Page 1

NTE1885

Integrated Circuit

Module, 4 Phase Stepping Motor Driver, 1.75A

Features:

D Low heat generation due to constant current chopper system.

D Functions of pause action and power down.

D Able to be used in any stepping motor of hybrid typ, P.M. type, V.R. type.

D Inverter buffer provides direct drive, for 4 phase dual excitation.

D Built in sensing power resistors for load current.

D Protection elements for fly–back voltage are included.

Absolute Maximum Ratings:

Supply Voltage, V

Phase Peak Current, I

(Quiescent) 50V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CC

OH

Operating Case Temperature, T

Junction Temperature, T

j

Storage Temperature Range, T

(TA = +25°C unless otherwise specified)

C

stg

Recommended Operating Conditions:

Supply Voltage Range, V

Phase Peak Current, I

Operating Characteristics:

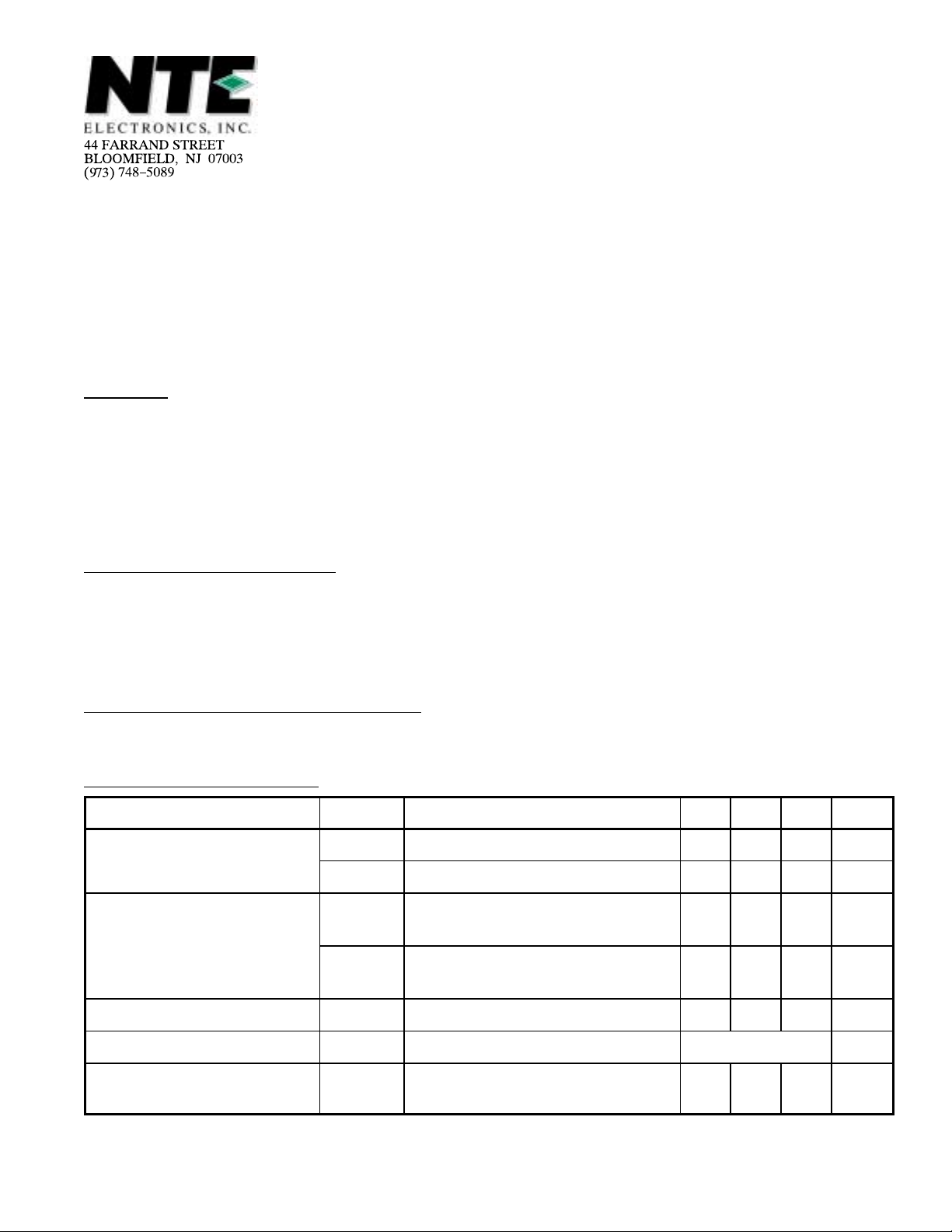

Parameter

Diode Forward Voltage V

Output Saturation Voltage V

Output Current I

1 22V to 45V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CC

OH

(TA = +25°C, VCC1 = 36V, VCC2 = 5V Unless otherwise specified)

Symbol Test Conditions Min Typ Max Unit

df–1

V

df–2

sat–1

V

sat–2

O–1

+105°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

+150°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

–40° to +125°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

(TA = +25°C Unless othrwise specified)

If = 0.3A – 1.5 1.8 V

If = 0.5A – 1.2 1.6 V

RL = 12Ω, Vin = GND,

V

1 = 22V

CC

RL = 21Ω, Vin = GND,

V

1 = 36V

CC

– 1.2 1.6 V

– 2.3 3.0 V

0.98 1.05 1.12 A

2.1A. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.5A. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

OSC Frequency f 24 (Fixed OSC) kHz

Thermal Resistance

(Note 1)

θ

j–c

TR1, TR6

TR2, TR3, TR4, TR5

–

–

8.0

13.5––

°C/W

Note 1. From Junction of each transistor or diode to substrate

Page 2

Description of Operation:

Constant Current Chopper Drive

a) When the phase drive input is activated, the motor winding current increases. At a predetermined

current (the rated current of the motor), the applied voltage of the winding begins to be switched

ON–OFF to maintain a constant current.

This is the constant–current chopper drive by PWM offering a higher efficiency (30% under a certain condition) than a constant–voltage drive, but causing relatively large noise due to the switching operation. The PWM method consists of self–excitation and separate excitation methods. For

the separate excitation, an oscillator is required, as PWM is externally conducted. The self excitation method has a simpler circuit, not requiring an oscillator, but using the resistance and inductance of the motor winding instead.

b) When a voltage several times larger than the rated voltage is applied to the motor, a change in

the winding currents occurs. The time when the currents reach 63.2% of the rated current (I

O

shows a higher–speed response with regard to the rise of the winding current and acts as a time

constant for the R–L series network with the rated applied voltage.

c) Without a constant current circuit, over current will ramp up to a constant value, so that a constant–

current chopper drive is needed. The chopping is conducted below the constant value, so that

the winding resistance and the rated current must satisfy the following equation:

V

– V

CC

<

I

O

sat

R

)

Where R: Winding resistance per a phase of the motor + RE1

V

sat

:V

sat–1

+ V

sat–2

With an increase in winding inductance, the flyback energy is increased and, when transistors for

each–phase drive are OFF, the power loss is increased. Considering b) and c), the following motor

is recommended:

Motor specification (4–phase unipolar stepping motor)

Rated current: 1.0 ± 0.5A/phase

Winding resistance: 10Ω/phase

Inductance: 1 ∼ 10mH/phase

Chopper Operation (Note: TR’s are internal transistors used for reference purposes; D’s are inter-

nal protection diodes; and L’s represent the motor windings)

The operation for a unipolar 2–phase excitation a of 4–phase stepping motor is described as:

When a High–Level input and a Low–Level input are applied to Pin5 (phase A) and Pin6 (phase

A) respectively , TR2 is turned ON. Since one terminal of 1/2 IC1 (comparator) is at GND potential,

the comparator output (point A becomes High), turning ON TR7. This also causes TR1 to be

turned ON and the current in the winding increases as shown by the equation:

– V(sat)

V

i =

CC

(l – ε

–t/

τ

)

R

Where τ: = L/R time constant

L: Winding inductance per phase

R: Winding resistance per phase plus emitter resistance, etc.

also V

V

V

:= V

sat

:VCE(sat) of chopper transistors (TR1, 6)

sat1

:VCE(sat) of phase–drive transistors (TR2, 3, 4, 5) and Vd (Diodes, internal)

sat2

sat–1

+ V

sat–2

Page 3

When the voltage drop of the emitter resistor R16 (internal) has increased up to the external standard voltage and the set voltage (the voltage of Pin9), the comparator output becomes Low and

TR7 turns OFF with TR1 OFF. The point at which the comparator output changes from Low to

High is called the Upper Trip Point and is expressed as V

UTP

.

V

UTP

=V9

=V

CC

2 x

2 + R16

R

O

1 + RO2 + R16

R

O

since R16 = 0.3Ω ±5%

and R16 << R

1, RO2 is negligible

O

RO2

therefore V

where R

UTP

=VCC2 x

1 and RO2 are the motor series winding resistors

O

R

1 + RO2

O

When the comparator output becomes Low with TR1 OFF, the winding current decreases as follows:

V

– V(sat)

CC

i =

x ε

–t/

τ

R

When the voltage at Pin8 reaches a certain value, the comparator output becomes High and TR1

turns ON with an increase in the winding current. These steps are repeated. The point at which

the comparator output is changed from Low to High is referred to as the Lower Trip Point, expressed as V

LTP

. At V

R17, D4 and L2, and feedbacked to L1. Therefore, half of I

Pin8 becomes 1/2 V

, energy stored in the winding L1 and is discharged through TR2, R16,

LTP

flows into R17 and the voltage at

OH

.

UTP

V

= 1/2 x V

LTP

UTP

The change of the motor winding current is as follows:

V

UTP

IOH =

R16

V

LTP

IOL =

R16

The flyback voltage generated by the turn OFF of TR2 phase drive, is returned to the power supply

through TR2, R16, R17, D4, L2, and D1, providing low power consumption.

Typical Application Circuit

1 (36V)

+V

CC

ZD (43V.3W)

0.1µf10µf

13

Power Down Input

Pause Action Input

+5V Reg Voltage

A

A

B

B

22k R

1k R

1

O

2

O

5

6

13

14

17

18

8

910

2

4

7

16

12

15

4 Phase Stepping Motor

Page 4

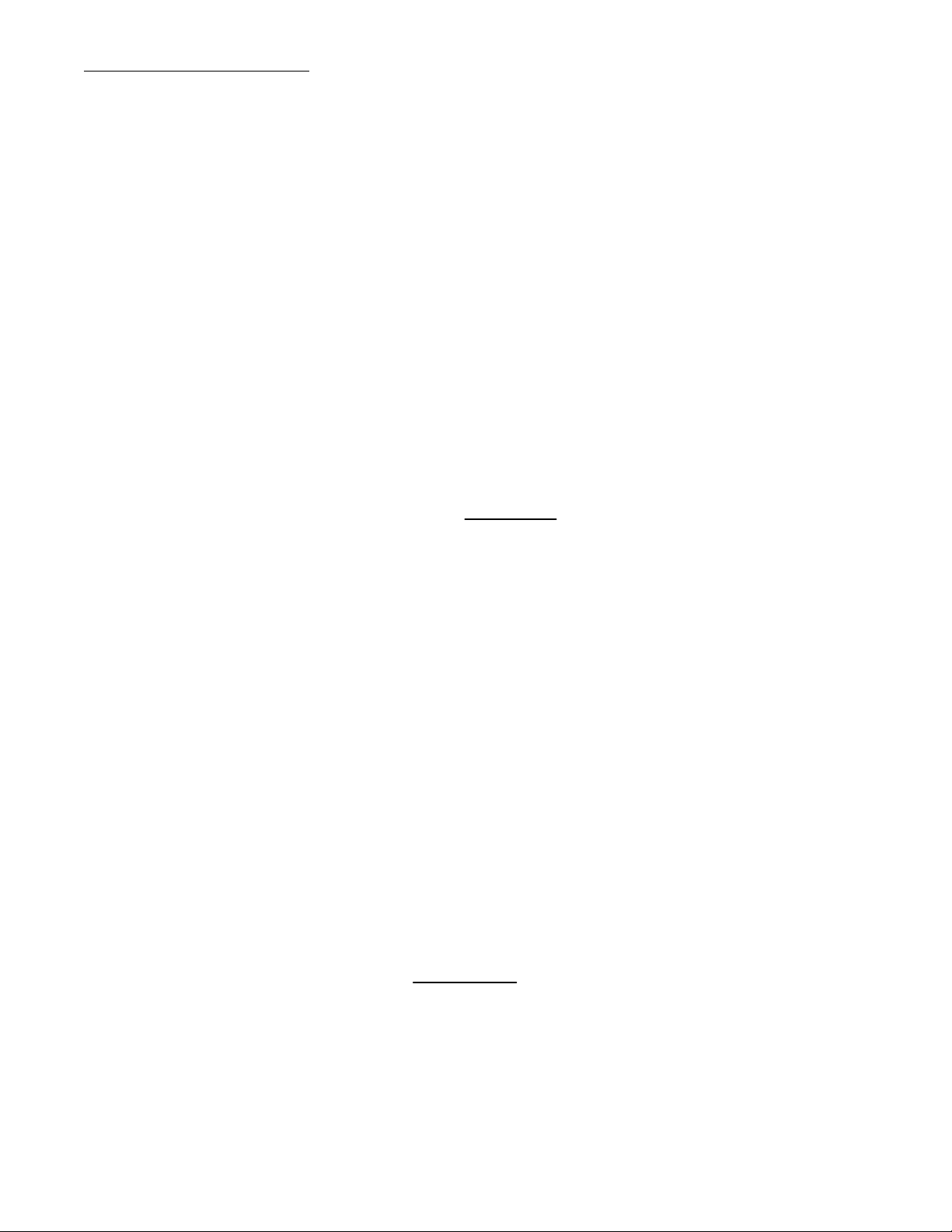

2.520 (64.0)

.141

(3.6)

Dia

(2 Holes)

2.190 (55.6)

118

.100 (2.54)

.334 (8.5)

1.440

(36.4)

.737

(18.7)

1.030

(32.5)

.158 (4.0)

.114 (5.5)1.700 (43.18)

Loading...

Loading...