Page 1

March 1997

ML6510*

Series Programmable Adaptive

Clock Manager (PACMan™)

GENERAL DESCRIPTION

The ML6510 (Super PACMan™) is a Programmable

Adaptive Clock Manager which offers an ideal solution for

managing high speed synchronous clock distribution in

next generation, high speed personal computer and

workstation system designs. It provides eight channels of

deskew buffers that adaptively compensate for clock skew

using only a single trace. The input clock can be either

TTL or PECL, selected by a bit in the control register.

Frequency multiplication or division is possible using the

M&N divider ratio, within the maximum frequency limit.

0.5X, 1X, 2X and 4X clocks can be easily realized.

The ML6510 is implemented using a low jitter PLL with

on-chip loop filter. The ML6510 deskew buffers adaptively

compensate for clock skew on PC boards. An internal

skew sense circuit is used to sense the skew caused by the

PCB trace and load delays. The sensing is done by

detecting a reflection from the load and the skew is

corrected adaptively via a unique phase control delay

circuit to provide low load-to-load skew, at the end of the

PCB traces. Additionally, the ML6510 supports PECL

reference clock outputs for use in the generation of clock

trees with minimal part-to-part skew. The chip configuration

can be programmed to generate the desired output

FEATURES

■ Input clocks can be either TTL or PECL with low

input to output clock phase error

■ 8 independent, automatically deskewed clock

outputs with up to 5ns of on-board deskew range

(10ns round trip)

■ Controlled edge rate TTL-compatible CMOS clock

outputs capable of driving 40Ω PCB traces

■ 10 to 80MHz (6510-80) or 10 to 130MHz (6510-130)

input and output clock frequency range

■ Less than 500ps skew between inputs at the

device loads

■ Small-swing reference clock outputs for minimizing

part-to-part skew

■ Frequency multiplication or division is possible using

the M&N divider ratio

■ Lock output indicates PLL and deskew buffer lock

■ Test mode operation allows PLL and deskew buffer

bypass for board debug

■ Supports industry standard processors like Pentium,™

Mips, SPARC,™ PowerPC,™ Alpha,™ etc.

frequency using the internal ROM or an external serial

EEPROM or a standard two-wire serial microprocessor

interface. *Some Packages Are Obsolete

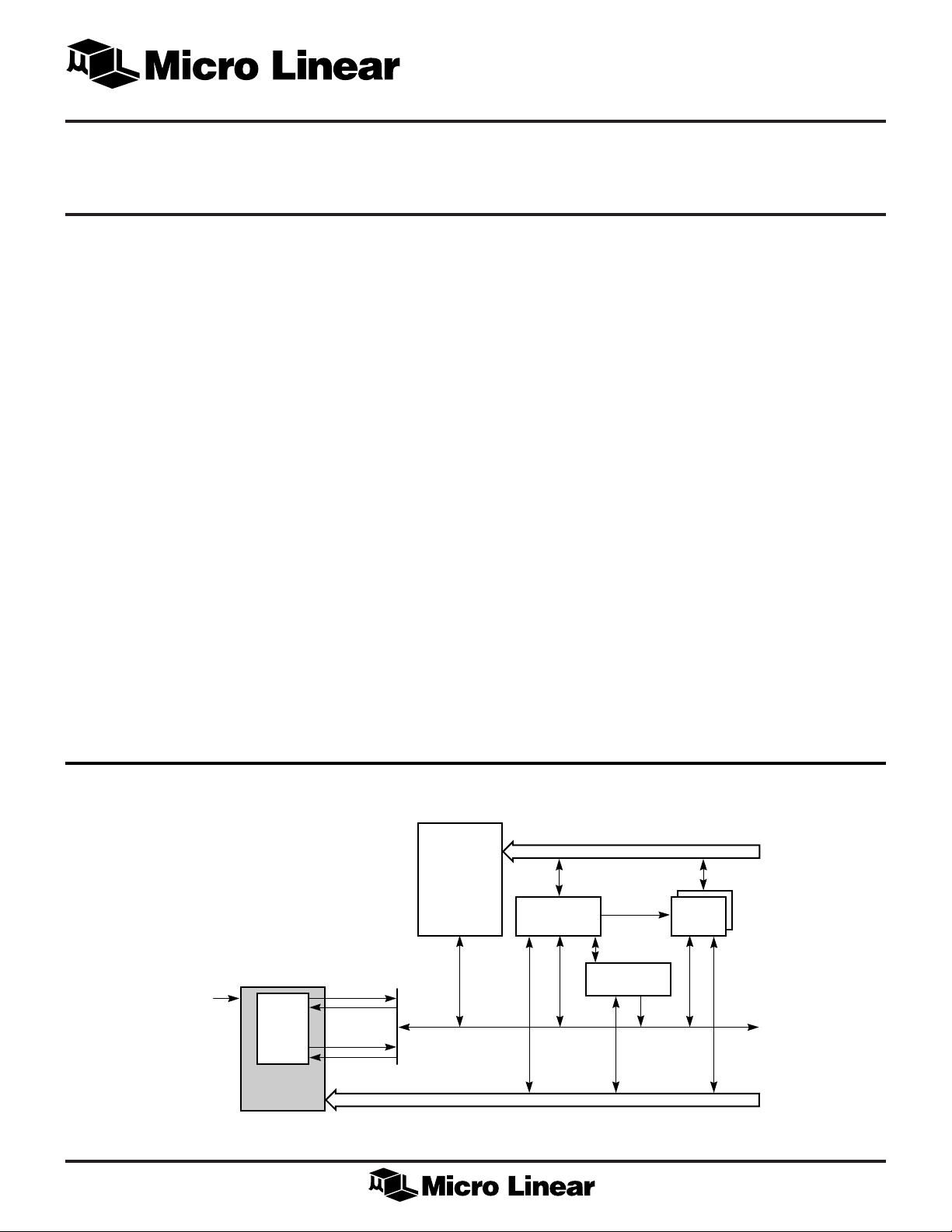

SYSTEM BLOCK DIAGRAM

CLOCK SUBSYSTEM

CLOCK IN

ML6510

LOCAL BUS

CPU

CACHE

CLK

•

8

•

•

CLOCK OUT TO

COMPONENTS

CONTROLLER

MEMORY BUS

CONTROLLER

MEMORY BUS

CACHE

RAM

1

Page 2

ML6510

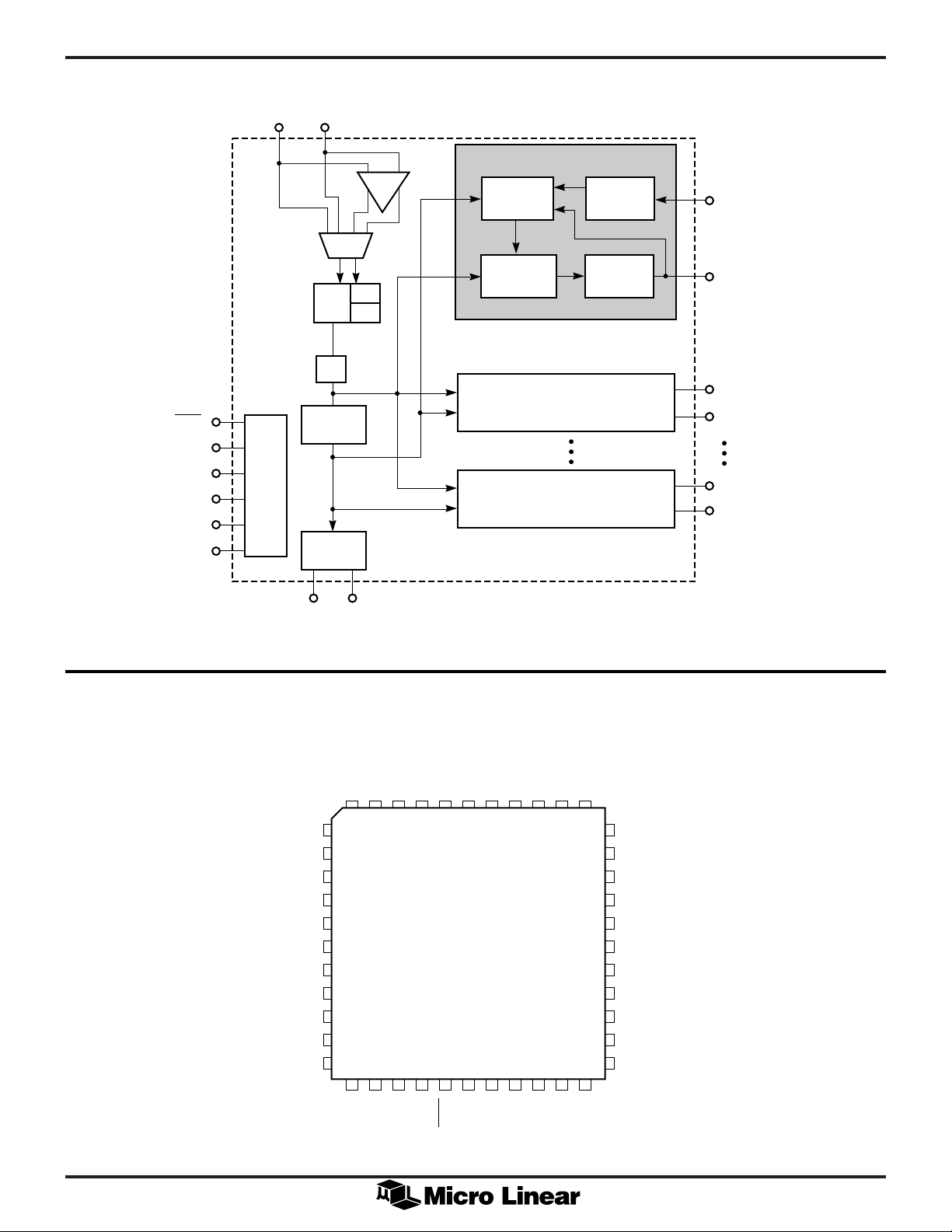

BLOCK DIAGRAM

CLK

INL

CLK

INH

DESKEW BUFFER 0

RESET

LOCK

MD

R0MMSB

MCLK

MD

OUT

PHASE

DETECTOR

VOLTAGE

CONTROLLED

M

PLL

N

R

MAXIMUM

DELAY

IN

MAX DELAY

CONTROL LOGIC

PROGRAMMING AND

REF

CLOCK

RCLKH RCLKL

MAX DELAY

ZERO DELAY

ZERO DELAY

DELAY

DESKEW BUFFER 1

DESKEW BUFFER 7

SENSE

CIRCUIT

DRIVE

CIRCUIT

FB0

(from remote chip)

CLK0

(to remote chip)

FB1

CLK1

FB7

CLK7

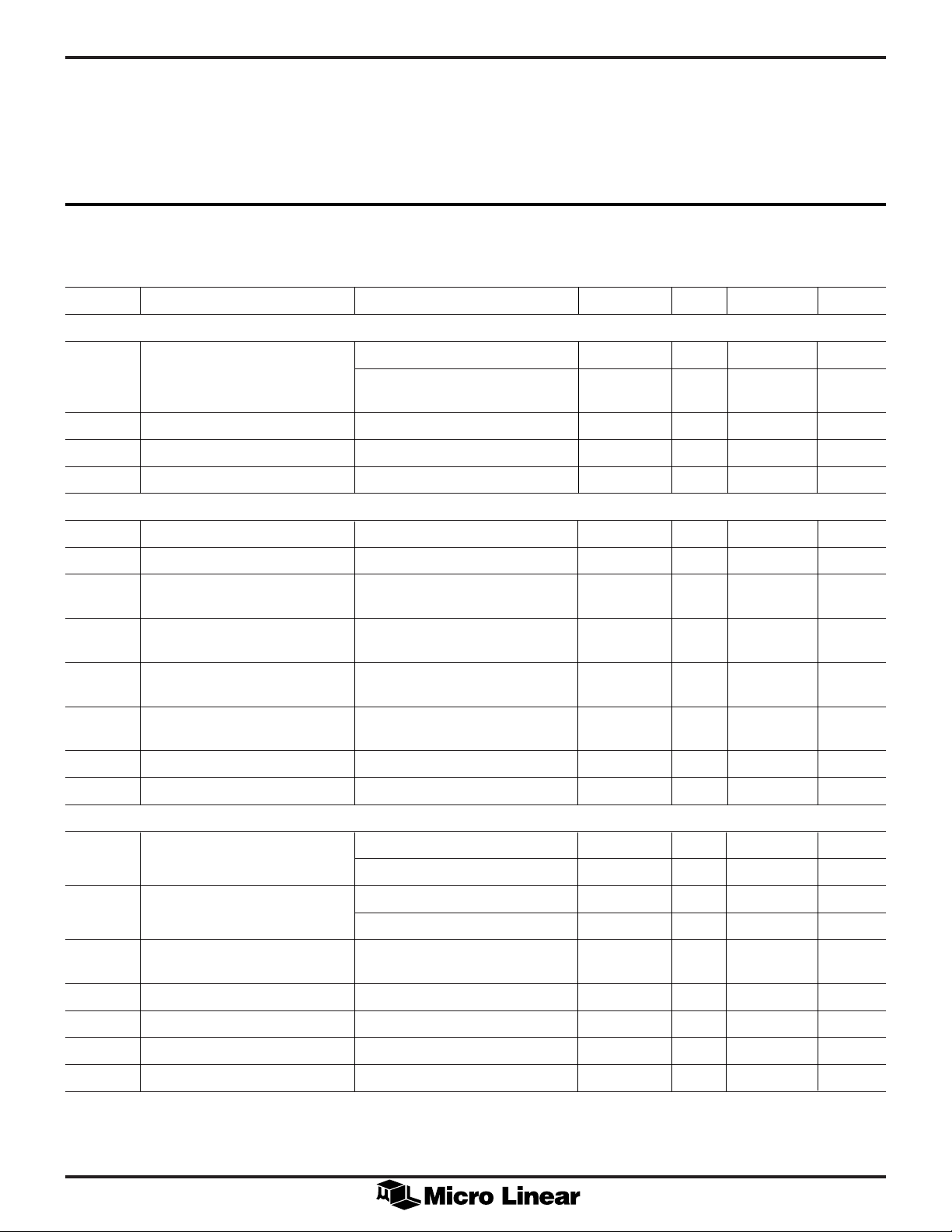

PIN CONNECTION

CLK3

DVCC23

CLK2

DGND2

FB2

FB1

DGND1

CLK1

DVCC01

CLK0

DGND0

DGND3

FB3

AGND1

AVCC1

65432

7

8

9

10

11

12

13

14

15

16

17

18 19 20 21 22

44-LEAD PLCC (Q44)

IN

FB0

MD

OUT

MD

MCLK

FB4

DGND4

CLK4

DVCC45

CLK5

DGND5

FB5

140

43

44

ML6510

TOP VIEW

23 28

25

24

LOCK

RESET

AGND3

42

26

AVCC3

41

27

RCLKL

RCLKH

39

38

37

36

35

34

33

32

31

30

29

INH

CLK

FB6

DGND6

CLK6

DVCC67

CLK7

DGND7

FB7

ROMMSB

AVCC2

AGND2

CLK

INL

2

Page 3

PIN DESCRIPTION

PIN NUMBER NAME DESCRIPTION

32 ROMMSB MSB of the internal ROM address. Tie to GND if not used. See section on

ML6510

Programming the ML6510.

20 MD

19 MD

21 MCLK Programming pin. See section on Programming the ML6510.

22 RESET Reset all internal circuits. Asserted polarity is low.

23 LOCK Indicates when the PLL and deskew buffers have locked. Asserted polarity is

28 CLK

29 CLK

16,14,9,7, CLK[0–7] Clock outputs

44, 42, 37, 35

18,12,11,5, FB[0–7] Clock feedback inputs for the deskew buffers

2, 40, 39, 33

3,31 AVCC[1–3] Analog circuitry supply pins, separated from noisy digital supply pins to

25 provide isolation. All supplies are nominally +5V.

4, 30, 24 AGND[1–3] Analog circuitry ground pins

15 DVCC01 Digital supply pin for CLK0 and CLK1 output buffers. Nominally +5V.

8 DVCC23 Digital supply pin for CLK2 and CLK3 output buffers. Nominally +5V.

43 DVCC45 Digital supply pin for CLK4 and CLK5 output buffers. Nominally +5V.

OUT

IN

INH

INL

Programming pin. See section on Programming the ML6510.

Programming pin. See section on Programming the ML6510.

high.

Input clock pins. For TTL clock reference use CLK

shorted to the CLK

Input clock type is selected by the CS bit in the shift register.

pin. For PECL clock reference drive pins differentially.

INL

INH

pin

36 DVCC67 Digital supply pin for CLK6 and CLK7 output buffers. Nominally +5V.

17, 13, 10, 6, DGND[0–7] Digital ground pins for CLK [0–7] output buffers. Each clock output buffer has

1, 41, 38, 34 its own ground pin to avoid crosstalk and ground bounce problems.

26 RCLKL Differential reference clock output used to minimize

27 RCLKH part-to-part skew when building clock trees with other PACMan

integrated circuits.

3

Page 4

ML6510

ABSOLUTE MAXIMUM RATINGS

VCC Supply Voltage Range ............................ –0.3V to 6V

Input Voltage Range .................................... –0.3V to VCC

Output Current

Junction Temperature .............................................. 150°C

Storage Temperature................................ –65°C to 150°C

Thermal Resistance (θJA)....................................... 54°C/W

CLK[0–7] ........................................................ 70mA

All other outputs ............................................. 10mA

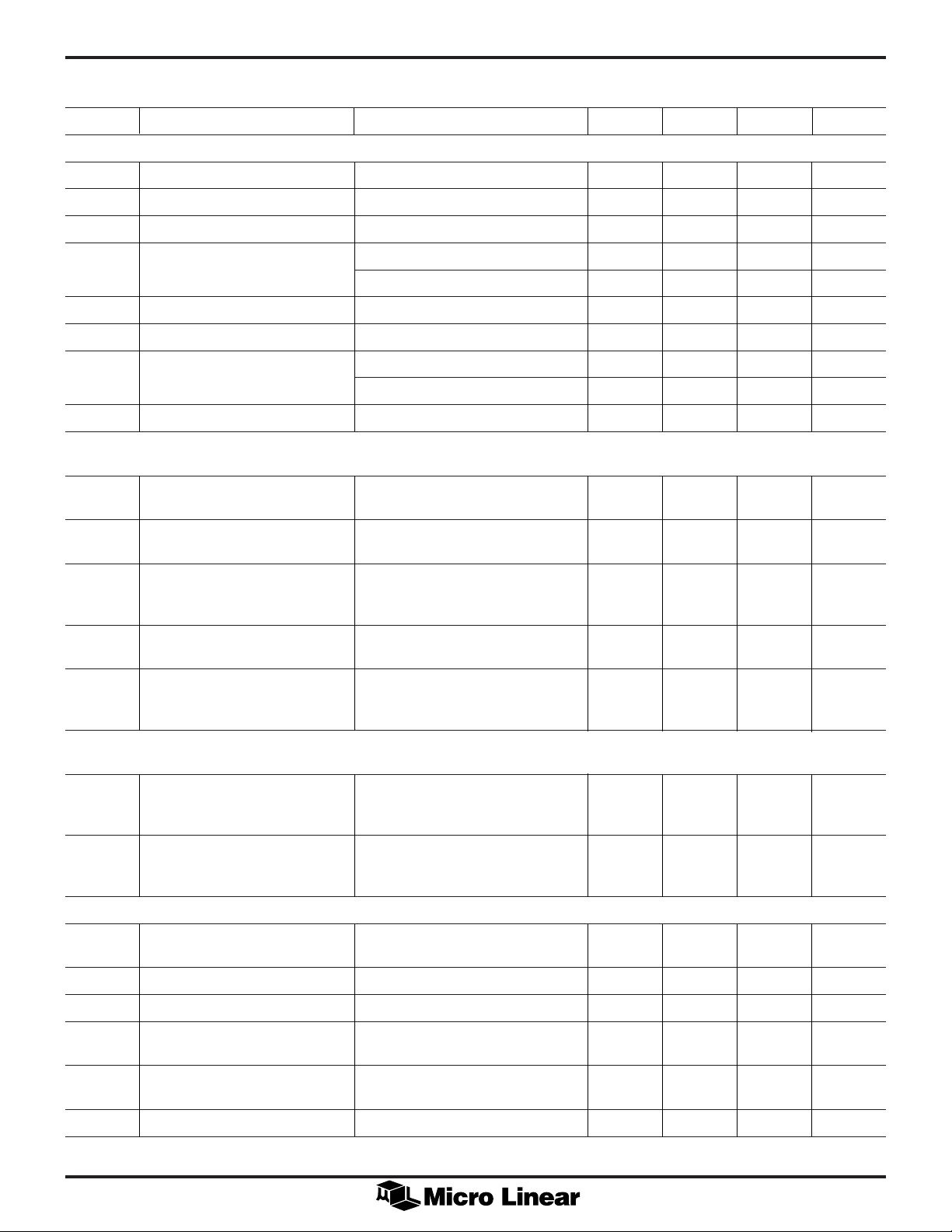

ELECTRICAL CHARACTERISTICS

The following specifications apply over the recommended operating conditions of DVCC = AVCC = 5V ± 5% and ambient

temperature between 0°C and 70°C. Loading conditions are specified individually (Note 1)

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNIT

SUPPLY

DVCCXX Supply Current for each pair f

of clock outputs

IAVCC1 Static supply current, AVCC1 pin 100 120 mA

IAVCC2 Static supply current, AVCC2 pin 35 40 mA

IAVCC3 Static supply current, AVCC3 pin 1 2 mA

LOW FREQUENCY INPUTS AND OUTPUTS (ROMMSB, MD

V

IH

V

IL

V

OH

High level input voltage DVCC – 0.5 V

Low level input voltage DGND + 0.5 V

High level output voltage, IOH = –100 µA DVCC – 0.5 V

MCLK and MDIN

= 0 50 µA

CLKX

CL= 20pF, ZO = 50Ω 40 60 mA

f

= 80MHz

OUT

, MDIN, MCLK, RESET, LOCK)

OUT

V

OL

Low level output voltage, IOL = +200 µA DGND + 0.5 V

MCLK and MDIN

V

OH

High level output voltage, IOH = –100 µA 2.4 V

LOCK output IOH = –10 µA DVCC – 0.5 V

V

OL

Low level output voltage, IOL = +1 mA 0.4 V

LOCK output

I

IN

C

IN

Static input current 10 µA

Input capacitance 5 pF

HIGH FREQUENCY INPUTS AND OUTPUTS (CLK

V

IH

V

IL

V

ICM

High level input voltage CS = 0 (TTL Input Clock) 2.0 V

Low level input voltage CS = 0 (TTL Input Clock) 0.8 V

Common mode input voltage CS = 1 (PECL Input Clock) 2.0 AVCC – 0.4 V

range for PECL reference clocks

I

IH

I

IL

V

OH

V

OL

High level input current VIH = 2.4V 100 µA

Low level input current VIL = 0.4V –400 µA

High level output voltage IOH = –60mA 2.4 V

Low level output voltage IOL = +60mA 0.4 V

INH

, CLK

, FB[0-7], CLK[0-7])

INL

CS = 1 (PECL Input Clock) AVCC – 1.165 AVCC – 0.88 V

CS = 1 (PECL Input Clock) AVCC – 1.810 AVCC – 1.475 V

4

Page 5

ML6510

ELECTRICAL CHARACTERISTICS (Continued)

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNIT

AC CHARACTERISTICS rise time, fall time and duty cycle are measured for a generic load; (see Load Conditions section).

t

R

t

F

f

IN

f

OUT

f

VCO

Rise time, LOAD [0-7] output 0.8 → 2.0V, 80MHz 150 1500 ps

Fall time, LOAD [0-7] output 2.0 → 0.8V, 80MHz 150 1500 ps

Input frequency, CLKIN pin 10 80 MHz

Output frequency , CLK [0-7] ML6510-80 10 80 MHz

output

ML6510-130 (Note 2) 10 130 MHz

PLL VCO operating frequency 80 160 MHz

DC Output duty cycle Measured at device load, at 1.5V 40 60 %

t

JITTER

Output jitter Cycle-to-cycle 75 ps

Peak-to-peak 150 ps

t

LOCK

PLL and deskew lock time After programming is complete 11 ms

SKEW CHARACTERISTICS All skew measurements are made at the load, at 1.5V threshold each output load can vary independently

within the specified range for a generic load (see Load Conditions section).

t

SKEWR

Output to output rising 500 ps

edge skew, all clocks

t

SKEWF

Output to output Output clock frequency ≥ 50MHz 1.5 ns

falling edge skew

t

SKEWIO

CLKIN input to any N = M = 0 600 ps

LOAD [0-7] output

rising edge skew N ≥ 2, M ≥ 2 1.25 ns

t

RANGE

t

SKEWB

Round trip delay CLKX to FBX Output frequency < 50MHz 0 10 ns

pin; output CLK period = t

CLK

Output frequency ≥ 50MHz 0 t

CLK

/2

Output-to-output rising Providing first (see LOAD 250 ps

edge skew, between matched conditions) order matching

loads order matching between outputs

PART-TO-PART SKEW CHARACTERISTICS Skew measured at the loads, at 1.5V threshold. Reference clock output pins drive clock

input pins of another ML6510.

t

PP1

Total load-to-load skew between Slave chip CS = 1, CM = 1 and 1 ns

multiple chips interfaced with N = 0, M = 0; RCLK outputs to

reference clock pins. CLKIN inputs distance less than 2"

t

PP2

Total load-to-load skew between Slave chip CS = 1, CM = 1 and 1 ns

multiple chips interfaced with N ≥ 2, M ≥ 2; RCLK outputs to

reference clock pins. CLKIN inputs distance less than 2"

PROGRAMMING TIMING CHARACTERISTICS

tRESET RESET assertion pulse 50 ns

width

t

A1

t

A2

t

A3

AUX mode MCLK high time 2000 ns

AUX mode MCLK low time 2000 ns

AUX mode MD

data 10 ns

OUT

hold time

t

A4

AUX mode MD

data 10 ns

OUT

setup time

t

A5

AUX mode MCLK period 5000 ns

5

Page 6

ML6510

ELECTRICAL CHARACTERISTICS (Continued)

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNIT

PROGRAMMING TIMING CHARACTERISTICS (continued)

t

M1

t

M2

t

M3

t

M4

MAIN mode MCLK high time 900 ns

MAIN mode MCLK low time 900 ns

MAIN mode MCLK period 1800 ns

MAIN mode 900 ns

MCLK to MD

OUT

valid

(EEPROM read time)

Note 1: Limits are guaranteed by 100% testing, sampling or correlation with worst case test conditions.

Note 2: If ML6510-130 is used in a master-slave mode, the maximum operating frequency is 120MHz.

ML6510 configured with bit CM = 0:

PECL INPUT CLOCKS

OR

TTL INPUT CLOCK

LOAD [0-7]

1st Order Match

OR

t

SKEWIO

t

SKEWF

t

SKEWB

t

SKEWR

CLK

CLK

V

ICM

AVCC – 0.4V

INH

INL

2.0 V

LOAD [0-7] with

no 1st order match

Note: All skew is measured at the device load input pin, NOT at the ML6510 clock output pin. Skew is always a positive number, regardless of which edge is leading and

which is trailing.

6

Page 7

AC/SKEW CHARACTERISTICS LOAD CONDITIONS

ML6510

ML6510-80

GENERIC

ML6510-80

FIRST-ORDER

MATCHED LOADS

LOAD

FBX

CLKX

FBX

CLKX

FBY

CLKY

PCB trace impedance

Z0 = 50Ω

R1

One way trip delay < t

PCB trace impedance

Z0 = 50Ω

R1

Length L

PCB trace impedance

Z0 = 50Ω

R1

Length L

One way trip delay < t

RANGE

X

Y

RANGE

LOAD

Lumped

CL ≤ 20pF

/2

LOAD

Lumped

C

LX

|CLX – CLY| < 5pF

|L

– LY| < 4"

X

Z

= Z

OX

OY

LOAD

Lumped

C

LY

/2

≤ 20pF

≤ 20pF

ML6510-130

GENERIC

ML6510-130

FIRST-ORDER

MATCHED LOADS

LOAD

FBX

CLKX

FBX

CLKX

FBY

CLKY

PCB trace impedance

Z

= 50Ω

0

R2

R3

One way trip delay < t

PCB trace impedance

Z0 = 50Ω

R2

R3

PCB trace impedance

Z0 = 50Ω

R2

R3

One way trip delay < t

Length L

Length L

X

Y

RANGE

LOAD

Lumped

CL ≤ 20pF

/2

RANGE

LOAD

Lumped

C

LX

|CLX – CLY| < 5pF

|L

– LY| < 4"

X

Z

= Z

OX

OY

LOAD

Lumped

C

LY

/2

≤ 20pF

≤ 20pF

ML6510

RCLKH RCLKL

CLK

CLK

INH

ML6510

SLAVE CHIP

(CM=1, CS=1)

INL

DISTANCE <2"

LOAD[0-7]

LOAD[8-15]

LOAD[0-7]

LOAD[8-15]

t

SKEWR

t

SKEWR

t

pp1

or t

(or t

(or t

pp2

SKEWB

SKEWB

)

)

7

Page 8

ML6510

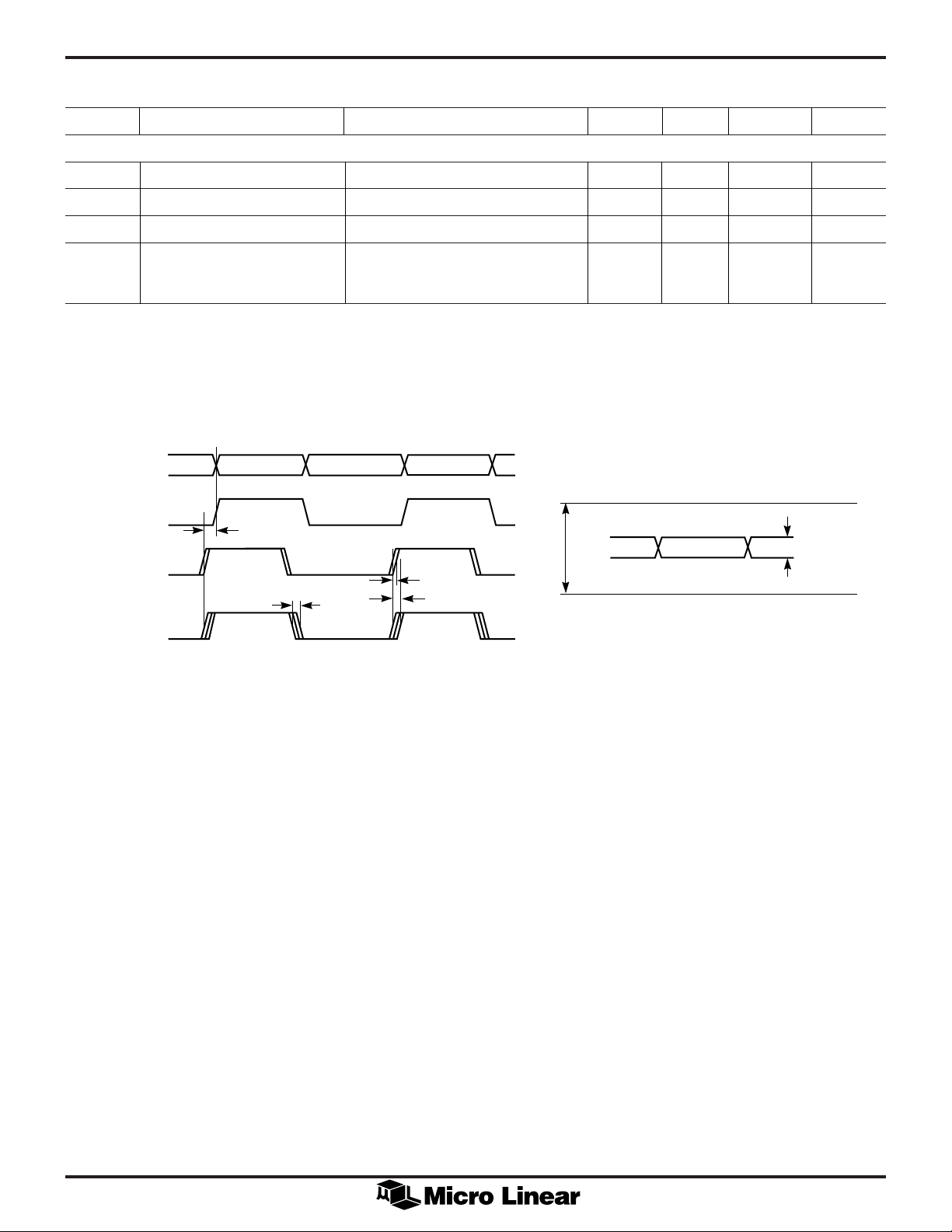

WRITE

SIGNAL

CLOCK AT

REMOTE CHIP

DATA AT

REMOTE CHIP

WRITE

SIGNAL

CLOCK AT

REMOTE CHIP

DATA AT

REMOTE CHIP

DATA

DATA

t

S

t

H

FUNCTIONAL DESCRIPTION

Micro Linear’s ML6510 is the first clock chip to use a

feedback mechanism to adaptively (on a real time basis),

eliminate clock skew in high speed personal computer

and workstation system designs. Figure 1 shows a basic

configuration of the ML6510 in a system. The skew

problem results due to the delaying of clock signals in the

system, as shown in Figure 2. Clock skew results from

variation in factors like trace length, PCB trace

characteristics, load capacitance, parasitic capacitance,

temperature and supply variations, etc. Figure 2 shows a

representation of the clock skew problem from a timing

perspective. It shows a worst case example where the

clock signal is delayed so much that its rising edge

completely misses the data it is intended to strobe.

Using a clock deskew mechanism, this problem can be

eliminated and the strobe with the appropriate setup and

hold times with respect to the data bus can be generated.

The ML6510 has eight deskew buffers, each with its own

independent the reflection and error correction circuit.

The deskew buffer eliminates skew by using the reflection

from a remote chip to measure the clock error and then

corrects it by generating the appropriate skew to the clock

output to compensate.

Eight individually deskewed copies of the clock are

provided by the ML6510.

The deskew buffers compensate internally for board-level

skew caused by the PCB trace length variations and

device load variations. This is accomplished by sensing

the round trip delay via a reflected signal, and then

delaying or advancing the clock edge so that all 8 output

clocks arrive at their loads in phase. Each of the eight

clock lines can have any length PCB trace (up to 5ns each

way or 1/4th of the output clock period, whichever is

smaller) and the device loads can vary from line to line.

The ML6510 will automatically compensate for these

variations, keeping the device load clocks in phase.

Although ML6510 will compensate for skew caused by

loading, excessive capacitive loading can cause rise/fall

time degradation at the load. Cascading one ML6510 to

another ML6510 should be done using the PECL reference

clock outputs, to minimize part-to-part skew.

CLOCK REGENERATION

The programmable adaptive clock deskew can function in

a clock regeneration mode to assist in building clock trees

or to expand the number of deskewed clock lines. In this

mode, it has the ability to do clock multiplication or

division as well, while maintaining low skew between

Figure 1. Basic System Configuration Using the ML6510.

CLOCK

GENERATOR

CLOCK IN

MICRO LINEAR

ML6510

CLOCK CHIP

CPU

CLOCK #0

FEEDBACK #0

CLOCK #1

FEEDBACK #1

CLOCK #7

FEEDBACK #7

DATA

REMOTE

CHIP

Figure 2. The Skew Problem.

8

Page 9

CLK

CLK

INH

INL

ECL INPUT BUFFER

TTL TO ECL

1

0

CS BIT

÷(M + 1)

[÷1 TO 64]

PHASE

DETECTOR

LOOP

FILTER

VCO

80-160 MHz

MAXIMUM

R

÷2

DELAY

ML6510

RCLKH

RCLKL

÷(N + 1)

[÷1 TO ÷128]

Figure 3. ML6510 Clock Generation Block Diagram.

input clock and output clocks. It can thus generate a 2x or

4x or 0.5x frequency multiplication or division from input

to output (e.g. 33 MHz input, 66 MHz output or 66 MHz

input, 33 MHz output, etc.). It also can generate a 1x

frequency output. The VCO frequency is defined by:

R

+

×

12

M

+

1

ff

=×

VCO REF

N

()

()

and the output frequency is still given by:

f

= f

OUT

R1 R0 INPUT/OUTPUT RANGE

0 0 80-130 MHz

0 1 40–80 MHz

1 0 20–40 MHz

1 1 10–20 MHz

Note: R implies R1, R0; for -80 version, Not valid: Defaults to R = 01

VCO

/2

R

The VCO still must remain in the range 80–160 MHz, and

the minimum phase detector input frequency is 625kHz =

(80 MHz/128). Thus the product of (N + 1) and 2R should

be limited to 128:

(N + 1) x 2

R

≤ 128 to make sure that the

phase detector inputs

remain above the minimum

frequency.

1

0

1

CM BIT

0

SYS_CLK

TO DESKEW BUFFERS

TEST

Example: Generating a 2x clock input frequency = 33 MHz

Set R = 01 (output range 40 – 80 MHz), N = 5 (0000101),

M = 2 (000010), M/S = 0

R

×

+

12

+

M

1

MHz MHz

=×

33

×

62

3

/2R = 132 MHz/21 = 66 MHz

1

132

=

ff

=×

VCO REF

f

= f

OUT

N

()

()

VCO

Example: Generating a 1x clock Input frequency = 66 MHz

Set R = 01 (output range 40–80 MHz), set M = 0

(000000), N = 0 (0000000), M/S = 0

1

12

×

=66

f MHz MHz

f

OUT

=×

VCO

= f

/2R = 132 MHz/21 = 66 MHz

VCO

1

132

For doing frequency multiplication and division, keep

M ≥ 2 and N ≥ 2 for the lowest skew between input

clock and output clock. Several configurations for doing

frequency multiplication and division are included in the

8 configurations stored in the on-chip ROM (see

PROGRAMMING the ML6510).

9

Page 10

ML6510

ADAPTIVE DESKEW BUFFERS

Each copy of the clock is driven by an adaptive deskew

buffer. The deskew buffer compensates for skew time

automatically in accordance to the flight time delay it

senses from the reflection on the transmission line.

Figure 4 shows the simplified functional block diagram of

the deskew circuit. The phase of the sense signal and the

driver signal is presented to a three-input phase

comparator and compared with the reference signal. The

phase comparator then controls the voltage controlled

delay in the output drive line to match the delay of the

fixed reference delay line. Therefore, the sum of the delay

of the driver circuit, PCB trace delay, rise time delay at the

load and the adjustable delay will always equal the fixed

maximum delay.

The sense circuit has an internal level detect such that any

skew caused by loading is also accounted for. Since the

delay of the circuit is matched for the entire loop, the

phase of all the drivers are in close alignment at the inputs

of the load.

FIXED

CLOCK IN

MAX

DELAY

LOAD CONDITIONS

The ML6510 has been designed to drive the wide range of

load conditions that are encountered in a high frequency

system. The eight output clock loads can each vary within a

range of trace length and lumped capacitive load, and the

ML6510 will maintain the low skew characteristics specified

in Electrical Characteristics. The clock skew can be further

minimized by providing some first-order matching

between any two loads that require particularly wellmatched clocks.

The ML6510-80 produces a 5V swing at the load and

requires a single external termination resistor for each

output. The ML6510-130 produces a 3V swing at the load

and requires two external termination resistors for each

output. The FB input pin is connected to the other side of

the termination resistor R1 or R2, with a short connection.

Termination resistor valves should be chosen as follows:

RZ R Z R Z121533

==×=×.

000

TRACE RESISTOR

IMPEDANCE VALUES

Z0 R1 R2 R3

40Ω 40 60 120

50Ω 50 75 150

63Ω 63 95 189

PHASE

DETECTOR

VOLTAGE

CONTROLLED

DELAY

SENSE

DRIVE

Figure 4. Deskew Circuit Block Diagram.

LOAD

10

Page 11

ML6510

CHIP

VCC

RESET

LOCK

t

RESET

t

LOCK

t

LOCK

PROGRAM IN THE

CONFIGURATION

PROGRAM IN THE

CONFIGURATION

0

5V

ML6510-80

GENERIC

ML6510-80

FIRST-ORDER

MATCHED LOADS

LOAD

FBX

CLKX

FBX

CLKX

FBY

CLKY

PCB trace impedance

Z0 = 40Ω to 65Ω

R1

One way trip delay < t

PCB trace impedance

Z0 = 40Ω to 65Ω

R1

Length L

PCB trace impedance

Z0 = 40Ω to 65Ω

R1

Length L

One way trip delay < t

RANGE

X

Y

RANGE

LOAD

Lumped

CL ≤ 20pF

/2

LOAD

Lumped

C

LX

|CLX – CLY| < 5pF

|L

– LY| < 4"

X

Z

= Z

OX

OY

LOAD

Lumped

C

LY

/2

≤ 20pF

≤ 20pF

ML6510-130

GENERIC

ML6510-130

FIRST-ORDER

MATCHED LOADS

LOAD

FBX

CLKX

FBX

CLKX

FBY

CLKY

PCB trace impedance

Z0 = 40Ω to 65Ω

R2

R3

One way trip delay < t

PCB trace impedance

Z0 = 40Ω to 65Ω

R2

R3

PCB trace impedance

Z0 = 40Ω to 65Ω

R2

R3

One way trip delay < t

Length L

Length L

X

Y

RANGE

LOAD

Lumped

CL ≤ 20pF

/2

RANGE

LOAD

Lumped

C

LX

|CLX – CLY| < 5pF

|L

– LY| < 4"

X

Z

= Z

OX

OY

LOAD

Lumped

C

LY

/2

≤ 20pF

≤ 20pF

EXTERNAL INPUT CLOCKS

The external input clock to the ML6510 can be either a

differential Pseudo-ECL clock or a single-ended TTL clock.

This is selected using the CS bit in the serial shift register.

For the single-ended TTL clock tie the CLK

and CLK

INH

INL

pins together. The ML6510 ensures that there is a welldefined phase difference between the input and output

clocks.

RESET AND LOCK

When RESET is de-asserted, the internal programming

logic will become active, loading in the configuration bits

(see Programming the ML6510). Once the configuration is

loaded, the PLL will lock onto the reference signal, and

then the deskew blocks will adapt to the load conditions.

When all eight output clocks are stable and deskewed,

LOCK will be asserted. The asserted polarity of lock is

high. Thus, LOCK can be used to indicate that the system

is ready, or it can be used to drive the RESET input of

another PACMan in a clock tree.

RESET may be reasserted at any time to reset the chip

operations. Following a RESET assertion of valid pulse

width (see Programming Electrical Characteristics), the

ML6510 must again be loaded with a configuration, then

it will re-lock and reassert lock when all eight clock

outputs are stable and deskewed.

11

Page 12

ML6510

PROGRAMMING THE ML6510

The configuration of the ML6510 is programmed by

loading 18 (ML6510-80) or 19 (ML6510-130) bits into the

configuration shift register. To load these bits, the user has

3 options: MAIN, AUX or ROM modes. Which mode is

used is determined by the logic level on the MDIN pin

when RESET is deasserted. If MDIN is tied high, the

ML6510 will assume AUX mode; if its tied low, ROM

mode. If MDIN is high-impedance (i.e. tied to the input of

an EEPROM), it will assume MAIN mode.

1. MAIN Mode

In this mode, the ML6510 will read the configuration bits

from an external serial EEPROM, such as the 93C46, using

the industry standard 3-wire serial I/O protocol. The serial

EEPROM should be a 1K organized in 64 x 16 bits and the

PACMan will read the configuration bits out of the two least

significant 16-bit words. To use this mode, simply connect

the EEPROM serial data input pin to MDIN (ML6510 pin 19),

the EEPROM serial data output pin to MD

20), and the EEPROM serial data clock pin to MCLK

(ML6510 pin 21) and CS pin for the EEPROM should be tied

to the RESET signal. After power up, when RESET is

deasserted, the ML6510 will automatically generate the

address and clock to read out the configuration bits. Refer

MAIN Mode waveform in Figure 5.

1K SERIAL

EEPROM

(64 X 16 BIT)

CLOCK

OPCODES

ADDRESS

DATA

RESET

CS

CLK

DATA IN

DATA OUT

MAIN Mode Configuration.

(ML6510 pin

OUT

ML6510

ROMMSB

MCLK

MD

IN

MD

OUT

RESET

2. AUX Mode

When MDIN is tied to VCC, programming the ML6510

will occur via the AUX Mode. This mode shifts the

configuration bits into the shift register directly from the

MD

pin. The first 18 (ML6510-80) or 19 (ML6510-

OUT

130) clock rising edges provided externally on the MCLK

pin after RESET is deasserted will be used to load the shift

register data, which should be provided on the MD

OUT

pin. See figure 6.

µ PROCESSOR

CLOCK

VCC

DATA

ML6510

ROMMSB

MCLK

MD

IN

MD

OUT

AUX Mode Configuration.

3. ROM Mode

When MDIN is tied to GND, programming the ML6510

will occur via the ROM Mode. This mode reads the

configuration bits directly from an on chip ROM. The

selection of one of the eight preset configuration codes is

accomplished by means of the pins ROMMSB, MCLK and

MD

as shown in Tables 1 and 2. The TEST mode

OUT

configuration (code 7) is enabled when the TEST bit is set.

In this mode the PLL is bypassed for low frequency testing.

Codes 0-2 are used when the ML6510 clock inputs are

driven from another PACMan’s reference clock outputs.

Code 3 is used when zero phase error is desired between

input and load clocks.

ML6510

ROM

ADDRESS

BITS

ROMMSB

MCLK

MD

OUT

MDIN

ROM

8 X 19 BIT

TO SHIFT REGISTER

SERIAL DATA IN

(Driven by

(Driven by

(Driven by

12

MCLK

ML6510)

MD

ML6510)

MD

OUT

EEPROM)

t

M1

01 02 03 04 05 06 07 08 09 10 11 12 • • • 25

IN

SB1OP1

1

t

M2

A50A40A30A20A10A0

OP0

0

t

M3

0

t

M4

ROM Mode Configuration.

D13 D15 D14

16 bits data at adddress 0

Figure 5. MAIN Mode Waveforms.

26 2713

• • •D15 D14

D0

2 bits at address 1

(3 bits for ML6510-130)

(28)

(D13)

Page 13

ML6510

TABLE 1: ML6510-80 ROM CODES

SELECTION BITS INPUT OUTPUT CONFIGURATION CODE

FREQ FREQ

CODE DESCRIPTION ROMMSB MCLK MD

0 PECL Input Clock, 1x mode 0 0 0 40-80 40-80 1 1 01 0 0 0

1 PECL Input Clock, 0.5x mode 0 0 1 40-80 20-40 1 1 10 5 2 0

2 PECL Input Clock, 2x mode 0 1 0 20-40 40-80 1 1 01 2 5 0

3 PECL Input Clock, 1x mode 0 1 1 40-80 40-80 1 0 01 0 0 0

4 TTL Input Clock, 1x mode 1 0 0 40-80 40-80 0 0 01 0 0 0

5 TTL Input Clock, 0.5x mode 1 0 1 40-80 20-40 0 0 10 5 2 0

6 TTL Input Clock, 2x mode 1 1 0 20-40 40-80 0 0 01 2 5 0

7 TEST mode, TTL Input clock 1 1 1 0-50 0-50 0 — — — — 1

TABLE 2: ML6510-130 ROM CODES

SELECTION BITS INPUT OUTPUT CONFIGURATION CODE

CODE DESCRIPTION ROMMSB MCLK MD

0 PECL Input Clock, 1x mode 0 0 0 80-130 80-130 1 1 00 0 0 0 0

1 PECL Input Clock, 0.5x mode 0 0 1 80-160 40-80 1 1 01 5 2 0 0

2 PECL Input Clock, 2x mode 0 1 0 40-65 80-130 1 1 00 2 5 0 0

3 PECL Input Clock, 1x mode 0 1 1 80-130 80-130 1 0 00 0 0 0 0

4 TTL Input Clock, 1x mode 1 0 0 80-130 80-130 0 0 00 0 0 0 0

5 TTL Input Clock, 0.5x mode 1 0 1 80-130 40-65 0 0 01 5 2 0 0

6 TTL Input Clock, 2x mode 1 1 0 40-65 80-130 0 0 00 2 5 0 0

7 TEST mode, TTL Input clock 1 1 1 0-50 0-50 0 — — — — — 1

(MHz) (MHz) CS CM R1, R0 M N TEST

OUT

FREQ FREQ

(MHz) (MHz) CS CM R1, R0 M N DDSK TEST

OUT

MCLK

(Input to ML6510)

MD

OUT

(Input to ML6510)

t

A2

M5 N0

t

A3

t

A1

t

A4

M4

t

A5

Figure 6. AUX Mode Waveform.

180201

13

Page 14

ML6510

REGISTER DEFINITIONS

REGISTER SIZE FUNCTION

N 7 bit This register is used to define the ratio for the desired frequency of the primary clock.

R 2 bit This register defines the frequency of the primary clocks, CLK [0-7].

CM 1 bit Set CM = 1 when the PECL input reference clock is from another 6510 reference clock output. Set

CM = 0 if the clock reference is TTL or PECL from an external source and minimum phase error

between input and output is desired.

CS 1 bit CS = 0 selects TTL input clock, CS = 1 selects PECL input clock.

TEST 1 bit When set to 1, the PLL is bypassed for low frequency testing.

M 6 bit This register is used to define the ratio for the desired frequency of the primary clock.

DDSK 1 bit When DDSK is set to 1, deskew is disabled. The chip will provide low skew clocks at the chip output

pins, but trace length variations will not be compensated. When DDSK is set to 0, normal deskew will

provide low skew clocks at the loads. This bit is only for ML6510-130.

ML6510-80 SHIFT REGISTER CHAIN

CM

CS M0

TEST M1 M2 M3 M4 M5

LSB

MSB

SERIAL DATA IN

(from EEPROM,

or µProcessor,

or internal ROM)

N1 N2 N3 N4 N5 N6

N0

LSB

MSBR0LSBR1MSB

ML6510-130 SHIFT REGISTER CHAIN

N1 N2 N3 N4 N5 N6

N0

SERIAL DATA IN

(from EEPROM,

or µProcessor,

or internal ROM)

LSB

MSBR0LSBR1MSB

DDSK

CM

CS M0

TEST M1 M2 M3 M4 M5

LSB

MSB

14

Page 15

APPLICATIONS

ML6510

ML6510

(SLAVE MODE)

ML6510

ZERO SKEW CLOCK GENERATION

The most advantageous feature of using PACMan is its

ability to deliver multiple copies of the clock to the load

with very low skew. Because of its unique ability in

deskewing, trace length and load consideration are no

longer critical in board design.

Because of the unique deskewing scheme, neither the

trace length nor the device loads need to be equal. This is

true for loads, <20pF. Higher loads can be driven if they

are placed close to the clock chip, to guarantee signal

integrity.

CLOCK

DRIVER

tO–tS1

1

t

tO–tS2

t

O–tS

t

2

S

3

t

3

S

ONE

DEVICE

LOAD

0t

t

S

TWO

DEVICE

LOAD

S

0t

S

THREE

DEVICE

LOAD

0

S

LOW SKEW CLOCK DISTRIBUTION

Clock distribution design is usually not a trivial task,

especially when multiple clock chips are needed. By

using closely grouped PACMans, 16 or more clock lines

can be created with low part-to-part skew. Additional

groups of clocks can be clustered and driven from

deskewed clock lines, to minimize the number of longdistance clock lines.

ML6510

ML6510

CLK0

CLK1

CLK2

• • • • • •

CLK0

CLK1

CLK2

ML6510

TO REMOTE GROUP

OF CLUSTERED LOADS

CLK0

CLK1

CLK2

CLK3

• • •

BOARD TO BOARD SYNCHRONIZATION

Distribution of the synchronous clock could present

significant difficulty at high frequency. With the system

clock generated by the ML6510, a zero skew clock

delivery to a backplane is now possible. By using the

ML6510 slave chip or the ML6510 in slave mode at the

receiver end, a near zero delay clock link can be

accomplished between the mother board and the satellite

boards.

Because the PACMan has frequency doubling capability, a

lower frequency signal can be used to route across a back

plane.

EXAMPLE CONFIGURATION

Shown in Figure 7 is an example configuration using

two ML6510-80 chips in tandem to generate eight 66

MHz clocks and eight 33MHz low-skew clocks from a

66MHz input reference. This requires only the termination

resistors. Configurations are loaded from the internal

ROM. PCB traces 0 to 15 are each 50Ω impedance and

the load capacitances CL0-C

are 0 to 20pF each. No

L15

trace length matching is required among separate clock

outputs. All traces are shown with a series termination at

the output. If ML6510-130’s are used in a master slave

mode the maximum operating frequency will be 120MHz.

t

pp2

LOAD[0-7]

LOAD[8-15]

33 MHz

t

SKEWR

t

SKEWR

(or t

(or t

SKEWB

SKEWB

)

)

15

Page 16

ML6510

SYSTEM RESET LOW

VCC

66MHz

TTL REFERENCE

RESET

ROMMSB

MCLK

MD

IN

MD

OUT

CLK

INH

CLK

INL

LOCK

ML6510-80

TTL 1X

MODE

RCLKH RCLKL

66MHz

CLK

INH

CLK

INL

CLK0

FB0

CLK1

FB1

CLK7

FB7

CLK0

50

50

50

50

PCB TRACE 0

PCB TRACE 1

PCB TRACE 7

PCB TRACE 8

LOAD7

LOAD0

66 MHz

C

L7

LOAD8

66 MHz

C

L0

LOAD1

33 MHz

66 MHz

C

L1

RESET

ROMMSB

MCLK

MD

VCC

MD

ALL_CLOCK_READY

IN

OUT

LOCK

ML6510-80

PECL 0.5X

MODE

FB0

CLK1

FB1

CLK7

FB7

50

50

PCB TRACE 9

PCB TRACE 15

LOAD15

33 MHz

C

L15

C

L8

LOAD9

33 MHz

C

L9

16

Figure 7. Example use of two ML6510-80 to generate multiple frequency clocks.

First ML6510-80 generates eight 66MHz clocks while second ML6510-80 takes 66MHz

small-swing reference from the first chip and generates eight 33MHz clocks.

Page 17

ML6510

PHYSICAL DIMENSIONS inches (millimeters)

0.685 - 0.695

(17.40 - 17.65)

0.650 - 0.656

(16.51 - 16.66)

1

Package: Q44

44-Pin PLCC

0.042 - 0.056

(1.07 - 1.42)

0.025 - 0.045

(0.63 - 1.14)

(RADIUS)

0.042 - 0.048

(1.07 - 1.22)

12

0.050 BSC

(1.27 BSC)

0.013 - 0.021

(0.33 - 0.53)

PIN 1 ID

23

0.026 - 0.032

(0.66 - 0.81)

34

0.165 - 0.180

(4.06 - 4.57)

SEATING PLANE

0.650 - 0.656

(16.51 - 16.66)

0.148 - 0.156

(3.76 - 3.96)

0.685 - 0.695

(17.40 - 17.65)

0.009 - 0.011

(0.23 - 0.28)

0.100 - 0.112

(2.54 - 2.84)

0.500 BSC

(12.70 BSC)

0.590 - 0.630

(14.99 - 16.00)

18

Page 18

ML6510

ORDERING INFORMATION

PART NUMBER TEMPERATURE RANGE PACKAGE

ML6510CQ-80 0°C to 70°C 44-pin PLCC (Q44)

ML6510CQ-1300°C to 70°C44-pin PLCC (Q44) (Obsolete)

© Micro Linear 1997 is a registered trademark of Micro Linear Corporation

Products described in this document may be covered by one or more of the following patents, U.S.: 4,897,611; 4,964,026; 5,027,116; 5,281,862; 5,283,483; 5,418,502; 5,508,570; 5,510,727; 5,523,940;

5,546,017; 5,559,470; 5,565,761; 5,592,128; 5,594,376; Japan: 2598946. Other patents are pending.

Micro Linear reserves the right to make changes to any product herein to improve reliability, function or design.

Micro Linear does not assume any liability arising out of the application or use of any product described herein,

neither does it convey any license under its patent right nor the rights of others. The circuits contained in this

data sheet are offered as possible applications only. Micro Linear makes no warranties or representations as to

whether the illustrated circuits infringe any intellectual property rights of others, and will accept no responsibility

or liability for use of any application herein. The customer is urged to consult with appropriate legal counsel

before deciding on a particular application.

18

2092 Concourse Drive

San Jose, CA 95131

Tel: 408/433-5200

Fax: 408/432-0295

DS6510-01

Loading...

Loading...