Page 1

FEATURES

LTC3454

1A Synchronous Buck-Boost

High Current LED Driver

U

DESCRIPTIO

■

High Effi ciency: >90% Typical in Torch Mode,

>80% in Flash Mode

■

Wide VIN Range: 2.7V to 5.5V

■

Up to 1A Continuous Output Current

■

3.5% LED Current Programming Accuracy

■

Internal Soft-Start

■

Open/Shorted LED Protection

■

Constant Frequency 1MHz Operation

■

Zero Shutdown Current

■

Overtemperature Protection

■

Small Thermally Enhanced 10-Lead (3mm × 3mm)

DFN Package

U

APPLICATIO S

■

Cell Phone Camera Flash

■

Cell Phone Torch Lighting

■

Digital Cameras

■

PDAs

■

Misc Li-Ion LED Drivers

The LTC®3454 is a synchronous buck-boost DC/DC

converter optimized for driving a single high power LED

at currents up to 1A from a single cell Li-Ion battery input. The regulator operates in either synchronous buck,

synchronous boost, or buck-boost mode depending on

input voltage and LED forward voltage. P

LED/PIN

effi ciency

greater than 90% can be achieved over the entire usable

range of a Li-Ion battery (2.7V to 4.2V).

LED current is programmable to one of four levels, including shutdown, with dual external resistors and dual enable

inputs. In shutdown no supply current is drawn.

A high constant operating frequency of 1MHz allows the

use of small external components. The LTC3454 is offered

in a low profi le (0.75mm) thermally enhanced 10-lead

(3mm × 3mm) DFN package.

, LTC and LT are registered trademarks of Linear Technology Corporation.

All other trademarks are the property of their respective owners.

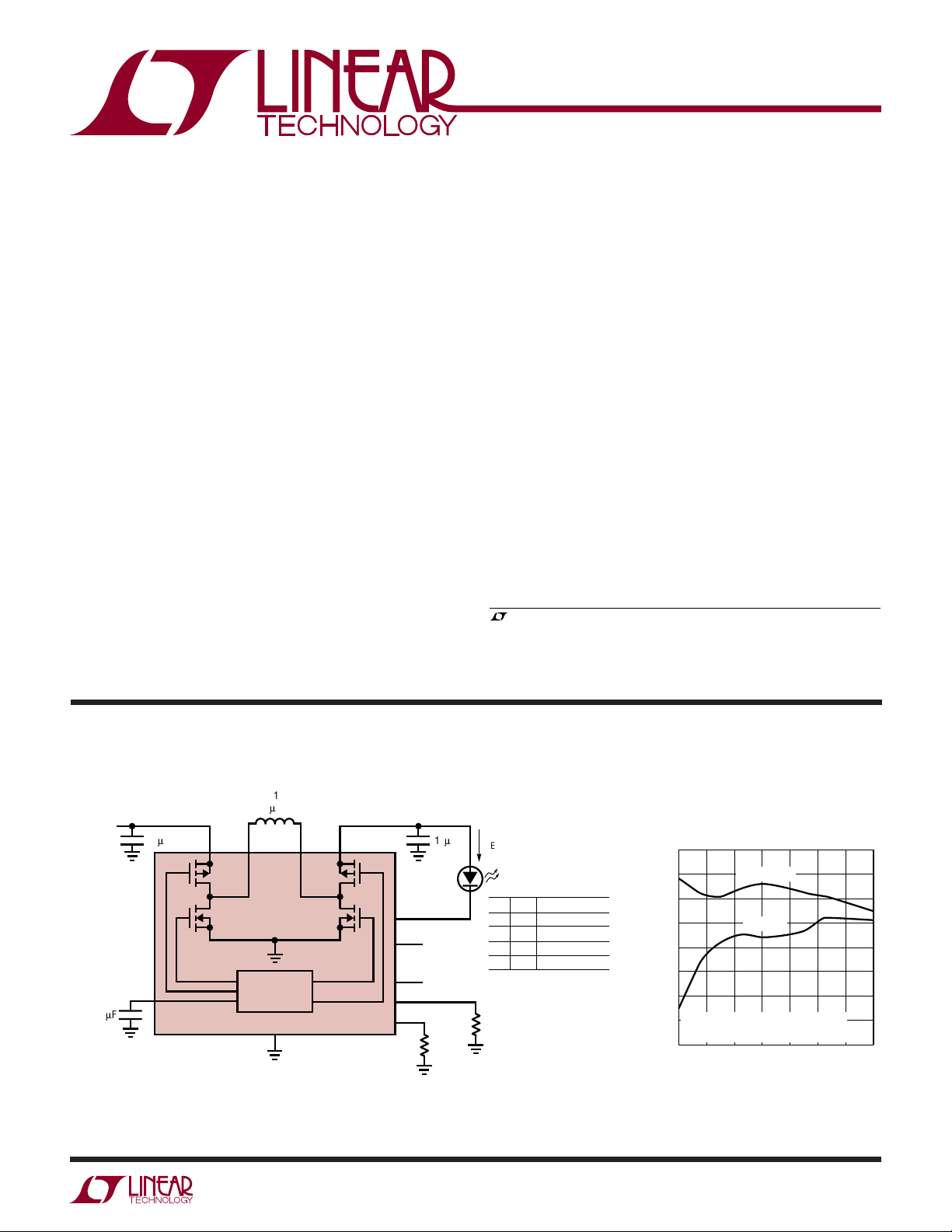

TYPICAL APPLICATIO

High Effi ciency Torch/Flash LED Driver

V

1-CELL

Li-Ion

2.7V-4.2V

0.1mF

IN

10mF

V

C

LED: LUMILEDS LXL-PWF1

L1: SUMIDA CDRH6D28-5RONC

V

IN

A

B

L1

5mH

SW1

1MHz

BUCK-BOOST

GND (EXPOSED PAD)

U

SW2 V

D

C

OUT

LTC3454

LED

I

SET1

I

SET2

10mF

LED

EN1 (TORCH)

EN2 (FLASH)

R

ISET2

3.65k

1%

I

LED

EN2 EN1 I

0 0 0 (SHUTDOWN)

0 1 150mA

1 0 850mA

111A

R

ISET1

20.5k

1%

3453 TA01a

LED

LED Power Effi ciency vs V

100

I

= 150mA

95

90

85

80

75

EFFICIENCY (%)

70

TA = 25°C

65

EFFICIENCY = (V

60

2.7

LED

I

LED

OUT

3.1 3.93.5 4.7

= 1A

– V

LED)ILED/VINIIN

4.3

(V)

V

IN

IN

5.55.1

3454 TA01b

3454f

1

Page 2

LTC3454

WW

W

ABSOLUTE AXI U RATI GS

(Note 1)

VIN, SW1, SW2, V

, EN1, EN2, I

V

C

Voltage .............................– 0.3V to (V

LED Peak Current ...................................................1.25A

Storage Temperature Range ...................–65°C to 125°C

Operating Temperature Range (Note 2) ...–40°C to 85°C

Junction Temperature (Note 3) ............................. 125°C

Voltage ......................–0.3V to 6V

OUT

, I

SET2

SET1

U

+ 0.3V) or 6V

IN

UUW

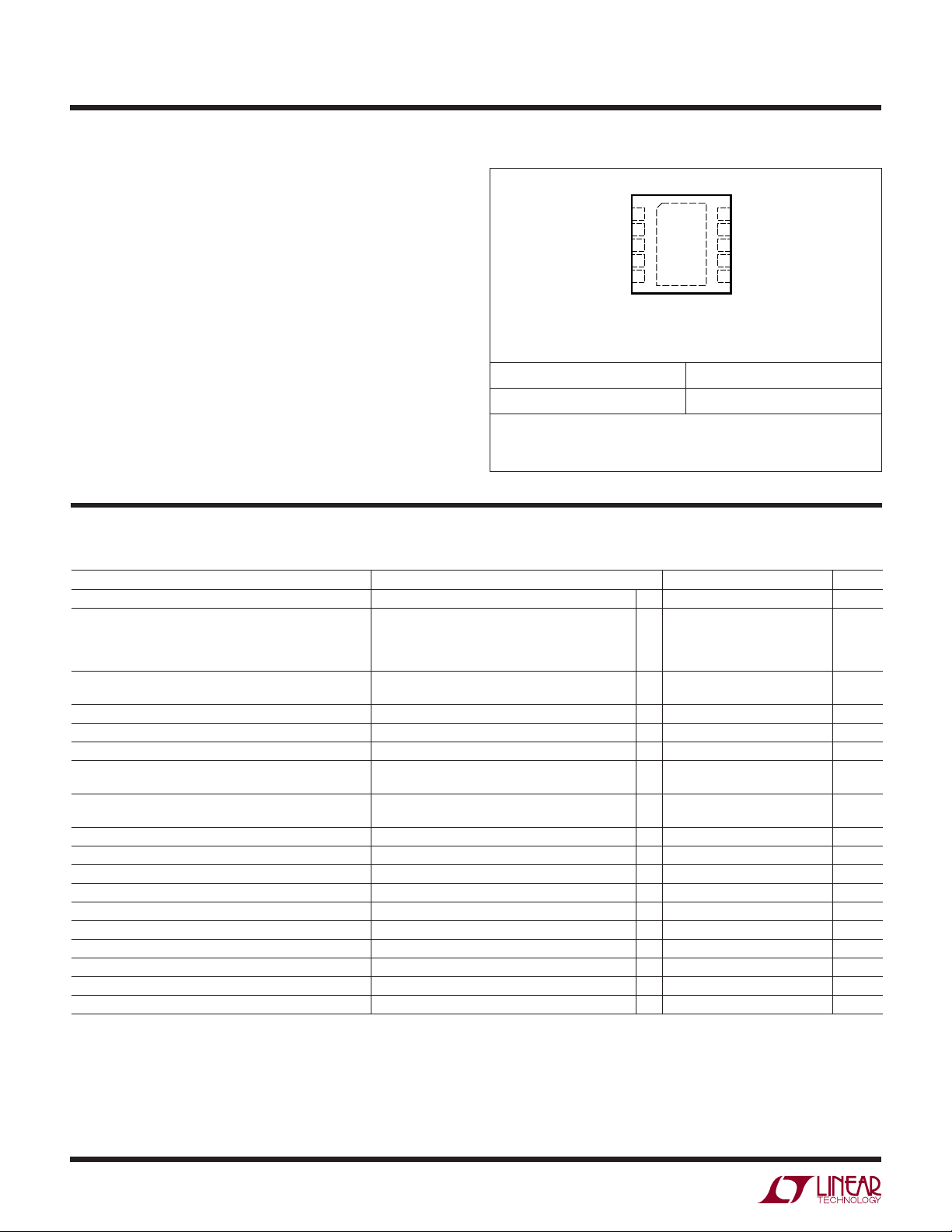

PACKAGE/ORDER I FOR ATIO

TOP VIEW

10

EN1

1

EN2

2

3

I

SET1

4

I

SET2

5

LED

10-LEAD (3mm × 3mm) PLASTIC DFN

EXPOSED PAD (PIN 11) IS GND, MUST BE SOLDERED TO PCB

DD PACKAGE

T

= 125°C, θJA = 40°C/W

JMAX

SW1

V

9

IN

V

811

C

7

V

OUT

6

SW2

ORDER PART NUMBER DD PART MARKING

LTC3454EDD

Order Options Tape and Reel: Add #TR

Lead Free: Add #PBF Lead Free Tape and Reel: Add #TRPBF

Lead Free Part Marking: http://www.linear.com/leadfree/

Consult LTC Marketing for parts specifi ed with wider operating temperature ranges.

●

The

ELECTRICAL CHARACTERISTICS

temperature range, otherwise specifi cations are at T

= 25°C, VIN = 3.6V, R

A

PARAMETER CONDITIONS MIN TYP MAX UNITS

Input Supply Voltage (V

)

IN

Input DC Supply Current (Typicals at V

Normal Operation 2.7V ≤ V

Shutdown 2.7V ≤ V

UVLO V

Undervoltage Lockout Threshold V

VIN Falling 1.75 1.90 V

V

, V

EN1

V

EN1

V

EN1

I

SET1

788 800 812 mV

DC Threshold for Normal Operation (VIH)

EN2

, V

DC Threshold for Shutdown (VIL)

EN2

, V

Input Current

EN2

and I

Servo Voltage 3.08k ≤ R

SET2

LED Output Current to Programming Current Ratio I

3775 3850 3925 mA/mA

LED Pin Voltage I

Regulated Maximum V

PMOS Switch R

NMOS Switch R

ON

ON

LED Pin Open, Programmed I

OUT

Switches A and D (V

Switches B and C 130 mΩ

< UVLO Threshold; V

IN

Rising

IN

/(I

LED

ISET1

= 1A 105 mV

LED

Forward Current Limit Switch A 2.5 3.4 A

Reverse Current Limit Switch D (V

PMOS Switch Leakage Switches A, D –1 1 µA

NMOS Switch Leakage Switches B, C –1 1 µA

Oscillator Frequency 0.9 1.0 1.15 MHz

Soft-Start Time 200 µs

Note 1: Absolute Maximum Ratings are those values beyond which the life

of a device may be impaired.

Note 2: The LTC3454 is guaranteed to meet specifi cations from 0°C to

70°C. Specifi cations over the –40°C to 85°C operating temperature range

are assured by design, characterization and correlation with statistical

process controls.

denotes the specifi cations which apply over the full operating

= 20.5k unless otherwise noted. (Note 2)

ISET

●

2.7 5.5 V

= 3.6V, R

IN

≤ 5.5V (Note 4)

IN

≤ 5.5V; V

IN

ISET1

EN1

||R

ISET2

+ I

), I

ISET2

OUT

= 3.6V) 275 mA

OUT

= R

ISET1

= V

EN2

= V

EN1

≤ 20.5k

= 500mA (Note 5)

LED

LED

= 20.5k)

ISET2

= 0V 0 1 µA

= VIN 5 10 µA

EN2

●

2.05 2.3 V

●

0.68 1.2 V

●

0.2 0.66 V

●

–1 1 µA

●

780 800 812 mV

●

3725 3850 3975 mA/mA

= 1A

●

4.95 5.15 5.35 V

= 3.6V) 170 mΩ

Note 3: T

is calculated from the ambient temperature TA and power

J

dissipation PD according to the following formula:

T

= TA + (PD • θJA °C/W).

J

Note 4: Dynamic supply current is higher due to the gate charge being

delivered at the switching frequency.

Note 5: This parameter is tested using a feedback loop which servos V

to 1.8V.

LBQX

825 1200 µA

C

3454f

2

Page 3

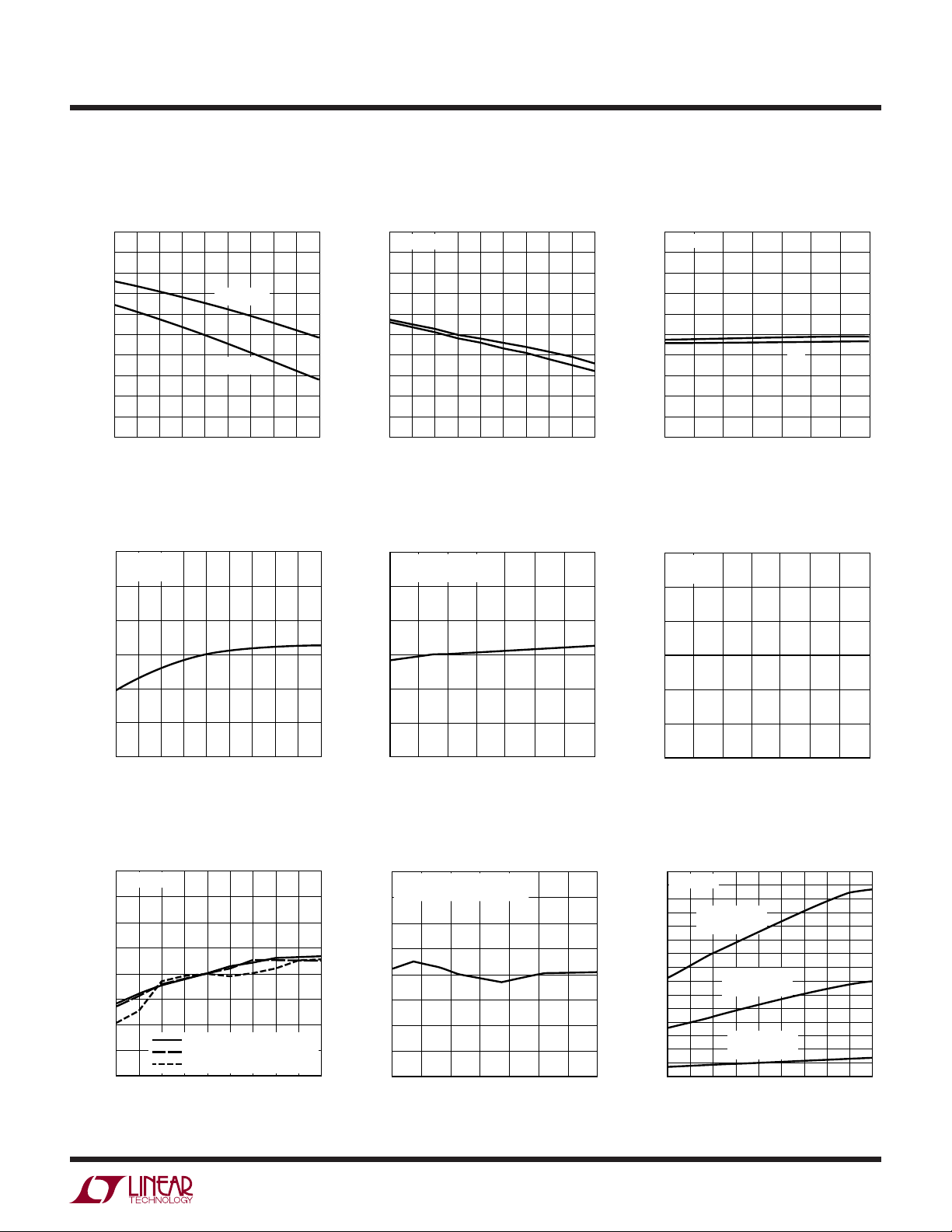

UW

TYPICAL PERFOR A CE CHARACTERISTICS

LTC3454

Undervoltage Lockout Threshold

vs Temperature

2.4

2.3

2.2

2.1

2.0

1.9

1.8

1.7

UVLO THRESHOLD (V)

1.6

1.5

1.4

–35 5

–15

–55

I

Servo Voltage

SET1,2

VIN RISING

VIN FALLING

45 125

65

25

TEMPERATURE (°C)

vs Temperature

812

VIN = 3.6V

= 15k

R

ISET1,2

808

804

(mV)

800

ISET1,2

V

796

Enable Thresholds

vs Temperature

1200

VIN = 3.6V

1100

1000

900

800

700

600

500

ENABLE THRESHOLDS (mV)

400

300

85

105

3454 G01

200

812

808

804

(mV)

800

ISET1,2

V

796

–35 5

–15

–55

I

Servo Voltage vs V

SET1,2

TA = 25°C

= R

R

ISET1

ISET2

45 125

25

TEMPERATURE (°C)

= 15k

V

IH

V

IL

85

105

65

3454 G02

IN

Enable Thresholds vs V

1200

TA = 25°C

1100

1000

900

800

700

600

500

ENABLE THRESHOLDS (mV)

400

300

200

3.1 3.9

3.5 5.5

Servo Voltage vs R

VIN = 3.6V

= 25°C

T

A

812

808

804

(mV)

800

ISET1,2

V

796

2.7

I

SET1,2

VIN (V)

4.3

IN

V

IH

V

IL

4.7

5.1

3454 G03

ISET

792

788

–35 5

–55

–15

TEMPERATURE (°C)

45 125

25

LED Current Programming Ratio

vs Temperature

4050

VIN = 3.6V

4000

3950

3900

3850

RATIO

3800

3750

3700

3650

–35 125

–55

PROGRAMMED I

PROGRAMMED I

PROGRAMMED I

–15

25

5

TEMPERATURE (°C)

45

65

65

85

LED

LED

LED

85

105

3454 G04

= 1A

= 500mA

= 150mA

105

3454 G07

792

788

2.7

3.1 3.5

4.3 5.1 5.5

3.9 4.7

VIN (V)

LED Current Programming Ratio

vs V

IN

4050

4000

3950

3900

3850

RATIO

3800

3750

3700

3650

PROGRAMMED I

= 25°C

T

A

3.1 5.5

2.7

LED

3.9 4.7

3.5

= 500mA

4.3

VIN (V)

3454 G05

5.1

3454 G08

792

788

150

120

(mV)

LED

V

3

711

vs Temperature

V

LED

VIN = 3.6V

90

60

30

0

–55

–35 –15

19 27 31

15 23

R

(kΩ)

ISET

PROGRAMMED

= 1A

I

LED

PROGRAMMED

= 500mA

I

LED

PROGRAMMED

= 100mA

I

LED

25

5 45 125

TEMPERATURE (°C)

3454 G06

65 85 105

3454 G09

3454f

3

Page 4

LTC3454

UW

TYPICAL PERFOR A CE CHARACTERISTICS

V

vs V

60

58

56

54

52

(mV)

50

LED

V

48

46

44

42

40

2.7

LED

PROGRAMMED I

T

= 25°C

A

3.1

3.5

IN

= 500mA

LED

4.3

3.9

VIN (V)

Maximum Regulated V

vs Programmed LED Current

5.40

VIN = 3.6V

5.35

= 25°C

T

A

5.30

5.25

5.20

(V)

5.15

OUT

V

5.10

5.05

5.00

4.95

4.90

200 1000

100

300

500

600

400

PROGRAMMED I

LED

700

4.7

OUT

(mA)

800

5.1

3454 G10

5.5

Maximum Regulated V

vs Temperature

5.40

PROGRAMMED I

5.35

= 3.6V

V

IN

5.30

5.25

5.20

(V)

5.15

OUT

V

5.10

5.05

5.00

4.95

4.90

–35 125

–55

–15

= 1A

LED

25

5

TEMPERATURE (°C)

OUT

45

105

65

85

Maximum Regulated V

vs V

IN

5.40

PROGRAMMED I

5.35

= 25°C

T

A

5.30

5.25

5.20

(V)

5.15

OUT

V

5.10

5.05

5.00

4.95

4.90

2.7

3.1

3.5

LED

3.9

= 1A

4.3

VIN (V)

OUT

4.7

5.1

5.5

3454 G12

900

3454 G13

PMOS R

300

MEASURED AT 500mA

270

240

210

(mΩ)

DS

180

R

150

120

90

–35 –15 5 25 45 125

–55

vs Temperature

DS(ON)

VIN = 2.7V

VIN = 3.6V

VIN = 4.2V

TEMPERATURE (°C)

VIN = 5.5V

65 85 105

3454 G14

NMOS R

200

MEASURED AT 500mA

180

160

140

120

(mΩ)

DS

R

100

80

60

40

VIN = 3.6V

–35 –15 5 25 45 125

–55

vs Temperature

DS(ON)

VIN = 2.7V

VIN = 4.2V

TEMPERATURE (°C)

VIN = 5.5V

65 85 105

3454 G15

4

Oscillator Frequency

vs Temperature

1100

V

= 3V

OUT

1080

1060

1040

1020

1000

980

FREQUENCY (kHz)

960

940

920

900

–55

–35 5

–15

VIN = 4.2V

VIN = 3.6V

TEMPERATURE (°C)

VIN = 5.5V

VIN = 2.7V

45 125

25

85

65

105

3454 G16

LED Power Effi ciency

vs LED Current

100

95

90

85

80

75

EFFICIENCY (%)

70

VIN = 3.6V

= 25°C

T

A

65

EFFICIENCY = (V

FRONT PAGE APPLICATION

60

200 1000

100

300

400

OUT

500

I

– V

LED

LED)ILED/VINIIN

600

(mA)

700

800

900

3454 G17

3454f

Page 5

UW

TYPICAL PERFOR A CE CHARACTERISTICS

LTC3454

Output Voltage Ripple

Back Page Application

20mV/DIV

IN

I

LED

= 3.6V

= 500mA

500ns/DIVV

3454 G19

UUU

PI FU CTIO S

EN1 (Pin 1): Enable Input Pin for I

EN2 (Pin 2): Enable Input Pin for I

(Pin 3): LED Current Programming Pin. A resistor

I

SET1

to ground programs the current through the LED to I

= 3850(0.8V/R

amount set by EN2/I

(Pin 4): LED Current Programming Pin. A resistor

I

SET2

). This amount of current adds to any

ISET1

if used.

SET2

to ground programs the current through the LED to I

= 3850(0.8V/R

amount set by EN1/I

). This amount of current adds to any

ISET2

if used.

SET1

LED (Pin 5): Low Dropout Output for LED Current Biasing.

Connect the LED between V

and the LED pin.

OUT

SW2 (Pin 6): Switching Node. External inductor connects between SW1 and SW2. Recommended value is

4.7µH/5µH.

SET1

SET2

Current.

Current.

LED

LED

Start-Up Transient

Back Page Application

CH1, V

OUT

1V/DIV

CH2, I

LED

500mA

FINAL VALUE

0V, 0A

0V

= 3.6V

IN

= 500mA

I

LED

(Pin 7): Buck-Boost Output Rail. Bypass to GND with

V

OUT

5ms/DIVV

3454 G19

CH3, V

1V/DIV

EN1

a ceramic capacitor. Recommended value is 10µF.

(Pin 8): Compensation Point for the Internal Error

V

C

Amplifi er Output. Connect a ceramic capacitor from V

C

to GND. Recommended value is 0.1µF.

(Pin 9): Voltage Input Supply Pin (2.7V ≤ VIN ≤ 5.5V).

V

IN

Bypass to GND with a ceramic capacitor. Recommended

value is 10µF.

SW1 (Pin 10): Switching Node. External inductor connects between SW1 and SW2. Recommended value is

4.7µH/5µH.

Exposed Pad (Pin 11): Ground Pin. Solder to PCB ground

for electrical contact and optimal thermal performance.

3454f

5

Page 6

LTC3454

BLOCK DIAGRA

W

V

2.7V TO 5.5V

OPTIONAL

10 6

LIMIT

SW1

GATE

DRIVERS

AND

ANTICROSS-

CONDUCTION

V

IN

IN

9

UNDERVOLTAGE

LOCKOUT

UV

SWITCH A

SWITCH B SWITCH C

FORWARD

CURRENT

+

OVERTEMP

PROTECTION

BANDGAP

REFERENCE

OT

3.4A 275mA

–

1.23V

+

LOGIC

–

AB PWM

COMPARATOR

UV

SW2

REVERSE

CURRENT

LIMIT

CD PWM

COMPARATOR

OT

SWITCH D

+

–

+

–

OPTIONAL

V

OUT

7

R

R

ISET1

ISET2

1MHz

V

C

8

V

OUT

377k

1.23V

–

+

800mV

123k

LED CURRENT

SETTING AMP 1

+

1.23V

OSCILLATOR

SAFETY

ERROR AMP

I

ISET1

AUTOZEROING

ERROR AMP

SOFT

START

CLAMP

CURRENT

MIRROR

LED

–

R

5

+

–

I

SET1

3

LED CURRENT

800mV

+

SETTING AMP 2

I

ISET2

∑

I

3850 I

R

–

I

SET2

4

EN1

1

EN2

2

SHUTDOWN

EXPOSED PAD (GND)

11

3454 BD

6

3454f

Page 7

OPERATIO

LTC3454

U

Buck-Boost DC-DC Converter

The LTC3454 employs an LTC proprietary buck-boost

DC/DC converter to generate the output voltage required to

drive a high current LED. This architecture permits higheffi ciency, low noise operation at input voltages above,

below or equal to the output voltage by properly phasing

four internal power switches. The error amp output voltage

on the V

Since the V

pin determines the duty cycle of the switches.

C

pin is a fi ltered signal, it provides rejection

C

of frequencies well below the factory trimmed switching

frequency of 1MHz. The low R

, low gate charge

DS(ON)

synchronous switches provide high frequency pulse width

modulation control at high effi ciency. Schottky diodes

across synchronous rectifi er switch B and synchronous

rectifi er switch D are not required, but if used do provide

a lower voltage drop during the break-before-make time

(typically 20ns), which improves peak effi ciency by typically 1% to 2% at higher loads.

Figure 1 shows a simplifi ed diagram of how the four internal

, V

power switches are connected to the inductor, V

IN

OUT

and GND. Figure 2 shows the regions of operation of the

buck-boost as a function of the control voltage V

. The

C

output switches are properly phased so transitions between

regions of operation are continuous, fi ltered and transparent to the user. When V

approaches V

IN

, the buck-boost

OUT

region is reached where the conduction time of the four

switch region is typically 150ns. Referring to Figures 1

and 2, the various regions of operation encountered as V

C

increases will now be described.

Buck Mode (V

IN

> V

OUT

)

In buck mode, switch D is always on and switch C is

always off. Referring to Figure 2, when the control

voltage V

Figure 1. Simplifi ed Diagram of Internal Power Switches

is above voltage V1, switch A begins to turn on

C

V

IN

9

PMOS A

SW1

10

NMOS B

SW2

V

OUT

7

PMOS D

6

NMOS C

3454 F01

each cycle. During the off time of switch A, synchronous

rectifi er switch B turns on for the remainder of the cycle.

Switches A and B will alternate conducting similar to a

typical synchronous buck regulator. As the control voltage increases, the duty cycle of switch A increases until

the maximum duty cycle of the converter in buck mode

reaches DC

DC

BUCK

where DC

|max given by:

BUCK

|max = 100% – DC

equals the duty cycle in % of the “four

4SW

4SW

switch” range.

DC

= (150ns • f) • 100%

4SW

where f is the operating frequency in Hz.

Beyond this point the “four switch” or buck-boost region

is reached.

Buck-Boost or Four-Switch Mode (V

IN

≈ V

Referring to Figure 2, when the control voltage V

OUT

)

is above

C

voltage V2, switch pair AD continue to operate for duty

cycle DC

|max, and the switch pair AC begins to phase

BUCK

in. As switch pair AC phases in, switch pair BD phases out

accordingly. When the V

voltage reaches the edge of the

C

buck-boost range at voltage V3, switch pair AC completely

phases out switch pair BD and the boost region begins at

duty cycle DC

. The input voltage VIN where the four

4SW

switch region begins is given by:

= V

V

IN

and the input voltage V

/[1 – (150ns • f)]

OUT

where the four switch region

IN

ends is given by

V

IN

75%

D

BOOST

D

BOOST

D

BUCK

DUTY

CYCLE

= V

MAX

MIN

MAX

0%

• (1 – DC

OUT

A ON, B OFF

PWM CD SWITCHES

FOUR SWITCH PWM

D ON, C OFF

PWM AB SWITCHES

Figure 2. Switch Control vs Control Voltage, V

) = V

4SW

BOOST REGION

BUCK/BOOST REGION

BUCK REGION

• [1 – (150ns • f)]

OUT

3454 F02

V4 (2.1V)

V3 (1.65V)

V2 (1.55V)

V1 (0.9V)

CONTROL

VOLTAGE, V

C

C

3454f

7

Page 8

LTC3454

U

WUU

APPLICATIO S I FOR ATIO

Boost Mode (VIN < V

In boost mode, switch A is always on and switch B is always

off. Referring to Figure 2, when the control voltage V

above voltage V3, switches C and D will alternate conducting similar to a typical synchronous boost regulator. The

maximum duty cycle of the converter is limited to 88%

typical and is reached when V

Forward Current Limit

If the current delivered from V

exceeds 3.4A (typical), switch A is shut off immediately.

Switches B and D are turned on for the remainder of the

cycle in order to safely discharge the forward inductor

current at the maximum rate possible.

Reverse Current Limit

If the current delivered from V

PMOS switch D exceeds 275mA (typical), switch D is

shut off immediately. Switches A and C are turned on for

the remainder of the cycle in order to safely discharge the

reverse inductor current at the maximum rate possible.

Undervoltage Lockout

To prevent operation of the power switches at high R

an undervoltage lockout is incorporated on the LTC3454.

When the input supply voltage drops below approximately

1.90V, the four power switches and all control circuitry

are turned off except for the undervoltage block, which

draws a few microamperes.

OUT

)

C

is above V4.

through PMOS switch A

IN

backwards through

OUT

DS(ON)

C

is

,

limiting the rate of duty cycle change as V

transitions

C

from the buck region through the buck-boost region into

the boost region. Once the soft-start times out, it can only

be reset by entering shutdown, or by an undervoltage or

overtemperature condition.

Autozero Error Amp

The error amplifi er is an autozeroing transconductance

amp with source and sink capability. The output of this

amplifi er drives a capacitor to GND at the V

pin. This

C

capacitor sets the dominant pole for the regulation loop.

(See the Applications Information section for selecting

the capacitor value). The feedback signal to the error

amp is developed across a resistor through which LED

current fl ows.

Safety Error Amp

The safety error amplifi er is a transconductance amplifi er

with sink only capability. In normal operation, it has no

effect on the loop regulation. However, if the LED pin opencircuits, the output voltage will keep rising, and the safety

error amp will eventually take over control of the regulation

loop to prevent V

runaway. The V

OUT

threshold at which

OUT

this occurs is approximately 5.15V.

LED Current Programming and Enable Circuit

Two enable pins work in conjunction with dual external

resistors to program LED current to one of three nonzero

settings. The table below explains how the current can

be set.

Overtemperature Protection

If the junction temperature of the LTC3454 exceeds 130°C

for any reason, all four switches are shut off immediately.

The overtemperature protection circuit has a typical hysteresis of 11°C.

Soft-Start

The LTC3454 includes an internally fi xed soft-start which

is active when powering up or coming out of shutdown.

The soft-start works by clamping the voltage on the V

C

node and gradually releasing it such that it requires 200µs

to linearly slew from 0.9V to 2.1V. This has the effect of

8

EN1 EN2 I

GND GND 0 (SHUTDOWN)

V

IN

GND V

V

IN

GND 3850 • 0.8V/R

IN

V

IN

(A)

LOAD

3850 • 0.8V/R

3850 • (0.8V/R

ISET1

ISET2

ISET1

+ 0.8V/R

ISET2

)

With either enable pin pulled high, the buck-boost will

regulate the output voltage at the current programmed

by R

ISET1

and/or R

ISET2

.

With both enable pins pulled to GND, the LTC3454 is in

shutdown and draws zero current. The enable pins are

high impedance inputs and should not be fl oated.

3454f

Page 9

LTC3454

U

WUU

APPLICATIO S I FOR ATIO

COMPONENT SELECTION

Inductor Selection

The high frequency operation of the LTC3454 allows the

use of small surface mount inductors. The inductor current ripple is typically set to 20% to 40% of the maximum

average inductor current. For a given ripple the inductance

term in Boost mode is:

VVV

L

>

and in Buck mode is:

()

L

>

where f = operating frequency, Hz

%Ripple = allowable inductor current ripple, %

2

•– •%

IN MIN OUT IN MIN

() ()

fI

VVV

IN MAX OUT OUT

fV Ripp

••%

()

•

OUT MAX

()

IN MAX

()

••% •Ripple V

()

–••%

ll e I

•

OUT

100

OUT

100

2

Input Capacitor Selection

Since the V

pin is the supply voltage for the IC it is recom-

IN

mended to place at least a 2.2µF, low ESR bypass capacitor

to ground. See Table 2 for a list of component suppliers.

Table 2. Capacitor Vendor Information

SUPPLIER WEB SITE

AVX www.avxcorp.com

Sanyo www.sanyovideo.com

Taiyo Yuden www.t-yuden.com

TDK www.component.tdk.com

Output Capacitor Selection

The bulk value of the capacitor is set to reduce the ripple

due to charge into the capacitor each cycle. The steady

state ripple due to charge is given by:

•– •

() ()

()

2

••

CV f

OUT OUT

100%%

%_

Ripple Boost

IVV

OUT MAX OUT IN MIN

=

V

V

V

I

OUT(MAX)

= minimum input voltage, V

IN(MIN)

IN(MAX)

OUT

= maximum input voltage, V

= output voltage, V

= maximum output load current

For high effi ciency, choose an inductor with a high frequency core material, such as ferrite, to reduce core loses.

The inductor should have low ESR (equivalent series

2

resistance) to reduce the I

R losses, and must be able

to handle the peak inductor current without saturating.

Molded chokes or chip inductors usually do not have

enough core to support peak inductor currents >1A. To

minimize radiated noise, use a toroid, pot core or shielded

bobbin inductor. For white LED application, a 4.7µH/5µH

inductor value is recommended. See Table 1 for a list of

component suppliers.

Table 1. Inductor Vendor Information

SUPPLIER WEB SITE

Coilcraft www.coilcraft.com

Cooper/Coiltronics www.cooperet.com

Murata www.murata.com

Sumida www.japanlink.com/sumida

Toko www.toko.com

Vishay-Dale www.vishay.com

–•

()

VfLC

()

IN MAX OUT

1100

%

2

%_

Ripple Buck

where C

= output fi lter capacitor, F

OUT

VV

()

IN MAX OUT

=

8

••••

The output capacitance is usually many times larger in

order to handle the transient response of the converter. For

a rule of thumb, the ratio of operating frequency to unitygain bandwidth of the converter is the amount the output

capacitance will have to increase from the above calculations in order to maintain desired transient response.

The other component of ripple is due to ESR (equivalent

series resistance) of the output capacitor. Low ESR capacitors should be used to minimize output voltage ripple.

For surface mount applications, Taiyo Yuden, TDK, AVX

ceramic capacitors, AVX TPS series tantalum capacitors

or Sanyo POSCAP are recommended. For the white LED

application, a 10µF capacitor value is recommended. See

Table 2 for a list of component suppliers.

Optional Schottky Diodes

Schottky diodes across the synchronous switches B and

D are not required, but provide a lower drop during the

break-before-make time (typically 20ns) of the NMOS to

PMOS transition, improving effi ciency. Use a Schottky

diode such as an MBRM120T3 or equivalent. Do not use

3454f

9

Page 10

LTC3454

U

WUU

APPLICATIO S I FOR ATIO

ordinary rectifi er diodes, since the slow recovery times

will compromise effi ciency.

In applications in which V

is greater than 4V and V

IN

GND short-circuit protection is needed, a Schottky diode

such as MBRM12OT3 or equivalent may be used from

SW1 to GND and/or a 2Ω/1nF series snubber from SW1

to GND. The Schottky diode should be added as close

to the pins as possible. Neither of these is required for

shorted LED protection.

Closing the Feedback Loop

The LTC3454 incorporates voltage mode PWM control.

The control to output gain varies with operation region

(Buck, Boost, Buck/Boost), but is usually no greater

than 15. The output fi lter exhibits a double pole response

given by:

f

FILTER POLE

where C

=

_

is the output fi lter capacitor.

OUT

2

1

•• •

π

LC

Hz

OUT

The output fi lter zero is given by:

f

FILTER ZERO

where R

=

_

is the capacitor equivalent series resistance.

ESR

•• •

2

1

RC

π

ESR OUT

Hz

A troublesome feature in Boost mode is the right-half

plane zero (RHP), and is given by:

2

V

f

=

RHPZ

2• • • •

IN

ILV

π

OUT OUT

Hz

The loop gain is typically rolled off before the RHP zero

frequency.

A simple Type I compensation network can be incorporated

to stabilize the loop but at a cost of reduced bandwidth

and slower transient response. To ensure proper phase

margin, the loop is required to be crossed over a decade

before the LC double pole.

The unity-gain frequency of the error amplifi er with the

Type I compensation is given by:

g

f

=

UG

m

π2• •

C

VC

OUT

to

where gm is the error amp transconductance (typically

1/5.2k) and C

pin. For the white LED application, a 0.1µF or greater

V

C

is the external capacitor to GND at the

VC

capacitor value is recommended.

Maximum LED Current

As described in the Operation section, the output LED

current with both enable pins logic high is equal to

I

LED

= 3850 [0.8V/(R

ISET1

|| R

ISET2

)]

Since the maximum continuous output current is limited to

1A, this sets a minimum limit on the parallel combination

of R

ISET1

R

MIN

and R

= (R

ISET1

ISET2

|| R

equal to

ISET2)|MIN

= 3850(0.8V/1A)

= 3080Ω

Although the LTC3454 can safely provide this current

continuously, the external LED may not be rated for this

high a level of continuous current. Higher current levels

are generally reserved for pulsed applications, such as

LED camera fl ash. This is accomplished by programming

a high current with one of the R

resistors and pulsing

ISET

the appropriate enable pin.

Varying LED Brightness

Continuously variable LED brightness control can be

achieved by interfacing directly to one or both of the I

SET

pins. Figure 3 shows four such methods employing a

voltage DAC, a current DAC, a simple potentiometer or a

PWM input. It is not recommended to control brightness

by PWMing the enable pins directly as this will toggle

the LTC3454 in and out of shutdown and result in erratic

operation.

LED Failure Modes

If the LED fails as an open circuit, the safety amplifi er takes

control of the regulation loop to prevent V

The V

threshold at which this occurs is about 5.15V.

OUT

runaway.

OUT

The safety amplifi er has no effect on loop regulation at

less than 5.15V.

V

OUT

If the LED fails as a short-circuit, the current limiting

circuitry detects this condition and limits the peak input

current to a safe level.

3454f

10

Page 11

LTC3454

U

WUU

APPLICATIO S I FOR ATIO

V

IN

ENx

LTC3454

VOLTAGE

DAC

I

SETx

R

≥ R

SET

V

DAC

V

IN

ENx

I

SETx

R

MIN

R

POT

MIN

LTC3454

LED

(3a)

LED

(3c)

I

I

LED

LED

= 3850

= 3850

0.8V – V

R

MIN

R

0.8V

V

SET

V

+ R

OUT

DAC

OUT

POT

CURRENT

DAC

R

100

SET

V

IN

ENx

LTC3454

I

SETx

IDAC ≤

0.8V

R

MIN

LED

I

= 3850 • IDAC

LED

V

OUT

(3b)

V

IN

ENx

LTC3454

R

V

SET

PWM

I

SETx

≥ R

MIN

f

PWM

LED

≥ 10kHz

I

LED

= 3850

= 3850

DV

CC

(3d)

V

OUT

0.8V – V

PWM

R

SET

0.8V – (DC% • V

R

SET

3454 F03

DVCC

)

Figure 3. Brightness control Methods: (a) Using Voltage DAC, (b) Using Current DAC, (c) Using Potentiometer, (d) Using PWM Input

U

PACKAGE DESCRIPTIO

DD Package

10-Lead Plastic DFN (3mm × 3mm)

(Reference LTC DWG # 05-08-1699)

0.675 ±0.05

3.50 ±0.05

NOTE:

1. DRAWING TO BE MADE A JEDEC PACKAGE OUTLINE M0-229 VARIATION OF (WEED-2).

CHECK THE LTC WEBSITE DATA SHEET FOR CURRENT STATUS OF VARIATION ASSIGNMENT

2. DRAWING NOT TO SCALE

3. ALL DIMENSIONS ARE IN MILLIMETERS

1.65 ±0.05

(2 SIDES)2.15 ±0.05

PACKAGE

OUTLINE

0.25 ± 0.05

RECOMMENDED SOLDER PAD PITCH AND DIMENSIONS

2.38 ±0.05

(2 SIDES)

0.50

BSC

PIN 1

TOP MARK

(SEE NOTE 6)

0.200 REF

R = 0.115

TYP

3.00 ±0.10

(4 SIDES)

0.75 ±0.05

4. DIMENSIONS OF EXPOSED PAD ON BOTTOM OF PACKAGE DO NOT INCLUDE

MOLD FLASH. MOLD FLASH, IF PRESENT, SHALL NOT EXCEED 0.15mm ON ANY SIDE

5. EXPOSED PAD SHALL BE SOLDER PLATED

6. SHADED AREA IS ONLY A REFERENCE FOR PIN 1 LOCATION ON THE

TOP AND BOTTOM OF PACKAGE

1.65 ± 0.10

(2 SIDES)

0.00 – 0.05

2.38 ±0.10

(2 SIDES)

BOTTOM VIEW—EXPOSED PAD

106

15

0.50 BSC

0.38 ± 0.10

(DD10) DFN 1103

0.25 ± 0.05

Information furnished by Linear Technology Corporation is believed to be accurate and reliable.

However, no responsibility is assumed for its use. Linear Technology Corporation makes no representation that the interconnection of its circuits as described herein will not infringe on existing patent rights.

3454f

11

Page 12

LTC3454

TYPICAL APPLICATIO

500mA LED Flashlight Driver

V

IN

SWA

SWB

3-CELL

ALKALINE

4.5V

2.2mF

0.1mF

EN1

V

C

LED: LUMILEDS, LXCL LW3C

L1: TOKO A997AS-4R7M

U

L1

4.7mH

SW1

1MHz

BUCK-BOOST

GND (EXPOSED PAD)

SW2 V

SWD

SWC

OUT

LTC3454

LED

EN2

I

SET1

I

SET2

4.7mF

LED

R

ISET1

6.19k

1%

I

LED

3453 TA02

= 500mA

LED Power Effi ciency vs V

100

95

90

85

80

75

EFFICIENCY (%)

70

I

= 500mA

LED

65

= 25°C

T

A

EFFICIENCY = (V

60

3.1 5.5

2.7

OUT

3.5

– V

3.9

VIN (V)

LED)ILED/VINIIN

4.7

4.3

IN

5.1

3454 TA02b

RELATED PARTS

PART NUMBER DESCRIPTION COMMENTS

LT1618 Constant Current, Constant Voltage 1.4MHz, High Effi ciency V

: 1.6V to 18V, V

IN

Boost Regulator MS10 Package/EDD Package

LT1930/LT1930A 1A (I

), 1.2MHz/2.2MHz, High Effi ciency Step-Up VIN: 2.6V to 16V, V

SW

DC/DC Converter ThinSOT Package

LT1932 Constant Current, 1.2MHz, High Effi ciency White LED V

: 1V to 10V, V

IN

OUT(MAX)

Boost Regulator ThinSOT Package

LT1937 Constant Current, 1.2MHz, High Effi ciency White LED V

: 2.5V to 10V, V

IN

Boost Regulator ThinSOT Package/SC70 Package

LTC3205 High Effi ciency, Multi-Display LED Controller V

: 2.8V to 4.5V, V

IN

QFN-24 Package

LTC3215 700mA Low Noise Charge Pump LED Driver V

: 2.9V to 4.4V, V

IN

DFN Package

LTC3216 1A Low Noise High Current Charge Pump LED V

: 2.9V to 4.4V, V

IN

Driver with Independent Flash/Torch Current DFN Package

LTC3440/ 600mA/1.2A I

, 2MHz/1MHz, Synchronous Buck-Boost VIN: 2.4V to 5.5V, V

OUT

LTC3441 DC/DC Converter MS-10 Package/DFN Package

LTC3443 600mA/1.2A I

, 600kHz, Synchronous Buck-Boost VIN: 2.4V to 5.5V, V

OUT

DC/DC Converter DFN Package

LTC3490 Single Cell 350mA LED Driver V

: 1V to 3.2V, V

IN

OUT(MAX)

DFN Package

LTC3453 Synchronous Buck-Boost High Power White LED Driver V

: 2.7V to 5.5V, Up to 500mA Continuous Output Current,

IN

QFN-16 Package

LT3465/LT3465A Constant Current, 1.2MHz/2.7MHz, High Effi ciency White LED V

: 2.7V to 16V, V

IN

Boost Regulator with Integrated Schottky Diode ThinSOT Package

LT3466 Dual Constant Current, 2MHz, High Effi ciency White LED V

: 2.7V to 24V, V

IN

Boost Regulator with Integrated Schottky Diode DFN Package

LT3479 3A, Full Featured DC/DC Converter with Soft-Start and V

: 2.5V to 24V, V

IN

Inrush Current Protection DFN Package/TSOPP Package

= 34V, IQ = 1.8mA, ISD = <1µA,

OUT(MAX)

= 34V, IQ = 4.2mA/5.5mA, ISD = <1µA,

OUT(MAX)

= 34V, IQ = 1.2mA, ISD = <1µA,

= 34V, IQ = 1.9mA, ISD = <1µA,

OUT(MAX)

= 6V, IQ = 50µA, ISD = <1µA,

OUT(MAX)

= 5.5V, IQ = 300µA, ISD = <2.5µA,

OUT(MAX)

= 5.5V, IQ = 300µA, ISD = <2.5µA,

OUT(MAX)

= 5.25V, IQ = 25µA/50µA, ISD = <1µA,

OUT(MAX)

= 5.25V, IQ = 28µA, ISD = <1µA,

OUT(MAX)

= 4V, IQ = 20µA, ISD = 20µA,

= 34V, IQ = 1.9mA, ISD = <1µA,

OUT(MAX)

= 40V, IQ = 5mA, ISD = <16µA,

OUT(MAX)

= 40V, IQ = 6.5mA, ISD = <1µA,

OUT(MAX)

12

Linear Technology Corporation

1630 McCarthy Blvd., Milpitas, CA 95035-7417

(408) 432-1900

●

FAX: (408) 434-0507 ● www.linear.com

3454f

LT 1105 • PRINTED IN USA

© LINEAR TECHNOLOGY CORPORATION 2005

Loading...

Loading...