Page 1

Semiconductor

MCTG35P60F1

PART WITHDRAWN

April 1999

PROCESS OBSOLETE - NO NEW DESIGNS

Features

• 35A, -600V

= -1.3V(Maximum) at I = 35A and +150oC

•V

TM

• 800A Surge Current Capability

• 800A/µs di/dt Capability

• MOS Insulated Gate Control

o

• 50A Gate Turn-Off Capability at +150

C

Description

The MCT is an MOS Controlled Thyristor designed for

switching currents on and off by negative and positive pulsed

control of an insulated MOS gate. It is designed for use in

motor controls, inverters, line switches and other power

switching applications.

The MCT is especially suited for resonant (zero voltage or

zero current switching) applications. The SCR like forward

drop greatly reduces conduction power loss.

MCTs allow the control of high power circuits with very small

amounts of input energy. They feature the high peak current

capability common to SCR type thyristors, and operate at

junction temperatures up to +150

PART NUMBER INFORMATION

PART NUMBER PACKAGE BRAND

MCTG35P60F1 TO-247 M35P60F1

NOTE: When ordering, use the entire part number.

o

C with active switching.

35A, 600V

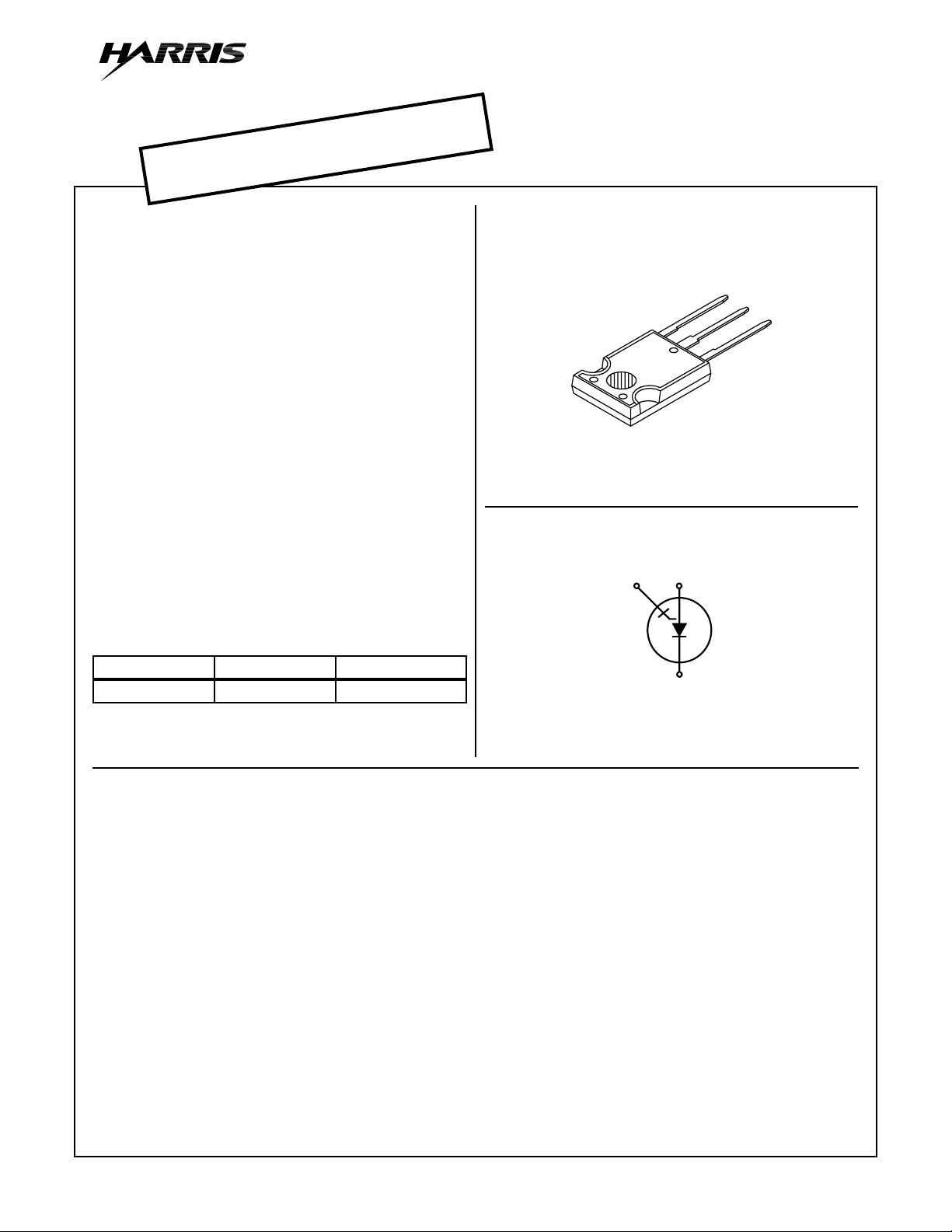

P-Type MOS Controlled Thyristor (MCT)

Package

JEDEC STYLE TO-247

A

K

G

Symbol

GA

K

Absolute Maximum Ratings T

Peak Off-State Voltage (See Figure 11). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . V

Peak Reverse Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . V

Continuous Cathode Current (See Figure 2)

TC = +25oC (Package Limited) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TC = +115oC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Non-Repetitive Peak Cathode Current (Note 1). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I

Peak Controllable Current (See Figure 10) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I

Gate-Anode Voltage (Continuous) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . V

Gate-Anode Voltage (Peak) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . V

Rate of Change of Voltage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . dv/dt See Figure 11

Rate of Change of Current . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . di/dt 800 A/µs

Maximum Power Dissipation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P

Linear Derating Factor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.43 W/oC

Operating and Storage Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . TJ, T

Maximum Lead Temperature for Soldering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

(0.063" (1.6mm) from case for 10s)

NOTE:

1. Maximum Pulse Width of 250µs (Half Sine) Assume TJ (Initial) = +90oC and TJ (Final) = TJ (Max) = +150oC

CAUTION: These devices are sensitive to electrostatic discharge. Users should follow proper ESD Handling Procedures.

Copyright

© Harris Corporation 1999

= +25oC, Unless Otherwise Specified

C

2-2

I

K25

I

K115

KSM

KC

T

DRM

RRM

GA

GAM

T

L

MCTG35P60F1 UNITS

-600 V

+5 V

60

35

800 A

50 A

±20 V

±25 V

178 W

STG

-55 to +150

260

File Number 3602.5

A

A

o

C

o

C

Page 2

Specifications MCTG35P60F1

Electrical Specifications T

PARAMETER SYMBOL TEST CONDITIONS MIN TYP MAX UNITS

Peak Off-State Blocking

Current

Peak Reverse Blocking

Current

On-State Voltage V

Gate-Anode Leakage Current I

Input Capacitance C

Current Turn-On Delay Time t

Current Rise Time t

Current Turn-Off Delay Time t

Current Fall Time t

= +25oC, Unless Otherwise Specified

C

I

DRM

VKA = -600V,

VGA = +18V

I

RRM

VKA = +5V

VGA = +18V

TM

IK = I

K115

,

VGA = -10V

GAS

ISS

VGA = ±20V - - 100 nA

VKA = -20V, TJ = +25oC

VGA = +18V

D(ON)I

L = 200µH, IK = I

K115

RG = 1Ω, VGA = +18V, -7V

RI

TJ = +125oC

VKA = -300V

D(OFF)I

FI

TC = +150oC - - 1.5 mA

TC = +25oC- - 50µA

TC = +150oC- - 2 mA

TC = +25oC- - 50µA

TC = +150oC - - 1.35 V

TC = +25oC - - 1.4 V

-5-nF

- 140 - ns

- 180 - ns

- 640 - ns

- 1.1 1.4 µs

Turn-Off Energy E

Thermal Resistance R

OFF

θJC

Typical Performance Curves

100

PULSE TEST

PULSE DURATION = 250µs

50

DUTY CYCLE < 2%

30

20

10

TJ = +150oC

5

3

, CATHODE CURRENT (A)

K

I

2

1

0 0.5 1.0 1.5 2.0

V

, CATHODE VOLTAGE (V)

TM

FIGURE 1. CATHODE CURRENT vs SATURATIONVOLTAGE

(TYPICAL)

TJ = -40oC

TJ = +25oC

- 5.6 - mJ

o

C/W

100

90

80

70

60

50

40

30

20

, DC CATHODE CURRENT (A)

K

I

10

0

20

PACKAGE LIMIT

40

30

50 60

- 0.6 0.7

70 80 90

TC, CASE TEMPERATURE (oC)

100

110 120 130 140 150

FIGURE 2. MAXIMUM CONTINUOUS CATHODE CURRENT

2-3

Page 3

MCTG35P60F1

Typical Performance Curves

T

= +150oC, RG = 1Ω, L = 200µH

200

175

150

125

100

, TURN-ON DELAY (ns)

D(ON)I

75

t

50

0 102030405060

VKA = -200V

IK, CATHODE CURRENT (A)

J

(Continued)

VKA = -300V

FIGURE 3. TURN-ON DELAY vs CATHODE CURRENT

(TYPICAL)

300

250

200

TJ = +150oC, RG = 1Ω, L = 200µH

VKA = -200V

1100

1000

900

800

700

, TURN-OFF DELAY (ns)

600

D(OFF)I

500

t

400

0102030

VKA = -200V

IK, CATHODE CURRENT (A)

TJ = +150oC, RG = 1Ω, L = 200µH

VKA = -300V

40

50

FIGURE 4. TURN-OFF DELAY vs CATHODE CURRENT

(TYPICAL)

1.5

1.25

VKA = -200V

TJ = +150oC, RG = 1Ω, L = 200µH

60

150

, RISE TIME (ns)

100

RI

t

50

0

0 102030405060

VKA = -300V

, CATHODE CURRENT (A)

I

K

FIGURE 5. TURN-ON RISE TIME vs CATHODE CURRENT

(TYPICAL)

2

1

VKA = -300V

0.5

, TURN-ON SWITCHING LOSS (mJ)

ON

E

0.1

0

10

I

, CATHODE CURRENT (A)

K

TJ = +150oC, RG = 1Ω, L = 200µH

VKA = -200V

20

30 40 50

1

, FALL TIME (µs)

FI

t

0.75

0.5

0102030

I

VKA = -300V

40

, CATHODE CURRENT (A)

K

50 60

FIGURE 6. TURN-OFF FALL TIME vs CATHODE CURRENT

(TYPICAL)

T

= +150oC, RG = 1Ω, L = 200µH

10

5

VKA = -300V

1

0.5

, TURN-OFF SWITCHING LOSS (mJ)

OFF

E

0.1

60

0

10

20

IK, CATHODE CURRENT (A)

J

VKA = -200V

30 40 50 60

FIGURE 7. TURN-ON ENERGY LOSS vsCATHODE CURRENT

(TYPICAL)

FIGURE8. TURN-OFFENERGY LOSSvsCATHODE CURRENT

(TYPICAL)

2-4

Page 4

MCTG35P60F1

Typical Performance Curves

100

50

30

20

10

f

= 0.05 / t

MAX1

5

f

MAX2

PD: ALLOWABLE DISSIPATION

3

P

: CONDUCTION DISSIPATION

C

2

(P

DUTY FACTOR = 50%)

C

, MAX OPERATING FREQUENCY (kHz)

R

= 0.6oC/W

θJC

1

MAX

f

51020

D(OFF)I

= (PD - PC) / E

IK, CATHODE CURRENT (A)

SWITCH

(Continued)

T

= +115oC, L = 200µH

C

VKA = -300V

VKA = -200V

30 50 100

FIGURE9. OPERATINGFREQUENCY vsCATHODECURRENT

(TYPICAL)

-725

-700

-675

-650

-625

-600

-575

-550

-525

-500

, BREAKDOWN VOLTAGE (V)

-475

DRM

-450

V

-425

0.1 1 10 100 1000 10000

dv/dt (V/µs)

TJ = +150oC, VGA = 18V

60

50

40

30

20

10

PEAK CATHODE CURRENT (A)

0

SAFE OPERATING AREA

0

-100 -200

VKA, PEAK TURN OFF VOLTAGE (V)

TURN-OFF

TJ = +150oC, VGA = 18V, L = 100µH

-300 -400

-500

FIGURE 10. TURN-OFF CAPABILITY vsANODE-CATHODE

VOLTAGE

200

CS = 0.1µF, TJ = +150oC

100

= 0.1µF, TJ = +25oC

C

S

= 1µF, TJ = +150oC

C

S

50

20

10

, SPIKE VOLTAGE (V)

SPIKE

5

V

2

0 5 10 15 20 25 30 35 40

CS = 2µF, TJ = +150oC

= 1µF, TJ = +25oC

C

S

C

= 2µF, TJ = +25oC

S

di/dt (A/µs)

-600

FIGURE 11. BLOCKING VOLTAGE vs dv/dt FIGURE 12. SPIKE VOLTAGE vs di/dt (TYPICAL)

Operating Frequency Information

Operating frequency information for a typical device

(Figure 9) is presented as a guide for estimating device performance for a specific application. Other typical frequency

vs cathode current (I

tion shown for a typical unit in Figure 3 to Figure 8. The operating frequency plot (Figure 9) of a typical device shows

f

or f

MAX1

MAX2

mation is based on measurements of a typical device and is

bounded by the maximum rated junction temperature.

f

is defined by f

MAX1

+t

D(OFF)I

deadtime (the denominator) has been arbitrarily

held to 10% of the on-state time for a 50% duty factor. Other

definitions are possible. t

the leading edge of the input pulse and the point where the

cathode current rises to 10% of its maximum value. t

is defined as the 90% point of the trailing edge of the input

pulse and the point where the cathode current falls to 90% of

) plots are possible using the informa-

AK

whichever is lower at each point. The infor-

MAX1

= 0.05 / (t

D(ON)I

D(ON)I+tD(OFF)I

is defined as the 10% point of

). t

D(OFF)I

D(ON)I

its maximum value. Device delay can establish an additional

frequency limiting condition for an application other than

T

JMAX.tD(OFF)I

is important when controlling output ripple

under a lightly loaded condition.

f

is defined by f

MAX2

allowable dissipation (P

R

. The sum of device switching and conduction losses

θJC

must not exceed P

. A 50% duty factor was used (Figure 10)

D

and the conduction losses (P

(V

AK•IAK

) / (duty factor/100). EONis defined as the sum of

=(PD-PC)/(EON+E

MAX2

) is defined by PD=(T

D

) are approximated by PC =

C

OFF

JMAX-TC

the instantaneous power loss starting at the leading edge of

the input pulse and ending at the point where the anodecathode voltage equals saturation voltage (V

AK=VTM

is defined as the sum of the instantaneous power loss starting at the trailing edge of the input pulse and ending at the

point where the cathode current equals zero (I

= 0).

K

2-5

). The

). E

)/

OFF

Page 5

Test Circuits

200µH

I

K

DUT

V

K

RURG3060

MCTG35P60F1

+

500Ω

-

20V

+

10kΩ

V

G

+

-

V

A

C

S

DUT

9V

+

4.7kΩ

I

K

-

FIGURE 13. SWITCHING TEST CIRCUIT FIGURE 14. V

MAXIMUM RISE AND FALL TIME OF VG IS 200ns

V

G

10%

-V

KA

90%

I

K

10%

t

D(OFF)I

t

FI

90%

t

D(ON)I

t

RI

FIGURE 15. SWITCHING TEST WAVEFORMS

Handling Precautions for MCTs

MOS Controlled Thyristors are susceptible to gate-insulation

damage by the electrostatic discharge of energy through the

devices. When handling these devices, care should be exercised to assure that the static charge built in the handler's

body capacitance is not discharged through the device.

MCT's can be handled safely if the following basic precautions are taken:

1. Prior to assembly into a circuit, all leads should be kept

shorted together either by the use of metal shorting

springs or by the insertion into conductive material such

*

as

“ECCOSORB LD26” or equivalent.

2.When devices are removed by hand from their carriers,

the hand being used should be grounded by any suitable

means - for example, with a metallic wristband.

3.Tips of soldering irons should be grounded.

TEST CIRCUIT

SPIKE

V

G

di/dt

I

K

V

AK

FIGURE 16. V

V

SPIKE

TEST WAVEFORMS

SPIKE

V

TM

4.Devices should neverbe inserted into or removed from circuits with power on.

5.Gate Voltage Rating - Never exceed the gate-voltage

rating of V

. Exceeding the rated VGAcan result in

GA

permanent damage to the oxide layer in the gate region.

6.Gate Termination - The gates of these devices are essentially capacitors. Circuits that leave the gate open-circuited

or floating should be avoided. These conditions can result

in turn-on of the device due to voltage buildup on the input

capacitor due to leakage currents or pickup.

7.Gate Protection - These devices do not have an internal

monolithic zener diode from gate to emitter. If gate protection is required an external zener is recommended.

† Trademark Emerson and Cumming, Inc.

2-6

Loading...

Loading...