Page 1

MMBT2222AWT1

Preferred Device

General Purpose Transistor

NPN Silicon

These transistors are designed for general purpose amplifier

applications. They are housed in the SOT–323/SC–70 package which

is designed for low power surface mount applications.

http://onsemi.com

MAXIMUM RATINGS

Rating Symbol Value Unit

Collector–Emitter Voltage V

Collector–Base Voltage V

Emitter–Base Voltage V

Collector Current – Continuous I

THERMAL CHARACTERISTICS

Characteristic Symbol Max Unit

Total Device Dissipation FR–5 Board

TA = 25°C

Thermal Resistance

Junction to Ambient

Junction and Storage Temperature TJ, T

CEO

CBO

EBO

P

R

C

D

JA

–55 to +150 °C

stg

40 Vdc

75 Vdc

6.0 Vdc

600 mAdc

150 mW

833 °C/W

COLLECTOR

3

1

BASE

2

EMITTER

3

1

2

SC–70

CASE 419

STYLE 3

MARKING DIAGRAM

P1 M

Semiconductor Components Industries, LLC, 2001

July, 2001 – Rev. 2

P1 = Specific Device Code

M = Date Code

ORDERING INFORMATION

Device Package Shipping

MMBT2222AWT1 SC–70

Preferred devices are recommended choices for future use

and best overall value.

1 Publication Order Number:

3000/Tape & Reel

MMBT2222AWT1/D

Page 2

MMBT2222AWT1

(V

CC

Vdc, V

BE

Vdc

(V

CC

Vdc, I

C

150 mAdc

ELECTRICAL CHARACTERISTICS (T

Characteristic

= 25°C unless otherwise noted)

A

OFF CHARACTERISTICS

Collector–Emitter Breakdown Voltage (Note 1.)

(IC = 1.0 mAdc, IB = 0)

Collector–Base Breakdown Voltage

(IC = 10 Adc, IE = 0)

Emitter–Base Breakdown Voltage

(IE = 10 Adc, IC = 0)

Base Cutoff Current

(VCE = 60 Vdc, VEB = 3.0 Vdc)

Collector Cutoff Current

(VCE = 60 Vdc, VEB = 3.0 Vdc)

ON CHARACTERISTICS (Note 1.)

DC Current Gain (Note 1.)

(IC = 0.1 mAdc, VCE = 10 Vdc)

(IC = 1.0 mAdc, VCE = 10 Vdc)

(IC = 10 mAdc, VCE = 10 Vdc)

(IC = 150 mAdc, VCE = 10 Vdc)

(IC = 500 mAdc, VCE = 10 Vdc)

Collector–Emitter Saturation Voltage (Note 1.)

(IC = 150 mAdc, IB = 15 mAdc)

(IC = 500 mAdc, IB = 50 mAdc)

Base–Emitter Saturation Voltage (Note 1.)

(IC = 150 mAdc, IB = 15 mAdc)

(IC = 500 mAdc, IB = 50 mAdc)

SMALL–SIGNAL CHARACTERISTICS

Current–Gain – Bandwidth Product

(IC = 20 mAdc, VCE = 20 Vdc, f = 100 MHz)

Output Capacitance

(VCB = 10 Vdc, IE = 0, f = 1.0 MHz)

Input Capacitance

(VEB = 0.5 Vdc, IC = 0, f = 1.0 MHz)

Input Impedance

(VCE = 10 Vdc, IC = 10 mAdc, f = 1.0 kHz)

Voltage Feedback Ratio

(VCE = 10 Vdc, IC = 10 mAdc, f = 1.0 kHz)

Small–Signal Current Gain

(VCE = 10 Vdc, IC = 10 mAdc, f = 1.0 kHz)

Output Admittance

(VCE = 10 Vdc, IC = 10 mAdc, f = 1.0 kHz)

Noise Figure

(VCE = 10 Vdc, IC = 100 Adc, RS = 1.0 k, f = 1.0 kHz)

SWITCHING CHARACTERISTICS

Delay Time

Rise Time

Storage Time

Fall Time

1. Pulse Test: Pulse Width 300 s, Duty Cycle 2.0%.

(VCC = 3.0 Vdc, VBE = –0.5 Vdc,

3.0

IC = 150 mAdc, IB1 = 15 mAdc)

(VCC = 30 Vdc, IC = 150 mAdc,

30

IB1 = IB2 = 15 mAdc)

0.5

Symbol Min Max Unit

V

(BR)CEO

V

(BR)CBO

V

(BR)EBO

I

BL

I

CEX

H

FE

V

CE(sat)

V

BE(sat)

f

T

C

obo

C

ibo

h

ie

h

re

h

fe

h

oe

NF – 4.0 dB

t

,

,

d

t

r

t

s

t

f

40 – Vdc

75 – Vdc

6.0 – Vdc

– 20 nAdc

– 10 nAdc

35

50

75

100

40

–

–

0.6

–

300 – MHz

– 8.0 pF

– 30 pF

0.25 1.25 k ohms

– 4.0 X 10

75 375 –

25 200 mhos

– 10

– 25

– 225

– 60

–

–

–

300

–

0.3

1.0

1.2

2.0

–

Vdc

Vdc

–4

ns

ns

http://onsemi.com

2

Page 3

MMBT2222AWT1

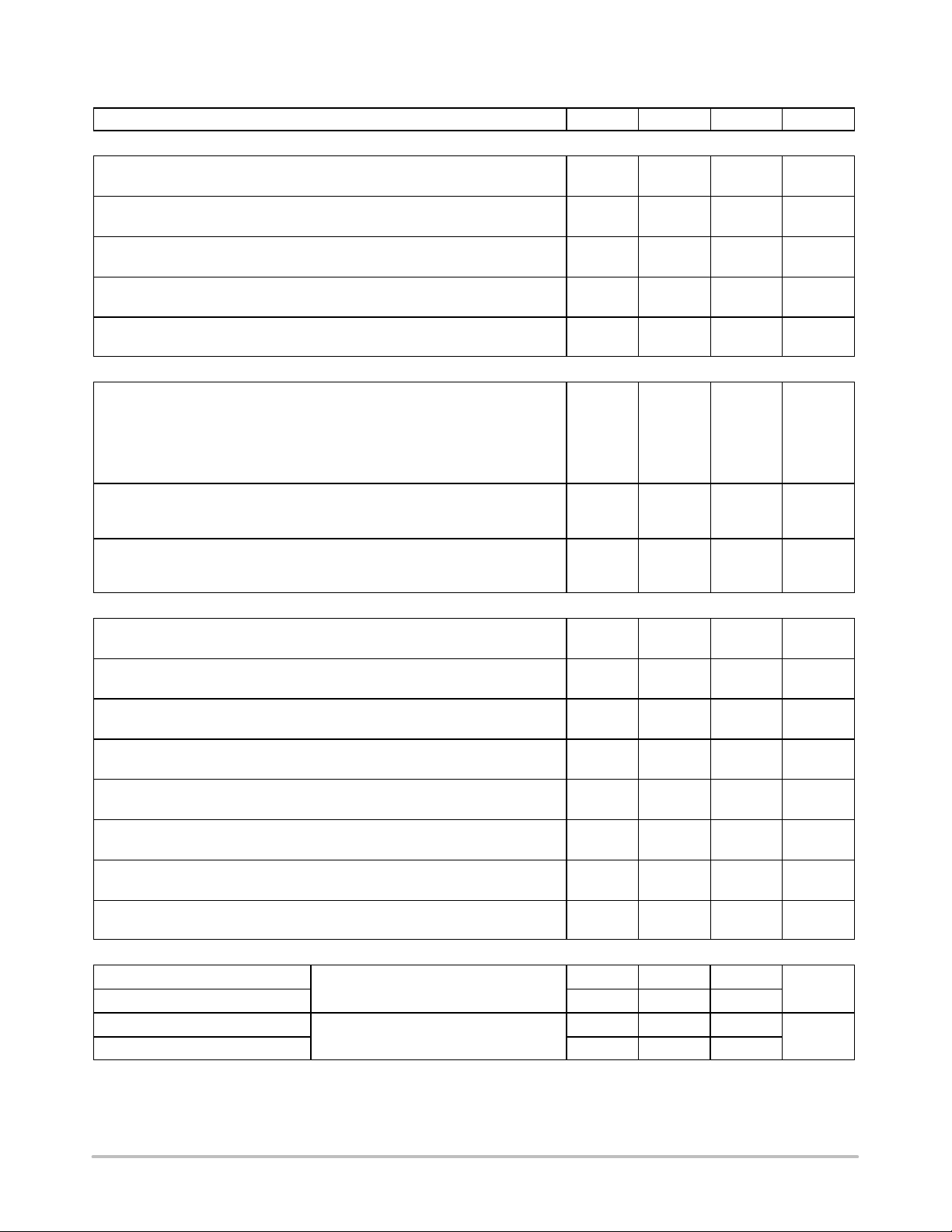

SWITCHING TIME EQUIVALENT TEST CIRCUITS

+16 V

0

-2 V

, DC CURRENT GAINV

FE

h

1000

700

500

300

200

100

+30 V

200

CS* < 10 pF

1.0 to 100 µs,

DUTY CYCLE ≈ 2.0%

< 2 ns

1 kΩ

+30 V

200

CS* < 10 pF

Scope rise time < 4 ns

*Total shunt capacitance of test jig, connectors, and oscilloscope.

+16 V

0

-14 V

1.0 to 100 µs,

DUTY CYCLE ≈ 2.0%

< 20 ns

1 k

1N914

-4 V

Figure 1. Turn–On Time Figure 2. Turn–Off Time

70

50

30

20

10

IC, COLLECTOR CURRENT (mA)

Figure 3. DC Current Gain

1.0

0.8

0.6

0.4

0.2

, COLLECTOR-EMITTER VOLTAGE (VOLTS)

CE

0

0.005 0.01 0.02 0.03 0.05 0.1 0.2 0.3 0.5 1.0 2.0 3.0 5.0 10 20 30 50

IB, BASE CURRENT (mA)

Figure 4. Collector Saturation Region

1.0 k0.1 0.2 0.3 0.5 0.7 1.0 2.0 3.0 5.0 7.0 10 20 30 50 70 100 200 300 500 700

http://onsemi.com

3

Page 4

MMBT2222AWT1

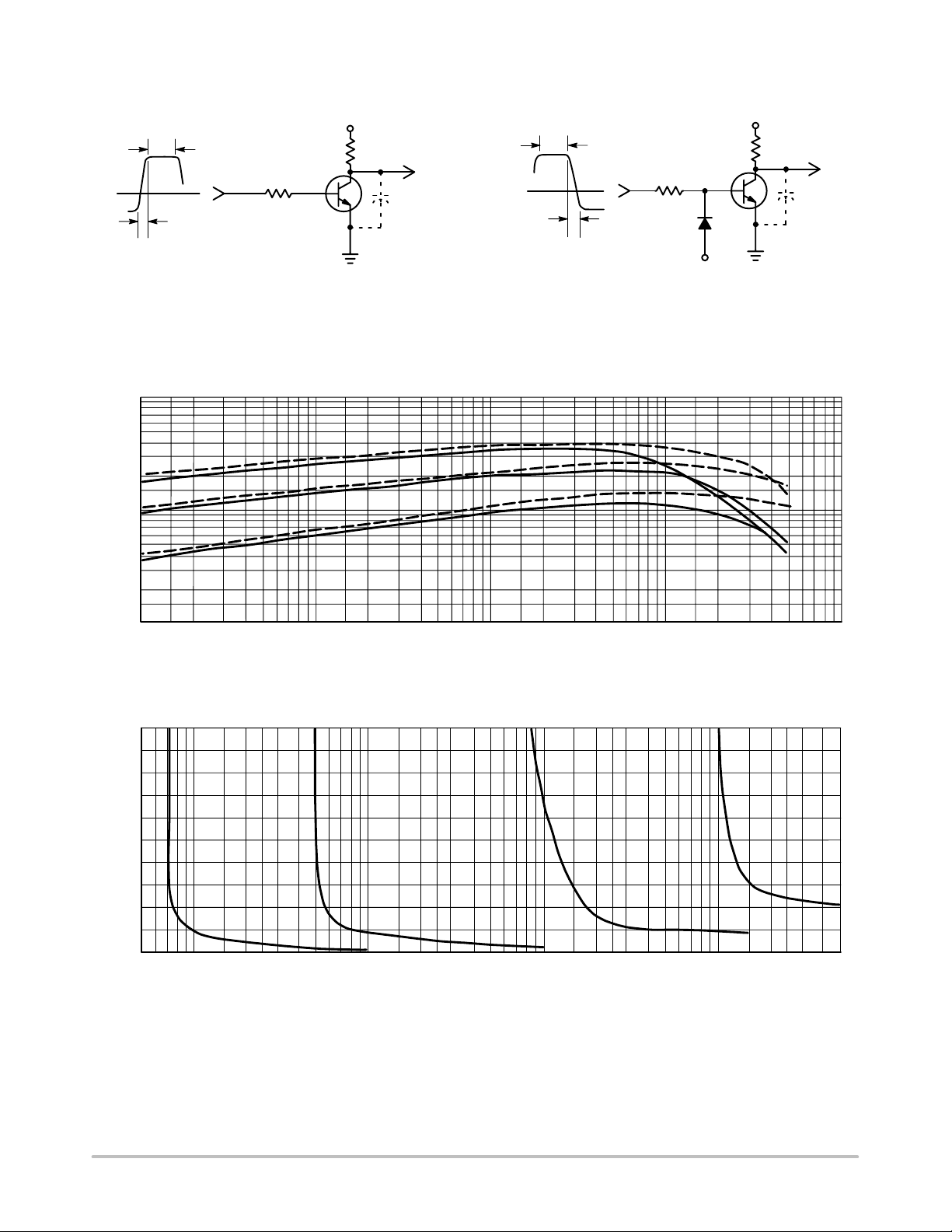

200

100

70

50

30

20

t, TIME (ns)

10

7.0

5.0

3.0

2.0

5.0 7.0 30 50

10 20

IC, COLLECTOR CURRENT (mA)

Figure 5. Turn–On Time

10

8.0

6.0

IC = 1.0 mA, R

500 µA, RS = 200 Ω

100 µA, RS = 2.0 kΩ

50 µA, RS = 4.0 kΩ

= 150 Ω

S

tr @ VCC = 30 V

td @ V

td @ V

70

= 2.0 V

EB(off)

= 0

EB(off)

100

RS = OPTIMUM

RS = SOURCE

RS = RESISTANCE

200

IC/IB = 10

T

= 25°C

J

300 500

t, TIME (ns)

500

300

200

100

7.0

5.0

8.0

6.0

VCC = 30 V

t′

= ts - 1/8 t

s

70

50

30

20

10

10 20 70 1005.0 7.0 30 50 200 300 500

IC, COLLECTOR CURRENT (mA)

f

t

f

IC/IB = 10

IB1 = I

B2

T

= 25°C

J

Figure 6. Turn–Off Time

10

f = 1.0 kHz

I

= 50 µA

C

100 µA

500 µA

1.0 mA

4.0

NF, NOISE FIGURE (dB)

2.0

0

0.01 0.02 0.05

30

20

10

7.0

5.0

CAPACITANCE (pF)

3.0

2.0

0.1

0.2 0.3 0.5 0.7

0.1

0.2 0.5

1.0 2.0 5.0 10 20

f, FREQUENCY (kHz)

Figure 7. Frequency Effects

C

eb

1.0 2.0 3.0 5.0 7.0 10 20

REVERSE VOLTAGE (VOLTS)

C

cb

50

100

30 50

4.0

NF, NOISE FIGURE (dB)

2.0

0

50 100 200 500

1.0 k 2.0 k 5.0 k 10 k 20 k 50 k 100 k

RS, SOURCE RESISTANCE (OHMS)

Figure 8. Source Resistance Effects

500

VCE = 20 V

T

= 25°C

300

200

100

70

, CURRENT-GAIN BANDWIDTH PRODUCT (MHz)

50

T

f

1.0 2.0 3.0 5.0 7.0 10 20

J

IC, COLLECTOR CURRENT (mA)

30 50 70 100

Figure 9. Capacitances

Figure 10. Current–Gain Bandwidth Product

http://onsemi.com

4

Page 5

MMBT2222AWT1

1.0

T

= 25°C

J

0.8

V

@ IC/IB = 10

BE(sat)

0.6

V

@ VCE = 10 V

BE(on)

0.4

V, VOLTAGE (VOLTS)

0.2

V

@ IC/IB = 10

CE(sat)

0

0.1 1.0 2.0 5.0 10 20

0.2 0.5

IC, COLLECTOR CURRENT (mA)

Figure 11. “On” Voltages

1.0 V

50

100 200 500 1.0 k

+0.5

0

°

-0.5

-1.0

-1.5

COEFFICIENT (mV/ C)

-2.0

-2.5

0.1 1.0 2.0 5.0 10 20 500.2 0.5 100 200 500

IC, COLLECTOR CURRENT (mA)

R

R

VC

VB

for V

for V

CE(sat)

BE

Figure 12. Temperature Coefficients

http://onsemi.com

5

Page 6

MMBT2222AWT1

INFORMATION FOR USING THE SC–70/SOT–323 SURFACE MOUNT PACKAGE

MINIMUM RECOMMENDED FOOTPRINT FOR SURFACE MOUNTED APPLICATIONS

Surface mount board layout is a critical portion of the total

design. The footprint for the semiconductor packages must

be the correct size to insure proper solder connection

0.025

0.65

0.035

0.9

0.028

SC–70/SOT–323 POWER DISSIPATION

The power dissipation of the SC–70/SOT–323 is a function of the pad size. This can vary from the minimum pad

size for soldering to the pad size given for maximum power

dissipation. Power dissipation for a surface mount device

is determined by T

, the maximum rated junction tem-

J(max)

perature of the die, RθJA, the thermal resistance from the

device junction to ambient; and the operating temperature,

TA. Using the values provided on the data sheet, PD can be

calculated as follows.

PD =

T

J(max)

R

θJA

– T

A

The values for the equation are found in the maximum

ratings table on the data sheet. Substituting these values into

interface between the board and the package. With the

correct pad geometry, the packages will self align when

subjected to a solder reflow process.

0.025

0.65

0.075

1.9

0.7

inches

mm

the equation for an ambient temperature TA of 25°C, one

can calculate the power dissipation of the device which in

this case is 200 milliwatts.

PD =

150°C – 25°C

0.625°C/W

= 200 milliwatts

The 0.625°C/W assumes the use of the recommended

footprint on a glass epoxy printed circuit board to achieve

a power dissipation of 200 milliwatts. Another alternative

would be to use a ceramic substrate or an aluminum core

board such as Thermal Clad. Using a board material such

as Thermal Clad, a higher power dissipation of 300 milliwatts can be achieved using the same footprint.

SOLDERING PRECAUTIONS

The melting temperature of solder is higher than the rated

temperature of the device. When the entire device is heated

to a high temperature, failure to complete soldering within

a short time could result in device failure. Therefore, the

following items should always be observed in order to

minimize the thermal stress to which the devices are

subjected.

• Always preheat the device.

• The delta temperature between the preheat and

soldering should be 100°C or less.*

• When preheating and soldering, the temperature of the

leads and the case must not exceed the maximum

temperature ratings as shown on the data sheet. When

using infrared heating with the reflow soldering

method, the difference should be a maximum of 10°C.

http://onsemi.com

• The soldering temperature and time should not exceed

260°C for more than 10 seconds.

• When shifting from preheating to soldering, the

maximum temperature gradient should be 5°C or less.

• After soldering has been completed, the device should

be allowed to cool naturally for at least three minutes.

Gradual cooling should be used as the use of forced

cooling will increase the temperature gradient and

result in latent failure due to mechanical stress.

• Mechanical stress or shock should not be applied dur-

ing cooling

* Soldering a device without preheating can cause excessive thermal shock and stress which can result in damage

to the device.

6

Page 7

MMBT2222AWT1

SOLDER STENCIL GUIDELINES

Prior to placing surface mount components onto a printed

circuit board, solder paste must be applied to the pads. A

solder stencil is required to screen the optimum amount of

solder paste onto the footprint. The stencil is made of brass

or stainless steel with a typical thickness of 0.008 inches.

TYPICAL SOLDER HEATING PROFILE

For any given circuit board, there will be a group of

control settings that will give the desired heat pattern. The

operator must set temperatures for several heating zones,

and a figure for belt speed. Taken together, these control

settings make up a heating “profile” for that particular

circuit board. On machines controlled by a computer, the

computer remembers these profiles from one operating

session to the next. Figure 7 shows a typical heating profile

for use when soldering a surface mount device to a printed

circuit board. This profile will vary among soldering

systems but it is a good starting point. Factors that can

affect the profile include the type of soldering system in

use, density and types of components on the board, type of

solder used, and the type of board or substrate material

being used. This profile shows temperature versus time.

The stencil opening size for the surface mounted package

should be the same as the pad size on the printed circuit

board, i.e., a 1:1 registration.

The line on the graph shows the actual temperature that

might be experienced on the surface of a test board at or

near a central solder joint. The two profiles are based on a

high density and a low density board. The Vitronics

SMD310 convection/infrared reflow soldering system was

used to generate this profile. The type of solder used was

62/36/2 Tin Lead Silver with a melting point between

177–189°C. When this type of furnace is used for solder

reflow work, the circuit boards and solder joints tend to

heat first. The components on the board are then heated by

conduction. The circuit board, because it has a lar ge surface

area, absorbs the thermal energy more efficiently, then

distributes this energy to the components. Because of this

effect, the main body of a component may be up to 30

degrees cooler than the adjacent solder joints.

200°C

150°C

100°C

50°C

STEP 1

PREHEAT

ZONE 1

RAMP"

DESIRED CURVE FOR HIGH

TIME (3 TO 7 MINUTES TOTAL)

STEP 2

VENT

SOAK"

MASS ASSEMBLIES

ZONES 2 & 5

150°C

100°C

DESIRED CURVE FOR LOW

HEATING

RAMP"

Figure 13. Typical Solder Heating Profile

STEP 3

ZONES 3 & 6

160°C

140°C

MASS ASSEMBLIES

STEP 4

HEATING

SOAK"

STEP 5

HEATING

ZONES 4 & 7

SPIKE"

170°C

SOLDER IS LIQUID FOR

40 TO 80 SECONDS

(DEPENDING ON

MASS OF ASSEMBLY)

T

MAX

STEP 6

VENT

STEP 7

COOLING

205° TO 219°C

PEAK AT

SOLDER JOINT

http://onsemi.com

7

Page 8

0.05 (0.002)

A

L

3

S

12

G

H

MMBT2222AWT1

PACKAGE DIMENSIONS

SC–70/SOT–323

CASE 419–04

ISSUE L

B

D

C

N

NOTES:

1. DIMENSIONING AND TOLERANCING PER ANSI

Y14.5M, 1982.

2. CONTROLLING DIMENSION: INCH.

DIM MIN MAX MIN MAX

A 0.071 0.087 1.80 2.20

B 0.045 0.053 1.15 1.35

C 0.032 0.040 0.80 1.00

D 0.012 0.016 0.30 0.40

G 0.047 0.055 1.20 1.40

H 0.000 0.004 0.00 0.10

J 0.004 0.010 0.10 0.25

K 0.017 REF 0.425 REF

J

K

L 0.026 BSC 0.650 BSC

N 0.028 REF 0.700 REF

S 0.079 0.095 2.00 2.40

STYLE 3:

PIN 1. BASE

2. EMITTER

3. COLLECTOR

MILLIMETERSINCHES

Thermal Clad is a registered trademark of the Bergquist Company

ON Semiconductor and are trademarks of Semiconductor Components Industries, LLC (SCILLC). SCILLC reserves the right to make changes

without further notice to any products herein. SCILLC makes no warranty, representation or guarantee regarding the suitability of its products for any particular

purpose, nor does SCILLC assume any liability arising out of the application or use of any product or circuit, and specifically disclaims any and all liability,

including without limitation special, consequential or incidental damages. “Typical” parameters which may be provided in SCILLC data sheets and/or

specifications can and do vary in different applications and actual performance may vary over time. All operating parameters, including “Typicals” must be

validated for each customer application by customer’s technical experts. SCILLC does not convey any license under its patent rights nor the rights of others.

SCILLC products are not designed, intended, or authorized for use as components in systems intended for surgical implant into the body, or other applications

intended to support or sustain life, or for any other application in which the failure of the SCILLC product could create a situation where personal injury or

death may occur. Should Buyer purchase or use SCILLC products for any such unintended or unauthorized application, Buyer shall indemnify and hold

SCILLC and its officers, employees, subsidiaries, affiliates, and distributors harmless against all claims, costs, damages, and expenses, and reasonable

attorney fees arising out of, directly or indirectly, any claim of personal injury or death associated with such unintended or unauthorized use, even if such claim

alleges that SCILLC was negligent regarding the design or manufacture of the part. SCILLC is an Equal Opportunity/Affirmative Action Employer.

PUBLICATION ORDERING INFORMATION

Literature Fulfillment:

Literature Distribution Center for ON Semiconductor

P.O. Box 5163, Denver, Colorado 80217 USA

Phone: 303–675–2175 or 800–344–3860 Toll Free USA/Canada

Fax: 303–675–2176 or 800–344–3867 Toll Free USA/Canada

Email: ONlit@hibbertco.com

N. American Technical Support: 800–282–9855 Toll Free USA/Canada

http://onsemi.com

JAPAN: ON Semiconductor, Japan Customer Focus Center

4–32–1 Nishi–Gotanda, Shinagawa–ku, Tokyo, Japan 141–0031

Phone: 81–3–5740–2700

Email: r14525@onsemi.com

ON Semiconductor Website: http://onsemi.com

For additional information, please contact your local

Sales Representative.

MMBT2222AWT1/D

8

Page 9

Loading...

Loading...