Page 1

FEATURES

Final Electrical Specifications

LT1910

Protected High Side

MOSFET Driver

August 2002

U

DESCRIPTION

■

8V to 48V Power Supply Range

■

Protected from –15V to 60V Supply Transients

■

Short-Circuit Protected

■

Automatic Restart Timer

■

Open-Collector Fault Flag

■

Fully Enhances N-Channel MOSFET Switches

■

Programmable Current Limit, Delay Time and

Autorestart Period

■

Voltage Limited Gate Drive

■

Defaults to OFF State with Open Input

■

Available in SO-8 Package

U

APPLICATIO S

■

Industrial Control

■

Avionics Systems

■

Automotive Switches

■

Stepper Motor and DC Motor Control

■

Electronic Circuit Breaker

The LT®1910 is a high side gate driver allowing the use of

low cost N-channel power MOSFETs for high side switching applications. It contains a completely self-contained

charge pump to fully enhance an N-channel MOSFET

switch with no external components.

When the internal drain comparator senses that the switch

current has exceeded the preset level, the switch is turned

off and a fault flag is asserted. The switch remains off for

a period of time set by an external timing capacitor and

then automatically attempts to restart. If the fault still

exists, this cycle repeats until the fault is removed, thus

protecting the MOSFET. The fault flag becomes inactive

once the switch restarts successfully.

The LT1910 has been specifically designed for harsh

operating environments such as industrial, avionics and

automotive applications where poor supply regulation

and/or transients may be present. The device will not

sustain damage from supply transients of –15V to 60V.

The LT1910 is available in the SO-8 package.

, LTC and LT are registered trademarks of Linear Technology Corporation.

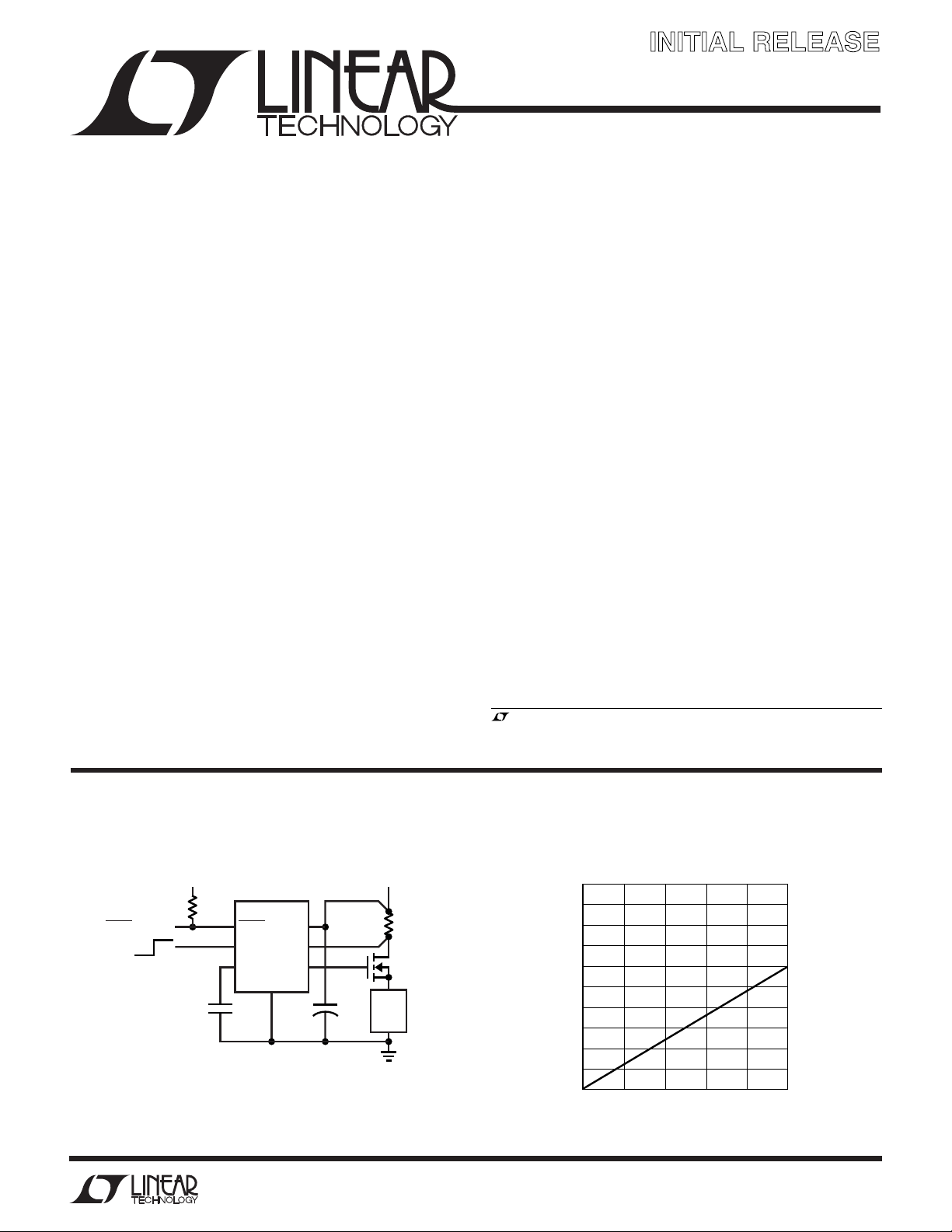

TYPICAL APPLICATIO

Fault Protected High Side Switch

5.1k

FAULT OUTPUT

OFF ON

U

Switch Drop vs Load Current

24V5V

LT1910

+

FAULT

IN

TIMER

0.1µF

V

SENSE

GATE

GND

+

10µF

50V

Information furnished by Linear Technology Corporation is believed to be accurate and reliable.

However, no responsibility is assumed for its use. Linear Technology Corporation makes no representation that the interconnection of its circuits as described herein will not infringe on existing patent rights.

0.01Ω

IRFZ34

LOAD

1910 TA01

0.50

0.45

0.40

0.35

0.30

0.25

0.20

TOTAL DROP (V)

0.15

0.10

0.05

0

0

1

3

2

LOAD CURRENT (A)

4

5

1910 TA02

1910i

1

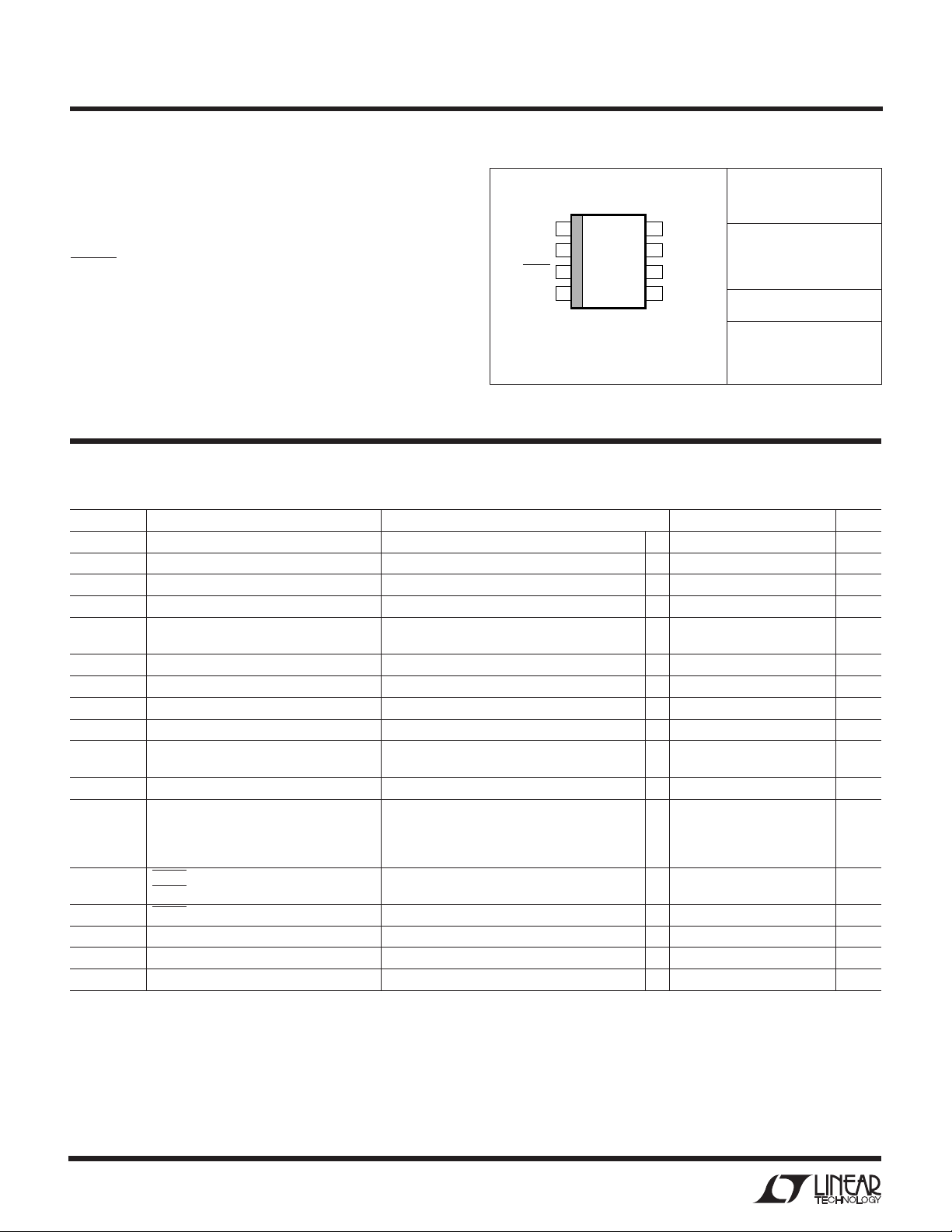

Page 2

LT1910

WW

W

ABSOLUTE MAXIMUM RATINGS

U

U

W

PACKAGE/ORDER INFORMATION

U

(Note 1)

Supply Voltage (Pin 8)............................... –15V to 60V

Input Voltage (Pin 4) .................... (GND – 0.3V) to 15V

GATE Voltage (Pin 5) .............................................. 75V

SENSE Voltage (Pin 6)....................................... V+ ±5V

FAULT Voltage (Pin 3) ............................................ 36V

Current (Pins 1, 2, 4, 5, 6, 8) ............................... 40mA

Operating Temperature Range (Note 2) ...–40°C to 85°C

Junction Temperature Range................ –40°C to 125°C

Storage Temperature Range ................. –65°C to 150°C

GND

TIMER

FAULT

IN

T

JMAX

TOP VIEW

1

2

3

4

S8 PACKAGE

8-LEAD PLASTIC SO

= 125°C, θJA = 150°C/W

+

8

V

NC

7

SENSE

6

GATE

5

ORDER PART

NUMBER

LT1910ES8

S8 PART MARKING

1910

Lead Temperature (Soldering, 10 sec).................. 300°C

Consult LTC Marketing for parts specified with wider operating temperature ranges.

ELECTRICAL CHARACTERISTICS

range, otherwise specifications are at TA = 25°C. V+ = 12V to 48V unless otherwise noted.

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

I

S

∆I

S(ON)

V

INH

V

INL

I

IN

C

IN

V

T(TH)

V

T(CL)

I

T

V

SENSE

I

SENSE

V

– V+Gate Voltage Above Supply V+ = 8V 4 4.5 6 V

GATE

V

F(TH)

V

FOL

t

ON

t

OFF

t

OFF(CL)

Supply Current (OFF State) V+ = 48V, VIN = 0.8V 1.2 1.9 2.5 mA

Delta Supply Current (ON State) VIN = 2V, Measure Increase in I

Input High Voltage ● 2V

Input Low Voltage ● 0.8 V

Input Current VIN = 2V ● 15 30 50 µA

Input Capacitance (Note 3) 5pF

Timer Threshold Voltage VIN = 2V, Adjust V

Timer Clamp Voltage VIN = 0.8V 3.2 3.5 3.8 V

Timer Charge Current VIN = VT = 2V 9 14 20 µA

Drain Sense Threshold Voltage 50 65 80 mV

Temperature Coefficient (Note 3) 0.33 %/°C

Drain Sense Input Current V+ = 48V, V

FAULT Output High Threshold Voltage VIN = 2V, IF = 1mA, Adjust V

FAULT Output Low Threshold Voltage 3.0 3.3 3.6 V

FAULT Output Low Voltage IF = 1mA ● 0.07 0.4 V

Turn-On Time V+ = 24V, V

Turn-Off Time V+ = 24V, V

Current Limit Turn-Off Time V+ = 24V, (V+ – V

The ● denotes specifications that apply over the full operating temperature

S

= 5V ● 55 110 185 µA

V

IN

T

= 65mV 0.5 1.5 µA

SENSE

+

= 12V ● 7 8.5 10 V

V

+

= 24V ● 10 12 14 V

V

V+ = 48V ● 10 12 14 V

T

GATE

GATE

= 32V, C

= 2V, C

SENSE

= 1nF 100 220 400 µs

GATE

= 1nF 25 100 µs

GATE

)→0.1V, C

= 1nF 20 50 µs

GATE

● 2.6 2.9 3.2 V

3.1 3.4 3.7 V

0.8 1.2 mA

Note 1: Absolute Maximum Ratings are those values beyond which the life

of a device may be impaired.

Note 2: The LT1910E is guaranteed to meet performance specifications

from 0°C to 70°C. Specifications over the –40°C to 85°C operating

temperature range are assured by design, characterization and correlation

with statistical process controls.

Note 3: Guaranteed but not tested.

2

1910i

Page 3

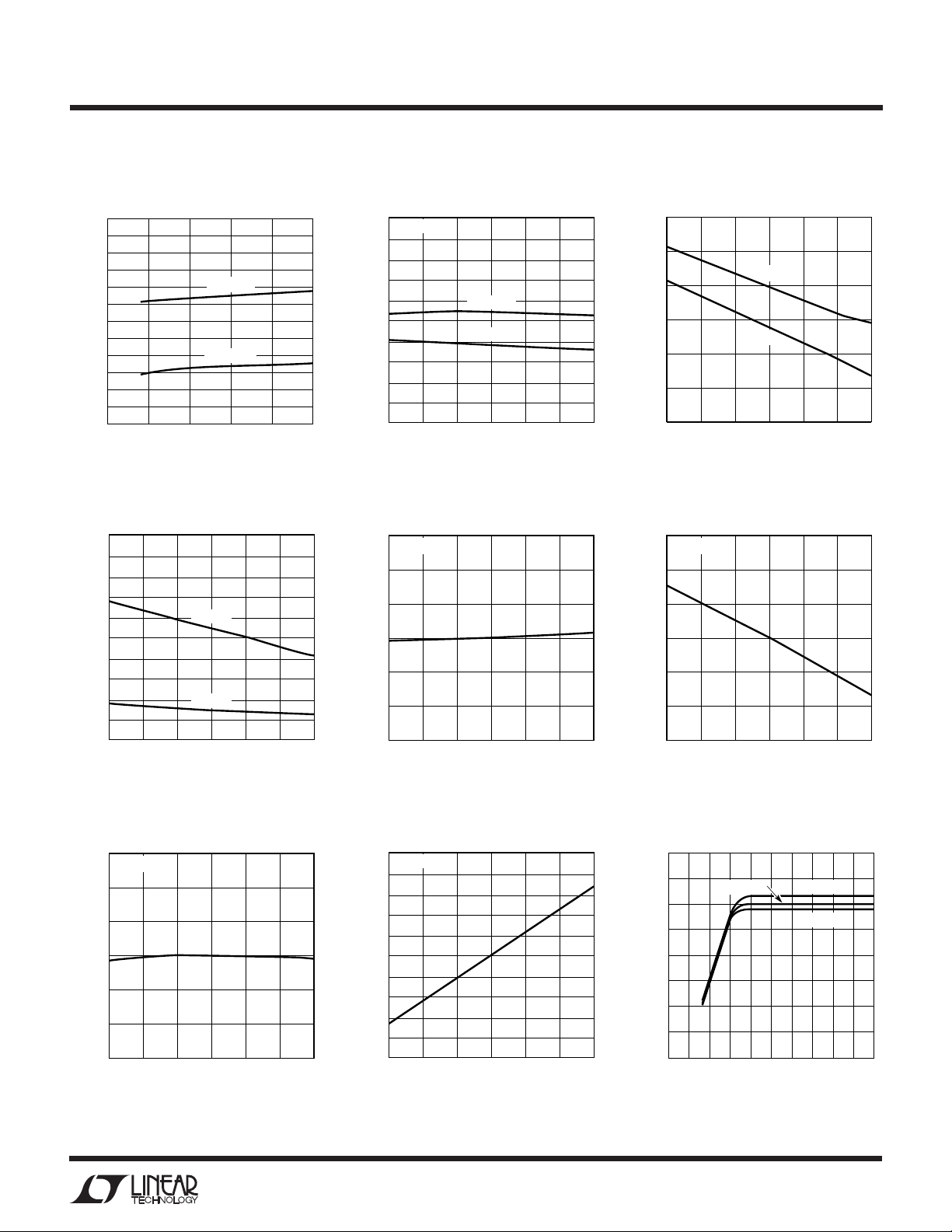

UW

TYPICAL PERFOR A CE CHARACTERISTICS

Supply Current vs Supply Voltage Supply Current vs Temperature Input Voltage vs Temperature

3.6

3.4

3.2

3.0

2.8

2.6

2.4

2.2

2.0

SUPPLY CURRENT (mA)

1.8

1.6

1.4

1.2

10

0

SUPPLY VOLTAGE (V)

20

ON STATE

OFF STATE

30

5.0

V+ = 48V

4.5

4.0

3.5

3.0

2.5

2.0

1.5

SUPPLY CURRENT (mA)

1.0

0.5

0

–25

40

50

1910 G01

–50

ON STATE

OFF STATE

25 50

0

TEMPERATURE (°C)

75

100

1910 G02

2.0

1.8

1.6

1.4

1.2

INPUT VOLTAGE (V)

1.0

0.8

–50

–25

V

V

02550

TEMPERATURE (°C)

LT1910

INH

INL

75 100

1910 G03

Input Current vs Temperature

200

180

160

140

120

100

80

60

INPUT CURRENT (µA)

40

20

0

–50

–25

VIN = 5V

VIN = 2V

25 50

0

TEMPERATURE (°C)

Timer Charge Current

vs Temperature

20

VIN = VT = 2V

18

16

14

12

TIMER CHARGE CURRENT (µA)

10

8

–50

02550

–25

TEMPERATURE (°C)

75

100

1910 G04

75 100

1910 G07

Timer Threshold Voltage

vs Temperature

3.2

VIN = 2V

3.1

3.0

2.9

2.8

2.7

TIMER THRESHOLD VOLTAGE (V)

2.6

–50

02550

–25

TEMPERATURE (°C)

Drain Sense Threshold Voltage

vs Temperature

90

V+ = 24V

85

80

75

70

65

60

55

50

45

DRAIN SENSE THRESHOLD VOLTAGE (mV)

40

–50

–25

25 50

0

TEMPERATURE (°C)

75 100

1910 G05

75

100

1910 G08

Timer Clamp Voltage

vs Temperature

3.8

VIN ≤ 0.8V

3.7

3.6

3.5

3.4

TIMER CLAMP VOLTAGE (V)

3.3

3.2

–50

02550

–25

TEMPERATURE (°C)

MOSFET Gate Voltage Above V

(V

– V+) vs Supply Voltage

GATE

16

) (V)

+

14

– V

GATE

12

(V

+

10

8

6

4

2

0

MOSFET GATE VOLTAGE ABOVE V

0

TA = 25°C

10 20 30 503551525 45

SUPPLY VOLTAGE (V)

75 100

1910 G06

+

TA = 85°C

TA = –40°C

40

LTC1266 • F04

1910i

3

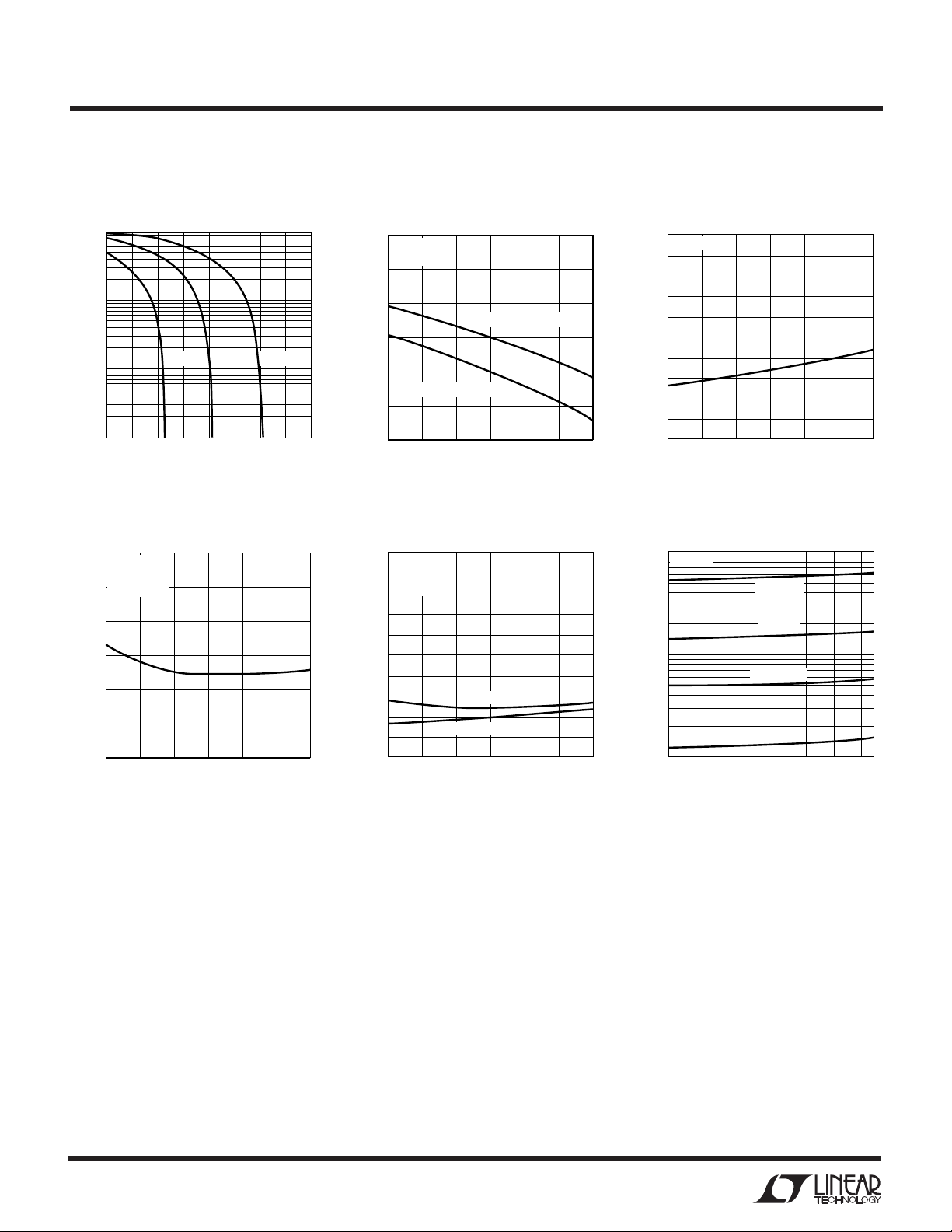

Page 4

LT1910

UW

TYPICAL PERFOR A CE CHARACTERISTICS

MOSFET Gate Drive Current

vs V

100

MOSFET GATE DRIVE CURRENT (µA)

GATE

10

1

0.1

024

+

– V

V+ = 8V V+ = 12V V+ ≥ 24V

6 8 10 12 14 16

V

– V+ (V)

GATE

1910 G10

Fault Threshold Voltage

vs Temperature

3.7

VIN = 2V

= 1mA

I

F

3.6

3.5

FAULT HIGH THRESHOLD

3.4

3.3

FAULT LOW THRESHOLD

3.2

FAULT THRESHOLD VOLTAGE (V)

3.1

–50

02550

–25

TEMPERATURE (°C)

Turn-On Time vs Temperature Turn-Off Time vs Temperature

400

V+ = 24V

= 32V

V

GATE

350

300

250

200

TURN-ON TIME (µs)

150

100

–50

C

GATE

= 1nF

02550

–25

TEMPERATURE (°C)

75 100

1910 G13

100

V+ = 24V

90

80

70

60

50

40

30

TURN-OFF TIME (µs)

20

10

0

–50

V

C

GATE

GATE

= 2V

= 1nF

CURRENT LIMIT

–25

0

TEMPERATURE (°C)

NORMAL

25 50

75 100

1910 G11

75

100

1910 G014

Fault Output Low Voltage

vs Temperature

0.20

IF = 1mA

0.18

0.16

0.14

0.12

0.10

0.08

0.06

0.04

FAULT OUTPUT LOW VOLTAGE (V)

0.02

0

–50

–25

25 50

0

TEMPERATURE (°C)

Automatic Restart Period

vs Temperature

1000

V+ = 24V

CT = 3.3µF

CT = 1µF

100

CT = 0.33µF

AUTOMATIC RESTART PERIOD (ms)

10

–50

–30

CT = 0.1µF

–10 10 30 50

TEMPERATURE (°C)

75

100

1910 G012

90

70

1910 G15

4

1910i

Page 5

LT1910

U

UU

PI FU CTIO S

GND (Pin 1): Common ground.

TIMER (Pin 2): A timing capacitor CT from the TIMER pin

to ground sets the restart time following overcurrent

detection. Upon detection of an overcurrent condition, C

is rapidly discharged to less than 1V and then recharged

by a 14µA nominal current source back to the 2.9V timer

threshold, whereupon the restart is attempted. Whenever

TIMER pulls below 2.9V, the GATE pin pulls low to turn off

the external switch. This cycle repeats until the overcurrent condition goes away and the switch restarts successfully. During normal operation the pin clamps at 3.5V

nominal.

FAULT (Pin 3): The FAULT pin monitors the TIMER pin

voltage and indicates the overcurrent condition. Whenever the TIMER pin is pulled below 3.3V at the onset of a

current limit condition, the FAULT pin pulls active LOW.

The FAULT pin resets HIGH immediately when the TIMER

pin ramps above 3.4V during autorestart. The FAULT pin

is an open-collector output, thus requiring an external

pull-up resistor. This pin is intended for logic interface

with a pull-up resistor. This resistor should be selected

with a typical 1mA pull-up at low status and less than 2mA

under worst-case conditions.

T

GATE (Pin 5): The GATE pin drives the power MOSFET

gate. When the IN pin is greater than 2V, the GATE pin is

pumped approximately 12V above the supply. It has

relatively high impedance (the equivalence of a few hundred kΩ) when pumped above the rail. Care should be

taken to minimize any loading by parasitic resistance to

ground or supply. The GATE pin pulls LOW when the

TIMER pin falls below 2.9V.

SENSE (Pin 6): The SENSE pin connects to the input of a

supply-referenced comparator with a 65mV nominal offset. When the SENSE pin is taken more than 65mV below

supply, the MOSFET gate is driven LOW and the timing

capacitor is discharged. The SENSE pin threshold has a

0.33%/°C temperature coefficient (TC), which closely

matches the TC of the drain sense resistor formed from the

copper trace of the PCB.

For loads requiring high inrush current, an RC timing delay

can be added between the drain sense resistor and the

SENSE pin to ensure that the current-sense comparator

does not false trigger during start-up (see Applications

Information). A maximum of 10kΩ can be inserted between a drain sense resistor and the SENSE pin. If current

sensing is not required, the SENSE pin is tied to supply.

IN (Pin 4): The IN pin threshold is TTL/CMOS compatible

and has approximately 200mV of hysteresis. When the IN

pin is pulled active HIGH above 2V, an internal charge

pump is activated to pull up the GATE pin. The IN pin can

be pulled as high as 15V regardless of whether the supply

is on or off. If the IN pin is left open, an internal 75k pulldown resistor pulls the pin below 0.8V to ensure that the

GATE pin is inactive LOW.

V+ (Pin 8): In addition to providing the operating current

for the LT1910, the V+ pin also serves as the Kelvin

connection for the current sense comparator. The V+ pin

must be connected to the positive side of the drain sense

resistor for proper current sensing operation.

1910i

5

Page 6

LT1910

BLOCK DIAGRA

+

V

W

TIMER

IN

OPERATIO

14µA

3.3V

2.9V

1.4V

75k

75k

–

+

+

–

+

–

U

(Refer to the Block Diagram)

FAULT

+

V

+

65mV

–

+

SENSE

–

+

1.4V

–

OSCILLATOR

AND

CHARGE PUMP

GATE

250Ω

1910 BD

The LT1910 GATE pin has two states, OFF and ON. In the

OFF state it is held LOW, while in the ON state it is pumped

to 12V above the supply by a self-contained 750kHz

charge pump. The OFF state is activated when either the IN

pin is below 0.8V or the TIMER pin is below 2.9V. Conversely, for the ON state to be activated, the IN pin must be

above 2V and the TIMER pin must be above 2.9V.

The IN pin has approximately 200mV of hysteresis. If it is

left open, the IN pin is held LOW by a 75k resistor. Under

normal conditions, the TIMER pin is held a diode drop

above 2.9V by a 14µA pull-up current source. Thus the

TIMER pin automatically reverts the GATE pin to the ON

state if the IN pin is above 2V.

The SENSE pin normally connects to the drain of the power

MOSFET, which returns through a low value drain sense

resistor to supply. In order for the sense comparator to

accurately sense the MOSFET drain current, the V+ pin

must be connected directly to the positive side of the drain

sense resistor. When the GATE pin is ON and the MOSFET

drain current exceeds the level required to generate a

65mV drop across the drain sense resistor, the sense

comparator activates a pull-down NPN which rapidly pulls

the TIMER pin below 2.9V. This in turn causes the timer

comparator to override the IN pin and set the GATE pin to

the OFF state, thus protecting the power MOSFET. When

the TIMER pin is pulled below 3.3V, the fault comparator

also activates the open-collector NPN to pull the FAULT

pin LOW, indicating an overcurrent condition.

When the MOSFET gate voltage is discharged to less than

1.4V, the TIMER pin is released. The 14µA current source

then slowly charges the timing capacitor back to 2.9V

where the charge pump again starts to drive the GATE pin

HIGH. If a fault condition still exists, the sense comparator

threshold will again be exceeded and the timer cycle will

repeat until the fault is removed. The FAULT pin becomes

inactive HIGH if the TIMER pin charges up successfully

above 3.4V (see Figure 1).

1910i

6

Page 7

OPERATIO

U

GATE

LT1910

OVERCURRENTNORMAL NORMALOFF

IN

0V

12V

+

V

0V

3.5V

2.9V

TIMER

0V

5V

FAULT

0V

Figure 1. Timing Diagram

WUUU

APPLICATIO S I FOR ATIO

Input/Supply Sequencing

There are no input/supply sequencing requirements for

the LT1910. The IN pin may be taken up to 15V with the

supply at 0V. When the supply is turned on with the IN pin

set HIGH, the MOSFET turn-on will be inhibited until the

timing capacitor charges up to 2.9V (i.e., for one restart

cycle).

Isolating the Inputs

Operation in harsh environments may require isolation to

prevent ground transients from damaging control logic.

The LT1910 easily interfaces to low cost optoisolators.

The network shown in Figure 2 ensures that the input will

be pulled above 2V, but not exceed the absolute maximum

rating for supply voltages of 12V to 48V over the entire

12V TO 48V

LOGIC

INPUT

2k

LOGIC GROUND

100k

51k

LT1910

4

IN

GND

1910 F02

1

3.4V

1910 F01

temperature range. The optoisolator must have less than

20µA of dark current (leakage) at hot in order to maintain

the OFF State (see Figure 2).

Drain Sense Configuration

The LT1910 uses supply referenced current sensing. One

input of the current sense comparator is connected to a

drain sense pin, while the second input is offset 65mV below

the supply inside the device. For this reason, Pin 8 of the

LT1910 must be treated not only as a supply pin, but also

as the reference input for the current sense comparator.

Figure 3 shows the proper drain sense configuration for

the LT1910. Note that the SENSE pin goes to the drain end

of the sense resistor, while the V+ pin is connected to the

24V

5V

FAULT OUTPUT

INPUT

R1

5.1k

3

4

2

FAULT

IN

TIMER

C

T

1µF

LT1910

SENSE

GND

1

GATE

8

+

V

6

5

+

C1

100µF

50V

R

S

0.02Ω

(PTC)

Q1

IRFZ34

24V

2A

SOLENOID

POWER GROUND

Figure 2. Isolating the Input

0V

Figure 3. Drain Sense Configuration

1910 F03

1910i

7

Page 8

LT1910

WUUU

APPLICATIO S I FOR ATIO

supply at the same point as the positive end of the sense

resistor.

The drain sense threshold voltage has a positive temperature coefficient, allowing PTC sense resistors to be used

(see Printed Circuit Board Shunts). The selection of R

S

should be based on the minimum threshold voltage:

RS = 50mV/I

SET

Thus the 0.02Ω drain sense resistor in Figure 3 will yield

a minimum trip current of 2.5A. This simple configuration

is appropriate for resistive or inductive loads that do not

generate large current transients at turn-on.

Automatic Restart Period

The timing capacitor CT shown in Figure 3 determines the

length of time the power MOSFET is held off following a

current limit trip. Curves are given in the Typical Performance Characteristics to show the restart period for

various values of CT. For example, CT = 0.33µF yields a

50ms restart period.

Defeating Automatic Restart

Some applications are required to remain off after a fault

occurs. When the LT1910 is being driven from CMOS

logic, this can be easily implemented by connecting resistor R2 between the IN and TIMER pins as shown in

Figure␣ 4. R2 supplies the sustaining current for an internal

SCR which latches the TIMER pin LOW under a fault

condition. The FAULT pin is set active LOW when the

TIMER pin falls below 3.3V. This keeps the MOSFET gate

from turning ON and the FAULT pin from resetting HIGH

5V

R1

5.1k

3

FAULT

4

IN

LT1910

2

CT

1µF

TIMER

GND

1

1910 F04

R2

2k

5V

CMOS

LOGIC

FAULT OUTPUT

ON = 5V

OFF = 0V

until the IN pin has been recycled. CT is used to prevent the

FAULT pin from glitching whenever the IN pin recycles to

turn on the MOSFET unsuccessfully under an existing fault

condition.

Inductive vs Capacitive Loads

Turning on an inductive load produces a relatively benign

ramp in MOSFET current. However, when an inductive

load is turned off, the current stored in the inductor needs

somewhere to decay. A clamp diode connected directly

across each inductive load normally serves this purpose.

If a diode is not employed, the LT1910 clamps the MOSFET

gate 0.7V below ground. This causes the MOSFET to

resume conduction during the current decay with (V+ +

VGS + 0.7V) across it, resulting in high dissipation peaks.

Capacitive loads exhibit the opposite behavior. Any load

that includes a decoupling capacitor will generate a current equal to C

• (∂V/∂t) during capacitor in-rush.

LOAD

With large electrolytic capacitors, the resulting current

spike can play havoc with the power supply and false trip

the current sense comparator.

Turn-on ∂V/∂t is controlled by the addition of the simple

network shown in Figure 5. This network takes advantage

of the fact that the MOSFET acts as a source follower

during turn-on. Thus the ∂V/∂t on the source can be

controlled by controlling the ∂V/∂t on the gate.

SENSE

LT1910

GND

1

GATE

50µF

V

50V

8

+

6

∂V/∂t CONTROL NETWORK

5

+

C2

CURRENT LIMIT

DELAY NETWORK

1N4148

C

D

RD (≤10k)

1N4148

R1

100kR2100k

C1

+

24V

R

S

0.01Ω

Q1

IRFZ34

15V

1N4744

C

LOAD

1910 F05

Figure 4. Latch-Off Configuration (Autorestart Defeated)

8

Figure 5. Control and Current Limit Delay

1910i

Page 9

WUUU

APPLICATIO S I FOR ATIO

LT1910

The turn-on current spike into C

VV

–

IC

= •

PEAK LOAD

GTH

RC

•11

is estimated by:

LOAD

where VTH is the MOSFET gate threshold voltage. VG is

obtained by plotting the equation:

V

I

GATE

on the graph of Gate Drive Current (I

(V

GATE

GATE

=

R

1

) vs Gate Voltage

GATE

) as shown in Figure 6. The value of V

GATE

at the

intersection of the curves for a given supply is VG. For

example, if V+ = 24V and R1 = 100k, then VG = 18.3V. For

VTH = 2V, C1 = 0.1µF and C

I

= 1.6A. The diode and the second resistor in the

PEAK

= 1000µF, the estimated

LOAD

network ensure fast current limit turn-off.

When turning off a capacitive load, the source of the

MOSFET can “hang up” if the load resistance does not

discharge C

as fast as the gate is being pulled down.

LOAD

If this is the case, a 15V zener may be added from gate to

source to prevent V

800

700

600

V+ = 24V

500

400

300

200

GATE DRIVE CURRENT (µA)

100

0

10 20 40

0

Figure 6. Gate Drive Current vs Gate Voltage

GS(MAX)

V+ = 12V

V+ = 8V

from being exceeded.

V+ = 48V

I

GATE

V

GATE

30

GATE VOLTAGE (V)

50

=

/10

1910 F06

5

60

Adding Current Limit Delay

When capacitive loads are being switched or in very noisy

environments, it is desirable to add delay in the drain

current sense path to prevent false tripping (inductive

loads normally do not need delay). This is accomplished

by the current limit delay network shown in Figure 5. R

D

and CD delay the overcurrent trip for drain currents up to

approximately 10 • I

, above which the diode conducts

SET

and provides immediate turn-off (see Figure 7). To ensure

proper operation of the timer, CD must be ≤CT.

10

)

D

C

D

1

0.1

TRIP DELAY TIME (1 = R

0.01

1

MOSFET DRAIN CURRENT (1 = SET CURRENT)

Figure 7. Current Limit Delay Time

10 100

1910 F07

Printed Circuit Board Shunts

The sheet resistance of 1oz copper clad is approximately

5 • 10–4Ω/square with a temperature coefficient of

0.39%/°C. Since the LT1910 drain sense threshold has a

similar temperature coefficient (0.33%/°C), this offers the

possibility of nearly zero TC current sensing using the

“free”

drain sense resistor made out of PC trace material.

A conservative approach is to use 0.02" of width for each

1A of current for 1oz copper. Combining the LT1910 drain

sense threshold with the 1oz copper resistance results in

a simple expression for width and length:

Width (1oz Cu) = 0.02" • I

SET

Length (1oz Cu) = 2"

The width for 2oz copper would be halved while the length

would remain the same.

Bends may be incorporated into the resistor to reduce

space; each bend is equivalent to approximately 0.6 • the

width of a straight length. Kelvin connection should be

employed by running a separate trace from the ends of the

resistor back to the LT1910’s V+ and SENSE pins. See

Application Note 53 for further information on printed

circuit board shunts.

1910i

9

Page 10

LT1910

WUUU

APPLICATIO S I FOR ATIO

Low Voltage/Wide Supply Range Operation

When the supply is less than 12V, the LT1910’s charge

pump does not produce sufficient gate voltage to fully

enhance the standard N-channel MOSFET. For these applications, a logic-level MOSFET can be used to extend the

operating supply down to 8V. If the MOSFET has a maximum VGS rating of 15V or greater, then the LT1910 can

also operate up to a supply voltage of 60V (absolute

maximum rating of the V+ pin).

Protecting Against Supply Transients

The LT1910 is 100% tested and guaranteed to be safe

from damage with 60V applied between the V+ and GND

pins. However, when this voltage is exceeded, even for a

few microseconds, the result can be catastrophic. For this

reason it is imperative that the LT1910 is not exposed to

supply transients above 60V. A transient suppressor, such

as Diodes Inc.’s SMAJ48A, should be added between the

V+ and GND pins for such applications.

For proper current sense operation, the V+ pin is required

to be connected to the positive side of the drain sense

resistor (see Drain Sense Configuration). Therefore, the

supply should be adequately decoupled at the node where

the V+ pin and drain sense resistor meet. Several hundred

microfarads may be required when operating with a high

current switch.

When the operating voltage approaches the 60V absolute

maximum rating of the LT1910, local supply decoupling

between the V+ and GND pins is highly recommended. An

RC snubber with a transient suppressor are an absolute

necessity. Note however that resistance should not be

added in series with the V+ pin because it will cause an

error in the current sense threshold.

Low Side Driving

Although the LT1910 is primarily targeted at high side

(grounded load) switch applications, it can also be used

for low side (supply connected load) switch applications.

Figures 8a and 8b illustrate the LT1910 driving low side

power MOSFETs. Because the LT1910 charge pump tries

to pump the gate of the N-channel MOSFET above the

supply, a clamp zener is required to prevent the V

GS

(absolute maximum) of the MOSFET from being exceeded.

12V TO 48V

5V

R1

5.1k

FAULT OUTPUT

INPUT

3

FAULTINV

4

LT1910

2

GND

C

T

1µF

0V

SENSE

GATETIMER

1

8

+

6

+

C1

100µF

100V

5

15V

1N4744

Figure 8a. Low Side Driver with Load Current Sensing

4A

LOAD

R

S

0.01Ω

(PTC)

Q1

IRFZ44

1910 F08a

10

FAULT OUTPUT

INPUT

5V

R1

5.1k

3

4

2

FAULT

IN

TIMER

C

T

1µF

LT1910

GND

8V TO 24V HV

8

+

SENSE

GATE

1

V

10µF

50V

6

5

+

C1

2N2222

51Ω

1N4744

LT1006

51Ω

Figure 8b. Low Side Driver for Source Current Sensing

15V

HV

LOAD

Q1

IRF630

+

R

S

0.02Ω

–

1910 F08b

1910i

Page 11

WUUU

APPLICATIO S I FOR ATIO

LT1910

The LT1910 gate drive is current limited for this purpose

so that no resistance is needed between the GATE pin and

zener.

Current sensing for protecting low side drivers can be

done in several ways. In the Figure 8a circuit, the supply

voltage for the load is assumed to be within the supply

operating range of the LT1910. This allows the load to be

returned to supply through current sense resistor RS,

providing normal operation of the LT1910 protection

circuitry.

U

PACKAGE DESCRIPTIO

S8 Package

8-Lead Plastic Small Outline (Narrow .150 Inch)

(Reference LTC DWG # 05-08-1610)

If the load cannot be returned to supply through RS, or the

load supply voltage is higher than the LT1910 supply, the

current sense must be moved to the source of the low side

MOSFET.

Figure 8b shows an approach to source sensing. An

operational amplifier (must common mode to ground) is

used to level shift the voltage across RS up to the drain

sense pin. This approach allows the use of a small sense

resistor which could be made from PC trace material. The

LT1910 restart timer functions the same as in the high side

switch application.

0.189 – 0.197*

(4.801 – 5.004)

7

8

5

6

0.228 – 0.244

(5.791 – 6.197)

0.010 – 0.020

(0.254 – 0.508)

0.008 – 0.010

(0.203 – 0.254)

*

DIMENSION DOES NOT INCLUDE MOLD FLASH. MOLD FLASH

SHALL NOT EXCEED 0.006" (0.152mm) PER SIDE

**

DIMENSION DOES NOT INCLUDE INTERLEAD FLASH. INTERLEAD

FLASH SHALL NOT EXCEED 0.010" (0.254mm) PER SIDE

×

°

45

0.016 – 0.050

(0.406 – 1.270)

0°– 8° TYP

0.053 – 0.069

(1.346 – 1.752)

0.014 – 0.019

(0.355 – 0.483)

TYP

0.150 – 0.157**

(3.810 – 3.988)

1

3

2

4

0.004 – 0.010

(0.101 – 0.254)

0.050

(1.270)

BSC

SO8 1298

1910i

11

Page 12

LT1910

TYPICAL APPLICATIO

Protected 1A Automotive Solenoid Driver with Overvoltage Shutdown

8V TO 24V OPERATING

32V TO 60V SHUTDOWN

POWER

GROUND

U

FAULT OUTPUT

30V

1N6011B

R2

10k

R3

5.1k

INPUT

5V

1N4148

2N3904

R1

5.1k

3

4

2

FAULT

IN

TIMER

C

T

1µF

LT1910

SENSE

GND

1

GATE

R

8

+

V

6

5

+

C1

10µF

100V

S

0.03Ω

(PTC)

Q1

MTD3055EL

24V

1A

SOLENOID

1910 TA03

RELATED PARTS

PART NUMBER DESCRIPTION COMMENTS

LTC®1153 Autoreset Electronic Circuit Breaker Programmable Trip Current, Fault Status Output

LTC1155 Dual High Side Micropower MOSFET Driver Operates from 4.5V to 18V, 85µA ON Current, Short-Circuit Protection

LT1161 Quad Protected High Side MOSFET Driver 8V to 48V Supply Range, Individual Short-Circuit Protection

LTC1163 Triple 1.8V to 6V High Side MOSFET Driver 0.01µA Standby Current, Triple Driver in SO-8 Package

LTC1255 Dual 24V High Side MOSFET Driver Operates from 9V to 24V, Short-Circuit Protection

LTC1477 Protected Monolithic High Side Switch Low R

LTC1623 SMBus Dual High Side Switch Controller 2-Wire SMBus Serial Interface, Built-In Gate Charge Pumps

LTC1693 Family High Speed Single/Dual N-Channel/P-Channel 1.5A Peak Output Current, 4.5V ≤ VCC ≤ 13.2V, SO-8 Package

MOSFET Drivers

LTC1710 SMBus Dual Monolithic High Side Switch Two Low R

LTC4412 Low Loss PowerPathTM Controller Implements “Ideal Diode” Function, ThinSOTTM Package

PowerPath and ThinSOT are trademarks of Linear Technology Corporation.

0.07Ω Switch, 2A Short-Circuit Protected

DS(ON)

0.4Ω/300mA Switches in 8-Lead MSOP Package

DS(ON)

12

Linear Technology Corporation

1630 McCarthy Blvd., Milpitas, CA 95035-7417

(408) 432-1900 ● FAX: (408) 434-0507

●

www.linear.com

1910i

LT/TP 0802 1.5K • PRINTED IN USA

LINEAR TECHNOLOGY CORPORATION 2002

Loading...

Loading...