Page 1

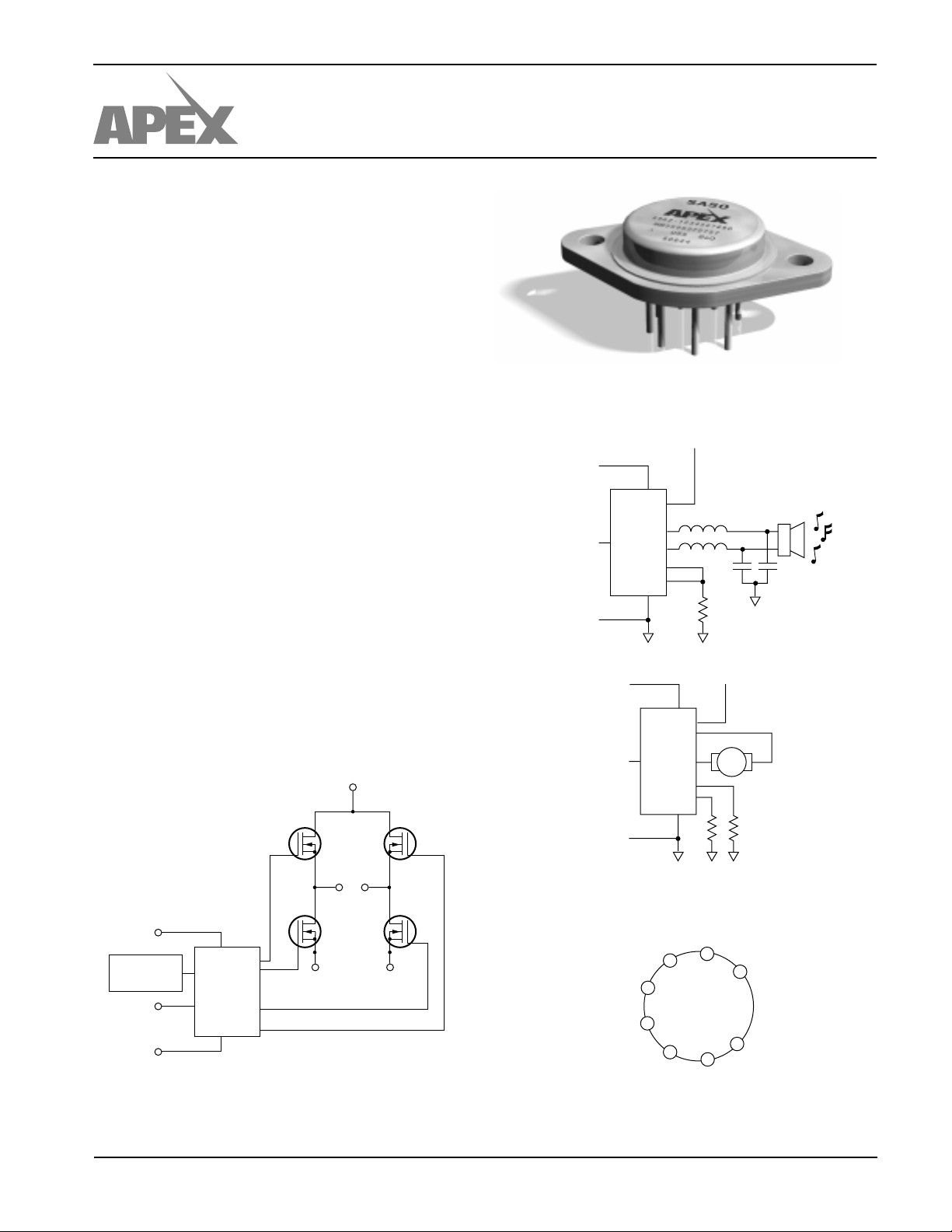

H/BRIDGE MOTOR DRIVER/AMPLIFIER

MICROTECHNOLOGY

HTTP://WWW.APEXMICROTECH.COM (800) 546-APEX (800) 546-2739

FEA TURES

• LOW COST COMPLETE H-BRIDGE

• SELF-CONTAINED SMART LOWSIDE/HIGHSIDE DRIVE

CIRCUITRY

• SINGLE SUPPLY OPERATION

• WIDE SUPPLY RANGE: UP TO 80V

• 5A CONTINUOUS OUTPUT

• HERMETIC SEALED PACKAGE

• HIGH EFFICIENCY: 97%

• FOUR QUADRANT OPERATION, TORQUE

CONTROL CAPABILITY

• INTERNAL PWM GENERATION

APPLICATIONS

• BRUSH TYPE MOTOR CONTROL

• CLASS D SWITCHMODE AMPLIFIER

• REACTIVE LOADS

• MAGNETIC COILS (MRI)

• ACTIVE MAGNETIC BEARING

• VIBRATION CANCELLING

SA50

TYPICAL APPLICATION

Vcc

AUDIO

INPUT

SA50

+V

S

DESCRIPTION

The SA50 is a pulse width modulation amplifier that can

supply 5A continuous current to the load. The full bridge

amplifier can be operated over a wide range of supply voltages. All of the drive/control circuitry for the lowside and

highside switches are internal to the hybrid. The PWM circuitry

is internal as well, leaving the user to only provide an analog

signal for the motor speed/direction, or audio signal for

switchmode audio amplification. The SA50 is packaged in a

space efficient isolated 8-pin TO-3 that can be directly connected to a heatsink.

+V

BLOCK DIAGRAM

V

CC

(+12V)

45KHz

PWM

GENERATOR

INPUT

GND

H-BRIDGE

CIRCUITRY

DRIVE

RSENSE B

S

(LOAD)

BA

RSENSE A

(CURRENT)

GND

Vcc

ANALOG

INPUT

GND

SA50

EXTERNAL CONNECTIONS

+V

S

3

A OUT

RSENSE A

4

TOP VIEW

5

6

Vcc

GND

+V

B OUT

2

7

S

DC MOTOR

RSENSE B

1

8

INPUT

SPEAKER

APEX MICROTECHNOLOGY CORPORATION • TELEPHONE (520) 690-8600 • FAX (520) 888-3329 • ORDERS (520) 690-8601 • EMAIL prodlit@apexmicrotech.com

Page 2

SA50

ABSOLUTE MAXIMUM RATINGS

SPECIFICATIONS

ABSOLUTE MAXIMUM RATINGS

SUPPLY VOLTAGE, +V

OUTPUT CURRENT, peak 7A

LOGIC SUPPLY VOLTAGE, Vcc 16V

POWER DISSIPATION, internal 120W

TEMPERATURE, pin solder - 10s 300°C

TEMPERATURE, junction

TEMPERATURE, storage –65 to +150°C

OPERATING TEMPERATURE RANGE, case –65 to +125°C

INPUT VOLTAGE +1 to Vcc – 1.5 Vdc

S

3

80V

1

150°C

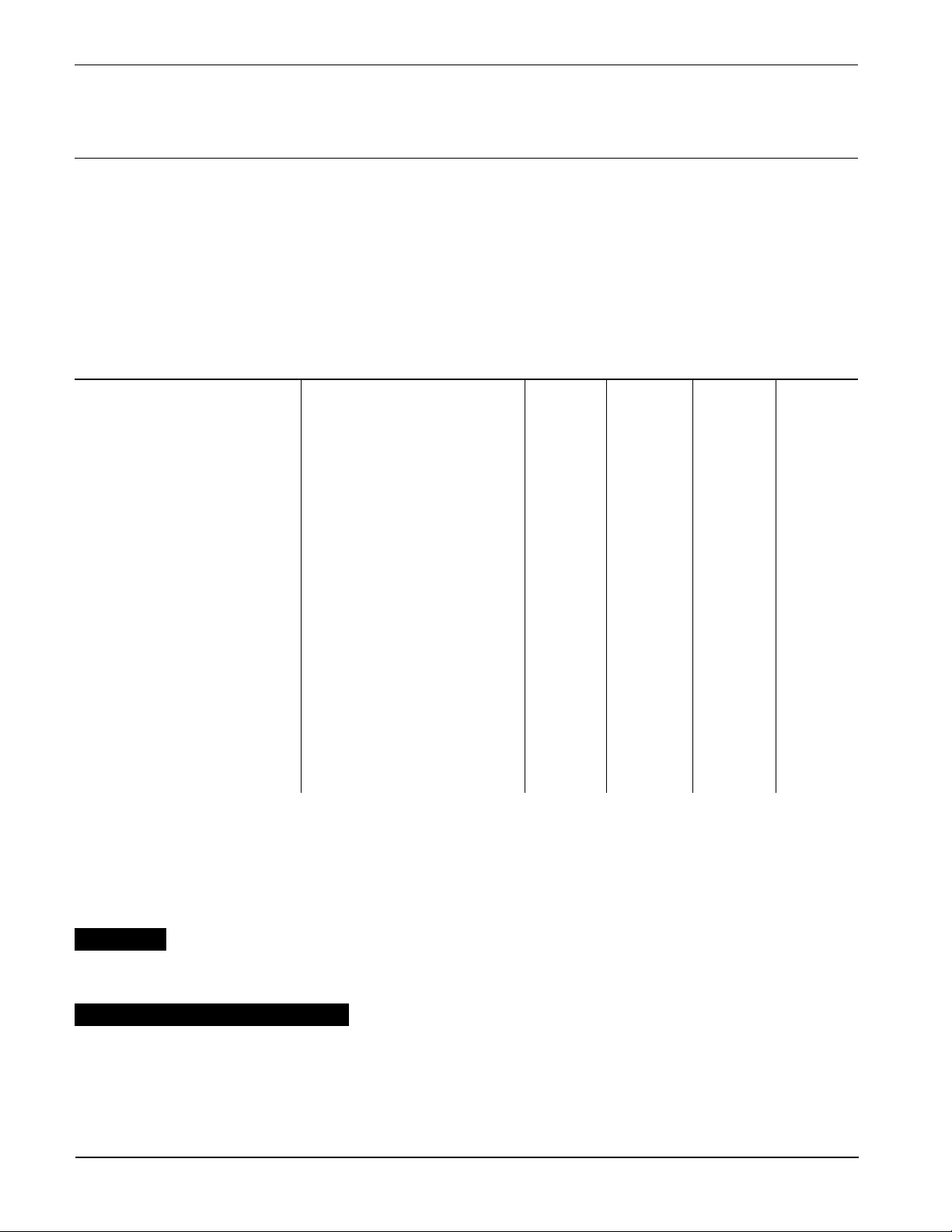

SPECIFICATIONS

PARAMETER TEST CONDITIONS

INPUT

ANALOG INPUT VOLTAGES Vcc = 12V

MOTOR A, B = 50% Duty Cycle 6 Vdc

MOTOR A = 100% Duty Cycle High 8 Vdc

MOTOR B = 100% Duty Cycle High 4 Vdc

OUTPUT

Vds (ON) VOLTAGE, each MOSFET Ids = 5A 1.25 1.8 Vdc

TOTAL Ron, both MOSFETs 0.5 Ω

EFFICIENCY, 5A OUTPUT +VS = 80V 97 %

SWITCHING FREQUENCY 40 45 50 Khz

CURRENT, continuous 5 A

CURRENT, peak t = 100 msec 7 A

SWITCHING CHARACTERISTICS

RISE TIME 36 54 nS

FALL TIME 170 250 nS

DEAD TIME 100 nS

4

+VS = 28V, Vcc = 12V, Ic =2A

2

MI N TYP MAX UNITS

POWER SUPPLY

+VS VOLTAGE +VS Current = Load Current 80 Vdc

Vcc VOLTAGE 9 12 16 Vdc

Vcc CURRENT Vcc = 12Vdc 15 20 mA

THERMAL

RESISTANCE, junction to case Full temp range, for each transistor 2.0 °C/W

RESISTANCE, junction to air Full temperature range 30 °C/W

TEMPERATURE RANGE, case –25 +85 °C

NOTES: 1. Each of the two active output transistors can dissipate 60W.

CAUTION

3

2. Unless otherwise noted: TC = 25°C, Vcc = 12Vdc.

3. Long term operation at the maximum junction temperature will result in reduced product life. Derate internal power

dissipation to achieve high MTTF. For guidance, refer to the heatsink data sheet.

4. Guaranteed but not tested.

The SA50 is constructed from MOSFET transistors. ESD handling procedures must be observed.

The internal substrate contains beryllia (BeO). Do not break the seal. If accidentally broken, do not crush, machine, or

subject to temperatures in excess of 850°C to avoid generating toxic fumes.

WARNING—AMPLIFIER PROTECTION

The SA50 contains an internal logic chip that turns on and

turns off output MOSFET drivers at a certain sequence. Noises

or oscillation caused by external wiring inductance, lack of

proper power supply bypass capacitors, ground, supply and

local internal loops, may be fed back to this logic chip and

cause it to turn on one or more MOSFET drivers at the wrong

time, thus destroying the SA50. A well laid out PC board with

low impedance copper ground plane is necessary for the

SA50 to function properly. The Apex EK-SA50 evaluation

board is recommended for fast and easy breadboarding of

circuits using the SA50.

APEX MICROTECHNOLOGY CORPORATION • 5980 NORTH SHANNON ROAD • TUCSON, ARIZONA 85741 • USA • APPLICATIONS HOTLINE: 1 (800) 546-2739

Page 3

TYPICAL PERFORMANCE

GRAPHS

SA50

60

POWER DERATING

50

INPUT CURRENT VS TEMP

1.05

0.95

0.85

40

30

20

0.75

0.65

0.55

0.45

10

EACH OUTPUT TRANSISTOR

0

INTERNAL POWER DISSIPATION, (W)

CASE TEMPERATURE, T (°C)

EFFICIENCY VS TEMP @ 80V EFFICIENCY VS TEMP @ 20V

100

99

I

98

97

I

OUT

96

95

EFFICIENCY, (%)

94

= 1A, V

OUT

= 5A, V

75

S

= 80V

1000 25 50 125

= 80V

S

C

93

92

–60 180–20 20 60 100 140

JUNCTION TEMPERATURE (°C)

PWM BIAS CURRENT, (µA)

0.35

0.25

–40 120

–20 0 20 40 60 80 100 4 5

CASE TEMPERATURE, (°C)

100

95

I

OUT

= 1A, V

90

85

I

OUT

= 5A, V

80

75

EFFICIENCY, (%)

70

65

–60 180

–20 20 60 100 140

JUNCTION TEMPERATURE (°C)

S

= 20V

= 20V

S

EFFICIENCY CONTOURS

80

(V)

S

70

60

50

97%

95%

40

30

20

SUPPLY VOLTAGE, V

10

0

123

90%

80%

70%

LOAD CURRENT, (A)

EFFICIENCY VS LOAD CURRENT

100

V

= 80V

V

V

S

S

V

= 60V

S

= 40V

S

= 20V

97

94

91

EFFICIENCY, (%)

88

85

12345

LOAD CURRENT, (A)

OUTPUT RESISTANCE DRIFT

2.5

2

1.5

1

0.5

0

–60 180–20 20 60 100 140

OUTPUT RESISTANCE, (NORMALIZED)

JUNCTION TEMPERATURE (°C)

VOLTAGE DROP (BOTH MOSFETS)

5

CASE TEMPERATURE

4

3

2

VOLTAGE DROP, (V)

1

0

051234

85°C

110°C

60°C

35°C

OUTPUT CURRENT, (A)

H-BRIDGE FET CAPACITANCE

500

400

300

200

100

DRAIN-TO-SOURCE CAP, (pF)

0

1 2 5 10 20 50 100

DRAIN-TO-SOURCE VOLTAGE, (V)

QUIESCENT CURRET VS PWM FREQ

15

14

13

12

11

QUIESCENT CURRENT, (mA)

10

0

200

400 600

PWM FREQUENCY (Hz)

QUIESCENT CURRENT VS VOLTAGE

14.0

12.0

10.0

8.0

6.0

4.0

QUIESCENT CURRENT, (mA)

2.0

8 9 10 11 13 1512 14

Vcc VOLTAGE (V)

APEX MICROTECHNOLOGY CORPORATION • TELEPHONE (520) 690-8600 • FAX (520) 888-3329 • ORDERS (520) 690-8601 • EMAIL prodlit@apexmicrotech.com

Page 4

SA50

OPERATING

CONSIDERATIONS

GENERAL

Helpful information about power supplies, heatsinking and

mounting can be found in the “General Operating Considerations” section of the Apex data book. For information on the

package outline, heatsinks, and mounting hardware see the

“Package Outlines” and “Accessories” section of the data

book. Also see Application Note 30 on “PWM Basics.”

PIN DESCRIPTION

VCC - is the low voltage supply for powering internal logic

and drivers for the lowside and highside MOSFETS. The

supplies for the highside drivers are derived from this voltage.

V

- is the higher voltage H-bridge supply. The MOSFETS

S

obtain the output current from this supply pin. The voltage on

this pin is limited to +80V by the drive IC. The MOSFETS are

rated at 100 volts. Proper by-passing to GND with sufficient

capacitance to suppress any voltage transients, and to ensure

removing any drooping during switching, should be done as

close to the pins on the hybrid as possible.

A OUT - is the output pin for one half of the bridge. Increasing

the input voltage causes increasing duty cycle at this output.

B OUT - is the output pin for the other half of the bridge.

Decreasing the input voltage causes increasing duty cycles at

this point.

RSENSE A - This is the connection for the bottom of the A

half bridge. This can have a sense resistor connected to the V

return ground for current limit sensing, or can be connected

directly to ground. The maximum voltage on this pin is ±2 volts

with respect to GND.

GND - is the return connection for the input logic and Vcc.

RESENSE B - This is the connection for the bottom of the B

half bridge. This can have a sense resistor connection to the

V

return ground for current limit sensing, or can be connected

S

directly to ground. The maximum voltage on this pin is ±2 volts

with respect to GND.

INPUT - is an analog input for controlling the PWM pulse

width of the bridge. A voltage higher than Vcc/2 will produce

greater than 50% duty cycle pulses out of A OUT. A voltage

lower than Vcc/2 will produce greater than 50% duty cycle

pulses out of B OUT.

TYPICAL SYSTEM OPERATION

+V

+V

S

3

S

4

2

5

1

RIN

Rf

SNUBBER NETWORK

100Ω

2W

1000pF

200V

+12V

MOTOR

SENSE

RESISTORS

0.1Ω

RDIVIDE

RDIVIDE

RIN

and negative spikes

S

+12V

6

GND

Vcc

MOTOR A

SA50

8

INPUT

MOTOR B

7

GND

RSENSE A

RSENSE B

NO OUTPUT

SWITCHING

CURRENT

CURRENT CONTROL

22µF

R

R

+12V

ANALOG

INPUT

S

This is a diagram of a typical application of the SA50. The

design Vcc voltage is +12 volts and should have a good low

ESR bypass capacitor such as a tantalum electrolytic. The

analog input can be an analog speed control voltage from a

potentiometer, other analog circuitry or by microprocessor and

a D/A converter. This analog input gets pulled by the current

control circuitry in the proper direction to reduce the current

flow in the bridge if it gets too high. The gain of the current

control amplifier will have to be set to obtain the proper amount

of current limiting required by the system.

Current sensing is done in this case by a 0.1Ω sense resistor

to sense the current from both legs of the bridge separately. It

is important to make the high current traces as big as possible

to keep inductance down. The storage capacitor connected to

the V

and the hybrid GND should be large enough to provide

S

the high energy pulse without the voltage sagging too far. A

low ESR capacitor will be required. Mount capacitor as close

to the hybrid as possible. The connection between GND and

the V

return should not be carrying any motor current. The

S

sense resistor signal is common mode filtered as necessary to

feed the limiting circuitry. This application will allow full four

quadrant torque control for a closed loop servo system.

A snubber network is usually required, due to the inductance

in the power loop. It is important to design the snubber network

to suppress any positive spikes above +V

below –2V with respect to pin 7 (GND).

MYLAR

(VCC÷2)

6.8µF

100V

POLY

RDIVIDE = 2X Rf

This data sheet has been carefully checked and is believed to be reliable, however, no responsibility is assumed for possible inaccuracies or omissions. All specifications are subject to change without notice.

APEX MICROTECHNOLOGY CORPORATION • 5980 NORTH SHANNON ROAD • TUCSON, ARIZONA 85741 • USA • APPLICATIONS HOTLINE: 1 (800) 546-2739

SA50U REV. D JANUARY 1998 © 1998 Apex Microtechnology Corp.

Loading...

Loading...