Page 1

November 1993 Order Number: 270500-008

M80C186

CHMOS HIGH INTEGRATION 16-BIT MICROPROCESSOR

Military

Y

Operation Modes Include:

Ð Enhanced Mode Which Has

Ð DRAM Refresh

Ð Power-Save Logic

Ð Direct Interface to New CMOS

Numerics Coprocessor

Ð Compatible Mode

Ð NMOS M80186 Pin-for-Pin

Replacement for Non-Numerics

Applications

Y

Integrated Feature Set

Ð Enhanced M80C86/C88 CPU

Ð Clock Generator

Ð 2 Independent DMA Channels

Ð Programmable Interrupt Controller

Ð 3 Programmable 16-Bit Timers

Ð Dynamic RAM Refresh Control Unit

Ð Programmable Memory and

Peripheral Chip Select Logic

Ð Programmable Wait State Generator

Ð Local Bus Controller

Ð Power Save Logic

Ð System-Level Testing Support (High

Impedance Test Mode)

Y

Available in 10 MHz and 12.5 MHz

Versions

Y

Direct Addressing Capability to

1 Mbyte and 64 Kbyte I/O

Y

Completely Object Code Compatible

with All Existing M8086/M8088

Software and Also Has 10 Additional

Instructions over M8086/M8088

Y

Complete System Development

Support

Ð All M8086 and NMOS M80186

Software Development Tools Can Be

Used for M80C186 System

Development

Ð Assembler, PL/M, Pascal, Fortran,

and System Utilities

Ð In-Circuit-Emulator (ICE

TM

-C186)

Y

Available in 68-Pin Ceramic Pin Grid

Array (PGA) and 68-Lead Ceramic Quad

Flat Pack

(See Packaging Outlines and Dimensions, OrderÝ231369)

Y

Available in Two Product Grades:

Ð MIL-STD-883,

b

55§Ctoa125§C(TC)

Ð Military Temperature Only (MTO),

b

55§Ctoa125§C(TC)

The Intel M80C186 is a CHMOS high integration microprocessor. It has features which are new to the M80186

family which include a DRAM refresh control unit, power-save mode and a direct numerics interface. When

used in ‘‘compatible’’ mode, the M80C186 is 100% pin-for-pin compatible with the NMOS M80186 (except for

M8087 applications). The ‘‘enhanced’’ mode of operation allows the full feature set of the M80C186 to be

used. The M80C186 is upward compatible with M8086 and M8088 software and fully compatible with M80186

and M80188 software.

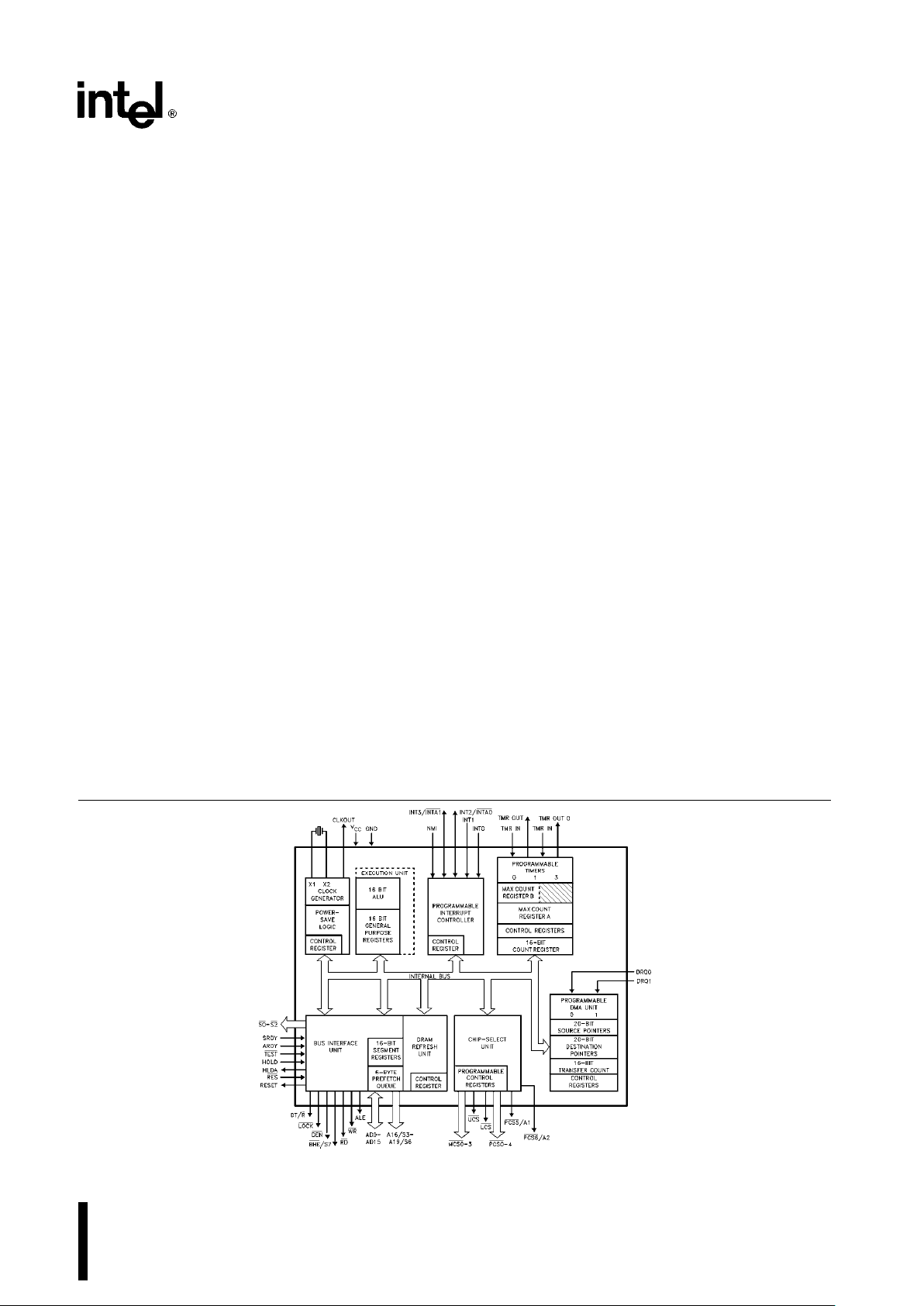

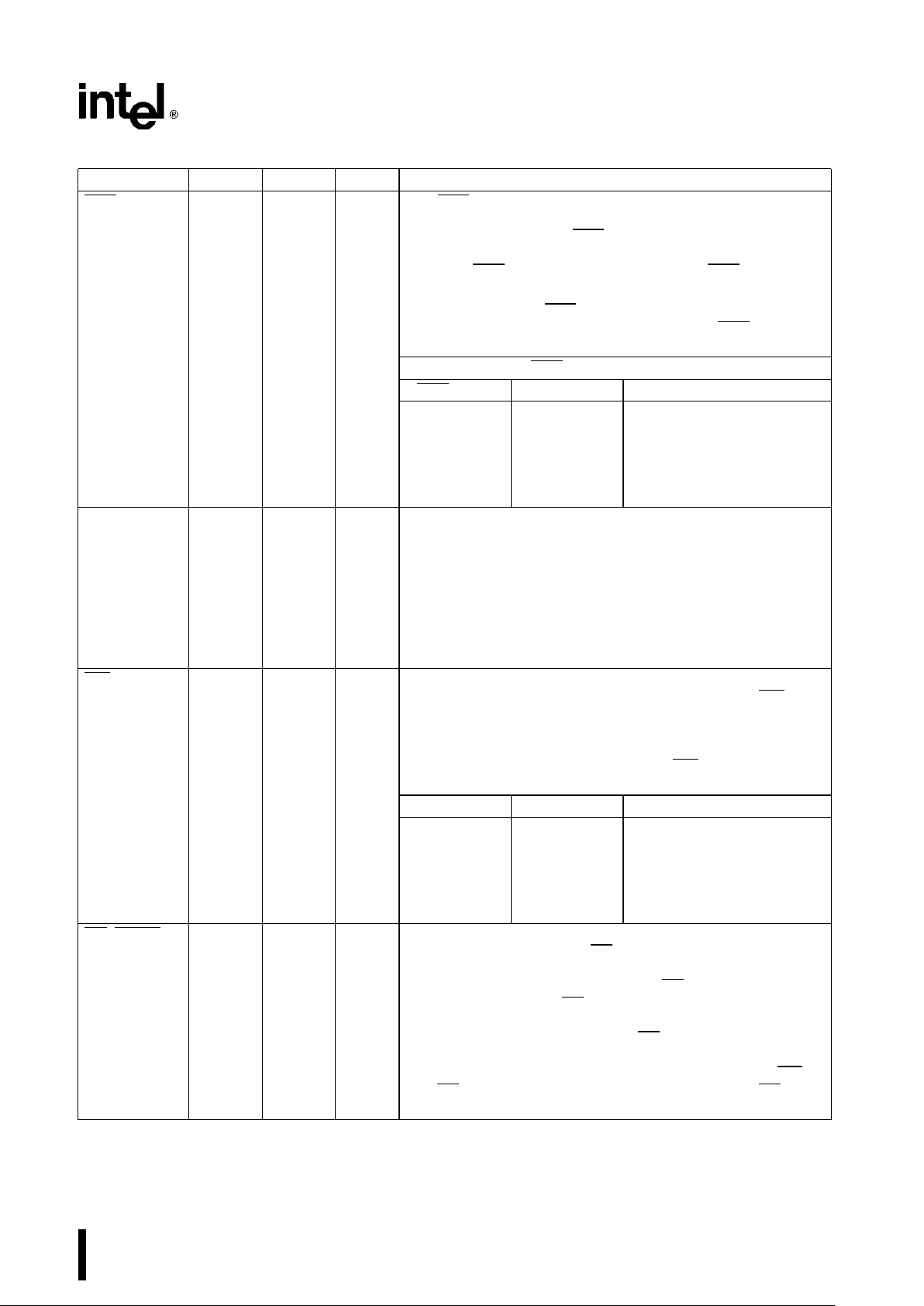

270500–1

Figure 1. M80C186 Block Diagram

Page 2

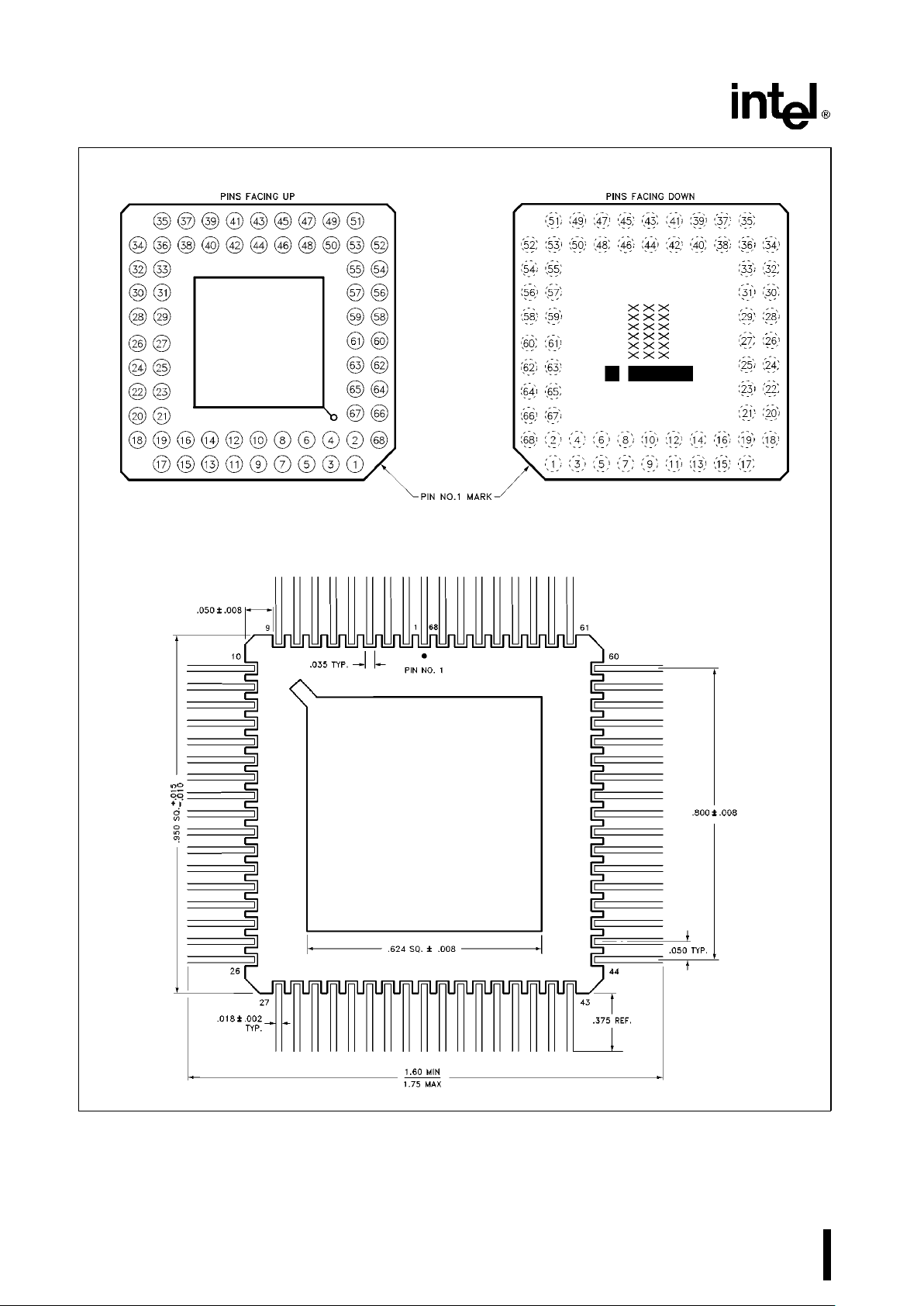

M80C186

Pin Grid Array

270500–30

Quad Flat Pack

270500–31

Figure 2. M80C186 Pinout Diagram

For additional packaging information refer to ‘‘Packaging Outlines and Dimensions’’, Order Number 231369

2

Page 3

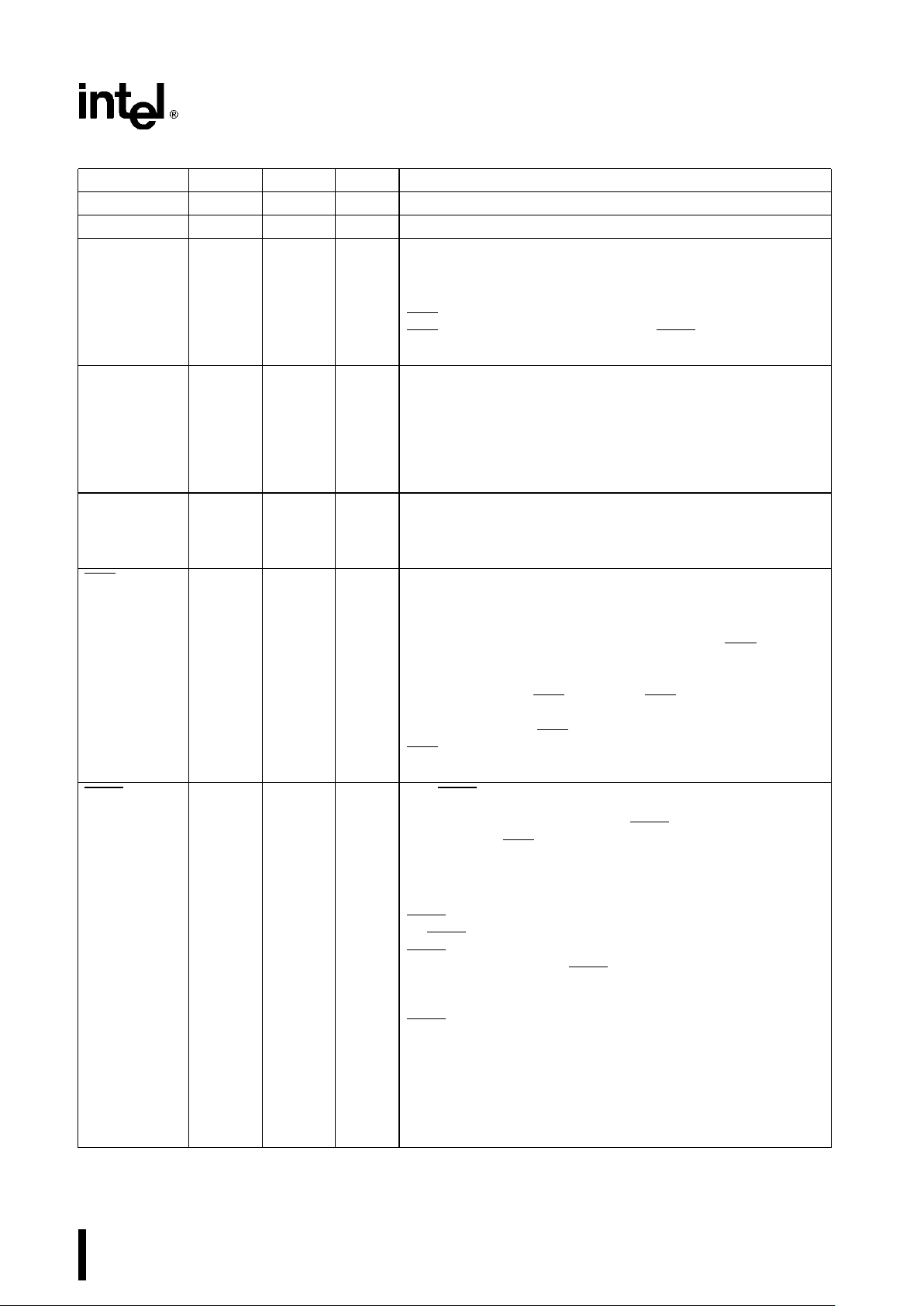

M80C186

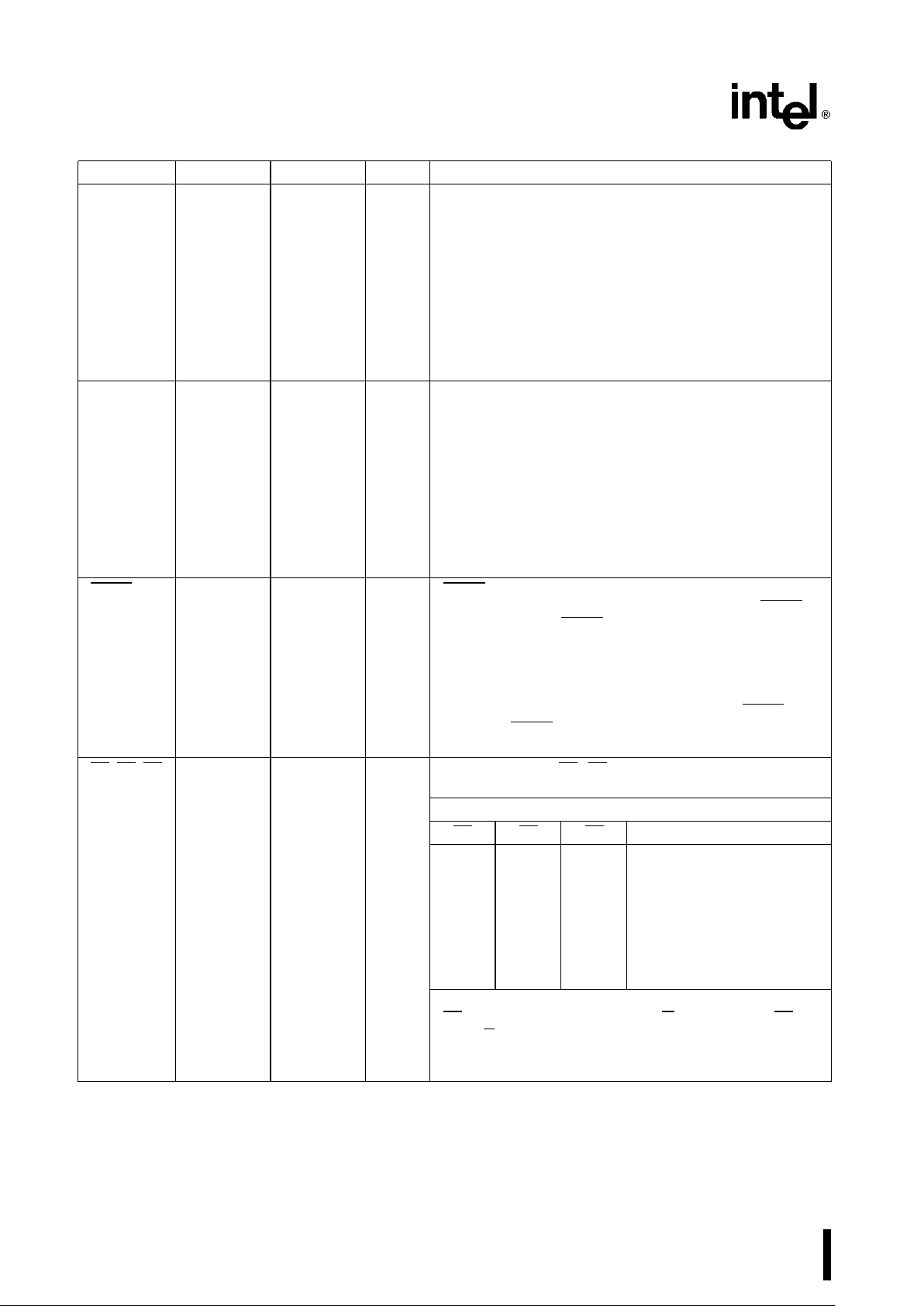

Table 1. M80C186 Pin Description

Symbol PGA QFP Type Name and Function

VCC,V

CC

9, 43 1, 35 I System Power:a5 volt power supply.

VSS,V

SS

26, 60 52, 18 I System Ground.

RESET 57 21 O Reset Output indicates that the M80C186 CPU is being

reset, and can be used as a system reset. It is active HIGH,

synchronized with the processor clock, and lasts an integer

number of clock periods corresponding to the length of the

RES

signal. Reset goes inactive 2 clockout periods after

RES

goes inactive. When tied to the TEST/BUSY pin, Reset

forces the M80C186 into enhanced mode.

X1, X2 59, 58 19, 20 I Crystal Inputs X1 and X2 provide external connections for a

fundamental mode or third overtone parallel resonant crystal

for the internal oscillator. X1 can connect to an external

clock instead of a crystal. In this case, minimize the

capacitance on X2 or drive X2 with complemented X1. The

input or oscillator frequency is internally divided by two to

generate the clock signal (CLKOUT).

CLKOUT 56 22 O Clock Output provides the system with a 50% duty cycle

waveform. All device pin timings are specified relative to

CLKOUT. CLKOUT has sufficient MOS drive capabilities for

the Numeric Processor Extension.

RES 24 54 I System Reset causes the M80C186 to immediately

terminate its present activity, clear the internal logic, and

enter a dormant state. This signal may be asynchronous to

the M80C186 clock. The M80C186 begins fetching

instructions approximately 7 clock cycles after RES is

returned HIGH. For proper initialization, V

CC

must be within

specifications and the clock signal must be stable for more

than 4 clocks with RES

held LOW. RES is internally

synchronized. This input is provided with a Schmitt-trigger to

facilitate power-on RES

generation via an RC network. When

RES

occurs, the M80C186 will drive the status lines to an

inactive level for one clock, and then float them.

TEST/BUSY 47 31 I The TEST pin is sampled during and after reset to determine

whether the M80C186 is to enter Compatible or Enhanced

Mode. Enhanced Mode requires TEST

to be HIGH on the

rising edge of RES

and LOW four clocks later. Any other

combination will place the M80C186 in Compatible Mode. A

weak internal pullup insures a HIGH state when the pin is not

driven.

TEST

ÐIn Compatible Mode this pin is configured to operate

as TEST

. This pin is examined by the WAIT instruction. If the

TEST

input is HIGH when WAIT execution begins, instruction

execution will suspend. TEST

will be resampled every five

clocks until it goes LOW, at which time execution will resume.

If interrupts are enabled while the M80C186 is waiting for

TEST

, interrupts will be serviced.

BUSYÐIn Enhanced Mode, this pin is configured to operate

as BUSY. The BUSY input is used to notify the M80C186 of

Numerics Processor Extension activity. Floating point

instructions executing in the M80C186 sample the BUSY pin

to determine when the Numerics Processor is ready to

accept a new command. BUSY is active HIGH.

3

Page 4

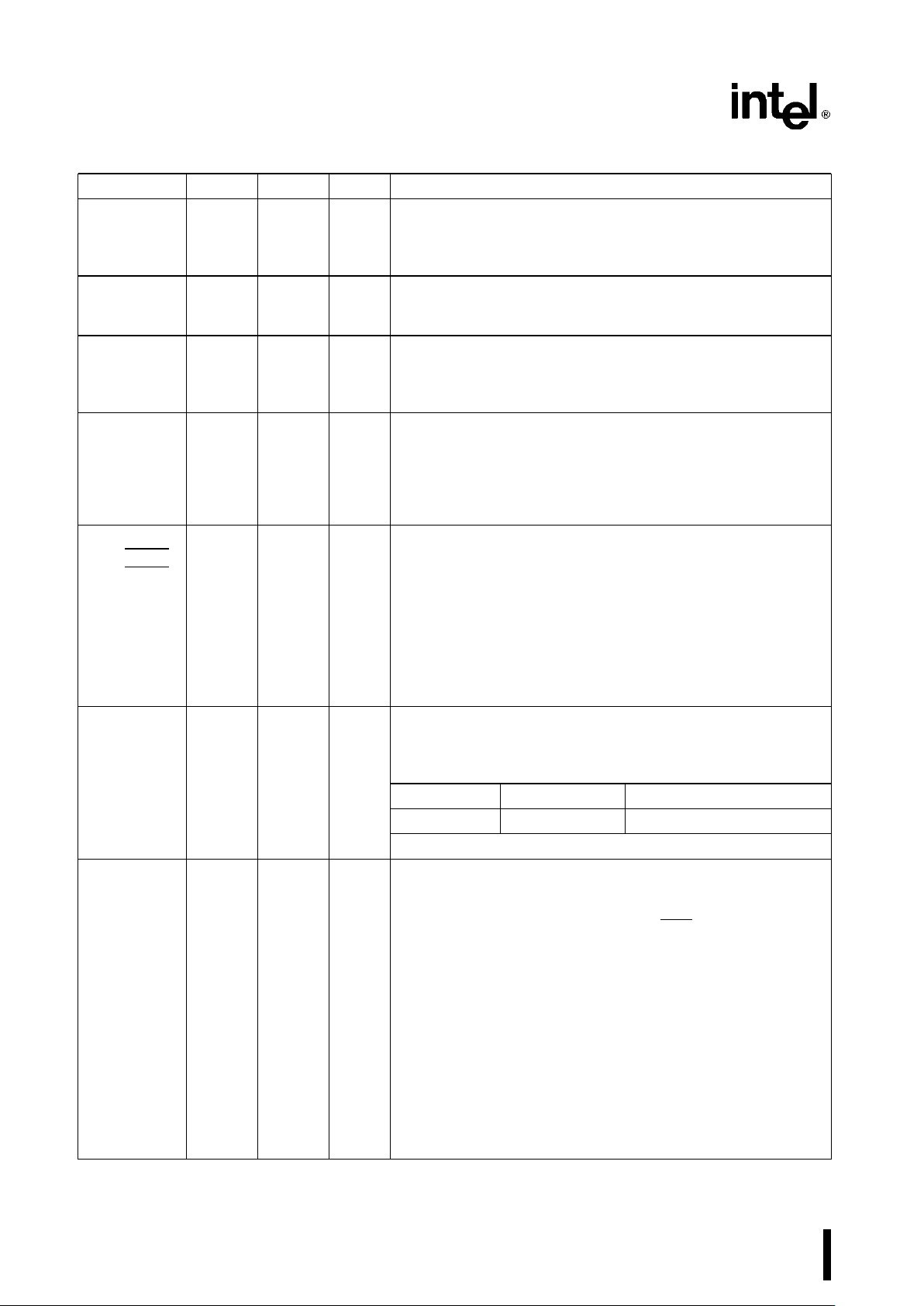

M80C186

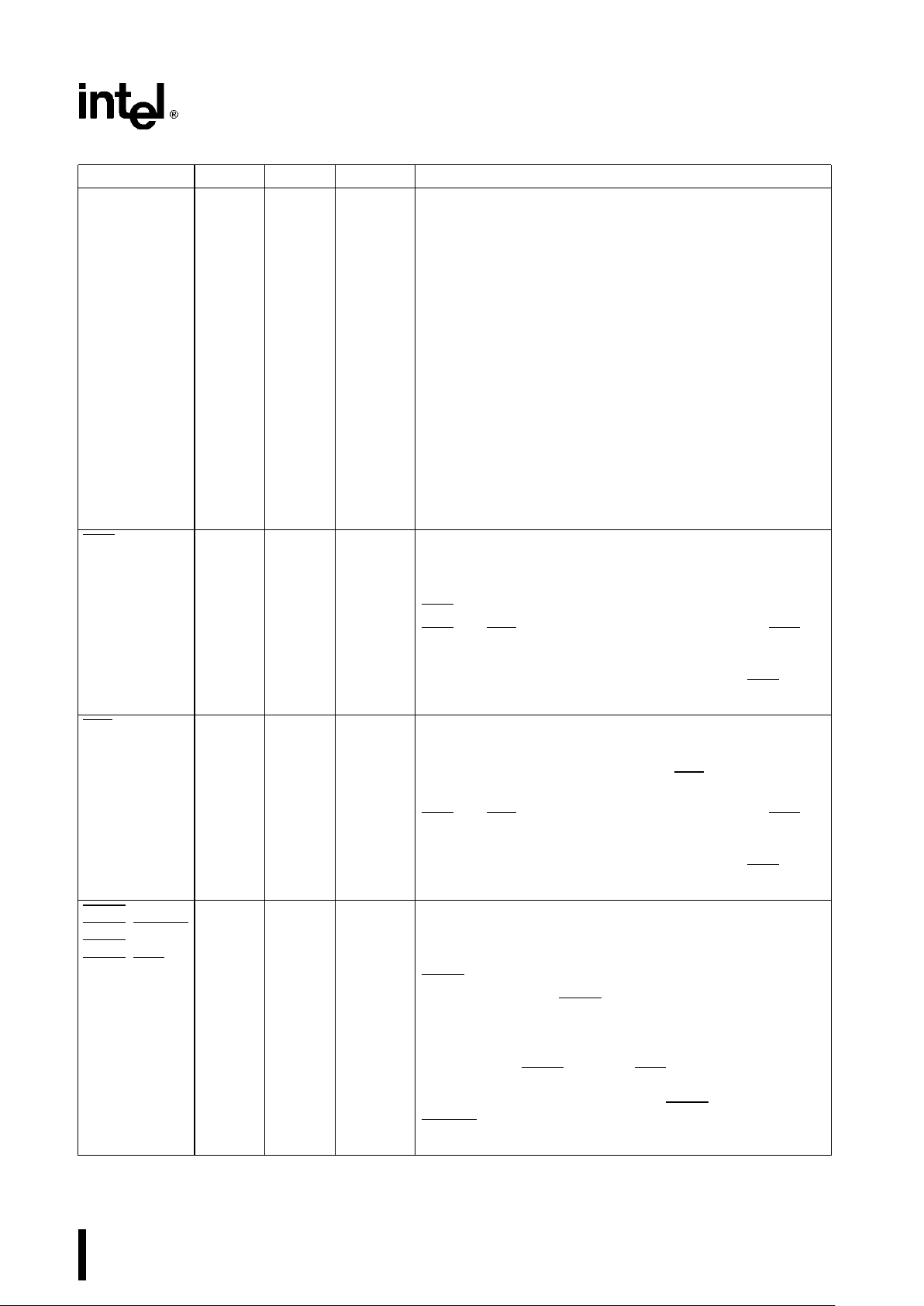

Table 1. M80C186 Pin Description (Continued)

Symbol PGA QFP Type Name and Function

TMR IN 1

TMR IN 0, 20

21

58

57 I

I Timer Inputs are used either as clock or control signals,

depending upon the programmed timer mode. These inputs

are active HIGH (or LOW-to-HIGH transitions are counted) and

internally synchronized.

TMR OUT 0,

TMR OUT 1 23

22 56

55 O

O Timer outputs are used to provide single pulse or continous

waveform generation, depending upon the timer mode

selected.

DRQ1

DRQ0 18

19 59

60 I

I

DMA Request is driven HIGH by an external device when it

desires that a DMA channel (Channel 0 or 1) perform a

transfer. These signals are active HIGH, level-triggered, and

internally synchronized.

NMI 46 32 I Non-Maskable Interrupt is an edge-triggered input which

causes a type 2 interrupt. NMI is not maskable internally. A

transition from a LOW to HIGH initiates the interrupt at the

next instruction boundary. NMI is latched internally. An NMI

duration of one clock or more will guarantee service. This input

is internally synchronized.

INT0, INT1

INT3/INTA1

INT2/INTA0

45, 44

41

42

33, 34

37

36

I/O

I/O

I Maskable Interrupt Requests can be requested by activating

one of these pins. When configured as inputs, these pins are

active HIGH. Interrupt Requests are synchronized internally.

INT2 and INT3 may be configured via software to provide

active-LOW interrupt-acknowledge output signals. All interrupt

inputs may be configured via software to be either edge- or

level-triggered. To ensure recognition, all interrupt requests

must remain active until the interrupt is acknowledged. When

slave mode is selected, the function of these pins changes

(see Interrupt Controller section of this data sheet).

A19/S6,

A16/S3

A17/S4,

A18/S5,

65

68

67

66

13

10

11

12

O

O

O

O

Address Bus Outputs (16 –19) and Bus Cycle Status (3 –6)

reflect the four most significant address bits during T1. These

signals are active HIGH. During T

2,T3,TW

, and T4, status

information is available on these lines as encoded below:

Low High

S6 Processor Cycle DMA Cycle

S3, S4, and S5 are defined as LOW during T2–T4.

AD15 1 9 I/O Address/Data Bus (0– 15) signals constitute the time

multiplexed memory or I/O address (T

1

) and data (T2,T3,TW,

AD14 3 7

and T

4

) bus. The

AD13 5 5

AD12 7 3 bus is active HIGH. A

0

is analogous to BHE for the lower byte

of the data bus, pins D

7

through D0. It is LOW during T1when

AD11 10 68

a byte is to be transferred onto the lower portion of the bus in

AD10 12 66

memory or I/O operations.

AD9 14 64

AD8 16 62

AD7 2 8

AD6 4 6

AD5 6 4

AD4 8 2

AD3 11 67

AD2 13 65

AD1 15 63

AD0 17 61

4

Page 5

M80C186

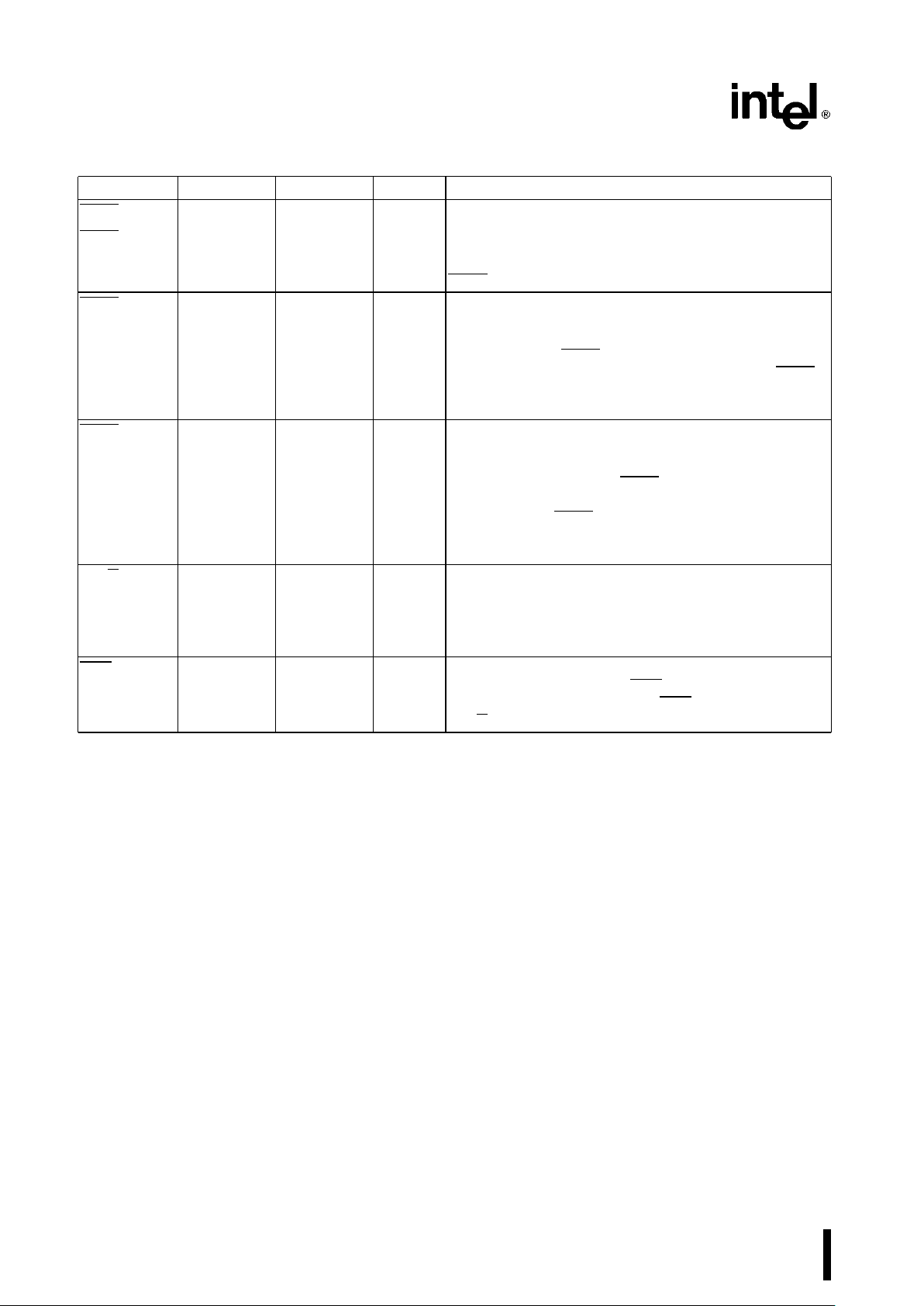

Table 1. M80C186 Pin Description (Continued)

Symbol PGA QFP Type Name and Function

BHE 64 14 O The BHE (Bus High Enable) signal is analogous to A0 in that

it is used to enable data on to the most significant half of the

data bus, pins D15 –D8. BHE

will be LOW during T1when the

upper byte is transferred and will remain LOW through T

3

AND TW. BHE does not need to be latched. BHE will float

during HOLD.

In Enhanced Mode, BHE will also be used to signify DRAM

refresh cycles. A refresh cycle is indicated by BHE

and A0

being HIGH.

BHE and A0 Encodings

BHE Value A0 Value Function

0 0 Word Transfer

0 1 Byte Transfer on upper half

of data bus (D15 –D8)

1 0 Byte Transfer on lower half

of data bus (D

7–D0

)

1 1 Refresh

ALE/QS0 61 17 O Address Latch Enable/Queue Status 0 is provided by the

M80C186 to latch the address. ALE is active HIGH.

Addresses are guaranteed to be valid on the trailing edge of

ALE. The ALE rising edge is generated off the rising edge of

the CLKOUT immediately preceding T1of the associated bus

cycle, effectively one-half clock cycle earlier than in the

standard M8086. The trailing edge is generated off the

CLKOUT rising edge in T

1

as in the M8086. Note that ALE is

never floated.

WR/QS1 63 15 O Write Strobe/Queue Status 1 indicates that the data on the

bus is to be written into a memory or an I/O device. WR

is

active for T

2,T3

, and TWof any write cycle. It is active LOW,

and floats during ‘‘HOLD.’’ It is driven HIGH for one clock

during Reset, and then floated. When the M80C186 is in

queue status mode, the ALE/QS0 and WR

/QS1 pins provide

information about processor/instruction queue interaction.

QS1 QS0 Queue Operation

0 0 No queue operation

0 1 First opcode byte fetched

from the queue

1 1 Subsequent byte fetched

from the queue

1 0 Empty the queue

RD/QSMD 62 16 O Read Strobe indicates that the M80C186 is performing a

memory or I/O read cycle. RD

is active LOW for T2,T3, and

T

W

of any read cycle. It is guaranteed not to go LOW in T

2

until after the Address Bus is floated. RD is active LOW, and

floats during ‘‘HOLD’’. RD is driven HIGH for one clock

during Reset, and then the output driver is floated. A weak

internal pull-up mechanism of the RD

line holds it HIGH when

the line is not driven. During RESET the pin is sampled to

determine whether the M80C186 should provide ALE, WR

and RD, or if the Queue-Status should be provided. RD

should be connected to GND to provide Queue-Status data.

5

Page 6

M80C186

Table 1. M80C186 Pin Description (Continued)

Symbol PGA QFP Type Name and Function

ARDY 55 23 I Asynchronous Ready informs the M80C186 that the

addressed memory space or I/O device will complete

a data transfer. The ARDY input pin will accept an

asynchronous input, and is active HIGH. Only the rising

edge is internally synchronized by the M80C186. This

means that the falling edge of ARDY must be

synchronized to the M80C186 clock. If connected to

V

CC

, no WAIT states are inserted. Asynchronous ready

(ARDY) or synchronous ready (SRDY) must be active

to terminate a bus cycle. If unused, this line should be

tied LOW to yield control to the SRDY pin.

SRDY 49 29 I Synchronous Ready must be synchronized externally

to the M80C186. The use of SRDY provides a relaxed

system-timing specification on the Ready input. This is

accomplished by eliminating the one-half clock cycle

which is required for internally resolving the signal level

when using the ARDY input. This line is active HIGH. If

this line is connected to V

CC

, no WAIT states are

inserted. Asynchronous ready (ARDY) or synchronous

ready (SRDY) must be active before a bus cycle is

terminated. If unused, this line should be tied LOW to

yield control to the ARDY pin.

LOCK 48 30 O LOCK output indicates that other system bus masters

are not to gain control of the system bus while LOCK

is

active LOW. The LOCK

signal is requested by the

LOCK prefix instruction and is activated at the

beginning of the first data cycle associated with the

instruction following the LOCK prefix. It remains active

until the completion of the instruction following the

LOCK prefix. No prefetches will occur while LOCK is

asserted. LOCK

is active LOW, is driven HIGH for one

clock during RESET, and then floated.

S0,S1,S2 52, 53, 54 26, 25, 24 O Bus cycle status S0–S2 are encoded to provide bus-

transaction information:

M80C186 Bus Cycle Status Information

S2 S1 S0 Bus Cycle Initiated

0 0 0 Interrupt Acknowledge

0 0 1 Read I/O

0 1 0 Write I/O

0 1 1 Halt

1 0 0 Instruction Fetch

1 0 1 Read Data from Memory

1 1 0 Write Data to Memory

1 1 1 Passive (no bus cycle)

The status pins float during HOLD/HLDA.

S2

may be used as a logical M/IO indicator, and S1 as

a DT/R

indicator.

The status lines are driven HIGH for one clock during

Reset, and then floated until a bus cycle begins.

6

Page 7

M80C186

Table 1. M80C186 Pin Description (Continued)

Symbol PGA QFP Type Name and Function

HLDA (output)

HOLD (input)

51

50

27

28

O

I HOLD indicates that another bus master is requesting the

local bus. The HOLD input is active HIGH. HOLD may be

asynchronous with respect to the M80C186 clock. The

M80C186 will issue a HLDA (HIGH) in response to a HOLD

request at the end of T

4

or Ti. Simultaneous with the

issuance of HLDA, the M80C186 will float the local bus and

control lines. After HOLD is detected as being LOW, the

M80C186 will lower HLDA. When the M80C186 needs to

run another bus cycle, it will again drive the local bus and

control lines.

In Enhanced Mode, HLDA will go low when a DRAM

refresh cycle is pending in the M80C186 and an external

bus master has control of the bus. It will be up to the

external master to relinquish the bus by lowering HOLD so

that the M80C186 may execute the refresh cycle. Lowering

HOLD for four clocks and returning HIGH will insure only

one refresh cycle to the external master. HLDA will

immediately go active after the refresh cycle has taken

place.

UCS 34 44 O Upper Memory Chip Select is an active LOW output

whenever a memory reference is made to the defined

upper portion (1K– 256K block) of memory. This line is not

floated during bus HOLD. The address range activating

UCS

is software programmable.

UCS and LCS are sampled upon the rising edge of RES.If

both pins are held low, the M80C186 will enter ONCE

Mode. In ONCE Mode all pins assume a high impedance

state and remain so until a subsequent RESET. UCS

has a

weak internal pullup for normal operation.

LCS 33 45 O Lower Memory Chip Select is active LOW whenever a

memory reference is made to the defined lower portion

(1K– 256K) of memory. This line is not floated during bus

HOLD. The address range activating LCS

is software

programmable.

UCS

and LCS are sampled upon the rising edge of RES.If

both pins are held low, the M80C186 will enter ONCE

Mode. In ONCE Mode all pins assume a high impedance

state and remain so until a subsequent RESET. UCS

has a

weak internal pullup for normal operation.

MCS0/PEREQ 38 40 I/O Mid-Range Memory Chip Select signals are active LOW

MCS1

/ERROR 37 41 I/O when a memory reference is made to the defined mid-

MCS2

36 42 O range portion of memory (8K – 512K). These lines are not

MCS3

/NPS 35 43 O floated during bus HOLD. The address ranges activating

MCS0

–3 are software programmable.

In Enhanced Mode, MCS0 becomes a PEREQ input

(Processor Extension Request). When connected to the

Numerics Processor Extension, this input is used to signal

the M80C186 when to make numeric data transfers to and

from the NPX. MCS3 becomes NPS (Numeric Processor

Select) which may only be activated by communication to

the Numerics Processor Extension. MCS1

becomes

ERROR in enhanced mode and is used to signal numerics

coprocessor errors.

7

Page 8

M80C186

Table 1. M80C186 Pin Description (Continued)

Symbol PGA QFP Type Name and Function

PCS0

PCS1–4 27, 28, 29, 302551, 50, 49, 48

53

O

O Peripheral Chip Select signals 0 –4 are active LOW

when a reference is made to the defined peripheral

area (64K byte I/O space). These lines are not floated

during bus HOLD. The address ranges activating

PCS0

–4 are software programmable.

PCS5/A1 31 47 O Peripheral Chip Select 5 or Latched A1 may be

programmed to provide a sixth peripheral chip select, or

to provide an internally latched A1 signal. The address

range activating PCS5

is software programmable. When

programmed to provide latched. A1, rather than PCS5

,

this pin will retain the previously latched value of A1

during a bus HOLD. A1 is active HIGH.

PCS6/A2 32 46 O Peripheral Chip Select 6 or Latched A2 may be

programmed to provide a seventh peripheral chip

select, or to provide an internally latched A2 signal. The

address range activating PCS6

is software

programmable. When programmed to provide latched

A2, rather than PCS6

, this pin will retain the previously

latched value of A2 during a bus HOLD. A2 is active

HIGH.

DT/R 40 38 O Data Transmit/Receive controls the direction of data

flow through the external M8286/M8287 data bus

transceiver. When LOW, data is transferred to the

M80C186. When HIGH the M80C186 places write data

on the data bus.

DEN 39 39 O Data Enable is provided as an M8286/M8287 data bus

transceiver output enable. DEN

is active LOW during

each memory and I/O access. DEN

is HIGH whenever

DT/R

changes state.

8

Page 9

M80C186

FUNCTIONAL DESCRIPTION

Introduction

The following Functional Description describes the

base architecture of the M80C186. This architecture

is common to the M8086, M8088, M80186 and

M80286 microprocessor families as well. The

M80C186 is a very high integration 16-bit microprocessor. It combines 15 –20 of the most common microprocessor system components onto one chip.

The M80C186 is object code compatible with the

M8086/M8088 microprocessors and adds 10 new

instruction types to the existing M8086/M8088 instruction set.

The M80C186 has two major modes of operation,

Compatible and Enhanced. In Compatible Mode the

M80C186 is completely compatible with NMOS

M80186, with the exception of M8087 support. All

pin functions, timings, and drive capabilities are

identical. The Enhanced mode adds three new features to the system design. These are Power-Save

control, Dynamic RAM refresh, and an asynchronous Numerics Co-processor interface.

M80C186 BASE ARCHITECTURE

The M8086, M8088, M80186, and M80286 family all

contain the same basic set of registers, instructions,

and addressing modes. The M80C186 processor is

upward compatible with the M8086, M8088, and

M80286 CPUs.

Register Set

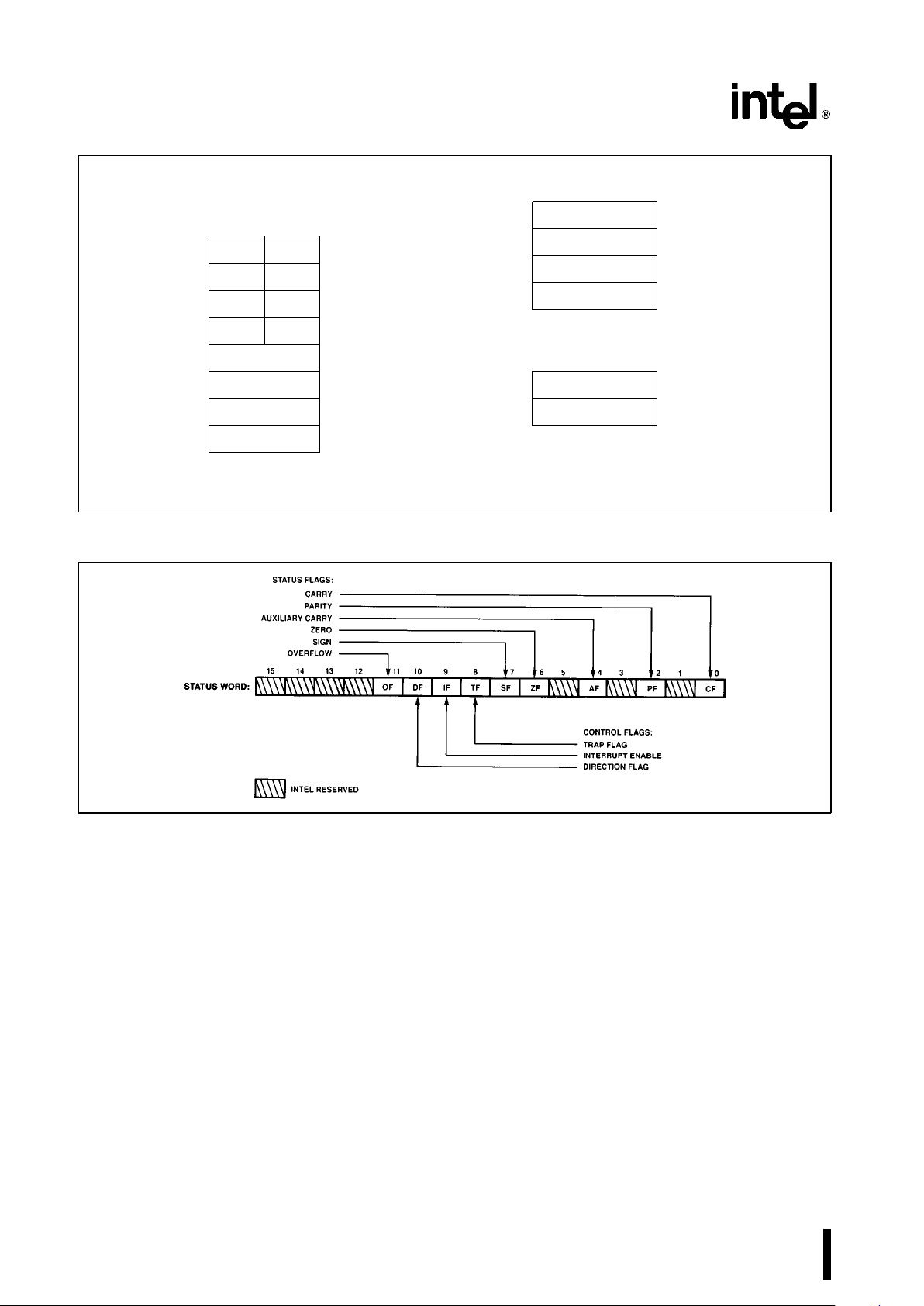

The M80C186 base architecture has fourteen registers as shown in Figures 3a and 3b. These registers

are grouped into the following categories.

General Registers

Eight 16-bit general purpose registers may be used

to contain arithmetic and logical operands. Four of

these (AX, BX, CX, and DX) can be used as 16-bit

registers or split into pairs of separate 8-bit registers.

Segment Registers

Four 16-bit special purpose registers select, at any

given time, the segments of memory that are immediately addressable for code, stack, and data. (For

usage, refer to Memory Organization.)

Base and Index Registers

Four of the general purpose registers may also be

used to determine offset addresses of operands in

memory. These registers may contain base addresses or indexes to particular locations within a segment. The addressing mode selects the specific registers for operand and address calculations.

Status and Control Registers

Two 16-bit special purpose registers record or alter

certain aspects of the M80C186 processor state.

These are the Instruction Pointer Register, which

contains the offset address of the next sequential

instruction to be executed, and the Status Word

Register, which contains status and control flag bits

(see Figures 3a and 3b).

Status Word Description

The Status Word records specific characteristics of

the result of logical and arithmetic instructions (bits

0, 2, 4, 6, 7, and 11) and controls the operation of

the M80C186 within a given operating mode (bits 8,

9, and 10). The Status Word Register is 16-bits wide.

The function of the Status Word bits is shown in

Table 2.

9

Page 10

M80C186

16-BIT SPECIAL

REGISTER REGISTER

NAME FUNCTIONS

7070

BYTE

ADDRESSABLE

AX AH AL

MULTIPLY/DIVIDE

REGISTER

(8-BIT

DX DH DL

I/O INSTRUCTIONS

*

SHOWN)

NAMES

CX CH CL

(

LOOP/SHIFT/REPEAT/COUNT

%

BX BH BL

BASE REGISTERS

BP

*

SI

INDEX REGISTERS

DI

*

SP

(

STACK POINTER

15 0

GENERAL

REGISTERS

15 0

CS CODE SEGMENT SELECTOR

DS DATA SEGMENT SELECTOR

SS STACK SEGMENT SELECTOR

ES EXTRA SEGMENT SELECTOR

SEGMENT REGISTERS

15 0

F STATUS WORD

IP INSTRUCTION POINTER

STATUS AND CONTROL

REGISTERS

Figure 3a. M80C186 Register Set

270500–4

Figure 3b. Status Word Format

10

Page 11

M80C186

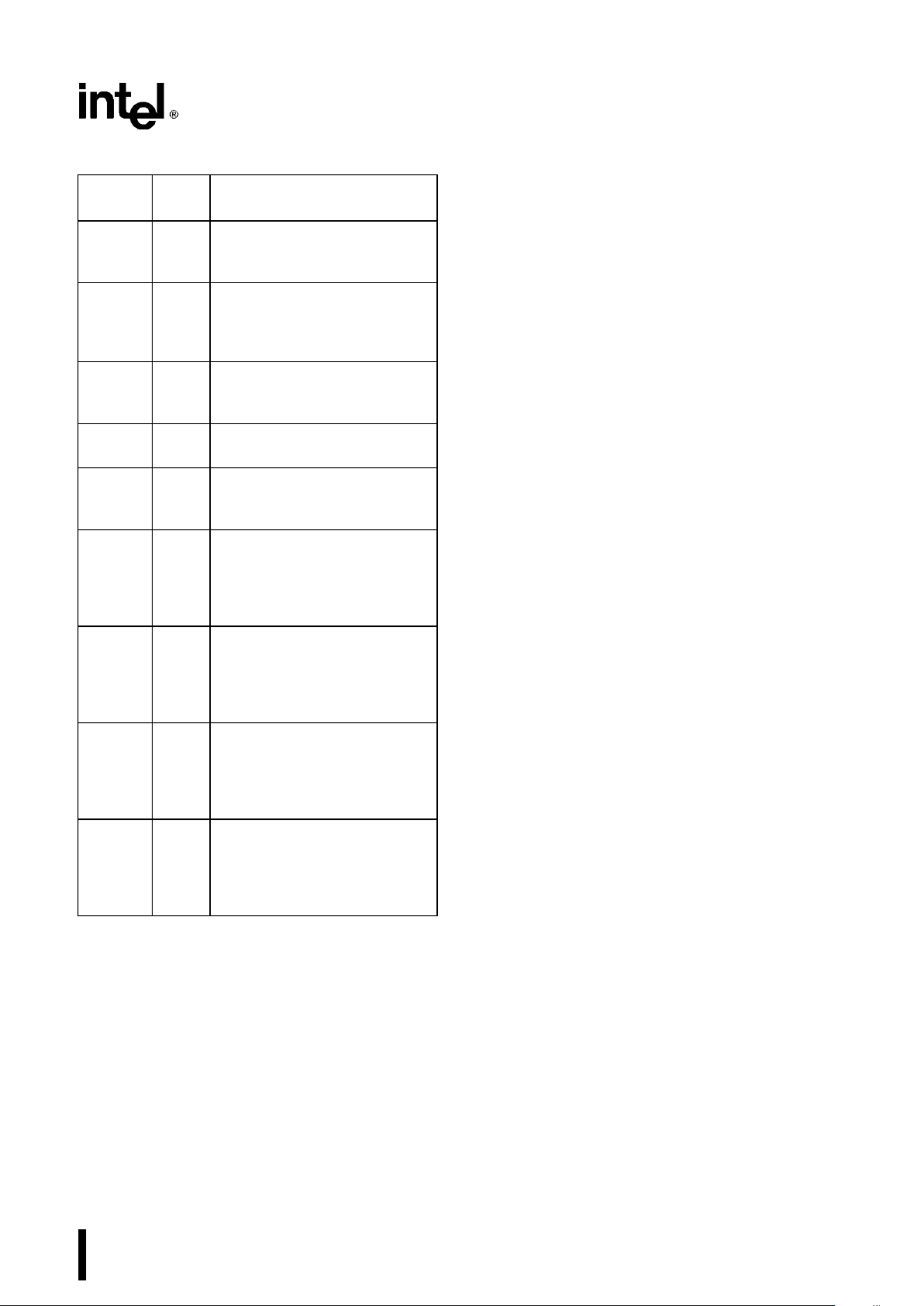

Table 2. Status Word Bit Functions

Bit

Name Function

Position

0 CF Carry FlagÐSet on high-order

bit carry or borrow; cleared

otherwise

2 PF Parity FlagÐSet if low-order 8

bits of result contain an even

number of 1-bits; cleared

otherwise

4 AF Set on carry from or borrow to

the low order four bits of AL;

cleared otherwise

6 ZF Zero FlagÐSet if result is zero;

cleared otherwise

7 SF Sign FlagÐSet equal to high-

order bit of result (0 if positive,

1 if negative)

8 TF Single Step FlagÐOnce set, a

single step interrupt occurs

after the next instruction

executes. TF is cleared by the

single step interrupt.

9 IF Interrupt-enable FlagÐWhen

set, maskable interrupts will

cause the CPU to transfer

control to an interrupt vector

specified location.

10 DF Direction FlagÐCauses string

instructions to auto decrement

the appropriate index register

when set. Clearing DF causes

auto increment.

11 OF Overflow FlagÐSet if the

signed result cannot be

expressed within the number

of bits in the destination

operand; cleared otherwise

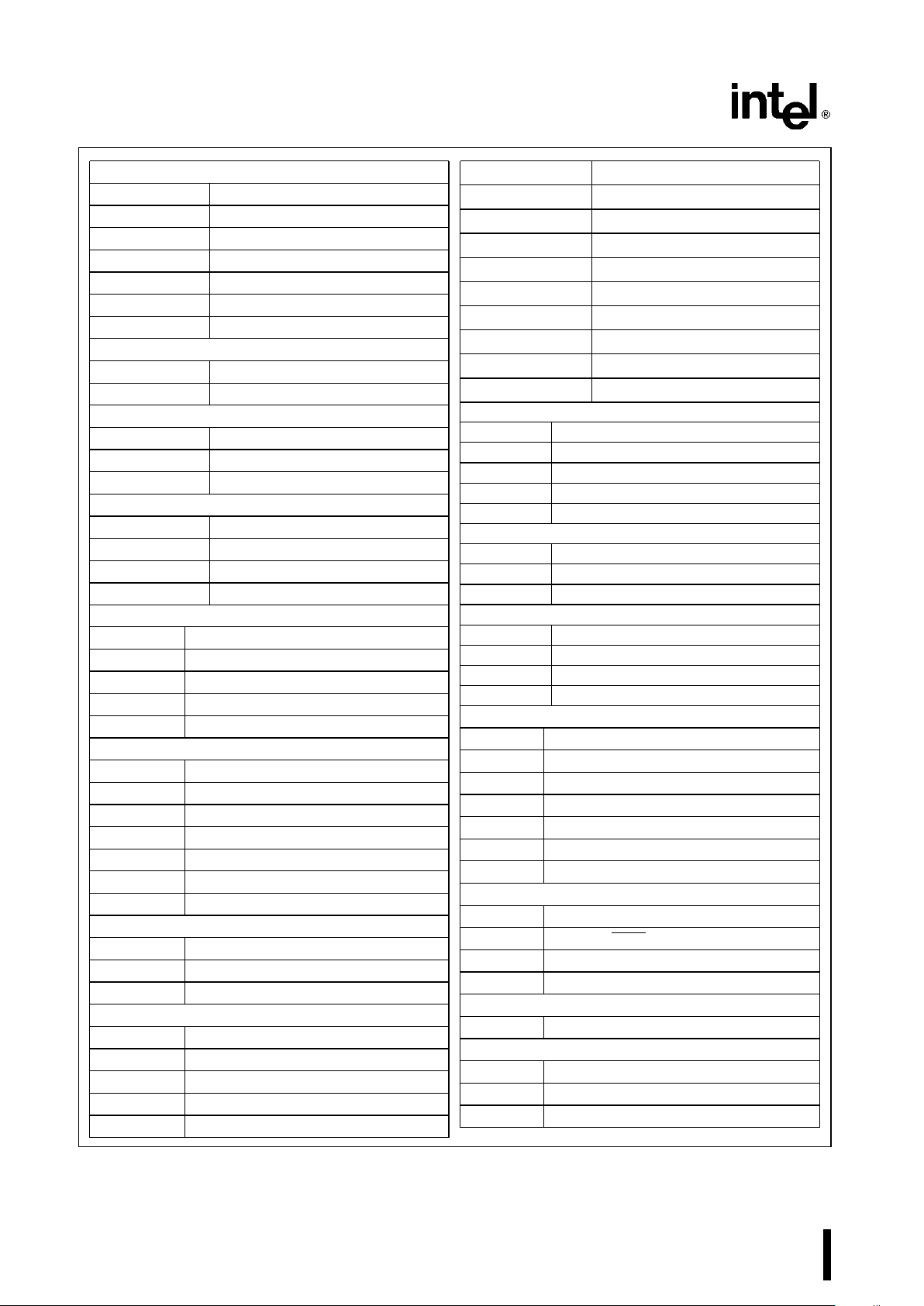

Instruction Set

The instruction set is divided into seven categories:

data transfer, arithmetic, shift/rotate/logical, string

manipulation, control transfer, high-level instructions, and processor control. These categories are

summarized in Figure 4.

An M80C186 instruction can reference anywhere

from zero to several operands. An operand can reside in a register, in the instruction itself, or in memory. Specific operand addressing modes are discussed later in this data sheet.

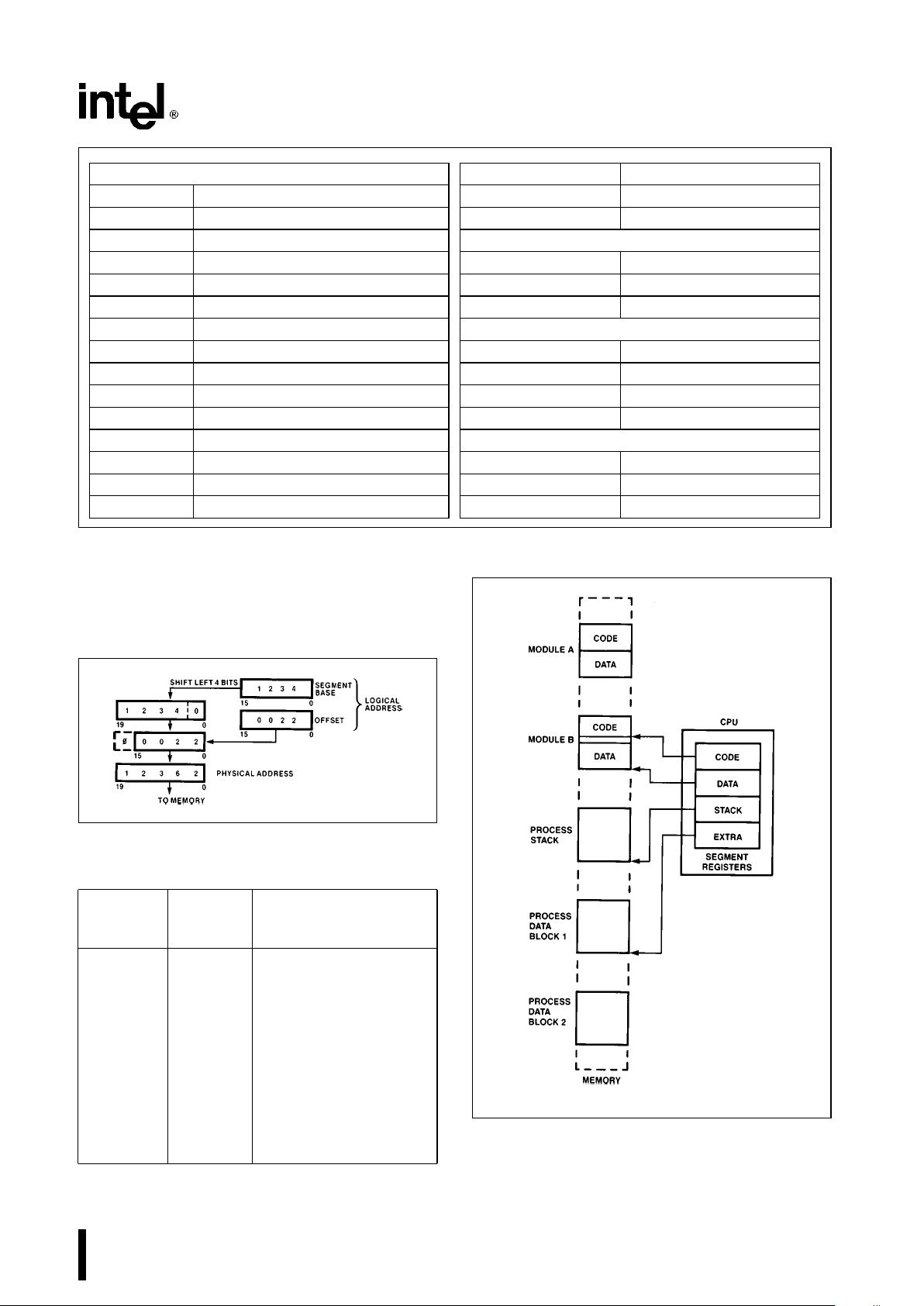

Memory Organization

Memory is organized in sets of segments. Each segment is a linear contiguous sequence of up to 64K

(2

16

) 8-bit bytes. Memory is addressed using a twocomponent address (a pointer) that consists of a 16bit base segment and a 16-bit offset. The 16-bit

base values are contained in one of four internal

segment register (code, data, stack, extra). The

physical address is calculated by shifting the base

value LEFT by four bits and adding the 16-bit offset

value to yield a 20-bit physical address (see Figure

5). This allows for a 1 MByte physical address size.

All instructions that address operands in memory

must specify the base segment and the 16-bit offset

value. For speed and compact instruction encoding,

the segment register used for physical address generation is implied by the addressing mode used (see

Table 3). These rules follow the way programs are

written (see Figure 6) as independent modules that

require areas for code and data, a stack, and access

to external data areas.

Special segment override instruction prefixes allow

the implicit segment register selection rules to be

overridden for special cases. The stack, data, and

extra segments may coincide for simple programs.

11

Page 12

M80C186

GENERAL PURPOSE

MOV Move byte or word

PUSH Push word onto stack

POP Pop word off stack

PUSHA Push all registers on stack

POPA Pop all registers from stack

XCHG Exchange byte or word

XLAT Translate byte

INPUT/OUTPUT

IN Input byte or word

OUT Output byte or word

ADDRESS OBJECT

LEA Load effective address

LDS Load pointer using DS

LES Load pointer using ES

FLAG TRANSFER

LAHF Load AH register from flags

SAHF Store AH register in flags

PUSHF Push flags onto stack

POPF Pop flags off stack

ADDITION

ADD Add byte or word

ADC Add byte or word with carry

INC Increment byte or word by 1

AAA ASCII adjust for addition

DAA Decimal adjust for addition

SUBTRACTION

SUB Subtract byte or word

SBB Subtract byte or word with borrow

DEC Decrement byte or word by 1

NEG Negate byte or word

CMP Compare byte or word

AAS ASCII adjust for subtraction

DAS Decimal adjust for subtraction

MULTIPLICATION

MUL Multiply byte or word unsigned

IMUL Integer multiply byte or word

AAM ASCII adjust for multiplyASCII

DIVISION

DIV Divide byte or word unsigned

IDIV Integer divide byte or word

AAD ASCII adjust for division

CBW Convert byte to word

CWD Convert word to doubleword

MOVS Move byte or word string

INS Input bytes or word string

OUTS Output bytes or word string

CMPS Compare byte or word string

SCAS Scan byte or word string

LODS Load byte or word string

STOS Store byte or word string

REP Repeat

REPE/REPZ Repeat while equal/zero

REPNE/REPNZ Repeat while not equal/not zero

LOGICALS

NOT ‘‘Not’’ byte or word

AND ‘‘And’’ byte or word

OR ‘‘Inclusive or’’ byte or word

XOR ‘‘Exclusive or’’ byte or word

TEST ‘‘Test’’ byte or word

SHIFTS

SHL/SAL Shift logical/arithmetic left byte or word

SHR Shift logical right byte or word

SAR Shift arithmetic right byte or word

ROTATES

ROL Rotate left byte or word

ROR Rotate right byte or word

RCL Rotate through carry left byte or word

RCR Rotate through carry right byte or word

FLAG OPERATIONS

STC Set carry flag

CLC Clear carry flag

CMC Complement carry flag

STD Set direction flag

CLD Clear direction flag

STI Set interrupt enable flag

CLI Clear interrupt enable flag

EXTERNAL SYNCHRONIZATION

HLT Halt until interrupt or reset

WAIT Wait for TEST pin active

ESC Escape to extension processor

LOCK Lock bus during next instruction

NO OPERATION

NOP No operation

HIGH LEVEL INSTRUCTIONS

ENTER Format stack for procedure entry

LEAVE Restore stack for procedure exit

BOUND Detects values outside prescribed range

Figure 4. M80C186 Instruction Set

12

Page 13

M80C186

CONDITIONAL TRANSFERS

JA/JNBE Jump if above/not below nor equal

JAE/JNB Jump if above or equal/not below

JB/JNAE Jump if below/not above nor equal

JBE/JNA Jump if below or equal/not above

JC Jump if carry

JE/JZ Jump if equal/zero

JG/JNLE Jump if greater/not less nor equal

JGE/JNL Jump if greater or equal/not less

JL/JNGE Jump if less/not greater nor equal

JLE/JNG Jump if less or equal/not greater

JNC Jump if not carry

JNE/JNZ Jump if not equal/not zero

JNO Jump if not overflow

JNP/JPO Jump if not parity/parity odd

JNS Jump if not sign

JO Jump if overflow

JP/JPE Jump if parity/parity even

JS Jump if sign

UNCONDITIONAL TRANSFERS

CALL Call procedure

RET Return from procedure

JMP Jump

ITERATION CONTROLS

LOOP Loop

LOOPE/LOOPZ Loop if equal/zero

LOOPNE/LOOPNZ Loop if not equal/not zero

JCXZ Jump if register CXe0

INTERRUPTS

INT Interrupt

INTO Interrupt if overflow

IRET Interrupt return

Figure 4. M80C186 Instruction Set (Continued)

To access operands that do not reside in one of the

four immediately available segments, a full 32-bit

pointer can be used to reload both the base (segment) and offset values.

270500–5

Figure 5. Two Component Address

Table 3. Segment Register Selection Rules

Memory Segment

Implicit Segment

Reference Register

Selection Rule

Needed Used

Instructions Code (CS) Instruction prefetch and

immediate data.

Stack Stack (SS) All stack pushes and

pops; any memory

references which use BP

Register as a base

register.

External Extra (ES) All string instruction

Data references which use

(Global) the DI register as an

index.

Local Data Data (DS) All other data references.

270500–6

Figure 6. Segmented Memory Helps

Structure Software

13

Page 14

M80C186

Addressing Modes

The M80C186 provides eight categories of addressing modes to specify operands. Two addressing

modes are provided for instructions that operate on

register or immediate operands:

#

Register Operand Mode:

The operand is located

in one of the 8- or 16-bit general registers.

#

Immediate Operand Mode:

The operand is in-

cluded in the instruction.

Six modes are provided to specify the location of an

operand in a memory segment. A memory operand

address consists of two 16-bit components: a segment base and an offset. The segment base is supplied by a 16-bit segment register either implicitly

chosen by the addressing mode or explicitly chosen

by a segment override prefix. The offset, also called

the effective address, is calculated by summing any

combination of the following three address elements:

#

the

displacement

(an 8- or 16-bit immediate value

contained in the instruction);

#

the

base

(contents of either the BX or BP base

registers); and

#

the

index

(contents of either the SI or DI index

registers).

Any carry out from the 16-bit addition is ignored.

Eight-bit displacements are sign extended to 16-bit

values.

Combinations of these three address elements define the six memory addressing modes, described

below.

#

Direct Mode:

The operand’s offset is contained in

the instruction as an 8- or 16-bit displacement element.

#

Register Indirect Mode:

The operand’s offset is in

one of the registers SI, DI, BX, or BP.

#

Based Mode:

The operand’s offset is the sum of

an 8- or 16-bit displacement and the contents of

a base register (BX or BP).

#

Indexed Mode:

The operand’s offset is the sum

of an 8- or 16-bit displacement and the contents

of an index register (SI or DI).

#

Based Indexed Mode:

The operand’s offset is the

sum of the contents of a base register and an

Index register.

#

Based indexed Mode with Displacement:

The operand’s offset is the sum of a base register’s contents, an index register’s contents, and an 8- or

16-bit displacement.

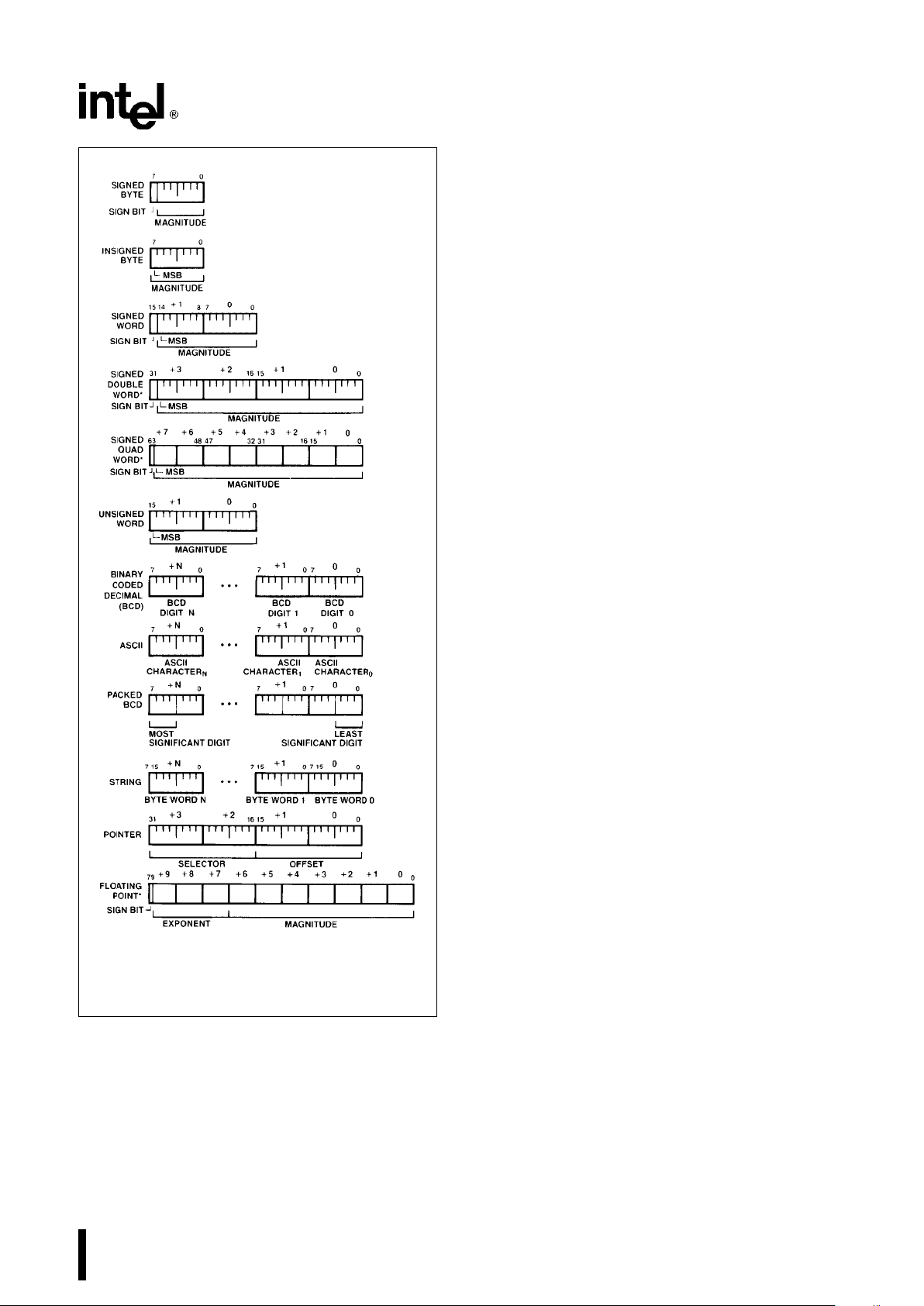

Data Types

The M80C186 directly supports the following data

types:

#

Integer:

A signed binary numeric value contained

in an 8-bit byte or a 16-bit word. All operations

assume a 2’s complement representation.

Signed 32- and 64-bit integers are supported using a Numeric Data Coprocessor with the

M80C186.

#

Ordinal:

An unsigned binary numeric value con-

tained in an 8-bit byte or a 16-bit word.

#

Pointer:

A 16- or 32-bit quantity, composed of a

16-bit offset component or a 16-bit segment base

component in addition to a 16-bit offset component.

#

String:

A contiguous sequence of bytes or words.

A string may contain from 1 to 64K bytes.

#

ASCII:

A byte representation of alphanumeric and

control characters using the ASCII standard of

character representation.

#

BCD:

A byte (unpacked) representation of the

decimal digits 0 – 9.

#

Packed BCD:

A byte (packed) representation of

two decimal digits (0– 9). One digit is stored in

each nibble (4-bits) of the byte.

#

Floating Point:

A signed 32-, 64-, or 80-bit real

number representation. (Floating point operands

are supported using a Numeric Data Coprocessor

with the M80C186.)

In general, individual data elements must fit within

defined segment limits. Figure 7 graphically represents the data types supported by the M80C186.

I/O Space

The I/O space consists of 64K 8-bit or 32K 16-bit

ports. Separate instructions address the I/O space

with either an 8-bit port address, specified in the instruction, or a 16-bit port address in the DX register.

8-bit port addresses are zero extended such that

A

15–A8

are LOW. I/O port addresses 00F8(H)

through 00FF(H) are reserved.

Interrupts

An interrupt transfers execution to a new program

location. The old program address (CS:IP) and machine state (Status Word) are saved on the stack to

allow resumption of the interrupted program. Interrupts fall into three classes: hardware initiated, INT

instructions, and instruction exceptions. Hardware

initiated interrupts occur in response to an external

input and are classified as non-maskable or maskable.

14

Page 15

M80C186

270500–7

NOTE:

*Supported by using a Numeric Data Coprocessor with

the M80C186.

Figure 7. M80C186 Supported Data Types

Programs may cause an interrupt with an INT instruction. Instruction exceptions occur when an unusual condition, which prevents further instruction

processing, is detected while attempting to execute

an instruction. If the exception was caused by executing an ESC instruction with the ESC trap bit set in

the relocation register, the return instruction will

point to the ESC instruction, or to the segment override prefix immediately preceding the ESC instruc-

tion if the prefix was present. In all other cases, the

return address from an exception will point at the

instruction immediately following the instruction

causing the exception.

A table containing up to 256 pointers defines the

proper interrupt service routine for each interrupt. Interrupts 0– 31, some of which are used for instruction exceptions, are reserved. Table 4 shows the

M80C186 predefined types and default priority levels. For each interrupt, an 8-bit vector must be supplied to the M80C186 which identifies the appropriate table entry. Exceptions supply the interrupt

vector internally. In addition, internal peripherals and

noncascaded external interrupts will generate their

own vectors through the internal interrupt controller.

INT instructions contain or imply the vector and allow access to all 256 interrupts. Maskable hardware

initiated interrupts supply the 8-bit vector to the CPU

during an interrupt acknowledge bus sequence.

Non-maskable hardware interrupts use a predefined

internally supplied vector.

Interrupt Sources

The M80C186 can service interrupts generated by

software or hardware. The software interrupts are

generated by specific instructions (INT, ESC, unused

OP, etc.) or the results of conditions specified by

instructions (array bounds check, INT0, DIV, IDIV,

etc.). All interrupt sources are serviced by an indirect

call through an element of a vector table. This vector

table is indexed by using the interrupt vector type

(Table 4), multiplied by four. All hardware-generated

interrupts are sampled at the end of each instruction. Thus, the software interrupts will begin service

first. Once the service routine is entered and interrupts are enabled, any hardware source of sufficient

priority can interrupt the service routine in progress.

The software generated M80C186 interrupts are described below.

DIVIDE ERROR EXCEPTION (TYPE 0)

Generated when a DIV or IDIV instruction quotient

cannot be expressed in the number of bits in the

destination.

SINGLE-STEP INTERRUPT (TYPE 1)

Generated after most instructions if the TF flag is

set. Interrupts will not be generated after prefix instructions (e.g., REP), instructions which modify segment registers (e.g., POP DS), or the WAIT instruction.

NON-MASKABLE INTERRUPTÐNMI (TYPE 2)

An external interrupt source which cannot be

masked.

15

Page 16

M80C186

Table 4. M80C186 Interrupt Vectors

Interrupt Vector Default Related

Name Type Priority

(4)

Instructions

Divide Error 0 1

(1)

DIV, IDIV

Exception

Single Step 1 12

(2)

All

Interrupt

NMI 2 1 All

Breakpoint 3 1

(1)

INT

Interrupt

INT0 Detected 4 1

(1)

INT0

Overflow

Exception

Array Bounds 5 1

(1)

BOUND

Exception

Unused-Opcode 6 1

(1)

Undefined

Exception Opcodes

ESC Opcode 7 1

(1), (5)

ESC Opcodes

Exception

Timer 0 Interrupt 8 2A

(3)

Timer 1 Interrupt 18 2B

(3)

Timer 2 Interrupt 19 2C

(3)

Reserved 9 3

DMA 0 Interrupt 10 4

DMA 1 Interrupt 11 5

INT0 Interrupt 12 6

INT1 Interrupt 13 7

INT2 Interrupt 14 8

INT3 Interrupt 15 9

NOTES:

1. These are generated as the result of an instruction execution.

2. This is handled as in the M8086.

3. All three timers constitute one source of request to the

interrupt controller. The Timer interrupts all have the same

default priority level with respect to all other interrupt

sources. However, they have a defined priority ordering

amongst themselves. (Priority 2A is higher priority than 2B.)

Each Timer interrupt has a separate vector type number.

4. Default priorities for the interrupt sources are used only if

the user does not program each source into a unique priority level.

5. An escape opcode will cause a trap if the M80C186 is in

compatible mode or if the processor is in enhanced mode

with the proper bit set in the peripheral control block relocation register.

BREAKPOINT INTERRUPT (TYPE 3)

A one-byte version of the INT instruction. It uses 12

as an index into the service routine address table

(because it is a type 3 interrupt).

INT0 DETECTED OVERFLOW EXCEPTION

(TYPE4)

Generated during an INT0 instruction if the 0F bit is

set.

ARRAY BOUNDS EXCEPTION (TYPE 5)

Generated during a BOUND instruction if the array

index is outside the array bounds. The array bounds

are located in memory at a location indicated by one

of the instruction operands. The other operand indicates the value of the index to be checked.

UNUSED OPCODE EXCEPTION (TYPE 6)

Generated if execution is attempted on undefined

opcodes.

ESCAPE OPCODE EXCEPTION (TYPE 7)

Generated if execution is attempted of ESC opcodes

(D8H– DFH). In compatible mode operation, ESC

opcodes will always generate this exception. In enhanced mode operation, the exception will be generated only if a bit in the relocation register is set. The

return address of this exception will point to the ESC

instruction causing the exception. If a segment override prefix preceded the ESC instruction, the return

address will point to the segment override prefix.

Hardware-generated interrupts are divided into two

groups: maskable interrupts and non-maskable interrupts. The M80C186 provides maskable hardware

interrupt request pins INT0 –INT3. In addition, maskable interrupts may be generated by the M80C186

integrated DMA controller and the integrated timer

unit. The vector types for these interrupts is shown

in Table 4. Software enables these inputs by setting

the interrupt flag bit (IF) in the Status Word. The interrupt controller is discussed in the peripheral section of this data sheet.

Further maskable interrupts are disabled while servicing an interrupt because the IF bit is reset as part

of the response to an interrupt or exception. The

saved Status Word will reflect the enable status of

the processor prior to the interrupt. The interrupt flag

will remain zero unless specifically set. The interrupt

return instruction restores the Status Word, thereby

restoring the original status of IF bit. If the interrupt

return re-enables interrupts, and another interrupt is

pending, the M80C186 will immediately service the

highest-priority interrupt pending, i.e., no instructions

of the main line program will be executed.

Non-Maskable Interrupt Request (NMI)

A non-maskable interrupt (NMI) is also provided.

This interrupt is serviced regardless of the state of

the IF bit. A typical use of NMI would be to activate a

power failure routine. The activation of this input

causes an interrupt with an internally supplied vector

value of 2. No external interrupt acknowledge sequence is performed. The IF bit is cleared at the

beginning of an NMI interrupt to prevent maskable

interrupts from being serviced.

16

Page 17

M80C186

Single-Step Interrupt

The M80C186 has an internal interrupt that allows

programs to execute one instruction at a time. It is

called the single-step interrupt and is controlled by

the single-step flag bit (TF) in the Status Word. Once

this bit is set, an internal single-step interrupt will

occur after the next instruction has been executed.

The interrupt clears the TF bit and uses an internally

supplied vector of 1. The IRET instruction is used to

set the TF bit and transfer control to the next instruction to be single-stepped.

Initialization and Processor Reset

Processor initialization or startup is accomplished by

driving the RES

input pin LOW. RES forces the

M80C186 to terminate all execution and local bus

activity. No instruction or bus activity will occur as

long as RES

is active. After RES becomes inactive

and an internal processing interval elapses, the

M80C186 begins execution with the instruction at

physical location FFFF0(H). RES

also sets some

registers to predefined values as shown in Table 5.

Table 5. M80C186 Initial Register State

after RESET

Status Word F002(H)

Instruction Pointer 0000(H)

Code Segment FFFF(H)

Data Segment 0000(H)

Extra Segment 0000(H)

Stack Segment 0000(H)

Relocation Register 20FF(H)

UMCS FFFB(H)

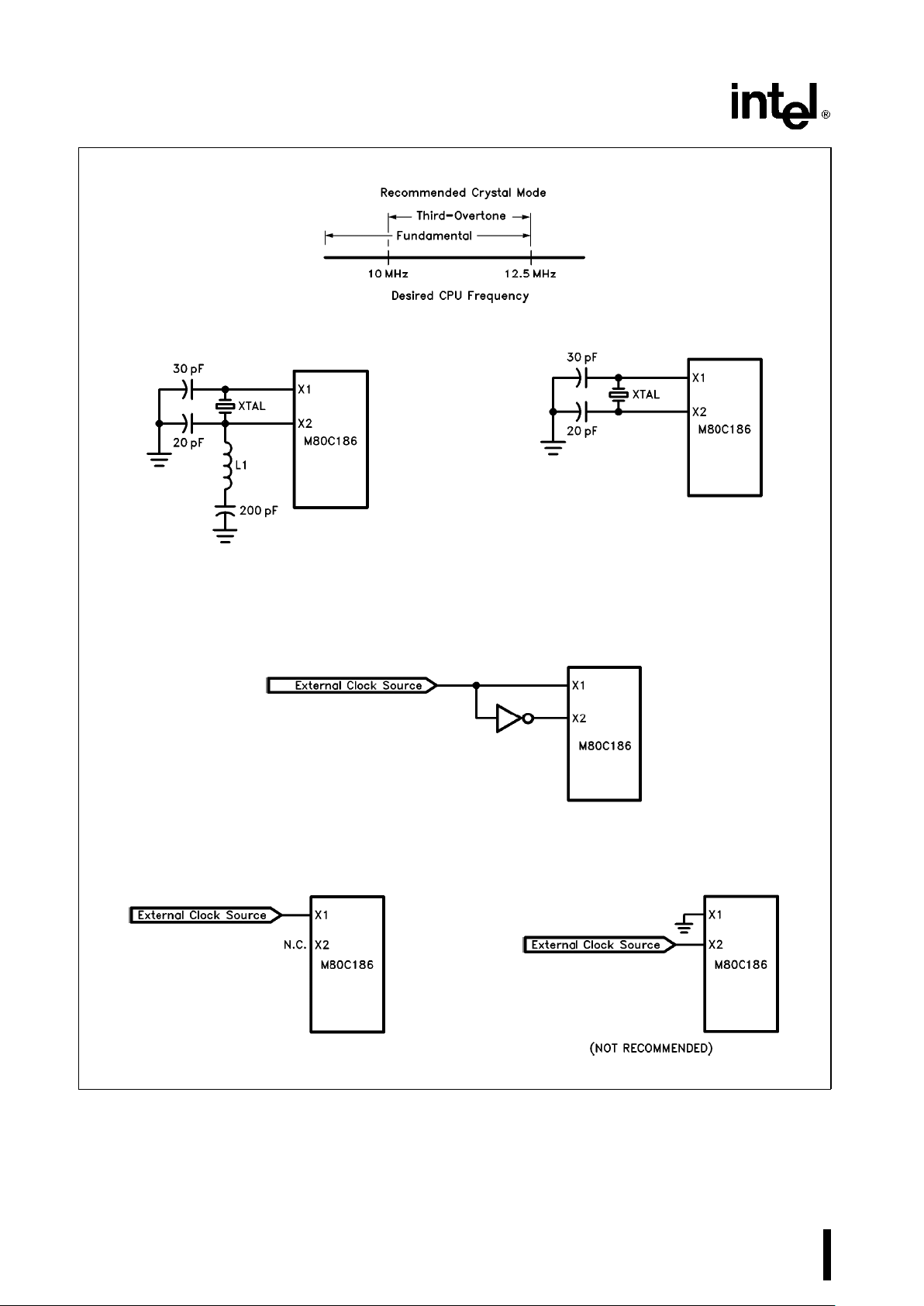

M80C186 CLOCK GENERATOR

The M80C186 provides an on-chip clock generator

for both internal and external clock generation. The

clock generator features a crystal oscillator, a divideby-two counter, synchronous and asynchronous

ready inputs, and reset circuitry.

Oscillator

The M80C186 oscillator circuit is designed to be

used with either a parallel resonant fundamental or

third-overtone mode crystal, depending upon the

frequency range of the application as shown in Figure 8a. This is used as the time base for the

M80C186. The crystal frequency chosen should be

twice the required processor frequency. Use of an

LC or RC circuit is not recommended.

The oscillator output is not directly available external

to the M80C186. The two recommended crys-

tal configurations are shown in Figures 8b and 8c.

When used in third-overtone mode the tank circuit

shown in Figure 8b is recommended for stable operation. The sum of the stray capacitances and loading capacitors should equal the values shown. It is

advisable to limit stray capacitance between the X1

and X2 pins to less than 10 pF. While a fundamental-mode circuit will require approximately 1 ms for

start-up, the third-overtone arrangement may require

1 ms to 3 ms to stabilize.

Alternately the oscillator pins may be driven from an

external source as shown in Figure 8d or Figure 8e.

The configuration shown in Figure 8f is not recommended.

The following parameters may be used for choosing

a crystal:

Temperature Range:

b

55§Ctoa125§C

ESR (Equivalent Series Resistance): 40X max

C

0

(Shunt Capacitance of Crystal): 7.0 pf max

C

1

(Load Capacitance): 20 pFg2pF

Drive Level: 1 mW max

Clock Generator

The M80C186 clock generator provides the 50%

duty cycle processor clock for the M80C186. It does

this by dividing the oscillator output by 2 forming the

symmetrical clock. If an external oscillator is used,

the state of the clock generator will change on the

falling edge of the oscillator signal. The CLKOUT pin

provides the processor clock signal for use outside

the M80C186. This may be used to drive other system components. All timings are referenced to the

output clock.

READY Synchronization

The M80C186 provides both synchronous and asynchronous ready inputs. Asynchronous ready synchronization is accomplished by circuitry which samples ARDY in the middle of T

2,T3

and again in the

middle of each T

W

until ARDY is sampled HIGH.

One-half CLKOUT cycle of resolution time is used.

Full synchronization is performed only on the rising

edge of ARDY, i.e., the falling edge of ARDY must

be synchronized to the CLKOUT signal if it will occur

during T

2,T3

,orTW. High-to-LOW transitions of

ARDY must be performed synchronously to the CPU

clock.

A second ready input (SRDY) is provided to interface with externally synchronized ready signals. This

input is sampled at the end of T

2,T3

and again at

the end of each T

W

until it is sampled HIGH. By

using this input rather than the asynchronous ready

input, the half-clock cycle resolution time penalty is

eliminated.

17

Page 18

M80C186

270500–8

(8a)

270500–25

(8b)

(8c)

270500–24

Note 1:

XTAL Frequency L1 Value

20 Mhz 12.0 mH

g

20%

25 Mhz 8.2 mH

g

20%

(8d)

270500–26

(8e)

270500–27

(8f)

270500–28

Figure 8. M80C186 Oscillator Configurations

18

Page 19

M80C186

This input must satisfy set-up and hold times to guarantee proper operation of the circuit.

In addition, the M80C186, as part of the integrated

chip-select logic, has the capability to program WAIT

states for memory and peripheral blocks. This is discussed in the Chip Select/Ready Logic description.

RESET Logic

The M80C186 provides both a RES input pin and a

synchronized RESET pin for use with other system

components. The RES

input pin on the M80C186 is

provided with hysteresis in order to facilitate poweron Reset generation via an RC network. RESET is

guaranteed to remain active for at least five clocks

given a RES input of at least six clocks. RESET may

be delayed up to two and one-half clocks behind

RES

.

Multiple M80C186 processors may be synchronized

through the RES

input pin, since this input resets

both the processor and divide-by-two internal counter in the clock generator. In order to insure that the

divide-by-two counters all begin counting at the

same time, the active going edge of RES

must satisfy a 25 ns setup time before the falling edge of the

M80C186 clock input. In addition, in order to insure

that all CPUs begin executing in the same clock cycle, the reset must satisfy a 15 ns setup time before

the rising edge of the CLKOUT signal of all the processors.

LOCAL BUS CONTROLLER

The M80C186 provides a local bus controller to generate the local bus control signals. In addition, it employs a HOLD/HLDA protocol for relinquishing the

local bus to other bus masters. It also provides control lines that can be used to enable external buffers

and to direct the flow of data on and off the local

bus.

Memory/Peripheral Control

The M80C186 provides ALE, RD, and WR bus control signals. The RD

and WR signals are used to

strobe data from memory to the M80C186 or to

strobe data from the M80C186 to memory. The ALE

line provides a strobe to address latches for the multiplexed address/data bus. The M80C186 local bus

controller does not provide a memory/I/O

signal. If

this is required, the user will have to use the S2

signal (which will require external latching), make the

memory and I/O spaces nonoverlapping, or use only

the integrated chip-select circuitry.

Transceiver Control

The M80C186 generates two control signals to be

connected to external transceiver chips. This capability allows the addition of transceivers for extra

buffering without adding external logic. These control lines, DT/R

and DEN, are generated to control

the flow of data through the transceivers. The operation of these signals is shown in Table 6.

Table 6. Transceiver Control Signals Description

Pin Name Function

DEN (Data Enable) Enables the output

drivers of the

transceivers. It is active

LOW during memory,

I/O, or INTA cycles.

DT/R

(Data Transmit/ Determines the direction

Receive) of travel through the

transceivers. A HIGH

level directs data away

from the processor

during write operations,

while a LOW level directs

data toward the

processor during a read

operation.

Local Bus Arbitration

The M80C186 uses a HOLD/HLDA system of local

bus exchange. This provides an asynchronous bus

exchange mechanism. This means multiple masters

utilizing the same bus can operate at separate clock

frequencies. The M80C186 provides a single HOLD/

HLDA pair through which all other bus masters may

gain control of the local bus. This requires external

circuitry to arbitrate which external device will gain

control of the bus from the M80C186 when there is

more than one alternate local bus master. When the

M80C186 relinquishes control of the local bus, it

floats DEN

,RD,WR,S0–S2, LOCK, AD0–AD15,

A16– A19, BHE

, and DT/R to allow another master

to drive these lines directly.

The M80C186 HOLD latency time, i.e., the time between HOLD request and HOLD acknowledge, is a

function of the activity occurring in the processor

when the HOLD request is received. A HOLD request is the highest-priority activity request which

the processor may receive: higher than instruction

fetching or internal DMA cycles. However, if a DMA

cycle is in progress, the M80C186 will complete the

transfer before relinquishing the bus. This implies

that if a HOLD request is received just as a DMA

transfer begins, the HOLD latency time can be as

great as 4 bus cycles. This will occur if a DMA word

transfer operation is taking place from an odd ad-

19

Page 20

M80C186

dress to an odd address. This is a total of 16 clocks

or more, if WAIT states are required. In addition, if

locked transfers are performed, the HOLD latency

time will be increased by the length of the locked

transfer.

Local Bus Controller and Reset

Upon receipt of a RESET pulse from the RES input,

the local bus controller will perform the following action:

#

Drive DEN,RD, and WR HIGH for one clock cycle, then float.

NOTE:

RD

is also provided with an internal pull-up device

to prevent the processor from inadvertently entering Queue Status mode during reset.

#

Drive S0 –S2 to the passive state (all HIGH) and

then float.

#

Drive LOCK HIGH and then float.

#

Float AD0 – 15, A16–19, BHE, DT/R.

#

Drive ALE LOW (ALE is never floated).

#

Drive HLDA LOW.

INTERNAL PERIPHERAL INTERFACE

All the M80C186 integrated peripherals are controlled via 16-bit registers contained within an internal 256-byte control block. This control block may

be mapped into either memory or I/O space. Internal

logic will recognize the address and respond to the

bus cycle. During bus cycles to internal registers, the

bus controller will signal the operation externally

(i.e., the RD

,WR, status, address, data, etc., lines

will be driven as in a normal bus cycle), but D

15–0

,

SRDY, and ARDY will be ignored. The base address

of the control block must be on an even 256-byte

boundary (i.e., the lower 8 bits of the base address

are all zeros). All of the defined registers within this

control block may be read or written by the

M80C186 CPU at any time. The location of any register contained within the 256-byte control block is

determined by the current base address of the control block.

The control block base address is programmed via a

16-bit relocation register contained within the control

block at offset FEH from the base address of the

control block (see Figure 9). It provides the upper 12

bits of the base address of the control block. The

control block is effectively an internal chip select

range and must abide by all the rules concerning

chip selects (the chip select circuitry is discussed

later in this data sheet). Any access to the 256 bytes

of the control block activates an internal chip select.

Other chip selects may overlap the control block

only if they are programmed to zero wait states and

ignore external ready. In addition, bit 12 of this register determines whether the control block will be

mapped into I/O or memory space. If this bit is 1, the

control block will be located in memory space,

whereas if the bit is 0, the control block will be located in I/O space. If the control register block is

mapped into I/O space, the upper 4 bits of the base

address must be programmed as 0 (since I/O addresses are only 16 bits wide).

In addition to providing relocation information for the

control block, the relocation register contains bits

which place the interrupt controller into slave mode,

and cause the CPU to interrupt upon encountering

ESC instructions. At RESET, the relocation register

is set to 20FFH. This causes the control block to

start at FF00H in I/O space. An offset map of the

256-byte control register block is shown in Figure

10.

The integrated M80C186 peripherals operate semiautonomously from the CPU. Access to them for the

most part is via software read/write of the control

block. Most of these registers can be both read and

written. A few dedicated lines, such as interrupts and

DMA request provide real-time communication between the CPU and peripherals as in a more conventional system utilizing discrete peripheral blocks.

The overall interaction and function of the peripheral

blocks has not substantially changed.

CHIP-SELECT/READY GENERATION

LOGIC

The M80C186 contains logic which provides

programmable chip-select generation for both

memories and peripherals. In addition, it can be programmed to provide READY (or WAIT state) generation. It can also povide latched address bits A1 and

A2. The chip-select lines are active for all memory

and I/O cycles in their programmed areas, whether

they be generated by the CPU or by the integrated

DMA unit.

Memory Chip Selects

The M80C186 provides 6 memory chip select outputs for 3 address areas; upper memory, lower

memory, and midrange memory. One each is provided for upper memory and lower memory, while four

are provided for midrange memory.

The range for each chip select is user-programmable and can be set to 2K, 4K, 8K, 16K, 32K, 64K,

128K (plus 1K and 256K for upper and lower chip

selects). In addition, the beginning or base address

20

Page 21

M80C186

15 14 131211109876543210

OFFSET: FEH ET SLAVE/MASTER X M/IO Relocation Address Bits R19 – R8

ET

e

ESC Trap / No ESC Trap (1/0)

M/IO

e

Register block located in Memory / I/O Space (1/0)

SLAVE/MASTER

e

Configures interrupt controller for Slave/Master Mode (1/0)

Figure 9. Relocation Register

OFFSET

Relocation Register FEH

DMA Descriptors Channel 1

DAH

D0H

DMA Descriptors Channel 0

CAH

C0H

Chip-Select Control Registers

A8H

A0H

Time 2 Control Registers

66H

60H

Time 1 Control Registers

5EH

58H

Time 0 Control Registers

56H

50H

Interrupt Controller Registers

3EH

20H

Figure 10. Internal Register Map

of the midrange memory chip select may also be

selected. Only one chip select may be programmed

to be active for any memory location at a time.

M80C186 memory is arranged in words but chip selects are sized in bytes. If sixteen 64K x 1 memories

are used then the memory block size will be 128K,

not 64K.

Upper Memory CS

The M80C186 provides a chip select, called UCS,

for the top of memory. The top of memory is usually

used as the system memory because after reset the

M80C186 begins executing at memory location

FFFF0H.

The upper limit of memory defined by this chip select

is always FFFFFH, while the lower limit is programmable. By programming the lower limit, the size of

the select block is also defined. Table 7 shows the

relationship between the base address selected and

the size of the memory block obtained.

Table 7. UMCS Programming Values

Starting

Memory UMCS Value

Address

Block (Assuming

(Base

Size R0

eR1eR2e

0)

Address)

FFC00 1K FFF8H

FF800 2K FFB8H

FF000 4K FF38H

FE000 8K FE38H

FC000 16K FC38H

F8000 32K F838H

F0000 64K F038H

E0000 128K E038H

C0000 256K C038H

The lower limit of this memory block is defined in the

UMCS register (see Figure 11). This register is at

offset A0H in the internal control block. The legal

values for bits 6 –13 and the resulting starting address and memory block sizes are given in Table 7.

Any combination of bits 6– 13 not shown in Table 7

will result in undefined operation. After reset, the

UMCS register is programmed for a 1K area. It must

be reprogrammed if a larger upper memory area is

desired.

Any internally generated 20-bit address whose upper 16 bits are greater than or equal to UMCS (with

bits 0–5 ‘‘0’’) will cause UCS to be activated. UMCS

bits R2 –R0 are used to specify READY mode for the

area of memory defined by this chip-select register,

as explained below.

Lower Memory CS

The M80C186 provides a chip select for low memory

called LCS

. The bottom of memory contains the in-

terrupt vector table, starting at location 00000H.

21

Page 22

M80C186

The lower limit of memory defined by this chip select

is always 0H, while the upper limit is programmable.

By programming the upper limit, the size of the

memory block is also defined. Table 8 shows the

relationship between the upper address selected

and the size of the memory block obtained.

Table 8. LMCS Programming Values

Upper

Memory LMCS Value

Address

Block (Assuming

Size R0

eR1eR2e

0)

003FFH 1K 0038H

007FFH 2K 0078H

00FFFH 4K 00F8H

01FFFH 8K 01F8H

03FFFH 16K 03F8H

07FFFH 32K 07F8H

0FFFFH 64K 0FF8H

1FFFFH 128K 1FF8H

3FFFFH 256K 3FF8H

The upper limit of this memory block is defined in the

LMCS register (see Figure 12). This register is at

offset A2H in the internal control block. The legal

values for bits 6 – 15 and the resulting upper address

and memory block sizes are given in Table 8. Any

combination of bits 6– 15 not shown in Table 8 will

result in undefined operation. After reset, the LMCS

register value is undefined. However, the LCS

chipselect line will not become active until the LMCS

register is accessed.

Any internally generated 20-bit address whose upper 16 bits are less than or equal to LMCS (with bits

0– 5 ‘‘1’’) will cause LCS

to be active. LMCS register

bits R2 –R0 are used to specify the READY mode for

the area of memory defined by this chip-select register.

Mid-Range Memory CS

The M80C186 provides four MCS lines which are

active within a user-locatable memory block. This

block can be located within the M80C186 1M byte

memory address space exclusive of the areas defined by UCS and LCS. Both the base ad-

dress and size of this memory block are programmable.

The size of the memory block defined by the midrange select lines, as shown in Table 9, is determined by bits 8–14 of the MPCS register (see Figure

13). This register is at location A8H in the internal

control block. One and only one of bits 8 –14 must

be set at a time. Unpredictable operation of the MCS

lines will otherwise occur. Each of the four chip-select lines is active for one of the four equal contiguous divisions of the mid-range block. Thus, if the total block size is 32K, each chip select is active for 8K

of memory with MCS0 being active for the first range

and MCS3

being active for the last range.

The EX and MS in MPCS relate to peripheral functionally as described in a later section.

Table 9. MPCS Programming Values

Total Block Individual MPCS Bits

Size Select Size 14 –8

8K 2K 0000001B

16K 4K 0000010B

32K 8K 0000100B

64K 16K 0001000B

128K 32K 0010000B

256K 64K 0100000B

512K 128K 1000000B

The base address of the mid-range memory block is

defined by bits 15– 9 of the MMCS register (see Figure 14). This register is at offset A6H in the internal

control block. These bits correspond to bits

A19– A13 of the 20-bit memory address. Bits

A12– A0 of the base address are always 0. The base

address may be set at any integer multiple of the

size of the total memory block selected. For example, if the mid-range block size is 32K (or the size of

the block for which each MCS

line is active is 8K),

the block could be located at 10000H or 18000H,

but not at 14000H, since the first few integer multiples of a 32K memory block are 0H, 8000H,

10000H, 18000H, etc. After reset, the contents of

both of these registers is undefined. However, none

of the MCS

lines will be active until both the MMCS

and MPCS registers are accessed.

1514131211109876543210

OFFSET: A0H 1 1 UUUUUUUU1 1 1R2R1R0

A19 A11

Figure 11. UMCS Register

1514131211109876543210

OFFSET: A2H 0 0 UUUUUUUU1 1 1R2R1R0

A19 A11

Figure 12. LMCS Register

22

Page 23

M80C186

1514131211109876543210

OFFSET: A8H 1 M6 M5 M4 M3 M2 M1 M0 EX MS 1 1 1 R2 R1 R0

Figure 13. MPCS Register

15 9 3 0

OFFSET: A6H UUUUUUU111111R2R1R0

A19 A13

Figure 14. MMCS Register

MMCS bits R2–R0 specify READY mode of operation for all mid-range chip selects. All devices in midrange memory must use the same number of WAIT

states.

The 512K block size for the mid-range memory chip

selects is a special case. When using 512K, the

base address would have to be at either locations

00000H or 80000H. If it were to be programmed at

00000H when the LCS

line was programmed, there

would be an internal conflict between the LCS

ready

generation logic and the MCS

ready generation logic. Likewise, if the base address were programmed

at 80000H, there would be a conflict with the UCS

ready generation logic. Since the LCS chip-select

line does not become active until programmed, while

the UCS

line is active at reset, the memory base can

be set only at 00000H. If this base address is selected, however, the LCS

range must not be pro-

grammed.

Peripheral Chip Selects

The M80C186 can generate chip selects for up to

seven peripheral devices. These chip selects are active for seven contiguous blocks of 128 bytes above

a programmable base address. This base address

may be located in either memory or I/O space.

Seven CS

lines called PCS0 – 6 are generated by the

M80C186. The base address is user-programmable;

however it can only be a multiple of 1K bytes, i.e.,

the least significant 10 bits of the starting address

are always 0.

PCS5

and PCS6 can also be programmed to provide

latched address bits A1, A2. If so programmed, they

cannot be used as peripheral selects. These outputs

can be connected directly to the A0, A1 pins used

for selecting internal registers of 8-bit peripheral

chips. This scheme simplifies the hardware interface

because the 8-bit registers of peripherals are simply

treated as 16-bit registers located on even boundaries in I/O space or memory space where only the

lower 8-bits of the register are significant: the upper

8-bits are ‘‘don’t cares.’’

The starting address of the peripheral chip-select

block is defined by the PACS register (see Figure

15). This register is located at offset A4H in the internal control block. Bits 15– 6 of this register correspond to bits 19 – 10 of the 20-bit Programmable

Base Address (PBA) of the peripheral chip-select

block. Bits 9 –0 of the PBA of the peripheral chip-select block are all zeros. If the chip-select block is

located in I/O space, bits 12– 15 must be programmed zero, since the I/O address is only 16 bits

wide. Table 10 shows the address range of each

peripheral chip select with respect to the PBA contained in PACS register.

15 6 5 3 0

OFFSET: A4H UUUUUUUUUU1 11R2R1R0

A19 A10

Figure 15. PACS Register

23

Page 24

M80C186

The user should program bits 15 – 6 to correspond to

the desired peripheral base location. PACS bits 0 –2

are used to specify READY mode for PCS0

–PCS3.

Table 10. PCS Address Ranges

PCS Line Active between Locations

PCS0 PBA ÐPBAa127

PCS1 PBA

a

128ÐPBAa255

PCS2 PBA

a

256ÐPBAa383

PCS3 PBA

a

384ÐPBAa511

PCS4 PBA

a

512ÐPBAa639

PCS5 PBAa640ÐPBAa767

PCS6 PBA

a

768ÐPBAa895

The mode of operation of the peripheral chip selects

is defined by the MPCS register (which is also used

to set the size of the mid-range memory chip-select

block, see Figure 13). This register is located at offset A8H in the internal control block. Bit 7 is used to

select the function of PCS5

and PCS6, while bit 6 is

used to select whether the peripheral chip selects

are mapped into memory or I/O space. Table 11

describes the programming of these bits. After reset,

the contents of both the MPCS and the PACS registers are undefined, however none of the PCS lines

will be active until both of the MPCS and PACS registers are accessed.

Table 11. MS, EX Programming Values

Bit Description

MS 1ePeripherals mapped into memory space.

0

e

Peripherals mapped into I/O space.

EX 0

e

5 PCS lines. A1, A2 provided.

1

e

7 PCS lines. A1, A2 are not provided.

MPCS bits 0– 2 are used to specify READY mode for

PCS4

–PCS6 as outlined below.

READY Generation Logic

The M80C186 can generate a ‘‘READY’’ signal internally for each of the memory or peripheral CS

lines. The number of WAIT states to be inserted for

each peripheral or memory is programmable to provide 0– 3 wait states for all accesses to the area for

which the chip select is active. In addition, the

M80C186 may be programmed to either ignore external READY for each chip-select range individually

or to factor external READY with the integrated

ready generator.

READY control consists of 3 bits for each CS

line or

group of lines generated by the M80C186. The interpretation of the ready bits is shown in Table 12.

Table 12. READY Bits Programming

R2 R1 R0 Number of WAIT States Generated

0 0 0 0 wait states, external RDY

also used.

0 0 1 1 wait state inserted, external RDY

also used.

0 1 0 2 wait states inserted, external RDY

also used.

0 1 1 3 wait states inserted, external RDY

also used.

1 0 0 0 wait states, external RDY

ignored.

1 0 1 1 wait state inserted, external RDY

ignored.

1 1 0 2 wait states inserted, external RDY

ignored.

1 1 1 3 wait states inserted, external RDY

ignored.

The internal ready generator operates in parallel

with external READY, not in series if the external

READY is used (R2

e

0). This means, for example,

if the internal generator is set to insert two wait

states, but activity on the external READY lines will

insert four wait states, the processor will only insert

four wait states, not six. This is because the two wait

states generated by the internal generator overlapped the first two wait states generated by the external ready signal. Note that the external ARDY and

SRDY lines are always ignored during cycles accessing internal peripherals.

R2– R0 of each control word specifies the READY

mode for the corresponding block, with the exception of the peripheral chip selects: R2–R0 of PACS

set the PCS0

–3 READY mode, R2 – R0 of MPCS set

the PCS4

–6 READY mode.

Chip Select/Ready Logic and Reset

Upon reset, the Chip-Select/Ready Logic will perform the following actions:

#

All chip-select outputs will be driven HIGH.

#

Upon leaving RESET, the UCS line will be programmed to provide chip selects to a 1K block

with the accompanying READY control bits set at

011 to allow the maximum number of internal wait

states in conjunction with external Ready consideration (i.e., UMCS resets to FFFBH).

#

No other chip select or READY control registers

have any predefined values after RESET. They

will not become active until the CPU accesses

their control registers. Both the PACS and MPCS

registers must be accessed before the PCS

lines

will become active.

24

Page 25

M80C186

DMA CHANNELS

The M80C186 DMA controller provides two independent high-speed DMA channels. Data transfers can

occur between memory and I/O spaces (e.g., Memory to I/O) or within the same space (e.g., Memory

to Memory or I/O to I/O). Data can be transferred

either in bytes (8 bits) or in words (16 bits) to or from

even or odd addresses. Each DMA channel maintains both a 20-bit source and destination pointer

which can be optionally incremented or decremented after each data transfer (by one or two depending

on byte or word transfers). Each data transfer consumes 2 bus cycles (a minimum of 8 clocks), one

cycle to fetch data and the other to store data.

DMA Operation

Each channel has six registers in the control block

which define each channel’s specific operation. The

control registers consist of a 20-bit Source pointer (2

words), a 20-bit destination pointer (2 words), a 16bit Transfer Counter, and a 16-bit Control Word. The

format of the DMA Control Blocks is shown in Table

13. The Transfer Count Register (TC) specifies the

number of DMA transfers to be performed. Up to

64K byte or word transfers can be performed with

automatic termination. The Control Word defines the

channel’s operation (see Figure 17). All registers

may be modified or altered during any DMA activity.

Any changes made to these registers will be reflected immediately in DMA operation.

Table 13. DMA Control Block Format

Register Name

Register Address

Ch. 0 Ch. 1

Control Word CAH DAH

Transfer Count C8H D8H

Destination Pointer (upper 4 C6H D6H

bits)

Destination Pointer C4H D4H

Source Pointer (upper 4 bits) C2H D2H

Source Pointer C0H D0H

270500–9

Figure 16. DMA Unit Block Diagram

25

Page 26

M80C186

1514131211109876543 2 10

T

D

M/ DESTINATION M/ SOURCE

TC INT SYN P

R

X

CHG/ ST/ B

/

IO

DEC INC IO DEC INC Q NOCHG STOP W

XeDON’T CARE.

Figure 17. DMA Control Register

DMA Channel Control Word Register

Each DMA Channel Control Word determines the

mode of operation for the particular M80C186 DMA

channel. This register specifies:

#

the mode of synchronization;

#

whether bytes or words will be transferred;

#

whether interrupts will be generated after the last

transfer;

#

whether DMA activity will cease after a programmed number of DMA cycles;

#

the relative priority of the DMA channel with respect to the other DMA channel;

#

whether the source pointer will be incremented,

decremented, or maintained constant after each

transfer;

#

whether the source pointer addresses memory or

I/O space;

#

whether the destination pointer will be incremented, decremented, or maintained constant after

each transfer; and

#

whether the destination pointer will address

memory or I/O space.