Page 1

64 Mbit (8Mb x8 or 4Mb x16, Boot Block)

FEATURES SUMMARY

■ SUPPLY VOLTAGE

–V

–V

■ ACCESS TIME: 70, 90 ns

■ PROGRAMMING TIME

– 10 µs per Byte/Word typical

– Double Word Programming Option

■ 135 MEMORY BLOCKS

– 1 Boot Block and 7 Parameter Blocks,

– 127 Main Blocks, 64 KBytes each

■ PROGRAM/E RA SE CONTROLLER

– Embedded Byte/Word Program algorithms

■ ERASE SUSPEND and RESUME MODES

– Read and Program another Block during

■ UNLOCK BYPASS PROGRAM COMMAND

– Faster Production/Batch Programm ing

■ V

PP

PROTECT

■ TEMPORARY BLOCK UNPROTECTION

MODE

■ COMMON FLASH INTERFACE

– 64-bit Security Code

■ EXTENDED MEMORY BLOCK

– Extra block used as security block or to store

■ LOW POWER CONSUMPTION

– Standby and Automatic Standby

■ 100,000 PROGRAM/ER ASE CYCL ES per

BLOCK

■ ELECTRONIC SIGNATURE

– Manufacturer Code: 0020h

– Top Device Code M29W640DT: 22DEh

– Bottom Device Code M29W640DB: 22DFh

2.7V to 3.6V for Program, Erase, Read

CC =

=12 V for Fast Program (optional)

PP

8 KBytes each (Top or Bottom Location)

Erase Suspend

/WP Pin for FAST PROGRAM and WRITE

additional information

M29W640DT

M29W640DB

3V Supply Fl ash Me m ory

PRELIMINARY DATA

Figure 1. Packages

TSOP48 (N)

12 x 20mm

FBGA

TFBGA63 (ZA)

63 ball array

April 2003

This is preliminary information on a new product now in development or undergoing evaluation. Details are subject to change without notice.

1/50

Page 2

M29W640DT, M29W640DB

TABLE OF CONTENTS

SUMMARY DESCRIPTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

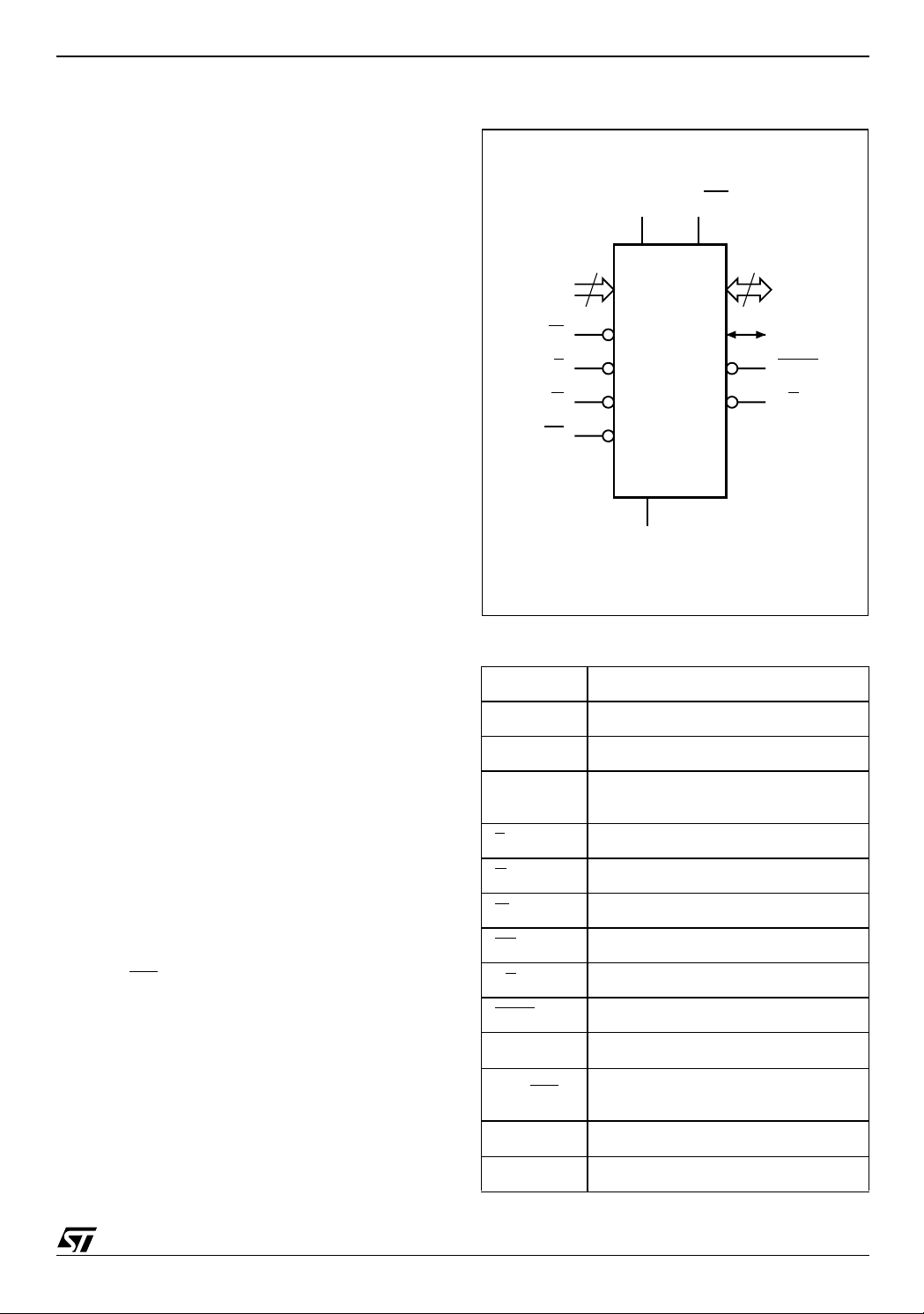

Figure 2. Logic Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Table 1. Signal Names . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

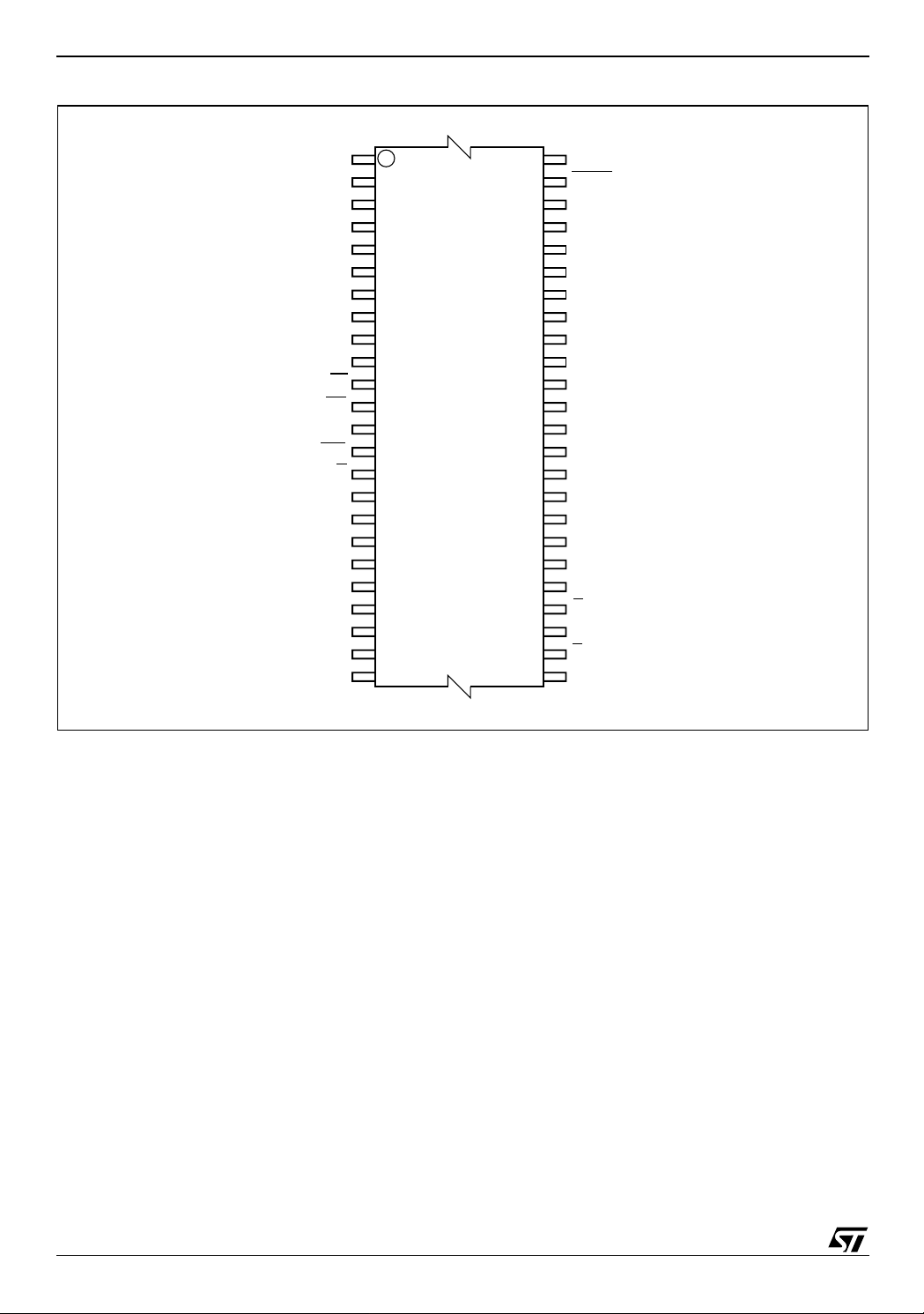

Figure 3. TSOP Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

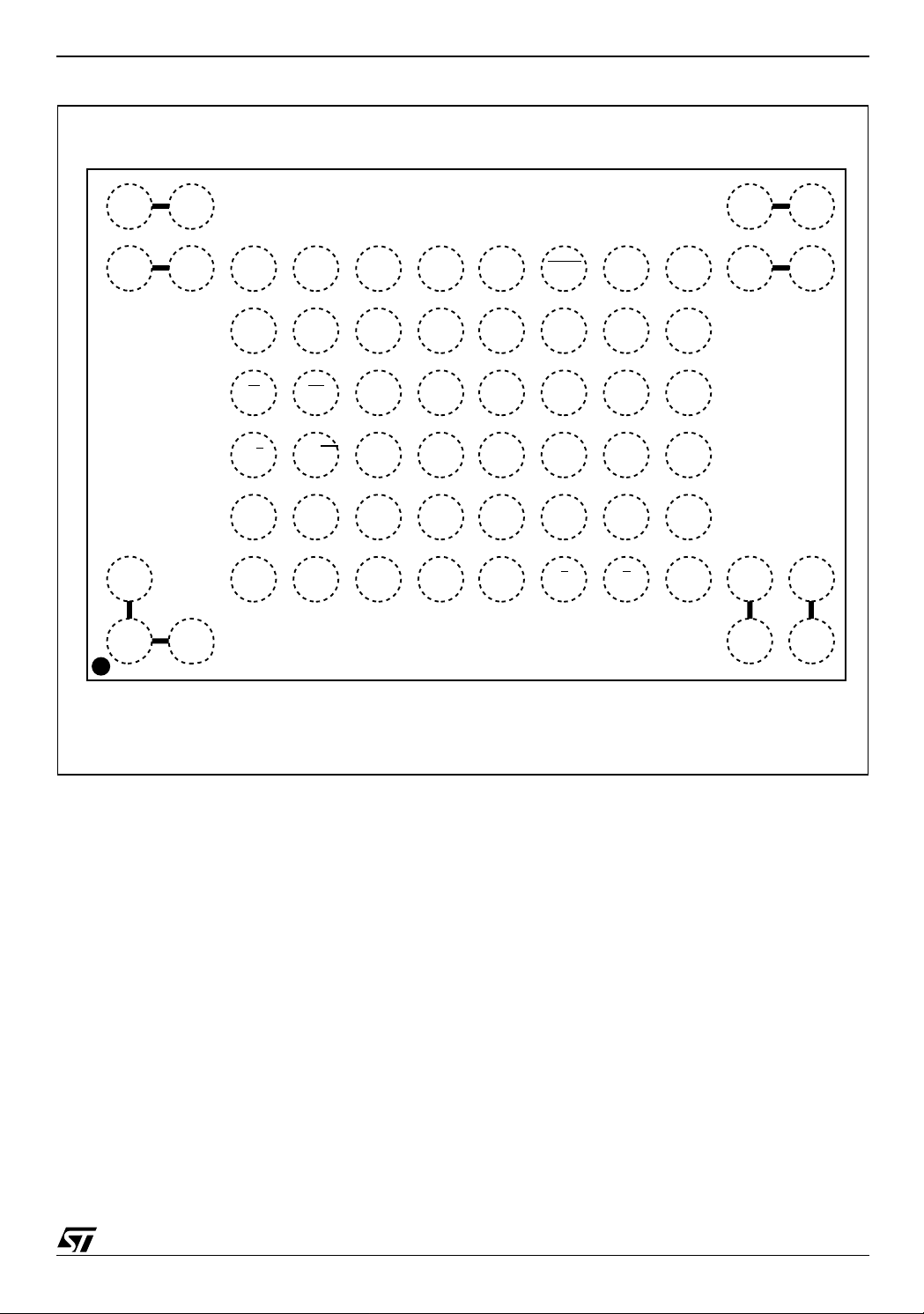

Figure 4. TFBGA Connections (Top view through package). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

SIGNAL DESCRIPTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Address Inputs (A0-A21). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Data Inputs/Outputs (DQ0-DQ7). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Data Inputs/Outputs (DQ8-DQ14). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Data Input/Output or Address Input (DQ15A–1). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Chip Enable (E). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Output Enable (G). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Write Enable (W). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

V

Write Protect (V

PP/

Reset/Block Temporary Unprotect (RP).. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Ready/Busy Output (RB). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Byte/Word Organization Select (BYTE). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

V

Supply Voltage (2.7V to 3.6V).. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

CC

V

Ground. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

SS

WP). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

PP/

BUS OPERATIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Bus Read. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Bus Write. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Output Disable. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Standby. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Automatic Standby. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Special Bus Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 0

Electronic Signature. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Block Protect and Chip Unprotect. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Block Protect and Chip Unprotect. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

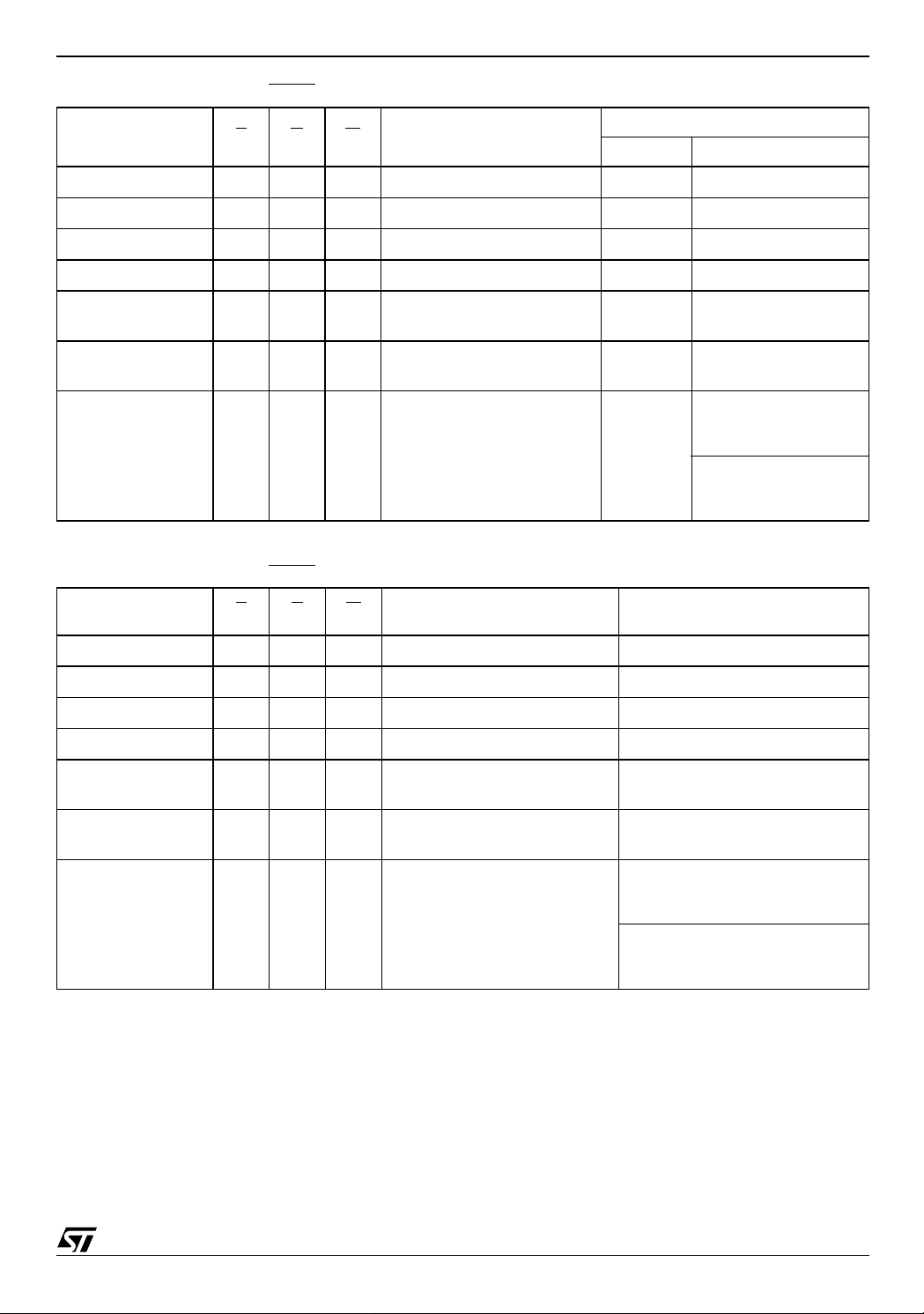

Table 2. Bus Operations, BYTE = V

Table 3. Bus Operations, BYTE = V

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

IL

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

IH

COMMAND INTERFACE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Read/Reset Command.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Auto Select Command. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Program Command. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Unlock Bypass Command. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 3

Unlock Bypass Program Command. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Unlock Bypass Reset Command. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Chip Erase Command. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Block Erase Command.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2/50

Page 3

M29W640DT, M29W640DB

Erase Suspend Comma nd. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Erase Resume Command. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Enter Extended Block Command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Exit Extended Block Command. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Table 4. Commands, 16-bit mode, BYTE = V

Table 5. Commands, 8-bit mode, BYTE = V

Table 6. Program, Erase Times and Program, Erase Endurance Cycles . . . . . . . . . . . . . . . . . . . . 17

STATUS REGISTER. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Data Polling Bit (DQ7). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Toggle Bit (DQ6).. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Error Bit (DQ5). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Erase Timer Bit (DQ3). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Alternative Toggle Bit (DQ2).. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Table 7. Status Register Bits. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Figure 5. Data Polling Flowchart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Figure 6. Data Toggle Flowchart. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 9

MAXIMUM RATING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

IH

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

IL

Table 8. Absolute Maximum Ratings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

DC and AC PARAMETERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Table 9. Operating and AC Measurement Condition s. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Figure 7. AC Measurement I/O Waveform . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Figure 8. AC Measurement Load Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Table 10. Device Capacitance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Table 11. DC Characteristics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Figure 9. Read Mode AC Waveforms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Table 12. Read AC Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Figure 10. Write AC Waveforms, Write Enable Controlled . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Table 13. Write AC Characteristics, Write Enable Controlled . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Figure 11. Write AC Waveforms, Chip Enable Controlled . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Table 14. Write AC Characteristics, Chip Enable Controlled . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Figure 12. Reset/Block Temporary Unprotect AC Waveforms . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Table 15. Reset/Block Temporary Unprotect AC Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Figure 13. Accelerated Program Timing Waveforms. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

PACKAGE MECHANICAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Figure 14. TSOP48 – 48 lead Plastic Thin Small Outline, 12 x 20mm, Package Outline . . . . . . . . 27

Table 16. TSOP48 – 48 lead Plastic Thin Small Outline, 12 x 20mm, Package Mechanical Data . 27

Figure 15. TFBGA63 7x11mm - 6x8 active ball array, 0.8mm pitch, Package Outline . . . . . . . . . . 28

Table 17. TFBGA63 7x11mm - 6x8 active ball array, 0.8mm pitch, Package Mechanical Data . . . 28

PART NUMBERING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Table 18. Ordering Information Scheme . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

3/50

Page 4

M29W640DT, M29W640DB

APPENDIX A. BLOCK ADDRESSES. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Table 19. Top Boot Block Addresses, M29W640DT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Table 20. Bottom Boot Block Addresses, M29W640DB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

APPENDIX B. COMMON FLASH INTERFACE (CFI) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Table 21. Query Structure Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

Table 22. CFI Query Identification String . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

Table 23. CFI Query System Interface Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

Table 24. Device Geometry Definition. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

Table 25. Primary Algorithm-Specific Extended Query Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Table 26. Security Code Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

APPENDIX C. EXTENDED MEMORY BLOCK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Factory Locked Extended Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Customer Lockable Extended Block. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Table 27. Extended Block Address and Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

APPENDIX D. BLOCK PROTECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Programmer Technique . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 4

In-System Technique . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Table 28. Programmer Technique Bus Operations, BYTE = V

or VIL . . . . . . . . . . . . . . . . . . . . . 44

IH

Figure 16. Programmer Equipment Group Protect Flowchart. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Figure 17. Programmer Equipment Chip Unprotect Flowchart . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Figure 18. In-System Equipment Group Protect Flowchart. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Figure 19. In-System Equipment Chip Unprotect Flowchart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

REVISION HISTORY. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Table 29. Document Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

4/50

Page 5

SUMMARY DESCRIPTION

The M29W640D is a 64 Mbit (8Mb x8 or 4Mb x16)

non-volatile memory that can be read, erased and

reprogrammed. These operations can be performed using a single low voltage (2.7 to 3.6V)

supply. On power-up the memory d efaults to its

Read mode where it can be read in the same way

as a ROM or EPROM.

The memory is divided into blocks that can be

erased independently so it is pos sible to pres erve

valid data while old data is erased. Blocks can be

protected in units of 256 KByte (generally groups

of four 64 KByte blocks), to prevent accidental

Program or Erase commands from modifying the

memory. Program and Erase com m ands are wri tten to the Command Interface of t he memory. An

on-chip Program/Erase Controller simplifies the

process of programming or erasing the memory by

taking care of all of the special operations that are

required to update the memory contents. The end

of a program or erase op eration can be de tected

and any error conditions identified. The command

set required to control the memory is consistent

with JEDEC standards.

The device features an asymmetrical blocked architecture. The device has an array of 135 blocks:

■ 8 Parameters Blocks of 8 KBytes each (or

4KWords each)

■ 127 Main Blocks of 64 KBytes each (or

32 KWords each)

M29W640DT has the Parameter Blocks at the top

of the memory address space while the

M29W640DB locates the Parameter Blo cks starting from the bottom.

The M29W640D has an extra block, the Extended

Block, (of 32 KWords in x16 mode or of 64 KBytes

in x8 mode) that can be accessed using a dedicated command. The Extended Block can be protected and so is useful for storing security information.

However the protection is not reversible, once protected the protection cannot be undone.

Chip Enable, Output Enable and Write Enable signals control the bus operation of the memory.

They allow simple conne ction to most m icroprocessors, often without additional logic.

The V

/WP signal is used to enable faster pro-

PP

gramming of the device, enabling double word

programming. If this signal is held at V

, the boot

SS

block, and its adjacent parameter blo ck, are protected from program and erase operations.

The memor y is del ivered with all t he bit s eras ed (set

to 1).

M29W640DT, M29W640DB

Figure 2. Logic Diagram

VPP/WP

V

CC

22

A0-A21

W

E

G

RP

Table 1. Signal Names

A0-A21 Address Inputs

DQ0-DQ7 Data Inputs/Outputs

DQ8-DQ14 Data Inputs/Outputs

DQ15A–1

(or DQ15)

E

G

W

RP

RB

BYTE

V

CC

VPP/WP

M29W640DT

M29W640DB

V

SS

Data Input/Output or Address Input

(or Data Input/Output)

Chip Enable

Output Enable

Write Enable

Reset/Block Temporary Unprotect

Ready/Busy Output

Byte/Word Organization Select

Supply Voltage

Supply Voltage for Fast Program

(optional) or Write Protect

15

DQ0-DQ14

DQ15A–1

BYTE

RB

AI05733

V

SS

NC Not Connected Internally

Ground

5/50

Page 6

M29W640DT, M29W640DB

Figure 3. TSOP Connections

A15

1

48

A14

A13

A12

A11

A10 DQ14

A9

A8

A19

A20

M29W640DT

M29W640DB

W

RP

A21

12

13

37

36

VPP/WP

RB

A18

A17

A7

A6

A5

A4

A3

A2

A1

24 25

AI05734

A16

BYTE

V

SS

DQ15A–1

DQ7

DQ6

DQ13

DQ5

DQ12

DQ4

V

CC

DQ11

DQ3

DQ10

DQ2

DQ9

DQ1

DQ8

DQ0

G

V

SS

E

A0

6/50

Page 7

Figure 4. TFBGA Connections (Top view through package)

M29W640DT, M29W640DB

8

7

6

5

4

3

2

1

NC

NC

NC

NC

(1)

(1)

(1)

(1)

NC

NC

NC

(1)

(1)

A12A13

A15A14

A16

BYTE

A11 DQ7

W

RB

RP

V

/

PP

WP

A20

DQ2

DQ12DQ5A19A21

A5

A1A2

(1)

A0A4A3

CBAEDFGH

DQ15

A–1

V

SS

DQ6DQ13DQ14A10A8A9

V

CC

DQ4

DQ3DQ11DQ10A18

DQ1DQ9DQ8DQ0A6A17A7

E

G

V

SS

JKLM

NC

NC

NC

NC

(1)

(1)

(1)

(1)

NC

NC

NC

NC

(1)

(1)

(1)

(1)

Note: 1. Bal l s ar e shorted to get her via the substrate but not connec ted to the die.

AI05735

7/50

Page 8

M29W640DT, M29W640DB

SIGNAL DESCRIPTIONS

See Figure 2, Logic Diagram, and T able 1, Sign al

Names, for a brief overview of the signals connected to this device.

Address Inputs (A0-A21). The Address Inputs select the cells i n the memory array to a ccess during Bus Read operations. During Bus Write operations they control the commands sent to the Command Interface of the Program/Erase Controller.

Data Inputs/Outputs (DQ0-DQ7). The Data I/O outputs the data stored at the selected address during a Bus Read operation. During Bus Write operations they represent the commands sent to the Command Interface of the Program/Erase Controller.

Data Inputs/Outputs (DQ8-DQ14). The Data I/O outputs the data stored at the selected address during a Bus Read operation when B Y TE V

. When BYTE is Low, VIL, these pins are not

IH

used and are high impedance. During Bus Write

operations the Command Register does not use

these bits. When reading the Status Register

these bits should be ignored.

Data Input/Output o r Address Input (DQ15A –1).

When BYTE

is High, VIH, this pin behaves as a

Data Input/Output pin (as DQ8-DQ14). When

is Low, VIL, this pin behaves as an address

BYTE

pin; DQ15A–1 Low will select the LSB of the addressed Word, DQ15A–1 High will select the MSB.

Throughout the text consider references to the

Data Input/Output to include this pin when BYTE

High and references to the Address Inputs to include this pin when BYTE

is Low except when

stated explicitly otherwise.

Chip Enable (E

). The Chip Enable, E, activates

the memory, allowing Bus Read and Bus Write operations to be performed. When Chip Enable is

High, V

Output Enable (G

, all other pins are ignored.

IH

). The Output Enable, G, con-

trols the Bus Read operation of the memory.

Write Enable (W

). The Write Enable, W, controls

the Bus Write operation of the memory’s Command Interf a c e .

Write Protect (VPP/WP). The VPP/Write

V

PP/

Protect

pin provides two functions. The VPP function allo ws the memory to use an exte rnal high

volt age power suppl y t o reduce t he time r e quire d

for Unlock Bypass Program operations. The

Write P ro tec t func ti on pr ov i des a ha rd ware met hod of protecting the two outermost boot blocks.

The V

/Write Protect pin must not be left floating

PP

or unconnected.

When V

/Write Protect is L ow , VIL, the memory

PP

protects the two outermost boot blocks; Program

is High,

is

and Erase operations in this block are ignored

while V

When V

/Write Protect is Low.

PP

/Write Protect is High, VIH, the memo r y

PP

reverts to the previous protection status of the two

outermost boot blocks. Program and Erase operations can now modify the data in the two outermost

boot blocks unless the block is protected using

Block Protection.

When V

/Write Protect is raised to V

PP

the mem-

PP

ory automatically enters the Unlock Bypass mode.

When V

/Write Protect returns to VIH or VIL nor-

PP

mal operation resumes. During Unlock Bypass

Program operations the memory draws I

PP

from

the pin to supply the programming circuits. See the

description of the Unlock Bypass comm and in the

Command Interface section. The transitions from

V

to VPP and from VPP to VIH must be slower

IH

than t

Never raise V

, see Figure 13.

VHVPP

/Write Protect to VPP from any

PP

mode except Read m ode, otherwise the memory

may be left in an indeterminate state.

A 0.1µF capacitor should be connected between

the V

/Write Protect pin and the VSS Ground pin

PP

to decouple the current surges from the power

supply. The PCB track widths must be sufficient to

carry the currents required during Unlock Bypass

Program, I

Reset/Block Temporary Unprotect (RP

PP

.

). The

Reset/Block Temporary Unprotect pin can be

used to apply a Hardware Reset to the memory or

to temporarily unprotect all Blocks that hav e b een

protected.

Note that i f V

/WP is at VIL, then the two ou ter-

PP

most boot blocks will remain protected even if RP

ID

.

is at V

A Hardware Reset is achieved by holding Reset/

Block Temporary Unprotect Low, V

. After Reset/Block Temporary Unprotect

t

PLPX

goes High, V

, the memory will be ready for Bus

IH

Read and Bus Write operations after t

t

, whichever occurs last. See the Ready/Busy

RHEL

, for at least

IL

PHEL

or

Output section, Table 15 and Figure 12, Reset/

Block Temporary Unprotect AC Characteristics,

for more details.

Holding RP

at VID will temporarily unprotect the

protected Blocks in the memory. Program and

Erase operations on all blocks will be possible.

The transition from V

t

PHPHH

.

Ready/Busy Output (RB

to VID must be slower than

IH

). The Ready/Busy pin

is an open-drain output that can be used to identify

when the device is performing a Program or Erase

operation. During Program or Erase operations

Ready/Busy is Low, V

. Ready/Busy is high-im-

OL

pedance during Read mode, Auto Select mode

and Erase Suspend mode.

8/50

Page 9

M29W640DT, M29W640DB

After a Hardware Reset, Bus Read and Bus Write

operations cannot begin until Ready/Busy becomes high-impedance. See Tabl e 15 and Figure

12, Reset/Block Temporary Unprotect AC Characteristics.

The use of an open-drain output allows the Ready/

Busy pins from several memories to be connected

to a single pull-up resistor. A Low will then indicate

that one, or more, of the memories is busy.

Byte/Word Organization Select (BYTE

). The

Byte/Word Organization Select pin is used to

switch between the x8 and x16 Bus modes of the

memory. When Byte/Word Organizati on Select is

Low, V

High, V

V

CC

, the memory is in x8 mode, when it is

IL

, the memory is in x16 mode.

IH

Supply Voltage (2.7V to 3.6V). VCC pro-

vides the power supply for all operations (Read,

Program and Erase).

The Command Interface is disabled when the V

CC

Supply Voltage is less than the L ockout Voltage,

V

. This prevents Bus Write operations from ac-

LKO

cidentally damaging the data during power up,

power down and power surges. If the Program/

Erase Controller is programming or erasing during

this time then the operation aborts and the memory contents being altered will be invalid.

A 0.1µF capacitor should be connected between

the V

Supply Voltage pin and the VSS Ground

CC

pin to decouple the current surges from the power

supply. The PCB track widths must be sufficient to

carry the currents required during Program and

Erase operations, I

Ground. VSS is the reference for all voltage

V

SS

measurements. The device f eatu res two V

CC3

.

pins

SS

which must be both connected to the system

ground.

9/50

Page 10

M29W640DT, M29W640DB

BUS OPERATIONS

There are five standard bus operations that control

the device. These are Bus Read, Bus Wri te, Output Disable, Standby and Automatic Standby. See

Table 2 and T able 3, Bus Operat ions, for a summary. Typically glitches of less than 5ns on Chip

Enable or Write Enable are ignored by the memory

and do not affect bus operations.

Bus Read. Bus Read operations read from the memory cells, or specific registers in the Command Interface. A valid Bus Read operation involves setting the desired address on the Address Inputs, applying a Low sig nal, V and Output Enable and keeping Write Enable High, V

. The Data Inputs/Outputs will output the

IH

value, see Figure 9, Read Mode AC Waveforms,

and Table 12, Read AC Characteristics, for details

of when the output becomes valid.

Bus Write. Bus Write operations write to the Command Interface. A valid Bus Write operation begins by setting the desire d address on t he Address Inputs. The Address Inputs are latched by the Command Interface on the falling edge of Chip Enable or Write Enable, whichever occurs last. The Data Inputs/Outputs a re latched by the Command Interface on the rising edge of Chip Enable or Write Enable, whichever occurs first. Output Enable must remain High, V

IH

Write operation. See Figure 10 and Figure 11,

Write AC Waveforms, and Table 13 and Table 14,

Write AC Characteristics, for details of the timing

requirements.

Output Disa bl e . The Data Inputs/Outputs are in the high impedance s tate when Output Enable is High, V

.

IH

Standby. When Chip Enable is High, V memory enters Standby mode and the Data Inputs/Outputs pins are placed in the high-impedance state. To reduce the S upply Current to the Standby Supply Current, I

CC2

, to Chip Enable

IL

, during the whole Bus

, the

IH

, Chip Enable should

be held within V

± 0.2V. For the Standby current

CC

level see Table 11, DC Characteristics.

During program or erase operations the memory

will continue to use the Program/Erase Supply

Current, I

, for Program or Erase operations un-

CC3

til the operation completes. Automatic Standby. If CMOS levels (V

± 0.2V)

CC

are used to drive the bus and the bus is inactive for

300ns or more the memory enters Automatic

Standby where the internal Supply Current is reduced to the Standby Supply Current, I

CC2

. The

Data Inputs/Outputs will still output data if a Bus

Read operation is in progress.

Special Bus Operations

Additional bus operations can be performed to

read the Electronic Signature and also to apply

and remove Block Protec tion. These bus operations are intended for use by programming equipment and are not usually used in applications.

They require V

to be applied to some pins.

ID

Electronic Signature. The memory has two codes, the manufacturer code and the device code, that can be read to identify the memory. These codes can be read by applying t he signals listed in Table 2 and Table 3, Bus Operations.

Block Protect and Chip Unprotect.

Groups of

blocks can be protected against accidental Program or Erase. The P rotec tion G roups are shown

in Appendix A, Table 19 and Table 20, Block Addresses. The whole chip can be unprotected to allow the data inside the blocks to be changed.

The V

the two outermost boot blocks. When V

Protect

/Write Protect pin ca n be used to prote c t

PP

is at V

the two outermost boot blocks are

IL

PP

/Write

protected an d remain pr otected regardless of t he

Block Protection Status or the Reset/Block Temporary Unprotect pin status.

Block Protect and Chip Unprote ct operations are

described in Appendix D.

10/50

Page 11

M29W640DT, M29W640DB

Table 2. Bus Operations, BYTE = V

Operation E G W

Bus Read

Bus Write

Output Disable X

Standby

Read Manufacturer

Code

Read Device Code

Extended Memory

Block Verify Code

Note: X = VIL or VIH.

V

V

V

V

V

V

V

IL

IL

IH

IL

IL

IL

IL

V

IH

V

IH

X X X Hi-Z Hi-Z

V

IL

V

IL

V

IL

Table 3. Bus Operations, BYTE = V

Operation E

Bus Read

Bus Write

Output Disable X

Standby

Read Manufacturer

Code

Read Device Code

Extended Memory

Block Verify Code

Note: X = VIL or VIH.

V

V

V

V

V

V

G W

V

IL

IL

IH

IL

IL

IL

IL

V

IH

V

IH

X X X Hi-Z

V

IL

V

IL

V

IL

IL

Address Inputs

DQ15A–1, A0-A21

V

Cell Address Hi-Z Data Output

IH

V

Command Address Hi-Z Data Input

IL

V

X Hi-Z Hi-Z

IH

A0 = VIL, A1 = VIL, A9 = VID,

V

IH

Others V

A0 = VIH, A1 = VIL,

V

IH

A9 = V

or V

IL

IH

, Others VIL or V

ID

DQ14-DQ8 DQ7-DQ0

IH

Data Inputs/Outputs

Hi-Z 20h

Hi-Z

DEh (M29W640DT)

DFh (M29W640DB)

98h (factory locked)

A0 = VIH, A1 = VIH, A6 = VIL,

V

IH

A9 = V

, Others VIL or V

ID

IH

Hi-Z

18h (not factory locked)

88h (factory locked)

08h (not factory locked)

IH

Address Inputs

A0-A21

V

Cell Address Data Output

IH

V

Command Address Data Input

IL

V

X Hi-Z

IH

A0 = VIL, A1 = VIL, A9 = VID,

V

IH

Others V

A0 = VIH, A1 = VIL, A9 = VID,

V

IH

Others V

IL

IL

or V

or V

IH

IH

Data Inputs/Outputs

DQ15A–1, DQ14-DQ0

22DEh (M29W640DT)

22DFh (M29W640DB)

M29W640DT

98h (factory locked)

A0 = VIH, A1 = VIH, A6 = VIL,

V

IH

A9 = V

, Others VIL or V

ID

IH

18h (not factory locked)

M29W640DB

88h (factory locked)

08h (not factory locked)

M29W640DT

M29W640DB

0020h

11/50

Page 12

M29W640DT, M29W640DB

COMMAND INTERFACE

All Bus Write operations t o the me mory are in terpreted by the Command Interface. Commands

consist of one or more sequential Bus Write operations. Failure to observe a valid sequence of Bus

Write operations will result in the memory returning to Read mode. The long command sequences

are imposed to maximize data security.

The address used for the commands changes depending on whether the memory is in 16-bit or 8bit mode. See either Table 4, or Table 5, depending on the configuration that is being used, for a

summary of the commands.

Read/Reset Command.

The Read/Reset command returns the memory to

its Read mode where it behaves like a ROM or

EPROM. It also resets the errors in the Status

Register. Either one or three Bus Write operations

can be used to issue the Read/Reset command.

The Read/Reset command can be issued, between Bus Write cycles before the start of a program or erase operation, to return the device to

read mode. If the Read/Reset command is issued

during the timeout of a Block erase operation then

the memory will take up to 10µs to abort. During

the abort period no valid data can be read from the

memory. The Read/Reset command will not abort

an Erase operation when issued while in Erase

Suspend.

Auto Select Command.

The Auto Select command is used to read the

Manufacturer Code, the Device Code , the Block

Protection Status and the Extended Memory Block

Verify Code. Three c onsecutive Bus W rite operations are required to iss ue the Auto Select command. Once the Auto Select command is issued

the memory remains in Auto Select mode until a

Read/Reset command is issued. Read CFI Query

and Read/Reset comma nds are ac cept ed i n Aut o

Select mode, all other commands are ignored.

In Auto Select mode the Manufac turer Code can

be read using a Bus Read operation with A0 = V

and A1 = VIL. The other address bits may be set to

either V

Microelectronics is 0020h.

The Device Code can be read using a B us Read

operation with A0 = V

address bits may be set to e ither V

Device Code for the M29W640DT is 22DEh and

for the M29W640DB is 22DFh.

The Bl ock Prot ection S tatus of each block can be

read using a Bus Read operation with A0 = V

A1 = V

the bl ock. The oth er addr ess bit s may b e set t o either V

then 01h is output on Data Inputs/Outputs DQ0DQ7, otherwise 00h is output.

or VIH. The Manufacturer Code f or ST-

IL

and A1 = VIL. The other

IH

, and A 12 -A 21 spec ify i n g t he address of

IH

or VIH. If t h e ad dr ess ed b loc k is pro tec te d

IL

or VIH. The

IL

IL

Read CFI Query Command

The Read CFI Query Command is used to read

data from the Common Flash Interface (CFI)

Memory Area. This command is valid when the device is in the Read Array mode, or when the device

is in Autose lec ted mode .

One Bus Write cycle is required to issue the Read

CFI Query Command. Once the command is issued subsequent Bus Read ope rations read from

the Common Flash Interface Memory Area.

The Read/Reset command m ust be issued to return the device to the previous mode (the Read Array mode or Autoselected mode). A second Read/

Reset command would be needed if the device is

to be put in the Read Array mode from Autoselected mode.

See Appendix B, Table 21 to Table 26 for details

on the information contained in the Common Flash

Interface (CFI) memory area.

Program Command.

The Program command can be used to program a

value to one address in the memory array at a

time. The command requires four Bus Write operations, the final write operation latches the address and data, and starts the Program/Erase

Controller.

If the address falls in a pro tected block then the

Program command is ignored, the data remains

unchanged. The Status Register is never read and

no error condition is given.

During the program operat ion the memo ry will ignore all commands. I t is n ot poss ible t o iss ue any

command to abort or pause the operation. Typical

program times are given in Table 6. Bus Read operations during the program o peration will output

the Status Register on the Data Inputs/Outputs.

See the section on the S tatus Register for more

details.

After the program operation has completed the

memory will return to the Read mode, unle ss an

IL

error has occurred. When an error occurs the

memory will continue to output the Status Register. A Read/Reset command must be issued to reset the error condition and return to Read mode.

Note that the Program command cannot change a

bit set at ’0’ bac k to ’1’. One of the E rase Commands must be used to set all the bits in a block or

in the whole memory from ’0’ to ’1’.

Fast Program Commands

There are two Fast Program com man ds availa ble

,

to improve the programming throughput, by writing

several adjacent words or bytes in parallel. The

Quadruple Byte Program command is available for

x8 operations, while the Double Word Program

command is available for x16 operations.

12/50

Page 13

M29W640DT, M29W640DB

Quadruple Byte Program Command. The Qua-

druple Byte Program command is used to write a

page of four adjacent Bytes in parallel. The four

bytes must differ only for addresses A0, DQ15A-1.

Five bus write cycles are necessary to issue the

Quadruple Byte Program command .

■ The first bus cycle sets up the Quadruple Byte

Program Command.

■ The second bus cycle latches the Address and

the Data of the first byte to be written.

■ The third bus cycle latches the Address and the

Data of the second byte to be written.

■ The fourth bus cycle latches the Address and

the Data of the third byte to be written.

■ The fifth bus cycl e latches the Addres s and th e

Data of the fourth byte to be written and starts

the Program/Erase Controller.

Double Word Program Command. The Double Word Program command is used to write a p age of two adjacent words in parallel. Th e two words must differ only for the address A0.

Three bus write cycles are necessary to issue the

Double Word Program command.

■ The first bus cycle sets up the Double Word

Program Command.

■ The second bus cycle latches the Address and

the Data of the first word to be written.

■ The third bus cycle latches the Address and the

Data of the second word to be written and starts

the Program/Erase Controller.

Only one bank can be programmed at any one

time. The other b ank must be in Read mode or

Erase Suspend.

Programming should not be attempted when V

is not at V

PPH

.

PP

After programming has started, Bus Read operations in the Bank being programmed output the

Status Register content, while Bus Read operations to the other B ank outpu t the cont ents of t he

memory ar ray.

After the program operation has completed the

memory will return to the Read mode, unle ss an

error has occurred. When an error occurs Bus

Read operations to the Bank where the command

was issued will continue to output the Status Register. A Read/Reset command must be issued to

reset the error condition and return t o Read mode.

Note that the Fast Program commands cannot

change a bit set at ’0’ back to ’1’. One of the Erase

Commands must be used to set all the bits in a

block or in the whole memory from ’0’ to ’1’.

Typical Program times are given in Tab le 6, Program, Erase Times and Program, Erase Endurance Cycles.

Unlock Bypass Command.

The Unlock Bypass command is used in conjunction with the Unlock Bypass Program command to

program the memory faster than with the standard

program commands. When th e cycle time to the

device is long (as with some EPROM programmers) considerable time saving can be m ade by

using these commands. Three Bus Write operations are required to issue the Unlock Bypass

command.

Once the Unlock Bypas s command has bee n issued the memory will only accept the Unloc k Bypass Program command and the Unlock Bypass

Reset command. The memory can be read as if in

Read mode.

When V

is applied to the VPP/Write Protect pin

PP

the memory automatically enters the Unlock Bypass mode and the Unlock Bypass Program command can be issued immediately.

Unlock Bypass Program Command.

The Unlock Bypass command is used in conjunction with the Unlock Bypass Program command to

program the memory. Whe n the cycle time t o the

device is long (as with some EPROM programmers) considerable time saving can be m ade by

using these commands. Three Bus Write operations are required to issue the Unlock Bypass

command.

Once the Unlock Bypas s command has bee n issued the memory will only accept the Unloc k Bypass Program command and the Unlock Bypass

Reset command. The memory can be read as if in

Read mode.

The memory offers accelerated program operations through the V

system asserts V

/Write Protect pin. When the

PP

on the VPP/Write Protect pin,

PP

the memory automatically enters the Unlock Bypass mode. The system may then write the twocycle Unlock Bypass program command sequence. The memory uses the higher voltage on

the V

/Write Protect pin, to accelerate the Unlock

PP

Bypass Program operation.

Never raise V

/Write Protect to VPP from any

PP

mode except Read m ode, otherwise the memory

may be left in an indeterminate state.

Unlock Bypass Reset Command.

The Unlock Bypass Rese t command can be used

to return to Read/Reset mode from Unlock Bypass

Mode. Two Bus Write operations are required to

issue the Unlock Bypass Reset command. Read/

Reset command does not exit from Unlock Bypass

Mode.

Chip Erase Command.

The Chip Erase command can be used to erase

the entire chip. Six Bus Write operations a re re-

13/50

Page 14

M29W640DT, M29W640DB

quired to issue the Chip Erase Command and start

the Program/Erase Controller.

If any blocks are protected then these are ignored

and all the other blocks are erased. If all of the

blocks are protect e d th e Chip Erase op erat i on ap-

pears to start but will terminate within about 100µs,

leaving the data unchanged. No error condition is

given when protected blocks are ignored.

During the erase operation the memory will ignore

all commands, including the Erase Suspen d command. It is not possible to i ssue any c ommand t o

abort the operation. Typical chip erase tim es are

given in Table 6. All Bus Read operations during

the Chip Erase operation will output the Status

Register on the Data Inputs/Outputs. See the section on the Status Register for more details.

After the Chip Erase operation has completed t he

memory will return to the Read Mode, unle ss an

error has occurred. When an error occurs the

memory will continue to output the Status Register. A Read/Reset command must be issued to reset the error condition and return to Read Mode.

The Chip Erase Command sets all of the bits in unprotected blocks of the memory to ’1’. All previous

data is lost.

Block Erase Command.

The Block Erase com mand can be used to erase

a list of one or more blocks. Six Bus Write operations are required to select the first block in the li st.

Each additional block in the list can be selected by

repeating the sixth Bus Write operation using the

address of the additional block. The B lock Erase

operation starts the Program/Erase Controller

about 50µs after the last Bus Write operation.

Once the Pr ogram /Erase Co ntroller st arts it is not

possible to select any more blocks. Each additional block must therefore be selected within 50µs of

the last block. The 50µs timer restarts when an additional block is selected. The Status Register can

be read after the sixth B us Write operation. See

the Status Register section for details on how to

identify if the Program/ Erase Con troller has st arted the Block Erase operation.

If any selected blocks are protected then these are

ignored and all the other selected blocks are

erased. If all of the selected blocks are p rotected

the Block Erase operation appears to start but will

terminate within about 100µs, leaving the data unchanged. No error condition is given when protected blocks are ignored.

During the Block Erase operation the me mory wi ll

ignore all commands except the Erase Susp end

command. Typical b lock era se tim es are g iven in

Table 6. All Bus Read operations during the Block

Erase ope ra tion will outp ut the S t atus R e gister on

the Data Inputs/Outputs. See the section on the

Status Register for more details.

After the Block Erase operation has completed the

memory will return to the Read Mode, unle ss an

error has occurred. When an error occurs the

memory will continue to output the Status Register. A Read/Reset command must be issued to reset the error condition and return to Read mode.

The Block Erase Command sets all of the bits in

the unprotected selected blocks to ’1’. All previous

data in the selected blocks is lost.

Erase Suspend Command.

The Erase Suspend Command may be used to

temporarily suspend a B lock Eras e operation and

return the memory to Read mode. T he comm and

requires one Bus Write operation.

The Program/Erase Controller will sus pend within

the Erase Suspend Latency time of the Erase Suspend Command being issued. Once the Program/

Erase Controller has stopped the mem ory will be

set to Read mode and the E ras e wi ll be s uspended. If the Erase Suspend command is issued during the period when the memory is waiting for an

additional block (before the Program/Er ase Controller starts) then the Erase is suspended immediately and will start immediately when the Erase

Resume Command is issued. It is not possibl e to

select any further blocks to erase after the Erase

Resume.

During Erase Suspend it is possible to Read and

Program cells in blocks that are not being erased;

both Read and Program operations behave as

normal on these blocks. If any attempt is made to

program in a protected block or in the suspended

block then the Program comm and is ignored and

the data remains unchanged. The Status Register

is not read and no error condi tion is given. Reading from blocks that are being erased will output

the Status Register.

It is also possible to issue the Auto Select, Read

CFI Query and Unlock Bypass commands du ring

an Erase Suspend. The Read/Reset command

must be issued to return the device to Read Array

mode before the Resume command will be accepte d.

Erase Resume Command.

The Erase Resume command must be used to restart the Program/Erase Controller after an Erase

Suspend. The device must be in Read Array mode

before the Resume command will be accepted. An

erase can be suspe nded and resumed mo re t han

once.

Enter Extended Block Command

The device has an extra 64 KByte block (Extended

Block) that can on ly be acc essed usin g the Enter

Extended Block command. Three Bus write cycles

are required to issue the Extended Block command. Once the c ommand has been issued the

device enters Extended Block mode where all Bus

14/50

Page 15

M29W640DT, M29W640DB

Read or Write operations to the Boot Block addresses access the Extended Bloc k. The Extended Block (with the same address as the Boot

Blocks) cannot be erased, and can be t reated as

one-time programmable (OTP) memory. In Extended Block mode the Boot Blocks are not accessible.

To exit from the Extended Block mode the Exit Extended Block command must be issued.

The Extended Block can be protected, however

once protected the protection cannot be undone.

Exit Extended Block Com m a n d

The Exit Extended Block command is used to exit

from the Extended Block mod e and ret urn the de-

vice to Read mode. Four Bus Write operations are

required to issue the command.

Block Protect and Chip Unprotect Commands

Groups of blocks can be protected against acci-

dental Program or Erase. The Protection Groups

are shown in Appendix A, T able 1 9 and T able 20,

Block Addresses. The whole chip can be unprotected to allow the data inside the blocks to be

changed.

Block Protect and Chip Unprote ct operations are

described in Appendix D.

15/50

Page 16

M29W640DT, M29W640DB

Table 4. Commands, 16-bit mode, BYTE = V

IH

Bus Write Operations

Command

1st 2nd 3rd 4th 5th 6th

Length

Addr Data Addr Data Addr Data Addr Data Addr Data Addr Dat a

1X F0

Read/Reset

3 555 AA 2AA 55 X F0

Auto Select 3 555 AA 2AA 55 555 90

Program 4 555 AA 2AA 55 555 A0 PA PD

Double Word Program 3 555 50 PA0 PD0 PA1 PD1

Unlock Bypass 3 555 AA 2AA 55 555 20

Unlock Bypass

Program

2X A0PAPD

Unlock Bypass Reset 2 X 90 X 00

Chip Erase 6 555 AA 2AA 55 555 80 555 AA 2AA 55 555 10

Block Erase 6+ 555 AA 2AA 55 555 80 555 AA 2AA 55 BA 30

Erase Suspend 1 X B0

Erase Resume 1 X 30

Read CFI Query 1 55 98

Enter Extended Block 3 555 AA 2AA 55 555 88

Exit Extended Block 4 555 AA 2AA 55 555 90 X 00

Note: X Don’t Care, PA Prog ram Addre ss , P D Program Data, BA An y address in the Block. All values in the table are in hexadecimal .

The Com ma nd In terf ace o nly us es A –1, A0-A 10 a nd DQ 0-DQ 7 t o ver ify the com man ds; A 11-A 2 0, D Q8-DQ1 4 a nd DQ 15 ar e D on’t

Care. DQ15A–1 is A– 1 when BYTE

is VIL or DQ15 when BYTE is VIH.

16/50

Page 17

M29W640DT, M29W640DB

Table 5. Commands, 8-bit mode, BYTE = V

IL

Bus Write Operations

Command

1st 2nd 3rd 4th 5th 6th

Length

Add Data Add Data Add Data Add Data Add Data Add Data

1X F0

Read/Reset

3 AAA AA 555 55 X F0

Auto Select 3 AAA AA 555 55 AAA 90

Program 4 AAA AA 555 55 AAA A0 PA PD

Quadruple Byte Program 5 AAA 55 PA0 PD0 PA1 PD1 PA2 PD2 PA3 PD3

Unlock Bypass 3 AAA AA 555 55 AAA 20

Unlock Bypass Program 2 X A0 PA PD

Unlock Bypass Reset 2 X 90 X 00

Chip Erase 6 AAA AA 555 55 AAA 80 AAA AA 555 55 AAA 10

Block Erase 6+ AAA AA 555 55 AAA 80 AAA AA 555 55 BA 30

Erase Suspend 1 X B0

Erase Resume 1 X 30

Read CFI Query 1 AA 98

Enter Extended Block 3 AAA AA 555 55 AAA 88

Exit Extended Block 4 AAA AA 555 55 AAA 90 X 00

Note: X Don’t Care, PA Prog ram Addre ss , P D Program Data, BA An y address in the Block. All values in the table are in hexadecimal .

The Com ma nd In terf ace o nly us es A –1, A0-A 10 a nd DQ 0-DQ 7 t o ver ify the com man ds; A 11-A 2 0, D Q8-DQ1 4 a nd DQ 15 ar e D on’t

Care. DQ15A–1 is A– 1 when BYTE

is VIL or DQ15 when BYTE is VIH.

Table 6. Program, Erase Times and Progra m , Erase Endurance Cycles

Parameter Min

Typ

(1, 2)

Chip Erase 80

Block Erase (64 KBytes) 0.8

Erase Suspend Latency Time

Program (Byte or Word) 10

Double Word Program (Byte or Word) 10

Chip Program (Byte by Byte) 80

Chip Program (Word by Word) 40

Chip Program (Quadruple Byte or Double Word) 20

Program/Erase Cycles (per Block) 100,000 cycles

Data Retention 20 years

Note: 1. Typi cal values measured at room temperature and nominal voltages.

2. Sampled, but not 100% tested.

3. Maximum value m easured at worst case conditions for both temperature and V

4. Maximum value m easured at worst case conditions for both temperature and V

after 100,0 0 program/erase cycle s.

CC

.

CC

Max

400

6

50

200

200

400

200

100

(4)

(4)

(3)

(3)

(3)

(3)

(3)

(3)

(2)

Unit

µs

µs

µs

s

s

s

s

s

17/50

Page 18

M29W640DT, M29W640DB

STATUS REGISTER

Bus Read operations from any address always

read the Status Register during Program and

Erase operations. It is also read during Erase Suspend when an address within a block being erased

is accessed.

The bits in the Status Register are summarized in

Table 7, Status Register Bits.

Data Polling Bit (DQ7). The Data Polling Bit can be used to identify whether the Program/Erase Controller has successfully completed its operation or if it has responded to an Erase Suspend. The Data Polling Bit is output on DQ7 when the Status Register is read.

During Program operations the Data Polling Bit

outputs the complement of the bit being programmed to DQ7. After successful completion of

the Program operation the memory returns to

Read mode and Bus Read operations from the address just programmed o utput DQ7, not its complement.

During Er ase ope rations the Data Polling Bit ou t-

puts ’0’, the complement of the erased state of

DQ7. After successful completion of the Erase operation the memory returns to Read Mode.

In Erase Suspend mode the Data Polling Bit will

output a ’1’ during a Bus Read operation within a

block being erased. The Data Polling Bit will

change from a ’0’ to a ’1’ when the Program/Erase

Controller has suspended the Erase operation.

Figure 5, Data Polling Flowchart, gives an example of how to use the Data Polling Bit. A Valid Address is the address being programmed or an

address within the block being erased.

Toggle Bit (DQ6). The Toggle Bit can be used to identify whether the Program/Erase Controller has successfully completed its operation or if it has responded to an Erase Suspen d. The Toggle Bit is output on DQ6 when the Status Register is read.

During Program and Erase operations the Toggle

Bit changes from ’0’ to ’ 1’ to ’ 0’, et c., with su ccessive Bus Read operations at any address. After

successful completion of the operation the memory returns to Read mode.

During Erase Suspend mode the Toggle Bit will

output when addressing a cell within a block being

erased. The Toggle Bit will stop toggling when the

Program/Erase Controller has suspended the

Erase operation.

Figure 6, Dat a Toggle Flowchart, gives an example of how to use the Data Toggle Bit.

Error Bit (DQ5). The Error Bit can be used to identify errors detected by the Program/Erase Controller. The Error B it is set to ’1’ when a Program, Block Erase or Chip Erase operation fails to write the correct data to the memory. If the Error Bit is set a Read/Rese t command must be iss ued before other commands are issued. The E rror bit is output on DQ5 when the Status Register is read.

Note that the Program command cannot change a

bit set to ’0’ back to ’1’ and attempting to do so will

set DQ5 to ‘1’. A Bus Read operation to that address will s h ow the bit is s ti ll ‘0’. One o f t he E r as e

commands must b e used to set all the bits in a

block or in the whole memory from ’0’ to ’1’.

Erase Timer Bit (DQ3). The Erase Timer Bit can be used to identify the start of Program/Erase Controller operation during a Block Erase command. Once the Program/Erase Controller starts erasing the Erase Timer Bit is set to ’1’. Before the Program/Erase Controller starts the Erase Timer Bit is set to ’0’ and additional block s to be erased may be written to the Command Interface. The Erase Timer Bit is output on DQ3 when the Status Register is read.

Alternative Toggle Bit (DQ2). The Alternative Toggle Bit can be used to monitor the Program/ Erase controller during Erase operations. The Alternative Toggle Bit is output on DQ2 when the Status Register is read.

During Chip Erase and Block Erase operations the

Toggle Bit changes from ’0’ to ’1’ to ’0’, etc., with

successive Bus Read operations from addresses

within the blocks being erased. A protected block

is treated the same as a block not being erased.

Once the operation completes the memory returns

to Read mode.

During Erase Suspend the Alternative Toggle Bit

changes from ’0’ to ’1’ to ’0’, etc. with successive

Bus Read operations from addresses within the

blocks being erased. Bus Read operations to addresses within blocks not being erased will ou tput

the memory cell data as if in Read mode.

After an Erase operation that c auses t he Error Bit

to be set the Alternative Toggle Bit can be used to

identify which block or blocks have caused the error. The Alternative Toggle Bit changes from ’0’ to

’1’ to ’0’, etc. with successive Bus Re ad Operations from addresses within blocks that have not

erased correctly. The Alternative Togg le Bit does

not change if the addressed block has erased correctly.

18/50

Page 19

M29W640DT, M29W640DB

Table 7. Status Register Bits

Operation Address DQ7 DQ6 DQ5 DQ3 DQ2

Program Any Address DQ7 Toggle 0 ––0

Program During Erase

Suspend

Any Address DQ7

Program Error Any Address DQ7

Toggle 0 – – 0

Toggle 1 – – 0

Chip Erase Any Address 0 Toggle 0 1 Toggle 0

Block Erase before

timeout

Erasing Block 0 Toggle 0 0 Toggle 0

Non-Erasing Block 0 Toggle 0 0 No Toggle 0

RB

Block Erase

Erasing Block 0 Toggle 0 1 Toggle 0

Non-Erasing Block 0 Toggle 0 1 No Toggle 0

Erasing Block 1 No Toggle 0 – Toggle 1

Erase Suspend

Non-Erasing Block Data read as normal 1

Good Block Address 0 Toggle 1 1 No Toggle 0

Erase Error

Faulty Block Address 0 Toggle 1 1 Toggle 0

Note: Unspecif ied data bit s should be ignored.

Figure 5. Dat a Po ll i ng Fl o wc h a rt Figure 6. Data Toggle Fl owchart

READ DQ6

DQ5 & DQ6

TOGGLE

NO

READ DQ6

TOGGLE

START

READ

DQ6

=

DQ5

= 1

TWICE

DQ6

=

NO

YES

YES

NO

YES

START

READ DQ5 & DQ7

at VALID ADDRESS

DQ7

YES

=

DATA

NO

NO

DQ5

= 1

YES

READ DQ7

at VALID ADDRESS

DQ7

YES

=

DATA

NO

FAIL PASS

AI90194

FAIL PASS

AI90195B

19/50

Page 20

M29W640DT, M29W640DB

MAXIMUM RATIN G

Stressing the device ab ove the rating listed in t he

Absolute Maximum Ratings table m ay cause permanent damage to the device. Exposure to Absolute Maximum Rating conditions for extended

periods may affect device reliability. These are

stress ratings only and operation of the dev ice at

Table 8. Absolute Maximum Ratings

Symbol Parameter Min Max Un it

T

BIAS

T

STG

V

IO

V

CC

V

ID

(3)

V

PP

Note: 1. M in i m um voltage ma y undershoot to –2V during transitio n and for less t han 20ns during transitions.

2. Maximum volta ge m ay oversho ot to V

3. V

PP

Temperature Under Bias –50 125 °C

Storage Temperature

Input or Output Voltage

(1,2)

Supply Voltage –0.6 4 V

Identification Voltage –0.6 13.5 V

Program Voltage –0.6 13.5 V

+2V during transition and for less than 20ns during transitions.

must not rem ai n at 12V for more than a total of 80hrs.

CC

these or any other conditions above those indicated in the Operating sections of this specification is

not implied. Refer also to the STMicroelectronics

SURE Program and ot her relevant quality documents.

–65 150 °C

V

–0.6

CC

+0.6

V

20/50

Page 21

M29W640DT, M29W640DB

DC AND AC PARAMETERS

This section summarizes the operat ing and measurement conditions, and the DC and AC characteristics of the device. The parameters in t he DC

and AC Characteristic tables that follow are derived from tests performed under the Measure-

Table 9. Operating and AC Measurement Conditions

Parameter

Min Max Min Max

V

Supply Voltage

CC

Ambient Operating Temperature –40 85 –40 85 °C

ment Conditions summarized in the relevant

tables. Designers should chec k th at the o perat ing

conditions in their circuit matc h the meas urement

conditions when relying on the quoted parameters.

M29W640D

3.0 3.6 2.7 3.6 V

Unit70 90

Load Capacitance (C

)

L

30 30 pF

Input Rise and Fall Times 10 10 ns

Input Pulse Voltages

Input and Output Timing Ref. Voltages

0 to V

CC

V

/2 VCC/2

CC

0 to V

CC

Figure 7. AC Measurement I/O Waveform Figure 8. AC Measurement Load Circuit

V

PP

V

CC

VCC/2

0V

AI05557

V

CC

DEVICE

UNDER

TEST

0.1µF

0.1µF

CL includes JIG capacitance

V

C

L

V

V

CC

25kΩ

25kΩ

AI05558

Table 10. Device Capacitance

Symbol Parameter Test Condition Min Max Unit

V

V

IN

OUT

= 0V

= 0V

6pF

12 pF

C

IN

C

OUT

Note: Sampled only, not 10 0% tested.

Input Capacitance

Output Capacitance

21/50

Page 22

M29W640DT, M29W640DB

Table 11. DC Characteristics

Symbol Parameter Test Condition Min Max Unit

I

I

LO

I

CC1

I

CC2

I

CC3

V

V

V

I

PP

V

V

V

V

LKO

Note: 1. Sampled only, not 100% tested.

Input Leakage Current

LI

Output Leakage Current

Supply Current (Read)

Supply Current (Standby)

Supply Current (Program/

Erase)

Input Low Voltage –0.5 0.8 V

IL

Input High Voltage

IH

PP

Voltage for V

Acceleration

Current for V

/WP Program

PP

/WP Program

PP

Acceleration

Output Low Voltage

OL

Output High Voltage

OH

Identification Voltage 11.5 12.5 V

ID

Program/Erase Lockout Supply

(1)

V oltage

0V ≤ V

0V ≤ V

E

= VIL, G = VIH,

f = 6MHz

E

= VCC ±0.2V,

RP

= VCC ±0.2V

Program/Erase

Controller active

= 3.0V ±10%

V

CC

= 3.0V ±10%

V

CC

I

= 1.8mA

OL

= –100µA

I

OH

IN

OUT

≤ V

≤ V

V

CC

CC

V

PP

V

IL

/WP = V

PP

/WP =

or V

IH

PP

±1

±1

10 mA

100

20 mA

20 mA

0.7V

CC

VCC +0.3

11.5 12.5 V

15 mA

0.45 V

V

–0.4

CC

1.8 2.3 V

µA

µA

µA

V

V

22/50

Page 23

Figure 9. Read Mode AC Waveforms

A0-A20/

A–1

tAVQV tAXQX

E

G

DQ0-DQ7/

DQ8-DQ15

tBHQV

BYTE

tELBL/tELBH tBLQZ

M29W640DT, M29W640DB

tAVAV

VALID

tELQV tEHQX

tELQX tEHQZ

tGLQX tGHQX

tGLQV

tGHQZ

VALID

AI05559

Table 12. Read AC Characteristics

Symbol Alt Parameter Test Condition

E

t

AVAV

t

AVQV

(1)

t

ELQX

t

ELQV

(1)

t

GLQX

t

GLQV

(1)

t

EHQZ

(1)

t

GHQZ

t

EHQX

t

GHQX

t

AXQX

t

ELBL

t

ELBH

t

BLQZ

t

BHQV

Note: 1. Sampled only, not 100% tested.

t

RC

t

ACC

t

LZ

t

CE

t

OLZ

t

OE

t

HZ

t

DF

t

OH

t

ELFL

t

ELFH

t

FLQZ

t

FHQV

Address Valid to Next Address Valid

Address Valid to Output Valid

Chip Enable Low to Output Transition

Chip Enable Low to Output Valid

Output Enable Low to Output Transition

Output Enable Low to Output Valid

Chip Enable High to Output Hi-Z

Output Enable High to Output Hi-Z

Chip Enable, Output Enable or Address

Transition to Output Transition

Chip Enable to BYTE Low or High Max 5 5 ns

BYTE Low to Output Hi-Z Max 25 30 ns

BYTE High to Output Valid Max 30 40 ns

= VIL,

G

= V

E

= VIL,

G

= V

G

= V

G

= V

E

= V

E

= V

G

= V

E

= V

IL

IL

IL

IL

IL

IL

IL

IL

M29W640D

Unit

70 90

Min 70 90 ns

Max 70 90 ns

Min 0 0 ns

Max 70 90 ns

Min 0 0 ns

Max 30 35 ns

Max 25 30 ns

Max 25 30 ns

Min 0 0 ns

23/50

Page 24

M29W640DT, M29W640DB

Figure 10. Write AC Waveforms, Write Enable Controlled

tAVAV

A0-A20/

A–1

tAVWL

E

VALID

tWLAX

tWHEH

tELWL

G

tWLWHtGHWL

W

tDVWH

DQ0-DQ7/

DQ8-DQ15

V

CC

RB

tVCHEL

VALID

tWHRL

Table 13. Write AC Characteristics, Write Enable Controlled

Symbol Alt Parameter

t

AVAV

t

ELWL

t

WLWH

t

DVWH

t

WHDX

t

WHEH

t

WHWL

t

AVWL

t

WLAX

t

GHWL

t

WHGL

(1)

t

WHRL

t

VCHEL

Note: 1. Sampled only, not 100% tested.

t

WC

t

CS

t

WP

t

DS

t

DH

t

CH

t

WPH

t

AS

t

AH

t

OEH

t

BUSY

t

VCS

Address Valid to Next Address Valid Min 70 90 ns

Chip Enable Low to Write Enable Low Min 0 0 ns

Write Enable Low to Write Enable High Min 45 50 ns

Input Valid to Write Enable High Min 45 50 ns

Write Enable High to Input Transition Min 0 0 ns

Write Enable High to Chip Enable High Min 0 0 ns

Write Enable High to Write Enable Low Min 30 30 ns

Address Valid to Write Enable Low Min 0 0 ns

Write Enable Low to Address Transition Min 45 50 ns

Output Enable High to Write Enable Low Min 0 0 ns

Write Enable High to Output Enable Low Min 0 0 ns

Program/Erase Valid to RB Low Max 30 35 ns

VCC High to Chip Enable Low

tWHGL

tWHWL

tWHDX

AI05560

M29W640D

Unit

70 90

Min 50 50 µs

24/50

Page 25

Figure 11. Write AC Waveforms, Chip Enable Controlled

tAVAV

A0-A20/

A–1

tAVEL

W

VALID

M29W640DT, M29W640DB

tELAX

tEHWH

tWLEL

G

tELEHtGHEL

E

tDVEH

DQ0-DQ7/

DQ8-DQ15

V

CC

RB

tVCHWL

VALID

tEHRL

Table 14. Write AC Characteristics, Chip Enable Controlled

Symbol Alt Parameter

t

AVAV

t

WLEL

t

ELEH

t

DVEH

t

EHDX

t

EHWH

t

EHEL

t

AVEL

t

ELAX

t

GHEL

t

EHGL

(1)

t

EHRL

t

VCHWL

Note: 1. Sampled only, not 100% tested.

t

WC

t

WS

t

CP

t

DS

t

DH

t

WH

t

CPH

t

AS

t

AH

t

OEH

t

BUSY

t

VCS

Address Valid to Next Address Valid Min 70 90 ns

Write Enable Low to Chip Enable Low Min 0 0 ns

Chip Enable Low to Chip Enable High Min 45 50 ns

Input Valid to Chip Enable High Min 45 50 ns

Chip Enable High to Input Transition Min 0 0 ns

Chip Enable High to Write Enable High Min 0 0 ns

Chip Enable High to Chip Enable Low Min 30 30 ns

Address Valid to Chip Enable Low Min 0 0 ns

Chip Enable Low to Address Transition Min 45 50 ns

Output Enable High Chip Enable Low Min 0 0 ns

Chip Enable High to Output Enable Low Min 0 0 ns

Program/Erase Valid to RB Low Max 30 35 ns

VCC High to Write Enable Low

tEHGL

tEHEL

tEHDX

AI05561

M29W640D

Unit

70 90

Min 50 50 µs

25/50

Page 26

M29W640DT, M29W640DB

Figure 12. Reset/Block Temporary Unp rotec t AC Waveforms

E, G

W,

tPHWL, tPHEL, tPHGL

RB

RP

Table 15. Reset/Block Temporary Unprotect AC Characteristics

Symbol Alt Parameter

(1)

t

PHWL

t

PHEL

(1)

t

PHGL

(1)

t

RHWL

(1)

t

RHEL

(1)

t

RHGL

t

PLPX

t

PLYH

(1)

t

PHPHH

(1)

t

VHVPP

Note: 1. Sampled only, not 100% tested.

t

RH

t

RB

t

RP

t

READY

t

VIDR

tPLPX

tPLYH

RP High to Write Enable Low, Chip Enable Low,

Output Enable Low

RB High to Write Enable Low, Chip Enable Low,

Output Enable Low

RP Pulse Width Min 500 500 ns

RP Low to Read Mode Max 50 50 µs

RP Rise Time to V

ID

VPP Rise and Fall Time

tRHWL, tRHEL, tRHGL

tPHPHH

AI02931B

M29W640D

Unit

70 90

Min 50 50 ns

Min 0 0 ns

Min 500 500 ns

Min 250 250 ns

Figure 13. Accelerated Program Timing Waveforms

V

PP

VPP/WP

V

or V

IL

IH

26/50

tVHVPP

tVHVPP

AI05563

Page 27

M29W640DT, M29W640DB

PACKAGE MECHANICAL

Figure 14. TSO P48 – 48 lead Plastic Thin Smal l Outline, 12 x 20mm, Package Outline

A2

1 N

e

E

B

N/2

D1

D

DIE

A

CP

C

TSOP-a

Note: Drawing is not to scale.

LA1 α

Table 16. TSOP48 – 48 lead Plastic Thin Small Outline, 12 x 20mm, Package Me chan ica l Data

Symbol

Typ Min Max Typ Min Max

A 1.200 0.0472

A1 0.100 0.050 0.150 0.0039 0.0020 0.0059

A2 1.000 0.950 1.050 0.0394 0.0374 0.0413

B 0.170 0.270 0.0067 0.0106

C 0.100 0.210 0.0039 0.0083

CP 0.100 0.0039

D 19.800 20.200 0.7795 0.7953

millimeters inches

D1 18.300 18.500 0.7205 0.7283

e 0.500 – – 0.0 197 – –

E 11. 900 12. 100 0.4685 0.4764

L 0.500 0.700 0.0197 0.0276

alfa 0 5 0 5

N48 48

27/50

Page 28

M29W640DT, M29W640DB

Figure 15. TFBGA63 7x11mm - 6x8 active ball array, 0.8mm pitch, Packa ge Ou tline

D

D1

FD

SD

e

E

Note: Drawing is not to scale.

E1

BALL "A1"

A

SE

FE

eb

A2

A1

BGA-Z33

ddd

Table 17. TFBGA63 7x11mm - 6x8 active ball array, 0.8mm pitch, Packag e Mechanical Data

Symbol

Typ Min Max Typ Min Max

A 1.200 0.0472

A1 0.2 50 0.0098

A2 0.9 00 0.0354

b 0.350 0.450 0.0138 0.0177

millimeters inches

D 7.000 6.900 7.100 0.2756 0.2717 0.2795

D1 5.600 – – 0.2205 – –

ddd – – 0.1 00 – – 0.0039

E 11.000 10.900 11.100 0.4331 0.4291 0.4370

E1 8.800 – – 0.3465 – –

e 0.800 – – 0.0 315 – –

FD 0.700 – – 0.0276 – –

FE 1.100 – – 0.0433 – –

SD 0.4 00 – – 0.0157 – –

SE 0.400 – – 0.0157 – –

28/50

Page 29

M29W640DT, M29W640DB

PART NUMBERING

Table 18. Ordering Information Scheme

Example: M29W 640DB 90 N 1 T

Device Type

M29

Operating Voltage

W = V

Device Function

640D = 64 Mbit (x8/x16), Boot Block

Array Matrix

T = Top Boot

B = Bottom Boot

Speed

70 = 70 ns

90 = 90 ns

= 2.7 to 3.6V

CC

Package

N = TSOP48: 12 x 20 mm

ZA = TFBGA63: 7x11mm, 0.80 mm pitch

Temperature Range

1 = 0 to 70 °C

6 = –40 to 85 °C

Option

T = Tape & Reel Packing

E = Lead-free Package, Standard Packing

F = Lead-free Package, Tape & Reel Packing

Note: This product is also available with the Extended Block factory locked. For further details and ordering

information contact your nearest ST sales office.

Devices are shipped from the factory with the memory content bits erased to 1. For a list of available options (Speed, Package, et c.) or for further i nformation on any as pect of t his device, p lease contact your

nearest ST Sales Office.

29/50

Page 30

M29W640DT, M29W640DB

APPENDIX A. BLOCK ADDRESSES

Table 19. Top Boot Block Addresses, M29W640DT

Block KBytes/K Words

Protection Block

Group

(x8) (x16)

0 64/32

1 64/32 010000h–01FFFFh 008000h–00FFFFh

Protection Group

2 64/32 020000h–02FFFFh 010000h–017FFFh

3 64/32 030000h–03FFFFh 018000h–01FFFFh

4 64/32

5 64/32 050000h–05FFFFh 028000h–02FFFFh

Protection Group

6 64/32 060000h–06FFFFh 030000h–037FFFh

7 64/32 070000h–07FFFFh 038000h–03FFFFh

8 64/32

9 64/32 090000h–09FFFFh 048000h–04FFFFh

Protection Group

10 64/32 0A0000h–0AFFFFh 050000h–057FFFh

11 64/32 0B0000h–0BFFFFh 058000h–05FFFFh

12 64/32

13 64/32 0D0000h–0DFFFFh 068000h–06FFFFh