Page 1

MLX90217 Hall-Effect Cam Sensor Rev 1.7 18/December/00 Page 1

MLX90217

Hall-Effect Cam Sensor

Description

The MLX90217 is a self adjusting digital output rotary position gear tooth sensor designed for use in

automotive camshaft sensing as well as other speed

sensing applications. It is designed to be used with a

bias magnet south facing the back (non-marked) side

of the IC. The device has an open collector output

which is short circuit protected.

The MLX90217 is a sophisticated IC featuring an

on-chip 10-bit A/D Converter and logic that acts as a

digital sample and hold circuit. A separate 4-bit A/D

converter provides a fixed hysteresis. The 90217 does

not have a chopper delay. The 90217 uses a single Hall

plate which is immune to rotary alignment problems.

The bias magnet can be from 50 to 400mT.

As the signal is sampled, the logic recognizes an increasing or decreasing flux density. The output will

turn on (BOP) after the flux has reached its peak and

decreased by an amount equal to the hysteresis. Similarly the output will turn off (BOP) after the flux has

reached its minimum value and increased by an

amount equal to the hysteresis.

Functional Diagram

Pin 1 - VDD (Supply)

Pin 2 - VSS (Ground)

Pin 3 - Output

Amplifier

Voltage

Regulator

ADC

ADC

Logic

Protected

Output

1 2 3

Hall

Plate

10-Bit

4-Bit

Features and Benefits

n Rotary Position Gear Tooth Sensor

n Short Circuit Protection

n On-chip 10 bit A/D Converter

n Self-Adjusting Magnetic Range

n High Speed Operation

n No Chopper Delay

n Zero Speed Detection

n No Rotary Orientation Concerns

Applications

n Camshaft Sensor

n Geartooth Sensor

n Linear Encoder

n Rotary Encoder

n Direction Detection*

*See applications example

Ordering Information

Part No. Temperature Suffix Package Temperature Range

MLX90217 L UA -40oC to 150oC Automotive

Note: Static sensitive device, please observe ESD precautions.

Page 2

MLX90217 Hall-Effect Cam Sensor Rev 1.7 18/December/00 Page 2

MLX90217

Hall-Effect Cam Sensor

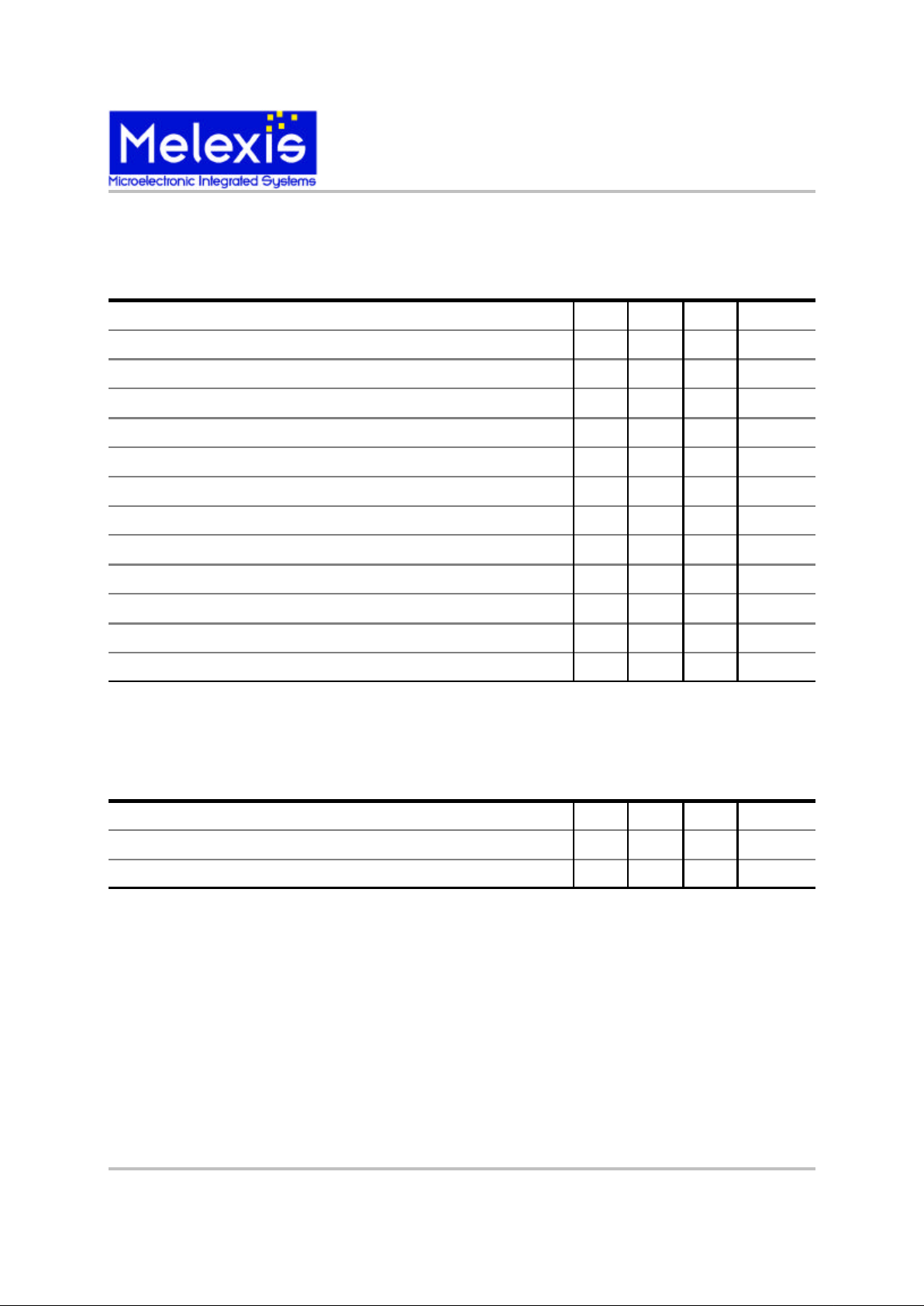

MLX90217 Electrical Specifications

DC Operating Parameters TA = -40oC to 150oC, VDD = 3.5V to 24V (unless otherwise specified).

Parameter Symbol Test Conditions Min Typ Max Units

Supply Voltage VDD Operating 3.5 - 24 V

Supply Current IDD VDD = 12V 1.5 3.0 4.5 mA

Supply Current IDD VDD = 3.5V to 24V 1 - 6 mA

Leakage Current I

LEAK

V

OUT

= 3.5V to 24V - - 10 µA

Output Current I

OUT

Operating - - 25 mA

Output Saturation Voltage V

SAT

VDD = 12V, I

OUT

= 25mA - - 600 mV

Output Short Circuit Current I

FAULT

Fault 50 100 150 mA

Output Short Circuit Shutdown T

FAULT

Fault 100 - 200 µS

Clock Frequency f

CLK

Operating 300 500 800 kHz

Output Rise Time tr VDD=12V R1 = 880W C1 = 20pf - 400 nS

Output Fall Time tf VDD=12V R1 = 880W C1 = 20pf - 400 nS

Bandwidth BW Operating - - 15 kHz

Thermal Resistance RTH Operating - - 200

o

C/Watt

MLX90217 Magnetic Specifications

DC Operating Parameters TA = -40oC to 150oC, VDD = 3.5V to 24V (Unless otherwise specified)

Parameter Symbol Test Conditions Min Typ Max Units

Back Bias Range B

BIAS

Operating -30 - 400 mT

Linear Region VDD = 12V 50 - 500 mT

Hysteresis B

hys

VDD = 3.5V to 24V 1.8 3.5 10 mT

Notes: 1 mT = 10 Gauss

Melexis Inc. reserves the right to make changes without further notice to any products herein to improve reliability, function or design. Melexis does

not assume any liability arising from the use of any product or application of any product or circuit described herein.

Melexis Inc. reserves the right to make changes without further notice to any products herein to improve reliability, function or design. Melexis does

not assume any liability arising from the use of any product or application of any product or circuit described herein.

Page 3

MLX90217 Hall-Effect Cam Sensor Rev 1.7 18/December/00 Page 3

MLX90217

Hall-Effect Cam Sensor

500

Flux Density at Hall Plate (mT)

Time

Switch Points

versus

Analog Magnetic Signal

(Cam Lobe)

MLX90217

100

200

300

400

Output

Signal

500

Flux Density at Hall Plate (mT)

Time

Switch Points

versus

Irregular Magnetic Signal

(Worn Gear)

MLX90217

100

200

300

400

Output

Signal

500

Flux Density at Hall Plate (mT)

Time

Switch Points

versus

Regular Magnetic Signal

(New Gear)

MLX90217

100

200

300

400

Output

Signal

Performance Graphs

Absolute Maximum Ratings

Supply Voltage (Operating), VDD 30V

Supply Current (Fault), IDD 50mA

Output Current (Fault), I

OUT

30mA

Output Current (Fault), I

fault

50mA

Output Voltage, V

OUT

30V

Power Dissipation, PD 100mW

Operating Temperature Range, TA 40°C to 150°C

Storage Temperature Range, TS 65°C to 150°C

Maximun Junction Temp, TJ 175°C

ESD Sensitivity +/- 7KV

Page 4

MLX90217 Hall-Effect Cam Sensor Rev 1.7 18/December/00 Page 4

MLX90217

Hall-Effect Cam Sensor

Application Notes

Maximum dynamic range is 500 mT. The hysteresis is

fixed at 5.0 mT. Best angular accuracy will be obtained when the magnetic circuit provides peak magnetic flux at the chip near the high end of the linear

range of 500 mT. EMC protection using external components are recommended. Two possibilities are

shown on the following page. Normally the South pole

faces the unbranded side of the device. A North pole

will enable a test sequence used in factory testing.

Unique Features

The output is reset to the high state at power on

(output driver is off) whatever the field is. The output

only changes after the first min is detected. The reset

state holds no information about the field. If the supply

of the chip is raised slowly, the reset state is not stable.

This has been observed at 0 field but it should be the

same with small and large fields.

Gear tooth sensors often need to be adjusted after the

module is assembled to align the magnet with differential Hall plates or orient with teeth. However the

MLX90217 is “self adjusting” over a wide range of

back bias flux eliminating the need for any trimming

in the application. The magnet may be glued to the

back surface (non branded side) of the IC using a

cyanoacrylate adhesive or suitable epoxy.

Page 5

MLX90217 Hall-Effect Cam Sensor Rev 1.7 18/December/00 Page 5

MLX90217

Hall-Effect Cam Sensor

Applications Examples

Edge Sensing (unidirectional)

S N

S N

Lobe Sensing (bidirectional)

Clockwise

Counter Clockwise

CW

CCW

B

RP

B

OP

B

RP

B

OP

B

RP

B

OP

B

OP

Flux Concentration - Tooth Position

Flux Concentration - Valley Position

S N

S N

Severe Environment and

Automotive Protection Circuit

V

DD

In severe cases it may be necessary to include a Zener diode to clamp positive

interference and Schottky diodes to clamp negative excursions.

C2

R2

R1 = 5.6kΩ

R2 =332Ω

C1 = 10nF

C2 = 2.2nF

MLX

90217

V

DD

C1

R1

Output

MLX

90217

Recommended Wiring and

Minimum Protection Circuit

V

DD

C1

R1

Output

R1 = 5.6kΩ

C1 = 10nF

Page 6

MLX90217 Hall-Effect Cam Sensor Rev 1.7 18/December/00 Page 6

MLX90217

Hall-Effect Cam Sensor

Physical Characteristics

17AB

4936

21 3

17AB

4936

1 2 3

All Dimensions in millimeters

2.13

1.87

0.45

0.41

Marked

Surface

1.53

1.27

UA Hall Plate / Chip Location

UA Marking and Pinout

First line (17) = part number of 90217.

First Line (AB) = series & die revision.

Pin 1 - VDD (Supply)

Pin 2 - VSS (GND)

Pin 3 - Output (open collector)

1.60

1.40

45

o

Typical

4.30

3.90

2.64

2.34

0.84

0.63

3.20

2.80

1.75

1.55

0.48

0.43

0.20

0.00

0.41

0.35

1.30

1.24

2.57

2.51

5

o

Typical

45

o

Typical

0.38

Typical

(see note 3)

15.5

14.5

0.41

0.35

NOTES:

1-Controling Dimension: mm

2-Leads must be free of flash and

plating voids

3-Leads must not arc toward

the rear of package

UA Package Dimensions

Second Line: Lot & Date Code.

(4) = Lot Identification.

(9) = Year 1999.

(36) = Week of Year.

For more information, please contact:

Melexis, Inc.

41 Locke Road

Concord, NH 03301

Phone: (603) 223-2362 Fax: (603) 223-9614

E-mail: sales@melexis.com

Web: www.melexis.com

Loading...

Loading...