOL PARAMETER CONDITIONS MIN. TYP. MAX. UNIT

Supplies

V

DD

supply voltage 4.5 − 5.5 V

I

DD

supply current (quiescent) T

amb

= 25 °C −−10 µA

Inputs

±I

I

input leakage current T

amb

= 25 °C −−100 nA

CMOS COMPATIBLE; X, Y, Z, NORM, CS0, CS1, LM0, LM1 AND VLE

V

IH

input voltage HIGH 0.7VDD−− V

V

IL

input voltage LOW −−0.3V

DD

V

SCHMITT TRIGGER INPUTS; ECS, RR AND SI

V

T+

positive-going threshold − 2.5 4 V

V

T−

negative-going threshold 1 1.5 − V

V

H

hysteresis 0.4 1 − V

OSCILLATOR INPUTS; OSCI AND FSI

V

IH

input voltage HIGH 0.7VDD−− V

V

IL

input voltage LOW −−0.3V

DD

V

Outputs

PUSH-PULL OUTPUTS; CB, CS, BK, ID, HD, VD, CLP AND CLO

V

OH

output voltage HIGH −IO = 2 mA; VDD = 5 V 4.5 −− V

V

OL

output voltage LOW IO = 2 mA; VDD = 5 V −−0.5 V

OSCILLATOR OUTPUTS; OSCO AND FSO

V

OH

output voltage HIGH −IO= 0.75 mA; VDD= 5 V 4.5 −− V

V

OL

output voltage LOW IO = 0.75 mA; VDD=5 V −−0.5 V

3-STATE OUTPUTS; WMP AND PH

V

OH

output voltage HIGH −IO = 2 mA; VDD = 5V 4.5 −− V

V

OL

output voltage LOW IO = 2 mA; VDD = 5V −−0.5 V

±I

OZ

OFF-state current T

amb

= 25 °C −−50 nA

Page 10

January 1990 10

Philips Semiconductors Product specification

Universal sync generator (USG) SAA1101

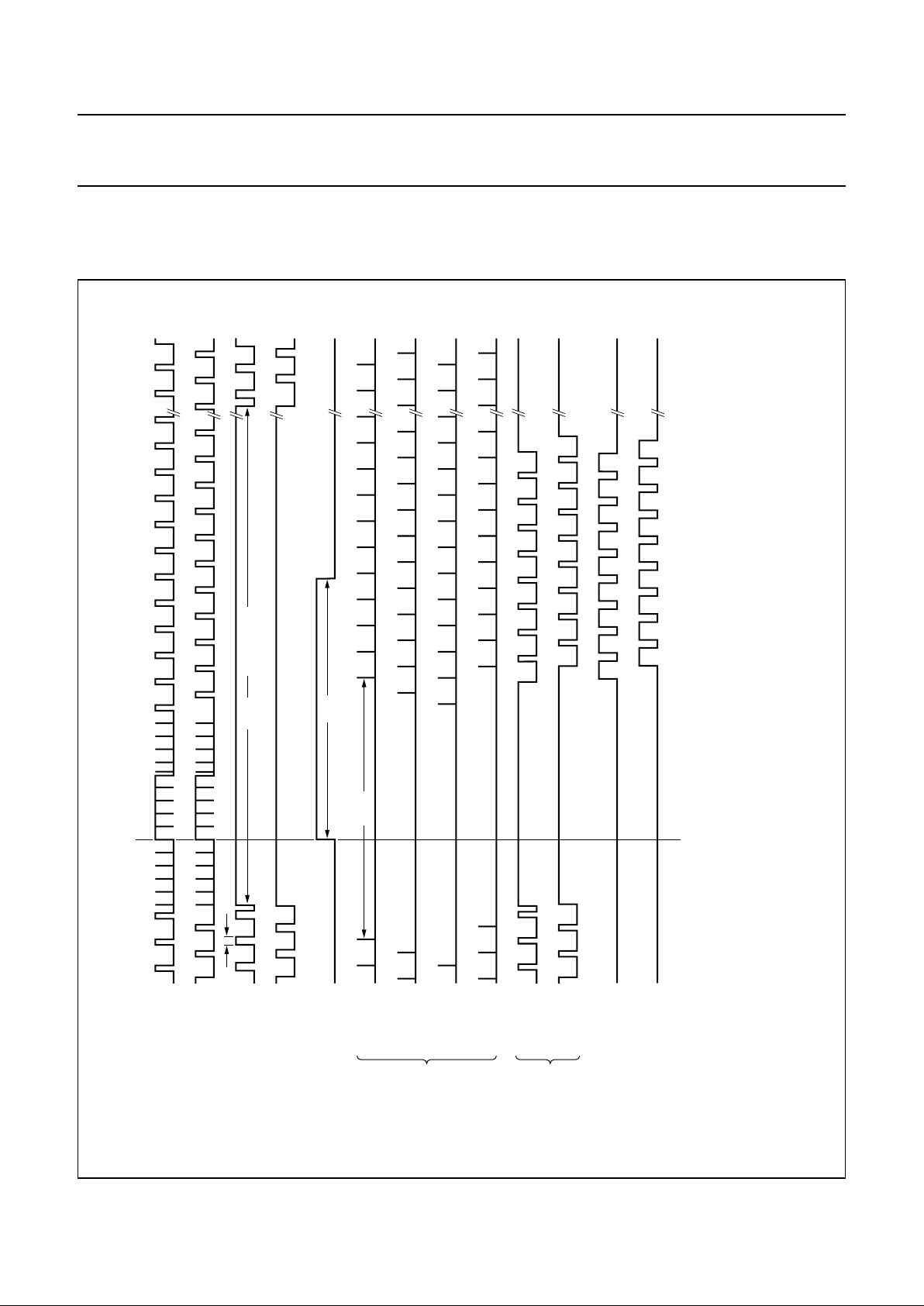

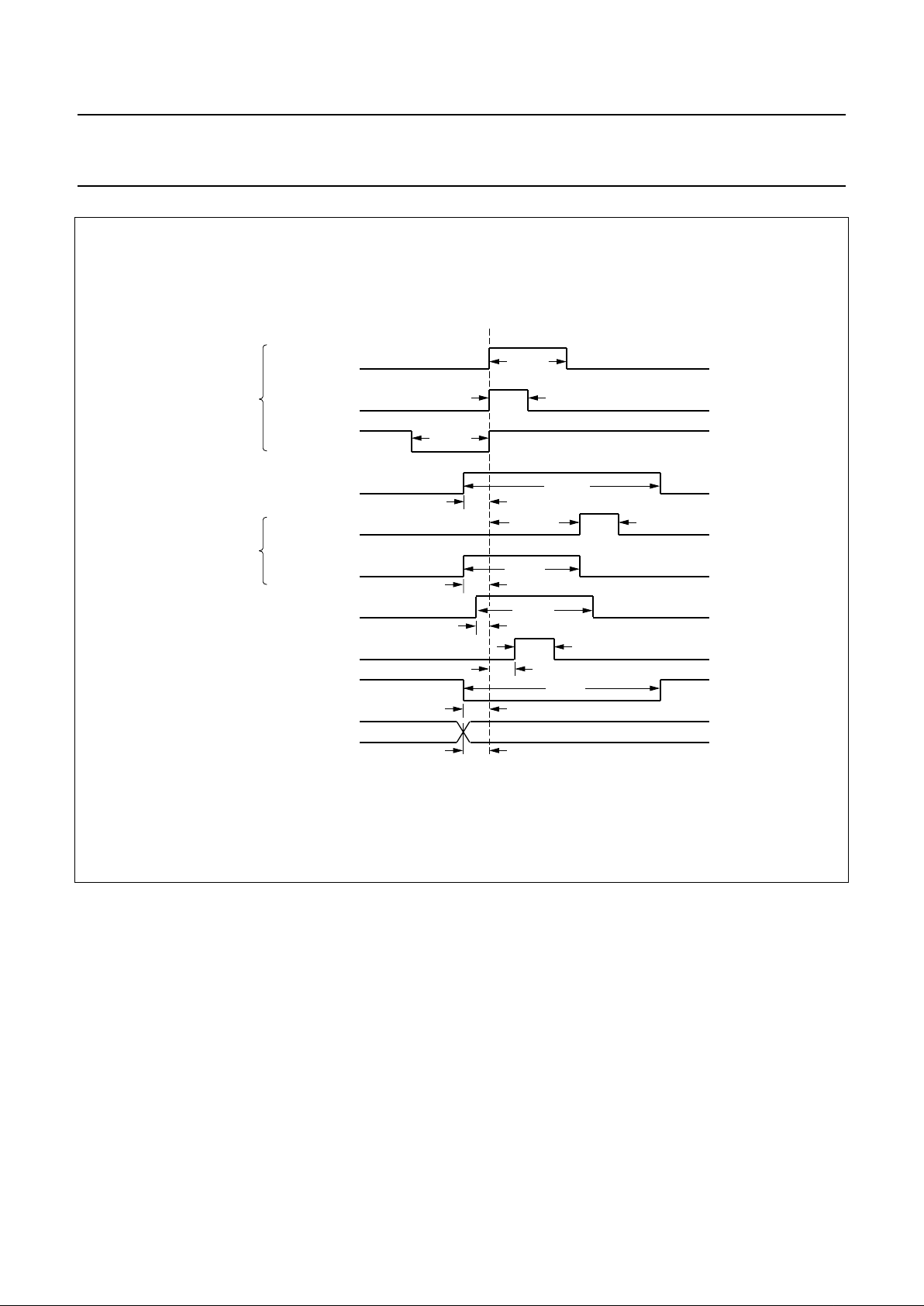

OUTPUT WAVEFORMS

The output waveforms for the different modes of operation are illustrated by Figs 5 and 6.

25H + t

WCB

ull pagewidth

MGH198

1st half

picture

2nd half

picture

1st half

picture

2nd half

picture

1st half

picture

2nd half

picture

3rd half

picture

4th half

picture

1st half

picture

2nd half

picture

1st half

picture

2nd half

picture

ID

ID

BK

BK

BK

BK

SECAM−1

CCIR/PAL

BK

BK

CB

CB

VD

CS

CS

9H

(1)

10H

t

WCB

start half picture

(1) H = 1 horizontal scan.

Fig.5 Typical output waveforms for PAL/CCIR and SECAM. In the 624-line mode the output waveforms are identical to the first half

picture of PAL/CCIR and are not interlaced.

Page 11

January 1990 11

Philips Semiconductors Product specification

Universal sync generator (USG) SAA1101

21H + t

WCB

u

ll pagewidth

MGH197

1st half

picture

2nd half

picture

1st half

picture

2nd half

picture

1st half

picture

2nd half

picture

1st half

picture

2nd half

picture

3rd half

picture

4th half

picture

1st half

picture

2nd half

picture

CB

CB

NTSC 2

(2)

BK

BK

BK

BK

PAL−M

BK

BK

NTSC 1 + 2

(2)

CB

CB

VD

NTSC 1

(2)

CS

CS

19H + t

WCB

9H

6H

t

WCB

start half picture

11H

(1)

(1) H = 1 horizontal scan.

(2) NTSC mode reset; the fourth half picture is identical to the second half picture for NTSC.

Fig.6 Typical output waveforms for NTSC and PAL-M. In the 524-line mode the output waveforms are identical to the first half picture of NTSC

and are not interlaced.

Page 12

January 1990 12

Philips Semiconductors Product specification

Universal sync generator (USG) SAA1101

WAVEFORM TIMING

The waveform timing depends on the frequency of the oscillator input (f

OSCI

). This is illustrated in the table below as the

number (N) of oscillations at OSCI. The timings are derived from N × t

OSCI

± 100 ns.

One horizontal scan (H) = 320 × t

OSCI

=1/fH.

Where t

OSCI

= 200 ns for PAL/SECAM and 198.6 ns for NTSC/PAL-M

SYMBOL PARAMETER PAL NTSC PAL-M SECAM UNIT N

Composite sync (CS)

t

WSC1

horizontal sync pulse

width

4.8 4.77 4.77 4.8 µs24

t

WSC2

equalizing pulse width 2.4 2.38 2.38 2.4 µs12

t

WSC3

serration pulse width 4.8 4.77 4.77 4.8 µs24

− duration of

pre-equalizing pulses

2.5 3 3 2.5 H −

− duration of

post-equalizing

pulses

2.5 3 3 2.5 H −

− duration of serration

pulses

2.5 3 3.5 2.5 H −

Composite blanking (CB)

HORIZONTAL BLANKING PULSE WIDTH

t

WCB

PAL/SECAM/PAL-M 12 − 11.12 12 µs60

t

WCB

NTSC1 − 11.12 −−µs56

t

WCB

NTSC2 − 10.53 (note1) −−µs53

FRONT PORCH

t

PCBCS

front porch 1.6 1.59 1.59 1.6 µs8

DURATION OF VERTICAL BLANKING

− PAL/SECAM/PAL-M 25H + t

WCB

− 21H + t

WCB

25H + t

WCB

−−

− NTSC1 − 21H + t

WCB

−−−−

−NTSC2 − 19H + t

WCB

−−−−

Burst key (BK) (not SECAM)

t

WBK

burst key pulse width 2.4 2.38 2.38 −µs12

t

PCSBK

CS to burst key delay 5.6 5.56 5.76 −µs28

− burst suppression 9 9 11 − H −

POSITION OF BURST SUPPRESSION

− first half picture H623 to H6 H523 to H6 H523 to H8 −−−

−second half picture H310 to H318 H261 to H269 H260 to H270 −−−

−third half picture H622 to H5 H523 to H6 H522 to H7 −−−

−fourth half picture H311 to H319 H261 to H269 H259 to H269 −−−

Page 13

January 1990 13

Philips Semiconductors Product specification

Universal sync generator (USG) SAA1101

Notes to the characteristics

1. Horizontal blanking pulse width for NTSC2 can be 11.12 µs maximum

2. SECAM1, first half picture: 25H + t

WBK

except H320 to H328. Second half picture: 24.5H + t

WBK

except H7 to H15.

3. SECAM2, first half picture: 25H + t

WBK

. Second half picture: 24.5H + t

WBK

.

Burst key (BK) (SECAM)

t

WBK

chroma pulse width −−−7.2 µs36

t

PBKCS

CS to chroma delay −−−1.6 µs8

DURATION OF VERTICAL BLANKING

− SECAM1 −−−note 2 −−

− SECAM2 −−−note 3 −−

Clamp pulse (CLP)

t

WCLP

clamp pulse width 2.4 2.38 2.38 2.4 µs12

t

PCSCLP

CS to CLP delay 1.6 1.59 1.59 1.6 µs8

Horizontal drive (HD)

t

WHD

pulse width 7.2 7.15 7.15 7.2 µs36

t

PHDCS

CS to HD delay 0.8 0.79 0.79 0.8 µs4

− repetition period 64 63.56 63.56 64 µs −

Vertical drive (VD)

− VD duration 10 6 6 10 H −

t

PVDCS

CS to VD delay 1.6 1.59 1.59 1.6 µs8

White measurement pulse (WMP)

− pulse width 2.4 2.38 2.38 2.4 µs12

− CS to WMP delay 34.4 34.16 34.16 34.4 µs 172

− duration of WMP 10 9 9 10 H −

POSITION OF WMP

− first half picture H163 to H173 H134 to H143 H134 to H143 H163 to H173 −−

− second half picture H475 to H485 H396 to H405 H396 to H405 H475 to H485 −−

Identification (ID)

t

WID

pulse width 12 11.12 11.12 12 µs60

t

PIDCS

CS to ID delay 1.6 1.59 1.59 1.6 µs8

POSITION OF ID

− first half picture H7 to H15 H8 to H22 H8 to H22 H7 to H15 −−

− second half picture H320 to H328 H271 to H285 H271 to H285 H320 to H328 −−

SYMBOL PARAMETER PAL NTSC PAL-M SECAM UNIT N

Page 14

January 1990 14

Philips Semiconductors Product specification

Universal sync generator (USG) SAA1101

Fig.7 Waveform timing.

handbook, full pagewidth

horizontal

sync pulse

equalizing pulse

serration pulse

horizontal

blanking pulse

burst key (PAL)

(SECAM)

chrominance

blanking

horizontal drive

clamp pulse

SECAM

identification

start, stop

vertical drives

CS

CB

BK

HD

CLP

ID

VD

composite

sync

composite

blanking

burst key/

chrominance

blanking

t

WSC1

t

WSC2

t

WSC3

t

WCB

t

PCBS2

t

PCBSK

t

WBK

t

WBK

t

PBKCS

t

WHD

t

PHDCS

t

WCPL

t

PCSCLP

t

WID

t

PIDCS

t

PVDCS

MLA029

Page 15

January 1990 15

Philips Semiconductors Product specification

Universal sync generator (USG) SAA1101

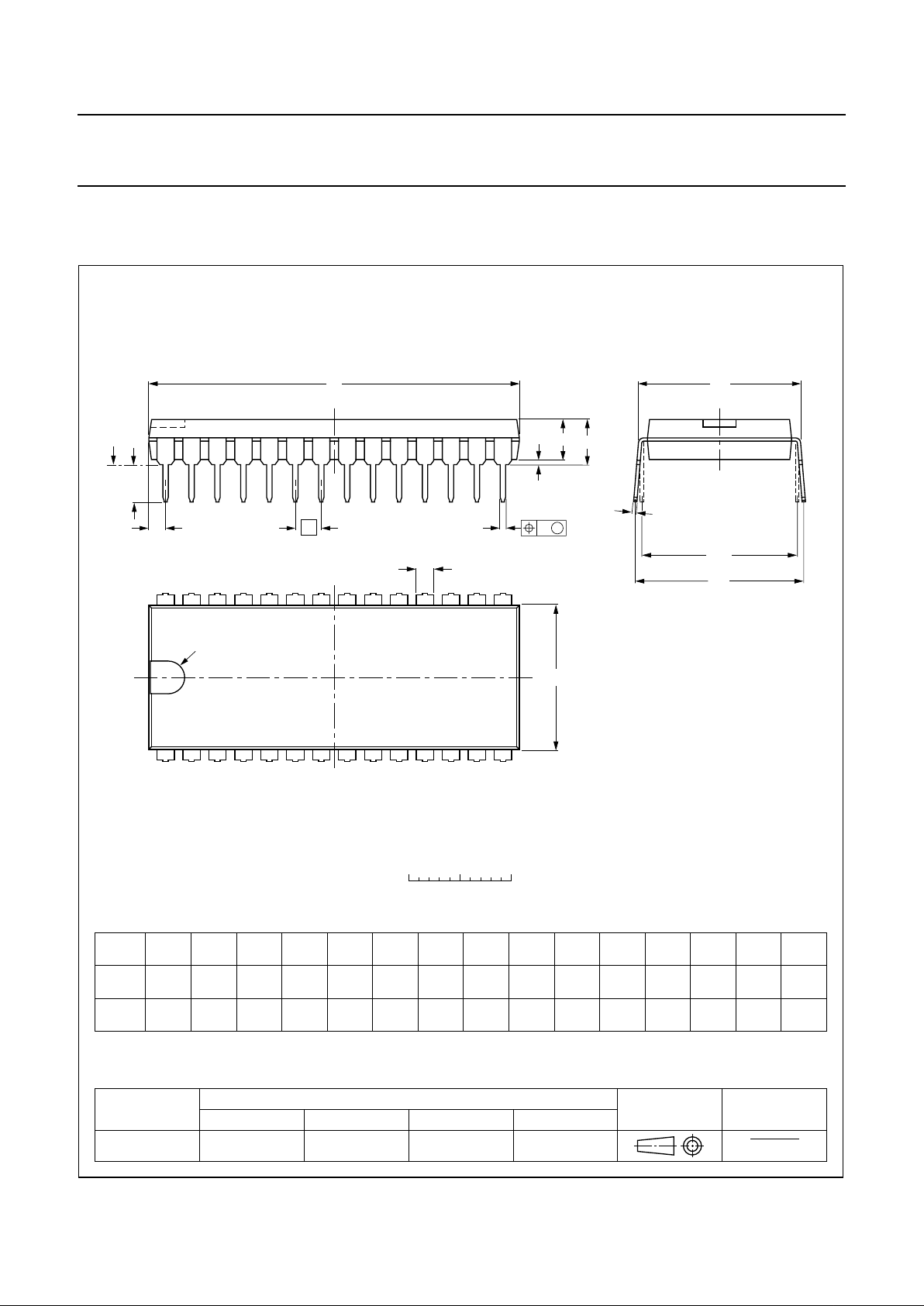

PACKAGE OUTLINES

UNIT

A

max.

1 2

b

1

(1)

(1) (1)

cD E weM

H

L

REFERENCES

OUTLINE

VERSION

EUROPEAN

PROJECTION

ISSUE DATE

IEC JEDEC EIAJ

mm

inches

DIMENSIONS (inch dimensions are derived from the original mm dimensions)

SOT117-1

92-11-17

95-01-14

A

min.

A

max.

b

Z

max.

M

E

e

1

1.7

1.3

0.53

0.38

0.32

0.23

36.0

35.0

14.1

13.7

3.9

3.4

0.252.54 15.24

15.80

15.24

17.15

15.90

1.75.1 0.51 4.0

0.066

0.051

0.020

0.014

0.013

0.009

1.41

1.34

0.56

0.54

0.15

0.13

0.010.10 0.60

0.62

0.60

0.68

0.63

0.0670.20 0.020 0.16

051G05 MO-015AH

M

H

c

(e )

1

M

E

A

L

seating plane

A

1

w M

b

1

e

D

A

2

Z

28

1

15

14

b

E

pin 1 index

0 5 10 mm

scale

Note

1. Plastic or metal protrusions of 0.25 mm maximum per side are not included.

handbook, full pagewidth

DIP28: plastic dual in-line package; 28 leads (600 mil)

SOT117-1

Page 16

January 1990 16

Philips Semiconductors Product specification

Universal sync generator (USG) SAA1101

UNIT

A

max.

A

1

A2A

3

b

p

cD

(1)E(1) (1)

eHELLpQ

Z

ywv θ

REFERENCES

OUTLINE

VERSION

EUROPEAN

PROJECTION

ISSUE DATE

IEC JEDEC EIAJ

mm

inches

2.65

0.30

0.10

2.45

2.25

0.49

0.36

0.32

0.23

18.1

17.7

7.6

7.4

1.27

10.65

10.00

1.1

1.0

0.9

0.4

8

0

o

o

0.25 0.1

DIMENSIONS (inch dimensions are derived from the original mm dimensions)

Note

1. Plastic or metal protrusions of 0.15 mm maximum per side are not included.

1.1

0.4

SOT136-1

X

14

28

w M

θ

A

A

1

A

2

b

p

D

H

E

L

p

Q

detail X

E

Z

c

L

v M

A

e

15

1

(A )

3

A

y

0.25

075E06 MS-013AE

pin 1 index

0.10

0.012

0.004

0.096

0.089

0.019

0.014

0.013

0.009

0.71

0.69

0.30

0.29

0.050

1.4

0.055

0.419

0.394

0.043

0.039

0.035

0.016

0.01

0.25

0.01

0.004

0.043

0.016

0.01

0 5 10 mm

scale

SO28: plastic small outline package; 28 leads; body width 7.5 mm

SOT136-1

95-01-24

97-05-22

Page 17

January 1990 17

Philips Semiconductors Product specification

Universal sync generator (USG) SAA1101

SOLDERING

Introduction

There is no soldering method that is ideal for all IC

packages. Wave soldering is often preferred when

through-hole and surface mounted components are mixed

on one printed-circuit board. However, wave soldering is

not always suitable for surface mounted ICs, or for

printed-circuits with high population densities. In these

situations reflow soldering is often used.

This text gives a very brief insight to a complex technology.

A more in-depth account of soldering ICs can be found in

our

“IC Package Databook”

(order code 9398 652 90011).

DIP

SOLDERING BY DIPPING OR BY WAVE

The maximum permissible temperature of the solder is

260 °C; solder at this temperature must not be in contact

with the joint for more than 5 seconds. The total contact

time of successive solder waves must not exceed

5 seconds.

The device may be mounted up to the seating plane, but

the temperature of the plastic body must not exceed the

specified maximum storage temperature (T

stg max

). If the

printed-circuit board has been pre-heated, forced cooling

may be necessary immediately after soldering to keep the

temperature within the permissible limit.

R

EPAIRING SOLDERED JOINTS

Apply a low voltage soldering iron (less than 24 V) to the

lead(s) of the package, below the seating plane or not

more than 2 mm above it. If the temperature of the

soldering iron bit is less than 300 °C it may remain in

contact for up to 10 seconds. If the bit temperature is

between 300 and 400 °C, contact may be up to 5 seconds.

SO

REFLOW SOLDERING

Reflow soldering techniques are suitable for all SO

packages.

Reflow soldering requires solder paste (a suspension of

fine solder particles, flux and binding agent) to be applied

to the printed-circuit board by screen printing, stencilling or

pressure-syringe dispensing before package placement.

Several techniques exist for reflowing; for example,

thermal conduction by heated belt. Dwell times vary

between 50 and 300 seconds depending on heating

method. Typical reflow temperatures range from

215 to 250 °C.

Preheating is necessary to dry the paste and evaporate

the binding agent. Preheating duration: 45 minutes at

45 °C.

W

AVE SOLDERING

Wave soldering techniques can be used for all SO

packages if the following conditions are observed:

• A double-wave (a turbulent wave with high upward

pressure followed by a smooth laminar wave) soldering

technique should be used.

• The longitudinal axis of the package footprint must be

parallel to the solder flow.

• The package footprint must incorporate solder thieves at

the downstream end.

During placement and before soldering, the package must

be fixed with a droplet of adhesive. The adhesive can be

applied by screen printing, pin transfer or syringe

dispensing. The package can be soldered after the

adhesive is cured.

Maximum permissible solder temperature is 260 °C, and

maximum duration of package immersion in solder is

10 seconds, if cooled to less than 150 °C within

6 seconds. Typical dwell time is 4 seconds at 250 °C.

A mildly-activated flux will eliminate the need for removal

of corrosive residues in most applications.

R

EPAIRING SOLDERED JOINTS

Fix the component by first soldering two diagonallyopposite end leads. Use only a low voltage soldering iron

(less than 24 V) applied to the flat part of the lead. Contact

time must be limited to 10 seconds at up to 300 °C. When

using a dedicated tool, all other leads can be soldered in

one operation within 2 to 5 seconds between

270 and 320 °C.

Page 18

January 1990 18

Philips Semiconductors Product specification

Universal sync generator (USG) SAA1101

DEFINITIONS

LIFE SUPPORT APPLICATIONS

These products are not designed for use in life support appliances, devices, or systems where malfunction of these

products can reasonably be expected to result in personal injury. Philips customers using or selling these products for

use in such applications do so at their own risk and agree to fully indemnify Philips for any damages resulting from such

improper use or sale.

Data sheet status

Objective specification This data sheet contains target or goal specifications for product development.

Preliminary specification This data sheet contains preliminary data; supplementary data may be published later.

Product specification This data sheet contains final product specifications.

Limiting values

Limiting values given are in accordance with the Absolute Maximum Rating System (IEC 134). Stress above one or

more of the limiting values may cause permanent damage to the device. These are stress ratings only and operation

of the device at these or at any other conditions above those given in the Characteristics sections of the specification

is not implied. Exposure to limiting values for extended periods may affect device reliability.

Application information

Where application information is given, it is advisory and does not form part of the specification.

Loading...

Loading...