Page 1

FEATURES

■

Single Gain Set Resistor: G = 1 to 10,000

■

Gain Error: G = 10, 0.3% Max

■

Gain Nonlinearity: G = 10, 30ppm Max

■

Input Offset Voltage: G = 10, 225µV Max

■

Input Offset Voltage Drift: 1µV/°C Max

■

Input Bias Current: 2nA Max

■

PSRR at G = 1: 80dB Min

■

CMRR at G = 1: 75dB Min

■

Supply Current: 1.3mA Max

■

Wide Supply Range: ±2.3V to ±18V

■

1kHz Voltage Noise: 7.5nV/√Hz

■

0.1Hz to 10Hz Noise: 0.28µV

■

Available in 8-Pin PDIP and SO Packages

■

Meets IEC 1000-4-2 Level 4 ESD Tests with

P-P

Two External 5k Resistors

U

APPLICATIO S

■

Bridge Amplifiers

■

Strain Gauge Amplifiers

■

Thermocouple Amplifiers

■

Differential to Single-Ended Converters

■

Medical Instrumentation

LT1920

Single Resistor Gain

Programmable, Precision

Instrumentation Amplifier

U

DESCRIPTIO

The LT®1920 is a low power, precision instrumentation

amplifier that requires only one external resistor to set gains

of 1 to 10,000. The low voltage noise of 7.5nV/√Hz (at 1kHz)

is not compromised by low power dissipation (0.9mA typical

for ±2.3V to ±15V supplies).

The high accuracy of 30ppm maximum nonlinearity and

0.3% max gain error (G = 10) is not degraded even for load

resistors as low as 2k (previous monolithic instrumentation

amps used 10k for their nonlinearity specifications). The

LT1920 is laser trimmed for very low input offset voltage

(125µV max), drift (1µV/°C), high CMRR (75dB, G = 1) and

PSRR (80dB, G = 1). Low input bias currents of 2nA max are

achieved with the use of superbeta processing. The output

can handle capacitive loads up to 1000pF in any gain configuration while the inputs are ESD protected up to 13kV (human

body). The LT1920 with two external 5k resistors passes the

IEC 1000-4-2 level 4 specification.

The LT1920, offered in 8-pin PDIP and SO packages, is a pin

for pin and spec for spec improved replacement for the

AD620. The LT1920 is the most cost effective solution for

precision instrumentation amplifier applications. For even

better guaranteed performance, see the LT1167.

, LTC and LT are registered trademarks of Linear Technology Corporation.

TYPICAL APPLICATIO

Single Supply Barometer

V

S

LT1634CCZ-1.25

392k

R5

3

8

+

2

R8

100k

–

1/2

LT1490

5

6

4

+

LT1490

–

50k

50k

1

2

R4

R3

1

R6

1k

1/2

LUCAS NOVA SENOR

NPC-1220-015-A-3L

4

5k

5k

2

6

R

SET

7

R7

50k

U

Gain Nonlinearity

V

S

R1

825Ω

R2

12Ω

–

2

1

8

3

7

5

VOLTS

2.800

3.000

3.200

6

INCHES Hg

TO

4-DIGIT

DVM

28.00

30.00

32.00

1920 TA01

NONLINEARITY (100ppm/DIV)

OUTPUT VOLTAGE (2V/DIV)

G = 1000

= 1k

R

L

= ±10V

V

OUT

1167 TA02

LT1920

G = 60

+

4

1

–

5k

5k

3

+

5

VS = 8V TO 30V

1

Page 2

LT1920

WW

W

ABSOLUTE MAXIMUM RATINGS

(Note 1)

Supply Voltage ...................................................... ±20V

Differential Input Voltage (Within the

Supply Voltage) ..................................................... ±40V

Input Voltage (Equal to Supply Voltage) ................±20V

Input Current (Note 3) ........................................ ±20mA

Output Short-Circuit Duration..........................Indefinite

Operating Temperature Range ................ – 40°C to 85°C

Specified Temperature Range

LT1920C (Note 4)....................................0°C to 70°C

LT1920I .............................................. – 40°C to 85°C

Storage Temperature Range ................. – 65°C to 150°C

Lead Temperature (Soldering, 10 sec).................. 300°C

ELECTRICAL CHARACTERISTICS

SYMBOL PARAMETER CONDITIONS (Note 6) MIN TYP MAX UNITS

G Gain Range G = 1 + (49.4k/RG) 1 10k

Gain Error G = 1 0.008 0.1 %

G/T Gain vs Temperature G < 1000 (Note 2) ● 20 50 ppm/°C

Gain Nonlinearity (Note 5) VO = ±10V, G = 1 10 ppm

V

OST

V

OSI

V

/T Input Offset Drift (RTI) (Note 3) ● 1 µV/°C

OSI

V

OSO

V

/T Output Offset Drift (Note 3) ● 515µV/°C

OSO

I

OS

I

B

e

n

Total RTI Noise = √e

e

ni

e

no

i

n

R

IN

C

IN(DIFF)

Total Input Referred Offset Voltage V

Input Offset Voltage G = 1000, VS = ±5V to ±15V 30 125 µV

Output Offset Voltage G = 1, VS = ±5V to ±15V 400 1000 µV

Input Offset Current 0.3 1 nA

Input Bias Current 0.5 2 nA

Input Noise Voltage, RTI 0.1Hz to 10Hz, G = 1 2.00 µV

2

+ (eno/G)

ni

Input Noise Voltage Density, RTI fO = 1kHz 7.5 nV/√Hz

Output Noise Voltage Density, RTI fO = 1kHz 67 nV/√Hz

Input Noise Current fO = 0.1Hz to 10Hz 10 pA

Input Noise Current Density fO = 10Hz 124 fA/√Hz

Input Resistance VIN = ±10V 200 GΩ

Differential Input Capacitance fO = 100kHz 1.6 pF

2

U

U

W

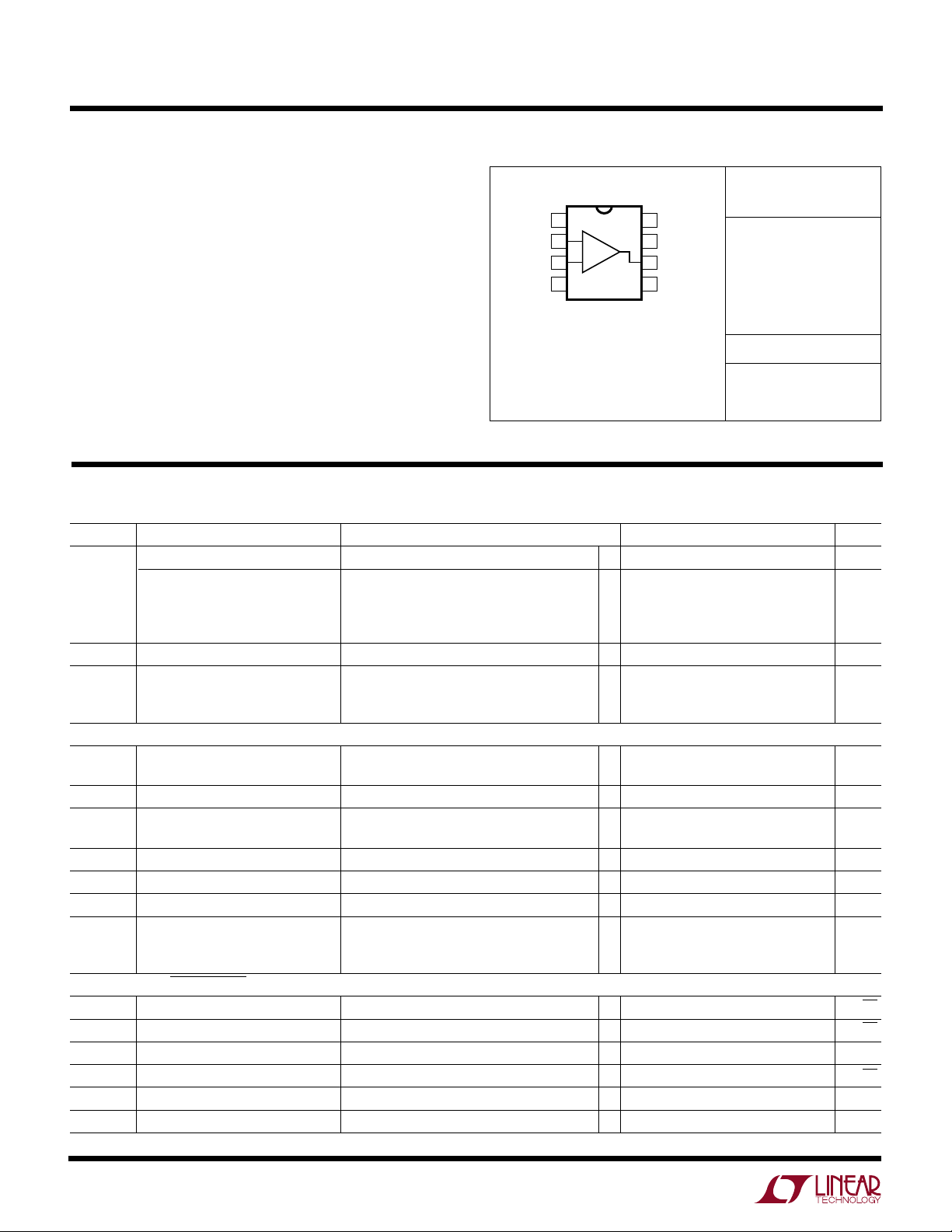

PACKAGE/ORDER INFORMATION

TOP VIEW

R

1

G

–IN

+IN

–V

T

JMAX

T

JMAX

Consult factory for Military grade parts.

–

2

+

3

4

S

N8 PACKAGE

8-LEAD PDIP

S8 PACKAGE

8-LEAD PLASTIC SO

= 150°C, θJA = 130°C/ W (N8)

= 150°C, θJA = 190°C/ W (S8)

8

7

6

5

RG

+V

S

OUTPUT

REF

VS = ±15V, VCM = 0V, TA = 25°C, RL = 2k, unless otherwise noted.

G = 10 (Note 2) 0.010 0.3 %

G = 100 (Note 2) 0.025 0.3 %

G = 1000 (Note 2) 0.040 0.35 %

V

= ±10V, G = 10 and 100 10 30 ppm

O

V

= ±10V, G = 100 and 1000 20 ppm

O

= V

+ V

OST

OSI

G = 1000, V

G = 1, V

0.1Hz to 10Hz, G = 10 0.50 µV

0.1Hz to 10Hz, G = 100 and 1000 0.28 µV

= ±5V to ±15V ● 1500 µV

S

/G

OSO

= ±5V to ±15V ● 185 µV

S

ORDER PART

NUMBER

LT1920CN8

LT1920CS8

LT1920IN8

LT1920IS8

S8 PART MARKING

1920

1920I

P-P

P-P

P-P

P-P

U

2

Page 3

LT1920

ELECTRICAL CHARACTERISTICS

SYMBOL PARAMETER CONDITIONS (Note 6) MIN TYP MAX UNITS

C

IN(CM)

V

CM

CMRR Common Mode Rejection Ratio 1k Source Imbalance,

PSRR Power Supply Rejection Ratio VS = ±2.3 to ±18V

I

S

V

OUT

I

OUT

BW Bandwidth G = 1 1000 kHz

SR Slew Rate G = 1, V

R

REFIN

I

REFIN

V

REF

A

VREF

The ● denotes specifications that apply over the full specified

temperature range.

Note 1: Absolute Maximum Ratings are those values beyond which the life

of a device may be impaired.

Note 2: Does not include the effect of the external gain resistor R

Note 3: This parameter is not 100% tested.

Note 4: The LT1920C is designed, characterized and expected to meet the

industrial temperature limits, but is not tested at –40°C and 85°C. I-grade

parts are guaranteed.

Common Mode Input Capacitance fO = 100kHz 1.6 pF

Input Voltage Range G = 1, Other Input Grounded

V

S

V

S

V

S

V

S

V

= 0V to ±10V

CM

G = 1 75 95 dB

G = 10 95 115 dB

G = 100 110 125 dB

G = 1000 110 140 dB

G = 1 80 120 dB

G = 10 100 135 dB

G = 100 120 140 dB

G = 1000 120 150 dB

Supply Current VS = ±2.3V to ±18V 0.9 1.3 mA

Output Voltage Swing RL = 10k

V

S

V

S

V

S

V

S

Output Current 20 27 mA

G = 10 800 kHz

G = 100 120 kHz

G = 1000 12 kHz

Settling Time to 0.01% 10V Step

G = 1 to 100 14 µs

G = 1000 130 µs

Reference Input Resistance 20 kΩ

Reference Input Current V

Reference Voltage Range –VS + 1.6 +VS – 1.6 V

Reference Gain to Output 1 ± 0.0001

REF

VS = ±15V, VCM = 0V, TA = 25°C, RL = 2k, unless otherwise noted.

= ±2.3V to ±5V –VS + 1.9 +VS – 1.2 V

= ±5V to ±18V –VS + 1.9 +VS – 1.4 V

= ±2.3V to ±5V ● –VS + 2.1 +VS – 1.3 V

= ±5V to ±18V ● –VS + 2.1 +VS – 1.4 V

= ±2.3V to ±5V –VS + 1.1 +VS – 1.2 V

= ±5V to ±18V –VS + 1.2 +VS – 1.3 V

= ±2.3V to ±5V ● –VS + 1.4 +VS – 1.3 V

= ±5V to ±18V ● –VS + 1.6 +VS – 1.5 V

= ±10V 1.2 V/µs

OUT

= 0V 50 µA

Note 5: This parameter is measured in a high speed automatic tester that

does not measure the thermal effects with longer time constants. The

magnitude of these thermal effects are dependent on the package used,

heat sinking and air flow conditions.

.

G

Note 6: Typical parameters are defined as the 60% of the yield parameter

distribution.

3

Page 4

LT1920

UW

TYPICAL PERFOR A CE CHARACTERISTICS

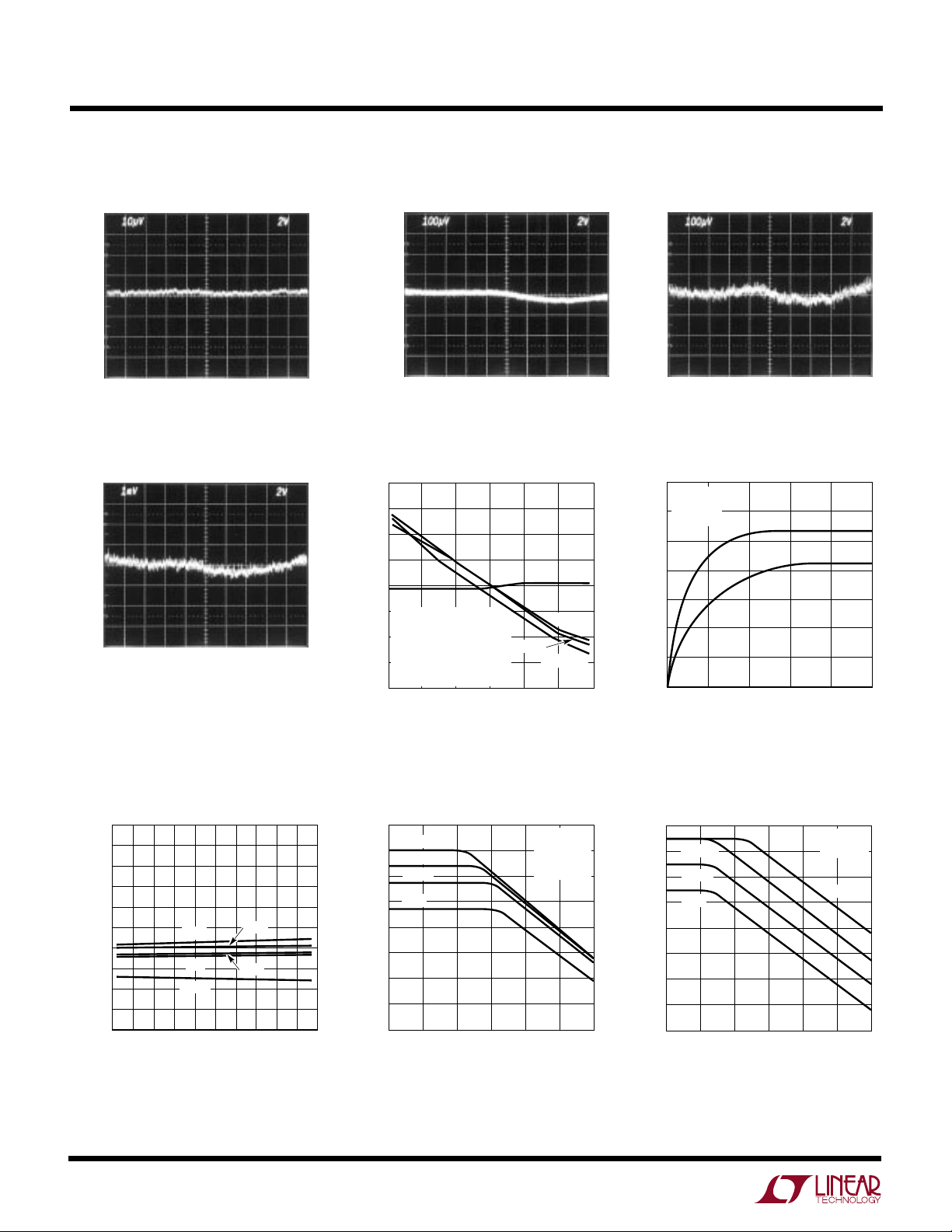

Gain Nonlinearity, G = 1

NONLINEARITY (1ppm/DIV)

OUTPUT VOLTAGE (2V/DIV)G = 1

= 2k

R

L

= ±10V

V

OUT

Gain Nonlinearity, G = 1000

NONLINEARITY (100ppm/DIV)

OUTPUT VOLTAGE (2V/DIV)

G = 1000

R

= 2k

L

= ±10V

V

OUT

1167 G01

1167 G04

Gain Nonlinearity, G = 10

NONLINEARITY (10ppm/DIV)

G = 10

R

V

OUTPUT VOLTAGE (2V/DIV)

= 2k

L

= ±10V

OUT

Gain Error vs Temperature

0.20

0.15

0.10

0.05

0

–0.05

VS = ±15V

GAIN ERROR (%)

–0.10

–0.15

–0.20

= ±10V

V

OUT

= 2k

R

L

*DOES NOT INCLUDE

TEMPERATURE EFFECTS

OF R

G

–50

0

–25

TEMPERATURE (°C)

1167 G02

G = 1

G = 10*

G = 100*

G = 1000*

25 100

75

50

1920 G06

Gain Nonlinearity, G = 100

NONLINEARITY (10ppm/DIV)

OUTPUT VOLTAGE (2V/DIV)

G = 100

R

= 2k

L

= ±10V

V

OUT

Warm-Up Drift

14

VS = ±15V

= 25°C

T

A

12

G = 1

10

8

6

4

CHANGE IN OFFSET VOLTAGE (µV)

2

0

12 5

0

TIME AFTER POWER ON (MINUTES)

1167 G03

S8

N8

34

1920 G09

Input Bias Current

vs Common Mode Input Voltage

500

400

300

200

100

0

–100

–200

INPUT BIAS CURRENT (pA)

–300

–400

–500

–12 12

–15

COMMON MODE INPUT VOLTAGE (V)

–9

–6

85°C

0°C

–40°C

–3

0

4

3

70°C

25°C

Common Mode Rejection Ratio

vs Frequency

160

G = 1000

140

G = 100

G = 10

120

G = 1

100

80

60

40

20

COMMON MODE REJECTION RATIO (dB)

0

6

9

15

1920 G13

110 1k

0.1

FREQUENCY (Hz)

100

VS = ±15V

= 25°C

T

A

1k SOURCE

IMBALANCE

10k

1920 G14

100k

Negative Power Supply Rejection

Ratio vs Frequency

160

G = 100

140

G = 10

120

G = 1

100

80

60

40

20

0

NEGATIVE POWER SUPPLY REJECTION RATIO (dB)

110 1k

0.1

FREQUENCY (Hz)

100

V+ = 15V

= 25°C

T

A

G = 1000

10k

1920 G15

100k

Page 5

UW

TYPICAL PERFOR A CE CHARACTERISTICS

Positive Power Supply Rejection

Ratio vs Frequency

160

140

G = 10

120

G = 1

100

80

60

40

20

0

POSITIVE POWER SUPPLY REJECTION RATIO (dB)

0.1

G = 100

110 1k

100

FREQUENCY (Hz)

V– = –15V

= 25°C

T

A

G = 1000

10k

100k

1920 G16

Gain vs Frequency

60

50

40

30

20

GAIN (dB)

10

0

–10

–20

0.01 1 10 1000

VS = ±15V

= 25°C

T

A

0.1

G = 1000

G = 100

G = 10

G = 1

100

FREQUENCY (kHz)

1920 G17

Supply Current vs Supply Voltage

1.50

1.25

1.00

SUPPLY CURRENT (mA)

0.75

0.50

0

5

10

SUPPLY VOLTAGE (±V)

LT1920

85°C

25°C

–40°C

15

20

1920 G18

Voltage Noise Density

vs Frequency

1000

VS = ±15V

= 25°C

T

A

1/f

CORNER

1/f

CORNER

1/f

CORNER

10 100 1k 100k10k

FREQUENCY (Hz)

VOLTAGE NOISE DENSITY (nV√Hz)

100

10

0

1

Current Noise Density

vs Frequency

1000

100

R

S

CURRENT NOISE DENSITY (fA/√Hz)

10

1

10 100 1000

FREQUENCY (Hz)

= 10Hz

= 9Hz

= 7Hz

GAIN = 1

GAIN = 10

GAIN = 100, 1000

BW LIMIT

GAIN = 1000

1920 G19

VS = ±15V

= 25°C

T

A

1920 G22

0.1Hz to 10Hz Noise Voltage,

G = 1

VS = ±15V

= 25°C

T

A

NOISE VOLTAGE (2µV/DIV)

2

1

0

3

5

4

TIME (SEC)

6

0.1Hz to 10Hz Current Noise

VS = ±15V

= 25°C

T

A

CURRENT NOISE (5pA/DIV)

2

1

0

3

TIME (SEC)

5

6

4

7

0.1Hz to 10Hz Noise Voltage, RTI

G = 1000

VS = ±15V

= 25°C

T

A

NOISE VOLTAGE (0.2µV/DIV)

2

1

7

8

10

9

1920 G20

0

3

5

4

TIME (SEC)

6

7

8

10

9

1920 G21

Short-Circuit Current vs Time

50

40

30

20

10

0

–10

–20

OUTPUT CURRENT (mA)

–30

(SINK) (SOURCE)

–40

–50

8

10

9

1920 G23

0

TIME FROM OUTPUT SHORT TO GROUND (MINUTES)

TA = –40°C

1

TA = –40°C

T

= 25°C

A

= 85°C

T

A

TA = 85°C

TA = 25°C

2

VS = ±15V

3

1920 G24

5

Page 6

LT1920

UW

TYPICAL PERFOR A CE CHARACTERISTICS

Large-Signal Transient Response

5V/DIV

G = 1

= ±15V

V

S

= 2k

R

L

= 60pF

C

L

10µs/DIV

Large-Signal Transient Response

5V/DIV

1167 G28

Small-Signal Transient Response

20mV/DIV

G = 1

V

= ±15V

S

= 2k

R

L

= 60pF

C

L

10µs/DIV

Small-Signal Transient Response

20mV/DIV

1167 G29

Overshoot vs Capacitive Load

100

VS = ±15V

90

80

70

60

50

40

OVERSHOOT (%)

30

20

10

= ±50mV

V

OUT

= ∞

R

L

AV = 1

AV = 10

AV ≥ 100

0

10

100 1000 10000

CAPACITIVE LOAD (pF)

Output Impedance vs Frequency

1000

VS = ±15V

= 25°C

T

A

G = 1 TO 1000

100

10

1920 G25

G = 10

= ±15V

V

S

= 2k

R

L

= 60pF

C

L

10µs/DIV

Large-Signal Transient Response

5V/DIV

G = 100

= ±15V

V

S

= 2k

R

L

= 60pF

C

L

10µs/DIV

1167 G31

1167 G34

= ±15V

V

S

= 2k

R

L

= 60pF

C

L

10µs/DIVG = 10

Small-Signal Transient Response

20mV/DIV

= ±15V

V

S

= 2k

R

L

= 60pF

C

L

10µs/DIVG = 100

1167 G32

1167 G35

1

OUTPUT IMPEDANCE (Ω)

0.1

1

10 100 1000

FREQUENCY (kHz)

Undistorted Output Swing

vs Frequency

35

G = 10, 100, 1000

30

G = 1

25

20

15

10

5

PEAK-TO-PEAK OUTPUT SWING (V)

0

1

10 100 1000

FREQUENCY (kHz)

1920 G26

VS = ±15V

= 25°C

T

A

1920 G27

6

Page 7

UW

TYPICAL PERFOR A CE CHARACTERISTICS

LT1920

Large-Signal Transient Response

5V/DIV

G = 1000

= ±15V

V

S

= 2k

R

L

= 60pF

C

L

50µs/DIV

Settling Time vs Step Size

10

VS = ±15

8

G = 1

= 25°C

T

A

6

= 30pF

C

L

= 1k

R

4

L

2

0

–2

OUTPUT STEP (V)

–4

–6

–8

–10

311

2

TO 0.1%

TO 0.1%

4

5

6

SETTLING TIME (µs)

Small-Signal Transient Response

20mV/DIV

1167 G37

TO 0.01%

0V

0V

8

7

G = 1000

= ±15V

V

S

= 2k

R

L

= 60pF

C

L

V

OUT

V

OUT

TO 0.01%

9

10

12

1920 G33

50µs/DIV

1167 G38

Settling Time vs Gain

1000

VS = ±15V

= 25°C

T

A

= 10V

∆V

OUT

1mV = 0.01%

100

10

SETTLING TIME (µs)

1

1

Slew Rate vs Temperature

1.8

VS = ±15V

= ±10V

V

OUT

G = 1

1.6

1.4

+SLEW

1.2

SLEW RATE (V/µs)

1.0

0.8

–50 –25

–SLEW

0

25

TEMPERATURE (°C)

10 100 1000

GAIN (dB)

50

75

100

125

1920 G36

1920 G30

Output Voltage Swing

vs Load Current

+V

S

+VS – 0.5

+V

+V

+V

–V

–V

–V

OUTPUT VOLTAGE SWING (V)

(REFERRED TO SUPPLY VOLTAGE)

–V

VS = ±15V

– 1.0

S

– 1.5

S

– 2.0

S

+ 2.0

S

+ 1.5

S

+ 1.0

S

+ 0.5

S

–V

S

0.01 1 10 100

0.1

OUTPUT CURRENT (mA)

85°C

25°C

–40°C

SOURCE

SINK

1920 G39

7

Page 8

LT1920

BLOCK DIAGRAM

W

–IN

+IN

+

V

R3

400Ω

2

–

V

1

R

G

8

R

G

3

V

–

R4

400Ω

+

V

Q1

Q2

VB

+

A1

–

C1

R1

24.7k

VB

+

A2

–

C2

R2

24.7k

R5

10k

R7

10k

R6

10k

–

A3

+

–

V

R8

10k

–

V

DIFFERENCE AMPLIFIER STAGEPREAMP STAGE

6

5

7

4

OUTPUT

REF

+

V

–

V

1920 F01

Figure 1. Block Diagram

U

THEORY OF OPERATIO

The LT1920 is a modified version of the three op amp

instrumentation amplifier. Laser trimming and monolithic

construction allow tight matching and tracking of circuit

parameters over the specified temperature range. Refer to

the block diagram (Figure 1) to understand the following

circuit description. The collector currents in Q1 and Q2 are

trimmed to minimize offset voltage drift, thus assuring a

high level of performance. R1 and R2 are trimmed to an

absolute value of 24.7k to assure that the gain can be set

accurately (0.3% at G = 100) with only one external

resistor R

determines the transconductance of the preamp stage. As

is reduced for larger programmed gains, the transcon-

R

G

ductance of the input preamp stage increases to that of the

input transistors Q1 and Q2. This increases the open-loop

gain when the programmed gain is increased, reducing

the input referred gain related errors and noise. The input

voltage noise at gains greater than 50 is determined only

by Q1 and Q2. At lower gains the noise of the difference

amplifier and preamp gain setting resistors increase the

noise. The gain bandwidth product is determined by C1,

C2 and the preamp transconductance which increases

. The value of RG in parallel with R1 (R2)

G

with programmed gain. Therefore, the bandwidth does not

drop proportional to gain.

The input transistors Q1 and Q2 offer excellent matching,

which is inherent in NPN bipolar transistors, as well as

picoampere input bias current due to superbeta processing. The collector currents in Q1 and Q2 are held constant

due to the feedback through the Q1-A1-R1 loop and

Q2-A2-R2 loop which in turn impresses the differential

input voltage across the external gain set resistor R

Since the current that flows through R

1 and R2, the ratios provide a gained-up differential volt-

R

age, G = (R1 + R2)/R

, to the unity-gain difference

G

also flows through

G

amplifier

.

G

A3. The common mode voltage is removed by A3, resulting in a single-ended output voltage referenced to the

voltage on the REF pin. The resulting gain equation is:

V

OUT

– V

REF

= G(V

IN

+

– V

IN

–

)

where:

G = (49.4kΩ/RG) + 1

solving for the gain set resistor gives:

RG = 49.4kΩ/(G – 1)

8

Page 9

THEORY OF OPERATIO

LT1920

U

Input and Output Offset Voltage

The offset voltage of the LT1920 has two components: the

output offset and the input offset. The total offset voltage

referred to the input (RTI) is found by dividing the output

offset by the programmed gain (G) and adding it to the

input offset. At high gains the input offset voltage dominates, whereas at low gains the output offset voltage

dominates. The total offset voltage is:

Total input offset voltage (RTI)

= input offset + (output offset/G)

Total output offset voltage (RTO)

= (input offset • G) + output offset

Reference Terminal

The reference terminal is one end of one of the four 10k

resistors around the difference amplifier. The output voltage of the LT1920 (Pin 6) is referenced to the voltage on

the reference terminal (Pin 5). Resistance in series with

the REF pin must be minimized for best common mode

rejection. For example, a 2Ω resistance from the REF pin

to ground will not only increase the gain error by 0.02%

but will lower the CMRR to 80dB.

Output Offset Trimming

The LT1920 is laser trimmed for low offset voltage so that

no external offset trimming is required for most applications. In the event that the offset needs to be adjusted, the

circuit in Figure 2 is an example of an optional offset adjust

circuit. The op amp buffer provides a low impedance to the

REF pin where resistance must be kept to minimum for

best CMRR and lowest gain error.

–

–IN

+IN

2

1

R

Figure 2. Optional Trimming of Output Offset Voltage

G

8

+

3

LT1920

REF

5

±10mV

ADJUSTMENT RANGE

6

OUTPUT

–

2

1

1/2

LT1112

3

+

10k

V

V

+

10mV

100Ω

100Ω

–10mV

–

1920 F02

Single Supply Operation

For single supply operation, the REF pin can be at the same

potential as the negative supply (Pin 4) provided the

output of the instrumentation amplifier remains inside the

specified operating range and that one of the inputs is at

least 2.5V above ground. The barometer application on the

front page of this data sheet is an example that satisfies

these conditions. The resistance R

from the bridge

SET

transducer to ground sets the operating current for the

bridge and also has the effect of raising the input common

mode voltage. The output of the LT1920 is always inside

the specified range since the barometric pressure rarely

goes low enough to cause the output to rail (30.00 inches

of Hg corresponds to 3.000V). For applications that require the output to swing at or below the REF potential, the

voltage on the REF pin can be level shifted. An op amp is

used to buffer the voltage on the REF pin since a parasitic

series resistance will degrade the CMRR. The application

in the back of this data sheet, Four Digit Pressure Sensor,

is an example.

Input Bias Current Return Path

The low input bias current of the LT1920 (2nA) and the

high input impedance (200GΩ) allow the use of high

impedance sources without introducing additional offset

voltage errors, even when the full common mode range is

required. However, a path must be provided for the input

bias currents of both inputs when a purely differential

signal is being amplified. Without this path the inputs will

float to either rail and exceed the input common mode

range of the LT1920, resulting in a saturated input stage.

Figure 3 shows three examples of an input bias current

path. The first example is of a purely differential signal

source with a 10kΩ input current path to ground. Since the

impedance of the signal source is low, only one resistor is

needed. Two matching resistors are needed for higher

impedance signal sources as shown in the second

example. Balancing the input impedance improves both

common mode rejection and DC offset. The need for input

resistors is eliminated if a center tap is present as shown

in the third example.

9

Page 10

LT1920

THEORY OF OPERATIO

U

–

MICROPHONE,

THERMOCOUPLE

10k

R

G

LT1920

+

Figure 3. Providing an Input Common Mode Current Path

U

HYDROPHONE,

ETC

200k

200k

WUU

APPLICATIONS INFORMATION

The LT1920 is a low power precision instrumentation

amplifier that requires only one external resistor to accurately set the gain anywhere from 1 to 1000. The output

can handle capacitive loads up to 1000pF in any gain

configuration and the inputs are protected against ESD

strikes up to 13kV (human body).

–

R

LT1920

G

+

CENTER-TAP PROVIDES

BIAS CURRENT RETURN

V

CC

J1

2N4393

R

IN

V

CC

J2

2N4393

–

R

LT1920

G

+

OPTIONAL FOR HIGHEST

ESD PROTECTION

V

CC

+

R

LT1920

G

1920 F03

OUT

REF

Input Protection

The LT1920 can safely handle up to ±20mA of input

current in an overload condition. Adding an external 5k

input resistor in series with each input allows DC input

fault voltages up to ±100V and improves the ESD immunity to 8kV (contact) and 15kV (air discharge), which is the

IEC 1000-4-2 level 4 specification. If lower value input

resistors are needed, a clamp diode from the positive

supply to each input will maintain the IEC 1000-4-2

specification to level 4 for both air and contact discharge.

A 2N4393 drain/source to gate is a good low leakage diode

for use with 1k resistors, see Figure 4. The input resistors

should be carbon and not metal film or carbon film.

RFI Reduction

In many industrial and data acquisition applications,

instrumentation amplifiers are used to accurately amplify

small signals in the presence of large common mode

voltages or high levels of noise. Typically, the sources of

these very small signals (on the order of microvolts or

millivolts) are sensors that can be a significant distance

from the signal conditioning circuit. Although these sen-

R

IN

Figure 4. Input Protection

–

V

EE

1920 F04

sors may be connected to signal conditioning circuitry,

using shielded or unshielded twisted-pair cabling, the cabling may act as antennae, conveying very high frequency

interference directly into the input stage of the LT1920.

The amplitude and frequency of the interference can have

an adverse effect on an instrumentation amplifier’s input

stage by causing an unwanted DC shift in the amplifier’s

input offset voltage. This well known effect is called RFI

rectification and is produced when out-of-band interference is coupled (inductively, capacitively or via radiation)

and rectified by the instrumentation amplifier’s input transistors. These transistors act as high frequency signal

detectors, in the same way diodes were used as RF

envelope detectors in early radio designs. Regardless of

the type of interference or the method by which it is

coupled into the circuit, an out-of-band error signal appears in series with the instrumentation amplifier’s inputs.

10

Page 11

LT1920

U

WUU

APPLICATIONS INFORMATION

To significantly reduce the effect of these out-of-band

signals on the input offset voltage of instrumentation

amplifiers, simple lowpass filters can be used at the

inputs. This filter should be located very close to the input

pins of the circuit. An effective filter configuration is

illustrated in Figure 5, where three capacitors have been

added to the inputs of the LT1920. Capacitors C

form lowpass filters with the external series resis-

C

XCM2

tors R

the input traces. Capacitor C

to any out-of-band signal appearing on each of

S1, 2

forms a filter to reduce any

XD

unwanted signal that would appear across the input traces.

An added benefit to using C

is that the circuit’s AC

XD

common mode rejection is not degraded due to common

mode capacitive imbalance. The differential mode and

common mode time constants associated with the capacitors are:

t

DM(LPF)

t

CM(LPF)

= (2)(RS)(CXD)

= (R

S1, 2

)(C

XCM1, 2

)

Setting the time constants requires a knowledge of the

frequency, or frequencies of the interference. Once this

frequency is known, the common mode time constants

can be set followed by the differential mode time constant.

Set the common mode time constants such that they do

not degrade the LT1920’s inherent AC CMR. Then the

differential mode time constant can be set for the bandwidth required for the application. Setting the differential

XCM1

and

mode time constant close to the sensor’s BW also minimizes any noise pickup along the leads. To avoid any

possibility of inadvertently affecting the signal to be processed, set the common mode time constant an order of

magnitude (or more) larger than the differential mode time

constant. To avoid any possibility of common mode to

differential mode signal conversion, match the common

mode time constants to 1% or better. If the sensor is an

RTD or a resistive strain gauge, then the series resistors

can be omitted, if the sensor is in proximity to the

R

S1, 2

instrumentation amplifier.

+

C

RS1

XCM1

0.001µF

1.6k

+

IN

C

XD

0.1µF

RS2

1.6k

–

IN

C

XCM2

0.001µF

EXTERNAL RFI

FILTER

f(–3dB) ≈ 500Hz

R

G

Figure 5. Adding a Simple RC Filter at the Inputs to an

Instrumentation Amplifier is Effective in Reducing Rectification

of High Frequency Out-of-Band Signals

V

+

LT1920

V

OUT

–

–

V

1920 F05

PACKAGE DESCRIPTION

0.300 – 0.325

(7.620 – 8.255)

0.065

(1.651)

0.009 – 0.015

(0.229 – 0.381)

+0.035

0.325

–0.015

+0.889

8.255

()

–0.381

*THESE DIMENSIONS DO NOT INCLUDE MOLD FLASH OR PROTRUSIONS.

MOLD FLASH OR PROTRUSIONS SHALL NOT EXCEED 0.010 INCH (0.254mm)

TYP

0.100 ± 0.010

(2.540 ± 0.254)

Information furnished by Linear Technology Corporation is believed to be accurate and reliable.

However, no responsibility is assumed for its use. Linear Technology Corporation makes no representation that the interconnection of its circuits as described herein will not infringe on existing patent rights.

U

Dimensions in inches (millimeters) unless otherwise noted.

N8 Package

8-Lead PDIP (Narrow 0.300)

(LTC DWG # 05-08-1510)

0.045 – 0.065

(1.143 – 1.651)

0.130 ± 0.005

(3.302 ± 0.127)

0.125

(3.175)

MIN

0.018 ± 0.003

(0.457 ± 0.076)

0.020

(0.508)

MIN

0.255 ± 0.015*

(6.477 ± 0.381)

0.400*

(10.160)

MAX

876

12

3

5

4

N8 1197

11

Page 12

LT1920

TYPICAL APPLICATION

U

Nerve Impulse Amplifier

PATIENT/CIRCUIT

+IN

PATIENT

GROUND

–IN

PROTECTION/ISOLATION

C1

0.01µF

1M

R1

12k

R2

–

1/2

1

LT1112

+

2

3

PACKAGE DESCRIPTION

0.010 – 0.020

(0.254 – 0.508)

0.008 – 0.010

(0.203 – 0.254)

*

DIMENSION DOES NOT INCLUDE MOLD FLASH. MOLD FLASH

SHALL NOT EXCEED 0.006" (0.152mm) PER SIDE

**

DIMENSION DOES NOT INCLUDE INTERLEAD FLASH. INTERLEAD

FLASH SHALL NOT EXCEED 0.010" (0.254mm) PER SIDE

× 45°

(1.346 – 1.752)

0°– 8° TYP

0.016 – 0.050

0.406 – 1.270

3V

R3

30k

R4

30k

AV = 101

POLE AT 1kHz

3

8

R

G

6k

1

2

+

–

LT1920

G = 10

4

–3V

7

6

5

C2

0.47µF

0.3Hz

HIGHPASS

R6

1M

R8

100Ω

5

6

U

Dimensions in inches (millimeters) unless otherwise noted.

S8 Package

8-Lead Plastic Small Outline (Narrow 0.150)

(LTC DWG # 05-08-1610)

0.053 – 0.069

0.014 – 0.019

(0.355 – 0.483)

0.004 – 0.010

(0.101 – 0.254)

0.050

(1.270)

TYP

0.228 – 0.244

(5.791 – 6.197)

8

1

3V

8

+

1/2

LT1112

–

4

–3V

C3

15nF

0.189 – 0.197*

(4.801 – 5.004)

7

2

R7

10k

6

3

7

5

4

OUTPUT

1V/mV

1920 TA03

0.150 – 0.157**

(3.810 – 3.988)

SO8 0996

RELATED PARTS

PART NUMBER DESCRIPTION COMMENTS

LTC1100 Precision Chopper-Stabilized Instrumentation Amplifier Best DC Accuracy

LT1101 Precision, Micropower, Single Supply Instrumentation Amplifier Fixed Gain of 10 or 100, IS < 105µA

LT1102 High Speed, JFET Instrumentation Amplifier Fixed Gain of 10 or 100, 30V/µs Slew Rate

LT1167 Single Resistor Gain Programmable Precision Upgraded Version of the LT1920

Instrumentation Amplifier

LTC®1418 14-Bit, Low Power, 200ksps ADC with Serial and Parallel I/O Single Supply 5V or ±5V Operation, ±1.5LSB INL

and ±1LSB DNL Max

LT1460 Precision Series Reference Micropower; 2.5V, 5V, 10V Versions; High Precision

LTC1562 Active RC Filter Lowpass, Bandpass, Highpass Responses; Low Noise,

Low Distortion, Four 2nd Order Filter Sections

LTC1605 16-Bit, 100ksps, Sampling ADC Single 5V Supply, Bipolar Input Range: ±10V,

Power Dissipation: 55mW Typ

1920f LT/TP 0299 4K • PRINTED IN USA

LINEAR TECHNOLOGY CORPORATION 1998

12

Linear T echnology Corporation

1630 McCarthy Blvd., Milpitas, CA 95035-7417

(408) 432-1900 ● FAX: (408) 434-0507

●

www.linear-tech.com

Loading...

Loading...