Page 1

NTE7133

Integrated Circuit

Horizontal and Vertical Deflection Controller

for VGA/XGA and Autosync Monitors

Description:

The NTE7133 is an integrated circuit in a 20–Lead DIP type package. This device is designed to provide an economical solution in VGA/XGA and autosync monitors by incorporating complete horizontal and vertical small signal processing. VGA–dependent mode detection and setting are performed

on–chip.

Features:

D VGA Operation Fully Implemented Including Alignment–Free Vertical and E/W Amplitude

Pre–Settings

D 4th VGA Mode Easy Applicable (XGA, Super VGA)

D Autosync Operation Externally Selectable

D Low Jitter

D All Adjustments DC–Controllable

D Alignment–Free Oscillators

D Sync Separators for Video or Horizontal and Vertical TTL Sync Levels Regardless or Polarity

D Horizontal Oscillator with P

D Constant Vertical and E/W Amplitude in Multi–Frequency Operation

D DC–Coupling to Vertical Power Amplifier

D Internal Supply Voltage Stabilization with Excellent Ripple Rejection to Ensure Stable Geometrical

Adjustments

for Sync and P

LL1

for Flyback

LL2

Absolute Maximum Ratings:

Supply Voltage (Pin1), V

Voltage (Pin3, Pin7), V3, V

Voltage (Pin8), V

8

Voltage (Pin5, Pin6, Pin9, Pin10, Pin13, Pin14, Pin18), V

Current (Pin2), I

Current (Pin3), I

Current (Pin7), I

Current (Pin8), I

2

3

7

8

Electrostatic Handling for All Pins (Note 1), V

Operating Junction Temperature, T

Operating Ambient Temperatrure Range, T

Storage Temperature Range, T

Thermal Resistance, Junction–to–Ambient (In Free Air), R

P

7

n

esd

J

A

stg

thJA

Note 1. Equivalent to discharging a 200pF capacitor through a 0Ω series resistor.

–0.5 to +16V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

–0.5 to +16V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

–0.5 to +7V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

–0.5 to +6.5V. . . . . . . . . . . . . . . . . . . . . .

±10mA. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

100mA. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

20mA. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

–10mA. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

±400V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

+150°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

0° to +70°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

–55° to +150°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

65K/W. . . . . . . . . . . . . . . . . . . . . . . .

Page 2

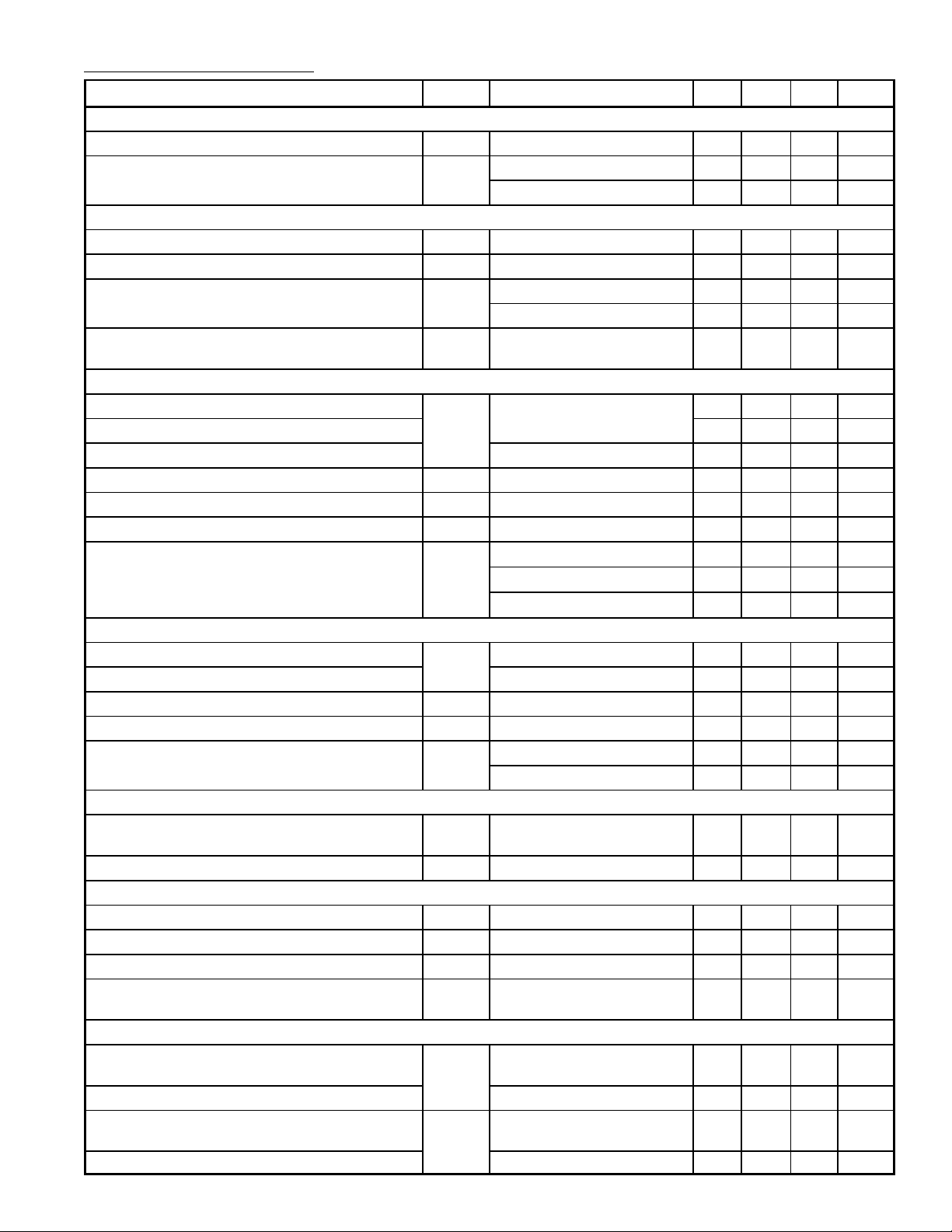

Electrical Characteristics: (VP = 12V, TA = +25°C unless otherwise specified)

Parameter Symbol Test Conditions Min Typ Max Unit

Supply

Positive Supply Voltage (Pin1) V

Supply Current I

P

I18 = –1.05mA – 36 44 mA

P

I18 = –3.388mA – 40 49 mA

Internal Reference Voltage

Internal Reference Voltage V

ref

Temperature Coefficient TC TA = +20° to +100°C – – ±90 10–6/K

Power Supply Ripple Rejection PSRR f = 1kHz Sine Wave 60 75 – dB

f = 1MHz Sine Wave 25 35 – dB

Supply Voltage (Pin1) to Ensure All Internal

V

P

Reference Voltages

Composite Sync Input (AC–Coupled, V10 = 5V)

Sync Amplitude of Video Input Signal (Pin9) V

i sync

Sync on Green – 300 – mV

Top Sync Clamping Level 1.1 1.28 1.5 V

Slicing Level Above Top Sync Level Sync on Green, RS = 50Ω 90 120 150 mV

Allowed Source Resistance for 7% Duty Cycle R

Differential Input Resistance r

Charging Current of Coupling Capacitor I

Vertical Sync Integration Time to Generate

Sync Pulse

t

V

S

9

9

int

> 200mV – – 1.5 kΩ

i sync

During Sync – 80 – Ω

V9 > 1.5V 1.3 2.0 3.0 µA

fH = 31kHz, I18 = –1.050mA 7 10 13 µs

fH = 64kHz, I18 = –2.169mA 3.5 5.0 6.5 µs

fH = 100kHz, I18 = –3.388mA 2.5 3.4 4.5 µs

Horizontal Sync Input (DC–Coupled, TTL–Compatible)

Sync Input Signal (Peak Value, Pin9) V

u sync

Slicing Level 1.2 1.4 1.6 V

Minimum Pulse Width t

Rise Time and Fall Time tr, t

Input Current I

p

f

V9 = 0.8V – – –200 µA

9

V9 5.5V – – 10 µA

Automatic Horizontal Polarity Switch (H–Sync on Pin9)

Horizontal Sync Pulse Width Related to t

H

t

p H/tH

(Duty Cycle for Automatic Polarity Correction)

Delay Time for Changing Sync Polarity t

p

Vertical Sync Input (DC–Coupled, TTL–Compatible,,V–Sync on Pin10)

Sync Input Signal (Peak Value, Pin10) V

i sync

Slicing Level 1.2 1.4 1.6 V

Input Current I

Maximum Vertical Sync Pulse Width for

t

p V

0 < V10 < 5.5V – – ±10 µA

10

Automatic Vertical Polarity Switch

Horizontal Mode Detector Output (VGA Mode)

Output Saturation Voltage LOW

V

I7 = 6mA – 0.275 0.33 V

7

(For Modes 1, 2, and 3)

Output Voltage HIGH Mode 4 – – V

Load Current to Force VGA Mode–Dependent

I

Modes 1, 2, and 3 2 – 6 mA

7

Vertical and Parabola Amplitudes

Output Current Mode 4 – 0 – mA

9.2 12.0 16.0 V

6.0 6.25 6.5 V

9.2 – 16.0 V

1.7 – – V

700 – – ns

10 – 500 ns

– – 30 %

0.3 – 1.8 ms

1.7 – – V

– – 300 µs

P

V

Page 3

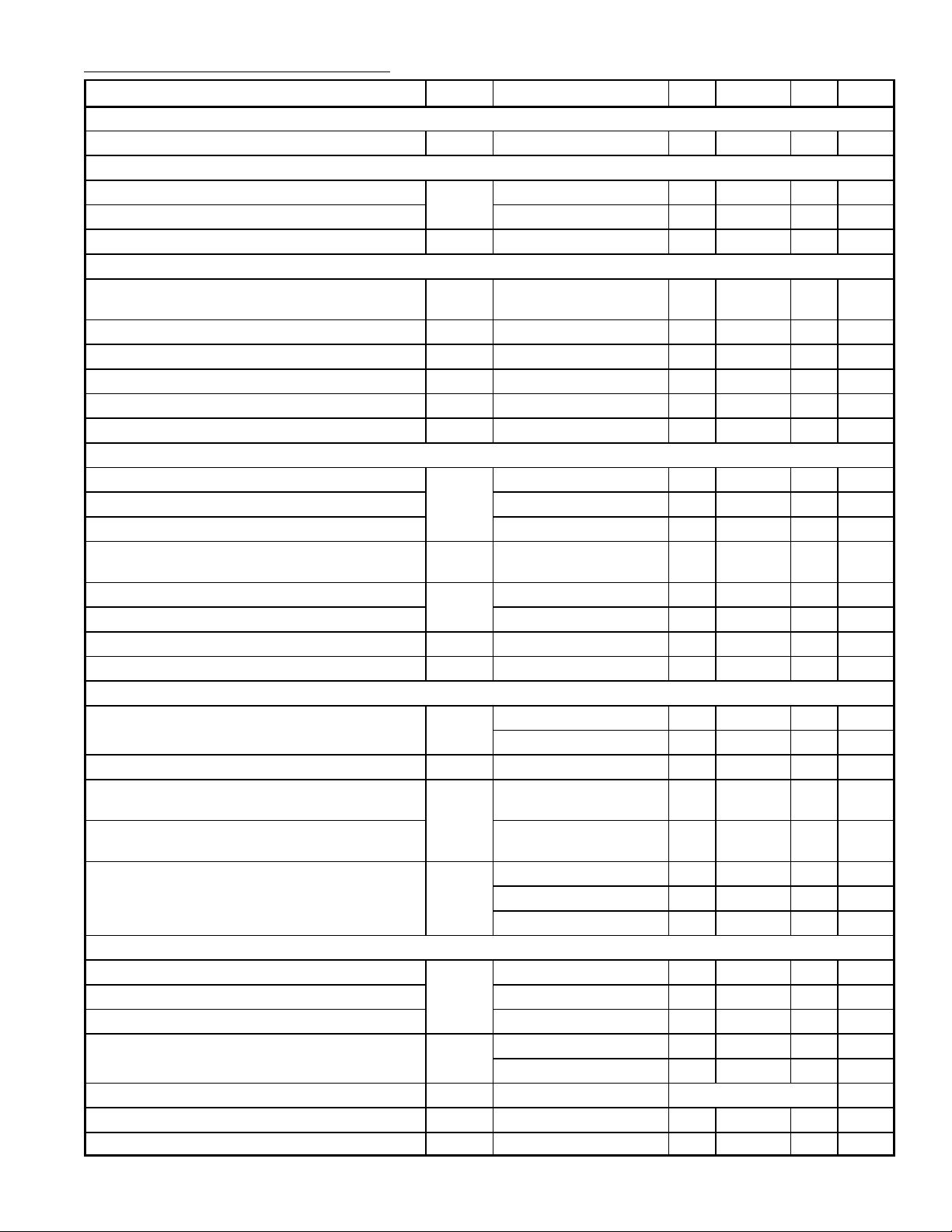

Electrical Characteristics (Cont’d): (VP = 12V, TA = +25°C unless otherwise specified)

Parameter Symbol Test Conditions Min Typ Max Unit

VGA/Autosync Mode Switch

Input Voltage LOW to Force Autosync Mode V

Horizontal Comparator P

LL1

Upper Control Voltage Limitation V

7

17

Lower Control Voltage Limitation

Control Current I

17

Horizontal Oscillator

Center Frequency f

OSC

R18 = 2.4kΩ (Pin18),

C19 = 10nF (Pin19)

Deviation of Center Frequency ∆f

OSC

Temperature Coefficient TC – +200 +300 10–6/K

Relative Holding/Catching Range ϕH/t

External Oscillator Current I

Voltage at Reference Current Input (Pin18) V

Horizontal P

LL2

Upper Clamping Level of Flyback Input V

H

18

18

I2 = 6mA – 5.5 – V

2

Lower Clamping Level of Flyback Input I2 = –1mA – –0.75 – V

H–Flyback Slicing Level – 3.0 – V

Delay Between Middle of Sync and Middle of

H–Flyback Related to t

H

Upper Control Voltage Limitation V

td/t

H

20

Lower Control Voltage Limitation – 4.8 – V

Control Current I

P

Control range Related to t

LL2

H

∆t/t

20

H

Horizontal Output (Open–Collector)

Output Voltage LOW V

I3 = 20mA – – 0.3 V

3

I3 = 60mA – – 0.8 V

tH Duty Cycle tp/t

Threshold to Activate Too Low Supply Voltage

H

V

Horizontal Output OFF – 5.6 – V

P

Protection

Threshold to Activate Too Low Supply Voltage

Horizontal Output ON – 5.8 – V

Protection

Jitter of Horizontal Output ∆t

f = 31kHz – – 3.5 ns

H

f = 64kHz – – 1.9 ns

f = 100kHz – – 1.2 ns

Horizontal Clamping/Blanking Generator Output

Output Voltage LOW V

8

Blanking Output Voltage Internal V Blanking 1.6 1.9 2.2 V

Clamping Output Voltage H–Sync on Pin9 5.15 5.4 5.65 V

Internal Sink Current for All Output Levels I

H and V Scanning 2.3 2.9 3.5 mA

8

External Load Current – – –3.0 mA

Clamping Pulse Start t

Clamping Pulse Width t

8

clp

Steepness of Rise and Fall Times S – 60 75 ns/V

0 – 50 mV

– 5.9 – V

– 5.1 – V

– ±0.083I

18

– µA

– 31.45 – kHz

– – ±3.0 %

±6.0 ±6.5 ±7.3 %

–0.5 – –4.3 mA

2.35 2.5 2.65 V

– 3.0 – %

– 6.2 – V

– ±0.083I

18

– µA

30 – – %

42 45 48 %

– – 0.9 V

With End of H–Sync

0.8 1.0 1.2 µs

Page 4

Electrical Characteristics (Cont’d): (VP = 12V, TA = +25°C unless otherwise specified)

Parameter Symbol Test Conditions Min Typ Max Unit

Vertical Oscillator (V

Vertical Free–Running Frequency f

Nominal Vertical Sync Range f

Voltage on Pin15 V

Delay Between Sync Pulse and Start of Vertical

Scan in VGA/XGA Mode

Delay Between Sync Pulse and Start of Vertical

Scan in Autosync Mode

Control Current for Amplitude Control I

Capacitor for Amplitude Control C

Vertical Differential Output

Differential Output Current Between Pin5 and

Pin6 (Peak–to–Peak Value)

Maximum Offset Current Error Io = 1mA – – ±2.5 %

Maximum Linearity Error – – ±1.5 %

Vertical Amplitude Adjustment (In Percent of Output Signal)

Input Voltage V

Adjustment Current I

VGA Mode–Dependent Pre–Settings Activated

by an External Resistor on Pin7

Mode 1

Mode 2 101.6 102.2 102.8 %

Mode 3 – 100 – %

Mode 4 – 100 – %

Autosync Operation

(VGA Operation Disabled)

E/W Output (Note 2)

Bottom Output Signal During Mid–Scan (Pin11) V

Top Output Signal During Flyback 4.2 4.5 4.8 V

Temperature Coefficient of Output Signal TC – – 250 10–6/K

E/W Amplitude Adjustment (Parabola)

Input Voltage (Pin14) V

Adjustment Current I

= 6.25V)

ref

o

V

15

t

d

12

12

I

o

13

13

∆Io/∆t

11

14

14

R15 = 22kΩ, C16 = 0.1µF – 42 – Hz

No fo Adjustment 50 – 110 Hz

R15 = 22kΩ 2.8 3.0 3.2 V

Measured on Pin8,

500 575 650 µs

Activated by an External

Resistor on Pin7

Measured on Pin8,

240 300 360 µs

V7 < 50mV

– ±200 – µA

– – 0.18 µF

Mode 3, I13 > –135µA,

0.9 1.0 1.1 mA

R15 = 22kΩ

– 5.0 – V

Iomax (100%) –110 –120 –135 µA

Iomin (Typically 58%) – 0 – µA

Table 2,Note 2 116.1 116.8 1 17.4 %

Table 2, Note 2,

– 100 – %

V7 < 50mV

Internally Stabilized 1.05 1.2 1.35 V

– 5.0 – V

100% Parabola –110 –120 –135 µA

Typicall 28% Parabola – 0 – µA

Note 2. ∆Io/∆t relative to value of Mode 3.

Note 3. Parabola amplitude tracks with mode–dependent vertical amplitude but not with vertical

amplitude adjustment. Tracking can be achieved by a resistor from ver tical am pli tude

potentiometer to Pin14.

Page 5

Functional Description:

Horizontal Sync Separator and Polarity Correction

An AC–coupled video signal or a DC–coupled TTL sync signal (H only or composite sync) is input

on Pin9. Video signals are clamped with top sync on 12.8V, and are sliced at 1.4V. This results in a

fixed absolute slicing level of 120mV relative to top sync.

DC–coupled TTL sync signals are also sliced at 1.4V, however with the clamping circuit in current limitation. The polarity of the separated sync is detected by internal integration of the signal, then the polarity is corrected.

The polarity information is fed to the VGA mode detector. The corrected sync is the input signal for

the vertical sync integrator and the P

LL1

stage.

Vertical Sync Separaztor, Polarity Correction and Vertical Sync Integrator

DC–coupled vertical TTL sync signals may be applied to Pin10. They are sliced at 1.4V. The polarity

of the separated sync is detected by internal integration, then polarity is corrected. The polarity information is fed to the VGA mode detector. If Pin10 is not used, it must be connected to GND.

The separated V

signal from Pin10, or the integrated composite sync signal from Pin9 (TTL or

i sync

video) directly triggers the vertical oscillator.

VGA Mode Detector and Mode Output

The three standard VGA modes and a 4th not fixed mode are decoded by the polarities of the horizontal and the vertical sync input signals. An external resistor (from VP to Pin7) is necessary to match

this function. In all three VGA modes the correxct amplitudes are activated. The presence of the 4th

mode is indicated by HIGH on Pin7. This signal can be used externally to switch any horizontal or

vertical parameters.

VGA Mode Detector Input

For autosync operation the voltage on Pin7 must be externally forced to a level of < 50mV. Vertical

amplitude pre–settings for VGA are then inhibited. The delay time between vertical trigger pulse and

the start of vertical deflection changes from 575 to 300µs (575µs is needed for VGA). The vertical

amplitude then remains constant in a frequency range from 50 to 110Hz.

Clamping and V–Blanking Generator

A combined clamping and V–blanking pulse is available on Pin8. The lower level of 1.9V is the blanking signal derived from the vertical blanking pulse from the internal vertical oscillator.

Vertical blanking equals the delay between vertical sync and the start of vertical scan. By this, an optimum blanking is acheived for VGA/XGA as well as for multi–frequency operation (selectable via

Pin7).

The upper level of 5.4V is the horizontal clamping pulse with internally fixed pulse width of 0.8µs. A

mono flop, which is triggered by the trailing edge of the horizontal sync pulse, generates this pulse.

If composite sync is applied one clamping pulse per H–period is generated during V–sync. The pahse

of the clamping pulse may change during V–sync.

P

Phase Detector

LL1

The phase detector is a standard one using switched current sources. The middle of the sync is

compared with a fixed point of the oscillator sawtooth voltage. The PLL filter is connected to Pin17.

If composite sync is applied, the distributed control voltage is corrected during V–sync.

Horizontal Oscillator

This oscillator is a relaxation type and requires a fixed capacitor of 10nF at Pin19. By changing the

current into Pin18 the whole frequency range from 13 to 100kHz can be covered.

The current can be generated either by a frequency to voltage converter or by a resistor. A frequency

adjustment may also be added if necessary.

The P

control voltage at Pin17 moduloates via a buffer stage the oscillator thresholds. A high DC–

LL1

loop gaqin ensures a stable phase relationship between horizontal sunc and line flyback pulses.

Page 6

Functional Description (Cont’d):

P

Phase Detector

LL2

This pahse detector is similar to the P

phase detector. Line flyback signals (Pin2) are compared

LL1

with a fixed point of the oscillator sawtooth voltage. Delays in the horizontal deflection circuit are compensated by adjusting the phase relationship between horizontal sync and horizontal output pulses.

A certain amount of phase adjustment is possible by injecting a DC current froma an external source

into the P

filter capacitor on Pin20.

LL2

Horizontal Driver

This open–collector output stage (Pin3) can directly drive an external driver transistor . The saturation

voltage is 300mV at 20mA. To protect the line deflection transistor, the horizontal output stage does

not conduct at VP < 6.4V (Pin1).

Vertical Oscillator and Amplitude Control

This stage is designed for fast stabilization of the vertical amplitude after changes in sync conditions.

The free–running frequency fo is determined by the values of R

VOS

and C

. The recommended

VOS

values should be altered marginally only to preserve the excellent linearity and noise performance.

The vertical drive currents I5 and I6 are in relation to the value of R

quency must be determined only by C

fo =

10.8 x R

1

VOS

x C

VOS

on Pin16.

VOS

. Therefore, the oscillator fre-

VOS

To acheive a stabilized amplitude the free–running frequency fo (without adjustment) must be lower

than the lowest occurring sync frequency. The contributions shown in Table 1 can be assumed.

Table 1. Calculation of fo Total Spread

Contributing Elements %

Minimum Frequency Offset Between fo and the Lowest Trigger Frequency 10

Spread of IC ±3

Spread of R (22kΩ) ±1

Spread of C (0.1µF) ±5

Total 19

Results for 50 to 110Hz application: fo =

50Hz

1.19

= 42Hz

Table 2. VGA Modes

Mode Horizontal/Vertical

Sync Polarity

1 +/– 31.45 70 350 LOW

2 –/+ 31.45 70 400 LOW

3 –/– 31.45 60 480 LOW

4 +/+ Fixed by External Circuitry – – HIGH

Autosync */* Fixed by External Circuitry – – Forced to GND

Horizontal

Frequency

(kHz)

Vertical

Frequency

(Hz)

Number of

Active Lines

Output

Mode Pin7

Page 7

Pin Connection Diagram

V

P

Horiz Flyback Input

Horiz Output

GND (0V)

Vert Output 1/Neg–Going Sawtooth

Vert Output 2/Pos–Going Sawtooth

4th Mode Output/Autosync In

Clamping/Blanking Pulse Out

Horiz Sync/Video In

Vert Sync In

1

2

3

4

5

6

7

8

20

19

18

17

16 Vert OSC Capacitor

15

14

13

10 11

P

Phase

LL2

Horiz OSC Capacitor

Horiz OSC Resistor

P

Phase

LL1

Vert OSC Resistor

E/W Amp Adj Input (Parabola)

V ert Amp Adj Input

Cap for Amp Control9 12

E/W Output (Parabola to Driver Stage)

20 11

.280 (7.12) Max

110

.995 (25.3) Max

.300 (7.62)

.280

(7.1)

.100 (2.54) .125 (3.17) Min .385 (9.8)

Loading...

Loading...