Page 1

MK715

Touch Screen Controller

General Description

The MK715 Touch Screen Controller IC provides all the

screen drive, Analog to Digital converter (ADC) and

control circuits to easily interface to 4-wire analog resistive

touch screens. It also includes a general purpose A to D

converter and a clock synthesizer.

The IC continually monitors the screen waiting for a

touch. In this mode, the supply current is typically 4µA.

When the screen is touched, the IC performs analog to

digital conversions to determine the location of the touch,

stores the X and Y locations in the registers, and issues

an interrupt. This process is repeated up to 303 times per

second until no further screen touches are detected, at

which time the low current mode is resumed.

The device has a general purpose input into the 10-bit

ADC, allowing for the measurement of other inputs such

as battery voltage. The MK715 can be powered from a

3.3V supply, and uses an inexpensive 32.768kHz watch

crystal as the input reference. An internal Phase-Lock

Loop clock synthesizer provides the high speed clock for

the ADC, and the option to have a clock output to drive

other digital chips in the system.

The tiny package is the same body size as the 14 pin

SOIC, with 25 mil spacings on the leads.

Features

Tiny 20 pin SSOP (150 mil body)

4 microamp standby current

Less than 3mA active current at 3.3V, including

screen drive

Touch pressure can be measured

One or two general purpose A to D inputs

On-chip voltage reference

32.768kHz crystal/clock input

MHz clock outputs available

Operates with four wire touch screens

Ratiometric conversion eliminates screen

calibration

Automatic wake up upon screen touch

Programmable conversion rate to a maximum of

303 points per second

3.3V or 5V supply (2.7V version available)

10 bit A/D converter

Full powerdown control

Touch screen is directly driven - no external

transistors are required

A to D Converter guaranteed monotonic

3 or 4 wire serial interface

Applications

Notebook Computers

Handheld Computers

PDAs

Touch-screen kiosks

MK715RevD020200

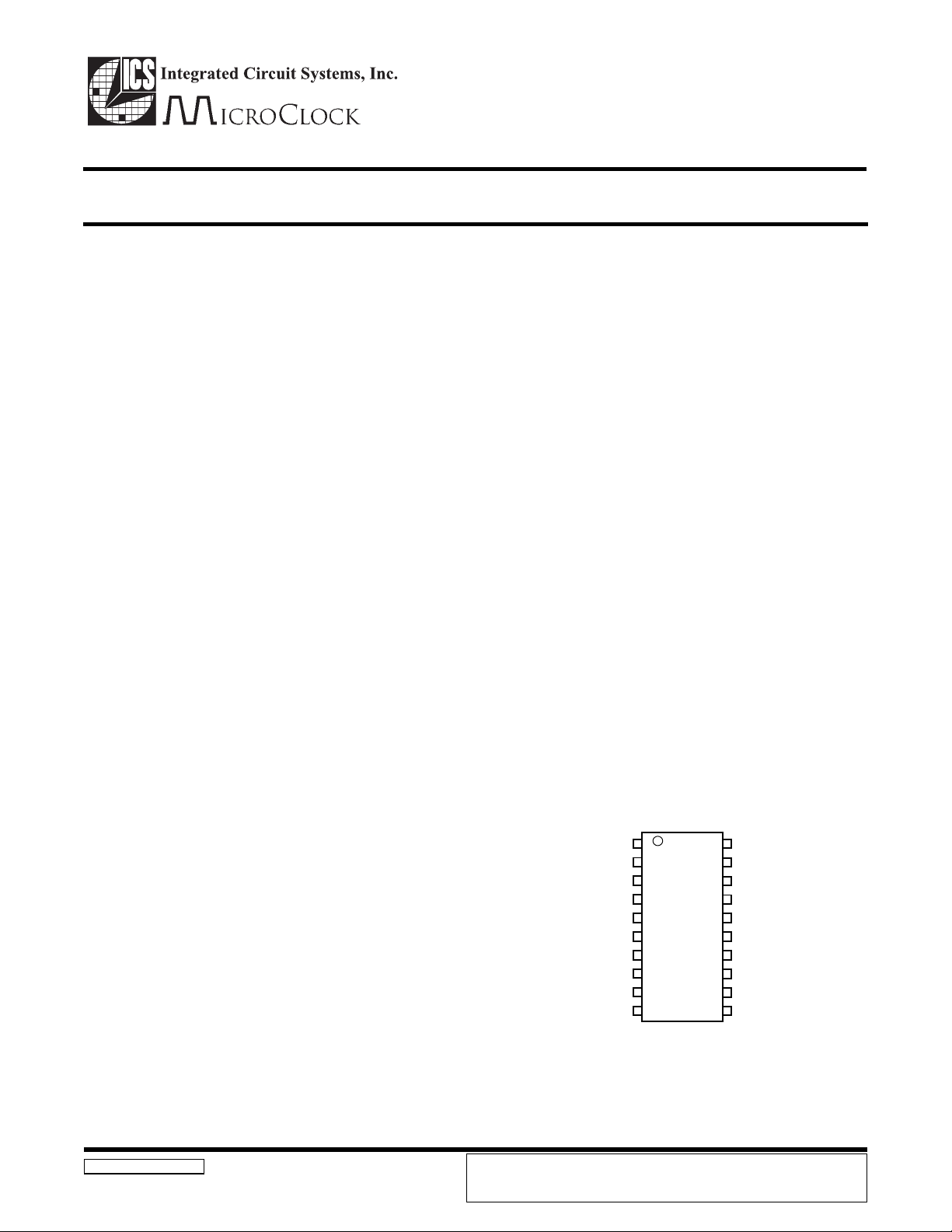

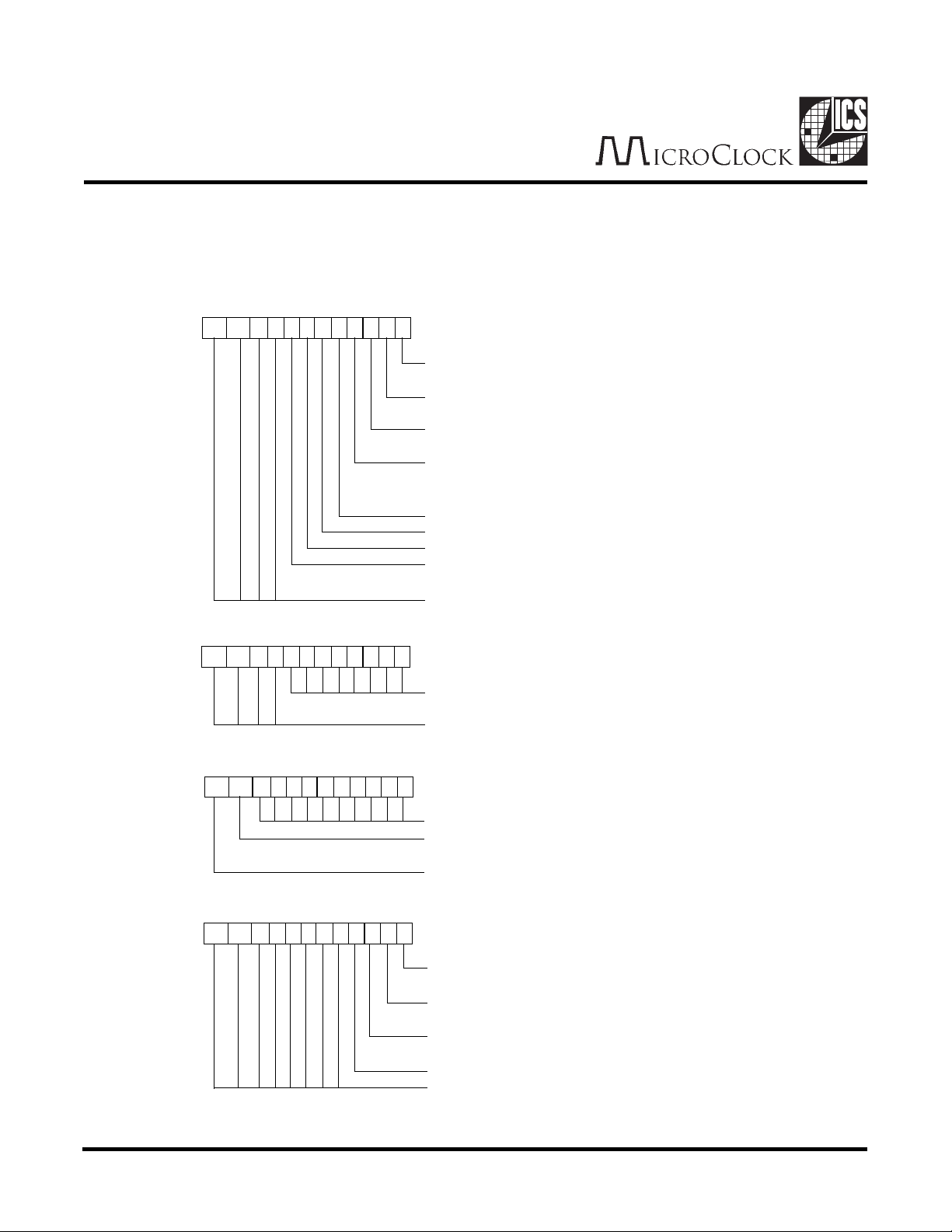

Pin Assignment

CS

SK

1

D0

2

DI

3

TOUCH#

XH

XL

YH

YL

PL

GP

4

5

6

7

8

9

10

MK715

20 pin SSOP

ICS reserves the right to make changes in the device data identified in this publication

without further notice. ICS advises its customers to obtain the latest version of all device

data to verify that any information being relied upon by the customer is current and accurate.

20

19

18

17

16

15

14

13

12

11

CLKOUT

INT

VDD

X2

X1

GND

CAP2

CAP1

CAP3

Page 2

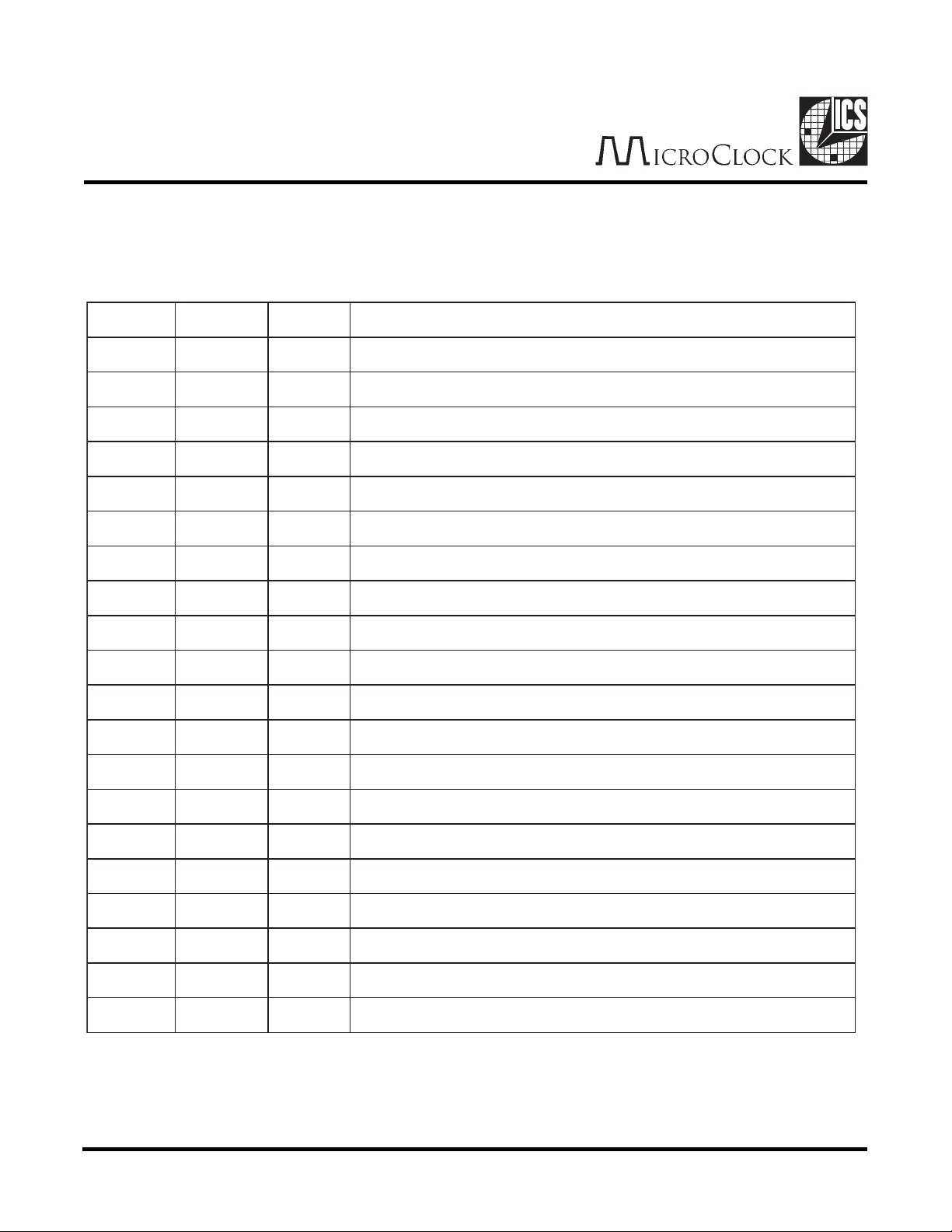

MK715

Pin Descriptions

#niPemaNepyTnoitpircseD

1KSI .kcolClaireS

2ODO .3nipottcennoc,troplaireseriw3roF.tuOataD

3IDI .2nipottcennoc,troplaireseriw3roF.nIataD

4#HCUOTO .tuokcolClanoitpO.dehcuotsineercsnehwwolseoG.langiShcuoT

5HXST.)edisthgir(neercshcuotnohgih-XottcennoC

6LXST.)edistfel(neercshcuotnowol-XottcennoC

7HYST.)pot(neercshcuotnohgih-YottcennoC

8LYST.)mottob(neercshcuotnowol-YottcennoC

9LPI .tupniCDAesopruplareneG

01PGI .tupniCDAesopruplareneG

113PAC- .dnuorgotroticapacFu10.0atcennoC

211PAC- .noitcennocretlifpooL

312PAC- .noitcennocretlifpooL

41DNGP .dnuorgottcennoC

511XI .tupnikcolcrofdnuorgro,latsyrczHk867.23ottcennoC

612XI .tupnikcolcrolatsyrczHk867.23ottcennoC

71DDVP .V3.3+roV5+ottcennoC

81TNIO .tuptuokcolclanoitpO.tpurretnilangisothgihseoG.tpurretnI

91TUOKLCO .tuptuozHMeboslanaC.zHk867.23yllacipyT.tuptuokcolC

02SCI .hgihevitcAtcelespihC

Key: I = Input, O = Output, I/O = Input and Output, P = Power, TS = Touch Screen pin.

2

Page 3

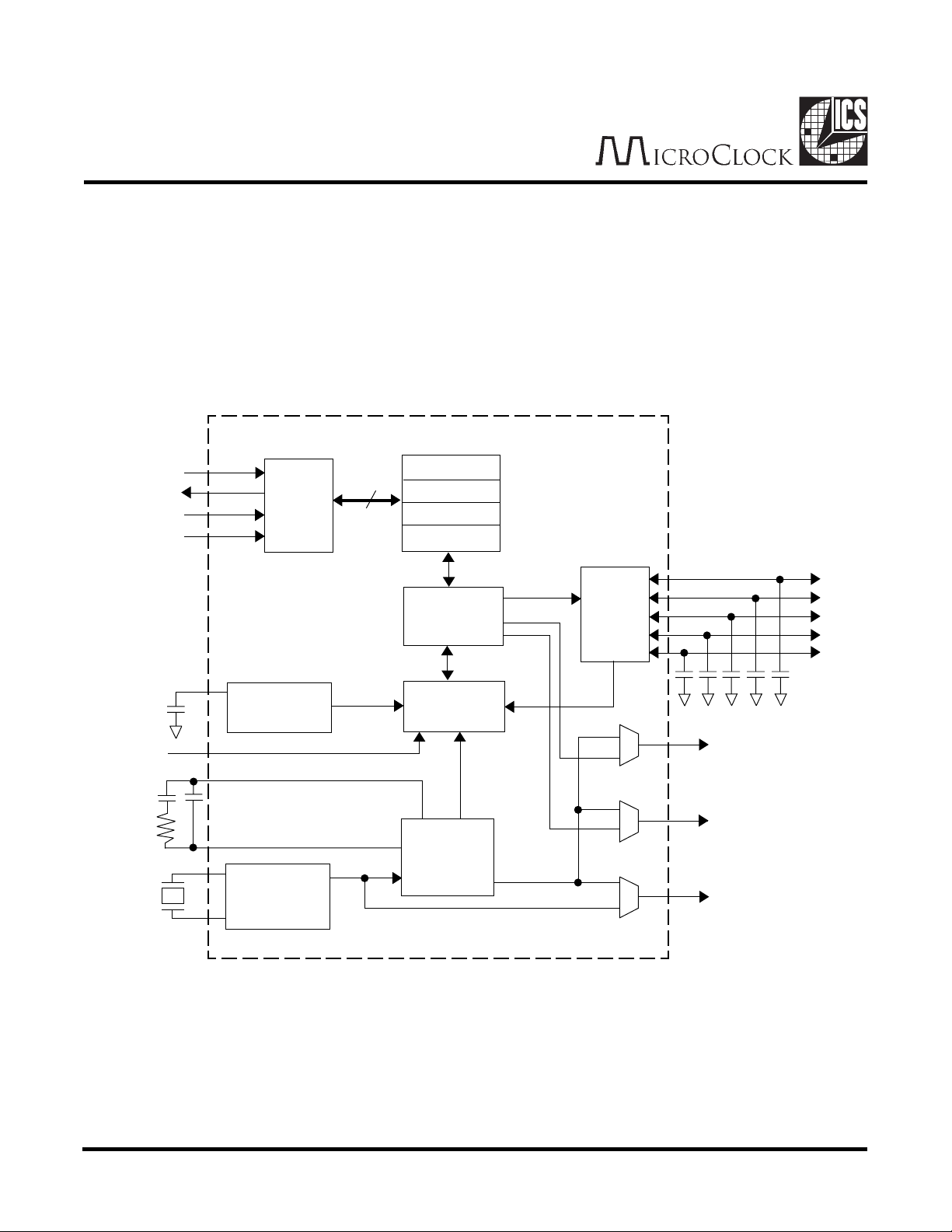

MK715

Chip Overview

The MK715 communicates via a 4 pin serial port. This may be connected as either a 3 or 4 wire

serial port. The port is connected to 4 registers that control the various modes and function of the

chip.

The primary function of the MK715 is to control resistive touchscreens. There are two ways to read

screen points, both controlled by the registers.

In the first method, which is enabled by setting the ENCONR bit, the MK715 performs periodic

conversions at a rate set by the rate register. The chip monitors the touch screen in a low power

condition (about 4 mA) until the screen is touched. When a touch is detected, the chip powers up

and starts converting screen points. The TOUCH# pin goes low and INT goes high to indicate a

change in touch status. The converter outputs a Y co-ordinate, then an X co-ordinate, then a Y coordinate, and so on. The X and Y co-ordinates are stored in the same register (RESULT) and each

conversion over-writes the previous conversion. When a co-ordinate is stored, the conversion

complete bit is asserted in the STATUS register. This bit is cleared when the RESULT register is

read. The inverted state of the TOUCH# pin also appears in the STATUS register. After each coordinate conversion, INT goes high and the screen is checked to see if it is still touched. If not,

conversions stop, TOUCH# goes high, INT goes high (to indicate a change in touch status) and

the chip reverts to the low power mode.

The second method to read a screen is to set the RD1PT (read one point) bit in the CONTROL

register. The chip will perform two conversions, a Y co-ordinate followed by an X co-ordinate. The

X co-ordinate overwrites the Y co-ordinate and so the X co-ordinate must be read before this

happens. Finally, RD1PT is cleared. The conversion pair takes about 3.5 ms.

The converter may also be used to measure voltages presented on the GP or PL pins. The range

of the converter is 0 to 1.279 V and so voltages outside this range must be scaled appropriately.

Again, the RD1PT bit is set to start the conversion but first either SELGP or SELPL must be set

to select the correct input. Only one conversion is performed. The result is stored in the RESULT

register and then RD1PT is cleared. The conversion takes about 1.7ms.

The final conversion mode is used to measure touch pressure. This is controlled identically to the

second method outlined above except that either RDPRESA or RDPRESB must first be set.

The MK715 allows for several different clocks to be generated, controlled by the registers. On the

CLKOUT pin, the output is either a a 32768 Hz clock from the crystal oscillator or a MHz - frequency

clock synthesized from the PLL. Similarly, this MHz - frequency clock can appear on the INT or

TOUCH# pins instead of their usual functions. In these cases, if the MHz clock needs to run

continuously, then the ENPLL bit must be set in order to override the automatic powerdown of the PLL.

Refer to page 12 for more details.

3

Page 4

MK715

Block Diagram

Registers

CAP3

GP

CAP1

CAP2

DI

D0

CS

SK

X1

X2

Serial

Port

Voltage

Reference

32.768kHz

Oscillator

12

Status

Rate

Result

Control

Controller

10 Bit A-D

Converter

Phase

Locked

Loop

0

1

2

3

XH

Screen

Drive

1

0

1

0

1

0

INT

TOUCH#

CLKOUT

XL

YH

YL

PL

4

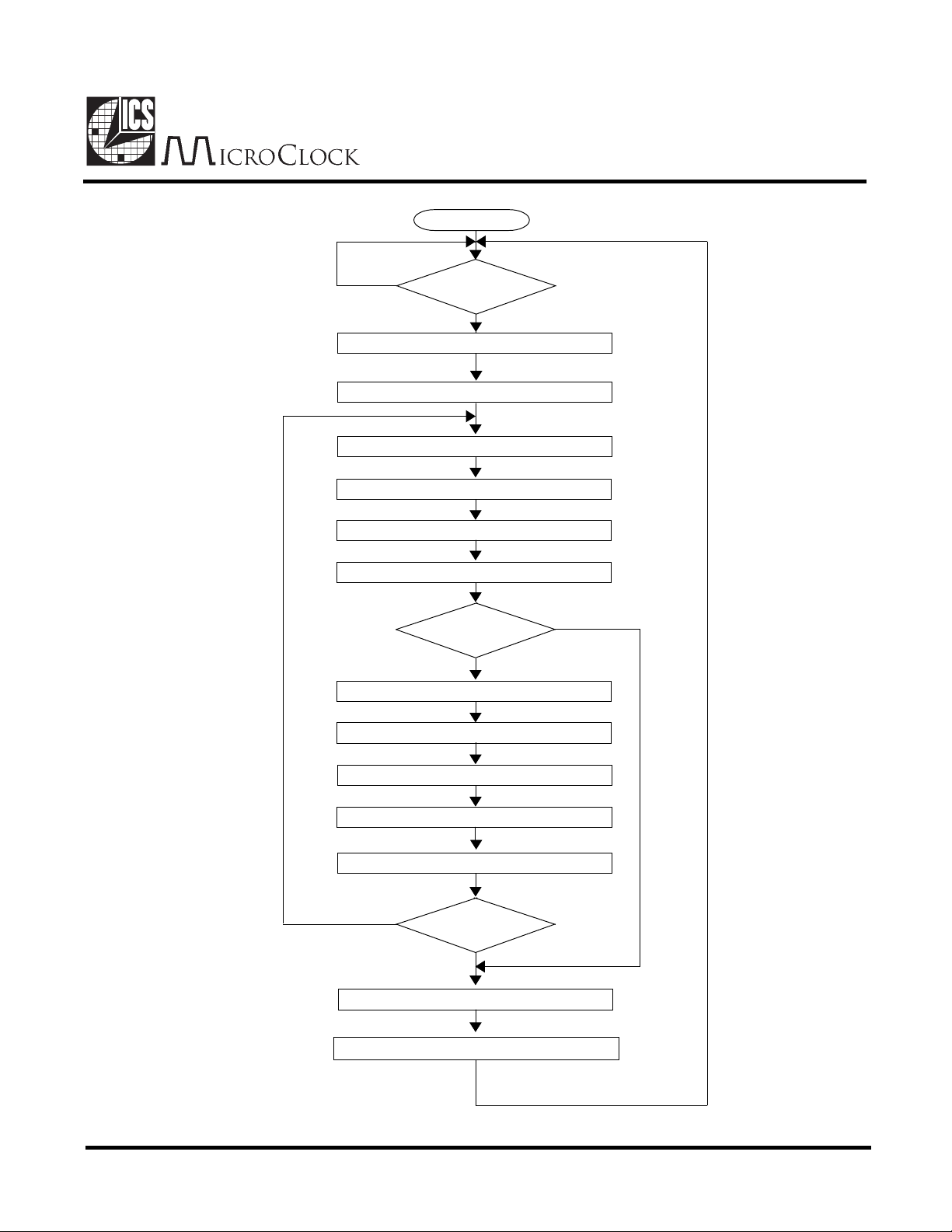

Page 5

MK715

IC Operation

(Periodic Conversions Enabled)

Power ON

N

Is screen

touched?

Y

Write D6 Reg 0 to 1 and TOUCH# = 0

Issue Interrupt, power-up ADC and PLL

Convert Y co-ordinates

Store Y co-ordinates in Register 2

Write D7 register 0 to 1

Issue interrupt

Is screen

touched?

N

Y

Convert X co-ordinates

Store X co-ordinates in Register 2

Write D7 register 0 to 1

Issue Interrupt

Wait. Duration controlled by Rate Register

Y

Is screen

touched?

N

Write D6 Reg 0 to 0 and TOUCH# = 1

Issue Interrupt, power-down ADC and PLL

5

Page 6

MK715

Register Description

The MK715 has four 12 bit registers. However, only 8 bits in each register can be written (D0-D7). The other 4 bits (D8D11) can never be written and are always read only.The RESULT register contains 2 levels, a read only level and a write

only level. Reading this register gives the conversion results. Writing this register changes 4 control bits.

DESCRIPTION

Read

and

Write

Read

and

Write

STATUS (ADDRESS 0)

11 10 9 8 7 6 5 34210

RATE (ADDRESS 1)

11 10 9 8 7 6 5 34210

RD1PT. Read one point. Cleared when

conversion complete.

ENCONR. Enable periodic screen conversions

at rate set by RATE register.

PD. Power Down. Chip powers down. See

CONTROL register bit 7.

ENPLL. Overrides automatic powerdown of

PLL between conversions and forces

continuous running.

SELGP. Select GP input to ADC.

SELPL. Select PL input to ADC.

Touch Status. 1 = touch.

Conversion complete. Cleared on next read

of RESULT register.

Always set to zero.

Controls frequency of screen conversions

when periodic conversions are enabled.

Always set to zero.

TYPE

R/W

R/W

R/W

R/W

R/W

R/W

RO

RO

RO

R/W

RO

Power-up

State

0

0

0

0

0

0

0

0

0

32

0

Read

Write

RESULT (ADDRESS 2)

11 10 9 8 7 6 5 34210

RESULT (ADDRESS 2)

11 10 9 8 7 6 5 34210

10-bit conversion result.

XSEL. Screen conversion status. 0 = Y

coordinate, 1 = X coordinate.

Conversion type. 0 = non-screen

conversion, 1 = screen conversion.

RDPRESA. Read pressure A. See

description of measuring touch pressure.

RDPRESB. Read pressure B. See

description of measuring touch pressure.

PLZERO. Forces PL pin to ground. Can be

used to control an external resistor divider.

Test mode. ALWAYS WRITE TO 0.

Don't Care.

6

RO

RO

RO

WO

WO

WO

WO

-

X

0

1

0

0

0

0

X

Page 7

Register Description (cont.)

MK715

DESCRIPTION

Read

CONTROL (ADDRESS 3)

11 10 9 8 7 6 5 34210

and

Write

SEL0. Clock select 0. See page 11.

SEL1. Clock select 1. See page 11.

SEL2. Clock select 2. See page 11.

SEL3. Clock select 3. See page 11.

SEL4. Clock select 4. See page 11.

CLKSEL. Clock frequency select.

See page 11. 0 = 14.3196 MHz

1 = 14.7456 MHz

Set to 0.

DIS32. Determines state of 32.768 kHz

oscillator when PD asserted (STATUS register).

Always set to zero.

R/W = Read/Write, RO = Read Only, WO = Write Only

Converter Control

BSERPDRASERPDRLPLESPGLESRNOCNETP1DRDEMROFREPNOISREVNOC

000001ot0

000010

TYPE

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

RO

Power-up

State

0

0

0

0

0

0

0

0

0

ehtnosnoisrevnoc2smrofreP

XnanehtdnaYa-neercs

.deraelcnehtsiTP1PR.noisrevnoc

tessaetartasnoisrevnocelbanE

sineercsnehW.retsigerETARni

setareporetrevnoc,dehcuot

sihcuotonlitnuylsuonitnoc

yllacitamotuanehtpihC.detceted

.etatsybdnats,rewopwolotseog

000101ot0

001001ot0

010001ot0

.deraelc

100001ot0

.deraelc

PGnonoisrevnocenosmrofreP

.deraelcsiTP1DR.tupni

LPnonoisrevnocenosmrofreP

.deraelcsiTP1DR.tupni

dnaYa,snoisrevnocowtsmrofreP

erusserphcuotevigot,Xnaneht

hcuotnonoitceseeS.atad

siTP1DR.tnemerusaemerusserp

dnaYa,snoisrevnocowtsmrofreP

erusserphcuotevigot,Xnaneht

hcuotnonoitceseeS.atad

siTP1DR.tnemerusaemerusserp

The converter must be sequenced correctly - before writing RD1PT to one, the appropriate bit (e.g. SELGP) must

first be set in a previous write. Only the combinations shown above are permitted. Other combinations will give

unpredictable behavior.

7

Page 8

MK715

Rate Register (Register 2) Programming

tnuoC.S.P.PtnuoC.S.P.PtnuoC.S.P.P

5ot0dettimreptoN527115804

6303623110983

7082729015963

89528260100143

92429230150123

017220300101113

11312138951103

21102235902192

31191333952182

41181430953162

51271538854142

61561048755122

71751541756112

81151054657102

91541559558191

02931065559181

12431561550271

22921077451261

32521575453251

42021082455241

P.P.S. = Points Per Second. With 14.7456 MHz clock selected.

Calculating Points Per Second

The formula for determining P.P.S. is:

P.P.S. =

fin

24072+(4096×COUNT)

Where fin is the frequency of the

internal clock (14.3196 MHz or

14.7456 MHz) and COUNT is

the value of the rate register.

Power-On Reset

On application of power, an internal reset is generated that clears all bits in registers 0, 2, and 3. Register 1 is set to

32 giving a rate of 92 PPS with 14.3196 MHz selected.

Initializing the MK715

The interrupt on the MK715 can only be cleared by reading any register or, alternatively, by writing PD (register 0, bit

2) to one, which forces a powerdown. After a fault condition, initialize the MK715 by writing PD to one, then writing

PD to zero. This will always clear pending interrupts.

8

Page 9

MK715

Warning - Operation under a Power Supply Switching Regulator

When using the MK715 in a system where the power is supplied by a switching regulator, do not perform screen

conversions when the regulator is operating in the power saving mode. Some switching regulators feature a low

power mode (for example, Linear Technology's "Burst Mode") where the output is turned on and off in order to save

power. The extra power supply noise generated when using this mode causes spurious data points to be returned

from the MK715, so it should be disabled when the MK715 is doing screen conversions.

Interrupts

The MK715 generates an interrupt to signal a change in touch status or to signal that a conversion is complete. The

INT pin (pin 2) goes high to signal an interrupt. Interrupts are then cleared by reading any register. However, if the

MK715 is in the process of generating an interrupt during a read cycle, then the interrupt is not cleared and INT will

stay high. This internal process may take 100ns, and so to guarantee that the interrupt is cleared, two successive read

cycles may be necessary.

Touch Screen Serial Port (Four Wire)

Data is written to, and read from, the MK715 via the serial port. When writing, only 8 data bits can be

written to each 12 bit register. The 4 highest order bits (D8-D11) in each register are read only and can

never be writtern. When reading, all 12 bits are returned.

The serial port has 4 pins - serial clock (SK), chip select (CS), data in (DI), and data out (DO). The SK acts on the rising

edge. The CS acts as a reset for the serial port with CS going high initiating a cycle. The cycle consists of 2 parts a write followed by a read. Each part consists of 12 bits. Refer to the serial port diagram on page 10 and timing

diagram on page 20.

After CS goes high, any number of leading zeros can occur on DI. When a one is presented (even if this is the first bit

after CS goes high), this becomes the start bit. The start bit is followed by 3 op-code bits. The first is a write bit (WR),

which determines whether the data following is actually loaded into the appropriate register or not. The next two bits

are address bits, which select 1 of 4 on-chip registers. The last 8 bits are data. If WR was low, then these data bits are

ignored.

On the fourteenth SK rising edge after a start bit, DO is released from tri-state and data is clocked out of the part. This

is the read part of the cycle. The register to be read is selected with the op-code address. The data are 12 bits long.

For the result of a conversion (which is stored in register 2), this data consists of 10 bits from the ADC, a bit identifying

an X or a Y coordinate, and a bit identifying a screen conversion or a general purpose conversion. For the other 3

registers, the data are only 8 bits long, so the 12 bit output word contains four leading zeros.

After the 12 data bits are clocked out, the DO pin stays active and bits will continue to appear until CS goes low. See

the following page for the timing diagram.

Three-Wire Serial Port

To configure the serial port for 3 wires, DI must be connected to DO to form a bi-directional data line. All other timing

and configuration remain unchanged.

9

Page 10

MK715

Using the General Purpose Inputs to the A to D Converter

The GP pin is a general purpose input to the 10 bit ADC. An on-chip 1.297 V reference is used, where 1.297 V is full

scale. In addition, when using a 4-wire touch screen, the PL pin is available as a general purpose input, or it can be

used as a power control for an external resistor divider:

Voltage to be

measured

Optional

Capacitor

For two voltages, the connection is as follows:

Voltage 1

GP

PL

SELGP

SELPL

MK715

SELGP, SELPL, and

PLZERO are all register

bits.

ADC

PLZERO

MK715

SELGP

Voltage 2

Optional

Capacitor

If PL or GP are unused, they should be connected to ground.

The capacitors connected to GP and PL are optional and will reduce noise on the ADC input.

GP

PL

ADC

SELPL

PLZERO=0

(transistor

off)

10

Page 11

MK715

Clock Control

X1

32.768kHz

X2

PD

DIS32

Clock Selection Tables

2LESDPLLPNE23SIDQERFTUOKLCSETON

00x 0 867.23etatSpu-rewoP

00x 1 867.23

01x 0 867.23

01x 1 FFO

100 x ZHM

10 1 x ZHMgninnuRsyawlA

110 x FFO

111 x FFO

PD

ENPLL

Phase

Locked

CLKSEL

To A-D Converter

/ 8

/ 4

/ 2

14.3196 or

SEL0, SEL1

3

2

1

INT

TOUCH#

CLOCKMHZ

1

SEL2

1

SEL3

1

SEL4

CLKOUT

INT

TOUCH#

nehwylnosnuR

dehcuotneercs

LESKC1LES0LESZHMKCOLC

000 6913.41

001 061.7

010 085.3

011 097.1

100 6547.41

10 1 8273.7

110 4686.3

111 2348.1

Clocks may be programmed to be on any of three pins per the description above. The clocks are controlled by the

following register bits (see register description for more details): STATUS register, bits 2 and 3; and CONTROL

register bits 0, 1, 2, 3, 4, 5, 7.

2LESTUOKCOLC

0zHk867.23

1ZHMKCOLC

4LES#HCUOT

0#HCUOT

1ZHMKCOLC

11

3LESTNI

0TNI

1ZHMKCOLC

Page 12

MK715

Power and Clock Control

The power consumed by the MK715 can be controlled by programming various register bits.

DP23SIDLLPNERNOCNE

10 X X X ffognihtyrevE0

11 X X X

0X 0 0 oN

0X 0 0 seY

0X 1 0 X

0X 0 1 oN

0X 1 1 ON

0X X 1 seY.gnitarepo.cte,LLP,CDA

neercSehtsI

?dehcuoT

noitidnoCpihCDDIlacipyT

latsyrctpecxeffognihtyrevE

fi(tuptuozHk23dnarotallicso

)detceles

latsyrctpecxeffognihtyrevE

zHk23dnarotallisco

snipTNIdna#HCUOT.tuptuo

latsyrctpecxeffognihtyrevE

zHk23dnarotallisco

snipTNIdna#HCUOT.tuptuo

latsyrctpecxeffognihtyrevE

.stuptuokcolcdnaLLP,rotallicso

otdnopsersnipTNIdna#HCUOT

.sutatsHCUOTnisegnahc

latsyrctpecxeffognihtyrevE

.stuptuokcolcdnarotallicso

latsyrctpecxeffognihtyrevE

.stuptuokcolcdnaLLP,rotallicso

4mA

4mA

.sutatshcuotnisegnahcotdnopser

04 mA

.sutatshcuotnisegnahcotdnopser

nosdneped(Am2

ycneuqerfkcolc

gnidaoldna

4mA

Am2

rewoPeeS(Am5

tnerruCylppuS

)shparg

12

Page 13

Recommended Circuit

MK715

Microprocessor

32.768 kHz

Analog Voltage

+ 3.3V or +5V

1mF

From

Crystal

0.01mF

DI

D0

CS

SK

X2

X1

PL

GP

0.01mF

470 pF

VDD

CAP3

GND

TOUCH#

CLKOUT

CAP2

100kW 0.01mF

CAP1

INT

XH

XL

YH

YL

To Power Management

To Interrupt Controller

To Microcontroller

To Touch

Screen

All 0.01mF

The capacitors connected to CAP1 and CAP3 must be low leakage, ceramic type capacitors.

Pen Bounce

When the screen is untouched, the Y plate is driven high and the X plate is driven low. When the screen is touched, the

X plate is pulled high, which is detected by the MK715. This initiates a conversion, as long as conversions at rate

(ENCONR) are enabled. Some de-bounce is provided by the time constant of the screen decoupling capacitors

combined with the screen resistance. However, once conversions have started, pen bounce will not be detected until

after the current X or Y points have been taken.

If the pen is lifted during a conversion, this will also not be detected until the conversion is complete.

13

Page 14

MK715

Optimizing Performance when Reading and Writing Registers

Reading and writing the MK715 generates digital noise that may reduce the accuracy of the A to D converter. This

noise has several causes, including board layout, and power supply voltage. By appropriately timing the register

operations, the effects of this noise can be minimized.

After an interrupt is issued or RDIPT is asserted, the MK715 allows a minimum of 1 millisecond to elapse before

initiating the conversion cycle. This allows the screen drivers to settle. For best performance, complete all register

operations within this 1ms window after an interrupt.

Resistive Touch Screen (4 Wire)

Resistive touch screens consist of 2 resistive plates that are separated by a small gap. Each plate has an electrode

at each end and when the screen is touched, the two plates are shorted together at that point.

If a voltage is applied, for example, between XL and XH, then a voltage divider is formed on the X PLATE. When the

Y PLATE is touched to the X PLATE, a voltage will be developed on the Y PLATE that is proportional to distance of

the touch from XL and XH. By accurately measuring this voltage, the position of the touch can be determined.

14

Page 15

MK715

Analog to Digital Converter Operation with a Touchscreen

The 10-bit ADC converts X and Y co-ordinates at a rate determined by register 1. The converter uses a ratiometric

technique to give absolute co-ordinates on the screen, largely independent of variations in screen resistance,

temperature or power supply voltage. The total voltage applied across the screen is defined as full-scale for the

converter (i.e. 1023) and any point touched on the screen is proportional to this. For example, if the screen is touched

exactly in the center, the converter will read 511. This feature may allow for the elimination of calibration upon startup.

However, the full scale voltage is defined at the IC pins and so any parasitic interconnect resistance will be included

in full scale. In addition, the interconnect resistances on the screen also account for up to 20% of the total resistance.

This means that approximately the bottom 10% and top 10% of full scale are inaccessible.

The converter is guaranteed to be monotonic, with no missing codes.

Board and Wire

Interconnect

XH

Full

MK715

Scale

(1023)

Screen

Interconnect

YL

XL

X

Coordinate

Screen

Screen

Interconnect

Board and Wire

Interconnect

15

Page 16

MK715

Measuring Touch Pressure

Measuring touch pressure can only be performed on 4-wire touchscreens. In normal operation, the screen drivers

force XH high and XL to ground and measure the voltage on the other plate. A schematic of this is as follows:

Voltage measured on YH is the same as at K

and L giving the X co-ordinate.

When RDPRESA is asserted, the screen drive changes as follows (XSEL=1):

Voltage measured on YH is now the voltage at

L. Voltage measured at XL is now the voltage

at K. The difference is proportional to the

touch pressure.

When RD1PT is asserted, the converter automatically performs two conversions. The status of the XSEL bit identifies

the conversions. The following table gives the four measurements available.

BSERPDRASERPDRLESXEVIRDDERUSAEMNIP

010 LX,HYHX

011 LY,HXHY

100 LX,HYLY

10 1 LY,HXLX

Both points returned

in one conversion pair.

Both points returned

in one conversion pair.

From these four measurements, the resistance of the touch can be calculated as a proportion of x-plate and y-plate

resistance. See the next section for suggestions about calculating the touch resistance. From this, the touch pressure

can be inferred. See the table on page 7 for the correct register sequencing of the converter.

16

Page 17

Calculating Touch Resistance

There are a total of six measurements possible:

BSERPDRASERPDRLESXEVIRDDERUSAEMNIPTLUSER

000 LY,HYHXC

001 LX,HXHYD

010 LX,HYHXE

011 LY,HXHYF

100 LX,HYLYG

10 1 LY,HXLXH

where the result is a number from 0 to 1023.

MK715

From simple network theory, R

D

1023

C

1023

X

D

· · (1023 - E) - RY +

1023

or R

or R

R

TOUCH

TOUCH

TOUCH

= RX · · ( - 1) where RX = X plate resistance

= RY · · ( - 1) where RY = Y plate resistance

R

=

E

TOUCH

H

can be represented in many ways, 3 are given below:

G

E

F

RY · C

1023

17

Page 18

MK715

Electrical Specifications

retemaraPsnoitidnoCmuminiMlacipyTmumixaMstinU

stuptuOkcolCdnastupnIDNGotdecnerefeR5.0-5.0+DDVV

erutarepmeTgnitarepOtneibmA 007C

erutarepmeTgniredloSsdnoces02foxaM062C

erutarepmeTegarotS 56-051C

DDV,egatloVgnitarepO 35.5V

egatloVhgiHtupnIV5=DDV2 V

LIV,egatloVwoLtupnIV5=DDV8.0V

HOV,egatloVhgiHtuptuOAm2-=HOI4.0-DDVV

HOV,egatloVhgiHtuptuO Am21=HOI,V5=DDV4.2V

LOV,egatloVwoLtuptuO Am21=LOI,V5=DDV40.V

HIV,egatloVhgiHtupnIV3.3=DDV9.1V

LIV,egatloVwoLtupnIV3.3=DDV4.0V

HOV,egatloVhgiHtuptuO Am6-=HOI,V3.3=DDV4.2V

LOV,egatloVwoLtuptuO Am6=LOI,V3.3=DDV4.0V

V5=DDVta,DDI,tnerruCylppuSgnitarepO2eton5Am

nwodrewopDDI,tnerruCylppuSgnitarepOkcolcon,1=DP2.03A

tnerruCtiucriCtrohStuptuohcaE05Am

ecnaticapaCtupnI 7Fp

noituloseR 01stib

ytiraenil-noN4eton,cinotonoM2BSL

ecnatsiseRneercShcuoT 0010002

ecnerefeRegatloVC52,V3.3=DDV662.1972.1292.1V

ycneuqerFlatsyrCrokcolCtupnI 867.23zHk

emiTesiRtuptuO V5=DDV,V0.2ot8.03sn

emITllaFtuptuO V5=DDV,V8.0ot0.23sn

)1etoN(SGNITARMUMIXAMETULOSBA

)detonsselnu(V5ROV3.3=DDV(SCITSIRETCARAHCCD

V3.3=DDVta,DDI,tnerruCylppuSgnitarepO2eton3Am

nokcolc,ybdnatsDDItnerruCylppuSgnitarepO3eton3A

±

±

)detonsselnu(V5ROV3.3=DDV(SCITSIRETCARAHCCA

m

m

W

Notes:

1. Stresses beyond those listed under Absolute Maximum Ratings could cause permanent damage to the device. Prolonged

exposure to levels above the operating limits but below the Absolute Maximums may affect device relaibility.

2. Assumes 300 W screen, 100 pps.

3. Assumes no touch.

4. With no missing codes.

18

Page 19

MK715 TIMING DIAGRAM

MK715

SK

CS

DI

DO

Tri-State

14

A

B

1234

C

D

15 16

WR A1

E

25

SK

CS

DI

DO

F

A SK Period 50 ns

B SK High TIme 15 (SK Period) -15 ns

C CS Setup to SK high 15 ns

D DI Setup to SK high 15 ns

E DI Hold from SK high 15 ns

F DO valid from SK high 20 ns

G CS hold from last SK high 50 ns

D11

Don't Care

F

D10 D9 D1 D0

G

MIN MAX

19

Page 20

MK715

20

Page 21

MK715

To

Touch

Screen

0.01µF

G

G

Pin 1

2

3

4

5

6

7

8

9

10

20

19

18

17

16

15

14

13

12

11

0.01µF

1000 pF

0.01µF

V

0.01µF

G

100kW

32768 Hz

G

G

= Connection to ground plane

V

= Connection to VDD plane

Notes: 1. All digital signals should be kept well away from pins 5, 6, 7, 8, 9, 10,

11, 12, 13, 15, 16 and any traces connected to those pins.

21

Page 22

MK715

Package Outline and Package Dimensions

(For current dimensional specifications, see JEDEC Publication No. 95.)

20 pin SSOP ( in inches)

A1 C

L

lobmySniMxaM

A350.0960.0

1A400.0010.0

B800.0210.0

C700.0010.0

D733.0443.0

E051.0751.0

eCSB520.0

H822.0442.0

L610.0050.0

B

Ordering Information

rebmuNredrO/traPgnikraMgnippihS

R517KMR517KMsebuT

RTR517KMR517KMleeRdnaepaT

L

Integrated Circuit Systems, Inc. 525 Race Street San Jose CA95126 (408)295-9800tel www.icst.com

ICS reserves the right to make changes in the device data identified in this publication

without further notice. ICS advises its customers to obtain the latest version of all device

data to verify that any information being relied upon by the customer is current and accurate.

22

Loading...

Loading...