Page 1

1/10

MP03 XXX 330 Series

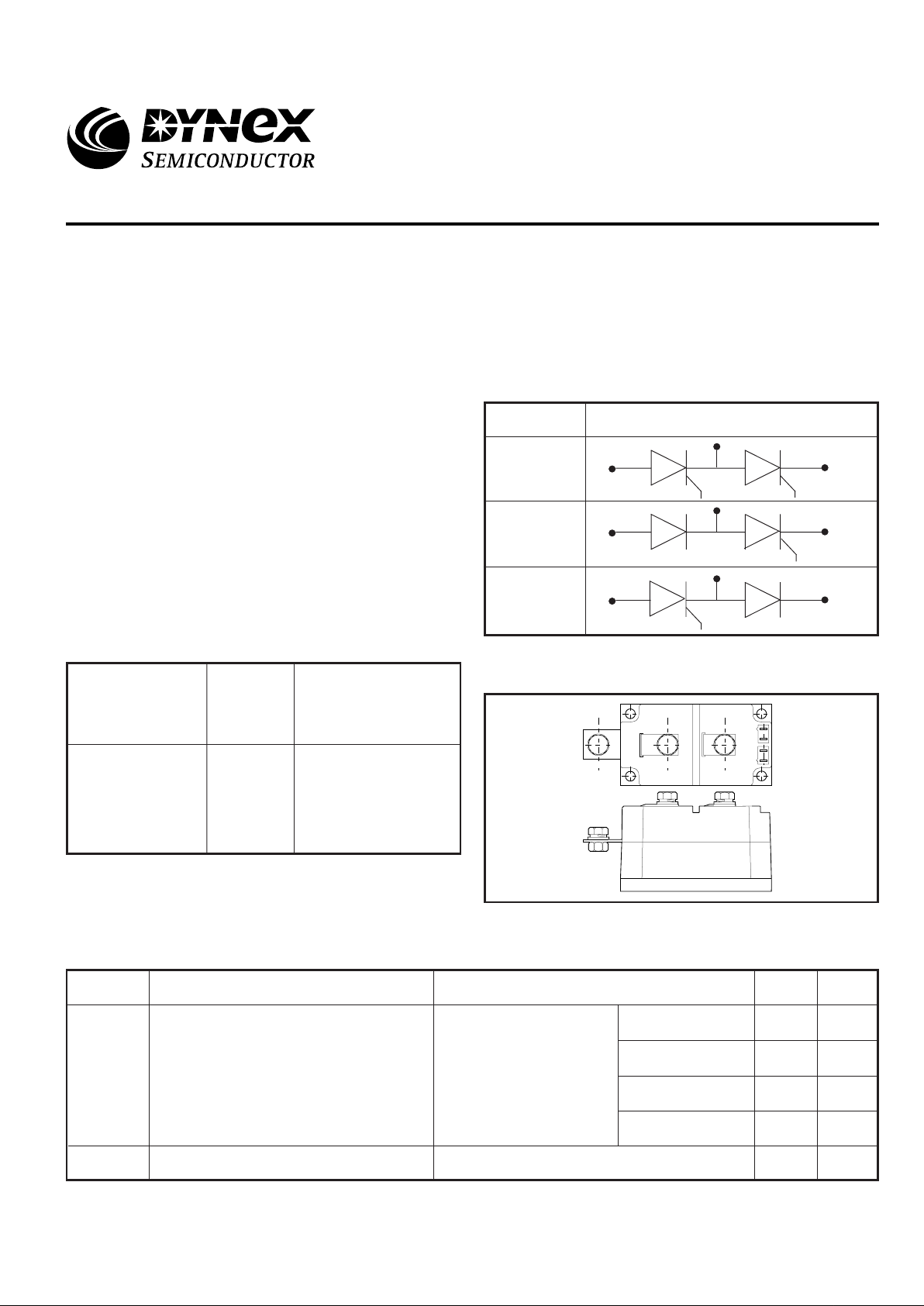

Code

Circuit

HBT

HBP

HBN

MP03/330 - 12

MP03/330 - 10

MP03/330 - 08

Symbol Max.

Units

334

289

A

A

Conditions

259

A

T

case

= 75oC

T

heatsink

= 75oC

T

heatsink

= 85oC

T

case

= 85oC

T

case

= 75oC

I

T(RMS)

RMS value

A

223

A525

Mean on-state current

Halfwave, resistive load

I

T(AV)

1200

1000

800

T

(vj)

= 130oC

I

DRM

= I

RRM

= 30mA

V

DSM

& V

RSM

=

V

DRM

& V

RRM

+ 100V

respectively

Module type code: MP03.

See Package Details for further information

FEATURES

■ Dual Device Module

■ Electrically Isolated Package

■ Pressure Contact Construction

■ International Standard Footprint

■ Alumina (non-toxic) Isolation Medium

APPLICATIONS

■ Motor Control

■ Controlled Rectifier Bridges

■ Heater Control

■ AC Phase Control

KEY PARAMETERS

V

DRM

1200V

I

TSM

10600A

I

T(AV)

(per arm) 334A

V

isol

2500V

VOLTAGE RATINGS

Type

Number

Repetitive

Peak

Voltages

V

DRM VRRM

CURRENT RATINGS - PER ARM

Parameter

Lower voltage grades available.

For full description of part number see "Ordering instructions"

on page 3.

Conditions

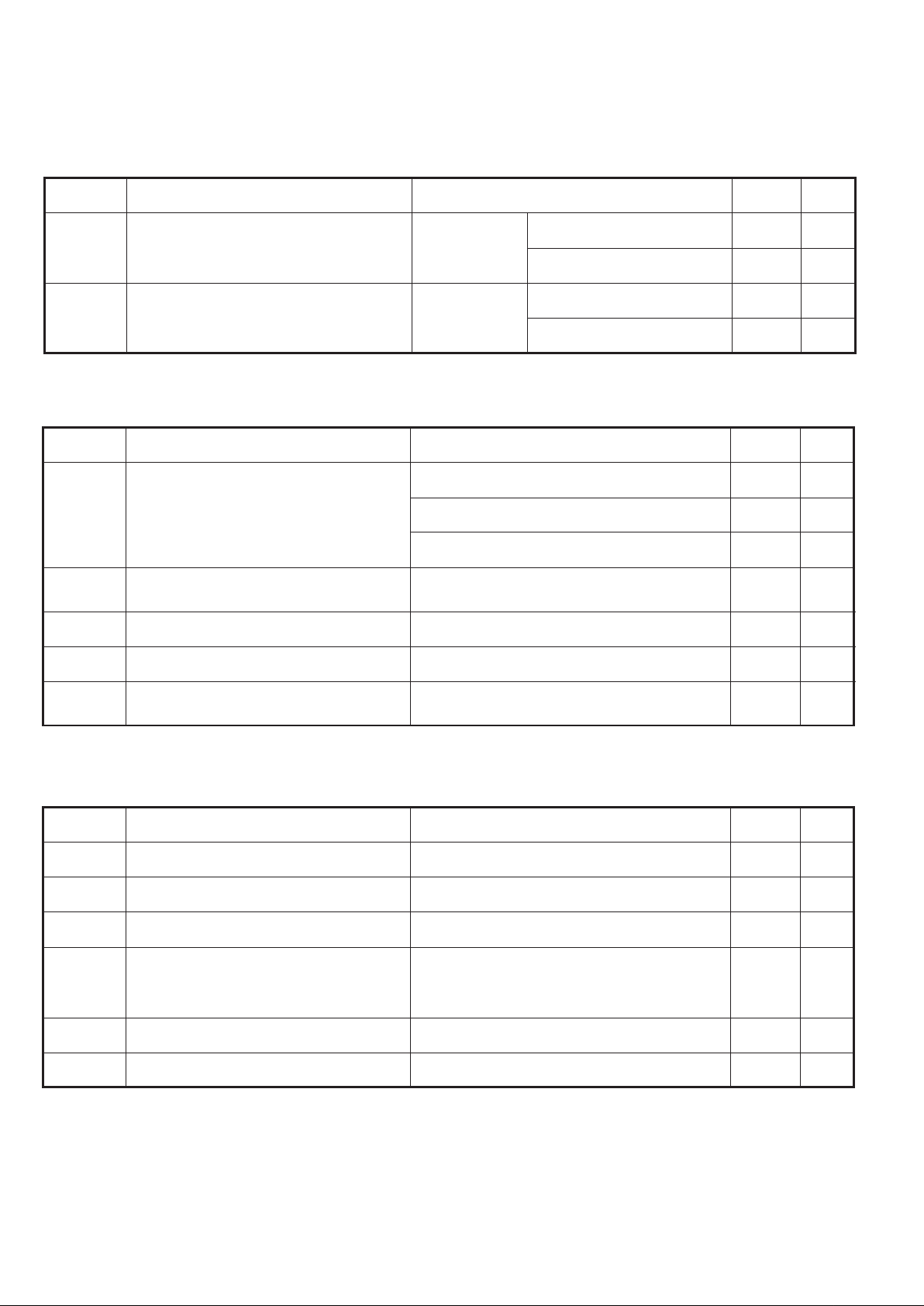

PACKAGE OUTLINE

CIRCUIT OPTIONS

MP03 XXX 330 Series

Phase Control Dual SCR, SCR/Diode Modules

Replaces December 1998 version, DS4483-4.0 DS4483-5.0 January 2000

Page 2

2/10

MP03 XXX 330 Series

Symbol Parameter Conditions Max. Units

A

VR = 0

VR = 50% V

RRM

VR = 0

VR = 50% V

RRM

A2s

10.6

Symbol Parameter Conditions

Thermal resistance - case to heatsink

per thyristor or diode

3 phase

Max.

Symbol

Peak reverse and off-state current

From 67% V

DRM

to 600A

Gate source 10V, 5Ω

Rise time 0.5µs, Tj =130oC

r

T

* Higher dV/dt values available, contact factory for particular requirements.

Note 1: The data given in this datasheet with regard to forward voltage drop is for calculation of the power dissipation in the

semiconductor elements only. Forward voltage drops measured at the power terminals of the module will be in excess of these

figures due to the impedance of the busbar from the terminal to the semiconductor.

kA

8.5

0.56 x 106A2s

0.36 x 10

6

10ms half sine;

Tj = 130˚C

10ms half sine;

Tj = 130˚C

Surge (non-repetitive) on-state current

I

TSM

I2t for fusing

I2t

dc

Thermal resistance - junction to case

per Thyristor or Diode

halfwave

R

th(j-c)

R

th(c-hs)

Mounting torque = 5Nm

with mounting compound

T

vj

Virtual junction temperature Off-state (Blocking)

T

stg

Storage temperature range

Commoned terminals to base plate

AC RMS, 1min, 50Hz

Isolation voltageV

isol

0.11

o

C/W

o

C/W

0.12

2.5 kV

-40 to 130oC

o

C130

0.05

o

C/W

0.13

o

C/W

Units

Conditions

Max.

At 1000A, T

case

= 25oC 1.50 V

At V

RRM/VDRM

, Tj = 130oC30mA

To 67% V

DRM Tj

= 130oC 200* V/µs

100 A/µs

0.8 VAt Tvj = 130oC

0.7

mΩ

At Tvj = 130oCOn-state slope resistance

V

T(TO)

Threshold voltage

Rate of rise of on-state current

dI/dt

Linear rate of rise of off-state voltagedV/dt

I

RRM/IDRM

On-state voltage

V

TM

THERMAL & MECHANICAL RATINGS

DYNAMIC CHARACTERISTICS- THYRISTOR

SURGE RATINGS - PER ARM

Units

Parameter

Page 3

3/10

MP03 XXX 330 Series

Symbol Parameter Conditions

Gate non-trigger voltage

V

3.0

0.25

Typ.

mA

V

V

GD

Gate trigger voltage

150

V

GT

I

GT

Gate trigger current

At V

DRM Tcase

= 25oC

V

DRM

= 5V, T

case

= 25oC

V

DRM

= 5V, T

case

= 25oC

-

-

-

V

30

0.25

V

V

RGM

Peak reverse gate voltage

V5.0A-

-

-

10

I

FGM

Peak forward gate current

Peak forward gate voltage

V

FGM

V

FGN

Peak forward gate voltage

Anode positive with respect to cathode

Anode negative with respect to cathode

Anode positive with respect to cathode

P

GM

P

G(AV)

Peak gate power

Mean gate power

tp = 25µs-

-

100

5

W

W

Max. Units

■ Adequate heatsinking is required to maintain the base

temperature at 75oC if full rated current is to be achieved. Power

dissipation may be calculated by use of V

T(TO)

and rT information in

accordance with standard formulae. We can provide assistance

with calculations or choice of heatsink if required.

■ The heatsink surface must be smooth and flat; a surface finish

of N6 (32µin) and a flatness within 0.05mm (0.002") are

recommended.

■ Immediately prior to mounting, the heatsink surface should be

lightly scrubbed with fine emery, Scotch Brite or a mild chemical

etchant and then cleaned with a solvent to remove oxide build up

and foreign material. Care should be taken to ensure no foreign

particles remain.

■ An even coating of thermal compound (eg. Unial) should be

applied to both the heatsink and module mounting surfaces. This

should ideally be 0.05mm (0.002") per surface to ensure optimum

thermal performance.

■ After application of thermal compound, place the module squarely

over the mounting holes, (or 'T' slots) in the heatsink. Using a

torque wrench, slowly tighten the recommended fixing bolts at

each end, rotating each in turn no more than 1/4 of a revolution at

a time. Continue until the required torque of 5Nm (44lb.ins) is

reached at both ends.

■ It is not acceptable to fully tighten one fixing bolt before starting

to tighten the others. Such action may DAMAGE the module.

GATE TRIGGER CHARACTERISTICS AND RATINGS

MOUNTING RECOMMENDATIONS

Examples:

MP03 HBP330 - 08

MP03 HBN330 - 12

MP03 HBT330 - 08

Part number is made up of as follows:

MP03 HBT 330 -10

MP = Pressure contact module

03 = Outline type

HBT = Circuit configuration code (see "circuit options" - front page)

330 = Nominal average current rating at T

case

= 75oC

10 = V

RRM

/100

NOTE: Diode ratings and characteristics are comparable with the SCR in types HBP or HBN

Types HBP or HBN can also be supplied with diode polarity reversed, to special order.

ORDERING INSTRUCTIONS

Page 4

4/10

MP03 XXX 330 Series

1600

1200

800

400

0

Instantaneous on-state current - (A)

0.6 1.0 1.4 1.8

Instantaneous on-state voltage - (V)

Measured under pulse conditions

Tj = 130˚C

0.8 1.2 1.6

CURVES

100

10

1

0.1

0.001 0.10.01

I

GD

0.1 10

I

FGM

100W

75W

50W

10W

5W

V

FGM

Lower Limit 1%

Upper Limit 99%

Tj = -40˚C

Tj = 25˚C

Tj = 125˚C

Region of

certain triggering

Gate trigger voltage - (V)

Gate trigger current - (A)

Table gives pulse power PGM in Watts

Pulse Width

µs

20

25

100

500

1ms

10ms

50

100

100

100

100

100

10

100

100

100

100

100

50

-

400

100

100

100

25

-

-

Frequency Hz

Fig. 1 Maximum (limit) on-state characteristics (thyristor or diode) - See Note 1

Fig. 2 Gate trigger characteristics

Page 5

5/10

MP03 XXX 330 Series

100101.00.10.010.001

Time - (s)

0.15

0

0.10

0.05

Thermal impedance - (˚C/W)

d.c.

20

15

10

5

0

Peak half sine wave on-state current - (kA)

11012345

50

ms Cycles at 50Hz

Duration

150

200

250

300

I

2

t value - (A

2

s x 10

3

)

I2t

I2t = Î2 x t

2

350

400

450

500

Fig. 3 Transient thermal impedance (DC) - (Thyristor or diode)

Fig. 4 Surge (non-repetitive) on-state current vs time (with 50% V

RRM

, T

case

= 130˚C (Thyristor or diode)

Page 6

6/10

MP03 XXX 330 Series

0 50 100 150 200 250

300

Mean on-state current - (A)

400

350

300

250

200

150

100

50

0

On-state power loss per device - (W)

180˚

120˚

90˚

60˚

30˚

450

500

350 400

d.c.

0 50 100 150 200 250

300

Mean on-state current - (A)

400

350

300

250

200

150

100

50

0

On-state power loss per device - (W)

180˚

120˚

90˚

60˚

30˚

450

500

350 400

Fig. 5 On-state power loss per arm vs forward current at various conduction angles, sine wave, 50/60Hz

Fig. 6 On-state power loss per arm vs forward current at various conduction angles, square wave, 50/60Hz

Page 7

7/10

MP03 XXX 330 Series

0 50 100 150 200 250

300

Mean on-state current - (A)

120

100

80

60

40

20

0

Maximum permissible case temperature - (˚C)

180˚

120˚90˚60˚30˚

140

350 400

0 50 100 150 200 250

300

Mean on-state current - (A)

120

100

80

60

40

20

0

Maximum permissible case temperature - (˚C)

180˚

120˚90˚60˚30˚

140

350 400

d.c.

Fig. 7 Maximum permissible case temperature vs forward current per arm at various conduction angles, sine wave, 50/60Hz

Fig. 8 Maximum permissible case temperature vs forward current per arm at various conduction angles, square wave, 50/60Hz

Page 8

8/10

MP03 XXX 330 Series

0 40 80 120 0 200

400

1200

1000

800

600

400

200

0

Total power - (W)

10060

20

Maximum ambient temperature - (˚C)

D.C. output current - (A)

600

R - Load

L - Load

R

th(hs-a)

˚C/W0.02

0.04

0.08

0.10

0.12

0.15

0.20

0.40

0.30

140

1400

0 40 80 120 0 200

400

1200

1000

800

600

400

200

0

Total power - (W)

10060

20

Maximum ambient temperature - (˚C)

D.C. output current - (A)

600

R & L- Load

R

th(hs-a)

˚C/W0.02

0.040.08

0.10

0.12

0.15

0.20

0.30

0.40

140

1400

Fig. 9 50/60Hz single phase bridge dc output current vs power loss and maximum permissible ambient temperature for

various values of heatsink thermal resistance.

(Note: R

th(hs-a)

values given above are true heatsink thermal resistances to ambient and already account for R

th(c-hs)

module contact thermal).

Fig. 9 50/60Hz 3- phase bridge dc output current vs power loss and maximum permissible ambient temperature for various

values of heatsink thermal resistance.

(Note: R

th(hs-a)

values given above are true heatsink thermal resistances to ambient and already account for R

th(c-hs)

module contact thermal).

Page 9

9/10

MP03 XXX 330 Series

HBT

G1K

1

1

2

HBP

1

2

HBN

K2 G

2

1

2

3

3

3

G1K

1

K2 G

2

35

5

28.5

80

50

52

92

3x M8

18

Ø5.5

38

6.5

2.8x0.8

32

42.5

5

5

1

2

3

K2

G2

G1

K1

Recommended fixings for mounting: M5 socket head cap screws.

Recommended mounting torque: 5Nm (44lb.ins)

Recommended torque for electrical connections: 8Nm (70lb.ins)

Maximum torque for electrical connections: 9Nm (80lb.ins)

Nominal weight: 950g

Module outline type code: MP03

PACKAGE DETAILS

For further package information, please contact your local Customer Service Centre. All dimensions in mm, unless stated otherwise.

DO NOT SCALE.

CIRCUIT CONFIGURATIONS

Page 10

10/10

MP03 XXX 330 Series

CUSTOMER SERVICE CENTRES

France, Benelux, Italy and Spain Tel: +33 (0)1 69 18 90 00. Fax: +33 (0)1 64 46 54 50

North America Tel: 011-800-5554-5554. Fax: 011-800-5444-5444

UK, Germany, Scandinavia & Rest Of World Tel: +44 (0)1522 500500. Fax: +44 (0)1522 500020

SALES OFFICES

France, Benelux, Italy and Spain Tel: +33 (0)1 69 18 90 00. Fax: +33 (0)1 64 46 54 50

Germany Tel: 07351 827723

North America Tel: (613) 723-7035. Fax: (613) 723-1518. Toll Free: 1.888.33.DYNEX (39639) /

Tel: (831) 440-1988. Fax: (831) 440-1989 / Tel: (949) 733-3005. Fax: (949) 733-2986.

UK, Germany, Scandinavia & Rest Of W orld Tel: +44 (0)1522 500500. Fax: +44 (0)1522 500020

These offices are supported by Representatives and Distributors in many countries world-wide.

© Dynex Semiconductor 2000 Publication No. DS4483-5 Issue No. 5.0 January 2000

TECHNICAL DOCUMENTATION – NOT FOR RESALE. PRINTED IN UNITED KINGDOM

HEADQUARTERS OPERATIONS

DYNEX SEMICONDUCTOR LTD

Doddington Road, Lincoln.

Lincolnshire. LN6 3LF. United Kingdom.

Tel: 00-44-(0)1522-500500

Fax: 00-44-(0)1522-500550

DYNEX POWER INC.

Unit 7 - 58 Antares Drive,

Nepean, Ontario, Canada K2E 7W6.

Tel: 613.723.7035

Fax: 613.723.1518

Toll Free: 1.888.33.DYNEX (39639)

This publication is issued to provide information only which (unless agreed by the Company in writing) may not be used, applied or reproduced for any purpose nor form part of any order or contract nor to be regarded as

a representation relating to the products or services concerned. No warranty or guarantee express or implied is made regarding the capability, performance or suitability of any product or service. The Company reserves

the right to alter without prior notice the specification, design or price of any product or service. Information concerning possible methods of use is provided as a guide only and does not constitute any guarantee that such

methods of use will be satisfactory in a specific piece of equipment. It is the user's responsibility to fully determine the performance and suitability of any equipment using such information and to ensure that any publication

or data used is up to date and has not been superseded. These products are not suitable for use in any medical products whose failure to perform may result in significant injury

or death to the user. All products and materials are sold and services provided subject to the Company's conditions of sale, which are available on request.

All brand names and product names used in this publication are trademarks, registered trademarks or trade names of their respective owners.

http://www.dynexsemi.com

e-mail: power_solutions@dynexsemi.com

Datasheet Annotations:

Dynex Semiconductor annotate datasheets in the top right hard corner of the front page, to indicate product status. The annotations are as follows:-

Target Information: This is the most tentative form of information and represents a very preliminary specification. No actual design work on the product has been started.

Preliminary Information: The product is in design and development. The datasheet represents the product as it is understood but details may change.

Advance Information: The product design is complete and final characterisation for volume production is well in hand.

No Annotation: The product parameters are fixed and the product is available to datasheet specification.

Loading...

Loading...