Page 1

July 1999

PRELIMINARY

ML6440*

Multi-Standard 8-bit Adaptive Digital Input Comb Filter

GENERAL DESCRIPTION

The ML6440 SmartComb™ is a single-chip, 8-bit digital

comb filter that incorporates line delays and adaption

algorithms for NTSC and PAL at both CCIR601 and square

pixel rates. The ML6440 implements bandsplit filters and

a proprietary adaption and decision logic block that

allows for optimum combing over a wide range of video

sources.

The ML6440 contains all the necessary circuitry to provide

high quality combed output of luminance and

chrominance in the Y/C format. Internal filters with

integrated adaption and compensation circuits provide

filtered outputs with optimal video bandwidth and

resolution while suppressing cross-color (rainbow), crossluminance (dot crawl) and other corrupting artifacts that

can reduce video compression efficiency.

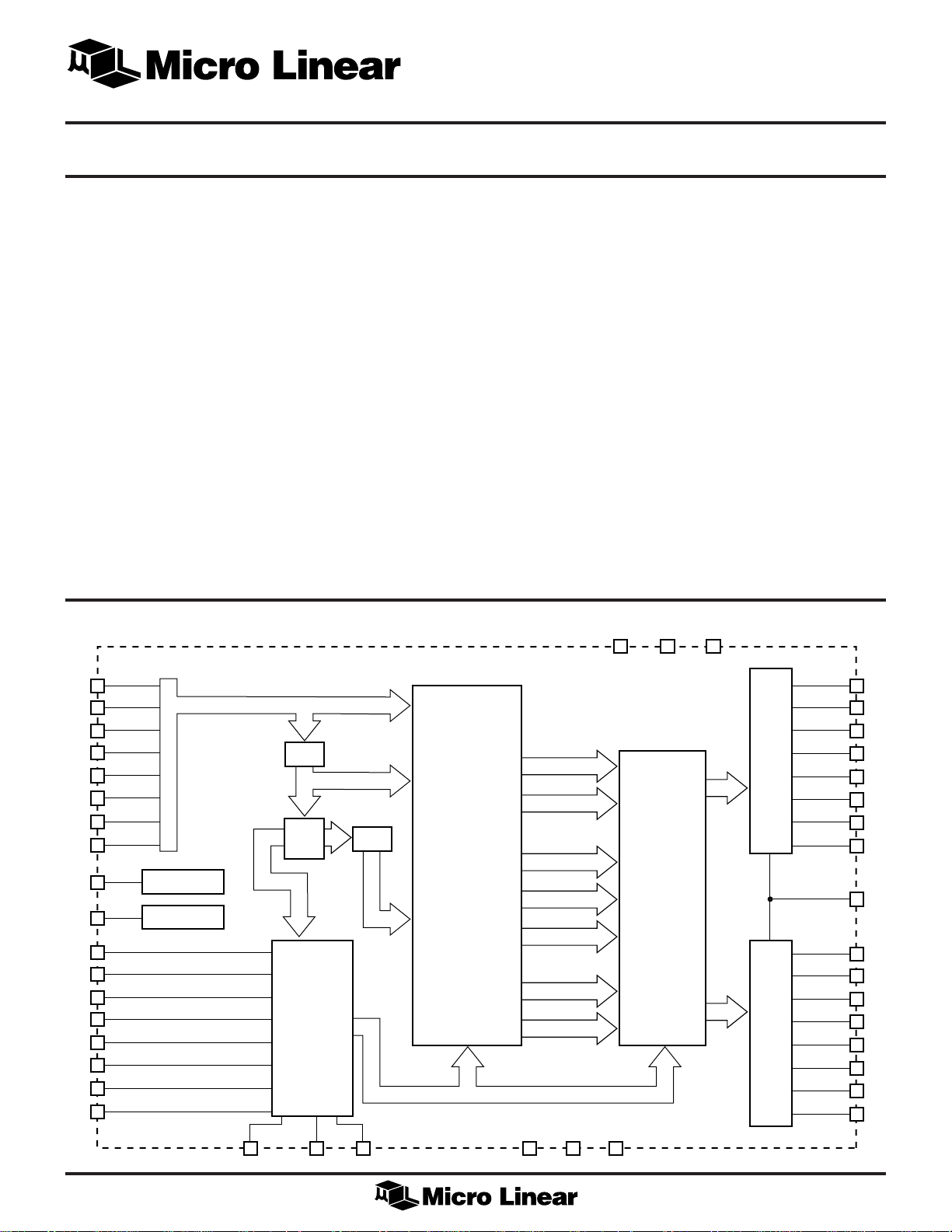

BLOCK DIAGRAM

YI0/CV0

18

19

20

21

22

23

24

25

7

6

8

9

10

11

12

13

14

15

YI1/CV1

YI2/CV2

YI3/CV3

YI4/CV4

YI5/CV5

YI6/CV6

YI7/CV7

CLK

RST

CI0/DI0

CI1/DI1

CI2/DI2

CI3/DI3

CI4/DI4

CI5/DI5

CI6/DI6

CI7/DI7

CLOCK BUFFER

DIGITAL

RESET LOGIC

PAL/NTSC MODE

CCIR601/SQ. PIXEL MODE

COMB MODE 0

COMB MODE 1

THRESHOLD CONTROL 0

THRESHOLD CONTROL 1

THRESHOLD CONTROL 2

Y+C/CV INPUT MODE

S/P

1HDL

D0

D1

D2

D3

D4

D5

D6

D7

S DATA

MUX

FILTER

AND

COMB

CONTROL

S CLK

LUMA BYPASS

1HDL

CONTROL

292826

BANDSPLIT

(NOTCH/DELAY)

FILTERS

FEATURES

■ SmartComb algorithm for automatic or manual

selection adaption thresholds

■ 3-line comb with 60+ line frame adjust

■ Comb/notch thresholds set dynamically over 60+ lines

automatically

■ 12-bit processing minimizes truncation errors and

maintains signal-to-noise performance

■ Optional 8-bit composite or separated Y/C digital inputs

■ Applications: digital TV, line doubler, imaging

■ Separate comb/notch filter thresholds for Luma and

Chroma channels

■ Optional pin controls or two-wire serial control

interface

■ Operating power dissipation less than 700mW

■ No external components, except diode and caps

* This Part Is End Of Life As Of August 1, 2000

39 16

V

CC

CC

CHROMA

BYPASS

DIGITAL

Y7

Y6

Y5

Y4

Y3

LUMINANCE

OUTPUT BUFFER

CHROMINANCE

OUTPUT BUFFER

Y2

Y1

Y0

OE

DIGITAL

C7

C6

C5

C4

C3

C2

C1

C0

30

31

32

33

34

35

36

37

27

40

41

42

43

44

1

2

3

V

HIGH BAND

LOW BAND

HIGH BAND

LOW BAND

TOTAL BAND

HIGH BAND

LOW BAND

GND GND GND

38174

5

AV

CC

SmartComb™

COMB

ADAPTION

AND

DECISION

LOGIC

1

Page 2

ML6440

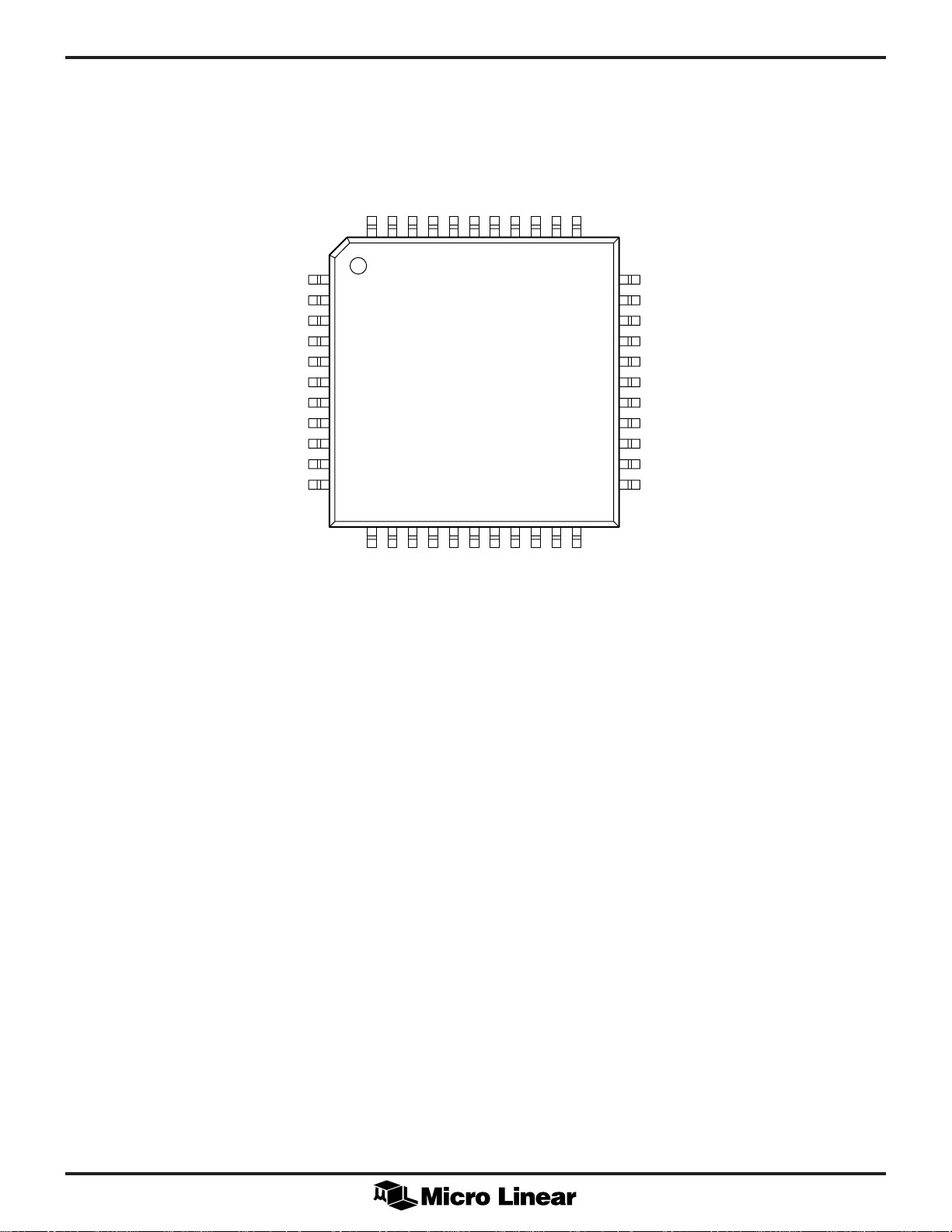

PIN CONFIGURATION

ML6440

44-Pin TQFP (H44-14)

C2

C1

C0

GND

V

CC

RST

CLK

CI0/DI0

CI1/DI1

CI2/DI2

CI3/DI3

C3C4C5C6C7

44 43 42 41 40

44 43 42 41 40

1

1

2

2

3

3

4

4

5

5

6

6

7

7

8

8

9

9

10

10

11

11

12 13 14 15 16

12 13 14 15 16 17 18 19 20 21 22

CI4/DI4

CI5/DI5

CI6/DI6

VCCGNDY0Y1Y2Y3

39 38 37 36 35 34

39 381937203621352234

17 18

CC

GND

AV

CI7/DI7

YI0/CV0

YI1/CV1

TOP VIEW

YI2/CV2

YI3/CV3

33

33

32

32

31

31

30

30

29

29

28

28

27

27

26

26

25

25

24

24

23

23

YI4/CV4

Y4

Y5

Y6

Y7

S CLK

S DATA

OE

S/P

YI7/CV7

YI6/CV6

YI5/CV5

2

Page 3

PIN DESCRIPTION

ML6440

PIN NAME FUNCTION

1 C2 Chrominance output

2 C1 Chrominance output

3 C0 Chrominance output

4 GND Digital ground pin

5V

6 RST Reset input active low. Resets comb

7 CLK TTL compatible clock reference

8 CI0/DI0 (LSB) Input Chrominance signal (PAL/

9 CI1/DI1 Input Chrominance signal (Square

10 CI2/DI2 Input Chrominance signal. (Comb

11 CI3/DI3 Input Chrominance signal (Comb

CC

Digital supply pin

logic including the internal data

register. Required at power up.

NTSC control pin in control pin mode:

register bit D0)

Pixel/CCIR control pin in control pin

mode: register bit D1)

mode 0 control pin in control pin

mode: register bit D2)

mode 1 control pin in control pin

mode: register bit D3)

PIN NAME FUNCTION

20 YI2/CV2 Luma or composite video input signal

21 YI3/CV3 Luma or composite video input signal

22 YI4/CV4 Luma or composite video input signal

23 YI5/CV5 Luma or composite video input signal

24 YI6/CV6 Luma or composite video input signal

25 YI7/CV7 Luma or composite video (MSB) input

signal

26 S/P Serial/Parallel program mode. If high,

allows 8-bit parallel control using the

eight digital chrominance input pins.

Data clocks in on the positive edge

transition. If low, serial port active.

27 OE Output enable. (Y[7:0] and C[7:0]) If

low, outputs high impedance.

28 S DATA Serial data input

29 S CLK Serial clock input. Positive-edge

clocks.

30 Y7 TTL compatible luminance output

(MSB)

31 Y6 Luminance output

12 CI4/DI4 Input Chrominance signal (Adaption

Threshold 0 control pin in control pin

mode: register bit D4)

13 CI5/DI5 Input Chrominance signal (Adaption

Threshold 1 control pin mode: register

bit D5)

14 CI6/DI6 Input Chrominance signal (Adaption

Threshold 2 control pin mode: register

bit D6)

15 CI7/DI7 (MSB) Input Chrominance

(Y+C/YI control pin in control pin

mode: register bit D7)

16 AV

17 GND Ground pin for analog delay line

18 YI0/CV0 TTL compatible (LSB) Input composite

19 YI1/CV1 Luma or composite video input signal

CC

Analog supply pin. Bypass to ground

with 1µF ceramic capacitor

video signal or Y in the Y+C bypass

mode

32 Y5 Luminance output

33 Y4 Luminance output

34 Y3 Luminance output

35 Y2 Luminance output

36 Y1 Luminance output

37 Y0 Luminance output (LSB)

38 GND Digital ground pin

39 V

40 C7 TTL compatible chrominance output

41 C6 Chrominance output

42 C5 Chrominance output

43 C4 Chrominance output

44 C3 Chrominance output

CC

Digital supply pin

(LSB)

3

Page 4

ML6440

ABSOLUTE MAXIMUM RATINGS

Absolute maximum ratings are those values beyond which

the device could be permanently damaged. Absolute

maximum ratings are stress ratings only and functional

device operation is not implied.

VCC............................................................................. 7V

Junction Temperature ............................................. 150°C

Storage Temperature Range...................... –65°C to 150°C

Lead Temperature (Soldering, 10 sec) ..................... 260°C

Thermal Resistance (

qJA) ...................................... 67°C/W

OPERATING CONDITIONS

Analog & Digital I/O ............. GND – 0.3V to VCC + 0.3V

Input Current .......................................................... 20µA

Temperature Range ........................................ 0°C to 70°C

VCC Range ...............................................4.75V to 5.25V

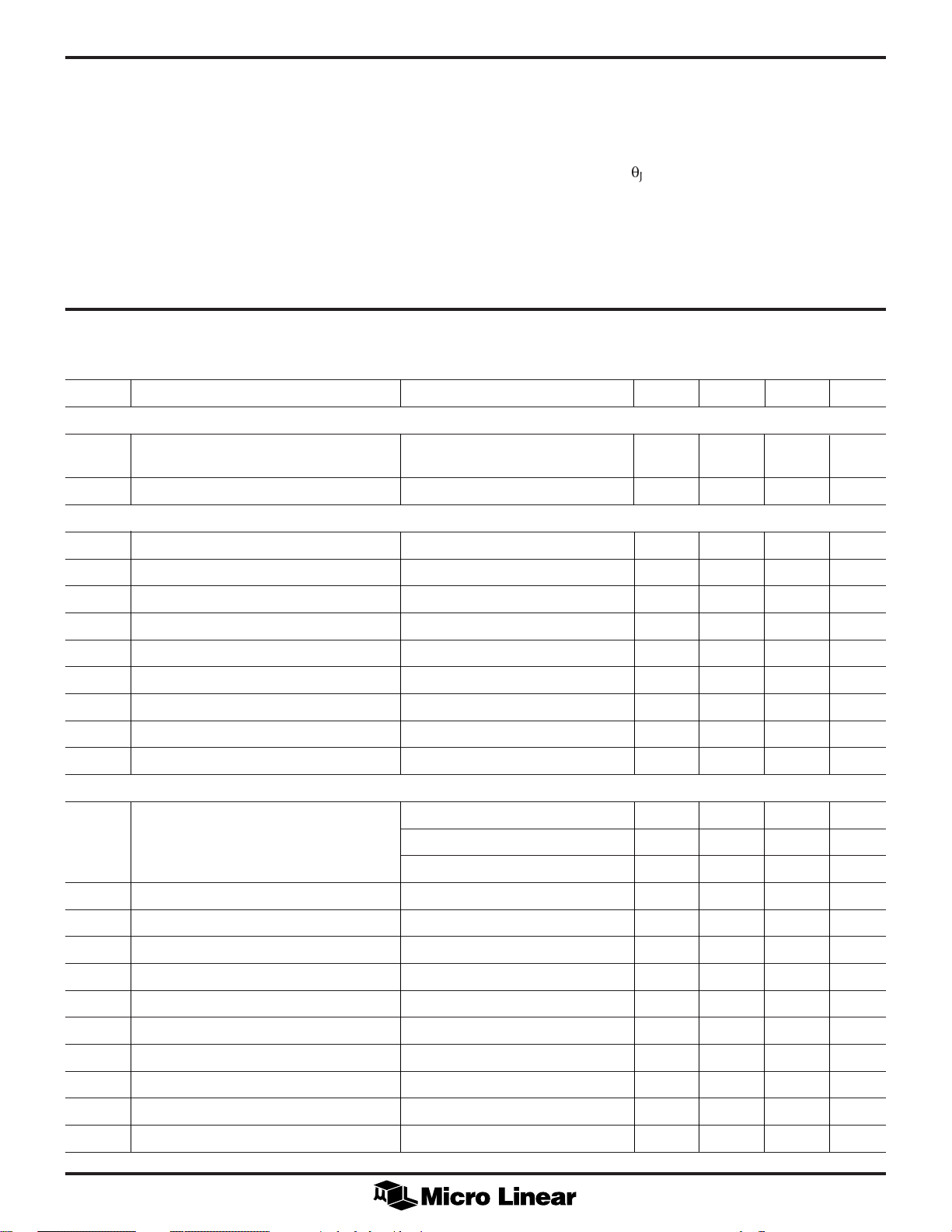

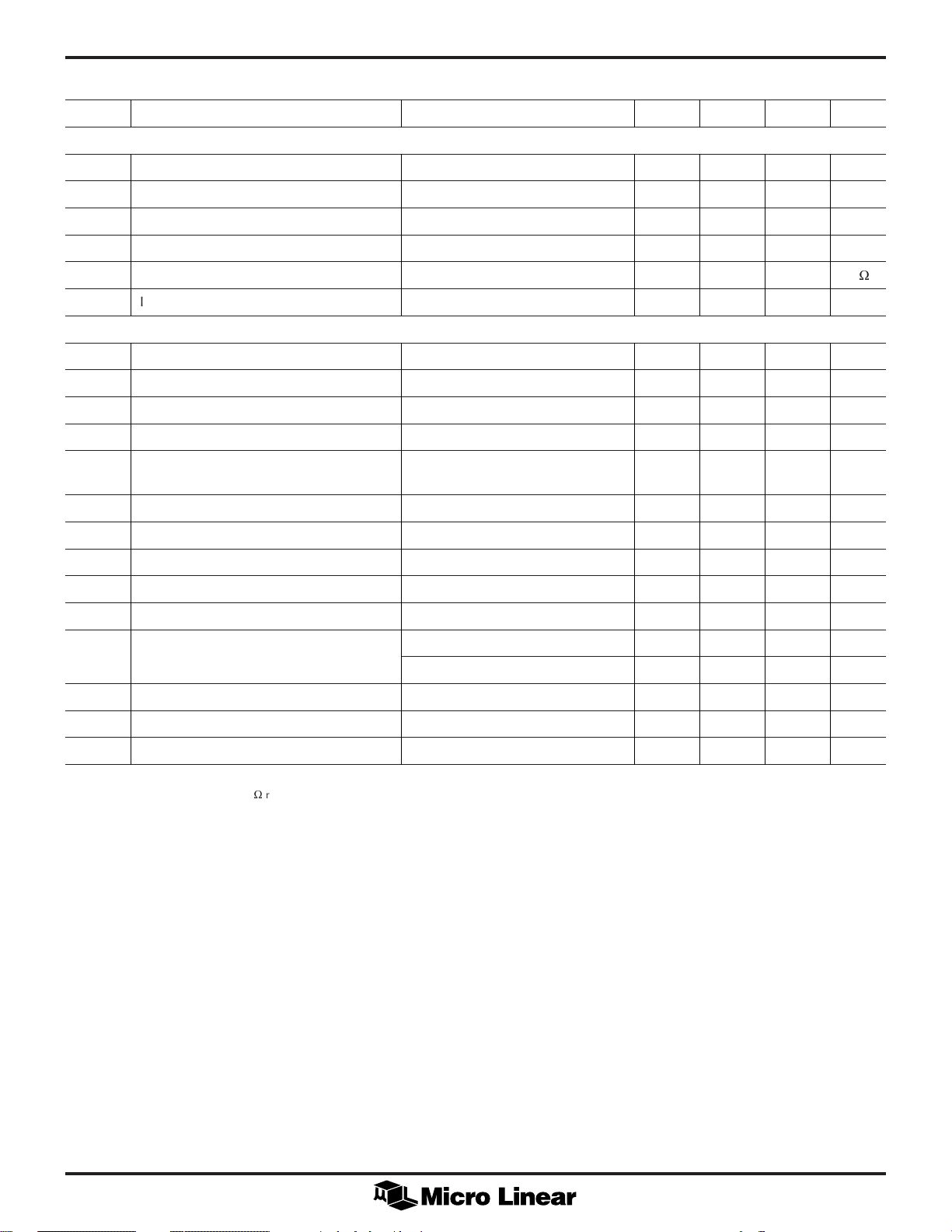

ELECTRICAL CHARACTERISTICS

Unless otherwise specified, VCC = 5V ±5%, CL = 50pF, TA = Operating Temperature Range (Notes 1, 2)

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

SUPPLY

I

CC

AV

LOGIC

V

V

I

I

C

V

V

Supply Current VCC=5.25V, CLK=14.75 MHz, 60 90 mA

PAL Square Pixel

Analog Supply Voltage Recommend Operation VCC–0.6 VCC–0.4 V

CC

Low Level Input Voltage 0.8 V

IL

High Level Input Voltage V

IH

Low Level Input Current 10 µA

IL

High Level Input Current 10 µA

IH

Input Capacitance 5pF

IN

Low Level Output Voltage IOL = –2mA 0.4 V

OL

High Level Output Voltage IOH = 2mA VCC – 1.0 V

OH

Output Current 3-state Mode 10 µA

– 1.5 V

CC

C

OUT

SYSTEM TIMING

f

CLK

t

SU

Output Capacitance 3-state Mode 5 pF

CLK Input Frequency Square Pixel PAL 14.75 MHz

Setup Time to Rising CLK Edge f

Clock Low Duration f

Clock High Duration f

Input Rise Time f

Input Fall Time f

Data Valid after Rising CLK Edge f

3-state Delay Time, Output Enable f

3-state Delay Time, Output Disable f

Output Rise time f

Output Fall time f

4

Square Pixel NTSC 12.70 MHz

CCIR601 13.50 MHz

= 14.75MHz 10 ns

CLK

= 14.75MHz 30 ns

CLK

= 14.75MHz 45 ns

CLK

= 14.75MHz, 10% to 90% 20 ns

CLK

= 14.75MHz, 90% to 10% 20 ns

CLK

= 14.75MHz 20 ns

CLK

= 14.75MHz 20 ns

CLK

= 14.75MHz 20 ns

CLK

= 14.75MHz, 10% to 90% 20 ns

CLK

= 14.75MHz, 90% to 10% 20 ns

CLK

Page 5

ML6440

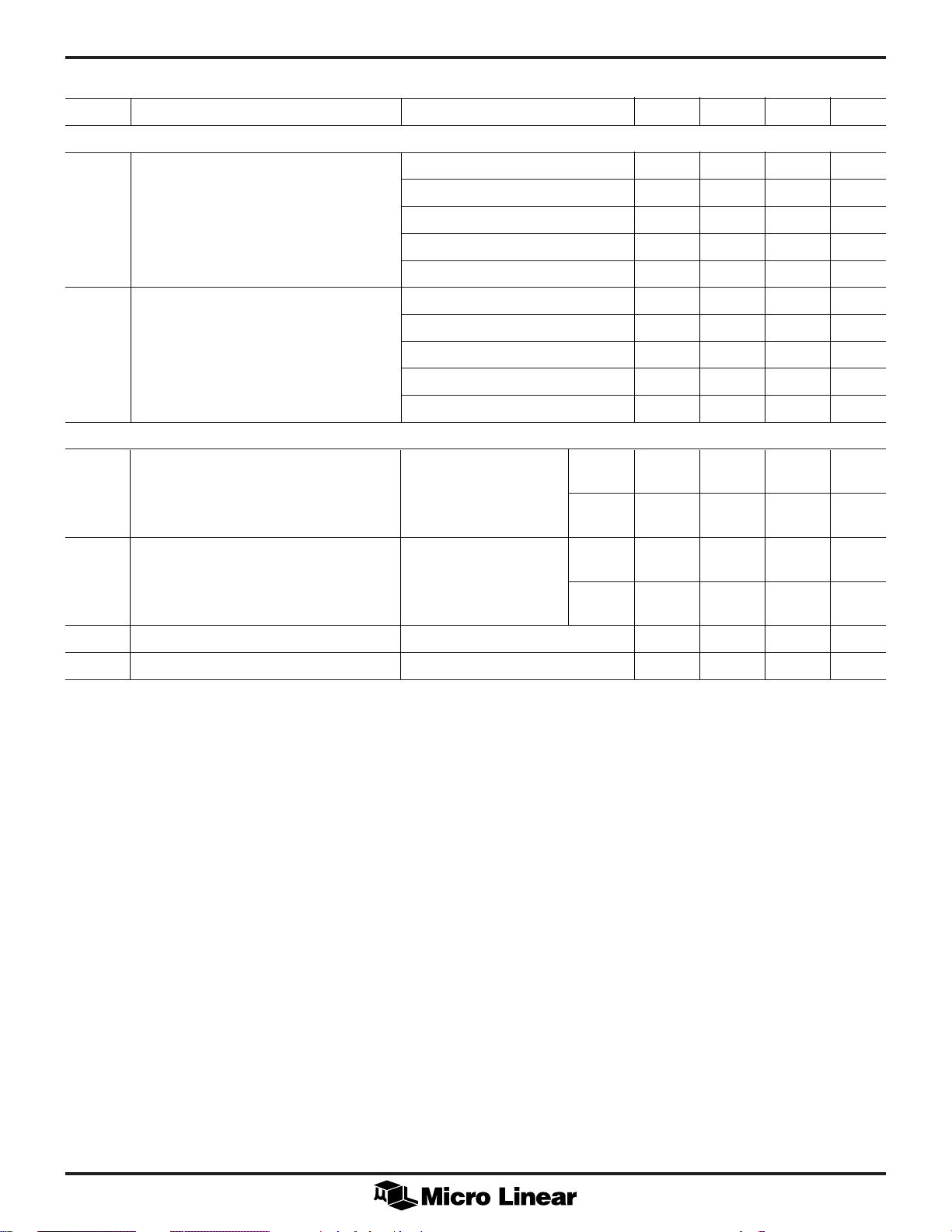

ELECTRICAL CHARACTERISTICS (Continued)

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

VIDEO SIGNAL PROCESSING

Effective Luminance Bandwidth NTSC/PAL, Comb On at –3dB (Note 3)

NTSC/CCIR601, Comb Off at –3dB 2.5 MHz

NTSC/Sq. Pixel , Comb Off at –3dB 2.5 MHz

PAL/CCIR601 , Comb Off at –3dB 2.5 MHz

PAL /Sq. Pixel, Comb Off at –3dB 2.5 MHz

Effective Chrominance Bandwidth NTSC/PAL, Comb On at –3dB (Note 3)

Centered at f

COMB FILTER CHARACTERISTICS

SNR

SNR

Signal to Noise Ratio, Chrominance Spurious Luma Artifact NTSC 48 dB

C

Signal to Noise Ratio, Luminance Spurious Subcarrier NTSC 48 dB

L

Comb Notch Depth at f

Comb Notch Bandwidth at –30dB 500 kHz

SC

SC

NTSC/CCIR601, Comb Off at –3dB 1.0 MHz

NTSC/Sq. Pixel, Comb Off at –3dB 1.0 MHz

PAL/CCIR601, Comb Off at –3dB 1.0 MHz

PAL /Sq. Pixel, Comb Off at –3dB 1.0 MHz

13.5MHz

PAL 45 dB

12.27MHz

Artifact 13.5MHz

PAL 45 dB

12.27MHz

NTSC/PAL –35 dB

5

Page 6

ML6440

ELECTRICAL CHARACTERISTICS (Continued)

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

SERIAL BUS LOGIC INPUT

Low Level Input Voltage 0 0.8 V

High Level Input Voltage VCC – 0.8 V

Low Level Input Current VIN = 0V 1.0 µA

High Level Input Current VIN = VCC D 1.0 µA

Input Impedance f

Input Capacitance (CIN)2pF

SYSTEM TIMING

S

CLK

Input Hysteresis (V

Spike Suppression (t

Power Setup Time to Valid Data Inputs VCC Settled to Within 1% 10 ms

Wait Time From STOP to START

On S

Hold Time for START On S

Setup Time for START On S

Min LOW Time On S

Min HIGH Time On S

Hold Time On S

Setup Time On (t

Frequency (f

(t

DATA

WAIT

CC

= 100kHz 1 M

CLK

) 100 kHz

CLOCK

) 0.2 V

HYS

) Max length for zero response 50 ns

SPIKE

) 1.3 µs

DATA (tHD/START

DATA (tSU/START

(t

CLK

LOW

(tHI) 0.6 µs

CLK

DATA (tHD/DATA

SU/DATA

) Fast mode (Note 4) 100 ns

) 1.3 µs

) 5.0 µs

) 0.6 µs

) 0.6 µs

Slow mode (Note 4) 250 ns

V

W

Rise Time for S

Fall Time for S

Setup Time for STOP On S

Note 1: Limits are guaranteed by 100% testing, sampling, or correlation with worst case test conditions.

Note 2: Supply voltage fed through 7.5W resistor to all VCC pins.

Note 3: No bandlimiting is performed on the signal bandwidth when the comb is in the “on” state.

Note 4: Parameter is luma dependent

CLK

CLK

& S

& S

DATA (tLH

DATA (tHL

DATA (tSU/STOP

) 30 300 ns

) 30 300 ns

) 0.6 µs

6

Page 7

FUNCTIONAL DESCRIPTION

ML6440

The ML6440 is an adaptive digital comb filter that offers

automatic self-adjusting or manual thresholds to handle

vertical and horizontal contouring during Y/C separation.

The ML6440 implements a SmartComb algorithm where

full bandwidth video and artifact suppression techniques

are used to automatically select suppression thresholds for

all video content. Video artifacts such as hanging dots, dot

crawl, and cross luminance are dramatically reduced. The

algorithm functionally performs a statistical analysis of the

video content of over 60 lines. It then calculates and

selects the best threshold for artifact reduction at 12-bit

resolution.

The ML6440 is a comb for NTSC (525 lines) and PAL (625

lines) with the ability to handle CCIR601 and square pixel

sampling rates.

CCIR601 is the existing standard for digitized video of

either NTSC or PAL at a 13.5MHz rate, and is used by

MPEG encoders and decoders for image compression. The

comb algorithms in the comb filter substantially reduce

rainbow and dot-crawl artifacts which interfere with

efficient image compression.

Square pixel is video digitized at 12.27MHz for NTSC,

and 14.75MHz for PAL, so that each sample corresponds

to a single pixel in computer displays without the effort or

expense of a multi-phase image resizing filter done in

hardware or software.

Using the ML6440 comb filter requires no external

components for operation. The comb filter can be

bypassed to accommodate selection of external S-video

signals. The comb filter is controllable via parallel pin or

serial interface.

SMARTCOMB OPERATION

The user supplies 8-bit video as either digital Y/C or digital

composite video inputs and receives delayed and combed

data at the Y/C digital outputs. Use of Y/C input assumes

that combing is unnecessary and sends the data through

the same delay as the composite video path to prevent

shifting of the video position on the screen. This makes the

ML6440 useful in source selection such as S-video inputs

and composite video. Composite video (CV), applied to

the ML6440 with comb operation enabled, permits the

separation of luminance and chrominance with minimal

artifacts.

The SmartComb controls the application of the comb filter

and bandsplit-notch filters on a pixel-by-pixel basis. The

digital video image is sampled, and an analysis is

performed. SmartComb step 1: looks for differences in the

low frequency spectra (vertical detail). SmartComb step 2:

searches for changes in phase angle/saturation of the

chroma sub-carrier, which represents changes in color in

the vertical direction. Finally, SmartComb step 3: an

averaging circuit is used as "smoothing function" to

eliminate dithering in the horizontal dimension caused by

excessive filter switching.

Figure 1 provides a simplified block diagram of the

SmartComb architecture. This architecture implements

several complex computations to determine the amount of

notch vs. comb filtering. Three 8-Bit detectors are used to

examine vertical and horizontal detail for luma and

chroma signals on a pixel-by-pixel basis for 3-line

analysis. These data are then fed into a weighting function

to determine the best filtering approach over the existing

3-lines of video. Furthermore, this data is then compared

CV

IN

HI-BAND

LOW BAND

LUMA VERTICAL

DETAIL DETECTOR

8-BIT

LUMA HORIZONTAL

DETAIL DETECTOR

8-BIT

CHROMA VERTICAL

DETAIL DETECTOR

8-BIT

1H

HI-BAND

LOW BAND

COMB/NOTCH

CONTROL FUNCTION

24-BIT, 3-LINE

COMB/NOTCH

THRESHOLD SELECT

MANUAL

THRESHOLD

SELECT

1H

COMP

COMB/NOTCH

CONTROL FUNCTION

12-BIT, FRAME, 60-LINE

Figure 1. SmartComb Architecture: Simplified Block Diagram

HI-BAND

LOW BAND

FADER

VIDEO

SIGNALS

MIXER

8-BIT

AUTOMATIC

THRESHOLD

SELECT

Y

OUT

C

OUT

7

Page 8

ML6440

PREAMBLE DATA ADDRESS (B3)

HEX

DATA (D[7:0]2)

Table 1. Serial Data Format

BIT D7 D6 D5 D4 D3 D2 D1 D0

Mode—Function Y+C or CV Adaption Adaption Adaption Comb Comb Square Pixel/ PAL

Select Threshold Threshold Threshold Mode Mode CCIR601 or NTSC

2 1 0 1 0 Select Select

Value Y+C = 1 AT2 = 0 AT1 = 0 AT0 = 0 CM1 = 0 CM0 = 0 Sq. Pixel = 1 PAL = 1

CV = 0 or 1 or 1 or 1 or 1 or 1 CCIR601 = 0 NTSC = 0

Parallel Mode CI7/DI7 CI6/DI6 CI5/DI5 CI4/DI4 CI3/DI3 CI2/DI2 CI1/DI1 CI0/DI0

Input Pin

Table 2. Control Register Format D[7:0] (Serial or Parallel Mode)

STANDARD/RATE CCIR601 SQUARE PIXEL

NTSC (f

PAL (f

= 3.58MHz) 13.5MHz 12.27MHz

SC

= 4.43MHz) 13.5MHz 14.75MHz

SC

Table 3. Clock Frequency Requirements

ADAPTION THRESHOLD D[6,5,4] ADAPTION THRESHOLD LEVEL

000 Automatic threshold for minimal comb artifact generation for various video

source material.

001 Threshold for computer graphics applications, minimizing dot crawl on

bold lettering.

010 to 110 Various degrees of thresholds.

111 Threshold for better reproduction of natural photographic images.

Table 4. Adaption Threshold Bit Table

COMB MODE, D[3,2] NTSC PAL

00 Y adaptive, C comb 100% active Y adaptive, C adaptive

01 Y adaptive, C adaptive Y adaptive, C comb 100% active

10 Y 100% comb active, C 100% comb active Y 100% comb active, C 100% comb active

Not recommended due reduced performance

11 Bandsplitting only (no combing) Bandsplitting only (no combing)

Table 5. Comb Mode Bit Table

8

Page 9

S DATA

ML6440

START

t

RISE

t

SET/START

S CLK

START: A Falling Edge on the S DATA While S CLK is Held High

STOP: A Rising Edge on the S DATA While S CLK is Held High

All Other S DATA Transitions Must Occur While S CLK is Low

Figure 2. Definition of START & STOP on Serial Data Bus

S DATA

S CLK

MSB MSB

A1 A0A6A7

0 1 2 7 8 9 10 11 16 17 18

9th pulse strobes address decoder

S CLK:

Rising edge enables data transfer

S CLK:

Value set to A6, Device Address (MSB-1)

S DATA:

Falling edge disables data transfer

S CLK:

Rising edge enables data transfer

S CLK:

Value set to A7, Device Address MSB

S DATA:

Falling edge in prep for first address transfer

S CLK:

Falling edge w/S CLK high means start of sequence

S DATA:

D7 D6 D1 D0

S DATA:

S DATA:

S CLK:

S CLK:

S DATA:

S CLK:

S CLK:

S DATA:

t

FALL

STOP

STOP

Rising edge with S CLK Hi = STOP

Value set low in prep for STOP

18th pulse strobes data shift register

Rising edge enables data transfer

Value set to D6, Data MSB-1

Falling edge disables data transfer

Rising edge enables data transfer

Value set to D7, Data MSB

Figure 3. Definition of DATA FORMAT on Serial Data Bus

S DATA

‘1’ ‘0’ ‘0’ ‘1’ Ø ØD7 D6 D5 D4 D3 D2 D1 D0‘0’‘1’ ‘1’ ‘1’

S CLK

0 1 2345 9ABCD E FGH I

DEVICE ADDR = ‘B3’ CONTROL REGISTER

687

S CLK:

Address decode strobed on 9th clock

[Data is ‘don’t care’ during strobe]

‘1011 0011’ shifted on next 8 clocks

S DATA:

Falling edge in prep for device address transfer

S CLK:

S

:

Final Clock strobes data into register

DATA

Control register, load MSB first

Figure 4. Typical Serial Bus Command

STROBE (ACK)

9

Page 10

ML6440

FUNCTIONAL DESCRIPTION (Continued)

to the video content of the last 60+ lines (frames) of video

—a frame weighing function— to determine the best

filtering approach of the current video content. Finally, 1

of 7 thresholds can be chosen to adjust either real-time

(automatically) by the ML6440 itself or fixed manually by

design. An internal 12-bit analysis is used for the filtering

algorithm. An additional fader circuit is included to

"smooth" the transitions between comb and notch filtering.

In NTSC, every other line of chroma is inverted while

there are no changes in luma (assuming there is no change

in color between adjacent lines). This permits data to be

added from the first stored line of data with the third line

of active high-band video data, each with a scaling of

0.25, and add the second stored line of data with a scaling

of 0.50. The result contains no chroma, only luma

information. Subtracting this information from the highband signal yields only chroma information.

In PAL, each line of data rotates the phase of the chroma

by 90 degrees. Therefore, by adding the first line of stored

high-band information from the active third line, the

chroma is canceled, leaving only luma information. Once

again, this information is subtracted with the appropriate

amplitude scaling from the original highband information

to yield only chroma.

The bandsplit-notch and comb filters were designed to

reduce color bar peak-to-peak dot edge crawl to <7.5%

for 75% color bars. Peak-to-peak cross color on the white

bar edge was designed to be <1% with 75% color bars.

SERIAL PROGRAM MODE

In Serial Program Mode, the comb filter can be controlled

with the serial interface. Control inputs may be clocked in

serially with S DATA and S CLK , when S/P is low. Serial

bus transfers require an 8-bit address followed by 8-bits of

data for the internal data register. The pattern is described

in Tables 1 through 5.

The serial bus control in the ML6440 has one level of

addressing followed by control register programming.

Figure 2 shows the physical waveforms generated in order

to address the ML6440. There are six basic parts of the

waveform:

1. Start indication: Clock Cycle 0

2. Device address shifted in: Clock Cycle 1 thru 8

3. Device address strobed /decoded: Clock Cycle 9

4. Data shifted in: Clock Cycle 10 thru 17

5. Data strobed to appropriate register: Clock Cycle 18

6. Stop indication: Clock Cycle 19

In bandsplit (notch) filtering and luma peaking, the digital

bandsplit filter is used as an alternate filter when the

SmartComb algorithm determines that the comb filter

output signal would be contaminated with cross chroma

artifacts. To maintain a reasonable amount of apparent

resolution in the luminance signal, luma peaking is

applied. This helps maintain image quality in the portion

of the video image where comb filtering would generate

artifacts.

The ML6440 SmartComb provides a real-time filtering

algorithm solution (automatic mode) for a wide variety of

video sources without the shortcomings of using fixed

thresholds (manual mode). The automatic threshold

tracking circuit responds quickly, adjusting itself in about

1/300th of a second (about 60 lines). The transition from

the comb to the digital bandsplit is made with a

continuous digital fader to prevents switching glitches.

RST

POWER ON

PARALLEL PROGRAM MODE

In Parallel Program Mode, the CI/DI[7:0] pins act as

programming pins for the internal 8-bit register (D[7:0])

such that CI7/DI7=D7, CI6/DI6=D6, ... CI0/DI0=D0. In

the parallel mode, the S/P serves as a rising edge-triggered

strobe pin for the internal registers of D[7:0]. When S/P

goes from low to high, data applied to the inputs (CI/

DI[7:0]), is loaded into the internal 8-bit register D[7:0]

directly. A transition on the S/P pin back to low will

reactivate the serial mode. If the S/P is held at a high, the

serial mode is inactive.

CONTROL REGISTER, D[7:0]

The internal register, D[7:0], controls the following

functions within the ML6440. Again, this register can be

programmed through either a serial or parallel interface.

The RST acts as a reset pin, forcing all the bits of the

AT LEAST 1µs LOW

10

AT LEAST 5µs HIGH

Figure 5: Reset Timing

Page 11

FUNCTIONAL DESCRIPTION (Continued)

ML6440

internal data register low (D[7:0]=0) which defaults to

automatic combing of NTSC/CCIR601 composite video.

The Y+C/CV selection bit, D7, controls whether Y+C or CV

format is the source for the comb filter. Setting this bit low

selects the composite input pins, which is combed by

default. Setting the bit high selects the Y+C inputs as the

source for video (see bypass section). This source is not

combed and the Y+C inputs are not activated until the S/P

pin is rising-edge triggered.

Adaption thresholds 2 through 0 are D6 through D4,

respectively. These set the adaption behavior from

automatic (D[6:4]=000) to one of seven settings ranging

from fine tuning of computer graphics to photographic

images. See Table 4.

Comb modes 1 and 0, (D3 and D2, respectively) are used

to enable and disable adaption separately on Y and C

data. For NTSC, if D[3:2]=<00>, then Y is adaptive and C

is always combed. For NTSC, if D[3:2]=<01>, both Y and

C are adaptive. For PAL, if D[3:2]=<00>, then both Y and

C are adaptive. For PAL, if D[3:2]=<01>, then Y is

adaptive and C is combed. For NTSC and PAL, if

D[3:2]=<10>, then Y and C are forced to comb mode. For

NTSC and PAL, if D[3:2]=<11>, then both Y and C are in

bandsplit filtering mode only. See Table 5.

The RST pin resets the comb logic including the internal

data register on active low but does not clear the line

delays. This part requires a timed reset pulse. On power

up or at any time a return to automatic combing of NTSC/

CCIR601 composite video is required the reset pin must

have been high for at least 5 micro seconds. Then taken

low for at least one micro second before returning high

again to resume normal operation. Neither pulse width

nor rise and fall times are critical.

In most applications a microprocessor will be available to

provide timing and control waveforms. It will provide this

reset pulse and if needed set the appropriate comb filter

mode. In non processor systems an R C network can

provide this reset pulse. See Figure 5.

CHROMA AND LUMA BYPASS OPERATION

This mode can be activated by setting the internal bit

D7 = 1 either through the serial or parallel programming

modes. Once the register is set (D7 = 1), the comb filter

will look at the inputs for luma on the CV[7:0] pins for a

luma bypass to the outputs of the Y[7:0] pins respectively;

as well as inputs for chroma on the CI/DI[7:0] pins for a

chroma bypass to the outputs of the C[7:0] pins

respectively. The comb filter will continue to look at the

inputs as long as D7 is set high.

The D1 bit sets the choice of data rates between CCIR601

and Square pixel. CCIR601 is active low. Square pixel is

active high. The last bit, D0, select the standard, NTSC or

PAL. NTSC is active low. PAL is active high. See Table 2.

The remaining pin function controls are independent of

the data register: CLK, RST, and OE. The CLK pin requires

a clock at the rates listed in Table 2. Its duty cycle must

meet the duration minimum for high and low.

60%

13.5MHz CLOCK

20ns

Y/C OUTPUT

Data presented to the inputs (CI/DI[7:0]) is not interrupted

in the color processing path when S/P is held high or low.

Therefore, it is recommended that S/P activity be limited to

sync or blanking intervals in the video to avoid unwanted

visual artifacts during register programming.

Clock Timing

Figure 6 depicts digital video input and output timing for

valid data.

40%

Y OR C DATA

15ns 0ns

Y OR C DATA

CV INPUT

CV DATA

Figure 6: Clock Timing

CV DATA

11

Page 12

ML6440

TYPICAL APPLICATIONS

Figure 7 depicts an application block diagram of the

ML6440. The ML6440 is easy to use in most standard

video applications in conjunction with an 8-bit A/D

converter or digital data for analog and digital

applications. High speed digital layout should be

observed. Pay special attention that the outputs are not

loaded beyond a 2mA load. An A/D, if used, should have

at least seven effective bits at Nyquist rates for good

quality video. Please note that startup of the part will

require at least two lines to flush out the line delays and

about 10 lines for the adaption to adjust. The automatic

adaption thresholding should not be discernible in most

video applications, but can be defeated with the fixed

adaption levels. In applications using video tape recorders

the comb may not be effective and can make results worse

if time jitter exceeds the clock period 70ns. Jitter of this

magnitude would misalign the line delays, making the

combing and adaption incorrect. In this case combing

should be turned off.

POWER SUPPLY REQUIREMENTS

The AV

0.4V drop from a 5V supply. Alternately, a 7.5W resistor

can be used instead of the diode. The AV

a 1µF surface mount capacitor to ground. See Figure 7.

Bypass caps must be within 3mm of the chip pins they

bypass. Direct traces are necessary.

Digital Video Values of Sync Tip and Peak White

As recommended by SMPTE and ITU-R BT.601, the

minimum value of digitized sync tip is decimal 16. The

maximum value of digitized video is decimal 255 (235

recommended is by SMPTE which allows for overshoots in

video). Normally, peak white is at 235; this avoids

clipping due to overshoots.

Figure 8 presents Micro Linear’s entire solution for

optimized video application designs. The ML6430 can be

used as high performance line lock clock that’s capable of

must be fed through a Schottky diode of about

CC

pin also needs

CC

generating horizontal and vertical syncs and a variety of

system clocks using common reference frequency crystals.

The ML6401 is a low cost A/D converter. The ML6421 is a

three channel filter with sinx/x equalization. The ML6424

is a precision filter used as a clamp circuit and antialiasing filter. (See Micro Linear's ML6440EVAL for more

information)

Test Patterns

When viewing test patterns, the fixed thresholds may give

better performance, since the automatic adaptive

threshold algorithm was optimized for live video.

There are various specific application uses of the ML6440

SmartComb :

• Large screen TVs

• HDTV

• Video projection

• MPEG encoding

• Video conferencing

• Imaging and video capture

• Format converters

• Time base correctors

• Professional video

• Line doublers and quadrapulers

Figure 9 illustrates the use of the ML6440 in a big screen

TV application. In this application, the ML6440 offers

automatic self-adjusting thresholds to optimize Y/C

separation while minimizing artifacts for a wide variety of

live video material without fixed threshold limitations. The

ML6440 supports S-video bypass or luma and chroma

separation enhancement, simplifying design for highperformance video source selection.

Figure 10 illustrates the use of the ML6440 in HDTV and

NTSC application. In hybrid TV sets, where both NTSC

and HDTV will be prevalent, the ML6440 SmartComb can

serve as a high-performance Y/C NTSC-separator in a

NTSC-HDTV video receiver.

12

Page 13

TYPICAL APPLICATIONS (Continued)

ML6440

5V

RESET

GENLOCK,

SYSTEM CLOCK

CV IN

SERIAL/PARALLEL (S/P)

OUTPUT ENABLE (OE)

SERIAL DATA IN (S DATA)

SERIAL CLOCK (S CLOCK)

CLAMP

FILTER

A/D

1µF

PARALLEL OR CHROMA

8

1

2

3

4

5

6

7

8

9

10

11

BYPASS INPUT

1µF

44 43 42 41 40

12 13 14 15 16 17 18 19 20 21 22

39 38 37 36 35 34

ML6440

SmartComb

*

1µF

5V

8

D/A CHROMA

8

D/A

33

32

31

30

29

28

27

26

25

24

23

FILTER

FILTER

LUMA

PIN 16

*

7.5Ω

5V

ALTERNATIVE

POWER SUPPLY

1µF

Figure 7. Typical Application Circuit

13

Page 14

ML6440

TYPICAL APPLICATIONS (Continued)

S VIDEO

COMPOSITE

VIDEO

ML6424

TUNER

FILTER

ML6431

GENLOCK

IF

ML6401

A/D

ML6440

COMB

FILTER

8

CLOCK

8

8

8

D/A

D/A

D/A

Figure 8. Micro Linear Application Solution

HDTV

PLL

HDTV

DETECTOR

NTSC

DETECTOR

DIGITAL

MPEG

DECODER

YUV

ML6421

FILTER

FILTER

FILTER

Y

C

CV

MUX MATRIX

LUMA

CHROMA

COMPOSITE

VIDEO

TO

DISPLAY

COMPOSITE VIDEO IN

COMPOSITE VIDEO

FROM TV TUNER

S VIDEO LUMA

S VIDEO CHROMA

GENLOCK

ML6440

SmartComb

CHROMINANCE

DEMODULATOR

YUV

Figure 9. Application Diagram: HDTV and NTSC Television

GENLOCK

CVIN/Y

MUX

A/D

A/D

IN

C

IN

ML6440

SmartComb

SERIAL

BUS

CONTROL

LUMA

CHROMA

CHROMINANCE

DEMODULATOR

Figure 10. Application Diagram: High-end Television/Monitor

R

MATRIX

U

V

G

B

TO

CRT

14

Page 15

PERFORMANCE DATA

ML6440

COMB FILTER PERFORMANCE

• Unrestricted Bandwidth. No band-limiting is performed

on the signal when the comb is on hence preventing a

signal loss.

• High frequency peaking allows for gentle transitions

from comb to notch modes.

• Spurious sub-carrier supression by 48dB removes color

sub-carrier which otherwise can cause large area dot

crawl

NOTCH FILTER PERFORMANCE

• When invoked by adaption threshold logic, hanging dot

suppression is 35dB.

ADAPTIVE THRESHOLD PERFORMANCE

• Seven fixed values to select threshold, the 8th value is

for automatic self-adjusting threshold mode.

• Adaptive thresholds improve around 10% per threshold

level. However, adaptive thresholds can surpass

optimum threshold thus causing smearing effects.

• D[6:4] = 000 is the automatic self-adjusting threshold

mode. D[6:4] = 001 is the low threshold and D[6:4] =

111 is the highest threshold, D[6:4] = 010 to 110 is

therefore the intermediate thresholds.

Figures 11 through 20 show the bandwidth of notch,

chroma bandpass, and comb filters for NTSC and PAL

video. These curves were taken from a VM700 using a

sweep frequency pattern using a TG2000 on the

ML6440EVAL board.

Figure 11 shows the NTSC luma filter at CCIR clock rates.

This shows significant notch from 3.3MHz to 4MHz

sufficient for hanging dot suppression. Figure 12 shows

the NTSC chroma bandpass filter for CCIR clock rates

where the filter at 3dB ranges from 3MHz to 4.5Mhz.

Figure 13 shows the luma notch filter for NTSC for

hanging dot suppression for Square Pixel clock rates. This

notch ranges from 3.3MHz to 4MHz. Figure 14 shows the

NTSC chroma bandpass filter running at Square Pixel

clock rates where it at 3dB ranges from 3MHz to 4.5MHz.

Figure 15 shows PAL luma response for hanging dot

suppression at Square Pixel clock rates where notch

ranges from 3.3MHz to 4MHz. Figure 16 shows the

response of the PAL chroma bandpass filter where at 3dB

down ranges from 3MHz to 4.2MHz. Figure 17 shows the

PAL notch filter for luma hanging dot suppression at CCIR

clock rates where the notch ranges from 4MHz to 4.3MHz

at zero amplitude. Figure 18 shows the bandpass filter for

PAL at the CCIR clock rate where at 3dB down ranges

from 3.3MHz to 4.7MHz. Figure 19 shows the NTSC

luma comb response over a line-to-line in phase

frequency sweep to 6MHz for CCIR clock rates. Figure 20

shows the NTSC luma response over a line-to-line in

phase frequency sweep to 6MHz for Square Pixel clock

rate.

1.5

1.0

0.5

AMPLITUDE (V)

0

–0.5

1

02 64

35

FREQUENCY (MHz)

Figure 11. NTSC Luma Notch Filter CCIR

1.5

1.0

0.5

AMPLITUDE (V)

0

–0.5

1

02 64

35

FREQUENCY (MHz)

Figure 12. NTSC Chroma Band Phase Filter, CCIR

15

Page 16

ML6440

1.5

1.0

0.5

AMPLITUDE (V)

0

–0.5

1

02 64

35

FREQUENCY (MHz)

1.5

1.0

0.5

AMPLITUDE (V)

0

–0.5

1

02 64

35

FREQUENCY (MHz)

Figure 13. NTSC Luma Notch Filter, Square Pixel Figure 14. NTSC Chroma Band Pass at Square Pixel

Clock

1.5

1.0

1.5

1.0

0.5

AMPLITUDE (V)

0

–0.5

1

02 64

35

FREQUENCY (MHz)

0.5

AMPLITUDE (V)

0

–0.5

1

02 64

35

FREQUENCY (MHz)

Figure 15. PAL Luma Notch Filter, Square Pixel Clock Figure 16. PAL Chroma Band Pass Filter, Square Pixel

Clock

1.5

1.0

0.5

AMPLITUDE (V)

0

1.5

1.0

0.5

AMPLITUDE (V)

0

16

–0.5

1

02 64

35

FREQUENCY (MHz)

Figure 17. PAL Luma Notch Filter

–0.5

1

02 64

35

FREQUENCY (MHz)

Figure 18. PAL Chroma Pand Pass, CCIR Clock Rate

Page 17

ML6440

1.5

1.0

0.5

AMPLITUDE (V)

0

–0.5

1

02 64

35

FREQUENCY (MHz)

1.5

1.0

0.5

AMPLITUDE (V)

0

–0.5

1

02 64

35

FREQUENCY (MHz)

Figure 19. NTSC Comb Luma, CCIR Clock Rate Figure 20. NTSC Luma Comb, Square Pixel

17

Page 18

ML6440

PHYSICAL DIMENSIONS inches (millimeters)

Package: H44-14

44-Pin (14 x 14 x 1mm) TQFP

0.630 BSC

(16.00 BSC)

0.551 BSC

(14.00 BSC)

34

0º - 7º

0.003 - 0.008

(0.09 - 0.20)

1

12

0.039 BSC

(1.00 BSC)

PIN 1 ID

0.014 - 0.020

(0.36 - 0.51)

ORDERING INFORMATION

PART NUMBER TEMPERATURE RANGE PACKAGE

ML6440CH (EOL) 0°C to 70°C 44 Pin TQFP (H44-14)

23

0.551 BSC

(14.00 BSC)

0.630 BSC

(16.00 BSC)

0.048 MAX

(1.20 MAX)

0.037 - 0.041

(0.95 - 1.05)

0.018 - 0.030

(0.45 - 0.75)

SEATING PLANE

© Micro Linear 2000. is a registered trademark of Micro Linear Corporation. All other trademarks are the

property of their respective owners.

Products described herein may be covered by one or more of the following U.S. patents: 4,897,611; 4,964,026; 5,027,116;

5,281,862; 5,283,483; 5,418,502; 5,508,570; 5,510,727; 5,523,940; 5,546,017; 5,559,470; 5,565,761; 5,592,128;

5,594,376; 5,652,479; 5,661,427; 5,663,874; 5,672,959; 5,689,167; 5,714,897; 5,717,798; 5,742,151; 5,747,977;

5,754,012; 5,757,174; 5,767,653; 5,777,514; 5,793,168; 5,798,635; 5,804,950; 5,808,455; 5,811,999; 5,818,207;

5,818,669; 5,825,165; 5,825,223; 5,838,723; 5.844,378; 5,844,941. Japan: 2,598,946; 2,619,299; 2,704,176; 2,821,714.

Other patents are pending.

Micro Linear makes no representations or warranties with respect to the accuracy, utility, or completeness of the contents of

this publication and reserves the right to make changes to specifications and product descriptions at any time without notice.

No license, express or implied, by estoppel or otherwise, to any patents or other intellectual property rights is granted by this

document. The circuits contained in this document are offered as possible applications only. Particular uses or applications

may invalidate some of the specifications and/or product descriptions contained herein. The customer is urged to perform its

own engineering review before deciding on a particular application. Micro Linear assumes no liability whatsoever, and

disclaims any express or implied warranty, relating to sale and/or use of Micro Linear products including liability or warranties

relating to merchantability, fitness for a particular purpose, or infringement of any intellectual property right. Micro Linear

products are not designed for use in medical, life saving, or life sustaining applications.

2092 Concourse Drive

San Jose, CA 95131

Tel: (408) 433-5200

Fax: (408) 432-0295

www.microlinear.com

18

DS6440-01

Loading...

Loading...