Datasheet NC4D-JP-DC110V, NC2D-PL2-DC48V, NC2D-JPL2-DC48V, NC2D-JPL2-DC6V, NC2D-L2-DC24V Datasheet (NAIS)

...Page 1

27.8

1.094

38.1

1.500

4.1

.161

11.2

.441

°

VDE

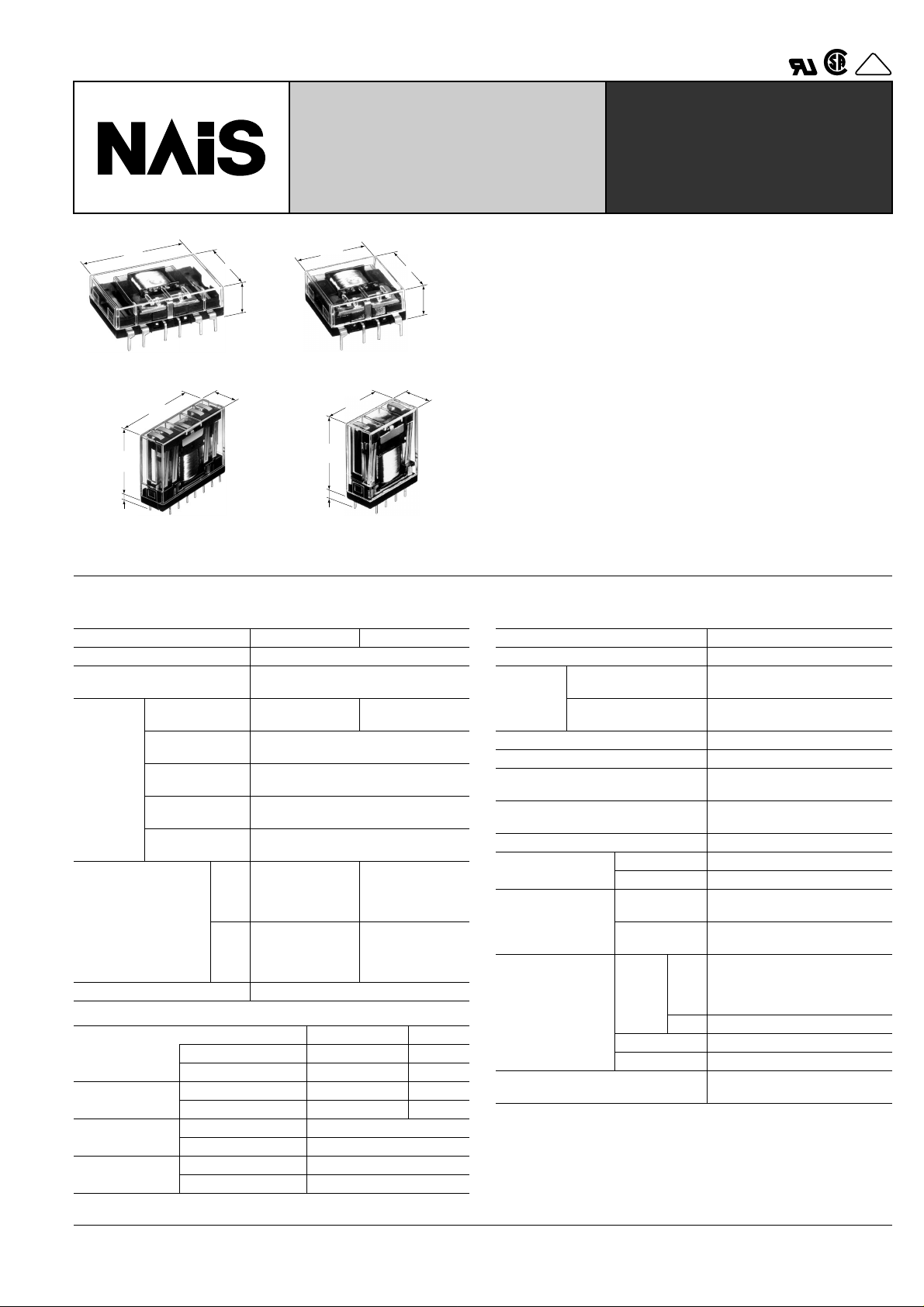

FLA T/VERTICAL TYPE

HIGH POWER BIFURCATED

NC-RELAYS

CONTACT

38.1

1.500

25.4

1.000

10.9

.429

25.4

1.000

4C Flat type 2C Flat type

25.4

1.000

27.8

1.094

4.1

.161

4C Vertical type (PC board) 2C Vertical type (PC board)

SPECIFICATIONS

Contacts

Types Standard Amber sealed

Arrangement 2 Form C, 4 Form C

Initial contact resistance, max.

(By voltage drop 6 V DC 1 A)

Max. switching

power

2C: 1,250 VA 150 W

4C: 1,000 VA 150 W

Max. switching

Rating

(resistive

load)

voltage

Max. switching

current

Max. switching

carrying current

Min. switching

power

10

5 A 250 V AC

2C

Expected life

(minimum)

4C

5 × 10

5 A 30 V DC

10

4 A 250 V AC

5 × 10

5 A 30 V DC

Contact material Gold-clad silver nickel

Coil (Polarized) (at 25 ° C 77 ° F)

Minimum

operating power

Nominal

operating power

Minimum set and

reset power

Nominal set and

reset power

2 C single side stable Approx. 200 mW 500 mW

4 C single side stable Approx. 400 mW 500 mW

2 C single side stable Approx. 360 mW 900 mW

4 C single side stable Approx. 720 mW 900 mW

2 C 2 coil latching Approx. 450 mW

4 C 2 coil latching Approx. 900 mW

2 C 2 coil latching Approx. 800 mW

4 C 2 coil latching Approx. 1,600 mW

50 m Ω

2C: 750 VA 150 W

4C: 500 VA 150 W

250 V AC

5 A

5 A

100 µ A 1 V DC

5

at

5

at

3 A 250 V AC

5 A 30 V DC

5

at

5

at

2 A 250 V AC

5 A 30 V DC

Up to 48 V DC 110 V DC

25.4

1.000

10

5 × 10

10

5 × 10

10.9

.429

11.2

.441

mm inch

5

at

5

at

5

at

5

at

FEATURES

• Space saver — Flat series and vertical series

• High contact reliability due to bifurcated contacts

— 2C: 5 A 250 V AC, 4C: 5 A 125 V AC, 4 A 250 V AC

• Latching types available

• Low operating power

— 2C: 200 mW, 4C: 400 mW (Single side stable)

• Soldering flux inflow prevented by terminal location

• Amber sealed types available

• High breakdown voltage for transient protection

— 1,000 Vrms between open contacts, contact sets

Characteristics (at 25 ° C 77 ° F 50% Relative humidity)

Max. operating speed

Initial insulation resistance Min. 100 M Ω at 500 V DC

Initial

breakdown

voltage*

Between open contacts,

contact sets

Between contacts and

1

coil

Operate time (at nominal voltage) Approx. 6 ms

Release time (at nominal voltage) Approx. 3 ms

Operate time (latching)

(at nominal voltage)

Reset time (latching)

(at nominal voltage)

Temperature rise (at nominal voltage) Max. 65

Shock resistance

Vibration

resistance

Functional*

Destructive*

Functional*

Destructive

2

3

4

58.8 m/s

at double amplitude of 1 mm

117.6 m/s

at double amplitude of 2 mm

up to 48 V DC: –40 ° C to +70 ° C

Conditions for operation, transport and

5

storage*

(Not freezing and

condensing at low

temperature)

(Single

side

2 C

110 V DC: –40 ° C to +55 ° C

stable)

4 C –40 ° C to +55 ° C –40 ° F to +131 ° F

(2 coil latching) –40 ° C to +55 ° C –40 ° F to +131 ° F

Humidity 5 to 85% R.H.

Unit weight

Remarks

* Specifications will vary with foreign standards certification ratings.

1

Detection current: 10 mA

*

2

*

Half-wave pulse of sine wave: 11ms; detection time: 10 µ s

3

*

Half-wave pulse of sine wave: 6ms

4

Detection time: 10 µ s

*

5

*

Refer to 5. Conditions for operation, transport and storage mentioned in

AMBIENT ENVIRONMENT (Page 61).

180 cpm

1,000 Vrms

2,000 Vrms

Approx. 6 ms

Approx. 6 ms

C

Min. 98 m/s

Min. 980 m/s

2

{10 G}

2

{100 G}

2

{6 G}, 10 to 55 Hz

2

{12 G}, 10 to 55 Hz

–40 ° F to +158 ° F

–40 ° F to +131 ° F

2C/Approx. 16 g .56 oz

4C/Approx. 18 g .63 oz

223

Page 2

NC

TYPICAL APPLICATIONS

Use NC Relays for power control up to 5 A or —

Tape recorders, temperature controls, video tape recorders

Telecommunications equipment, measuring controls, copiers

Date processing equipment, computer peripherals

Automatic vendors, copiers, automatic storage controls, N.C. machines

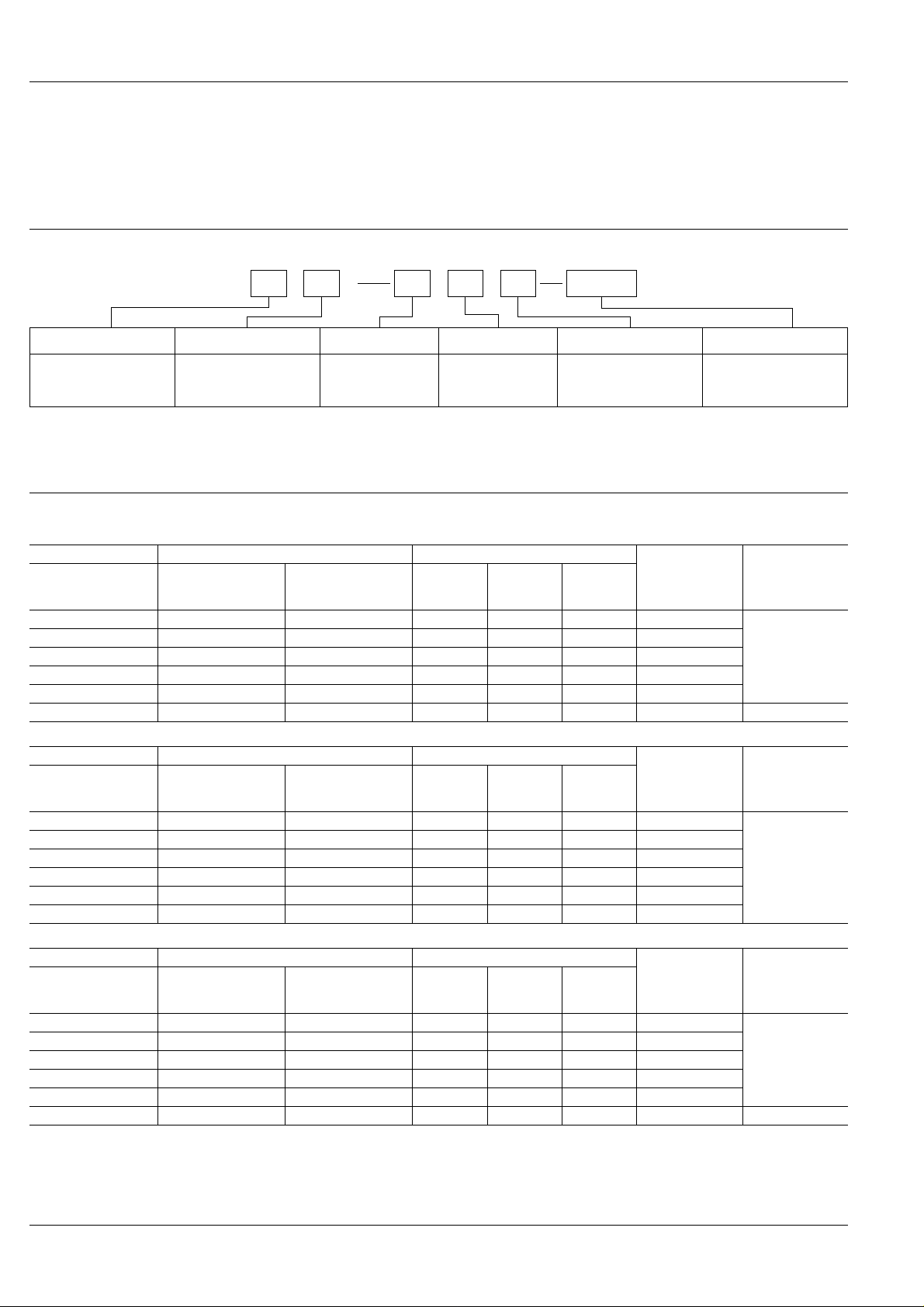

ORDERING INFORMATION

Ω ( ±

Ω ( ±

Ω ( ±

NC DEx.

2

Contact arrangement

2: 2 Form C

4: 4 Form C

(Notes) 1. Flat series are available in PC board terminal types only.

2. For VDE recognized type, add suffix VDE.

3. Standard packing Carton: 20 pcs. Case: 200 pcs.

4. UL/CSA, approved type is standard.

Type classification

Nil: Standard type

EB: Amber sealed type

EB

Housing

Nil: Vertical

series

J: Flat series

TYPE AND COIL DATA (at 20 ° C 68 ° F)

J

P L2

Mounting method

Nil: Plug-in

P: PC board

termial

(Coil data for Amber sealed types are same as those for standard types .)

DC 12V

Operating function

Nil: Single side stable

L2: 2 coil latching

Coil voltage

DC 5, 6, 12, 24, 48,

110 V

2 Form C Single side stable

Flat series Vertical series Coil voltage, V DC

PC board terminal Plug-in PC board terminal

NC2D-JP-DC5V NC2D-DC5V NC2D-P-DC5V 4.0 0.5 6.75 69.4

NC2D-JP-DC6V NC2D-DC6V NC2D-P-DC6V 4.8 0.6 8.1 100

NC2D-JP-DC12V NC2D-DC12V NC2D-P-DC12V 9.6 1.2 16.2 400

NC2D-JP-DC24V NC2D-DC24V NC2D-P-DC24V 19.2 2.4 32.4 1,600

NC2D-JP-DC48V NC2D-DC48V NC2D-P-DC48V 38.4 4.8 64.8 6,400

NC2D-JP-DC110V NC2D-DC110V NC2D-P-DC110V 88.0 11.0 121 13,500 900

Pick-up

voltage

(max.)

Drop-out

voltage

(min.)

Maximum

allowable

voltage

Coil resistance,

10%)

Nominal

operating power ,

2 Form C 2 coil latching

Flat series Vertical series Coil voltage, V DC

PC board terminal Plug-in PC board terminal

NC2D-JPL2-DC5V NC2D-L2-DC5V NC2D-PL2-DC5V 4.0 4.0 5.5 31.3

NC2D-JPL2-DC6V NC2D-L2-DC6V NC2D-PL2-DC6V 4.8 4.8 6.6 45.0

NC2D-JPL2-DC12V NC2D-L2-DC12V NC2D-PL2-DC12V 9.6 9.6 13.2 180

NC2D-JPL2-DC24V NC2D-L2-DC24V NC2D-PL2-DC24V 19.2 19.2 26.4 720

NC2D-JPL2-DC48V NC2D-L2-DC48V NC2D-PL2-DC48V 38.4 38.4 52.8 2,880

NC2D-JPL2-DC110V NC2D-L2-DC110V NC2D-PL2-DC110V 88.0 88.0 121 15,125

Pick-up

voltage

(max.)

Reset

voltage

(max.)

Maximum

allowable

voltage

Coil resistance,

10%)

Nominal

operating power ,

4 Form C Single side stable

Flat series Vertical series Coil voltage, V DC

PC board terminal Plug-in PC board terminal

NC4D-JP-DC5V NC4D-DC5V NC4D-P-DC5V 4.0 0.5 5.5 34.7

NC4D-JP-DC6V NC4D-DC6V NC4D-P-DC6V 4.8 0.6 6.6 50

NC4D-JP-DC12V NC4D-DC12V NC4D-P-DC12V 9.6 1.2 13.2 200

NC4D-JP-DC24V NC4D-DC24V NC4D-P-DC24V 19.2 2.4 26.4 800

NC4D-JP-DC48V NC4D-DC48V NC4D-P-DC48V 38.4 4.8 52.8 3,200

NC4D-JP-DC110V NC4D-DC110V NC4D-P-DC110V 88.0 11.0 121 13,500 900

Pick-up

voltage

(max.)

Drop-out

voltage

(min.)

Maximum

allowable

voltage

Coil resistance,

10%)

Nominal

operating power ,

mW

360

mW

800

mW

720

224

Page 3

Ω ( ±

4 Form C 2 coil latching

Flat series Vertical series Coil voltage, V DC

Maximum

allowable

voltage

(within 2 min.)

PC board terminal Plug-in PC board terminal

Pick-up

voltage

(max.)

Reset

voltage

(max.)

NC4D-JPL2-DC5V NC4D-L2-DC5V NC4D-PL2-DC5V 4.0 4.0 5.5 15.6

NC4D-JPL2-DC6V NC4D-L2-DC6V NC4D-PL2-DC6V 4.8 4.8 6.6 22.5

NC4D-JPL2-DC12V NC4D-L2-DC12V NC4D-PL2-DC12V 9.6 9.6 13.2 90

NC4D-JPL2-DC24V NC4D-L2-DC24V NC4D-PL2-DC24V 19.2 19.2 26.4 360

NC4D-JPL2-DC48V NC4D-L2-DC48V NC4D-PL2-DC48V 38.4 38.4 52.8 1,440

NC4D-JPL2-DC110V NC4D-L2-DC110V NC4D-PL2-DC110V 88.0 88.0 121 7,560

Notes:

1.T w o coil latching rela y 4C series are f or intermittent operation only. Power should

be applied to coil continuously for no more than two minutes.

2.Coil resistance is the measured value at a coil temperature of 20 ° C. Compensate

coil resistance by plus or minus 0.4% for each degree ( ° C) of coil temperature

change.

3."Maximum allowable voltage" is that value at maximum contact rating and maximum ambient temperature. The graph shown in the data describes the inter-relationship; care should be taken to pre vent the total of ambient temperature and the

coil temperature rise from exceeding 120 ° C.

Coil resistance,

10%)

NC

Nominal

operating power ,

mW

1,600

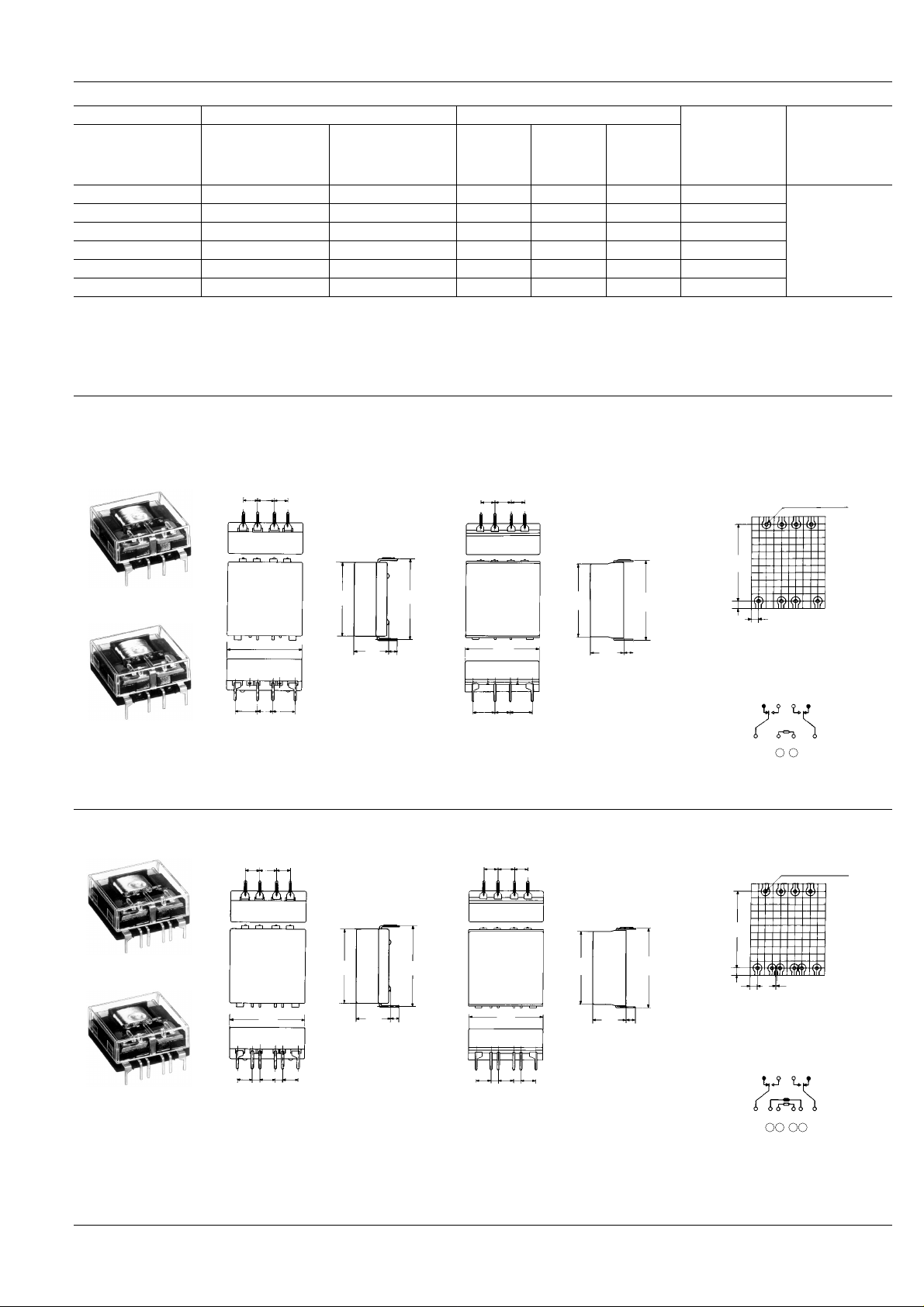

DIMENSIONS

Flat series

2C single side stable

(NC2D-JP)

(NC2ED-JP)

2C 2 coil latching

(NC2D-JPL2)

Standard type Amber sealed type

5.08

5.08

.200

7.62

.300

.200

25.4

1.000

5.08

.200

5.08

.200

7.62

.300

25.4

1.000

10.9

.429

27.94

1.100

3.5

.138

5.08

.200

7.62

.300

5.08

.200

25.4

1.000

5.08

.200

5.08

.200

7.62

.300

General tolerance: ± 0.5 ± .020

Standard type Amber sealed type

5.08

5.08

5.08

.200

5.08

.200

5.08

.200

.200

.200

5.08

.200

25.4

1.000

10.9

.429

27.94

1.100

3.5

.138

mm inch

PC board pattern (Copper-side view)

8-1.2 DIA. HOLES

8-.047 DIA. HOLES

11 12 13 14

27.94

1.100

7 5 4 2

2.54

2.54

.100

.100

Tolerance: ± 0.1 ± .004

Schematic (Top view)

14 13 12

11

4 25 7

+

–

Deenergized position

PC board pattern (Copper-side view)

10-1.2 DIA. HOLES

10-.047 DIA. HOLES

11 12 13 14

(NC2ED-JPL2)

5.08

.200

2.54

.100

25.4

1.000

5.08

.200

2.54

.100

5.08

.200

10.9

.429

27.94

1.100

3.5

.138

25.4

1.000

General tolerance: ± 0.5 ± .020

5.08

.200

2.54

.100

25.4

1.000

5.08

.200

2.54

.100

5.08

.200

25.4

1.000

10.9

.429

27.94

1.100

27.94

1.100

3.5

.138

2.54

.100

2.54

.100

7 5 4 2

0.5

.020

Tolerance: ± 0.1 ± .004

Schematic (Top view)

14 13 12

4 23 45 7

– –

Diagram shows the "reset" position

when terminals 3 and 6 are energized.

Energize terminals 4 and 5 to transfer

contacts.

11

++

225

Page 4

NC

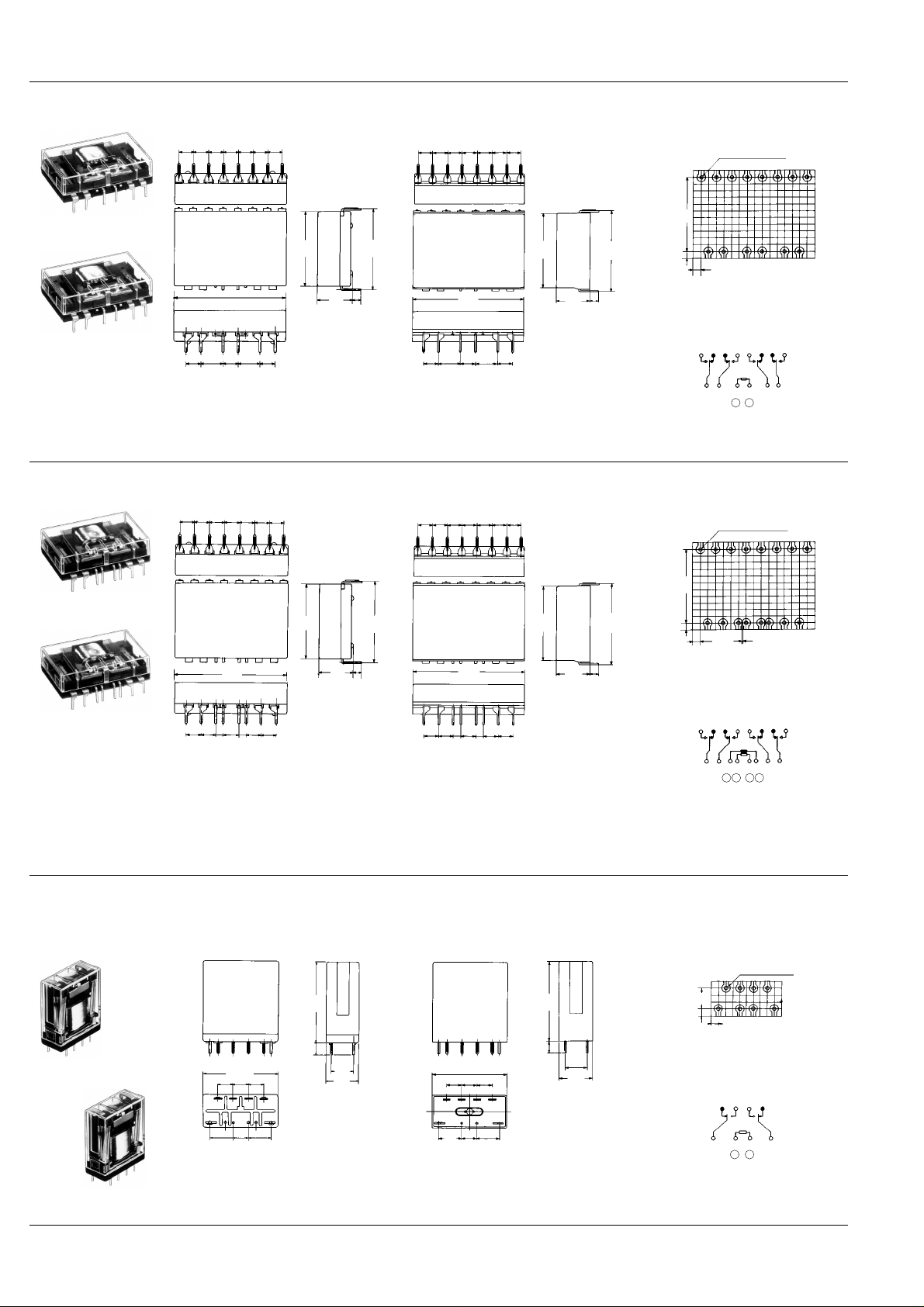

4C single side stable

(NC4D-JP)

(NC4ED-JP)

5.08

.200

5.08

.200

Standard type Amber sealed type

5.08

5.08

5.08

5.08

5.08

.200

7.62

.300

.200

.200

38.1

1.500

5.08

.200

.200

7.62

.300

.200

5.08

.200

5.08

.200

10.9

.429

27.94

1.100

3.5

.138

25.4

1.000

General tolerance: ± 0.5 ± .020

5.08

.200

5.08

.200

5.08

.200

7.62

.300

5.08

.200

5.08

.200

38.1

1.500

5.08

.200

5.08

.200

7.62

.300

5.08

.200

5.08

.200

5.08

.200

25.4

1.000

10.9

.429

PC board pattern (Copper-side view)

14-1.2 DIA. HOLES

14-.047 DIA. HOLES

10 11 12 13 14 15 16 9

27.94

1.100

27.94

1.100

3.5

.138

2.54

.100

7 5 4 2 1 8

2.54

.100

Tolerance: ± 0.1 ± .004

Schematic (Top view)

16 15 14 13 12 11 10 9

4 12 75 8

+

–

Deenergized position

mm inch

4C 2 coil latching

(NC4D-JPL2)

(NC4ED-JPL2)

Slim series

PC board series

2C single side stable

(NC2D-P)

(NC2ED-PL2)

5.08

.200

5.08

.200

Standard type Amber sealed type

5.08

5.08

5.08

5.08

5.08

.200

5.08

.200

.200

2.54

.100

.200

38.1

1.500

5.08

.200

2.54

.100

.200

5.08

.200

.200

5.08

.200

5.08

.200

25.4

1.000

10.9

.429

27.94

1.100

3.5

.138

5.08

.200

5.08

.200

5.08

.200

5.08

.200

5.08

.200

2.54

.100

5.08

.200

38.1

1.500

5.08

.200

2.54

.100

5.08

.200

General tolerance: ± 0.5 ± .020

Standard type Amber sealed type

27.8

1.094

4.1

7.62

.300

.161

7.62

.300

11.2

.441

235467

25.4 1.000

5.08

5.08

.200

.200

5.08

7.62

.200

.300

5.08

.200

7.62

.300

General tolerance: ± 0.5 ±.020

25.4

1.000

5.08

5.08

5.08

.200

.200

.200

11 12 13 14

5.08

7.62

.200

.300

5.08

.200

5.08

.200

5.08

.200

5.08

.200

25.4

1.000

1.094

4.1

.161

27.8

10.9

.429

7.62 .300

11.2

.441

PC board pattern (Copper-side view)

16-1.2 DIA. HOLES

16-.047 DIA. HOLES

10 12 11 13 15 14 16 9

27.94

1.100

27.94

1.100

3.5

.138

2.54

.100

7 5 6 3 4 2 1 8

2.54

0.5

.100

.020

Tolerance: ± 0.1 ± .004

Schematic (Top view)

16 15 14 13 12 11 10 9

4 3 12 75 6 8

++

– –

Diagram shows the "reset" position

when terminals 3 and 6 are energized.

Energize terminals 4 and 5 to transfer

contacts.

PC board pattern (Copper-side view)

8-1.2 DIA. HOLES

8-.047 DIA. HOLES

12 11 13 14

7.62

.300

7 5 4 2

2.54

2.54

.100

.100

Tolerance: ±0.1 ±.004

Schematic (Bottom view)

11 12 13 14

5 274

+

–

Deenergized position

226

Page 5

2C 2 coil latching

(NC2D-PL2)

(NC2ED-P)

4C single side stable

(NC4D-P)

(NC4ED-P)

Standard type Amber sealed type

27.8

1.094

4.1

.161

25.4

1.000

5.08

5.08

5.08

.200

.200

.200

11 12 13 14

5.08

7.62

.200

.200

.300

2.54

.100

234567

5.08

7.62

.300

11.2

.441

25.4 1.000

5.08

.200

5.08

.200

2.54

.100

5.08

.200

5.08

.200

5.08

.200

.200

2.54

.100

General tolerance: ±0.5 ±.020

Standard type Amber sealed type

38.9

1.520

38.1

1.500

27.8

1.094

4.1

.161

38.1

1.500

5.08

5.08

5.08

5.08

5.08

.200

.200

5.08

.200

.200

7.62

.300

5.08

.200

5.08

.200

.200

.200

11 12 13 14 15 16109

87654321

7.62

5.08

.300

.200

5.08

.200

7.62

.300

11.2

.441

5.08

.200

5.08

.200

5.08

.200

7.62

.300

5.08

.200

General tolerance: ±0.5 ±.020

5.08

.200

5.08

.200

5.08

5.08

.200

7.62

.300

5.08

.200

5.08

.200

5.08

.200

1.094

4.1

.161

27.8

1.094

4.1

.161

27.8

7.62 .300

11.2

.441

7.62 .300

11.2

.441

NC

mm inch

PC board pattern (Copper-side view)

10-1.2 DIA. HOLES

10-.047 DIA. HOLES

11 12 13 14

7.62

.300

7

6 3 5 4 2

2.54

2.54

0.5

.100

.100

.020

Tolerance: ±0.1 ±.004

Schematic (Bottom view)

11 12 13 14

5 6 3 274

++

– –

Diagram shows the "reset" position

when terminals 3 and 6 are energized.

Energize terminals 4 and 5 to transfer

contacts.

PC board pattern (Copper-side view)

14-1.2 DIA. HOLES

14-.047 DIA. HOLES

910 151614131211

7.62

.300

87 1245

2.54

2.54

.100

.100

Tolerance: ±0.1 ±.004

Schematic (Bottom view)

9

10 11 12 13 14 15 16

5 7 2 184

+

–

Deenergized position

4C 2 coil latching

(NC4D-PL2)

(NC4ED-PL2)

Standard type Amber sealed type

38.1

1.500

5.08

5.08

5.08

5.08

5.08

.200

.200

2.54

.100

.200

5.08

.200

5.08

.200

2.54

.100

5.08

.200

.200

.200

.200

11 12 13 14 15 16109

8 7 65 43 2 1

5.08

5.08

.200

.200

5.08

27.8

1.094

4.1

.161

7.62 .300

5.08

.200

11.2

.441

General tolerance: ±0.5 ±.020

5.08

.200

5.08

.200

5.08

.200

5.08

.200

5.08

.200

1.520

1.500

5.08

.200

2.54

.100

38.9

38.1

5.08

.200

5.08

5.08

.200

.200

5.08

.200

.200

2.54

.100

5.08

5.08

.200

4.1

.161

27.8

1.094

7.62 .300

11.2

.441

PC board pattern (Copper-side view)

16-1.2 DIA. HOLES

16-.047 DIA. HOLES

910 151614131211

7.62

.300

87 124356

2.54

2.54

.100

0.5

.020

.100

Tolerance: ±0.1 ±.004

Schematic (Bottom view)

9

10 11 12 13 14 15 16

5 7 2 184 6 3

++

– –

Diagram shows the "reset" position

when terminals 3 and 6 are energized.

Energize terminals 4 and 5 to transfer

contacts.

227

Page 6

NC

Slim series

Plug-in series

2C single side stable

(NC2D)

Standard type Amber sealed type

mm inch

Schematic (Bottom view)

11 12 13 14

(NC2ED)

2C 2 coil latching

(NC2D-L2)

(NC2ED-L2)

27.8

1.094

6.1

.240

25.4

1.000

5.08

5.08

5.08

.200

.200

.200

13 141211

765432

5.08

7.62

7.62

.200

.300

.300

7.62

.300

11.2

.441

5.08

.200

7.62

.300

25.4

1.000

5.08

.200

5.08

.200

5.08

.200

7.62

.300

General tolerance: ±0.5 ±.020

Standard type Amber sealed type

27.8

1.094

6.1

.240

25.4

1.000

5.08

5.08

5.08

.200

.200

.200

13 141211

765432

5.08

5.08

5.08

.200

.200

.200

2.54

2.54

.100

.100

7.62

.300

11.2

.441

5.08

.200

5.08

.200

25.4

1.000

5.08

.200

5.08

.200

2.54

.100

General tolerance: ±0.5 ±.020

5.08

.200

5.08

.200

2.54

.100

.240

1.094

.240

27.8

1.094

6.1

27.8

6.1

7.62

.300

11.2

.441

7.62

.300

11.2

.441

5 274

+

–

Deenergized position

Schematic (Bottom view)

11 12 13 14

5 6 3 274

++

– –

Diagram shows the "reset" position

when terminals 3 and 6 are energized.

Energize terminals 4 and 5 to transfer

contacts.

4C single side stable

(NC4D)

(NC4ED-L2)

4C 2 coil latching

(NC4D-L2)

(NC4ED-L2)

Standard type Amber sealed type

38.9

1.520

38.1

1.500

27.8

1.094

6.1

.240

38.1

1.500

5.08

5.08

5.08

5.08

5.08

.200

.200

5.08

.200

5.08

.200

.200

13 14 15 161211109

7.62

.300

.200

.200

76854321

7.62

5.08

.300

.200

5.08

.200

5.08

.200

7.62

.300

11.2

.441

5.08

.200

5.08

.200

5.08

.200

7.62

.300

5.08

.200

5.08

.200

5.08

.200

General tolerance: ±0.5 ±.020

Standard type Amber sealed type

38.9

1.520

38.1

1.500

27.8

1.094

6.1

.240

38.1

1.500

5.08

5.08

5.08

5.08

5.08

.200

2.54

.100

.200

5.08

.200

.200

13 14 15 161211109

.200

2.54

.100

5.08

5.08

.200

.200

.200

.200

76854321

5.08

5.08

.200

.200

5.08

5.08

.200

7.62

.300

11.2

.441

5.08

.200

5.08

.200

5.08

.200

5.08

.200

5.08

.200

General tolerance: ±0.5 ±.020

2.54

.100

5.08

.200

5.08

.200

5.08

.200

7.62

.300

5.08

5.08

.200

.200

5.08

.200

2.54

.100

5.08

5.08

.200

.200

5.08

.200

5.08

.200

5.08

.200

1.094

6.1

.240

1.094

6.1

.240

27.8

27.8

7.62

.300

11.2

.441

7.62

.300

11.2

.441

Schematic (Bottom view)

9

10 11 12 13 14 15 16

5 7 2 184

+

–

Deenergized position

Schematic (Bottom view)

9 10 11 12 13 14 15 16

5 6 87 24 3 1

++

– –

Diagram shows the "reset" position

when terminals 3 and 6 are energized.

Energize terminals 4 and 5 to transfer

contacts.

228

Page 7

Schematic

— Energize relays only in the polarities shown —

1. Single side stable

Same operation as conventional magnetic relays.

Contacts will transfer only when coil is energized under indicated polarity.

2C 4C

2. 2 coil latching

Contacts will transfer only when coil is energized under indicated polarity.

Once transferred, contacts remain in that position even with power off until opposite coil is energized at indicated polarity.

2C 4C 2C 4C

NC

deenergized coil

energized coil

set

Diagrams show the "set" position when

terminals 4 (–) and 5 (+) are energized.

When the coil current is switched off,

these contacts remain in "make" position.

ResetReset

set

Energize terminals 3 (–) and 6 (+) to

transfer the contacts.

Diagrams show the "reset" position when

terminals 3 (–) and 6 (+) are energized.

Reset Reset

set

Energize terminals 4 (–) and 5 (+) to

transfer the contacts.

REFERENCE DATA

Standard type

1.-(1) Life curve

DC load (2C, 4C) AC load (2C) AC load (4C)

10,000

4

1,000

Expected life, ×10

100

110 V DC resistive

220 V DC resistive

0.1 1.0 10

Contact carrying current, A

30 V DC resistive

4

5,000

1,000

Expected life, ×10

250 V AC resistive

100

10

0

250 V AC inductive (pf=0.4)

12345

Contact carrying current, A

4

Expected life, ×10

5,000

1,000

100

10

0

set

125 V AC resistive

250 V AC resistive

125 V AC inductive (pf=0.4)

250 V AC inductive (pf=0.4)

12345

Contact carrying current, A

2.-(1) Temperature rise characteristics for single side stable

Measured portion: Inside the coil

80

70

3 A (Contact carring current)

5 A (Contact carring current)

3 A (Contact carring current)

4C

2C

100 110 120 130 140 150%V

Operating

power

Coil voltage

2C : up to

(

48 V DC

2C : 100 V DC

(

4C : all types

60

50

5 A (Contact carring current)

Temperature rise, °C

40

30

20

0.4 0.6 0.8 1.0 1.2 1.4 1.6 1.8W

)

100 120 140 160 180 200 220%V

)

2.-(2) Temperature rise characteristics for 2 coil

latching

Measured portion: Inside the coil

5 A (Max. contact carring current)

70

60

50

40

30

Temperature rise, °C

20

10

0

0 A (No. contact carring current)

5 A (Max. contact carring current)

0 A (No. contact carring current)

4C

2C

51015 2520

Energizing time, min.

229

Page 8

NC

3. Operate time for single side stable 4. Release time for single side stable

20

18

16

14

12

10

8

Operate time, ms

6

4

2

80 100

4c

2c

90

Coil applied voltage,%V

110

Max.

Max.

Min.

Min.

5

4

3

2

Release time, ms

1

80 100

90

Coil applied voltage,%V

5. Rate of change of pick-up and drop-out voltage

2 Form C single side stable 4 Form C single side stable

120

110

Pick-up voltage

100

90

Rated of change, %

80

Drop-out voltage

120

110

100

Pick-up voltage

90

Rated of change, %

80

Drop-out voltage

4c

2c

110

Max.

Min.

Max.

Min.

–40 –20 0 20 40 60 80

Ambient temperature, °C

6.-(1) Ambient temperature vs Max. continuous

voltage

Sample: NC2D-P-DC24 V (2c slim single side stable)

250

200

150

Max. continuous voltage, %V

100

0 A (Contact carring current)

3 A (Contact carring current)

5 A (Contact carring current)

40 50 60 70

Ambient temperature, °C

–40 –20 0 20 40 60 80

Ambient temperature, °C

6.-(2) Ambient temperature vs Max. continuous

voltage

Sample: NC2D-P-DC110 V (2c slim single side stable), NC4D-P-DC24 V (4c slim single side stable)

250

200

150

Max. continuous voltage, %V

100

0 A (Contact carring current)

3 A (Contact carring current)

5 A (Contact carring current)

30 40 50

Ambient temperature, °C

230

Page 9

ACCESSORIES

NC2 Flat NC4 Flat NC2 Slim NC4 Slim

Sockets incorporate a spring clip at each

end permitting single "snap-in" attachment to chassis or panels - no screws

necessary. Relays are held firmly in the

socket by clips integrally molded into the

socket.

TYPES

For Flat series

Part No. Terminals Mating relay

NC2-JPS P/C board NC2D-JP

NC4-JPS P/C board NC4D-JP

NC2-JPL2S P/C board NC2D-JPL2

NC4-JPL2S P/C board NC4D-JPL2

Standard packing:

Carton: 20 pieces

Case: 200 pieces

NC

For Slim series

Part No. Terminals Mating relay

NC2-PS P/C board NC2D-P

NC4-PS P/C board NC4D-P

NC2-SS Solder NC2D

NC4-SS Solder NC2D

NC2-L2PS P/C board NC4D-PL2

NC4-L2PS P/C board NC2D-PL2

NC4-L2SS Solder NC2D-L2

NC4-L2SS Solder NC4D-L2

SPECIFICATIONS

Maximum continuous current Flat series: 5 A 250 V AC Slim series: 5 A 250 V AC

Initial breakdown voltage 2,000 V AC (Except for coil-coil of L2 types: 1,500 V AC)

Initial insulation resistance 100 MΩ at 500 V DC

Heat resistance 150°C (302°F) for one hour

Caution: Do not insert or remove relays while in the energized condition.

231

Page 10

NC

3.9

.154

0.1 MAX.

.004

DIMENSIONS

Flat series

NC2-JPS

NC2-JPL2S

Terminal width: 0.9 .035

Terminal thickness: 0.4 .016

2-3.5 DIA. HOLES

10.16

.400

25.4

1.000

2-.138 DIA. HOLES

34.9

1.374

14.8

.582

Terminals 3 and 6 excluded for NC2-JPS.

44.3

1.744

27.94

1.100

15.24

.600

5.08

.200

11 12 13 14

765 243

5.08.200

10.16 .400

20.32

.800

Terminal portion

3.9

.154

0.1 MAX.

.004

PC board pattern

(copper-side view)

11 12 13 14

27.94

1.100

7

2.54

.100

0.5

.020

2.54

.100

10-1.2 DIA. HOLES

10-.047 DIA. HOLES

23456

mm inch

NC4-JPS

NC4-JPL2S

Slim series

NC2-SS

NC2-L2S

General tolerance: ±0.5 ±.020

Terminal width: 0.9 .035

Terminal thickness: 0.4 .016

2-3.5 DIA. HOLES

20.32

.800

40

1.575

2-.138 DIA. HOLES

34.9

1.374

14.8

.582

Terminals 3 and 6 excluded for NC4-JPS.

General tolerance: ±0.5 ±.020

Terminal width: 1.9 .075

Terminal thickness: 0.4 .016

8.6

20.4

.339

.803

3.9

.154

1.0

.039

29.9

1.177

12.6

.496

Terminals 3 and 6 excluded for NC2-SS.

8.0

.315

9 10111213141516

44.3

27.94

1.744

1.100

27.9

1.100

35.56 1.400

25.4 1.000

15.24

.600

5.08.200

78654321

5.08.200

10.16

.400

20.32.800

30.48

1.200

11.2

.441

10.16

5.08

.400

20.32

.200

.800

7.62

.300

Terminal portion

15.24

5.08

.660

.200

Tolerance: ±0.1 ±.004

PC board pattern

(copper-side view)

91011 151612 13 14

27.94

1.100

2.54

.100 2.54

.100

78654321

0.5

.020

16-1.2 DIA. HOLES

16-.047 DIA. HOLES

Tolerance: ±0.1 ±.004

Chassis cutout

28.4

1.118

11.5

.453

Chassis thickness range: 1.0 to 2.0

.039 to .079

NC2-PS

NC2-L2P

232

Terminal width: 0.9 .035

Terminal thickness: 0.4 .016

20.4

8.6

.803

.339

3.9

.154

.039

29.9

1.177

12.6

.496

Terminals 3 and 6 excluded for NC2-PS.

General tolerance: ±0.5 ±.020

11.2

.441

5.08

.40020.32

.200

7.62

.300

1.0

4.6

.181

27.9

1.100

10.16

.800

General tolerance: ±0.5 ±.020

5.08

.200

15.24

.660

PC board pattern

(copper-side view)

11 12 13 14

7.62

.300

65 43 2

7

2.54

.100

0.5

.020

2.54

.100

10-1.2 DIA. HOLES

10-.047 DIA. HOLES

Tolerance: ±0.1 ±.004

Page 11

NC4-SS

NC4-L2S

Terminal width: 1.9 .075

Terminal thickness: 0.4 .016

20.4

.803

.154

44.0

1.732

12.6

.496

Terminals 3 and 6 excluded for NC4-SS.

8.6

8.0

.339

.315

3.9

1.0

.039

30.48

1.200

20.32

.800

General tolerance: ±0.5 ±.020

10.16

.400

5.08

.200

11.2

.441

7.62

.300

5.08

.200

15.24

.600

25.4

1.000

35.56

1.400

Chassis cutout

42.5

11.5

.453

1.673

42.0

1.654

Chassis thickness range: 1.0 to 2.0

NC

.039 to .079

NC4-PS

NC4-L2P

Terminal width: 0.9 .035

Terminal thickness: 0.4 .016

12.6

.496

44.0

1.732

NOTES

1. To maintain insulation between coils of

2 coil latching series, terminals 5 and 6 for

flat series, and terminals 3 and 4 for slim

series should be connected to provide

common return.

5

4

6

Reset coilSet coil

3

Reset switchSet switch

11.2

10.16

.400

5.08

.200

.441

7.62

.300

20.4

.803

3.9

.154

8.6

.339

.039

1.0

4.6

.181

42.0

1.654

30.48

1.200

20.32

.800

Terminals 3 and 6 excluded for NC4-PS.

General tolerance: ±0.5 ±.020

(2) "Bottom View" wiring diagram is indicated for the Slim series because terminals can not be seen from above.

5.08

.200

15.24

.600

PC board pattern

(copper-side view)

9 10111213141516

25.4

1.000

35.56

1.400

7.62

.300

2.54

.100

78654321

0.5

2.54

.020

.100

Tolerance: ±0.1 ±.004

5. Sockets

(1) When PC board series are used with

socket, do not apply loads exceeding 3 A.

(2) Soldering should be done quickly to

avoid damaging the thermoplastic body.

(3) Insulation will be optimum when wire

connections are soldered as shown with

all slim sockets.

16-1.2 DIA. HOLES

16-.047 DIA. HOLES

2. 2 coil latching series 4C are f or intermittent operation only. Power should be applied to coils continuously for no more

than two minutes.

3. When designing printed circuit board

patterns, note that:

4. When using slim series in close proximity , mount all rela ys f acing the same direction.

Different mounting directions may cause

change in the relay characteristics be-

cause NC relays are polarized.

(1) "Top Vie w" wiring diagram is indicated

for the Flat series because terminals can

be seen from above.

Same direction

For Cautions for Use, see Relay Technical Information (Page 48 to 76).

9/1/2000 All Rights Reserved, © Copyright Matsushita Electric Works, Ltd.

Go To Online Catalog

233

Loading...

Loading...