Page 1

Philips Semiconductors Linear Products Product specification

NE/SE5537Sample-and-hold amplifier

884

August 31, 1994 853-1044 13721

DESCRIPTION

The NE5537 monolithic sample-and-hold amplifier combines the

best features of ion-implanted JFETs with bipolar devices to obtain

high accuracy, fast acquisition time, and low droop rate. This device

is pin-compatible with the LF198, and features superior performance

in droop rate and output drive capability. The circuit shown in Figure

1 contains two operational amplifiers which function as a unity gain

amplifier in the sample mode. The first amplifier has bipolar input

transistors which give the system a low offset voltage. The second

amplifier has JFET input transistors to achieve low leakage current

from the hold capacitor. A unique circuit design for leakage current

cancellation using current mirrors gives the NE5537 a low droop

rate at higher temperature. The output stage has the capability to

drive a 2kΩ load. The logic input is compatible with TTL, PMOS or

CMOS logic. The differential logic threshold is 1.4V with the sample

mode occurring when the logic input is high. It is available in 8-lead

TO-5, 8-pin plastic DIP packages, and 14-pin SO packages.

FEATURES

•Operates from ±5V to ±18V supplies

•Hold leakage current 6pA @ T

J

= 25°C

•Less than 4µs acquisition time

•TTL, PMOS, CMOS compatible logic input

•0.5mV typical hold step at CH=0.01µF

•Low input offset: 1MV (typical)

•0.002% gain accuracy with R

L

=2kΩ

•Low output noise in hold mode

•Input characteristics do not change during hold mode

•High supply rejection ratio in sample or hold

•Wide bandwidth

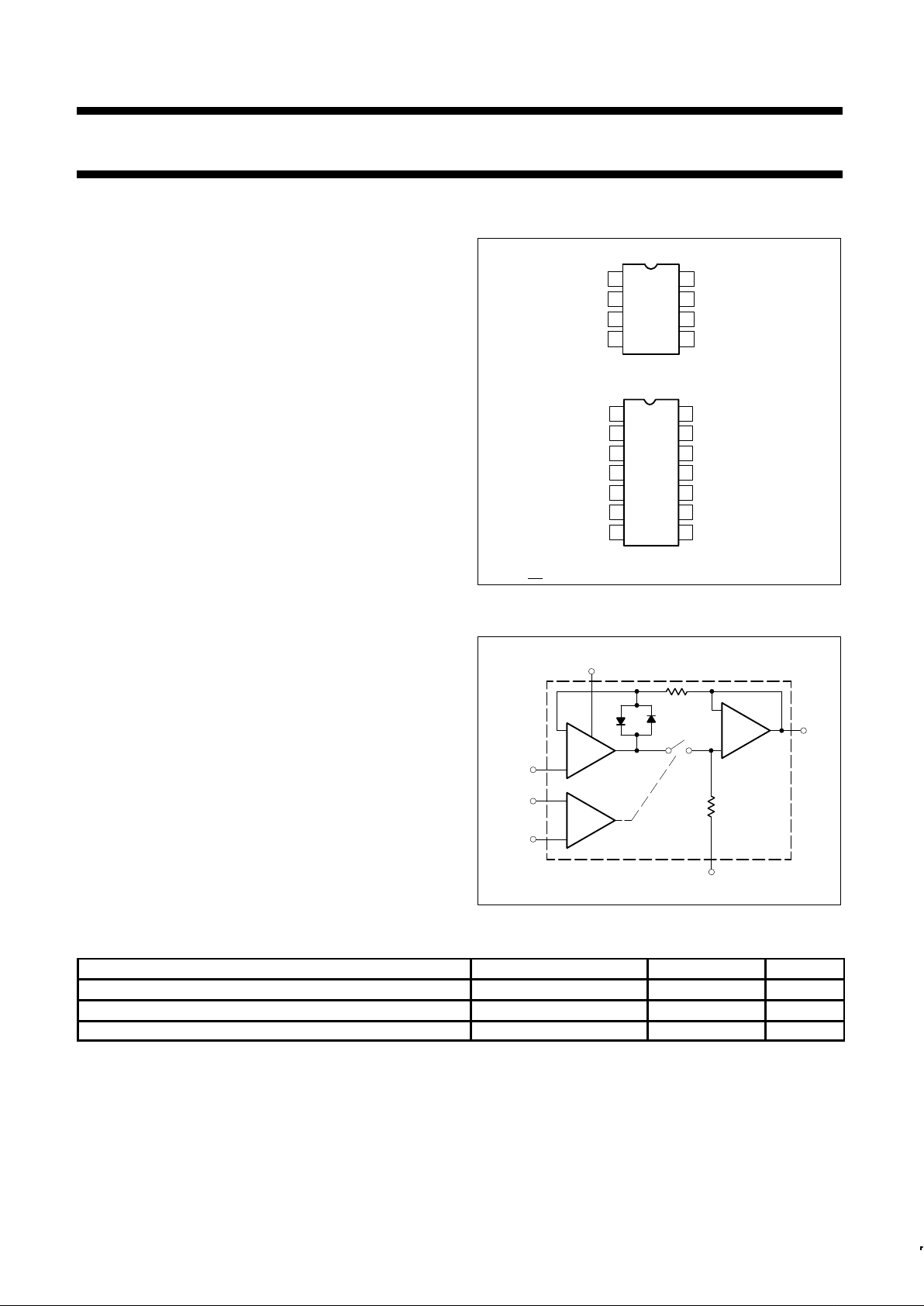

PIN CONFIGURATIONS

FE and N Packages

D

1

Package

NOTE:

1. SO and

non-standard pinouts.

1

2

3

4 5

6

7

8

1

2

3

4

5

6

7 8

14

13

12

11

10

9

V+

OFFSET ADJUST

INPUT

V–

NC

LOGIC

LOGIC REFERENCE

OUTPUT

C

h

V–

INPUT

OUTPUT

NC

NC

V+

LOGIC REFERENCE

NC

C

h

NC

V

OS

ADJ

NC

LOGIC

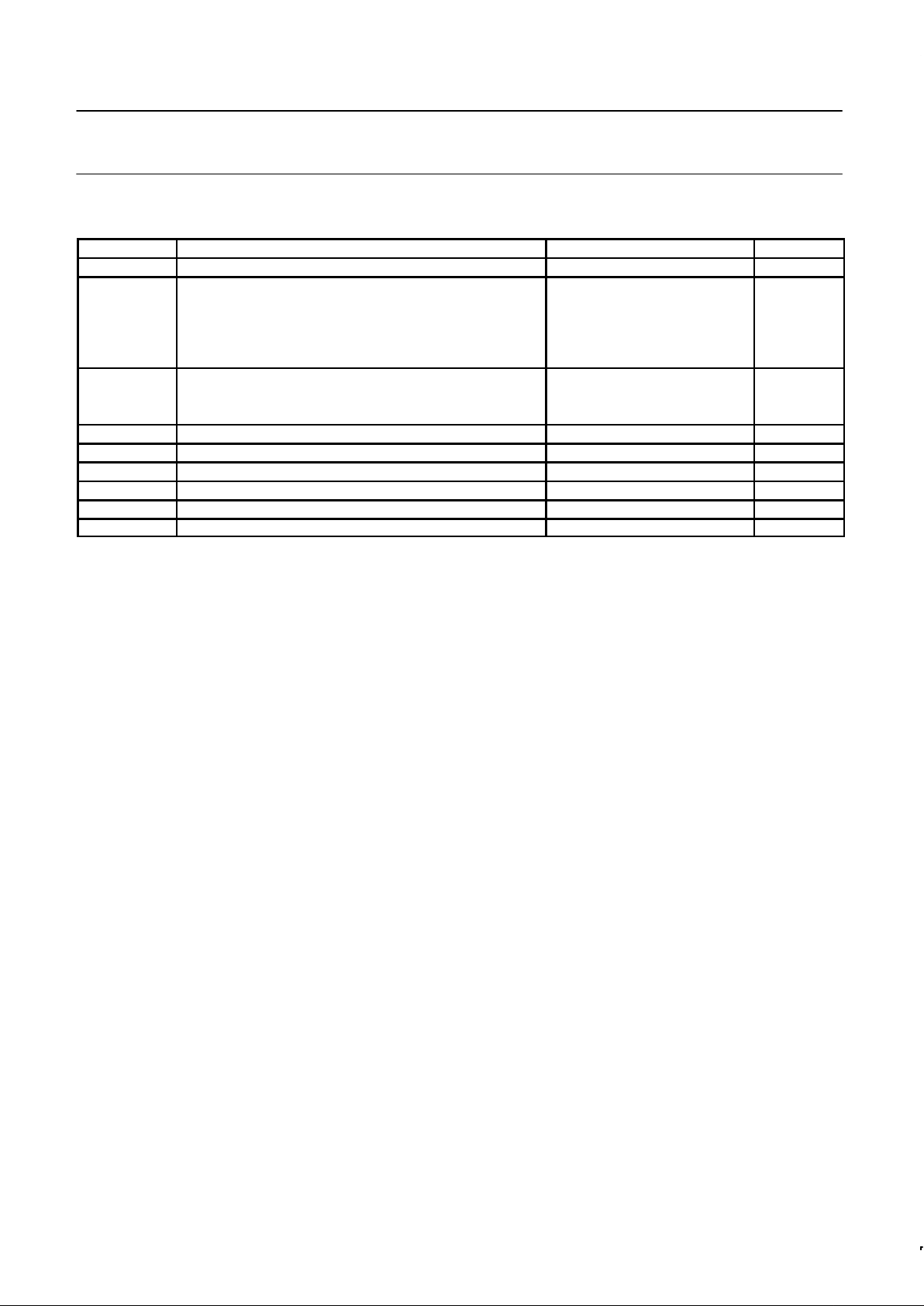

BLOCK DIAGRAM

OFFSET

OUTPUT

INPUT

LOGIC

LOGIC

REFERENCE

HOLD

CAPACITOR

300

30k

2

3

8

7

6

5

–

+

–

+

ORDERING INFORMATION

DESCRIPTION TEMPERATURE RANGE ORDER CODE DWG #

8-Pin Plastic Dual In-Line Package (DIP) 0 to +70°C NE5537N 0404B

14-Pin Plastic Small Outline (SO) Package 0 to +70°C NE5537D 0175D

8-Pin Plastic Dual In-Line Package (DIP) -55°C to +125°C SE5537FE 0404B

Page 2

Philips Semiconductors Linear Products Product specification

NE/SE5537Sample-and-hold amplifier

August 31, 1994

885

ABSOLUTE MAXIMUM RATINGS

SYMBOL PARAMETER RATING UNIT

V

S

Voltage supply ±18 V

P

D

Maximum power dissipation

T

A

=25°C (still-air)

1

N package 1160 mW

D package 1090 mW

FE package 780 mW

T

A

Operating ambient temperature range

SE5537 -55 to +125 °C

NE5537 0 to +70 °C

T

STG

Storage temperature range -65 to +150 °C

V

IN

Input voltage Equal to supply voltage

Logic to logic reference differential voltage

2

+7, -30 V

Output short circuit duration Indefinite

Hold capacitor short circuit duration 10 s

T

SOLD

Lead soldering temperature (10sec max) 300 °C

NOTES:

1. Derate above 25°C at the following rates:

FE package at 6.2mW/°C

N package at 9.3mW/°C

D package at 8.3mW/°C

2. Although the differential voltage may not exceed the limits given, the common-mode voltage on the logic pins may be equal to the supply

voltages without causing damage to the circuit. For proper logic operation, however, one of the logic pins must always be at least 2V below

the positive supply and 3V above the negative supply.

Page 3

Philips Semiconductors Linear Products Product specification

NE/SE5537Sample-and-hold amplifier

August 31, 1994

886

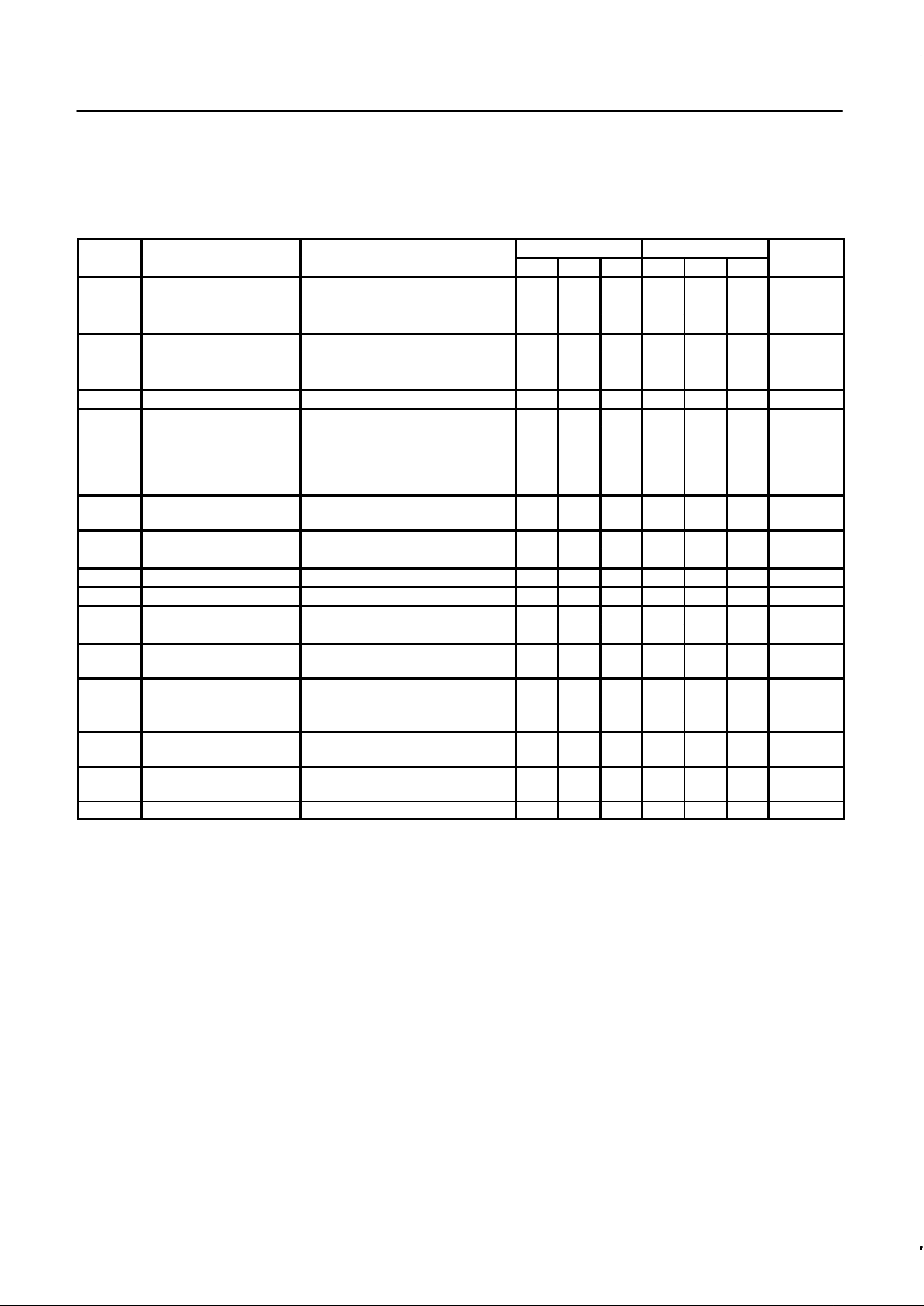

DC ELECTRICAL CHARACTERISTICS

1

SE5537 NE5537

SYMBOL

PARAMETER

TEST CONDITIONS

Min Typ Max Min Typ Max

UNIT

TJ=25°C 1 3 2 7 mV

V

OS

Input offset voltage

4

Full temperature range 5 10 mV

TJ=25°C 5 25 10 50 nA

I

BIAS

Input bias current

4

Full temperature range 75 100 nA

Input impedance TJ=25°C 10

10

10

10

Ω

Gain error TJ=25°C 0.002 0.007 0.004 0.01 %

-10V≤VIN≤10V, RL=2kΩ

-11.5V≤V

IN

≤11.5V,

R

L

=10kΩ

Full temperature range 0.02 0.02 %

Feedthrough attenuation

ratio at 1kHz

TJ=25°C, CH=0.01µF 86 96 80 90 dB

Output impedance TJ=25°C, “HOLD” mode 0.5 2 0.5 4 Ω

Full temperature range 4 6

“HOLD” Step

2

TJ=25°C, CH=0.01µF, V

OUT

=0 0.5 2.0 1.0 2.5 mV

I

CC

Supply current

4

TJ=25°C 4.5 6.5 4.5 7.5 mA

Logic and logic reference

input current TJ=25°C 2 10 2 10 µA

Leakage current into hold

capacitor

4

TJ=25°C “hold” mode

3

6 50 6 100 pA

Acquisition time to 0.1%

V

OUT

=10V,

C

H

=1000pF

4 4 µs

CH=0.01µF 20 20 µs

Hold capacitor charging

current

VIN-V

OUT

=2V 5 5 mA

SVRR

Supply voltage rejection

ratio

V

OUT

=0V 80 110 80 110 dB

Differential logic threshold TJ=25°C 0.8 1.4 2.4 0.8 1.4 2.4 V

NOTES:

1. Unless otherwise specified, the following conditions apply: Unit is in “sample” mode. V

S

=±15V, TJ=25°C, -11.5V≤VIN≤11.5V, CH=0.01µF, and

R

L

=2kΩ. Logic reference voltage=0V and logic voltage=2.5V.

2. Hold step is sensitive to stray capacitive coupling between input logic signals and the hold capacitor. 1pF, for instance, will create an

additional 0.5mV step with a 5V logic swing and a 0.01F hold capacitor. Magnitude of the hold step is inversely proportional to hold capacitor

value.

3. Leakage current is measured at a junction temperature of 25°C. The effects of junction temperature rise due to power dissipation or elevated

ambient can be calculated by doubling the 25°C value for each 11°C increase in chip temperature. Leakage is guaranteed over full input

signal range.

4. These parameters guaranteed over a supply voltage range of ±5 to ±18V.

Page 4

Philips Semiconductors Linear Products Product specification

NE/SE5537Sample-and-hold amplifier

August 31, 1994

887

TYPICAL PERFORMANCE CHARACTERISTICS

Input Bias Current Output Short-Circuit Current Gain Error

Hold Step

Leakage Current Into

Hold Capacitor

Hold Step vs Input Voltage

Acquisition Time Aperture Time Capacitor Hysteresis

25

20

15

10

5

0

–5

–10

–15

–50 –25 0 25 50 75 100 125 150

CURRENT (nA)

JUNCTION TEMPERATURE (°C)

30

28

26

24

22

20

18

16

14

12

10

–50 –25 0 25 50 75 100 125 150

JUNCTION TEMPERATURE (°C)

SOURCING

SINKING

CURRENT (mA)

100

10

1

0.1

0.01

100pF 1000pF

0.01µF 0.1µF 1µF

HOLD STEP (mV)

HOLD CAPACITOR

V+ = V– = 15V

TJ = 25°C

10

VS = ±15V

V

OUT

= 0

HOLD MODE

CURRENT (nA)

1

10

–1

10

–2

10

–3

JUNCTION TEMPERATURE (°C)

–50 –25 0 25 50 75 100 125 150

TIME (ns)

2

1.8

1.6

1.4

1.2

1

0.8

0.6

0.4

0.2

0

–15 –10 –5 0 5 10 15

NORMALIZED HOLD STEP AMPLITUDE

INPUT VOLTAGE (V)

TJ = 100°C

T

J

= 25°C

T

J

= –55°C

1

–15 –10 –5 0 5 10 15

INPUT VOLTAGE (V)

INPUT VOLTAGE — OUTPUT VOLTAGE (mV)

0.8

0.6

0.4

0.2

0

–0.2

–0.4

–0.6

–0.8

–1

TJ = 25°C

R

L

= 2kΩ

SAMPLE MODE

1

10

100

1000

0.001 0.01 0.1

TJ = 25°C

TIME ( s)

HOLD CAPACITOR (µF)

V

IN

= 0 TO ±10V

1%

0.1%

0.01%

µ

100

0.1 1 10 100

FINAL SAG (mV)

SAMPLE TIME (ms)

10

1

0.1

MYLAR

TIME

CONSTANT

MYLAR

HYSTERESIS

POLYPROPYLENE

AND POLYSTYRENE

TIME CONSTANT

POLYPROPYLENE

AND POLYSTYRENE

HYSTERSIS

250

–50 –25

225

200

175

150

125

100

75

50

25

0

0 25 50 75 100 125 150

JUNCTION TEMPERATURE (°C)

V+ = V– = 15V

∆V

OUT

≤ 1mV

∆VIN – 10V

NEGATIVE

INPUT

STEP

POSITIVE

INPUT

STEP

Page 5

Philips Semiconductors Linear Products Product specification

NE/SE5537Sample-and-hold amplifier

August 31, 1994

888

TYPICAL PERFORMANCE CHARACTERISTICS (Continued)

JUNCTION TEMPERATURE (°C)

HOLD CAPACITOR

Dynamic Sampling Error Output Droop Rate

Hold Settling Time

Phase and Gain

(Input-to-Output, Small-Signal)

Power Supply Rejection

Output Noise

Feedthrough Rejection

Ratio (Hold Mode)

10

0

10

–1

10

–2

10

–3

10

–4

100pF 1000pF 0.01µF 0.1µF 1µF

TJ = 85°C

TJ = 25°C

V/ T (V/SEC)

∆ ∆

2

1.8

1.6

1.4

1.2

1

0.8

0.6

0.4

0.2

0

–50 –25 0 25 50 75 100 125 150

TIME ( S)

µ

V+ = V– = 15V

SETTLING TO 1mV

160

140

120

100

80

60

40

20

0

100 1k 10k 100k 1M

FREQUENCY (Hz)

REJECTION (dB)

NEGATIVE

SUPPLY

POSITIVE

SUPPLY

TJ = 25°C

V+ = V– = 15V

V

OUT

= 0V

160

140

120

100

80

60

40

20

0

10 100 1k 10k 100k

FREQUENCY (Hz)

“HOLD” MODE

SAMPLE MODE

NOISE (nV/ Hz)

RATIO (dB)

FREQUENCY (Hz)

–130

–120

–110

–100

–90

–80

–70

–60

–50

1 10 100 1k 10k 100k 1M

Ch = 0.1µF

Ch = 0.01µF

Ch = 1000pF

V+ = V– = 15V

V

IN

= 10V

P-P

V

7,8

= 0

T

J

= 25°C

ERROR (mV)

INPUT SLEW RATE (V/ms)

1k

10k 100k

1M

10M

80

70

60

50

40

30

20

10

0

100

10

–10

–100

±1

0.1 1 10 100 1000

1000pF

3300pF

330pF

0.01µF

0.033µF

0.03µF

0.1µF

5

0

–5

–10

FREQUENCY (Hz)

GAIN—INPUT TO OUTPUT (dB)

INPUT TO OUTPUT PHASE DELAY (DEG)

Page 6

Philips Semiconductors Linear Products Product specification

NE/SE5537Sample-and-hold amplifier

August 31, 1994

889

SAMPLE-AND-HOLD

For many years designers have used the sample-and-hold (or

track-and-hold) to operate on analog information in a time frame

which is expedient.

By sampling a segment of the information and holding it until the

proper timing for converting to some form of control signal or

readout, the designer maintains certain freedom in performing

predetermined manipulative functions. Therefore, the

sample-and-hold can be defined as a “selective analog memory

cell”.

The memory is volatile and will also decay with time.

When using the sample-and-hold method for evaluating signal

information, the designer is given the added feature of eliminating

outside noise elements. With the analog-to-digital converter

products available today, the “DC memory” of the sample-and-hold

can be easily converted to digital format and further incorporated

into microprocessor-based systems.

Parametric evaluation of the sample-and-hold will be discussed in

the following paragraphs.

DEFINITION OF TERMS

Acquisition Time —

The time required to acquire a new analog input voltage with an

output step of 10V. Note that acquisition time is not just the time

required for the output to settle, but also includes the time required

for all internal nodes to settle so that the output assumes the proper

value when switched to the hold mode.

Aperture Delay Time —

The time elapsed from the hold command to the opening of the

switch.

Aperture Jitter —

Also called “aperture uncertainty time”, it is the time variation or

uncertainty with which the switch opens, or the time variation in

aperture delay.

Aperture Time —

The delay required between “HOLD” command and an input analog

transition, so that the transition does not affect the held output.

Bandwidth —

The frequency at which the gain is down 3dB from its DC value. It’s

measured in sample (track) mode with a small-signal sine wave that

doesn’t exceed the slew rate limit.

Dynamic Sampling Error —

The error introduced into the hold output due to a changing analog

input at the time the hold command is given. Error is expressed in

mV with a given hold capacitor value and input slew rate. Note that

this error term occurs even for long sample times.

Effective Aperture Delay —

The time difference between the hold command and the time at

which the input signal is at the held voltage.

Figure of Merit —

The ratio of the available charging current during sample mode to

the leakage current during hold mode.

Gain Error —

The ratio of output voltage swing to input voltage swing in the

sample mode expressed as a percent difference.

Hold Mode Droop —

The output voltage change per unit of time while in hold. Commonly

specified in V/s, µV/µs or other convenient units.

Hold Mode Feedthrough —

The percentage of an input sinusoidal signal that is measured at the

output of a sample-hold when it’s in hold mode.

Hold Settling Time —

The time required for the output to settle within 1mV of final value

after the “HOLD” logic command.

Hold Step —

The voltage step at the output of the sample-and-hold when

switching from sample mode to hold mode with a steady (DC)

analog input voltage. Logic swing is 5V .

Sample-to-Hold Offset Error —

The difference in output voltage between the time the switch starts

to open, and the time when the output has settled completely. It is

caused by charge being transferred to the hold capacitor switch as it

opens.

Slew Rate —

The fastest rate at which the sample-and-hold output can change

(specified in V/µs).

Threshold Level —

That level which causes the switch control to change state.

BASIC BLOCK DIAGRAM

The basic circuit concept of the sample-and-hold circuit incorporates

the use of two (2) operational amplifiers and a switch control

mechanism (which determines sample, hold or track conditions).

The block diagram of the NE5537 is a closed loop, non-inverting

unity gain sample-and-hold system. The input buffer amplifier

supplies the current necessary to charge the hold capacitor, while

the output buffer amplifier closes the loop so that the output voltage

is identical to the input voltage (with consideration for input offset

voltage, offset current, and temperature variations which are

common to all sample-and-hold circuits, be they monolithic, hybrid

or modular).

When the sampling switch is open (in the hold mode), the clamping

diodes close the loop around the input amplifier to keep it from being

overdriven into saturation.

The switch control is driven by external logic levels via a timing

sequence remote from the sample-and-hold device (See Figure 1).

The switch control has a floating reference (Pin 7), referred to as the

logic reference which makes the sample-and-hold device compatible

to several types of external logic signals (TTL, PMOS, and CMOS).

The switching device operates at a threshold level of 1.4V .

Page 7

Philips Semiconductors Linear Products Product specification

NE/SE5537Sample-and-hold amplifier

August 31, 1994

890

Figure 1. Typical Connection

V+

V–

OUTPUT

1

4

5

6

7

8

3

ANALOG INPUT

SAMPLE

HOLD5V0V

LOGIC

INPUT

C

h

The switch mechanism is on (sampling an information stream) when

the logic level is high (Pin 8 is 1.4V higher than Pin 7) and presents

a load of 5µA to the input logic signal. The analog sampled signal is

amplified, stored (in the external holding capacitor), and buffered. At

the end of the sampling period, the internal switch mechanism turns

off (switch opens) and the “stored analog memory” information on

the external capacitor (Pin 6) is loaded down by an operational

amplifier connected in the unity gain non-inverting configuration.

This input impedance of this amplifier is effectively:

R = R

IN

(AOL) / (1 + 1/A)

where R = Effective input impedance

RIN= Open-loop input impedance

AOL= Open-loop gain

A = AC loop gain

Therefore, the higher the open-loop gain of the second operational

amplifier, the larger the effective loading on the capacitor. The larger

the load, the lower the “leakage” current and the better the droop

characteristics.

In actuality, the amplifiers are designed with special leakage current

cancellation circuits along with FET input devices. The leakage

current cancellation circuits give better high temperature operation.

(Remember that the FET amplifiers double in required bias current

for every 10 degree increase in junction temperature.)

Sampling time for the NE5537 is less than 10µs (measured to 0.1%

of input signal). Leakage current is 6pA at a rate output load of 2kΩ.

BASIC APPLICATIONS

Multiplying DAC

As depicted in the block diagram of Figure 2, the sample-and-hold

circuit is used to supply a “variable” reference to the digital-to-analog

converter. As the input reference varies, the output will change in

accordance with Equation 1, shown in Figure 2.

Varying the input signal reference level can aid the system in

performing both compression and expansion operations. The

multiplying DACs used are the Philips Semiconductors NE/SE5008;

however, if the rate of change of the reference variation is kept slow

enough, a microprocessor-compatible DAC can be incorporated,

such as the NE5018 or the NE5020.

DATA ACQUISITION SYSTEMS

As mentioned earlier, the designer may wish to operate on several

different segments of an “analog” signal; however, he is limited by

the fact that only one analog-to-digital converter channel is available

to him. Figure 3 shows the means by which a multiplexing system

may be accomplished.

APPLICATION HINTS

Hold Capacitor

A significant source of error in an accurate sample-and-hold circuit

is dielectric absorption in the hold capacitor. A mylar cap, for

instance, may “sag back” up to 0.2% after a quick change in voltage.

A long “soak” time is required before the circuit can be put back in

the hold mode with this type of capacitor. Dielectrics with very low

hysteresis are polystyrene, polypropylene, and teflon. Other types

such as mica and polycarbonate are not nearly as good. Ceramic is

unusable with >1% hysteresis. The advantage of polypropylene over

polystyrene is that it extends the maximum ambient temperature

from 85°C to 100°C. The hysteresis relaxation time constant in

polystyrene, for instance, is 10-50ms. If A-to-D conversion can be

made within 1ms, hysteresis error will be reduced by a factor of ten.

DC ZEROING

DC zeroing is accomplished by connecting the offset adjust pin to

the wiper of a 1k

Ω potentiometer which has one end tied to V+ and

the other end tied through a resistor to ground. The resistor should

be selected to give 0.6mA through the 1k

Ω potentiometer.

Sampling Dynamic Signals

Sampling errors due to moving (changing) input signals are of

significant concern to designers employing sample-and-hold circuits.

There exist finite phase delays through the sample-and-hold circuit

causing an input-output phase of differential for moving signals. In

addition, the series protection resistor (300Ω to Pin 6 of the NE5537)

will add an RC time constant, over and above the slew rate limitation

of the input buffer/current drive amplifier. This means that at the

moment the “HOLD” command arrives, the hold capacitor voltage

may be somewhat different from the actual analog input. The effect

of these delays is opposite to the effect created by delays in the

logic which switches the circuit from sample to hold. For example,

consider an analog input of 20 V

P-P

at 10kHz. Maximum dV/dt is

0.6V/µs. With no analog phase delay and 100ns logic delay, one

could expect up to (0.1µs) (0.6V/µs) =60mV error if the “HOLD”

signal arrived near maximum dV/dt of the input. A positive-going

input would give a ±60mV error. Now assume a 1MHz (3dB)

bandwidth for the overall analog loop. This generates a phase delay

of 160ns. If the hold capacitor sees this exact delay, then error due

to analog delay will be (0.16µs) (0.6V/µs)=-96mV (analog) for a total

of -36mV. To add to the confusion, analog delay is proportional to

hold capacitor value, while digital delay remains constant. A family

of curves (dynamic sampling error) is included to help estimate

errors.

Page 8

Philips Semiconductors Linear Products Product specification

NE/SE5537Sample-and-hold amplifier

August 31, 1994

891

V

OUT

Figure 2. Multiplying DAC Application

V

IN

+VREF

IN

NE5537

5k

5008/DAC-08 530

5k

D0-D7

NOTE:

V

OUT

VINx

1

256

(20 D0 21D1 27D7) Equation 1

Figure 3. Analog Data Multiplexing

SD5000

NE5537

A/D

CONVERTER

ANALOG INPUT 1

CONTROL 1

ANALOG INPUT 2

CONTROL 2

ANALOG INPUT 3

CONTROL 3

ANALOG INPUT 4

CONTROL 4

SUCCESSIVE APPROXIMATION

(NE5034, NE5037)

or INTEGRATING TYPE ADC

SUBSTRATE

D

0

D

7

A curve labeled “Aperture Time” has been included for sampling

conditions where the input is steady during the sampling period, but

may experience a sudden change nearly coincident with the “HOLD”

command. This curve is based on a 1mV error fed into the output.

A second curve, “Hold Settling Time,” indicates the time required for

the output to settle to 1mV after the “HOLD” command.

Digital Feedthrough

Fast rise time logic signals can cause hold errors by feeding

externally into the analog input at the same time the amplifier is put

into the hold mode. To minimize this problem, board layout should

keep logic lines as far as possible from the analog input. Grounded

guarding traces may also be used around the input line, especially if

it is driven from a high impedance source. Reducing high amplitude

logic signals to 2.5V will also help.

Logic signals also couple to the hold capacitor. This hold capacitor

should be guarded by a PC card trace connected to the

sample-and-hold output. This will also minimize board leakage.

SPECIAL NOTES

1. Not all definitions herein defined are measured parametrically for

the NE5537, but are legitimate terms used in sample-and-hold

systems.

2. Reference should be made to Design Engineering, Volumes 23

(Nov. 8, 1978), 25 (Dec. 6, 1978) and 26 (Dec. 20, 1978) for

articles written by Eugene Zuch of Datel Systems, Inc., for a

further discussion of sample-and-hold circuits.

3. Reference also made to National Semiconductor Corporation’s

Special Functions Data Book (1976).

Loading...

Loading...