Page 1

MK712

ICRO

C

LOCK

Description Features

The MK712 Touch Screen Controller IC provides

all the screen drive, A to D converter and control

circuits to easily interface to 4-wire analog resistive

touch screens.

The IC continually monitors the screen waiting

for a touch. In this mode, the supply current is

typically 0.5µA. When the screen is touched, the

IC performs analog to digital conversions to

determine the location of the touch, stores the X

and Y locations in the registers, and issues an

interrupt. This process is repeated up to 197 times

per second until no further screen touches are

detected, at which time the low current mode is

resumed.

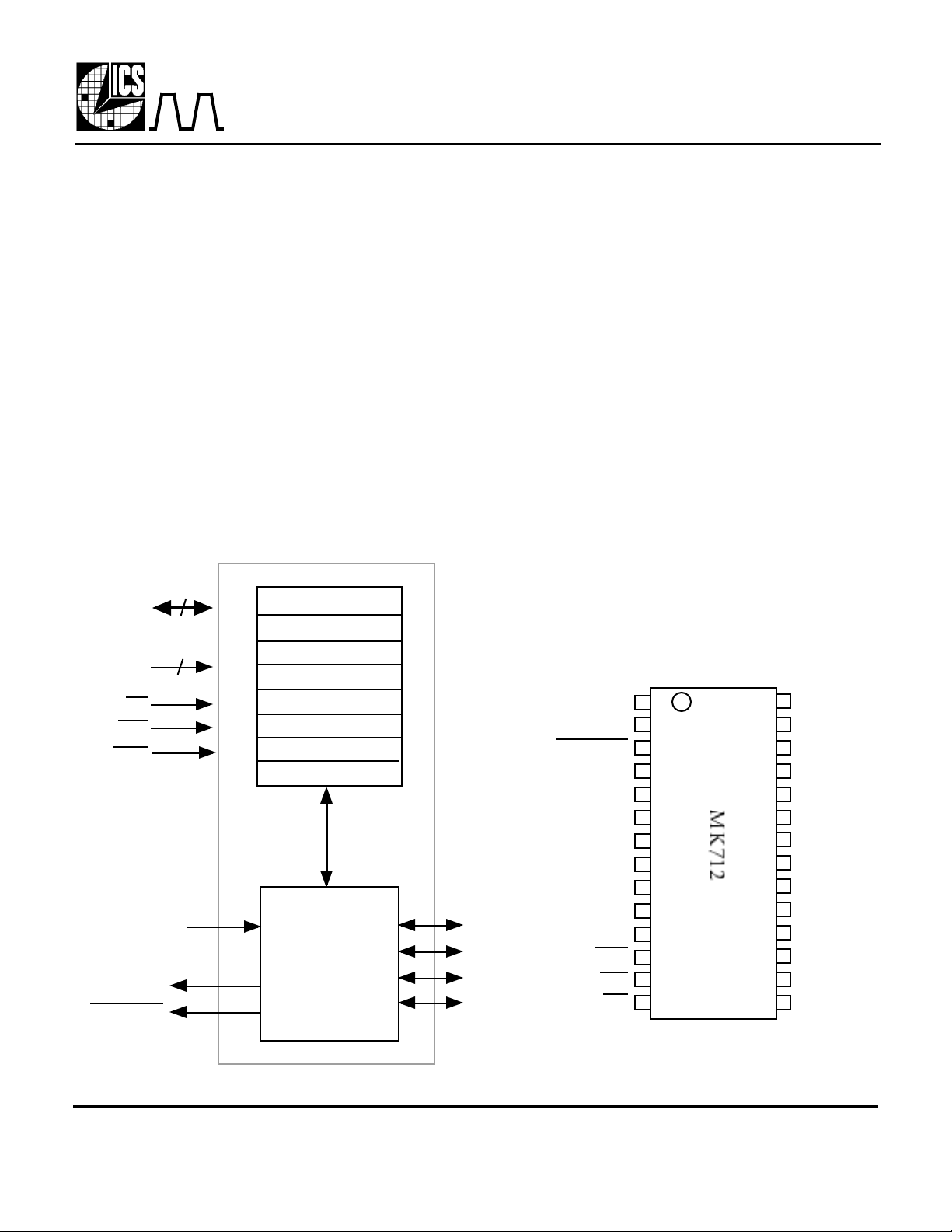

Block Diagram

8

D0-D7

3

A0-A2

CS

RD

WR

CLKIN

(14.318 MHz)

INT

TOUCH

REGISTERS

STATUS LOW

STATUS HIGH

X-LOW

X-HIGH

Y-LOW

Y-HIGH

CONTROL

RATE

12 Bit A/D,

Screen Driver

and

Controller

0

1

2

3

4

5

6

7

• Fully integrated, lowest power solution

• Low standby current of 0.5µA (typical) at 5.0V

• Active current while converting less than 10 mA

• Resolves 350 dots/inch on 10.5” display

• Maximum speed of 197 points/second

• Ratiometric conversion may eliminate screen

calibration

• Automatically wakes up and goes back to standby

• 3.3V or 5V supply

• 12 bit A/D converter

• Simplifies the writing of software for touch screens

• Extended temperature range available

• Capacitors are the only external components

required

• Touch screen is directly driven - no external

transistors are required

• Programmable conversion rate

• A to D Converter is monotonic

• Parallel interface

• See the MK715 for a serial interface

Pin Assignment

XH

XL

YH

YL

Touch Screen Controller

NC

INT

TOUCH

VDD

VDD

XH

XL

YH

YL

GND

GND

WR

RD

CS

1

2

3

4

5

6

7

8

9

10

11

12

13

14

28

27

26

25

24

23

22

21

20

19

18

17

16

15

D0

D1

D2

D3

D4

VDD

D6

D7

CLKIN

A0

A1

A2

D5

GND

MDS 712 I 1 Revision 100899 Printed 11/16/00

Integrated Circuit Systems, Inc.•525 Race St.•San Jose•CA•95126•(408)295-9800tel•www.icst.com

Page 2

MK712

ICRO

C

LOCK

Touch Screen Controller

Pin Descriptions

Number Name Type Description

1 NC - No Connect

2 INT O Interrupt. Goes high to signal an interrupt. Cleared on next read.

3 TOUCH O Touch signal. Goes low when screen is touched. Goes high when not touched.

4 VDD P Connect to +5V or +3.3V.*

5 VDD P Connect to +5V or +3.3V.*

6 XH TS Connect to X-high on touch screen. (Right side)

7 XL TS Connect to X-low on touch screen. (Left side)

8 YH TS Connect to Y-high on touch screen. (Top)

9 YL TS Connect to Y-low on touch screen. (Bottom)

10 GND P Connect to ground.

11 GND P Connect to ground.

12 WR I Write enable. Active low.

13 RD I Read enable. Active low.

14 CS I Chip select. Active low.

15 A2 I Register address 2.

16 A1 I Register address 1.

17 A0 I Register address 0.

18 CLKIN I Clock input. Typically 14.3 MHz. Best if driven by a MicroClock clock synthesizer.

19 D7 I/O Data bit 7.

20 D6 I/O Data bit 6.

21 GND P Connect to ground.

22 VDD P Connect to +5V or +3.3V.*

23 D5 I/O Data bit 5.

24 D4 I/O Data bit 4.

25 D3 I/O Data bit 3.

26 D2 I/O Data bit 2.

27 D1 I/O Data bit 1.

28 D0 I/O Data bit 0.

Key: I = Input, O = Output, I/O = Input and Output, P = Power, TS = Touch Screen pin..

*Note: All VDD’s must be connected to the same voltage.

Interrupts

Interrupts are controlled by register 6 (see Register Description). The INT pin (pin 2) goes high to

signal an interrupt. Interrupts are then cleared by reading any register. However, if the MK712 is in the

process of generating an interrupt during a read cycle, then the interrupt is not cleared and INT will stay

high. This internal process may take 100ns, and so to guarantee that the interrupt is cleared, two

successive read cycles may be necessary.

MDS 712 I 2 Revision 100899 Printed 11/16/00

Integrated Circuit Systems, Inc.•525 Race St.•San Jose•CA•95126•(408)295-9800tel•www.icst.com

Page 3

MK712

ICRO

C

LOCK

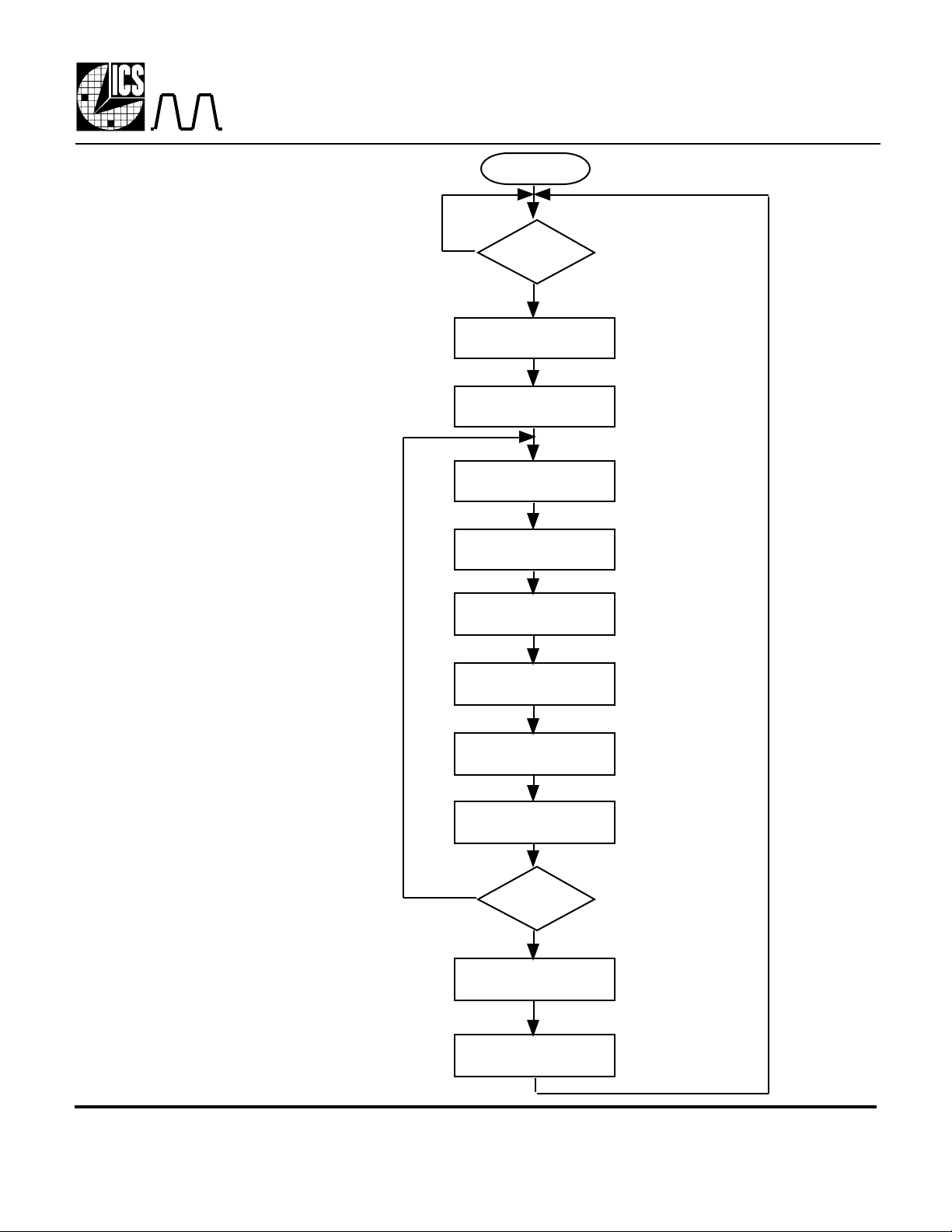

IC Operation

(Periodic Conversions Enabled)

Power ON

Is

Screen

N

Touched?

Y

Write D4, D5 Reg 0 And

D2, D3 Reg 1 To 1

Issue Interrupt

(If Enabled)

Convert

Y Co-Ordinates

Store Y Co-Ordinates In

Reg 4 and Reg 5

Touch Screen Controller

Convert

X Co-Ordinates

Store X Co-Ordinates in

Reg 2 and Reg 3

Write D7 Reg 0 To 1

Issue Interrupt

(If Enabled)

Is

Screen

Y

Touched?

N

Write D4, D5 Reg 0 And

D2, D3 Reg 1 To 0

Issue Interrupt

(if Enabled)

MDS 712 I 3 Revision 100899 Printed 11/16/00

Integrated Circuit Systems, Inc.•525 Race St.•San Jose•CA•95126•(408)295-9800tel•www.icst.com

Page 4

MK712

ICRO

C

LOCK

Touch Screen Controller

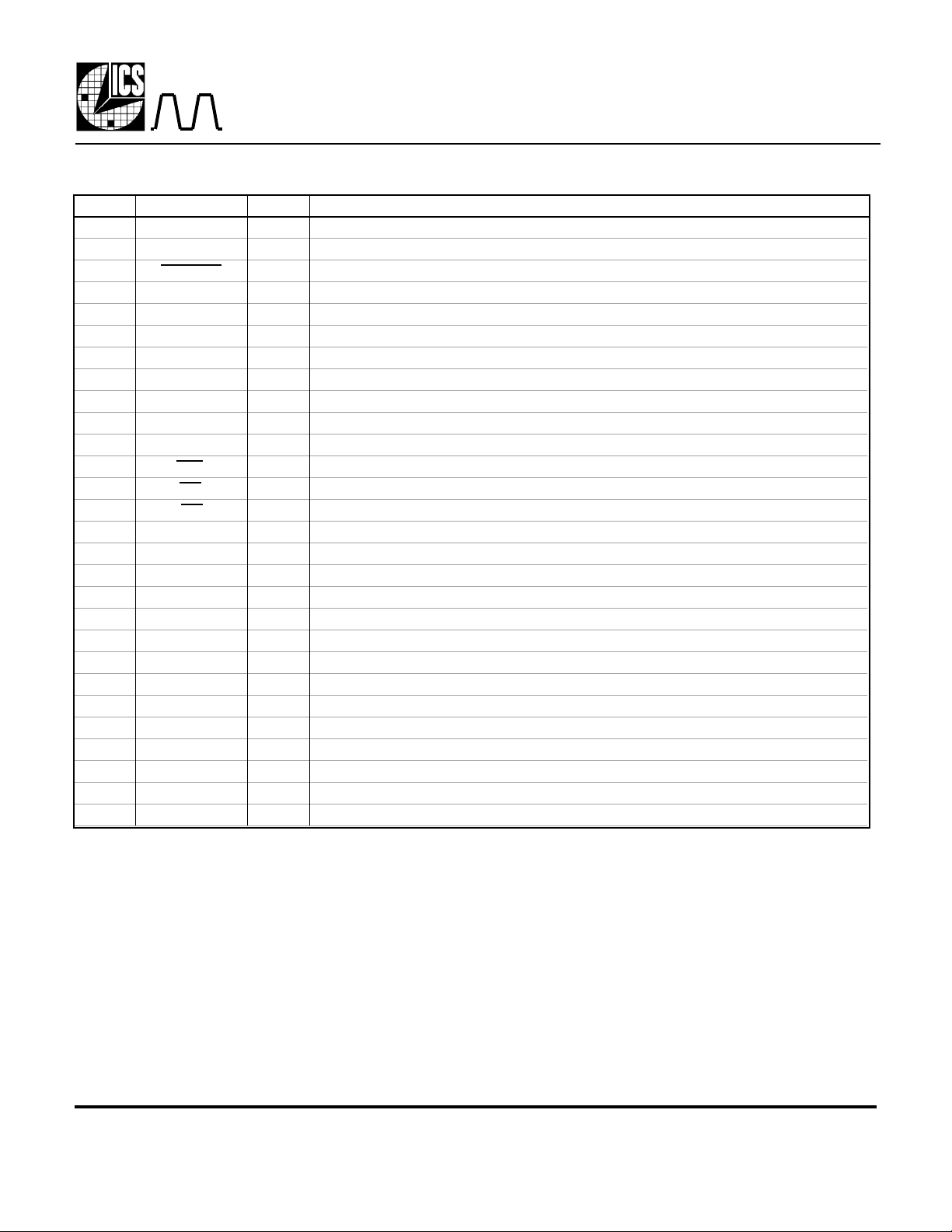

Register Description

The MK712 register set is designed to be compatible with the Gazelle pen digitizer registers allowing a

software driver for the Gazelle digitizer to be used with the MicroClock MK712. The eight 8-bit registers

are defined below:

STATUS LOW (0 READ)

7 1 03 25 46

Always zero

1 = touch

Always zero

1 = conversion complete,

cleared on Y-HIGH read

NOTE: When the screen is touched bits 4 and 5,

register 0, and bits 2 and 3 of register 1 are all set to one.

STATUS HIGH (1 READ)

7 1 03 25 46

Always zero

1 = touch

Always zero

X-LOW (2 READ)

7 1 03 25 46

Low order bits of X co-ordinate

X-HIGH (3 READ)

7 1 03 25 46

High order bits of X co-ordinate

Always zero

Y-LOW (4 READ)

7 1 03 25 46

Low order bits of Y co-ordinate

Y-HIGH (5 READ)

7 1 03 25 46

High order bits of Y co-ordinate

Always zero

CONTROL (6 R/W)

7 1 03 25 46

1 = enable interrupts

1 = interrupt on conversion

complete ( if bit 0 = 1)

1 = interrupt on change in

touch status (if bit 0 = 1)

1 = interrupt on change in

touch status (if bit 0 = 1)

1 = enable periodic conversions at

rate indicated by RATE register

1 = read one point. Cleared when

conversion complete. Only functions

when bit 4 = 0

0 = powerdown (PD). Conversions,

interrupts and TOUCH output disabled

1 = powerdown (PD). Conversions,

interrupts and TOUCH output

disabled.

NOTE: Bits 2 or 3 and bits 6 or 7 are logically OR’d. For

example writing bit 2 or bit 3 to a one will enable interrupts

on change in touch status.

RATE (7 R/W)

7 1 03 25 46

Count controls frequency of

conversion when periodic

conversions are enabled. See

table on page 5.

MDS 712 I 4 Revision 100899 Printed 11/16/00

Integrated Circuit Systems, Inc.•525 Race St.•San Jose•CA•95126•(408)295-9800tel•www.icst.com

Page 5

MK712

ICRO

C

LOCK

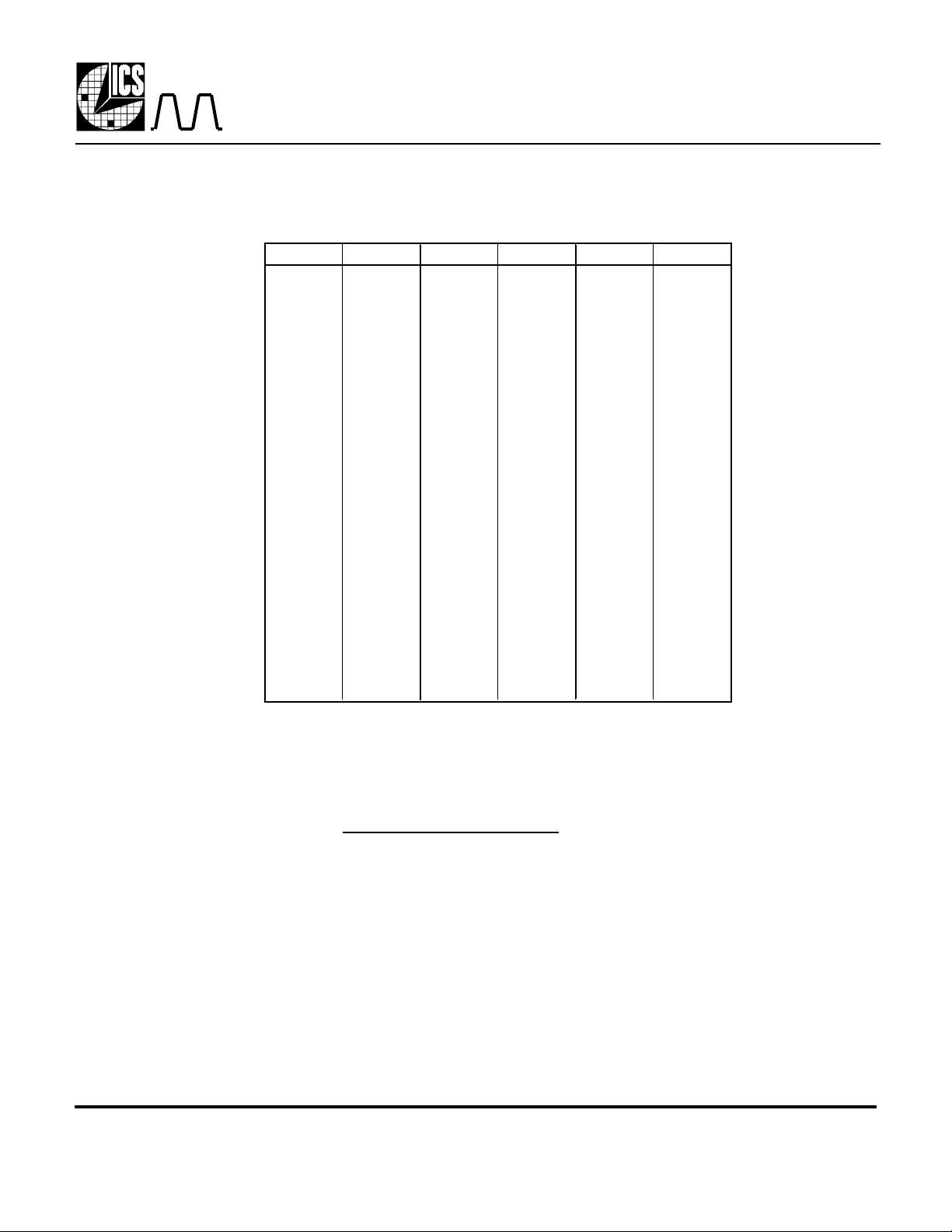

Rate Register (Register 7) Programming

Count P.P.S. Count P.P.S. Count P.P.S.

0 to 8

10 187 30 90 110 29

11 177 31 88 115 28

12 169 32 86 120 27

13 161 33 84 125 26

14 154 34 82 130 25

15 147 35 80 135 24

16 141 40 72 140 24

17 136 45 65 145 23

18 131 50 60 150 22

19 126 55 55 155 21

20 122 60 51 165 20

21 118 65 47 175 19

22 114 70 44 185 18

23 110 75 42 195 17

24 107 80 39 205 16

25 104 85 37 225 15

26 101 90 35 235 14

27 98 95 34 255 13

Not Permitted

9 197 29 93 105 31

Touch Screen Controller

28 95 100 32

P.P.S. = Points Per Second. With a 14.318 MHz clock.

Calculating Points Per Second

The formula for determining P.P.S. is:

fin

P.P.S. =

35716 + (4096 x COUNT)

Where fin is the frequency

of the CLKIN input.

Power-On Reset

On application of power, an internal reset is generated that clears all bits in registers 0, 1, and 6. Register 7 is

set to 32 giving a rate of 86 PPS. Note that clearing register 6 puts the IC into the power down condition.

Initializing the MK712

The interrupt on the MK712 can only be cleared by reading a register or by writing register 6 to the

power down condition. After a fault condition, initialize the MK712 by writing register 6 to zero and

then writing register 6 to the desired value. This will always clear pending interrupts.

MDS 712 I 5 Revision 100899 Printed 11/16/00

Integrated Circuit Systems, Inc.•525 Race St.•San Jose•CA•95126•(408)295-9800tel•www.icst.com

Page 6

MK712

ICRO

Recommended Circuit

From

Microprocessor

14.318 MHz

+3.3V or +5V

22µF

0.1µF

C

0.1µF

LOCK

RD

CS

WR

A0 - A2

D0 - D7

CLKIN

VDD

VDD

VDD

GND

GND

GND

TOUCH

INT

XH

XL

YH

YL

Touch Screen Controller

To Power Management

To Interrupt Controller

X HIGH

To

Touch

Screen

0.1µF

X LOW

Y HIGH

Y LOW

0.1µF0.01µF 0.01µF

Pen Bounce

When the screen is untouched, the Y plate is driven high and the X plate is driven low. When the screen is

touched, the X plate is pulled high, which is detected by the MK712. This initiates a conversion (as long as

periodic conversions are enabled). Some de-bounce is provided by the time constant of the screen

decoupling capacitors combined with the screen resistance. However, once conversions have started, pen

bounce will not be detected until after both the X and Y points have been taken.

If the pen is lifted during a conversion, this will also not be detected until the conversion is complete. This is

typically indicated by a point with the correct Y coordinates, but minimum (for that screen) X coordinates.

Screen Decoupling

The component values suggested should give excellent results. However, for screens with a high

resistance operating at a high conversion rate, extra interrupts may be issued. This is because the time

constant of the screen decoupling capacitors and screen resistance is high, resulting in the screen

appearing to be untouched and then touched between conversions. These extra interrupts can be

eliminated by reducing the size of the screen decoupling capacitors on pins XH, XL, YH, and YL.

This will, however, slightly reduce the noise rejection, which could decrease the accuracy of the

conversion.

MDS 712 I 6 Revision 100899 Printed 11/16/00

Integrated Circuit Systems, Inc.•525 Race St.•San Jose•CA•95126•(408)295-9800tel•www.icst.com

Page 7

MK712

ICRO

C

LOCK

Touch Screen Controller

Optimizing Performance when Reading and Writing Registers

Reading and writing the MK712 generates digital noise that may reduce the accuracy of the A to D

converter. This noise has several causes, including board layout, data bus loading, and power supply

voltage. By appropriately timing the register operations, the effects of this noise can be minimized.

After an interrupt is issued, the MK712 allows a minimum of 1 millisecond to elapse before

initiating the conversion cycle. This allows the screen drivers to settle. For best performance,

complete all register operations within this 1ms window after an interrupt.

Power Down/Stopping the Clock

If the screen is untouched, the supply current is under 3µA. If the input clock is stopped, the supply

current is also less than 3µA. When the screen is touched with no clock, TOUCH goes low and INT

goes high, but no further operations occur until the clock starts. A to D conversions are invalid until

after the clock has stabilized at the correct frequency and one full conversion cycle has been

completed.

Input Clock

The MK712 is highly tolerant of different clock frequencies (from 12 to 20 MHz), rise times, and

duty cycles. However, any input clock undershoot or overshoot will cause the MK712 to draw extra

current. This can be eliminated by using a MicroClock clock synthesizer and properly terminating

the clock driver. MicroClock makes low power clock synthesizers with 14.3 MHz power down.

Resistive Touch Screen (4 Wire)

Resistive touch screens consist of 2 resistive plates that are separated by a small gap. Each plate has an

electrode at each end and when the screen is touched, the two plates are shorted together at that point.

YH

Y PLATE

X PLATE

Electrode

XL

YL

If a voltage is applied, for example, between XL and XH, then a voltage divider is formed on the X

PLATE. When the Y PLATE is touched to the X PLATE, a voltage will be developed on the Y PLATE

that is proportional to distance of the touch from XL and XH. By accurately measuring this voltage, the

position of the touch can be determined.

XH

MDS 712 I 7 Revision 100899 Printed 11/16/00

Integrated Circuit Systems, Inc.•525 Race St.•San Jose•CA•95126•(408)295-9800tel•www.icst.com

Page 8

MK712

ICRO

C

LOCK

Touch Screen Controller

Recommended Method for Reading Points

If the user is pressing lightly on the touch screen, it is likely that the screen contact will be intermittent.

The screen will bounce, causing false points. This effect can be reduced by insuring that the screen is

touched both before and after a conversion. By doing this, the first and last point in a series of points

are discarded. The following algorithm checks that a point has valid touches both before and after a

conversion, and it distinguishes between change-in-touch interrupts and conversion complete

interrupts. Register 6 bits 0, 1, and 2 must all be true (logical 1) in order to use this method.

Start

Wait for Interrupt

Interrupt

Increment

n

Read Register 0 D7D5, store as D7D5(n)

No

Is D7D5(n-1) = 11b

and D7D5(n) =11b?

Yes

Write point n-1 to display

Read X and Y, store as point n

Are this point and the previous point valid?

(11b = binary 11)

Write previous point.

Warning - When Using a Switching Regulator Power Supply

When using the MK712 in a system where the power is supplied by a switching regulator, do not

perform screen conversions when the regulator is operating in the power saving mode. Some switching

regulators feature a low power mode (for example, Linear Technology’s “Burst Mode”) where the

output is turned on and off in order to save power. The extra power supply noise generated when using

this mode causes spurious data points to be returned from the MK712, so it should be disabled when

the MK712 is doing screen conversions.

MDS 712 I 8 Revision 100899 Printed 11/16/00

Integrated Circuit Systems, Inc.•525 Race St.•San Jose•CA•95126•(408)295-9800tel•www.icst.com

Page 9

MK712

ICRO

C

LOCK

Touch Screen Controller

Analog to Digital Converter Operation

The 12-bit ADC converts X and Y co-ordinates at a rate determined by registers 6 and 7. The

converter uses a ratiometric technique to give absolute co-ordinates on the screen, largely independent

of variations in screen resistance, temperature or power supply voltage. The total voltage applied across

the screen is defined as full-scale for the converter (i.e. 4095) and any point touched on the screen is

proportional to this. For example, if the screen is touched exactly in the center, the converter will read

2047. This feature may allow for the elimination of calibration upon startup.

However, the full scale voltage is defined at the IC pins and so any parasitic interconnect resistance will

be included in full scale. In addition, the interconnect resistances on the screen also account for about

20% of the total resistance. This means that approximately the bottom 10% and top 10% of full scale

are inaccessible.

The converter is guaranteed to be monotonic, with no missing codes.

BOARD AND WIRE

INTERCONNECT

MK712

XH

YL

XL

FULL

SCALE

(4095)

SCREEN

INTERCONNECT

SCREEN

X

CO-ORDINATE

SCREEN

INTERCONNECT

BOARD AND WIRE

INTERCONNECT

MDS 712 I 9 Revision 100899 Printed 11/16/00

Integrated Circuit Systems, Inc.•525 Race St.•San Jose•CA•95126•(408)295-9800tel•www.icst.com

Page 10

MK712

exposure to levels above the operating limits but below the Absolute Maximums may affect device reliability.

2. Consult MicroClock about the best device to use to generate the input clock.

3. With no missing codes.

4. Assumes no 14.3MHz input clock overshoot, 300 Ω screen, 100 PPS

5. Assumes no 14.3MHz input clock overshoot, no touch

6. With no touch, no clock

ABSOLUTE MAXIMUM RATINGS (note 1)

ICRO

C

LOCK

Touch Screen Controller

Electrical Specifications

Parameter Conditions Minimum Typical Maximum Units

Supply voltage, VDD Referenced to GND 7 V

Inputs and Clock Outputs Referenced to GND -0.5 VDD+0.5 V

Ambient Operating Temperature 0 70 °C

Soldering Temperature Max of 20 seconds 260 °C

Storage temperature -65 150 °C

DC CHARACTERISTICS

Operating Voltage, VDD 3.0 5.5 V

Input High Voltage, VIH VDD=5V 2.0 V

Input Low Voltage, VIL VDD=5V 0.8 V

Output High Voltage, VOH IOH=-2mA VDD-0.4 V

Output High Voltage, VOH VDD=5V, IOH=-12mA 2.4 V

Output Low Voltage, VOL VDD=5V, IOL=12mA 0.4 V

Input High Voltage, VIH VDD=3.3V 1.9 V

Input Low Voltage, VIL VDD=3.3V 0.4 V

Output High Voltage, VOH VDD=3.3V, IOH=-6mA 2.4 V

Output Low Voltage, VOL VDD=3.3V, IOL=6mA 0.4 V

Operating Supply Current, IDD, at VDD=5V 300 Ω screen, 100 PPS 5 mA

Operating Supply Current, IDD, at VDD=3.3V note 4 3 mA

Operating Supply Current, IDD standby, clock note 5 0.5 3 µA

Operating Supply Current, IDD standby note 6 0.5 3 µA

Operating Supply Current, IDD power down PD=0 or PD=1, no clock 0.2 3 µA

Short Circuit Current Each output ±50 mA

Input Capacitance 7 pF

AC CHARACTERISTICS

Input Clock Frequency, pin 18 Note 2 12 14.32 20 MHz

Input Clock Duty Cycle, pin 18 at 1.5V 25 75 %

Output Rise Time 0.8 to 2.0V, VDD=5V 3 ns

Output Fall Time 2.0 to 0.8V, VDD=5V 3 ns

Resolution 12 bits

Non-linearity Monotonic, note 3 ±2 LSB

Touch Screen Resistance 100 2000 Ω

Notes: 1. Stresses beyond those listed under Absolute Maximum Ratings could cause permanent damage to the device. Prolonged

MDS 712 I 10 Revision 100899 Printed 11/16/00

Integrated Circuit Systems, Inc.•525 Race St.•San Jose•CA•95126•(408)295-9800tel•www.icst.com

Page 11

MK712

READ AND WRITE CYCLES

READ CYCLE ONLY

WRITE CYCLE ONLY

ICRO

C

LOCK

Touch Screen Controller

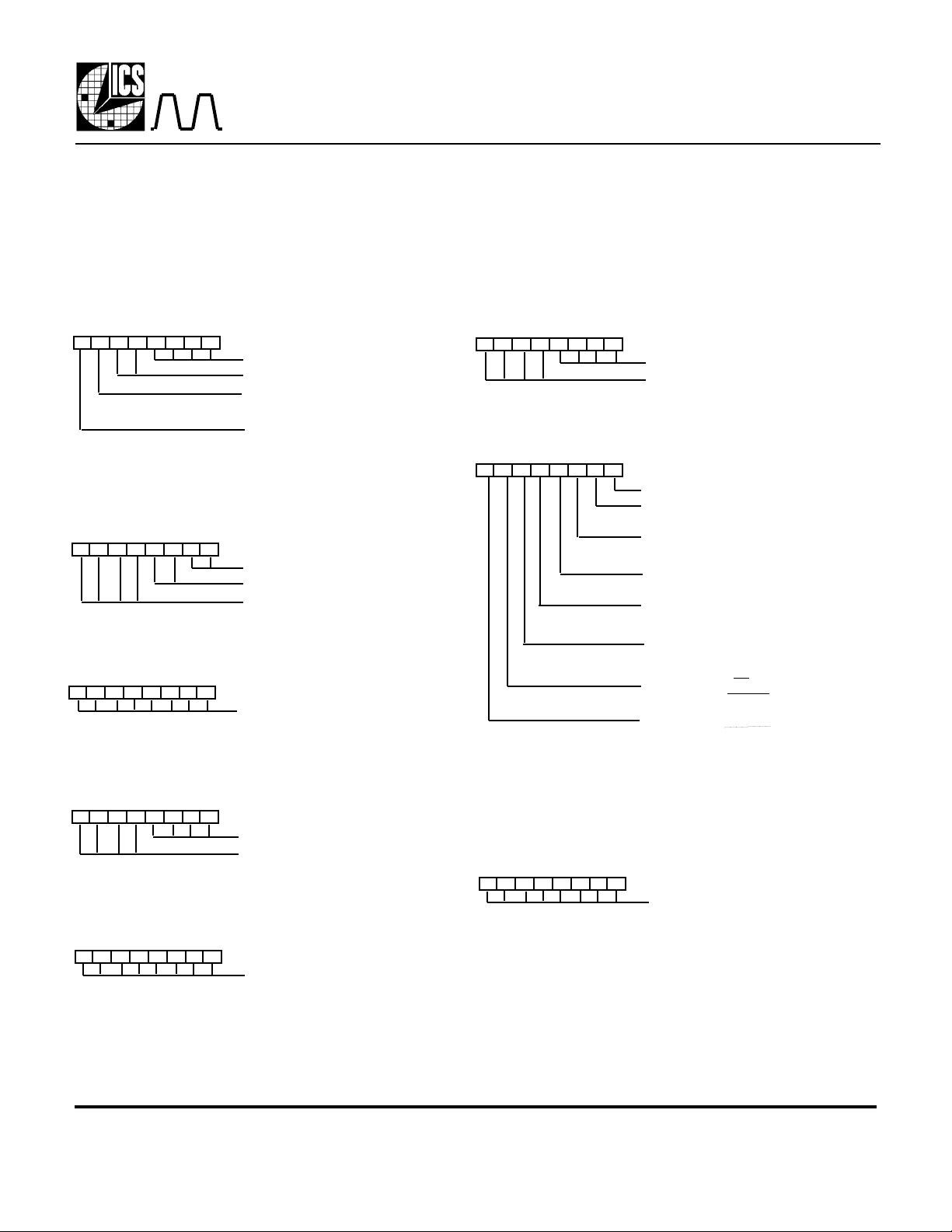

Register Interface Timing

# Symbol Description Min Max Unit Note

READ AND WRITE CYCLES

1 TRASC Address Setup to CS Low 5 ns

2 TRAHC Address Hold from CS High 0 ns

3 TRCCY CS High to CS Low 40 ns

READ CYCLE ONLY

4 TRSCR CS Low to RD Low 10 ns

5 TRRD RD Pulse Width 40 ns

6 TRCHR1 RD High to CS High 0 ns

7 TRCHR2 RD High to CS Low 40 ns

8 TRDC CS Low to Data 35 ns

9 TRDR RD Low to Data 35 ns

10 TRDHC CS High to Data Release 2 20 ns 1

11 TRDHR RD High to Data Release 2 20 ns 1

WRITE CYCLE ONLY

12 TRCSW CS Low to WR Low 10 ns

13 TRWR WR Pulse Width 40 ns

14 TRCHW WR High to CS High 0 ns 2

15 TRWH WR High to CS Low 40 ns

16 TRWCY WR High to WR Low 40 ns

17 TRDW Data Setup to WR High 15 ns 3

18 TRDHW Data Hold from WR High 15 ns 4

19 TRDWC Data Setup to CS High 15 ns 3

20 TRDHWC Data Hold from CS High 15 ns 4

Notes: 1. RD edges may precede or follow CS edges.

2. WR edges may precede or follow CS edges.

3. Either TRDW or TRDWC specification must be met.

4. Either TRDHW or TRDHWC specification must be met.

5. It is not permitted to have both RD and WR low at the same time.

MDS 712 I 11 Revision 100899 Printed 11/16/00

Integrated Circuit Systems, Inc.•525 Race St.•San Jose•CA•95126•(408)295-9800tel•www.icst.com

Page 12

MK712

Register Read

A0 - A2

CS

RD

D0 - D7

Register Write

ICRO

1

C

4

8

LOCK

5

9

Touch Screen Controller

2

3

6

7

10

11

A0 - A2

CS

WR

D0 - D7

1 2

12 13

19

14

1817

20

3

15

16

MDS 712 I 12 Revision 100899 Printed 11/16/00

Integrated Circuit Systems, Inc.•525 Race St.•San Jose•CA•95126•(408)295-9800tel•www.icst.com

Page 13

MK712

IDD

(mA)

Touch Screen Controller

12

ICRO

C

LOCK

MK712 Power Supply Current vs. Touchscreen Resistance

10

8

6

4

2

0

100 1000 10000

Touchscreen Resistance (Ω)

VDD=3.3V

197 points per second

147 points per second

86 points per second

13 points per second

Graph 1

IDD

(mA)

18

16

MK712 Power Supply Current vs. Touchscreen Resistance

VDD=5V

14

12

10

8

6

4

2

0

100 1000 10000

MK712 Power Supply Current vs. Touchscreen Resistance

Vdd= 5 V

197 points per second

147 points per second

86 points per second

13 points per second

Touchscreen Resistance (Ω)

Graph 2

MDS 712 I 13 Revision 100899 Printed 11/16/00

Integrated Circuit Systems, Inc.•525 Race St.•San Jose•CA•95126•(408)295-9800tel•www.icst.com

Page 14

MK712

IDD

(mA)

ICRO

9

8

7

6

5

4

3

2

1

0

0 50 100 150 200

C

LOCK

MK712 Power Supply Current vs. Conversion Rate

Screen Resistance = 320Ω

Conversion Rate (Points Per Second)

Touch Screen Controller

VDD=5V

VDD=3.3V

Graph 3

MDS 712 I 14 Revision 100899 Printed 11/16/00

Integrated Circuit Systems, Inc.•525 Race St.•San Jose•CA•95126•(408)295-9800tel•www.icst.com

Page 15

MK712

Suggested Layout

0.01µF

To

Touch

Screen

0.1µF

ICRO

22µF

G

0.1µF

C

LOCK

0.1µF

0.01µF

V

G

Pin 1

2

3

4

5

6

7

8

9

10

11

12

13

14

Touch Screen Controller

28

27

26

25

24

23

22

21

20

19

18

17

16

15

G

0.1µF

V

G = connection to ground plane

= connection to VDD plane

V

Notes:

1. The 14.318 MHz input clock on pin 18 should have a 33Ω series termination resistor at its source.

Consult MicroClock for the best way to generate this clock.

2. All digital signals should be kept well away from pins 4, 5, 6, 7, 8, 9, 10, and 11, and any traces

connected to those pins.

MDS 712 I 15 Revision 100899 Printed 11/16/00

Integrated Circuit Systems, Inc.•525 Race St.•San Jose•CA•95126•(408)295-9800tel•www.icst.com

Page 16

MK712

Inches

Millimeters

Millimeters

ICRO

C

LOCK

Package Outline and Package Dimensions

E H

h x 45°

D

Q

e

b

c

Ordering Information

Touch Screen Controller

28 pin SOIC wide

Symbol Min Max Min Max

A 0.092 0.104 2.3368 2.6416

b 0.014 0.019 0.356 0.483

c 0.009 0.012 0.229 0.305

D 0.696 0.712 17.678 18.085

E 0.290 0.300 7.366 7.620

H 0.394 0.419 10.008 10.643

e

h 0.016 0.406

Q 0.003 0.011 0.076 0.279

28 pin SSOP (QSOP)

Symbol Min Max

A 1.55 1.73

A

b 0.203 0.305

c 0.190 0.254

D 9.780 10.160

E 3.810 4.064

H 5.840 6.223

e

h 0.410

Q 0.127 0.254

Part/Order Number Marking Package Temperature

MK712S MK712S 28 pin SOIC 0 to +70°C

MK712STR MK712S Add tape and reel 0 to +70°C

MK712SI MK712SI 28 pin SOIC -30 to +70°C

MK712SITR MK712SI Add tape and reel -30 to +70°C

MK712R MK712R 28 pin SSOP 0 to +70°C

MK712RTR MK712R Add tape and reel 0 to +70°C

MK712RI MK712RI 28 pin SSOP -30 to +70°C

MK712RITR MK712RI Add tape and reel -30 to +70°C

While the information presented herein has been checked for both accuracy and reliability, Integrated Circuit Systems, Incorporated (ICS) assumes no responsibility for either its

use or for the infringement of any patents or other rights of third parties, which would result from its use. No other circuits, patents, or licenses are implied. This product is

intended for use in normal commercial applications. Any other applications such as those requiring special processing, high reliability, or other extraordinary environmental

requirements are not recommended without additional processing by ICS. ICS reserves the right to change any circuitry or specifications without notice. ICS does not authorize or

warrant any ICS product for use in life support devices or critical medical instruments.

©1995 ICS/MicroClock

MDS 712 I 16 Revision 100899 Printed 11/16/00

Integrated Circuit Systems, Inc.•525 Race St.•San Jose•CA•95126•(408)295-9800tel•www.icst.com

Loading...

Loading...