Page 1

FEATURES SUMMARY

■ SUPPLY VOLTAGE

–V

2.7V to 3.6V for Program, Erase and

CC =

Read

■ ACCESS TIME: 70, 90ns

■ PROGRAMMING TIME

– 10µs per Byte typical

■ 32 UNIFORM 64 KByte MEMORY BLOCKS

■ PROGRAM/ERA SE CON T ROL LER

– Embedded Byte Program algorithms

■ ERASE SUSPEND and RESUME MODES

– Read and Program another Block during

Erase Suspend

■ UNLOCK BYPASS PROGRAM COMMAND

– Faster Production/Batch Programm ing

■ TEMPORARY BLOCK UNPROTECTION

MODE

■ COMMON FLASH INTERFACE

– 64 bit Security Code

■ LOW POWER CONSUMPTION

– Standby and Automatic Standby

■ 100,000 PROGRAM/ER ASE CYCL ES per

BLOCK

■ ELECTRONIC SIGNATURE

– Manufacturer Code: 20h

– Device Code: C8h

M29W017D

16 Mbit (2Mb x8, Uniform Block)

3V Supply Fl ash Me m ory

PRELIMINARY DATA

Figure 1. Packages

TSOP40 (N)

10 x 20mm

FBGA

TFBGA48 (ZA)

6 x 8 ball array

April 2002

This is preliminary information on a new product now in development or undergoing evaluation. Details are subject to change without notice.

1/36

Page 2

M29W017D

TABLE OF CONTENTS

SUMMARY DESCRIPTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

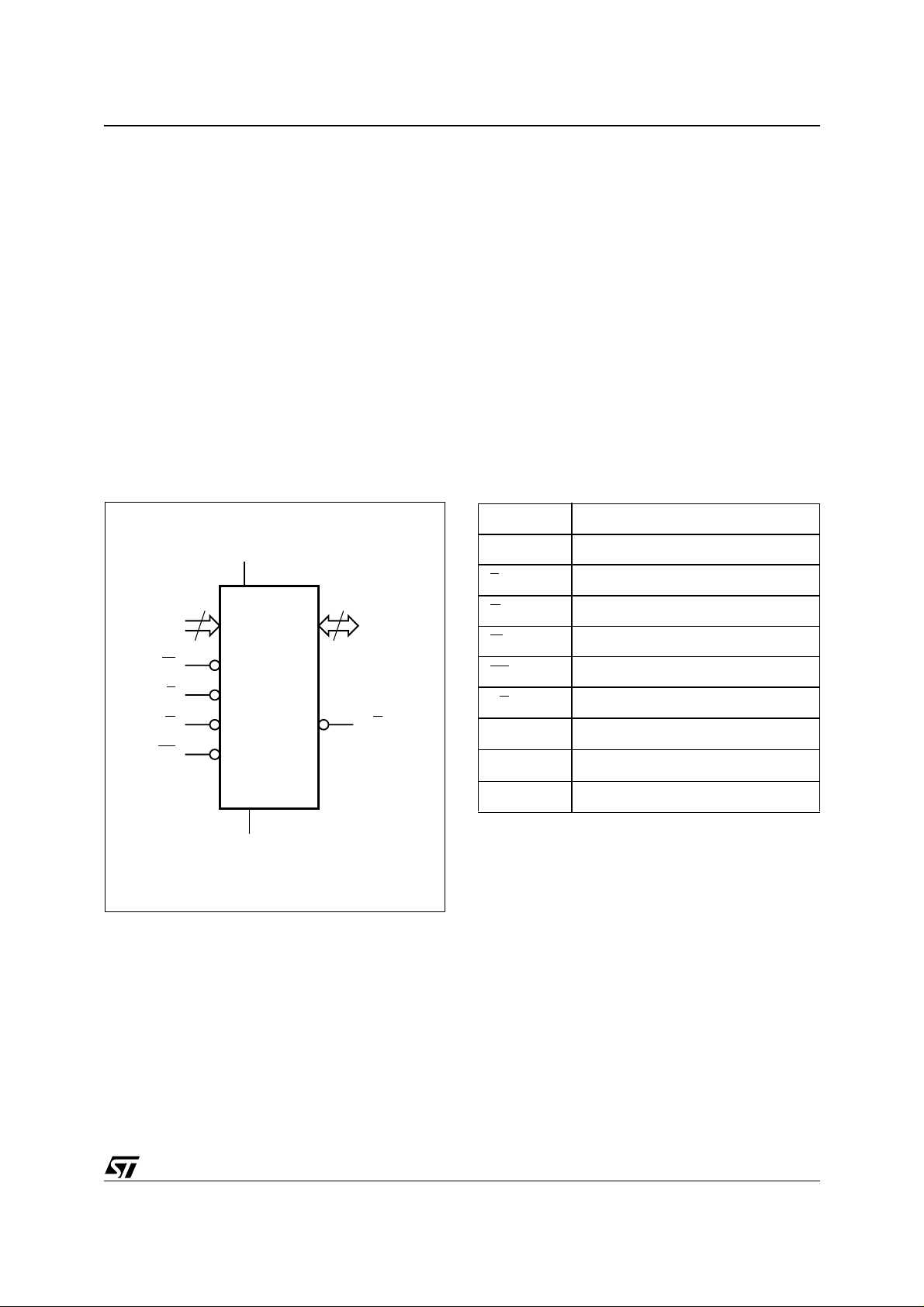

Figure 2. Logic Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Table 1. Signal Names . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

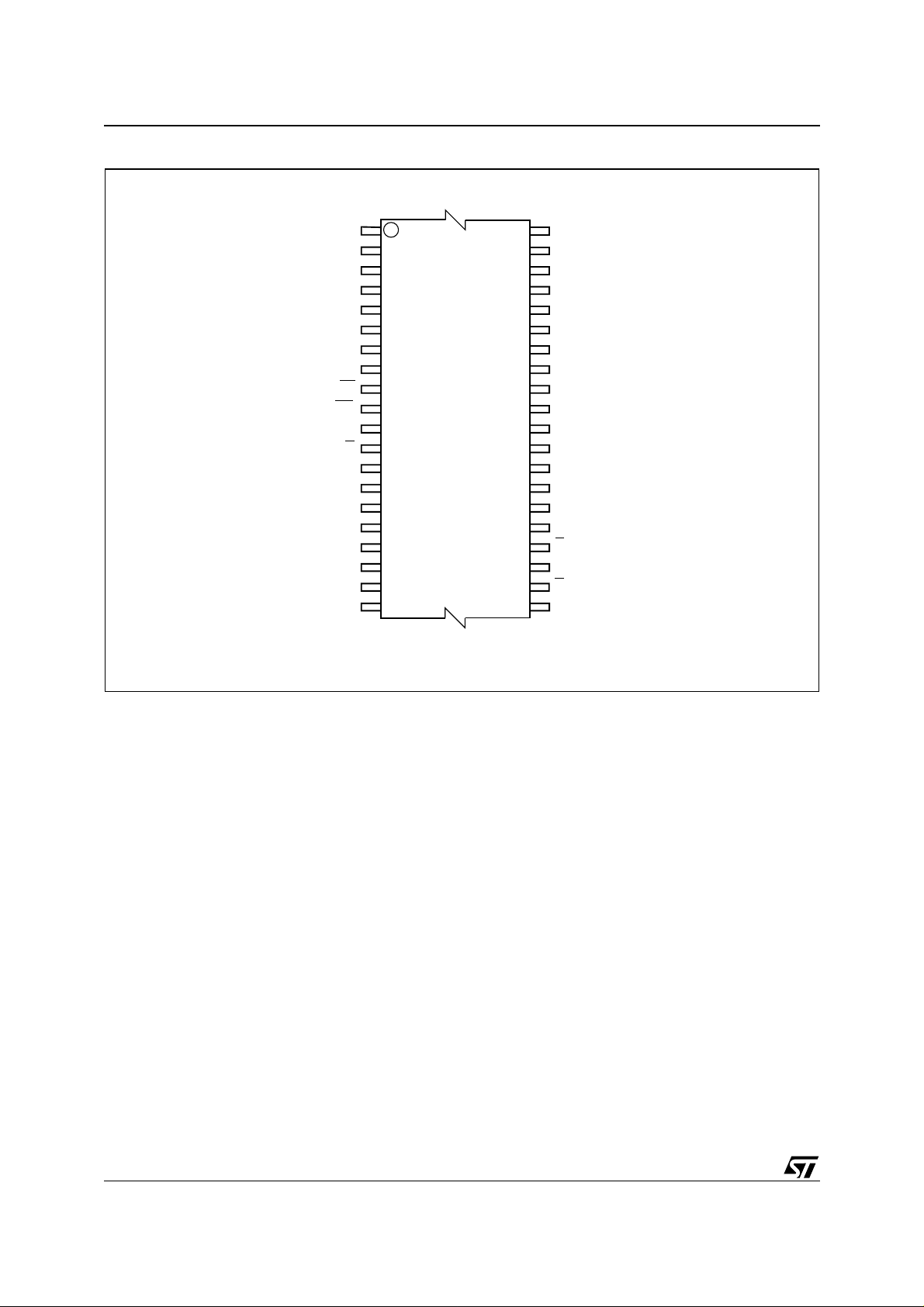

Figure 3. TSOP Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

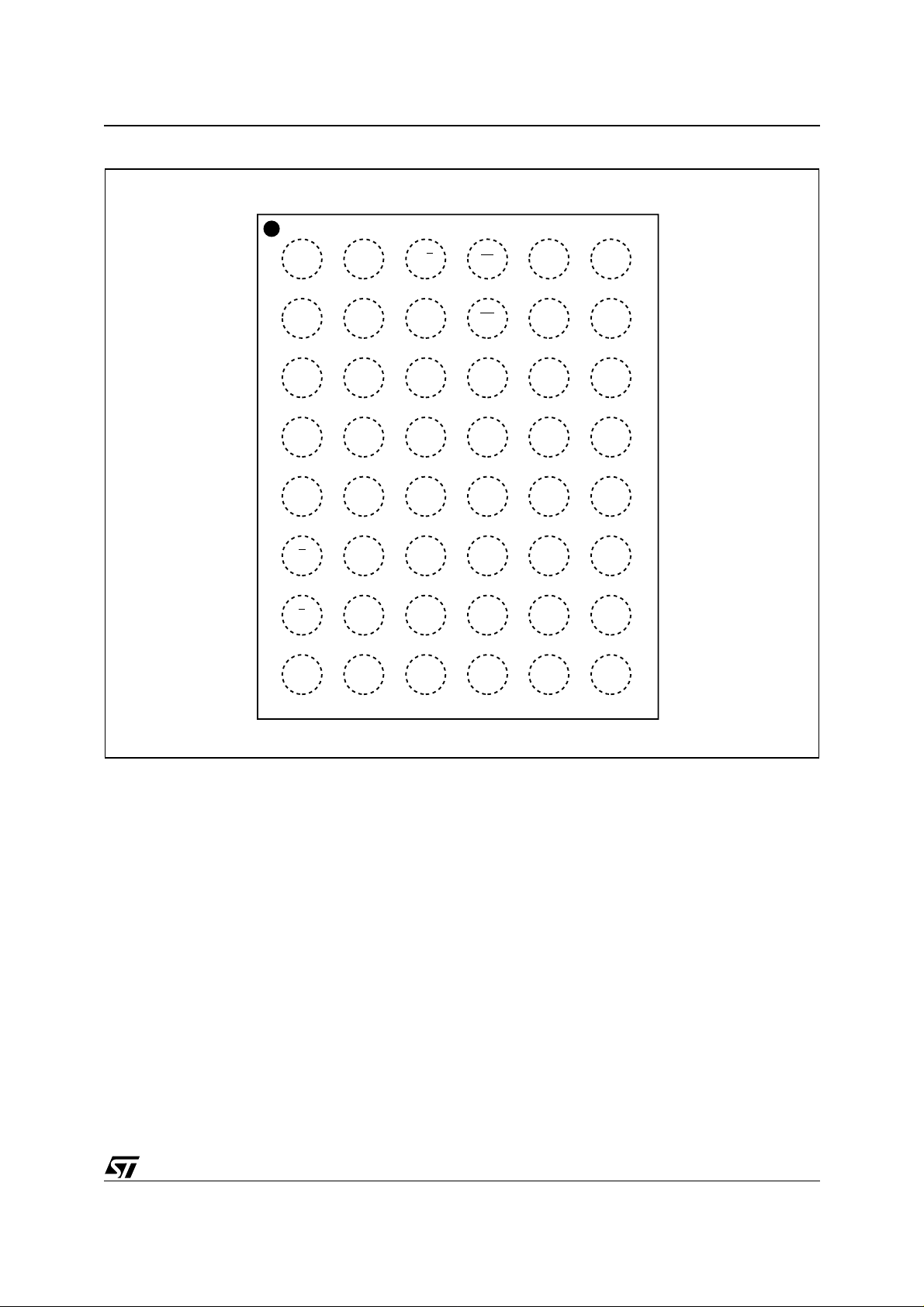

Figure 4. TFBGA Connections (Top view through package). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Table 16. Block Addresses, M29W017D. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

SIGNAL DESCRIPTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Address Inputs (A0-A20). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Data Inputs/Outputs (DQ0-DQ7). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Chip Enable (E). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Chip Enable (E). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Output Enable (G). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Write Enable (W). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Reset/Block Temporary Unprotect (RP).. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Ready/Busy Output (RB). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

V

Supply Voltage (2.7V to 3.6V).. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

CC

V

Ground. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

SS

BUS OPERATIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Bus Read. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Bus Write. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Output Disable. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 0

Standby. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Automatic Standby. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Special Bus Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Electronic Signature. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Block Protection and Blocks Unprotection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Table 2. Bus Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

COMMAND INTERFACE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Read/Reset Command.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Auto Select Command. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 1

Program Command. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Unlock Bypass Command. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Unlock Bypass Program Command. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Unlock Bypass Reset Command. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Chip Erase Command. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Block Erase Command.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Erase Suspend Comma nd. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Erase Resume Command. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Read CFI Query Command. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Block Protect and Chip Unprotect Commands.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2/36

Page 3

M29W017D

Table 3. Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Table 4. Program, Erase Times and Program, Erase Endurance Cycles . . . . . . . . . . . . . . . . . . . . 14

STATUS REGISTER. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Data Polling Bit (DQ7). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Toggle Bit (DQ6).. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Error Bit (DQ5). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Erase Timer Bit (DQ3). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 4

Alternative Toggle Bit (DQ2).. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Table 5. Status Register Bits. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Figure 6. Data Polling Flowchart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 6

Figure 7. Data Toggle Flowchart. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

MAXIMUM RATING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Table 6. Absolute Maximum Ratings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

DC and AC PARAMETERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 8

Table 7. Operating and AC Measurement Conditions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Figure 8. AC Measurement I/O Waveform . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Figure 9. AC Measurement Load Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Table 8. Device Capacitance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Table 9. DC Characteristics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Figure 10. Read AC Waveforms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Table 10. Read AC Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Figure 11. Write AC Waveforms, Write Enable Controlled . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Table 11. Write AC Characteristics, Write Enable Controlled . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Figure 12. Write AC Waveforms, Chip Enable Controlled . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Table 12. Write AC Characteristics, Chip Enable Controlled . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Figure 13. Reset/Block Temporary Unprotect AC Waveforms . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Table 13. Reset/Block Temporary Unprotect AC Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . 23

PACKAGE MECHANICAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

TSOP40 – 40 lead Plastic Thin Small Outline, 10 x 20mm, Package Outline . . . . . . . . . . . . . . . . 24

TSOP40 – 40 lead Plastic Thin Small Outline, 10 x 20mm, Package Mecha nical Data . . . . . . . . 24

TFBGA48 8x9mm – 6x8 active ball array – 0.80mm pitch, Bottom View Packag e Outline . . . . . . 25

TFBGA48 8x9mm – 6x8 active ball array – 0.80mm pitch, Package Mec hanical Data . . . . . . . . . 25

PART NUMBERING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Table 14. Ordering Information Scheme . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

REVISION HISTORY. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Table 15. Document Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

3/36

Page 4

M29W017D

APPENDIX A. BLOCK ADDRESS TABLE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Table 16. Block Addresses, M29W017D. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

APPENDIX B. COMMON FLASH INTERFACE (CFI) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Table 17. Query Structure Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Table 18. CFI Query Identification String . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Table 19. CFI Query System Interface Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Table 20. Device Geometry Definition. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

Table 21. Primary Algorithm-Specific Extended Query Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Table 22. Security Code Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

APPENDIX C. BLOCK PROTECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Programmer Technique . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

In-System Technique . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Table 23. Programmer Technique Bus Operations, BYTE = V

Figure 14. Programmer Equipment Block Protect Flowchart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Figure 15. Programmer Equipment Chip Unprotect Flowchart . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

Figure 16. In-System Equipment Block Protect Flowchart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Figure 17. In-System Equipment Chip Unprotect Flowchart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

or VIL . . . . . . . . . . . . . . . . . . . . . 31

IH

4/36

Page 5

SUMMARY DESCRIPTION

The M29W017D is a 16 Mbit (2Mb x8) non-volatile

memory that can be read, erased and reprogrammed. These operations can be performed using a single low voltage (2.7 to 3 .6V) supply. On

power-up the memory defaults to its Read mode

where it can be read in the same way as a ROM or

EPROM.

The memory is divided into 32 blocks of 64KBytes

(see Table 16, Block Addresses) that can be

erased independently so it is pos sible to pres erve

valid data while old data is erased. Each block can

be protected independently to prev ent accidental

Program or Erase commands from modifying the

memory. Program and Erase com m ands are wri tten to the Command Interface of t he memory. An

process of programming or erasing the memory by

taking care of all of the special operations that are

required to update the memory contents. The end

of a program or erase op eration can be de tected

and any error conditions identified. The command

set required to control the memory is consistent

with JEDEC standards.

Chip Enable, Output Enable and Write Enable signals control the bus operation of the memory.

They allow simple conne ction to most m icroprocessors, often without additional logic.

The memory is offer ed in TSOP40 (10 x 20mm) and

TFBGA48 (0.8mm pitch) pac kages. The memory is

supplied with all the bi ts erased (se t t o ’ 1’).

on-chip Program/Erase Controller simplifies the

Figure 2. Logi c D iag ram Table 1. Si gn a l Nam es

A0-A20 Address Inputs

M29W017D

A0-A20

W

RP

V

CC

21

E

G

M29W017D

V

SS

8

DQ0-DQ7

RB

AI04186

DQ0-DQ7 Data Inputs/Outputs

E

G

W

RP

RB

V

CC

V

SS

NC Not Connected Internally

Chip Enable

Output Enable

Write Enable

Reset/Block Temporary Unprotect

Ready/Busy Output

Supply Voltage

Ground

5/36

Page 6

M29W017D

Figure 3. TSOP Connections

A16

A15

A14

A13

A12

1

40

A17

V

SS

A20

A19

A10

A11 DQ7

31

30

21

DQ6

DQ5

DQ4

V

CC

V

CC

NC

DQ3

DQ2

DQ1

DQ0

G

V

SS

E

A0

A9

A8

W

RP

NC

RB

A18

A7

A6

A5

A4

A3

A2

A1

10

11

20

M29W017D

AI04187

6/36

Page 7

Figure 4. TFBGA Connections (Top view through package)

M29W017D

654321

A

B

C

D

E

F

G

H

A3

A4

A2

A1

A0

E

G

V

SS

A7

A18

A6

A5 NC

DQ0

NC

NC

DQ1

RB

NC

NC

DQ2

DQ3

V

CC

NC

W

RP

NC

NC

DQ5

NC

V

CC

DQ4

A9

A8

A11

A12

A19

A10

DQ6

DQ7

A14

A13

A15

A16

A17

NC

A20

V

SS

AI04188

7/36

Page 8

M29W017D

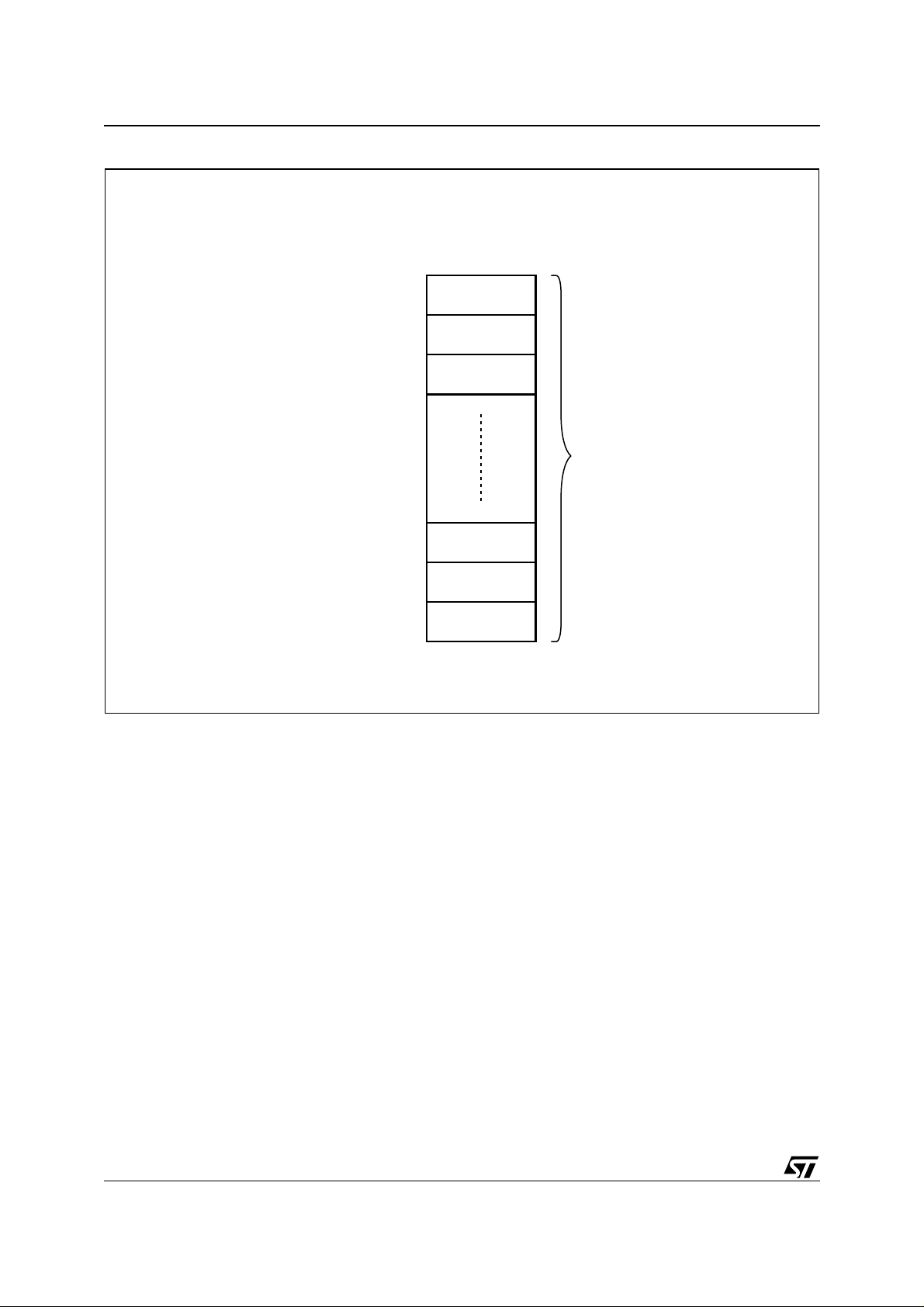

Figure 5. Block Addresses

M29W017D

Block Addresses

1FFFFFh

1F0000h

1EFFFFh

1E0000h

1DFFFFh

1D0000h

1CFFFFh

02FFFFh

020000h

01FFFFh

010000h

00FFFFh

000000h

64 KByte

64 KByte

64 KByte

Total of 32

64 KByte Blocks

64 KByte

64 KByte

64 KByte

AI05429

8/36

Page 9

SIGNAL DESCRIPTIONS

See Figure 2, Logic Diagram, and Table 1, Sign al

Names, for a brief overview of the signals connected to this device.

Address Inputs (A0-A20). The Address Inputs

select the cells i n the memory array to a ccess during Bus Read operations. During Bus Write operations they control the commands sent to the

Command Interface of the internal state machine.

Data Inputs/Outputs (DQ0-DQ7). The Data I/O

outputs the data stored at the selected address

during a Bus Read operation. During Bus Write

operations they represent the commands sent to

the Command Interface of the internal state machine.

Chip Enable (E

). The Chip Enable, E, activates

the memory, allowing Bus Read and Bus Write operations to be performed. When Chip Enable is

High, V

Output Enable (G

, all other pins are ignored.

IH

). The Output Enable, G, con-

trols the Bus Read operation of the memory.

Write Enable (W

). The Write Enable, W, controls

the Bus Write operation of the memory’s Command Interf a c e.

Reset/Block Temporary Unprotect (RP). The

Reset/Block Temporary Unprotect pin can be

used to apply a Hardware Reset to the memory or

to temporarily unprotect all Blocks that hav e b een

protected.

A Hardware Reset is achieved by holding Reset/

Block Temporary Unprotect Low, V

. After Reset/Block Temporary Unprotect

t

PLPX

goes High, V

, the memory will be ready for Bus

IH

Read and Bus Write operations after t

t

, whichever occurs last. See the Ready/Busy

RHEL

, for at least

IL

PHEL

or

Output section, Table 13 and Figure 13, Reset/

Temporary Unprotect AC Characteristics for more

details.

Holding RP

at VID will temporarily unprotect the

protected Blocks in the memory. Program and

Erase operations on all blocks will be possible.

M29W017D

The transition from V

t

PHPHH

.

Ready/Busy Output (RB

is an open-drain output that can be used to identify

when the device is performing a Program or Erase

operation. During Program or Erase operations

Ready/Busy is Low, V

pedance during Read mode, Auto Select mode

and Erase Suspend mode.

After a Hardware Reset, Bus Read and Bus Write

operations cannot begin until Ready/Busy becomes high-impedance. See Tabl e 13 and Figure

13, Reset/Temporary Unprotect AC Characteristics .

The use of an open-drain output allows the Ready/

Busy pins from several memories to be connected

to a single pull-up resistor. A Low will then indicate

that one, or more, of the memories is busy.

Supply Voltage (2.7V to 3.6V). VCC pro-

V

CC

vides the power supply for all operations (Read,

Program and Erase).

The Command Interface is disabled when the V

Supply Voltage is less than the L ockout Voltage,

V

. This prevents Bus Write operations from ac-

LKO

cidentally damaging the data during power up,

power down and power surges. If the Program/

Erase Controller is programming or erasing during

this time then the operation aborts and the memory contents being altered will be invalid.

A 0.1µF capacitor should be connected between

the V

Supply Voltage pin and the VSS Ground

CC

pin to decouple the current surges from the power

supply. See Figure 10, AC Measurement Load Circuit. T he PCB track widths must be sufficient to

carry the currents required during program and

erase operations, I

Ground. VSS is the reference for all voltage

V

SS

measurements.

to VID must be slower than

IH

). The Ready/Busy pin

. Ready/Busy is high-im-

OL

.

CC3

CC

9/36

Page 10

M29W017D

BUS OPERATIONS

There are five standard bus operations that control

the device. These are Bus Read, Bus Wri te, Output Disable, Standby and Automatic Standby. See

Tables 2, Bus Operations, for a summary. Typically glitches of less than 5ns on Chip Enable or Write

Enable are ignored by t he mem ory and do not a ffect bus operations.

Bus Read. Bus Read operations read from the

memory cells, or specific registers in the Command Interface. A valid Bus Read operation involves setting the desired address on the Address

Inputs, applying a Low sig nal, V

and Output Enable and keeping Write Enable

High, V

. The Data Inputs/Outputs will output the

IH

value, see Figure 10, Read Mode AC Waveforms,

and Table 10, Read AC Characteristics, for details

of when the output becomes valid.

Bus Write. Bus Write operations write to the

Command Interface. A valid Bus Write operation

begins by setting the desire d address on t he Address Inputs. The Address Inputs are latched by

the Command Interface on the falling edge of Chip

Enable or Write Enable, whichever occurs last.

The Data Inputs/Outputs a re latched by the Command Interface on the rising edge of Chip Enable

or Write Enable, whichever occurs first. Output Enable must remain High, V

IH

Write operation. See Figures 11 and 12, Write AC

Waveforms, and Tables 11 and 12, Write AC

Characteristics, for details of the timing requirements.

Output Disa bl e . The Data Inputs/Outputs are in

the high impedance s tate when Output Enable is

High, V

.

IH

Standby. When Chip Enable is High, V

memory enters Standby mode and the Data Inputs/Outputs pins are placed in the high-imped-

, to Chip Enable

IL

, during the whole Bus

, the

IH

ance state. To reduce the S upply Current to the

Standby Supply Current, I

be held within V

± 0.2V. For the Standby current

CC

, Chip Enable should

CC2

level see Table 9, DC Characteristics.

During program or erase operations the memory

will continue to use the Program/Erase Supply

Current, I

, for Program or Erase operations un-

CC3

til the operation completes.

Automatic Standby. If CMOS levels (V

± 0.2V)

CC

are used to drive the bus and the bus is inactive for

300ns or more the memory enters Automatic

Standby where the internal Supply Current is reduced to the Standby Supply Current, I

CC2

. The

Data Inputs/Outputs will still output data if a Bus

Read operation is in progress.

Special Bus Operations

Additional bus operations can be performed to

read the Electronic Signature and also to apply

and remove Block Protec tio n. These bus operations are intended for use by programming equipment and are not usually used in applications.

They require V

to be applied to some pins.

ID

Electronic Signature. The memory has two

codes, the manufacturer code and the device

code, that can be read to identify the memory.

These codes can be read by applying t he signals

listed in Tables 2, Bus Operations.

Block Protection and Blocks Unprotection.

Each block can be separately protected against

accidental Program or Erase. Protected blocks

can be unprotected to allow data to be changed.

There are two methods available for protecting

and unprotecting the blocks, one for use on programming equipment and the other for in-system

use. Block Protect and Chip Unprot ec t operat ions

are described in Appendix C.

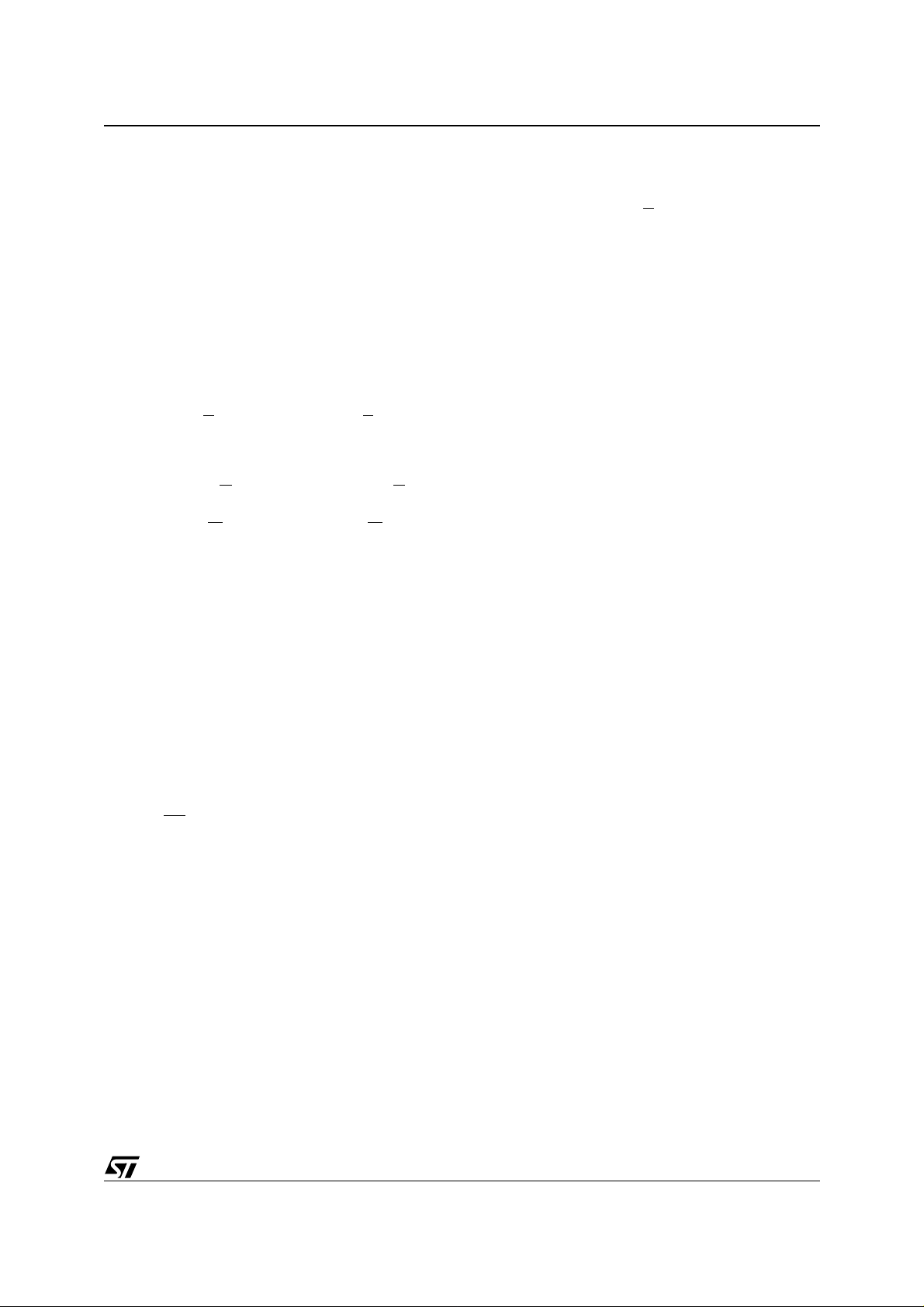

Table 2. Bus Operations

Operation E G W

Bus Read

Bus Write

Output Disable X

Standby

Read Manufacturer

Code

Read Device Code

Note: X = VIL or VIH.

10/36

V

IL

V

IL

V

IH

V

IL

V

IL

Address Inputs

A0-A20

V

IL

V

IH

V

IH

X X X Hi-Z

V

IL

V

IL

V

Cell Address Data Output

IH

V

Command Address Data Input

IL

V

X Hi-Z

IH

A0 = VIL, A1 = VIL, A9 = VID,

V

IH

Others V

A0 = VIH, A1 = VIL,

V

IH

A9 = V

or V

IL

IH

, Others VIL or V

ID

IH

Data Inputs/Outputs

DQ7-DQ0

C8h

20h

Page 11

COMMAND INTERFACE

All Bus Write operations t o the me mory are in terpreted by the Command Interface. Commands

consist of one or more sequential Bus Write operations. Failure to observe a valid sequence of Bus

Write operations will result in the memory returning to Read mode. The long command sequences

are imposed to maximize data security.

Refer to Table 3, Commands, in conjunc tion with

the following text descriptions.

Read/Reset Command. The Read/Reset command returns the memory to its Read mode where

it behaves like a ROM or EPROM, unless otherwise stated. It also resets t he errors in the S tatus

Register. Either one or three Bus Write operations

can be used to issue the Read/Reset command.

The Read/Reset Command can be issued, between Bus Write cycles before the start of a program or erase operation, to return the device to

read mode. Once the program or erase operation

has started the Read/Reset command is no longer

accepted. The Read/Reset command will not

abort an Erase operation when issued while in

Erase Suspend.

Auto Select Command. The Auto Select command is used to read the Manufacturer Code, the

Device Code and the Block Protection Status.

Three consecutive Bus Write operations are required to issue the Auto Select command. Once

the Auto Select comma nd is issued the memory

remains in Auto Select mode until a Read/Reset

command is issued. Read CFI Query and Read/

Reset commands are accepted in Auto Select

mode, all other commands are ignored.

From the Auto Select mode the Manufacturer

Code can be read using a Bus Read operation

with A0 = V

may be set to either V

and A1 = VIL. The other address bits

IL

or VIH. The Manufa cturer

IL

Code for STMicroelectronics is 20h.

The Device Code can be read using a B us Read

operation with A0 = V

address bits may be set to e ither V

and A1 = VIL. The other

IH

or VIH. The

IL

Device Code for the M29W017D is C8h.

The Bl ock Protection Status of each block can be

read using a Bus Read operation with A0 = V

A1 = V

, and A 16 -A 20 spec ify i n g t he address of

IH

IL

the bl ock. The oth er addr ess bit s may b e set t o either V

or VIH. If t h e ad dr ess ed b loc k is pro tec te d

IL

then 01h is output on Data Inputs/Outputs DQ0DQ7, otherwise 00h is output.

Program Command. The Program command

can be used to program a value to one address in

the memory array at a time. The command requires four Bus Write operations, the final write operation latches the address and data in the internal

state machine and starts the Program/Erase Controller.

M29W017D

If the address falls in a pro tected block then the

Program command is ignored, the data remains

unchanged. The Status Register is never read and

no error condition is given.

During the program operat ion the memo ry will ignore all commands. I t is n ot poss ible t o iss ue any

command to abort or pause the operation. Typical

program times are given in Table 4. Bus Read operations during the program o peration will output

the Status Register on the Data Inputs/Outputs.

See the section on the S tatus Register for more

details.

After the program operation has completed the

memory will return to the Read mode, unle ss an

error has occurred. When an error occurs the

memory will continue to output the Status Register. A Read/Reset command must be issued to reset the error condition and return to Read mode.

Note that the Program command cannot change a

bit set at ’0’ bac k to ’1’. One of the E rase Commands must be used to set all the bits in a block or

in the whole memory from ’0’ to ’1’.

Unlock Bypass Command. The Unlock Bypass

command is used in conjunction with the Unlock

Bypass Program command to program the memory. When the cycle time to the device is long (as

with some EPROM programmers) considerable

time saving can be made by using these commands. Three Bus Write operations are requ ired

to issue the Unlock Bypass command.

Once the Unlock Bypas s command has bee n issued the memory will only accept the Unloc k Bypass Program command and the Unlock Bypass

Reset command. The memory can be read as if in

Read mode.

Unlock Bypass Program Command. The Unlock Bypass Prog ra m command can be u sed to

program one address in the memory array at a

time. The command requires two Bus Write operations, the final write operation latches the address and data in the internal state machine and

starts the Program/Erase Controller.

The Program operation using the Unlock Bypass

,

Program command behaves identically to the Program operation using the Program command. A

protected block cannot be programmed; the operation cannot be aborted and the Status Register is

read. Errors must be reset using the Read/Re set

command, which l eaves the d evice in Unlo ck Bypass Mode. See the Program command for details

on the behavior.

Unlock Bypass Reset Command. The Unlock

Bypass Reset command can be used to return t o

Read/Reset mode from Unlock Bypass Mode.

Two Bus Write operations are required to issue the

Unlock Bypass Reset command. Read/Reset

11/36

Page 12

M29W017D

command does not exit from Unlock Bypass

Mode.

Chip Erase Command. The Chip Erase command can be used to erase the entire chip. Six Bus

Write operations are required to issue the Chip

Erase Command and start the Program/Erase

Controller.

If any blocks are protected th en these are ignored

and all the other blocks are erased. If all of the

blocks are protect e d th e Chip Erase op erat i on ap-

pears to start but will terminate within about 100µs,

leaving the data unchanged. No error condition is

given when protected blocks are ignored.

During the erase operation the memory will ignore

all commands, including the Erase Suspen d command. It is not possible to i ssue any c ommand t o

abort the operation. Typical chip erase tim es are

given in Table 4. All Bus Read operations during

the Chip Erase operation will output the Status

Register on the Data Inputs/Outputs. See the section on the Status Register for more details.

After the Chip Erase operation has completed t he

memory will return to the Read Mode, unle ss an

error has occurred. When an error occurs the

memory will continue to output the Status Register. A Read/Reset command must be issued to reset the error condition and return to Read Mode.

The Chip Erase Command sets all of the bits in unprotected blocks of the memory to ’1’. All previous

data is lost.

Block Erase Command. The Block Erase command can be use d to erase a list of one or more

blocks. Six Bus Write operations are required to

select the first block in the list. Each additional

block in the list can be selected by repeating the

sixth Bus Write operation using the address of the

additional block. The Block Erase operation starts

the Program/Erase Controller about 50µs after the

last Bus Write operation. Once the Program/Erase

Controller starts it is not possible to select any

more blocks. Each additional block must therefore

be selected within 50µs of the last block. The 50µs

timer restarts when an additional block is selected.

The Status Register can be read after the sixth

Bus Write operation. See the Status Register section for details o n how to identify if the Program/

Erase Controller has started the Block Erase operation.

If any selected blocks are protected then these are

ignored and all the other selected blocks are

erased. If all of the selected blocks are p rotected

the Block Erase operation appears to start but will

terminate within about 100µs, leaving the data unchanged. No error condition is given when protected blocks are ignored.

During the Block Erase operation the me mory wi ll

ignore all commands except the Erase Susp end

command. Typical b lock era se times a re g iven in

Table 4. All Bus Read operations during the Block

Erase ope ra tion will outp ut the S t atus R e gister on

the Data Inputs/Outputs. See the section on the

Status Register for more details.

After the Block Erase operation has completed the

memory will return to the Read Mode, unle ss an

error has occurred. When an error occurs the

memory will continue to output the Status Register. A Read/Reset command must be issued to reset the error condition and return to Read mode.

The Block Erase Command sets all of the bits in

the unprotected selected blocks to ’1’. All previous

data in the selected blocks is lost.

Erase Suspend Command. The Erase Suspend

Command may be used to temporarily suspend a

Block Erase operation and return the memory to

Read mode. The command requires one Bus

Write operation.

The Program/Erase Controller will sus pend within

15µs of the Erase Suspend Command being issued. Once the Program/Erase Controller has

stopped the memory will be set to Read mode and

the Erase will be suspended. If the Erase Suspend

command is issued during the period when the

memory is waiting for an additional block (before

the Program/Erase Controller starts) then the

Erase is suspended immediate ly and wi ll start immediately when the Erase Resume Comm and is

issued. It is not possible to select any further

blocks to erase after the Erase Resume. During

Erase Suspend it is possible to Read and Program

cells in blocks that are not being erased; both

Read and Program operations beh ave as normal

on these blocks. If any attempt i s made to progra m

in a protected block or in the suspended block then

the Program command is ignored and the data remains unchanged. The Status Register is not read

and no error condition is given. Reading from

blocks that ar e bei n g era se d will output the Status

Register.

It is also possible to issue the Auto Select, Read

CFI Query and Unlock Bypass commands during

an Erase Suspend. The Read/Reset command

must be issued to return the device to Read Array

mode before the Resume command will be accepte d.

Erase Resume Command. The Erase Resume

command must be used to restart the Program/

Erase Controller after an Erase Suspend. The device must be in Read Array mode before t he Resume command will be accepted. An erase can be

suspended and resumed more than once.

Read CFI Query Command. The Read CFI

Query Command is used to read data from the

Common Flash Interface (CFI) Memory Area. This

command is valid when the device i s in the Read

12/36

Page 13

M29W017D

Array mode, or when the device is in Autoselected

mode.

One Bus Write cycle is required to issue the Read

CFI Query Command. Once the command is issued subsequent Bus Read ope rations read from

the Common Flash Interface Memory Area.

The Read/Reset command m ust be issued to return the device to the previous mode (the Read Array mode or Autoselected mode). A second Read/

Reset command would be needed if the device is

See Appendix B, Tables 17, 18, 19, 20, 21 and 22

for details on the information contained in the

Common Flash Interface (CFI) memory area.

Block Protect and Chip Unprot ect Commands.

Each block can be separately protected against

accidental Program or E ras e. The whole chip can

be unprotected to allow the data inside t he blo cks

to be changed.

Block Protect and Chip Unprote ct operations are

described in Appendix C.

to be put in the Read Array mode from Autoselected mode.

Table 3. Commands

Bus Write Operations

Command

Read/Reset

Auto Select 3 x AA x 55 x 90

Program 4 x AA x 55 x A0 PA PD

Unlock Bypass 3 x AA x 55 x 20

Unlock Bypass

Program

Unlock Bypass Reset 2 x 90 x 00

Chip Erase 6 x AA x 55 x 80 x AA x 55 x 10

Block Erase 6+ x AA x 55 x 80 x AA x 55 BA 30

1x F0

3 x AA x 55 x F0

2x A0PAPD

1st 2nd 3rd 4th 5th 6th

Length

Addr Data Addr Data Addr Data Addr Data Addr Data Addr Data

Erase Suspend 1 x B0

Erase Resume 1 x 30

Read CFI Query 1 55 98

Note: x Don’t Care, PA Progr am A ddress, PD P rogram Data, BA Any addres s in the Block. All values in the table are in hexadecim al .

13/36

Page 14

M29W017D

Table 4. Program, Erase Times and Progra m, Erase Endu ran ce Cycle s

Parameter Min

Chip Erase 25 25 120 s

Block Erase (64 KBytes) 0.8 6 s

Program (Byte) 10 200 µs

Chip Program (Byte by Byte) 25 120 s

Program/Erase Cycles (per Block) 100,000 cycles

Note: 1. TA = 25°C, VCC = 3.3V.

Typ

(1)

STATUS REGISTER

Bus Read operations from any address always

read the Status Register during Program and

Erase operations. It is also read during Erase Suspend when an address within a block being erased

is accessed.

The bits in the Status Register are summarized in

Table 5, Status Register Bits.

Data Polling Bit (DQ7). The Data Polling Bit can

be used to identify whether the Program/Erase

Controller has successfully completed its operation or if it has responded to an Erase Suspend.

The Data Polling Bit is output on DQ7 when the

Status Register is read.

During Program operations the Data Polling Bit

outputs the complement of the bit being programmed to DQ7. After successful completion of

the Program operation the memory returns to

Read mode and Bus Read operations from the address just programmed o utput DQ7, not its complement.

During Er ase ope rations the Data Polling Bit ou t-

puts ’0’, the complement of the erased state of

DQ7. After successful completion of the Erase operation the memory returns to Read Mode.

In Erase Suspend mode the Data Polling Bit will

output a ’1’ during a Bus Read operation within a

block being erased. The Data Polling Bit will

change from a ’0’ to a ’1’ when the Program/Erase

Controller has suspended the Erase operation.

Figure 6, Data Polling Flowchart, gives an example of how to use the Data Polling Bit. A Valid Address is the address being programmed or an

address within the block being erased.

Toggle Bit (DQ6). The Toggle Bit can be used to

identify whether the Program/Erase Controller has

successfully completed its operation or if it has responded to an Erase Suspen d. The Toggle Bit is

output on DQ6 when the Status Register is read.

During Program and Erase operations the Toggle

Bit changes from ’0’ to ’ 1’ to ’ 0’, et c., with su cces-

sive Bus Read operations at any address. After

successful completion of the operation the memory returns to Read mode.

During Erase Suspend mode the Toggle Bit will

output when addressing a cell within a block being

erased. The Toggle Bit will stop toggling when the

Program/Erase Controller has suspended the

Erase operation.

If any attempt is made to erase a protected bl ock,

the operation is abort ed, no error is sig nalle d and

DQ6 toggles for approximately 100µs. If any attempt is made to program a protected block or a

suspended block, the operation is abort ed, no error is signalled and DQ6 toggles for approximately

1µs.

Figure 7, Data Toggle Flowchart, g ives an example of how to use the Data Toggle Bit.

Error Bit (DQ5). The Error Bit can be used to

identify errors detected by the Program/Erase

Controller. The Error B it is set to ’1’ when a Program, Block Erase or Chip Erase operation fails to

write the correct data to the memory. If the Error

Bit is set a Read/Rese t command must be iss ued

before other commands are issued. The E rror bit

is output on DQ5 when the Status Register is read.

Note that the Program command cannot change a

bit set to ’0’ back to ’1’ and attempting to do so will

set DQ5 to ‘1’. A Bus Read operation to that address will s h ow the bit is s ti ll ‘0’. One o f t he E r as e

commands must b e used to set all the bits in a

block or in the whole memory from ’0’ to ’1’.

Erase Timer Bit (DQ3). The Erase Timer Bit can

be used to identify the start of Program/Erase

Controller operation during a Block Erase command. Once the Program/Erase Controller starts

erasing the Erase Timer Bit is set to ’1’. Before the

Program/Erase Controller starts the Erase Timer

Bit is set to ’0’ and additional block s to be erased

may be written to the Command Interface. The

Erase Timer Bit is output on DQ3 when the Status

Register is read.

Typical after

100k W/E Cycles

(1)

Max Unit

14/36

Page 15

M29W017D

Alternative Toggle Bit (DQ2). The Alternative

Toggle Bit can be used to monitor the Program/

Erase controller during Erase operations. The Alternative Toggle Bit is output on DQ2 when the

Status Register is read.

During Chip Erase and Block Erase operations the

Toggle Bit changes from ’0’ to ’1’ to ’0’, etc., with

successive Bus Read operations from addresses

within the blocks being erased. A protected block

is treated the same as a block not being erased.

Once the operation completes the memory returns

to Read mode.

During Erase Suspend the Alternative Toggle Bit

Bus Read operations from addresses within the

blocks being erased. Bus Read operations to addresses within blocks not being erased will ou tput

the memory cell data as if in Read mode.

After an Erase operation that c auses t he Error Bit

to be set the Alternative Toggle Bit can be used to

identify which block or blocks have caused the error. The Alternative Toggle Bit changes from ’0’ to

’1’ to ’0’, etc. with successive Bus Re ad Operations from addresses within blocks that have not

erased correctly. The Alternative Togg le Bit does

not change if the addressed block has erased correctly.

changes from ’0’ to ’1’ to ’0’, etc. with successive

Table 5. Status Register Bits

Operation Addre ss DQ7 DQ6 D Q5 DQ3 DQ2

Program Any Address DQ7 Toggle 0 ––0

Program During Erase

Suspend

Program Error Any Address DQ7

Chip Erase Any Address 0 Toggle 0 1 Toggle 0

Block Erase before

timeout

Block Erase

Erase Suspend

Any Address DQ7

Erasing Block 0 Toggle 0 0 Toggle 0

Non-Erasing Block 0 Toggle 0 0 No Toggle 0

Erasing Block 0 Toggle 0 1 Toggle 0

Non-Erasing Block 0 Toggle 0 1 No Toggle 0

Erasing Block 1 No Toggle 0 – Toggle 1

Non-Erasing Block Data read as normal 1

Toggle 0 – – 0

Toggle 1 – – 0

RB

Erase Error

Good Block Address 0 Toggle 1 1 No Toggle 0

Faulty Block Address 0 Toggle 1 1 Toggle 0

Note: Unspecif ied data bit s should be ignored.

15/36

Page 16

M29W017D

Figure 6. Dat a Po ll i ng Fl o wc h a rt Figure 7. Dat a Toggle Flow c hart

START

READ DQ5 & DQ7

at VALID ADDRESS

DQ7

DATA

NO

DQ5

READ DQ7

at VALID ADDRESS

DQ7

DATA

FAIL PASS

= 1

YES

=

NO

YES

YES

=

NO

AI05252

START

READ

DQ5 & DQ6

READ DQ6

DQ6

=

TOGGLE

YES

NO

DQ5

= 1

YES

READ DQ6

TWICE

DQ6

=

TOGGLE

YES

FAIL PASS

NO

NO

AI05253

16/36

Page 17

MAXIMUM RATIN G

Stressing the device ab ove the rating listed in t he

Absolute Maximum Ratings table may cause permanent damage to the device. Exposure to Absolute Maximum Rating conditions for extended

periods may affect device reliability. These are

these or any other conditions above those indicated in the Operating sections of this specification is

not implied. Refer also to the STMicroelectronics

SURE Program and ot her relevant quality documents.

stress ratings only and operation of the dev ice at

Table 6. Absolute Maximum Ratings

Symbol Parameter Min Max Unit

T

BIAS

T

STG

V

IO

V

CC

V

ID

Note: 1. Minimum voltage ma y undershoo t t o –2V during transition and for less than 20ns during transitions.

2. Max imum voltage m ay oversho ot to V

Temperature Under Bias –50 125 °C

Storage Temperature

Input or Output Voltage

Supply Voltage –0.6 4 V

Identification Voltage –0.6 13.5 V

(1,2)

+2V during transition and less than 20ns during transitions.

CC

–65 150 °C

V

–0.6

CC

+0.6

M29W017D

V

17/36

Page 18

M29W017D

DC AND AC PARAMETERS

This section summarizes t he operating m easurement conditions, and the DC and AC characteristics of the device. The parameters in the DC and

AC characteristics Tables that follow, are derived

from tests performed under the Measurement

Table 7. Operating and AC Measurement Conditions

Parameter

Min Max Min Max

V

Supply Voltage

CC

Ambient Operating Temperature –40 85 –40 85 °C

Conditions summarized in Table 7, Operating and

AC Measurement Conditions. Designers should

check that the operating cond itions in their circuit

match the operating conditions when relying on

the quoted parameters.

M29W017D

3.0 3.6 2.7 3.6 V

Unit70 90

Load Capacitance (C

)

L

30 100 pF

Input Rise and Fall Times 10 10 ns

Input Pulse Voltages

Input and Output Timing Ref. Voltages

0 to V

CC

V

/2 VCC/2

CC

0 to V

CC

Figure 8. AC Measurement I/O Waveform Figure 9. AC Measurement Load Circuit

V

CC

V

CC

VCC/2

0V

AI05254

CL includes JIG capacitance

DEVICE

UNDER

TEST

0.1µF

V

CC

C

L

V

V

25kΩ

25kΩ

AI05255

Table 8. Device Capacitance

Symbol Parameter Test Condition Min Max Unit

V

V

IN

OUT

= 0V

= 0V

6pF

12 pF

C

IN

C

OUT

Note: Sampled only, not 10 0% tested.

Input Capacitance

Output Capacitance

18/36

Page 19

M29W017D

Table 9. DC Characteristics

Symbol Parameter Test Condition Min Max Unit

I

LI

I

LO

I

CC1

I

CC2

I

CC3

V

IL

V

IH

V

OL

V

OH

V

ID

I

ID

V

LKO

Note: 1. Sampled only, not 100% tested.

Input Leakage Current

Output Leakage Current

Supply Current (Read)

Supply Current (Standby)

(1)

Supply Current (Program/Erase)

Input Low Voltage –0.5 0.8 V

Input High Voltage

Output Low Voltage

Output High Voltage IOH = –100µA

Identification Voltage 11.5 12.5 V

Identification Current

Program/Erase Lockout Supply

Voltage

0V ≤ V

0V ≤ V

E

≤ V

IN

CC

≤ V

OUT

= VIL, G = VIH,

f = 6MHz

E

= VCC ±0.2V,

RP

= VCC ±0.2V

Program/Erase

Controller active

I

= 1.8mA

OL

A9 = V

ID

CC

±1

±1

10 mA

100

20 mA

0.7V

CC

VCC +0.3

0.45 V

V

–0.4

CC

100

1.8 2.3 V

µA

µA

µA

V

V

µA

19/36

Page 20

M29W017D

Figure 10. Read AC Waveforms

A0-A20

E

G

DQ0-DQ7

tAVAV

VALID

tAVQV tAXQX

tELQV tEHQX

tELQX tEHQZ

tGLQX tGHQX

tGLQV

tGHQZ

VALID

AI05248

Table 10. Read AC Characteristics

Symbol Alt Parameter Test Condition

E

t

AVAV

t

AVQV

(1)

t

ELQX

t

ELQV

(1)

t

GLQX

t

GLQV

(1)

t

EHQZ

(1)

t

GHQZ

t

EHQX

t

GHQX

t

AXQX

Note: 1. Sampled only, not 100% tested.

t

t

ACC

t

t

t

OLZ

t

t

t

t

Address Valid to Next Address Valid

RC

Address Valid to Output Valid

Chip Enable Low to Output Transition

LZ

Chip Enable Low to Output Valid

CE

Output Enable Low to Output

Transition

Output Enable Low to Output Valid

OE

Chip Enable High to Output Hi-Z

HZ

Output Enable High to Output Hi-Z

DF

Chip Enable, Output Enable or

OH

Address Transition to Output Transition

= VIL,

G

= V

E

= VIL,

G

= V

G

= V

G

= V

= V

E

E

= V

G

= V

E

= V

IL

IL

IL

IL

IL

IL

IL

IL

M29W017D

Unit

70 90

Min 70 90 ns

Max 70 90 ns

Min 0 0 ns

Max 70 90 ns

Min 0 0 ns

Max 30 35 ns

Max 25 30 ns

Max 25 30 ns

Min 0 0 ns

20/36

Page 21

Figure 11. Write AC Waveforms, Write Enable Controlled

tAVAV

A0-A20

tAVWL

E

VALID

M29W017D

tWLAX

tWHEH

tELWL

G

tWLWHtGHWL

W

tDVWH

DQ0-DQ7

V

CC

RB

tVCHEL

VALID

tWHRL

Table 11. Write AC Characteristics, Write Enable Controlled

Symbol Alt Parameter

t

AVAV

t

ELWL

t

WLWH

t

DVWH

t

WHDX

t

WHEH

t

WHWL

t

AVWL

t

WLAX

t

GHWL

t

WHGL

(1)

t

WHRL

t

VCHEL

Note: 1. Sampled only, not 100% tested.

t

WC

t

t

WP

t

t

DH

t

CH

t

WPH

t

t

t

OEH

t

BUSY

t

VCS

Address Valid to Next Address Valid Min 70 90 ns

Chip Enable Low to Write Enable Low Min 0 0 ns

CS

Write Enable Low to Write Enable High Min 45 50 ns

Input Valid to Write Enable High Min 45 50 ns

DS

Write Enable High to Input Transition Min 0 0 ns

Write Enable High to Chip Enable High Min 0 0 ns

Write Enable High to Write Enable Low Min 30 30 ns

Address Valid to Write Enable Low Min 0 0 ns

AS

Write Enable Low to Address Transition Min 45 50 ns

AH

Output Enable High to Write Enable Low Min 0 0 ns

Write Enable High to Output Enable Low Min 0 0 ns

Program/Erase Valid to RB Low Max 30 35 ns

VCC High to Chip Enable Low

tWHGL

tWHWL

tWHDX

AI05249

M29W017D

Unit

70 90

Min 50 50 µs

21/36

Page 22

M29W017D

Figure 12. Write AC Waveforms, Chip Enable Controlled

tAVAV

A0-A20

tAVEL

W

VALID

tELAX

tEHWH

tWLEL

G

tELEHtGHEL

E

tDVEH

DQ0-DQ7

V

CC

RB

tVCHWL

VALID

tEHRL

Table 12. Write AC Characteristics, Chip Enable Controlled

Symbol Alt Parameter

t

AVAV

t

WLEL

t

ELEH

t

DVEH

t

EHDX

t

EHWH

t

EHEL

t

AVEL

t

ELAX

t

GHEL

t

EHGL

(1)

t

EHRL

t

VCHWL

Note: 1. Sampled only, not 100% tested.

t

WC

t

WS

t

t

t

DH

t

WH

t

CPH

t

t

t

OEH

t

BUSY

t

VCS

Address Valid to Next Address Valid Min 70 90 ns

Write Enable Low to Chip Enable Low Min 0 0 ns

Chip Enable Low to Chip Enable High Min 45 50 ns

CP

Input Valid to Chip Enable High Min 45 50 ns

DS

Chip Enable High to Input Transition Min 0 0 ns

Chip Enable High to Write Enable High Min 0 0 ns

Chip Enable High to Chip Enable Low Min 30 30 ns

Address Valid to Chip Enable Low Min 0 0 ns

AS

Chip Enable Low to Address Transition Min 45 50 ns

AH

Output Enable High Chip Enable Low Min 0 0 ns

Chip Enable High to Output Enable Low Min 0 0 ns

Program/Erase Valid to RB Low Max 30 35 ns

VCC High to Write Enable Low

tEHGL

tEHEL

tEHDX

AI05250

M29W017D

Unit

70 90

Min 50 50 µs

22/36

Page 23

Figure 13. Reset/Block Temporary Unprotect AC Wavefo rms

E, G

W,

tPHWL, tPHEL, tPHGL

RB

RP

tPLPX

tPLYH

Table 13. Reset/Block Temporary Unprotect AC Characteristics

Symbol Alt Parameter

(1)

t

PHWL

t

PHEL

(1)

t

PHGL

(1)

t

RHWL

(1)

t

RHEL

(1)

t

RHGL

t

PLPX

(1)

t

PLYH

(1)

t

PHPHH

Note: 1. Sampled only, not 100% tested.

t

t

t

t

READY

t

VIDR

RP High to Write Enable Low, Chip Enable Low,

RH

Output Enable Low

RB High to Write Enable Low, Chip Enable Low,

RB

Output Enable Low

RP Pulse Width Min 500 500 ns

RP

RP Low to Read Mode Max 10 10 µs

RP Rise Time to V

ID

M29W017D

tRHWL, tRHEL, tRHGL

tPHPHH

AI02931B

M29W017D

Unit

70 90

Min 50 50 ns

Min 0 0 ns

Min 500 500 ns

23/36

Page 24

M29W017D

PACKAGE MECHANICAL

TSOP40 – 40 lead Plastic Thin Small Outline, 10 x 20mm, Package Outline

A2

Note: Drawing is not to scale.

1 N

N/2

TSOP-a

D1

DIE

E

A

D

C

e

B

CP

LA1 α

TSOP40 – 40 lead Plastic Thin Small Outline, 10 x 20mm, Package Mechan ic al Data

Symbol

Typ Min Max Typ M in Max

A 1.200 0.0472

A1 0.050 0.150 0.0020 0.0059

A2 0.950 1.050 0.0374 0.0413

millimeters inches

B 0.170 0.270 0.0067 0.0106

C 0.100 0.21 0 0.0039 0.0083

D 1 9.800 20.200 0.7795 0.7953

D1 18.30 0 18.500 0.7205 0.7283

E 9.900 10.100 0.3898 0.3976

e 0 .500 – – 0.0197 – –

L 0.500 0.70 0 0.0197 0.0276

α

0° 5° 0° 5°

N40 40

CP 0.100 0.0039

24/36

Page 25

M29W017D

TFBGA48 8x9mm – 6x8 active ball array – 0.80mm pitch, Bottom View Package Ou tline

D

FD

FE

D1

SD

SE

ddd

A2

A1

BGA-Z14

BALL "A1"

Note: Drawing is not to scale.

E1E

eb

A

TFBGA48 8x9mm – 6x8 active ball array – 0.80mm pitch, Pack age Mechan i cal Data

Symbol

Typ Min Max Typ Min Max

A 1.350 0.0531

A1 0 .300 0.200 0.350 0.0118 0.0079 0.0138

A2 1.000 0.0394

b 0.30 0 0.550 0.0118 0.0217

D 8.000 7.900 8 .100 0.3150 0.3110 0.3189

millimeters inches

D1 4.000 – – 0.1575 – –

ddd 0.100 0.0039

e 0.800 – – 0.031 5 – –

E 9 .000 8.900 9.100 0.3543 0.3504 0.3583

E1 5 .600 – – 0.2205 – –

FD 2.000 – – 0.0787 – –

FE 1.700 – – 0.0669 – –

SD 0 .400 – – 0.0157 – –

SE 0.400 – – 0.0157 – –

25/36

Page 26

M29W017D

PART NUMBERING

Table 14. Ordering Information Scheme

Example: M29W017D 90 N 1 T

Device Type

M29

Operating Voltage

W = V

Device Function

017D = 16 Mbit (x8), Uniform Block

Speed

70 = 70 ns

90 = 90 ns

Package

N = TSOP40: 10 x 20 mm

ZA = TFBGA48: 0.80mm pitch

= 2.7 to 3.6V

CC

Temperature Range

1 = 0 to 70 °C

6 = –40 to 85 °C

Option

T = Tape & Reel Packing

Devices are shipped from the factory with the memory content bits erased to ’1’.

For a list of available options (Speed, Pac kage, etc...) or for furthe r information on any aspect of this device, please contact the ST Sales Office nearest to you.

REVISION HIST ORY

Table 15. Document Revision History

Date Version Revision Details

May-2001 -01 First Issue (Brief Data)

18-Jun-2001 -02 Document expanded to full Product Preview, TFBGA Package Mechanical changed.

26-Jul-2001 -03 Document type: from Product Preview to Preliminary Data

03-Dec-2001 -04 Block Protection Appendix added, Read/Reset operation during Erase Suspend clarified .

05-Apr-2002 -05

Description of Ready/Busy signal clarified (and Figure 13 modified)

Clarified allowable commands during block erase

Clarified the mode the device returns to in the CFI Read Query command section

26/36

Page 27

APPENDIX A. BLOCK ADDRESS TABLE

M29W017D

Table 16. Block Addresses, M29W017D

#

31 64 1F0000h-1FFFFFh

30 64 1E0000h-1EFFFFh

29 64 1D0000h-1DFFFFh

28 64 1C0000h-1CFFFFh

27 64 1B0000h-1BFFFFh

26 64 1A0000h-1AFFFFh

25 64 190000h-19FFFFh

24 64 180000h-18FFFFh

23 64 170000h-17FFFFh

22 64 160000h-16FFFFh

21 64 150000h-15FFFFh

20 64 140000h-14FFFFh

19 64 130000h-13FFFFh

18 64 120000h-12FFFFh

17 64 110000h-11FFFFh

16 64 100000h-10FFFFh

Size

(KBytes)

Address Range

#

15 64 0F0000h-0FFFFFh

14 64 0E0000h-0EFFFFh

13 64 0D0000h-0DFFFFh

12 64 0C0000h-0CFFFFh

11 64 0B0000h-0BFFFFh

10 64 0A0000h-0AFFFFh

9 64 090000h-09FFFFh

8 64 080000h-08FFFFh

7 64 070000h-07FFFFh

6 64 060000h-06FFFFh

5 64 050000h-05FFFFh

4 64 040000h-04FFFFh

3 64 030000h-03FFFFh

2 64 020000h-02FFFFh

1 64 010000h-01FFFFh

0 64 000000h-00FFFFh

Size

(KBytes)

Address Range

27/36

Page 28

M29W017D

APPENDIX B. COMMON FLASH INTERFACE (CFI)

The Common Flash Interface is a JEDEC approved, standardized data structure that can be

read from the Flash memory device. It allows a

system software to query the device to det ermine

various electrical and t iming parameters, density

information and functions supported by the memory. The system can interface easily with the device, enabling the software to upgrade itself when

necessary.

When the CFI Query Command is issued the device enters CFI Query mode and the data structure

Table 17. Query Structure Overvi ew

Address Sub-section Name Description

10h CFI Query Identification String Command set ID and algorithm data offset

1Bh System Interface Information Device timing & voltage information

27h Device Geometry Definition Flash device layout

is read from the memory. Tables 17, 18, 19, 20, 21

and 22 show the address es used to retrieve the

data.

The CFI data structure also contains a security

area where a 64 bit unique security number is written (see Table 22, Security Code area). This area

can be accessed only in Read mode by the final

user. It is impossible to change t he secu rity number after it has been written by ST. Issue a Read/

Reset command to return to Re ad mode.

40h

61h Security Code Area 64 bit unique device number

Note: Query data are always presented on the lowest order data outputs.

Primary Algorithm-specific Extended Query

table

Additional information specific to the Primary

Algorithm (optio nal)

Table 18. CFI Query Identification String

Address Data Description Value

10h 51h "Q"

11h 52h Query Unique ASCII String "QRY" "R"

12h 59h "Y"

13h 02h

14h 00h

15h 40h

16h 00h

17h 00h

18h 00h

19h 00h

1Ah 00h

Primary Algorithm Command Set and Control Interface ID code 16 bit ID code

defining a specific algorithm

Address for Primary Algorithm extended Query table (see Table 20) P = 40h

Alternate Vendor Command Set and Control Interface ID Code second vendor

- specified algorithm supported

Address for Alternate Algorithm extended Query table

AMD

Compatible

NA

NA

28/36

Page 29

M29W017D

Table 19. CFI Query System Interface Information

Address Data Description Value

V

Logic Supply Minimum Program/Erase voltage

1Bh 27h

1Ch 36h

1Dh 00h

1Eh 00h

1Fh 04h

20h 00h

21h 0Ah

22h 00h

23h 04h

24h 00h

25h 03h

26h 00h

CC

bit 7 to 4 BCD value in volts

bit 3 to 0 BCD value in 100 mV

Logic Supply Maximum Program/Erase voltage

V

CC

bit 7 to 4 BCD value in volts

bit 3 to 0 BCD value in 100 mV

V

[Programming] Supply Minimum Program/Erase voltage

PP

V

[Programming] Supply Maximum Program/Erase voltage

PP

n

Typical timeout per single byte/word program = 2

µs

Typical timeout for minimum size write buffer program = 2

ms

n

ms

n

times typical

n

times typical

n

times typical

Typical timeout per individual block erase = 2

Typical timeout for full chip erase = 2

n

Maximum timeout for byte/word program = 2

Maximum timeout for write buffer program = 2

Maximum timeout per individual block erase = 2

Maximum timeout for chip erase = 2

n

times typical

n

µs

2.7V

3.6V

NA

NA

16µs

NA

1s

NA

256µs

NA

8s

NA

Table 20. Device Geometry Definition

Address Data Description Value

27h 15h

28h

29h

2Ah

2Bh

00h

00h

00h

00h

2Ch 01h

2Dh

2Eh

2Fh

30h

1Fh

00h

00h

01h

n

Device Size = 2

in number of bytes

Flash Device Interface Code description

n

Maximum number of bytes in multi-byte program or page = 2

Number of Erase Block Regions within the device.

It specifies the number of regions within the device containing contiguous

Erase Blocks of the same size.

Region 1 Information

Number of identical size erase block = 001Fh+1

Region 1 Information

Block size in Region 1 = 0100h * 256 byte

2 MByte

Async.

64 KByte

x8

NA

1

32

29/36

Page 30

M29W017D

Table 21. Primary Algorithm-Sp ecific Extend ed Qu ery Ta ble

Address Data Description Valu e

40h 50h

"P"

41h 52h "R"

42h 49h "I"

43h 31h Major version number, ASCII "1"

44h 30h Minor version number, ASCII "0"

45h 01h Address Sensitive Unlock (bits 1 to 0)

46h 02h Erase Suspend

47h 01h Block Protection

48h 01h Temporary Block Unprotect

49h 04h Block Protect /Unprotect

4Ah 00h Simultan eous Operati ons, 00 = not supporte d No

4Bh 00h Burst Mode, 00 = not supported, 01 = supported No

4Ch 00h Page Mode, 00 = not supported, 01 = 4 page word, 02 = 8 page word No

Primary Algorithm extended Query table unique ASCII string “PRI”

00 = required, 01= not required

Silicon Revision Number (bits 7 to 2)

00 = not supported, 01 = Read only, 02 = Read and Write

00 = not supported, x = number of blocks per group

00 = not supported, 01 = supported

04 = M29W400B mode

Table 22. Security Code Area

Address Data Description

61h XX

62h XX

63h XX

64h XX

65h XX

66h XX

67h XX

68h XX

64 bit: unique device number

No

2

1

Yes

4

30/36

Page 31

APPENDIX C. BLOCK PROTECTION

Block protection can be used to prevent any operation from modifying the data s tored in the Flash.

Each Block can be protected individually. Once

protected, Program and Erase operations on the

block fail to change the data.

There are three techniques that can be used to

control Block Protection, these are the Programmer technique, the In-System technique and Temporary Unprotection. Temporary Unprotection is

controlled by the Reset/B lock Temporary Unprotection pin, RP

; this is described in the Signal De-

scriptions section.

Unlike the Command Interface of the Program/

Erase Controller, the techniques for protecting and

unprotecting blocks change between different

Flash memory suppliers. For example , the techniques for AMD parts will not work on STMicroelectronics parts. Care should be taken when

changing drivers for one part to work on another.

Programm er Technique

The Programmer techniq ue uses high (V

) volt-

ID

age levels on some of the bus pins. These cannot

be achieved using a standard microprocessor bus,

therefore the technique is recommended on ly for

use in Programming Equipment.

To protect a block follow the flowchart in Figure 14,

Programmer Equipment Block Prot ect Flowchart.

To unprotect the whole chip it is necessary to protect all of the blocks f irst, then all blocks can be unprotected at the same time. To unprotect the chip

follow Figure 15, Programmer Equipment Chip

Unprotect Flowchart. Table 23, Programmer

M29W017D

Technique Bus Operations, gives a summary of

each operation.

The timing on these flowcharts is critical. Care

should be taken to en sure that, where a pau se is

specified, it is followed as closely as possible. Do

not abort the procedure be fore reaching the end.

Chip Unprotect can take several seconds and a

user message should be provided to show that the

operation is progressing.

In-System Technique

The In-System technique requires a high volt age

level on the Reset/Blocks Temporary Unprotect

pin, RP

maximum ratings of the components on the microprocessor bus, therefore this technique is suitable

for use after the Flash has been fitted to the system.

To protect a block follow the flowchart in Figure 16,

In-System Block Protect Flowchart. To unprotect

the whole chip it is ne cessary to protect all of the

blocks first, then all the blocks can be unprotected

at the same time. To unprotect the chip follow Figure 17, In-System Chip Unprotect Flowchart.

The timing on these flowcharts is critical. Care

should be taken to en sure that, where a pau se is

specified, it is followed as closely as possible. Do

not allow the microprocessor to s ervice interrupts

that will upset the timing and do not abort the procedure before reaching the end. Chip Unprotect

can take several seconds and a user message

should be provided to show that the operation is

progressing.

. This can be achieved without violating the

Table 23. Programmer Technique Bus Op erati ons , BYTE

Operation E G W

Block Protect

Chip Unprotect

Block Protection

Verify

Block Unprotection

Verify

V

IL

V

IDVIDVIL

V

IL

V

IL

VIDVIL Pulse

Pulse

V

V

V

IL

IL

IH

V

IH

A9 = V

A0 = VIL, A1 = VIH, A6 = VIL, A9=VID,

A0 = VIL, A1 = VIH, A6 = VIH, A9 = VID,

Address Inputs

A0-A20

, A12-A20 Block Address

ID

Others = X

A9 = V

, A12 = VIH, A15 = VIH

ID

Others = X

A12-A20 Block Address

Others = X

A12-A20 Block Address

Others = X

= VIH or V

IL

Data Inputs/Outputs

DQ15A–1, DQ14 -DQ0

X

X

Pass = XX01h

Retry = XX00h

Retry = XX01h

Pass = XX00h

31/36

Page 32

M29W017D

Figure 14. Programmer Equipment Block Protect Flowchart

START

ADDRESS = BLOCK ADDRESS

W = V

IH

n = 0

G, A9 = VID,

E = V

IL

Wait 4µs

W = V

IL

Wait 100µs

Verify Protect Set-upEnd

W = V

IH

E, G = VIH,

A0, A6 = VIL,

A1 = V

IH

E = V

IL

Wait 4µs

G = V

IL

Wait 60ns

Read DATA

DATA

=

01h

YES

A9 = V

IH

E, G = V

IH

PASS

NO

++n

= 25

A9 = V

E, G = V

NO

YES

IH

IH

32/36

FAIL

AI03469

Page 33

Figure 15. Programmer Equipme nt Chip Unprotect Flowchart

START

PROTECT ALL BLOCKS

M29W017D

CURRENT BLOCK = 0

ADDRESS = CURRENT BLOCK ADDRESS

A0 = VIL, A1, A6 = V

n = 0

A6, A12, A15 = V

E, G, A9 = V

Wait 4µs

W = V

IL

Wait 10ms

W = V

IH

E, G = V

IH

E = V

IL

Wait 4µs

(1)

IH

ID

IH

Verify Unprotect Set-upEnd

G = V

IL

Wait 60ns

Read DATA

=

00h

YESNO

DATA

++n

NO

= 1000

YES

A9 = V

IH

E, G = V

IH

FAIL PASS

CURRENT BLOCK

LAST

BLOCK

YES

A9 = V

IH

E, G = V

IH

INCREMENT

NO

AI03470

33/36

Page 34

M29W017D

Figure 16. In-System Equipment Block Protect Flowchart

START

n = 0

RP = V

ID

Verify Protect Set-upEnd

ADDRESS = BLOCK ADDRESS

ADDRESS = BLOCK ADDRESS

ADDRESS = BLOCK ADDRESS

ADDRESS = BLOCK ADDRESS

A0 = VIL, A1 = VIH, A6 = V

WRITE 60h

A0 = VIL, A1 = VIH, A6 = V

WRITE 60h

A0 = VIL, A1 = VIH, A6 = V

Wait 100µs

WRITE 40h

A0 = VIL, A1 = VIH, A6 = V

Wait 4µs

READ DATA

DATA

RP = V

=

01h

NO

YES

IH

IL

IL

IL

IL

++n

= 25

NO

34/36

ISSUE READ/RESET

COMMAND

PASS

YES

RP = V

IH

ISSUE READ/RESET

COMMAND

FAIL

AI03471

Page 35

Figure 17. In-System Equipment Chip Unprotect Flowchart

START

PROTECT ALL BLOCKS

M29W017D

Verify Unprotect Set-upEnd

CURRENT BLOCK = 0

A0 = VIL, A1 = VIH, A6 = V

A0 = VIL, A1 = VIH, A6 = V

ADDRESS = CURRENT BLOCK ADDRESS

A0 = VIL, A1 = VIH, A6 = V

ADDRESS = CURRENT BLOCK ADDRESS

A0 = VIL, A1 = VIH, A6 = V

n = 0

RP = V

ID

WRITE 60h

ANY ADDRESS WITH

WRITE 60h

ANY ADDRESS WITH

Wait 10ms

WRITE 40h

Wait 4µs

READ DATA

IH

IH

IH

IH

INCREMENT

CURRENT BLOCK

++n

NO

= 1000

YES

RP = V

IH

ISSUE READ/RESET

COMMAND

FAIL

DATA

=

00h

YESNO

LAST

BLOCK

RP = V

ISSUE READ/RESET

COMMAND

PASS

NO

YES

IH

AI03472

35/36

Page 36

M29W017D

Information furnished is believed to be ac curate and reli able. Howev er, STMicroel ectronics assumes no responsibilit y for the consequence s

of use of such information nor for any infringement of patents or other rights of third parties which may result from its use. No license is granted

by implic ation or otherwise under any patent or patent rights of STMi croelectr onics. Specifications mentioned in thi s publicati on are subject

to change without notice. This publication supersedes and replaces all information previously supplied. STMicroelectronics products are not

authorized for use as cri tical comp onents in life support dev i ces or systems wi t hout express written ap proval of STMi croelect ro nics.

The ST log o i s registered trademark of STMicroelectronics

All other nam es are the pro perty of their respective owners

© 2002 STMicroelectronics - All Rights Reserved

STMicroelectron ic s group of com panies

Austra lia - Brazil - Can ada - China - Finl and - France - Germany - Hong Kong -

India - Israel - Italy - Japan - Malay sia - Malta - M orocco - Sing apore - Spai n - S weden - Switz erland - Un it ed Kingdom - United States.

www.st.com

36/36

Loading...

Loading...