Datasheet SA25C020LEMNFX, SA25C020LEMNX, SA25C020LEN, SA25C020LENF, SA25C020LENFX Datasheet (SAIFUN)

...Page 1

Features

•= Saifun NROM™ Cell

•= Serial Peripheral Interface (SPI) Compatible,

Supports SPI Modes 0 (0,0) and 3 (1,1)

•= Byte and Page Write Operation:

– 1024 pages (256 Bytes/Page)

– Single Byte or Page Write Cycle in 10ms Typical

•= Single Supply Voltage: 2.7V to 3.6V

•= 25MHz Clock Rate

•= Block Write Protection: Protect Quarter, Half or Entire Array

•= Write Protect Pin and Write Disable Instructions of Both

Hardware and Software Data Protection

•= 100,000 Erase Cycles (Minimum)

•= More than 20-Year Data Retention

•= Low-power Standby Current (less than 1µA)

•= 8-SOIC Narrow Package

•= MLF Leadless Package

•= Temperature Range:

– Industrial: -40°C to +85°C

– Commercial: 0°C to +70°C

SA25C020

Advanced

Information

2Mb EEPROM with

25MHz SPI Bus

Interface

http://www.saifun.com

Saifun NROMTM is a trademark of Saifun Semiconductors Ltd.

This Data Sheet states Saifun's current technical specifications regarding the Products described herei n. This Data

Sheet may be revised by subsequent versions or modifications due to changes in technical specifications.

Publication# 1911 Rev: 0 Amendment: 0

Issue Date: 20 July 2003

Page 2

SA25C020 Advanced Information

SAIFUN

2

General Description

The SA25C020 is a 2Mb (512K X 4) CMOS

non-volatile serial EEPROM. This device

fully conforms to the SPI 4-wire protocol, is

enabled through the Chip Select (CSb) pin,

and uses Clock (SCK), Data-in (SI) and

Data-out (SO) pins to synchronously control

data transfer between the SPI

microcontroller and the Serial EEPROM.

The memory can be written from 1 up to

256 bytes at a time via the Byte / Page

Write (PW) instruction.

The memory consists of 1024 pages or

262,144 bytes.

Each device requires only a 3.0V power

supply (2.7 V to 3.6 V) for both read and

write functions. Internally generated and

regulated voltages are provided for the

program and erase operations. The

SA25C020 does not require a V

The HOLDb pin may be used to suspend

any serial communication without resetting

the serial sequence. In addition, the serial

interface allows a minimal-pin-count

packaging designed to simplify PC board

layout requirements and offers the designer

a variety of low-voltage and low-power

options.

supply.

PP

The SA25C020 is available in a

space-saving, 8-lead narrow SOIC package

The SA25C020 is part of the SPI EEPROM

family. It is designed to work with any SPIcompatible, high-speed microcontroller, and

offers both hardware (WPb pin) and

Software (“block protect”) data protection.

For example, programming a 2-bit code into

the status register prevents program with

top ¼, top ½ or entire array write protection

and enables block write protection.

Separate program enable and program

disable instructions are provided for

additional data protection. Hardware data

protection is provided via the WPb pin to

protect against inadvertent write attempts to

the status register.

Saifun’s SPI Serial EEPROM products are

designed and tested for applications

requiring high endurance and low power

consumption for a continuously reliable

non-volatile solution for all markets.

Page 3

SA25C020 Advanced Information

SAIFUN

3

Table of Contents

Features........................................................................... 1

General Description ........................................................ 2

Memory Organization...................................................... 5

Connection Diagrams..................................................... 6

Ordering Information ...................................................... 7

Product Specifications ................................................... 8

Absolute Maximum Ratings....................................... 8

ESD/Latch Up Specification (JEDEC 8 Spec) ........... 8

Operating Conditions................................................. 8

DC Characteristics .......................................................... 9

AC Test Conditions ....................................................... 10

Timing Diagrams........................................................... 11

Signal Description......................................................... 13

Chip Select (CSb).................................................... 13

Serial Clock (SCK) .................................................. 13

Serial Input (SI) ....................................................... 13

Serial Output (SO)................................................... 13

Hold (HOLDb).......................................................... 13

Write Protect (WPb) ................................................ 13

Serial Interface Description.......................................... 14

SPI Modes............................................................... 14

Master ............................................................. 14

Slave ............................................................... 14

Transmitter/Receiver ....................................... 14

Serial Opcode.................................................. 14

Invalid Opcode ................................................ 14

Chip Select (CSb)............................................ 15

Hold Condition................................................. 15

Write Protect ................................................... 16

Functional Description ................................................. 17

Instructions.............................................................. 17

Read Status Register (RDSR)................................. 18

Write Enable (WREN) ............................................. 20

Write Disable (WRDI).............................................. 20

Write Status Register (WRSR)................................ 21

Read Data Bytes (READ)........................................ 23

Byte or Page Write (PW) ......................................... 24

Read Electronic Signature (Read_Id) ...................... 26

Powerup and Powerdown........................................ 27

Physical Dimensions..................................................... 28

Contact Information ...................................................... 31

Life Support Policy........................................................ 31

Page 4

SA25C020 Advanced Information

SAIFUN

4

List of Figures

Figure 1. SA25C020 Block Diagram................................ 5

Figure 2. SOIC 8 (150 mil)/PDIP/MLF Package

(Top View)............................................................. 6

Figure 3. SA25C020 Ordering Information ...................... 7

Figure 4. SPI Mode 0 (0,0) Input Timing........................ 11

Figure 5. SPI Mode 0 (0,0) Output Timing..................... 11

Figure 6. AC Measurements I/O Waveform................... 12

Figure 7. Supported SPI Modes .................................... 14

Figure 8. Hold Condition................................................ 15

Figure 9. SPI Serial Interface ........................................ 17

Figure 10. Read Status Register (RDSR) Instruction

Sequence ............................................................ 19

Figure 11. Write Enable (WREN) Instruction Sequence 20

Figure 12. Write Disable (WRDI) Instruction Sequence. 20

Figure 13. Write Status Register (WRSR) Instruction

Sequence ............................................................ 22

Figure 14. Read (READ) Instruction Sequence ............. 23

Figure 16. Read Electronic Signature (Read Id) Instruction

Sequence ............................................................ 26

Figure 17. 8-pin SOIC Package..................................... 28

Figure 18. 8-pin MLF Leadless Package ....................... 29

Figure 19. Molded Dual-in-line Package (N) Package

Number N08E...................................................... 30

List of Tables

Table 1. Pin Names......................................................... 6

Table 2. DC Characteristics............................................. 9

Table 3. AC Test Conditions.......................................... 10

Table 4. AC Measurements........................................... 12

Table 5. Instruction Set ................................................. 17

Table 6. Status Register Format.................................... 17

Table 7. Read Status Register Definition....................... 18

Table 8. Block Write Protect Bits................................... 21

Table 9. WPBEN Operation .......................................... 21

Table 10. Powerup ........................................................ 27

Figure 15. Byte or Page Write (PW) Instruction

Sequence ............................................................ 25

Page 5

SA25C020 Advanced Information

SAIFUN

5

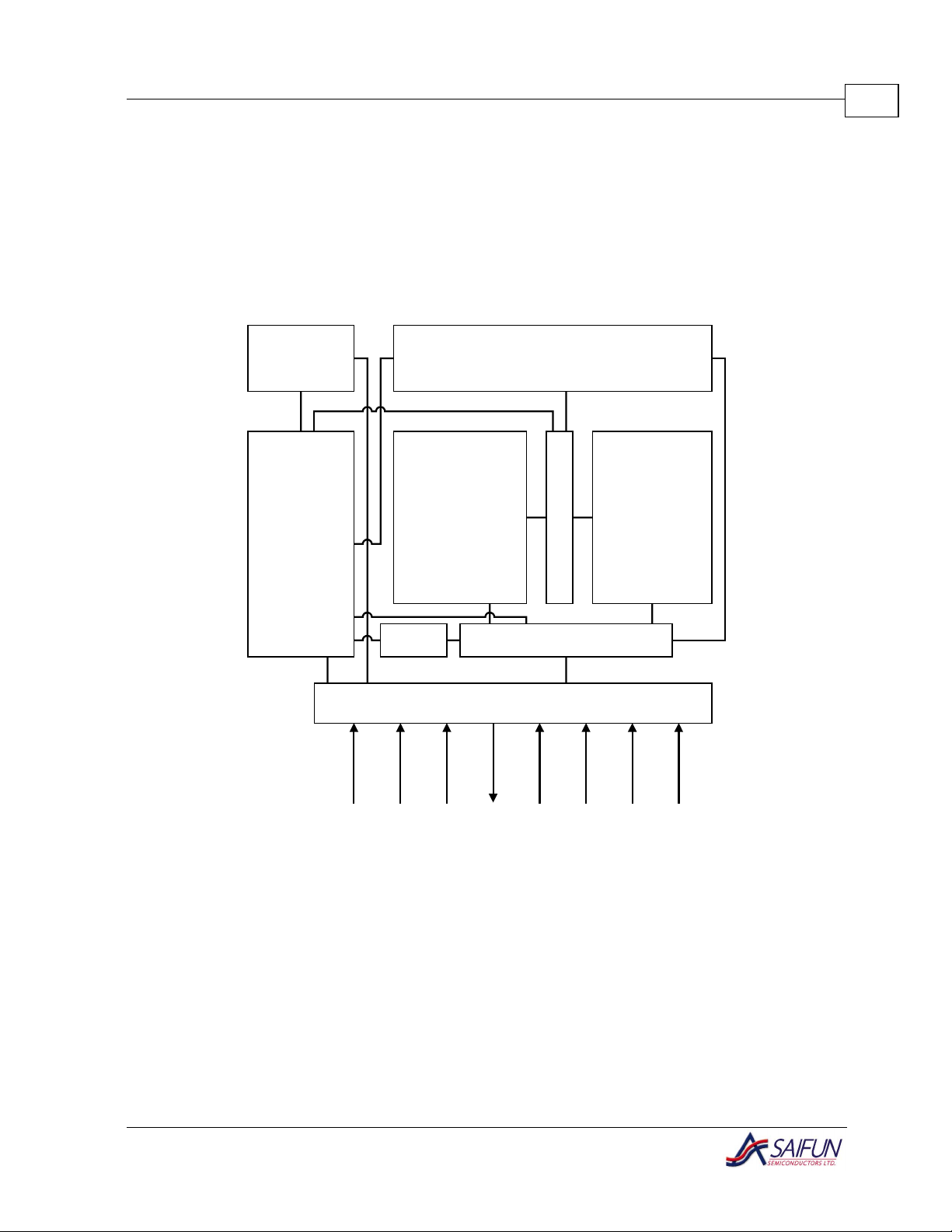

Memory Organization

The memory is organized in the following

manner:

•= 262,144 bytes (8 bits each)

•= 1024 pages (256 bytes each)

Array - L

Logic

Each byte or page can be individually

written with the bits programmed from

1 to 0 and from 0 to 1.

PSSRAM

X

D

E

C

Array - R

DATA PATHRD

IO

SI

CSb

SCK

SO

Vcc

GND

Figure 1. SA25C020 Block Diagram

WPb

HOLDb

Page 6

SA25C020 Advanced Information

SAIFUN

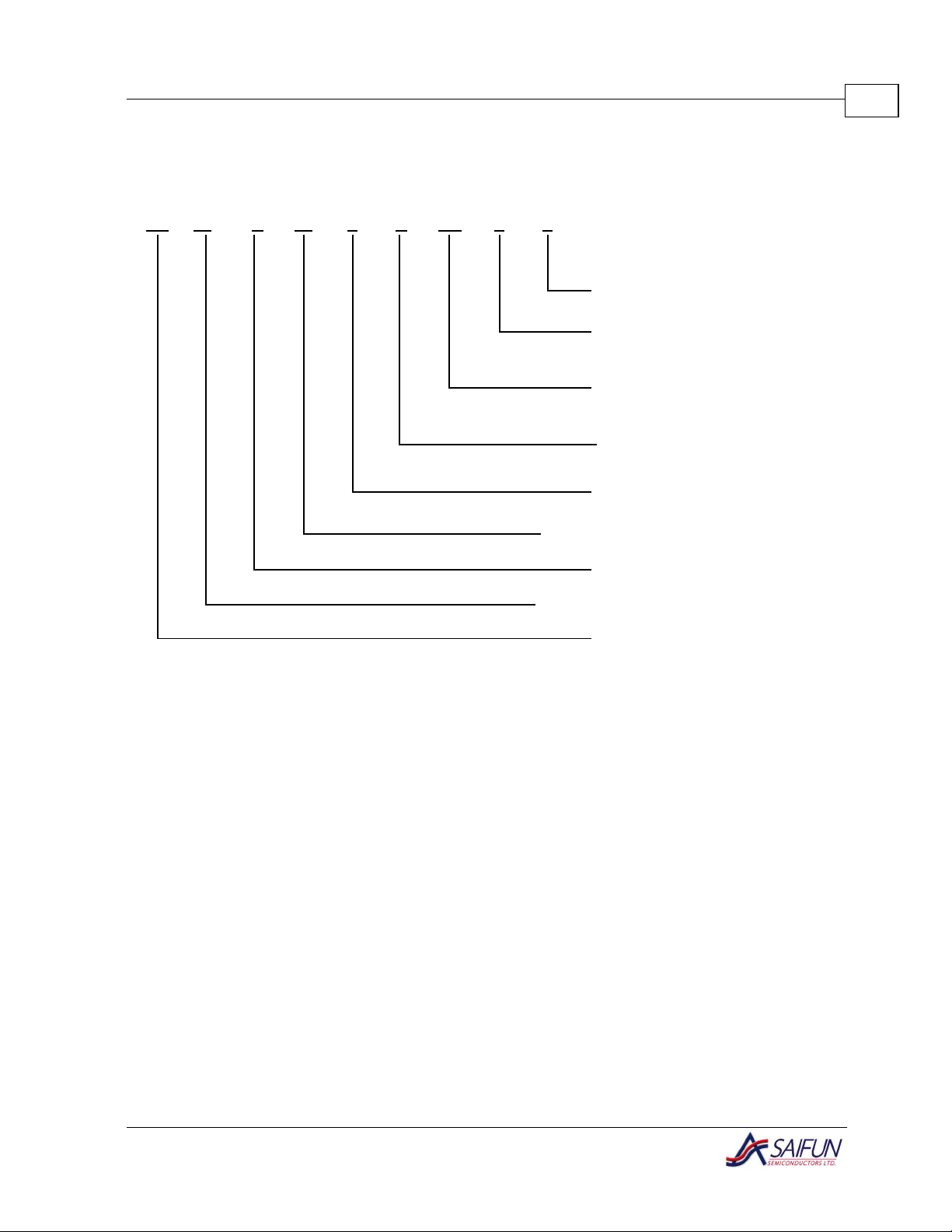

Connection Diagrams

6

CSb

SO

WPb

GND

1

2

SA25C020

3

4

VCC

8

HOLDb

7

SCK

6

SI

5

Figure 2. SOIC 8 (150 mil)/PDIP/MLF Package (Top View)

Table 1. Pin Names

Pin Name Signal Name

CSb Chip Select

SCK Serial Data Clock

SI Serial Data Input

SO Serial Data Output

GND Ground

VCC Power Supply

WPb Write Protect

HOLDb Suspend Serial Input

Page 7

SA25C020 Advanced Information

SAIFUN

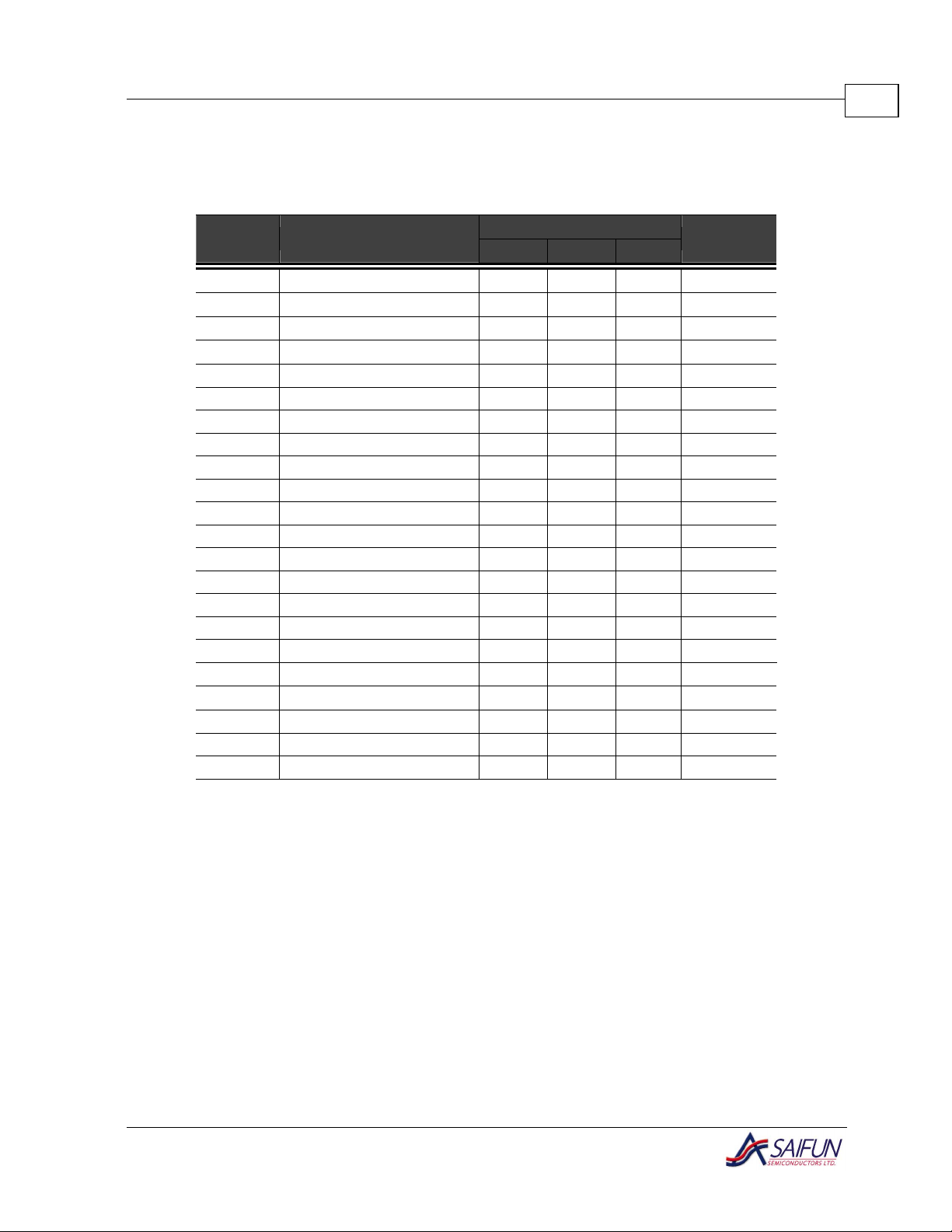

Ordering Information

7

FPPELXXC25SA Letter

Volt ag e Op er at in g

X

Package

Temp. Range

Range

Density

Interface

Blank

X

Blank

F

N

MN

MLF

Blank

E

L

020

C

25

SA

Description

Tube

Tape and Reel

Non Lead Fr ee

Lead Fr ee

8-pi n D IP

8-pi n SOIC ( 150 mil )

8-lead M LF

0 to 70 C

-40 to +85 C

2.7 V to 3.6 V

2 Mb with Wri te Pr otect

CMOS

SPI-2 Wir es

Saifun Non-Volatile

Memory

o

o

Figure 3. SA25C020 Ordering Information

Page 8

SA25C020 Advanced Information

SAIFUN

Product Specifications

Absolute Maximum Ratings

8

Storage Temperature

All input or output voltages with

respect to Ground

Lead Temperature

(Soldering, 10 seconds)

-65 °C to +150 °C

4.5 V to -0.3 V

+235 °C

ESD/Latch Up Specification (JEDEC 8 Spec)

Human Body Model Minimum 4 KV

Machine Model Minimum 500 V

Charge Device Model Minimum 1 KV

Latch Up

100 mA on all pins +125°C

Operating Conditions

Operating Temperature:

SA25C020

SA25C020 E

Positive Power Supply:

SA25C020

0 °C to +70 °C

-40 °C to +85 °C

2.7 V to 3.6 V

Page 9

SA25C020 Advanced Information

SAIFUN

DC Characteristics

Applicable over recommended operating range from TAI = -40 ºC to 85 ºC, VCC = 2.7-3.6 V.

Table 2. DC Characteristics

9

Symbol Parameter Test Conditions

Limits

Min Typ* Max

VCC Supply Voltage 2.7 3 3.6

Active Power Supply

I

CC1

Current (Read)

Active Power Supply

I

CC2

Current (Page Write)

Active Power Supply

I

CC3

Current (WRSR)

ISB Standby Current

IIL Input Leakage Current V

IOL Output Leakage Current V

SCK = 0.1VCC/0.9 VCC @

25 MHz

9 12

CSb = VCC 15 mA

CSb = VCC 15 mA

= 3.6 V,

V

CC

CSb = V

IN

IN

CC

= GND to VCC 1

= GND to VCC 1

1

VIL Input Low Voltage -0.3 0.3 VCC

VIH Input High Voltage 0.7 V

VOH Output High Voltage IOH = -0.1 mA

VCC -

0.2

CC

VCC +

0.5

Unit

V

mA

µA

µA

µA

V

V

V

VOL Output Low Voltage IOL = 1.6 mA; VCC = 2.7 V 0.4

*Typical values are at TAI = 25 ºC and 3 V.

V

Page 10

SA25C020 Advanced Information

SAIFUN

AC Test Conditions

Table 3. AC Test Conditions

10

Symbol Parameter

F

SCK Clock Frequency D.C. 25 MHz

SCK

t

t

t

t

CRT

CFT

WH

WL

Clock Rise Time (Slew Rate) 0.1

Clock Fall Time (Slew Rate) 0.1

SCK High Time 18

SCK Low Time 18 ns

Min Typ Max

tCS CSb High Time 100 ns

**

t

t

t

t

CSS

CSH

HD

CD

**

**

CSb Setup Time 10 ns

**

CSb HOLD Time 10 ns

HOLDb Setup Time 10 ns

HOLDb Hold Time 10 ns

tV Output Valid 0 15 ns

tHO Output Hold Time 0 ns

t

Data in Hold Time 5 ns

HD:DAT

t

Data in Setup Time 5 ns

SU:DAT

**

t

t

t

DIS

t

WPS

t

WPH

LZ

HZ

HOLDb to Output Low Z 15 ns

**

HOLDb to Output High Z 20 ns

**

Output Disable Time 15 ns

**

Write Protect Setup Time 20 ns

**

Write Protect Hold Time 100 ns

tPW* Byte or Page Write 10 15 ms

t

Release SP Mode 1000 ns

RES

Endurance 100K Erase cycles

* 256 bytes in the checkerboard programming formation.

** Value guaranteed by characterization, not 100% tested in production

25 MHz

Unit

V/ns

V/ns

ns

Page 11

SA25C020 Advanced Information

SAIFUN

Timing Diagrams

All timing diagrams are based on SPI protocol modes 0 and 1.

t

CS

CS

SCK

t

CSH

t

CSS

t

SU:DATtHD:DAT

t

CRT

t

CFT

t

CSH

t

CSS

11

SI

SO

CS

SCK

SO

MSB IN

LSB IN

High Impedance

Figure 4. SPI Mode 0 (0,0) Input Timing

t

WH

t

V

t

HO

t

V

t

HO

t

WL

t

DIS

LSB OUT

Figure 5. SPI Mode 0 (0,0) Output Timing

Page 12

SA25C020 Advanced Information

SAIFUN

12

Input Levels

0.8Vcc

0.2Vcc

Input and Output

Timing Reference Levels

0.7Vcc

0.3Vcc

Figure 6. AC Measurements I/O Waveform

Table 4. AC Measurements

Symbol Parameter Min Max Unit

C

L

Load Capacitance 30 PF

Input Rise and Fall Times 5 ns

Input Pulse Voltage 0.2 VCC to 0.8 VCC V

Input and Output Timing

Reference Voltages

0.3 VCC to 0.7 VCC V

Page 13

SA25C020 Advanced Information

SAIFUN

13

Signal Description

Chip Select (CSb)

This is an active-low input pin to the device

that is generated by the master controlling

the device. A low level on this pin selects

the device, while a high level deselects the

device. All serial communications with the

device are enabled only when this pin is

held low.

Serial Clock (SCK)

This is an input pin to the device that is

generated by the master controlling the

device. It is a clock signal that

synchronizes the communication between

a master and the device. All input

information (SI) to the device is latched on

the rising edge of this clock input, while

output data (SO) from the device is driven

after the falling edge of this clock input.

Serial Output (SO)

This is an output pin from the device that is

used to transfer output data to the

controlling master. Output data is serially

shifted out on this pin after the falling edge

of the SCK.

Hold (HOLDb)

This is an active low input pin to the device

that is generated by the master controlling

the device. When driven low, this pin

suspends any current communication with

the device. The suspended communication

can be resumed by driving this pin high.

This feature eliminates the need to

re-transmit the entire sequence by

enabling the master to resume the

communication from where it was left off.

This pin should be tied high if this feature is

not used. Refer to Hold Condition,

page 15, for additional details.

Serial Input (SI)

This is an input pin to the device that is

generated by the master controlling the

device. The master transfers input

information (instruction, addresses and the

data to be programmed) into the device

serially via this pin. This input information is

latched on the rising edge of the SCK.

Write Protect (WPb)

This is an active low input pin to the device.

This pin allows enabling and disabling of

writes to the device's memory array and

status register. When this pin is held low,

writes to the memory array and status

register are disabled; when it is held high,

they are enabled. Refer to Write Protect,

page 16, for additional details.

Page 14

SA25C020 Advanced Information

SAIFUN

14

Serial Interface Description

SPI Modes

These devices can be driven by a

microcontroller with its SPI peripheral

running in either of the two following

modes:

•= CPOL=0, CPHA=0

•= CPOL=1, CPHA=1

CPOL CPHA

CS

0

1

0

CS

1

SO

SI

MSB

In both of these modes, input data is

latched on the rising edge of SCK, and

output data is available from the falling

edge of SCK. The difference between the

two modes, as shown in Figure 7, is the

clock polarity when the bus master is in

Standby mode and is not transferring data,

as follows:

•= SCK remains at 0 for CPOL = 0,

CPHA = 0

•= SCK remains at 1 for CPOL = 1,

CPHA = 1

MSB

Figure 7. Supported SPI Modes

Master

The device that generates the SCK.

Slave

As the SCK pin is always an input, the

SA25C020 always operates as a slave.

Transmitter/Receiver

The SA25C020 has separate pins

designated for data transmission and

reception.

Serial Opcode

The first byte is received after the device is

selected. This byte contains the opcode

that defines the operation to be performed

(for more details, refer to Table 5,

page 17).

Invalid Opcode

If an invalid opcode is received, no data is

shifted into the SA25C020, and the serial

output pin remains in a high impedance

state until a CSb falling edge is detected

again, which reinitializes the serial

communication.

Page 15

SA25C020 Advanced Information

SAIFUN

15

Chip Select (CSb)

The SA25C020 is selected when the CSb

pin is low. When the device is not selected,

data is not accepted via the SI pin, and the

SO pin remains in a high impedance state.

Hold Condition

The HOLDb pin is used in conjunction with

the CSb pin to select the SA25C020. When

the device is selected and a serial

sequence is underway, HOLDb can be

used to pause the serial communication

with the master device without resetting the

serial sequence.

To enter the hold condition the device must

be selected, with CSb low.

As shown in Figure 8, the Hold condition

starts on the falling edge of the HOLDb

signal, provided that SCK is low. The Hold

condition ends on the rising edge of the

HOLDb signal, provided that SCK is low. If

the falling edge does not coincide with SCK

being low, the Hold condition starts only

after SCK next goes low.

Similarly, if the

rising edge does not coincide with SCK

being low, the Hold condition ends only

after SCK next goes low.

During the Hold condition, SO is high

impedance, and SI and SCK are Don’t

Care. In most cases, the device is kept

selected, with CSb driven low, for the entire

duration of the Hold condition, which

ensures that the internal logic state

remains unchanged from the moment it

enters the Hold condition.

NOTE:

Driving CSb high while HOLDb is still

low is not a legal operation.

SCK

HOLD

Hold

Condition

(Standard Use)

Figure 8. Hold Condition

Hold

Condition

(Non-Standard Use)

Page 16

SA25C020 Advanced Information

SAIFUN

Write Protect

The WPb pin enables write operations to

the status register when held high. When

the WPb pin is brought low and the

WPBEN bit is 1, all write operations to the

status register are inhibited (for more

details, refer to Table 9, page 21). If WPb

goes low while CSb is still low, the write to

the status register is interrupted. If the

internal write cycle has already been

initiated, WPb going low has no effect on

any write operations to the status register.

The WPb pin function is blocked when the

WPBEN bit in the status register is 0,

which enables the user to install the

SA25C020 in a system with the WPb pin

tied to ground but still able to write to the

status register. All WPb pin functions are

enabled when the WPBEN bit is set to 1.

16

Page 17

SA25C020 Advanced Information

SAIFUN

17

Functional Description

Instructions

Figure 9 presents a schematic diagram of

the SA25C020 's SPI serial interface.

MASTER:

MICROCONTROLLER

DATA OUT

DATA IN

SERIAL CLOCK

SSO

SS1

SS2

SS3

Figure 9. SPI Serial Interface

SLAVE

SA25C020

SI

SO

SCK

CSb

SI

SO

SCK

CSb

SI

SO

SCK

CSb

SI

SO

SCK

CSb

The SA25C020 's SPI consists of an 8-bit

instruction register that decodes a specific

instruction to be executed. Thirteen

different instructions (called opcodes) are

incorporated in the device for various

operations. Table 5 lists the instruction set

and the format for proper operation. All

opcodes, array addresses and data are

transferred in an MSB-first-LSB-last

fashion. Detailed information about each of

these opcodes is provided for the individual

instruction descriptions in the sections that

follow.

Table 5. Instruction Set

Instruction

Name

WREN 0000 0110

WRDI 0000 0100

RDSR 0000 0101

WRSR 0000 0001

READ 0000 0011

Byte or Page

Write

READ_ID

Instruction

Format

0000 0010

1010 1011

+3 dummy bytes

Operation

Set Write Enable

Latch

Reset Write Enable

Latch

Read Status

Register

Write Status

Register

Read Data from

Memory Array

Write Data to

Memory Array

Read ID

In addition to the instruction register, the

device also contains an 8-bit status register

that can be accessed by RDSR and WRSR

instructions. The byte defines the Block

Write Protection (BP1 and BP0) levels,

Write Enable (WEN) status, Busy/Rdy

(/RDY) status and Hardware Write Protect

(WPBEN) status of the device. Table 6

illustrates the format of the status register.

Table 6. Status Register Format

Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit1 Bit 0

WPBEN X X X BP1 BP0 WEN /RDY

Page 18

SA25C020 Advanced Information

SAIFUN

18

Read Status Register (RDSR)

The RDSR instruction provides read

access to the status register. The

BUSY/RDY and WREN statuses of the

device can also be determined by this

instruction. In addition, the Block Write

Protection bits indicate the extent of

protection employed. In order to determine

the status of the device, the value of the

/RDY bit can be continuously polled before

sending any write instruction.

Table 7. Read Status Register Definition

Bit Definition

Bit 0 = 0 (/RDY) indicates that the

Bit 0 (/RDY)

Bit 1 (WEN)

Bit 2 (BP0) Block Write Protect Bit 0

Bit 3 (BP1) Block Write Protect Bit 1

Bit 7

(WPBEN)

device is READY.

Bit 0 = 1 indicates that a write

cycle is in progress.

Bit 1 = 0 indicates that the device

is not write enabled.

Bit 1 = 1 indicates that the device

is write enabled.

Write Protect Mode Enable Bit

Bit 7 (WPBEN) is Hardware Write Protect

mode. If this bit is a 1, this mode is enabled

and the status register is write protected.

Bits 6 through 4 are always 0.

Bit 3 (BP1) and Bit 2 (BP0) together

indicate a Block Write Protection previously

sent to the device.

Bits 0 and 1 are 1 during an internal write

cycle.

Bit 1 (WEN) indicates the Write Enable

status of the device. This bit is read by

executing an RDSR instruction. If this bit is

1, the device is write enabled; if it is 0, it is

write disabled.

Bit 0 (/RDY) indicates the Busy/Ready

status of the device. This bit is a read-only

bit and is read by executing an RDSR

instruction. If this bit is 1, the device is busy

doing a Program or Erase cycle; if it is 0,

the device is ready.

Page 19

SA25C020 Advanced Information

SAIFUN

19

The RDSR command requires the following

sequence:

1. The CSb pin is pulled low to select

the device and the RDSR opcode is

transmitted on the SI pin.

CS

SCK

SI

SO

1 32109876540 14131211

Instruction

High Impedanc e

MSB

Figure 10. Read Status Register (RDSR) Instruction Sequence

2. The data on the SI pin becomes

Don't Care.

3. The data from the status register is

shifted out on the SO pins, with the

D7 bit first and the D0 bit last, as

shown in Figure 10.

15 181716 22212019

Status Register Out

132 07654

Status Register Out

MSB

23

7

132 07654

MSB

Page 20

SA25C020 Advanced Information

SAIFUN

20

Write Enable (WREN)

The device powers up in the Write Disable

state when V

instructions must be preceded by a WREN

instruction. The instruction sequence is

shown in Figure 11, with SO in high

impedance.

is applied. All programming

CC

CS

SCK

1

Write Disable (WRDI)

To protect the device against inadvertent

writes, the WRDI instruction disables all

programming modes. The WRDI

instruction is independent of the WP pin's

status. The WREN instruction should be

executed after the WRDI instruction to

re-enable all programming modes. The

instruction sequence is shown in Figure 12,

with SO in high impedance.

3276540

Instruction

SI

CS

SCK

SI

Figure 11. Write Enable (WREN) Instruction Sequence

1

Figure 12. Write Disable (WRDI) Instruction Sequence

3276540

Instruction

Page 21

SA25C020 Advanced Information

SAIFUN

21

Write Status Register (WRSR)

The WRSR instruction enables the user to

select one of four levels of protection. The

SA25C020 is divided into four array

segments. The top quarter, top half or all of

the memory segments can be protected

(for more details, refer to Table 8). The

data within a selected segment is therefore

read-only.

Table 8. Block Write Protect Bits

Level

Status Register Bits

BP1 BP0

0

1/4

1/2

All

0 0 None

0 1 30000 - 3FFFF

1 0 20000 - 3FFFF

1 1 00000 - 3FFFF

The WRSR instruction (as shown in

Table 9) also allows the user to enable or

disable the WPb pin via the WPBEN bit.

Hardware write protection is enabled when

the WPb pin is low and the WPBEN bit is

1, and disabled when either the WP pin is

high or the WPBEN bit is 0. When the

device is hardware write protected, writes

to the status register are disabled.

Array Addresses

Protected

Table 9. WPBEN Operation

WPb WPBEN WEN

X 0 0 Protected Protected Protected

X 0 1 Protected Writeable W riteable

Low 1 0 Protected Protected Protected

Low 1 1 Protected Writeable Protected

High X 0 Protected Protected Protected

High X 1 Protected Writeable Writeable

Protected

Blocks

Un-

protected

Blocks

Status

Register

The WRSR instruction is enabled:

1. When the WPb pin is held high

and the device has been

previously write enabled via the

WREN instruction.

2. When the WPb pin is held low, the

WPBEN bit is 0 and the device

has been previously write enabled

via the WREN instruction.

NOTE:

When the WPBEN bit is hardware write

protected, it cannot be changed back

to 0 while the WPb pin is held low.

Page 22

SA25C020 Advanced Information

SAIFUN

22

The WRSR command requires the

following sequence:

1. The CSb pin is pulled low to select

the device.

CS

1 32109876540 14131211 15

SCK

Instruction Status Register In

SI

SO

Figure 13. Write Status Register (WRSR) Instruction Sequence

High Impedance

2. The WRSR opcode is then

transmitted on the SI pin, followed

by the data to be programmed.

The instruction sequence is shown in

Figure 13.

132 07654

MSB

Page 23

SA25C020 Advanced Information

SAIFUN

23

Read Data Bytes (READ)

Reading the memory via the serial SPI link

requires the following sequence:

1. After the CSb line is pulled low to

select the device, the READ

opcode is transmitted via the SI

line, followed by the 3-byte address

to be read (address bits A23 to A18

are Don’t Care).

2. Upon completion, any data on the

SI line is ignored.

3. The data (D7-D0) at the specified

address is then shifted out onto the

SO line. Each bit is shifted out at a

maximum SCK frequency of F

CS

SCK

.

If only one byte is to be read, the CSb line

should be driven high after the data comes

out. The READ sequence can be

continued, as the byte address is

automatically incremented and data

continues to shift out. When the highest

address is reached, the address counter

rolls over to the lowest address, enabling

the entire memory to be read in one

continuous READ cycle. The instruction

sequence is shown in Figure 14.

Driving CSb high terminates the READ

instruction, which can be done at any time

during data output. Any READ instruction

executed while an Erase, Program or

WRSR cycle is in progress is rejected

without having any effect on the cycle in

progress.

SCK

SI

SO

1 32109876540 31302928

Instruction

23 2122 132

High Impedance

24-Bit

Address

Figure 14. Read (READ) Instruction Sequence

3635343332 393837

0

DATA OUT 1 DATA OUT 2

132 07654

7

MSB

MSB

Page 24

SA25C020 Advanced Information

SAIFUN

24

Byte or Page Write (PW)

The Byte or Page Write instruction allows

bytes to be programmed and erased in the

memory (changing bits from 1 to 0 and

from 0 to 1). In order to program to the

SA25C020, two separate instructions must

be executed. The device must first be write

enabled via the WREN instruction, and

then a Byte or Page Write sequence

(which consists of four bytes plus data)

may be executed. The address of the

memory locations to be written must be

outside the protected address field location

selected by the Block Write Protection

level. During an internal Write cycle, all

commands are ignored except the RDSR

instruction.

A Byte or Page Write instruction requires

the following sequence:

After the CSb line is pulled

low to select the device, the

WRITE opcode is transmitted

via the SI line, followed by the

byte address and the data

(D7-D0) to be written.

Programming starts after the CSb pin is

brought high. The CSb pin's low-to-high

transition must occur during the SCK low

time, immediately after the clock in the D0

(LSB) data bit. The instruction sequence is

shown in Figure 15, page 25.

As soon as CSb is driven high, the

self-timed Write cycle (whose duration is

defined as T

) is initiated. While the Page

PW

Write cycle is in progress, the status

register may be read to check the value of

the Write in Progress (/RDY) bit. The /RDY

bit is 1 during the self-timed Page Write

cycle, and 0 when it is completed. The

Write Enable Latch (WEN) bit is reset at

some unspecified time before the cycle is

completed.

The SA25C020's PW operation is capable

of up to a 256-byte writing, from 1 to 256

bytes at a time (changing bits from 1 to 0

and from 0 to 1), provided that they lie in

consecutive addresses on the same page

of memory. After each byte is received, the

eight low-order address bits are internally

incremented by one. If more than 256

bytes of data are transmitted, the address

counter rolls over and the previously

written data is overwritten. The SA25C020

is automatically returned to the write

disable state at the completion of a Write

cycle.

NOTES:

1. If the device is not write enabled,

the device ignores the PW

instruction and returns to the

standby state when CSb is brought

high. A new CSb falling edge is

required to re-initiate the serial

communication.

2. A PW instruction applied to a page

that is protected by the Block

Protect (BP1, BP0) bits (as

described in Table 7, page 18, and

Table 8, page 21) is not executed.

Page 25

SA25C020 Advanced Information

SAIFUN

CS

25

SCK

SI

CS

SCK

SI

1 3210987654031302928

Instruction

23 2122 132 0

MSB

4443424140 474645 5251594948 555453

Data Byte 2

132 07654

MSBMSB

24-Bit

Address

Data Byte 3

Data Byte 1

MSB

2072

2074

2073

Data Byte 256

132 07654

MSB

Figure 15. Byte or Page Write (PW) Instruction Sequence

3635343332 393837

2075

132 07654

2079

2078

2077

2076

132 07654

Page 26

SA25C020 Advanced Information

SAIFUN

26

Read Electronic Signature (Read_Id)

The device features an 8-bit Electronic

Signature, whose value for the SA25C020

is 11h. This can be read using the RES

instruction.

The Read Id instruction always provides

access to the Electronic Signature of the

device (except while a Byte/Page Write or

Write Status Register cycle is in progress).

Any Read Id instruction executed while a

Byte/Page Write or Write Status Register

cycle is in progress is not decoded, and

has no effect on the cycle in progress.

The device is first selected by driving CSb

low. The instruction code is followed by

three dummy bytes, each bit being latched

in on SI during the rising edge of SCK.

CS

The 8-bit Electronic Signature, which

stored in the memory, is then shifted out on

SO, with each bit being shifted out during

the falling edge of SCK. The instruction

sequence is shown in Figure 16.

Driving CSb high after the Electronic

Signature has been read at least once

terminates the Read Id instruction. Sending

additional clock cycles on SCK, while CSb

is driven low causes the Electronic

Signature to be output repeatedly.

When CSb is driven high, the device is put

into Standby mode. The transition to

Standby mode is delayed by t

must remain high for at least t

, and CSb

RES

(max), as

RES

specified in Table 3 on page 10. Once in

Standby mode, the device waits to be

selected, so that it can receive, decode and

execute instructions.

SCK

SI

SO

1 32109876540 31302928

Instruction

23 2122 132 0

MSB

High Impedance

3 Dummy

Bytes

MSB

Software Protect Mode Standby Mode

3635343332 393837

Electonic ID

t

RES

132 07654

Figure 16. Read Electronic Signature (Read Id) Instruction Sequence

Page 27

SA25C020 Advanced Information

SAIFUN

27

Powerup and Powerdown

The device must not be selected at

powerup or powerdown (that is, CSb must

follow the voltage applied on V

reaches the correct value, as follows:

•= V

(min) at powerup, and then for a

CC

further delay of t

(as described in

PU

Table 10)

•= V

at powerdown

SS

A simple pull-up resistor on CSb can

usually be used to insure safe and proper

powerup and powerdown. To avoid data

corruption and inadvertent write operations

during powerup, a Power On Reset (POR)

circuit is included. The logic inside the

device is held at reset while V

than the POR threshold value (V

operations are disabled and the device

does not respond to any instructions.

The device ignores all instructions until a

time delay of t

moment that V

has elapsed after the

PU

rises above the VWI

CC

threshold. However, correct operation of

the device is not guaranteed if by this time

is still below VCC(min). No Write Status

V

CC

Register, Program or Erase instructions

should be sent until t

minimum V

threshold after VCC.

CC

PU

) until VCC

CC

is less

CC

), all

POR

reaches the

At powerup, the device is in Standby mode

(not SP mode) and the WEN bit is reset.

Normal precautions must be taken for

supply rail decoupling to stabilize the V

CC

feed. Each device in a system should have

the V

rail decoupled by a suitable

CC

capacitor close to the package pins (this

capacitor is generally of the order of

0.1 µF).

All operations are disabled and the device

does not respond to any instructions when

drops at powerdown from the

V

CC

operating voltage to below the V

POR

threshold. (The designer must be aware

that if a powerdown occurs while a Write,

Program or Erase cycle is in progress, data

corruption can result.)

Table 10. Powerup

Symbol Parameter Min. Max. Unit

V

POR

tPU

POR Threshold

V

CC

Value

(min) to CS

low

2.2

2

2.4 V

ms

Page 28

SA25C020 Advanced Information

SAIFUN

Physical Dimensions

All measurements are in inches (millimeters), unless otherwise specified.

28

Figure 17. 8-pin SOIC Package

Page 29

SA25C020 Advanced Information

SAIFUN

29

Figure 18. 8-pin MLF Leadless Package

Page 30

SA25C020 Advanced Information

SAIFUN

30

Figure 19. Molded Dual-in-line Package (N) Package Number N08E

Page 31

SA25C020 Advanced Information

SAIFUN

Contact Information

International Headquarters United States

Saifun Semiconductors Ltd.

ELROD Building

45 Hamelach St.

Sappir Industrial Park

Netanya 42504

Israel

Tel.: +972-(0) 9-892-8444

Fax: +972- (0) 9-892-8445

Email: tech_support@saifun.com

http://www.saifun.com

Saifun Semiconductors Inc.

2350 Mission College Blvd.

Suite 1070

Santa Clara, CA 95054

U.S.A.

Tel: +1-408-982-5888

Fax: +1-408-982-5890

31

Revision History

Rev Date Description of Change

0.0 20-July-03 Initial Release

© Saifun Semiconductors Ltd. 2003

Saifun reserves the right, without notice, to change any of the products described in this guide, in order to improve

functionality, reliability or design. Saifun assumes no liability arising from the application or use of any product described in

this guide; and under its patent rights, gives no authorization for the use of this product or associated products. The Buyer

will not hold Saifun responsible for direct or indirect damages and expenses, as well as any claim of injury or death,

associated with the unauthorized use, including claims of manufacture or design negligence.

Saifun and Saifun NROM are trademarks or registered trademarks of Saifun Semiconductors Ltd. Other company and brand

products and service names are trademarks or registered trademarks of their respective holders.

Life Support Policy

Saifun's products are not authorized for use as critical components in life support devices or systems without the express written

approval of the President of Saifun Semiconductors Ltd. As used herein:

1. Life support devices or systems are devices

or systems which, (a) are intended for

surgical implant into the body, or (b) support

or sustain life, and whose failure to perform,

when properly used in accordance with

instructions for use provided in the labeling,

can be reasonably expected to result in a

significant injury to the user.

2. A critical component is any component of

a life support device or system whose

failure to perform can be reasonably

expected to cause the failure of the life

support device or system, or to affect its

safety or effectiveness.

Loading...

Loading...