Page 1

FEATURES

LINE VOLTAGE (V

P-P

)

0

HARMONIC DISTORTION (dBc)

–60

–70

–80

–90

–100

1886 TA01a

2 4 6 8 10 12 14 16

VS = 12V

A

V

= 10

f = 200kHz

100Ω LINE

1:2 TRANSFORMER

HD2

HD3

■

700MHz Gain Bandwidth

■

±200mA Minimum I

■

Low Distortion: –72dBc at 1MHz, 4V

■

Stable in AV ≥ 10, Simple Compensation for AV < 10

■

±4.3V Minimum Output Swing, VS = ±6V, RL = 25Ω

■

7mA Supply Current per Amplifier

■

200V/µs Slew Rate

■

Stable with 1000pF Load

■

6nV/√Hz Input Noise Voltage

■

2pA/√Hz Input Noise Current

■

4mV Maximum Input Offset Voltage

■

4µA Maximum Input Bias Current

■

400nA Maximum Input Offset Current

■

±4.5V Minimum Input CMR, VS = ±6V

■

Specified at ±6V, ±2.5V

OUT

, 25Ω, A

P-P

U

APPLICATIO S

V

= 2

LT1886

Dual 700MHz, 200mA

Operational Amplifier

U

DESCRIPTIO

The LT®1886 is a 200mA minimum output current dual op

amp with outstanding distortion performance. The amplifiers are gain-of-ten stable, but can be easily compensated

for lower gains. The LT1886 features balanced, high

impedance inputs with 4µA maximum input bias current,

and 4mV maximum input offset voltage. Single supply

applications are easy to implement and have lower total

noise than current feedback amplifier implementations.

The output drives a 25Ω load to ±4.3V with ±6V supplies.

On ±2.5V supplies the output swings ±1.5V with a 100Ω

load. The amplifier is stable with a 1000pF capacitive

load which makes it useful in buffer and cable driver

applications.

The LT1886 is manufactured on Linear Technology’s

advanced low voltage complementary bipolar process and

is available in a thermally enhanced SO-8 package.

■

DSL Modems

■

xDSL PCI Cards

■

USB Modems

■

Line Drivers

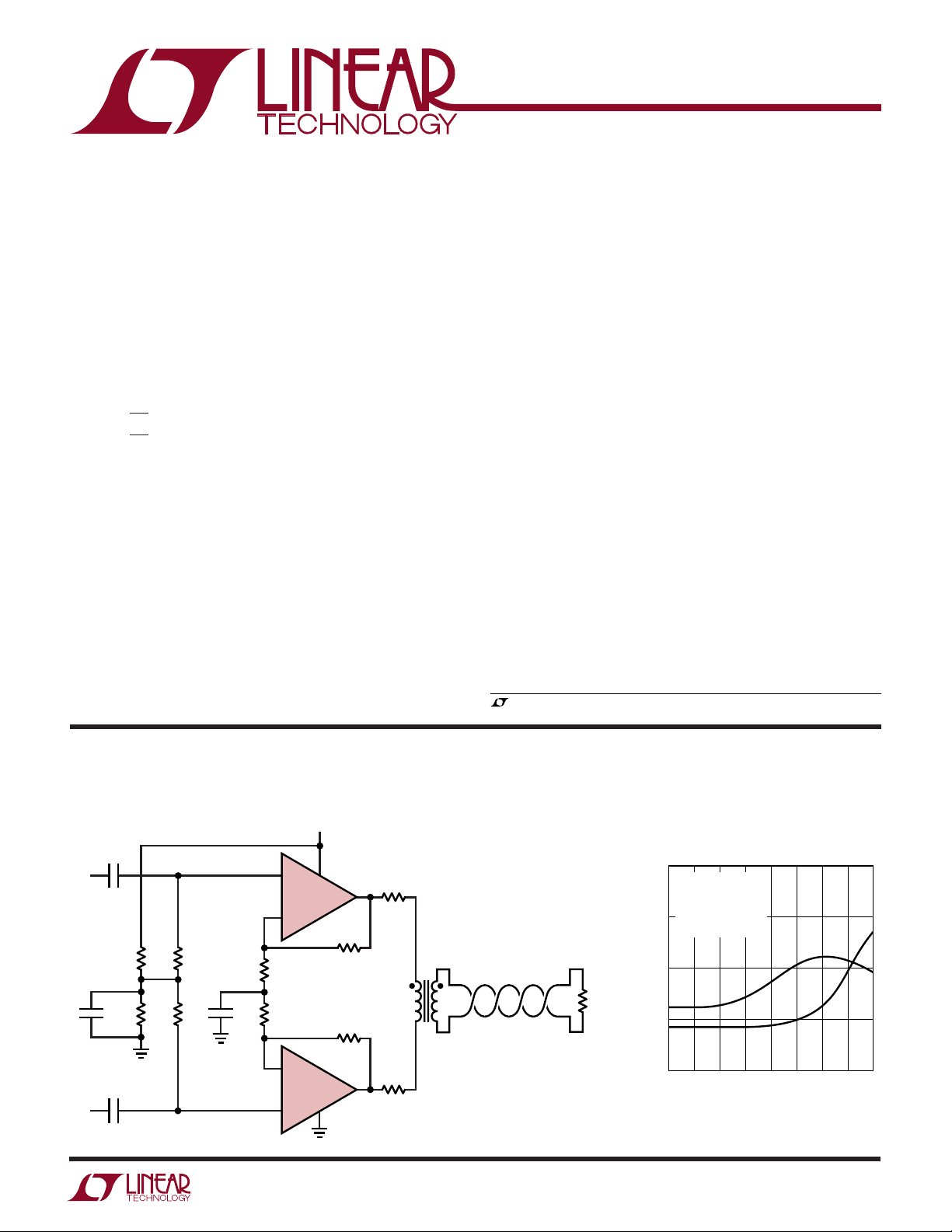

TYPICAL APPLICATIO

0.1µF

+

IN

1µF

0.1µF

–

IN

10k 20k

U

Single 12V Supply ADSL Modem Line Driver

12V

+

1/2 LT1886

–

100Ω

20k10k

1µF

100Ω

–

1/2 LT1886

+

909Ω

909Ω

12.4Ω

12.4Ω

1:2*

1886 TA01

, LTC and LT are registered trademarks of Linear Technology Corporation.

ADSL Modem Line Driver Distortion

100Ω

*COILCRAFT X8390-A

OR EQUIVALENT

1

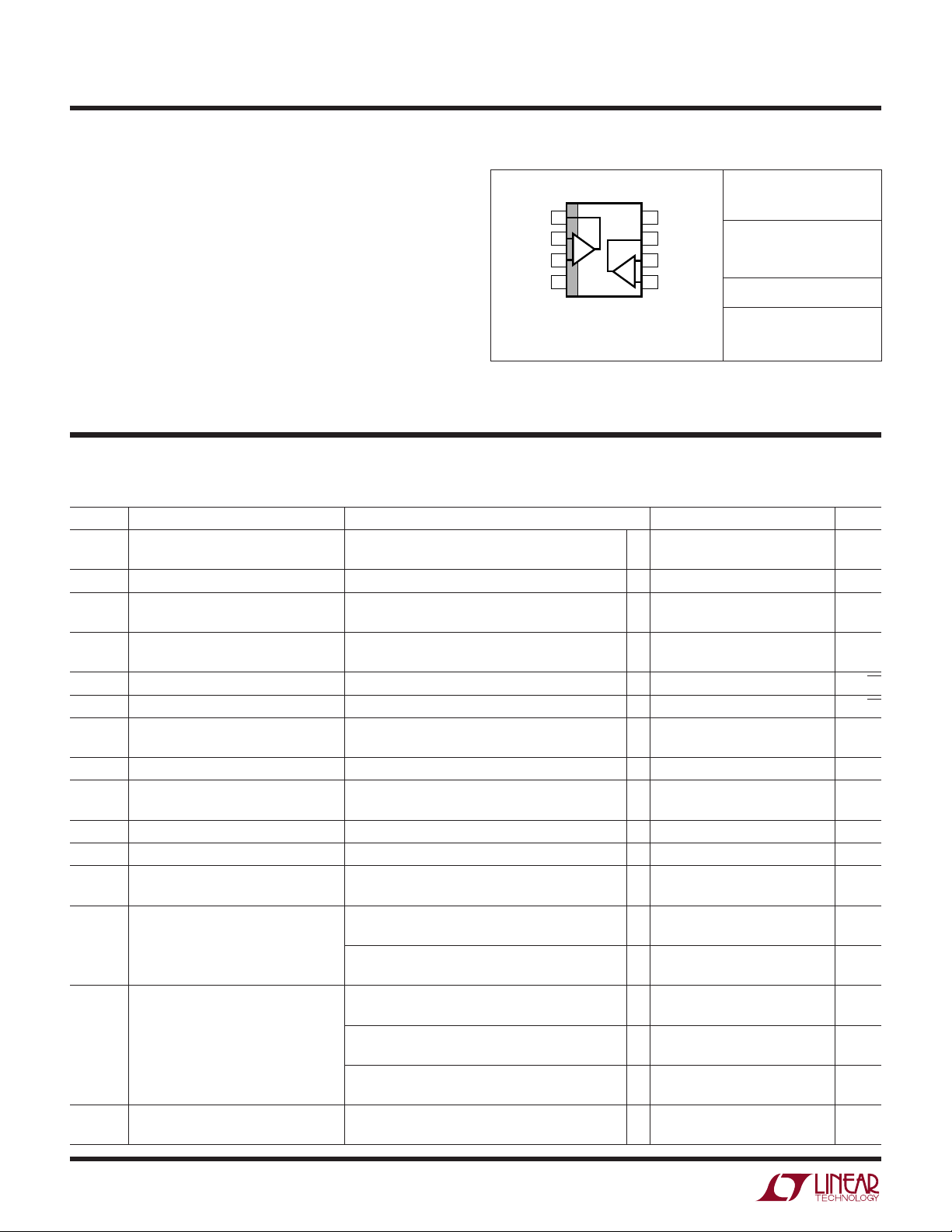

Page 2

LT1886

1

2

3

4

8

7

6

5

TOP VIEW

V

+

OUT B

–IN B

+IN B

OUT A

–IN A

+IN A

V

–

S8 PACKAGE

8-LEAD PLASTIC SO

B

A

WW

W

ABSOLUTE MAXIMUM RATINGS

U

PACKAGE

/

O

RDER I FOR ATIO

WU

(Note 1)

Total Supply Voltage (V+ to V–) ........................... 13.2V

Input Current (Note 2) ....................................... ±10mA

Input Voltage (Note 2) ............................................ ±V

Maximum Continuous Output Current (Note 3)

S

ORDER PART

NUMBER

LT1886CS8

DC ............................................................... ±100mA

AC ............................................................... ±300mA

Operating Temperature Range (Note 10) –40°C to 85°C

Specified Temperature Range (Note 9).. – 40°C to 85°C

T

= 150°C, θJA = 80°C/W (Note 4)

JMAX

S8 PART MARKING

1886

Maximum Junction Temperature ......................... 150°C

Storage Temperature Range ................ –65°C to 150°C

Consult factory for Industrial and Military grade parts.

Lead Temperature (Soldering, 10 sec)................. 300°C

ELECTRICAL CHARACTERISTICS

erature range, otherwise specifications are at T

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

V

OS

I

OS

I

B

e

n

i

n

R

IN

C

IN

CMRR Common Mode Rejection Ratio VCM = ±4.5V ● 77 98 dB

PSRR Power Supply Rejection Ratio VS = ±2V to ±6.5V 80 86 dB

A

VOL

V

OUT

I

SC

Input Offset Voltage (Note 5) 1 4 mV

Input Offset Voltage Drift (Note 8) ● 317µV/°C

Input Offset Current 150 400 nA

Input Bias Current 1.5 4 µA

Input Noise Voltage f = 10kHz 6 nV/√Hz

Input Noise Current f = 10kHz 2 pA/√Hz

Input Resistance VCM = ±4.5V 5 10 MΩ

Input Capacitance 2pF

Input Voltage Range (Positive) ● 4.5 5.9 V

Input Voltage Range (Negative)

Minimum Supply Voltage Guaranteed by PSRR ● ±2V

Large-Signal Voltage Gain V

Output Swing RL = 100Ω, 10mV Overdrive 4.85 5 ±V

Short-Circuit Current (Sourcing) (Note 3) 800 mA

Short-Circuit Current (Sinking) 500 mA

= 25°C. VS = ±6V, V

A

Differential 35 kΩ

= ±4V, RL = 100Ω 5.0 12 V/mV

OUT

V

= ±4V, RL = 25Ω 4.5 12 V/mV

OUT

RL = 25Ω, 10mV Overdrive 4.30 4.6 ±V

I

= 200mA, 10mV Overdrive 4.30 4.5 ±V

OUT

The ● denotes specifications which apply over the full operating temp-

= 0V, pulse power tested unless otherwise noted. (Note 9)

CM

● 5mV

● 600 nA

● 6 µA

● –5.2 –4.5 V

● 78 dB

● 4.5 V/mV

● 4.0 V/mV

● 4.70 ±V

● 4.10 ±V

● 4.10 ±V

2

U

Page 3

LT1886

ELECTRICAL CHARACTERISTICS

erature range, otherwise specifications are at T

= 25°C. VS = ±6V, V

A

The ● denotes specifications which apply over the full operating temp-

= 0V, pulse power tested unless otherwise noted. (Note 9)

CM

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

SR Slew Rate AV = –10 (Note 6) 133 200 V/µs

● 110 V/µs

Full Power Bandwidth 4V Peak (Note 7) 8 MHz

GBW Gain Bandwidth f = 1MHz 700 MHz

tr, t

Rise Time, Fall Time AV = 10, 10% to 90% of 0.1V, RL = 100Ω 4ns

f

Overshoot AV = 10, 0.1V, RL = 100Ω 1%

Propagation Delay AV = 10, 50% VIN to 50% V

t

S

Settling Time 6V Step, 0.1% 50 ns

Harmonic Distortion HD2, AV = 10, 2V

= 10, 2V

HD3, A

V

, f = 1MHz, RL = 100Ω/25Ω – 75/–63 dBc

P-P

, f = 1MHz, RL = 100Ω/25Ω – 85/–71 dBc

P-P

, 0.1V, RL = 100Ω 2.5 ns

OUT

IMD Intermodulation Distortion AV = 10, f = 0.9MHz, 1MHz, 14dBm, RL = 100Ω/25Ω –81/–80 dBc

R

OUT

I

S

Output Resistance AV = 10, f = 1MHz 0.1 Ω

Channel Separation V

= ±4V, RL = 25Ω 82 92 dB

OUT

● 80 dB

Supply Current Per Amplifier 7 8.25 mA

● 8.50 mA

The ● denotes specifications which apply over the full operating temperature range, otherwise specifications are at TA = 25°C.

V

= ±2.5V, V

S

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

V

OS

I

OS

I

B

e

n

i

n

R

IN

C

IN

CMRR Common Mode Rejection Ratio VCM = ±1V ● 75 91 dB

A

VOL

V

OUT

= 0V, pulse power tested unless otherwise noted. (Note 9)

CM

Input Offset Voltage (Note 5) 1.5 5 mV

● 6mV

Input Offset Voltage Drift (Note 8) ● 517µV/°C

Input Offset Current 100 350 nA

● 550 nA

Input Bias Current 1.2 3.5 µA

● 5.5 µA

Input Noise Voltage f = 10kHz 6 nV/√Hz

Input Noise Current f = 10kHz 2 pA/√Hz

Input Resistance VCM = ±1V 10 20 MΩ

Differential 50 kΩ

Input Capacitance 2pF

Input Voltage Range (Positive) ● 1 2.4 V

Input Voltage Range (Negative)

Large-Signal Voltage Gain V

= ±1V, RL = 100Ω 5.0 10 V/mV

OUT

V

= ±1V, RL = 25Ω 4.5 10 V/mV

OUT

● –1.7 –1 V

● 4.5 V/mV

● 4.0 V/mV

Output Swing RL = 100Ω, 10mV Overdrive 1.50 1.65 ±V

● 1.40 ±V

RL = 25Ω, 10mV Overdrive 1.35 1.50 ±V

● 1.25 ±V

I

= 200mA, 10mV Overdrive 0.87 1 ±V

OUT

● 0.80 ±V

3

Page 4

LT1886

ELECTRICAL CHARACTERISTICS

erature range, otherwise specifications are at T

= 25°C. VS = ±2.5V, V

A

The ● denotes specifications which apply over the full operating temp-

= 0V, pulse power tested unless otherwise noted. (Note 9)

CM

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

I

SC

Short-Circuit Current (Sourcing) (Note 3) 600 mA

Short-Circuit Current (Sinking) 400 mA

SR Slew Rate AV = –10 (Note 6) 66 100 V/µs

● 60 V/µs

Full Power Bandwidth 1V Peak (Note 7) 16 MHz

GBW Gain Bandwidth f = 1MHz 530 MHz

tr, t

Rise Time, Fall Time AV = 10, 10% to 90% of 0.1V, RL = 100Ω 7ns

f

Overshoot AV = 10, 0.1V, RL = 100Ω 5%

Propagation Delay AV = 10, 50% VIN to 50% V

Harmonic Distortion HD2, AV = 10, 2V

= 10, 2V

HD3, A

V

, f = 1MHz, RL = 100Ω/25Ω – 75/–64 dBc

P-P

, f = 1MHz, RL = 100Ω/25Ω – 80/–66 dBc

P-P

, 0.1V, RL = 100Ω 5ns

OUT

IMD Intermodulation Distortion AV = 10, f = 0.9MHz, 1MHz, 5dBm, RL = 100Ω/25Ω – 77/–85 dBc

R

OUT

I

S

Note 1: Absolute Maximum Ratings are those values beyond which the life

of a device may be impaired.

Note 2: The inputs are protected by back-to-back diodes. If the differential

input voltage exceeds 0.7V, the input current should be limited to less than

10mA.

Note 3: A heat sink may be required to keep the junction temperature

below absolute maximum.

Note 4: Thermal resistance varies depending upon the amount of PC board

metal attached to the device. θ

covered with 2 oz copper on both sides.

Note 5: Input offset voltage is exclusive of warm-up drift.

Output Resistance AV = 10, f = 1MHz 0.2 Ω

Channel Separation V

= ±1V, RL = 25Ω 82 92 dB

OUT

● 80 dB

Supply Current Per Amplifier 5 5.75 mA

● 6.25 mA

Note 6: Slew rate is measured between ±2V on a ±4V output with ±6V

supplies, and between ±1V on a ±1.5V output with ±2.5V supplies.

Note 7: Full power bandwidth is calculated from the slew rate:

FPBW = SR/2πV

.

P

Note 8: This parameter is not 100% tested.

Note 9: The LT1886C is guaranteed to meet specified performance from 0°C

to 70°C. The LT1886C is designed, characterized and expected to meet

specified performance from –40°C to 85°C but is not tested or QA sampled

is specified for a 2500mm2 test board

JA

at these temperatures. For guaranteed I-grade parts, consult the factory.

Note 10: The LT1886C is guaranteed functional over the operating temperature

range of –40°C to 85°C.

UW

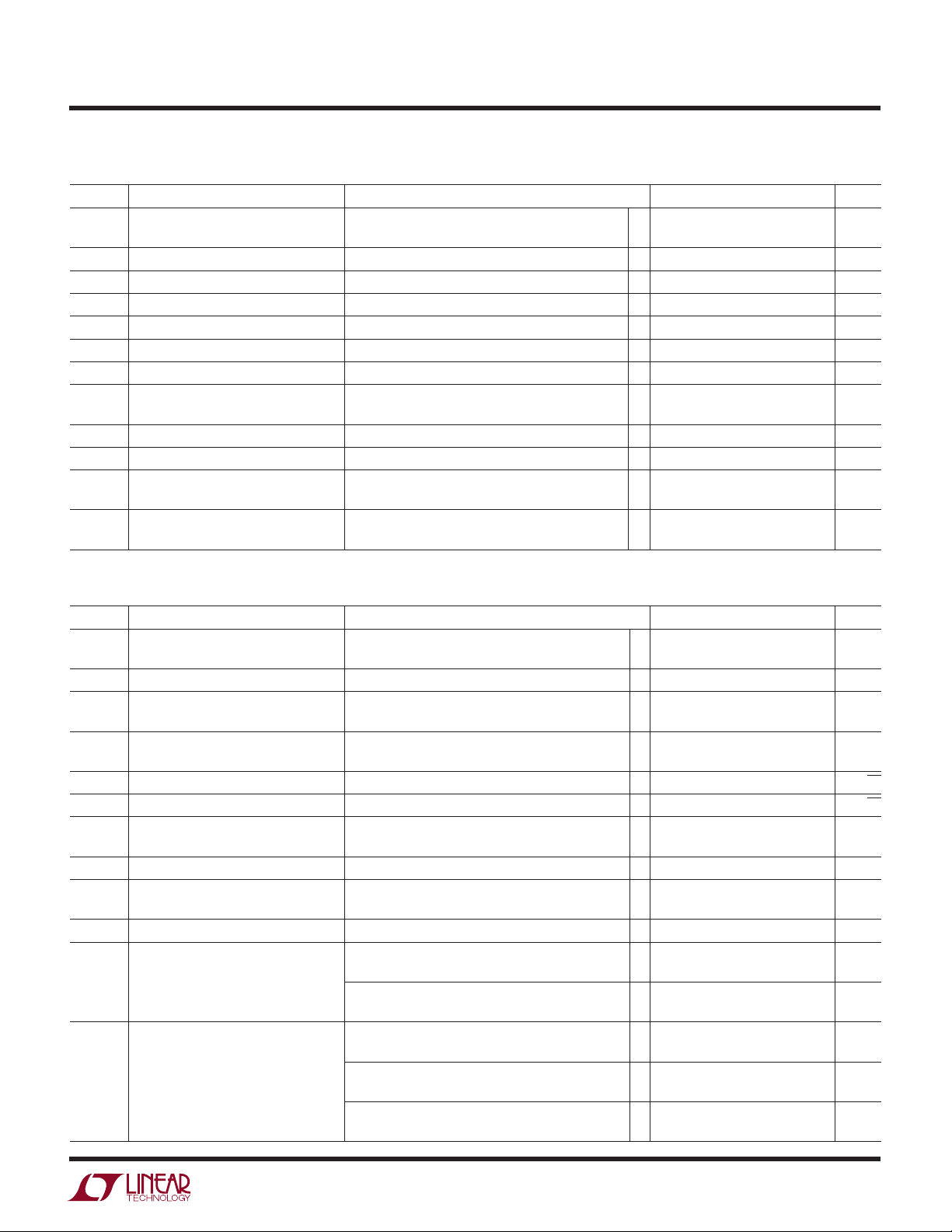

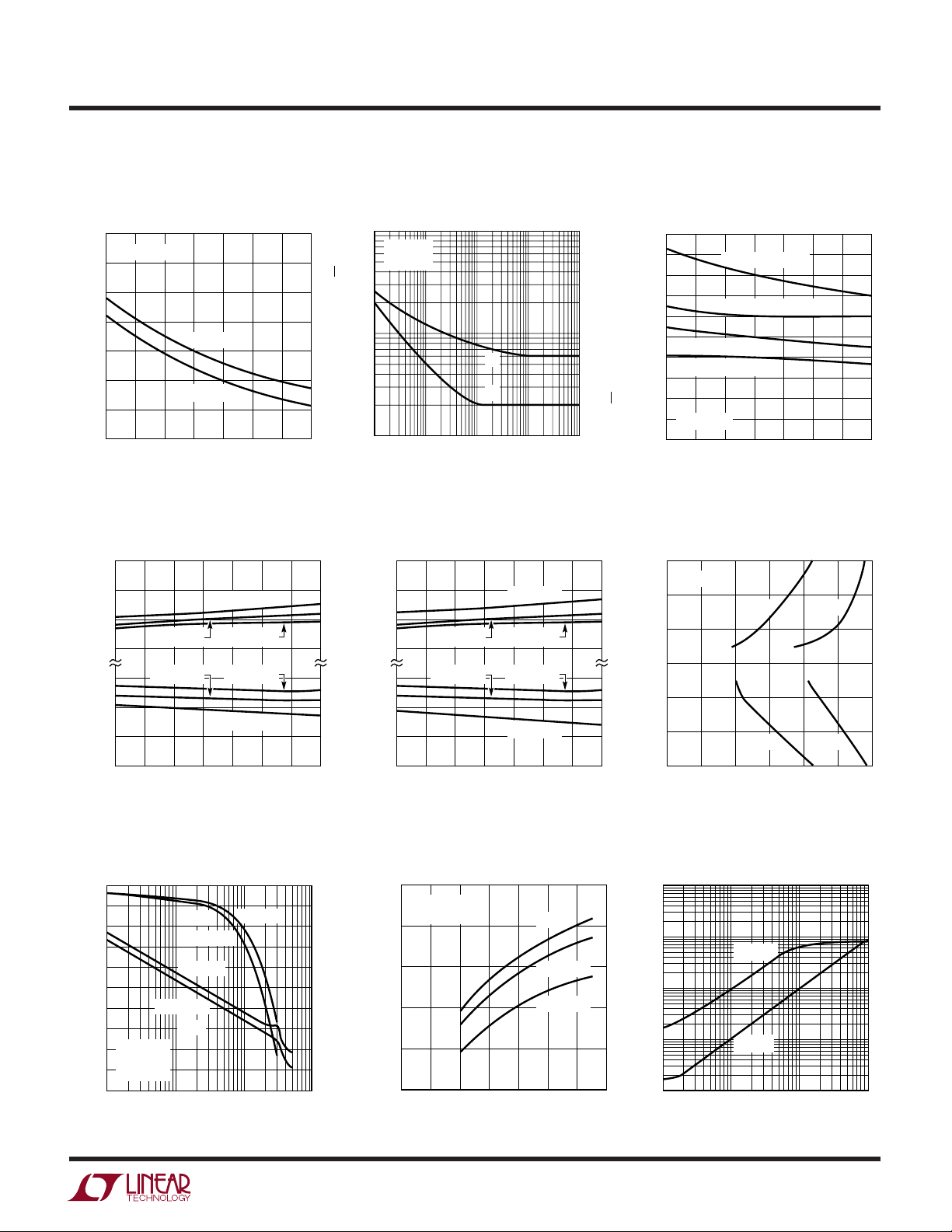

TYPICAL PERFOR A CE CHARACTERISTICS

Input Common Mode Range vs

Supply Current vs Temperature

15

VS = ±6V

10

VS = ±2.5V

5

SUPPLY CURRENT (mA)

0

–50 –25 0 25 50 75 100 125

TEMPERATURE (°C)

1886 G01

Supply Voltage

+

V

–0.1

–0.2

–0.3

TA = 25°C

> 1mV

∆V

1.5

1.0

COMMON MODE RANGE (V)

0.5

V

OS

–

0 2 4 6 8 10 12 14

TOTAL SUPPLY VOLTAGE (V)

4

1886 G02

Input Bias Current vs Input

Common Mode Voltage

3.0

TA = 25°C

= (I

+ + IB–)/2

I

B

2.5

2.0

1.5

1.0

INPUT BIAS CURRENT (µA)

0.5

0

B

VS = ±6V

VS = ±2.5V

–6 –2 2–4 0 4 6

INPUT COMMON MODE VOLTAGE (V)

1886 G03

Page 5

UW

TYPICAL PERFOR A CE CHARACTERISTICS

LT1886

Input Bias Current vs

Temperature Input Noise Spectral Density

3.5

IB = (I

+ + IB–)/2

3.0

2.5

2.0

1.5

1.0

INPUT BIAS CURRENT (µA)

0.5

0

B

VS = ±6V

VS = ±2.5V

–50 –25 0 25 50 75 100 125

TEMPERATURE (°C)

Output Saturation Voltage vs

Temperature, V

+

V

–0.5

–1.0

–1.5

1.5

1.0

0.5

OUTPUT SATURATION VOLTAGE (V)

–

V

IL = 150mA IL = 200mA

IL = 150mA IL = 200mA

–50 –25 0 25 50 75 100 125

= ±6V

S

RL = 100Ω

RL = 100Ω

TEMPERATURE (°C)

1886 G04

1886 G07

100

TA = 25°C

= 101

A

V

10

INPUT VOLTAGE NOISE (nV/√Hz)

1

10

1k 100k100 10k

FREQUENCY (Hz)

Output Saturation Voltage vs

Temperature, V

+

V

–0.5

–1.0

–1.5

1.5

1.0

0.5

OUTPUT SATURATION VOLTAGE (V)

–

V

–50 –25 0 25 50 75 100 125

IL = 150mA IL = 200mA

IL = 150mA IL = 200mA

TEMPERATURE (°C)

Output Short-Circuit Current vs

Temperature

100

10

e

n

i

n

1

1886 G05

= ±2.5V Settling Time vs Output Step

S

RL = 100Ω

RL = 100Ω

1886 G08

1000

900

INPUT CURRENT NOISE (pA/√Hz)

800

700

600

500

400

300

200

100

OUTPUT SHORT-CIRCUIT CURRENT (mA)

0

–50 –25 0 25 50 75 100 125

6

4

2

0

–2

OUTPUT STEP (V)

–4

–6

0204010 30 50 60

SOURCE, VS = ±6V

SOURCE, VS = ±2.5V

SINK, VS = ±6V

SINK, VS = ±2.5V

∆VIN = 0.2V

TEMPERATURE (°C)

VS = ±6V

SETTLING TIME (ns)

10mV 1mV

10mV 1mV

1886 G06

1886 G09

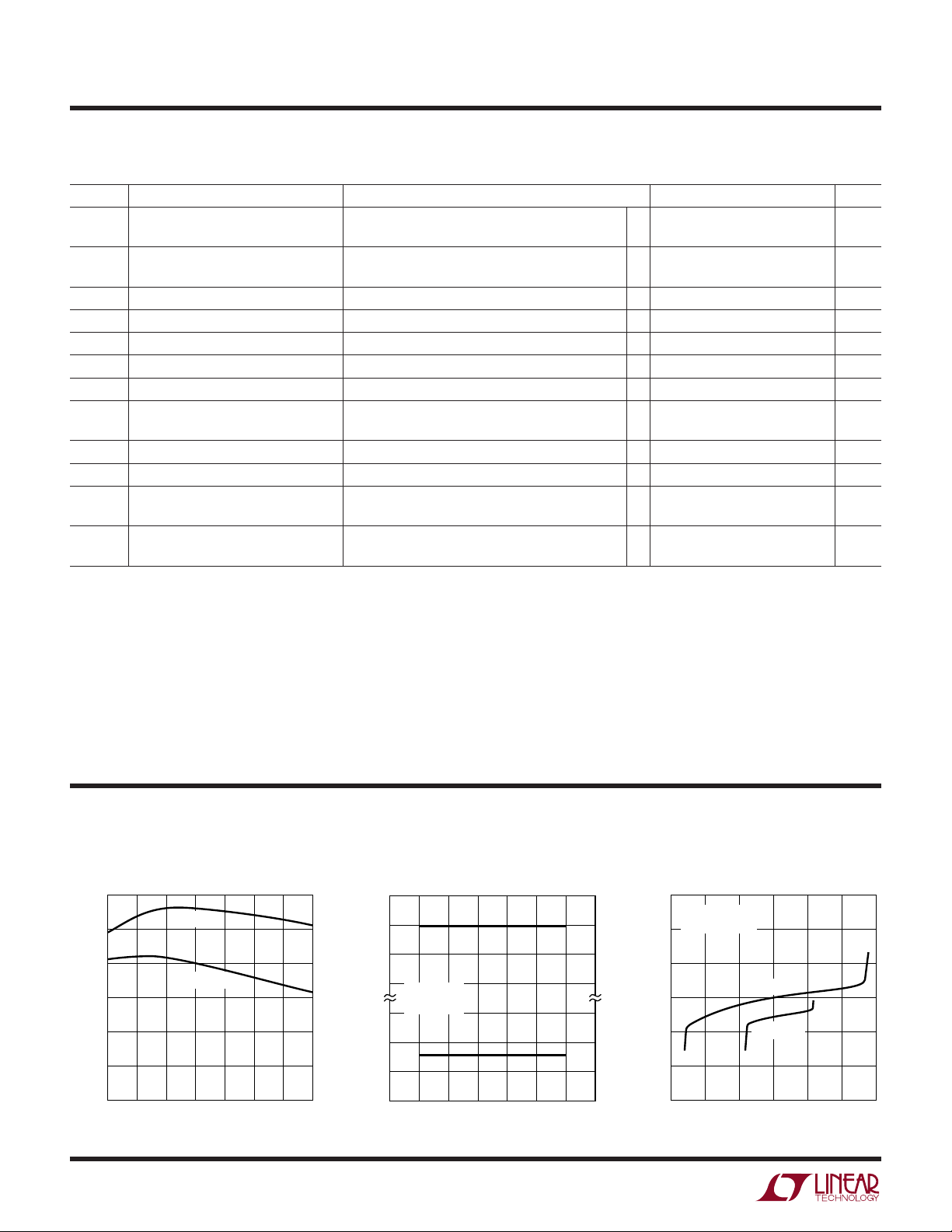

Gain and Phase vs Frequency

80

70

60

50

40

30

GAIN (dB)

20

10

0

–10

–20

1M

TA = 25°C

= –10

A

V

= 100Ω

R

L

PHASE

VS = ±2.5V

VS = ±6V

VS = ±2.5V

GAIN

10M 100M 1G

FREQUENCY (Hz)

VS = ±6V

1886 G10

100

80

60

40

PHASE (DEG)

20

0

–20

–40

–60

–80

–100

Gain Bandwidth vs Supply

Voltage Output Impedance vs Frequency

800

TA = 25°C

= –10

A

V

700

600

500

GAIN BANDWIDTH (MHz)

400

300

2 4 6 8 10 12 14

0

TOTAL SUPPLY VOLTAGE (V)

RL = 1k

RL = 100Ω

RL = 25Ω

1886 G11

100

10

1

0.1

OUTPUT IMPEDANCE (Ω)

0.01

100k 10M 100M

AV = 100

AV = 10

1M

FREQUENCY (Hz)

1886 G12

5

Page 6

LT1886

UW

TYPICAL PERFOR A CE CHARACTERISTICS

Frequency Response vs Supply

Voltage, AV = 10

23

TA = 25°C

22

= 10

A

V

21

= 100Ω

R

L

20

19

18

GAIN (dB)

17

16

15

14

13

1M 100M 1G

VS = ±2.5V

10M

FREQUENCY (Hz)

VS = ±6V

Frequency Response vs Supply

Voltage, AV = –1

3

2

1

0

–1

–2

TA = 25°C

GAIN (dB)

–3

A

V

R

L

–4

R

F

–5

R

C

C

C

–6

SEE FIGURE 2

–7

1M 100M 1G

= –1

= 100Ω

= RG = 1k

= 124Ω

= 100pF

VS = ±2.5V

VS = ±6V

10M

FREQUENCY (Hz)

1886 G13

1886 G16

Frequency Response vs Supply

Voltage, AV = –10

23

TA = 25°C

22

= –10

A

V

21

= 100Ω

R

L

20

19

18

GAIN (dB)

17

16

15

14

13

1M 100M 1G

VS = ±2.5V

10M

FREQUENCY (Hz)

VS = ±6V

1886 G14

Frequency Response vs Supply

Voltage, AV = 2

9

8

7

6

5

4

TA = 25°C

GAIN (dB)

3

A

V

R

2

R

R

1

C

C

0

SEE FIGURE 3

–1

1M 100M 1G

= 2

= 100Ω

L

= RG = 1k

F

= 124Ω

C

= 100pF

VS = ±2.5V

VS = ±6V

10M

FREQUENCY (Hz)

Frequency Response vs

Capacitive Load Slew Rate vs Temperature

38

VS = ±6V

35

= 25°C

T

A

32

= 10

A

V

NO R

29

26

23

GAIN (dB)

20

17

14

11

8

L

1M 100M 1G

10M

FREQUENCY (Hz)

1000pF

500pF

200pF

100pF

50pF

1886 G17

350

AV = –10

300

250

200

150

SLEW RATE (V/µs)

100

= 100Ω

R

L

VS = ±6V

VS = ±2.5V

50

0

–50 –25 0 25 50 75 100 125

TEMPERATURE (°C)

1886 G15

+SR

–SR

+SR

–SR

1886 G18

Power Supply Rejection vs

Frequency

100

90

80

70

60

50

40

30

20

POWER SUPPLY REJECTION (dB)

10

0

100k 10M 100M

(–) SUPPLY

(+) SUPPLY

1M

FREQUENCY (Hz)

6

VS = ±6V

= 10

A

V

1886 G19

Common Mode Rejection Ratio vs

Frequency Amplifier Crosstalk vs Frequency

100

90

80

70

60

50

40

30

20

10

COMMON MODE REJECTION RATIO (dB)

0

100k 10M 100M

1M

FREQUENCY (Hz)

VS = ±6V

= 25°C

T

A

1886 G20

0

VS = ±6V

–10

= 10

A

V

–20

= 100Ω

R

L

INPUT = –20dBm

–30

–40

–50

–60

–70

–80

OUTPUT TO INPUT CROSSTALK (dB)

–90

–100

1M 100M 1G

B → A

A → B

10M

FREQUENCY (Hz)

1886 G21

Page 7

UW

PEAK OUTPUT CURRENT (mA)

HIGHEST HARMONIC DISTORTION (dBc)

0

1886 G30

–30

–40

–50

–60

–70

–80

100

200 300 400 500

RL = 5Ω

RL = 10Ω

TA = 25°C

A

V

= 10

f = 1MHz

RL = 25Ω

TYPICAL PERFOR A CE CHARACTERISTICS

LT1886

Harmonic Distortion vs

Frequency, AV = 10, V

0

TA = 25°C

–10

–20

–30

–40

–50

–60

DISTORTION (dBc)

–70

–80

–90

–100

100k

= 10

A

V

OUT

2V

P-P

RL = 25Ω

FREQUENCY (Hz)

= ±6V

S

2nd

3rd

1M 10M

Harmonic Distortion vs Resistive

Load

0

TA = 25°C

–10

= ±2.5V

V

S

–20

= 10

A

V

OUT

2V

P-P

–30

f = 1MHz

–40

–50

–60

DISTORTION (dBc)

–70

–80

–90

–100

1 100 1k

10

LOAD RESISTANCE (Ω)

2nd

3rd

2nd

3rd

RL = 100Ω

1886 G22

1886 G25

Harmonic Distortion vs

Frequency, AV = 10, V

0

TA = 25°C

–10

–20

–30

–40

–50

–60

DISTORTION (dBc)

–70

–80

–90

–100

100k

A

2V

= 10

V

P-P

OUT

RL = 25Ω

FREQUENCY (Hz)

= ±2.5V

S

2nd

2nd

3rd

3rd

RL = 100Ω

1M 10M

Harmonic Distortion vs Output

Swing, AV = 10, V

0

TA = 25°C

–10

f = 1MHz

–20

–30

–40

–50

–60

DISTORTION (dBc)

–100

2nd

–70

3rd

–80

2nd

–90

3rd

024681012

OUTPUT VOLTAGE (V

= ±6V

S

RL = 25Ω

RL = 100Ω

P-P

)

1886 G23

1886 G26

Harmonic Distortion vs Resistive

Load

0

TA = 25°C

–10

= ±6V

V

S

–20

= 10

A

V

OUT

2V

P-P

–30

f = 1MHz

–40

–50

–60

DISTORTION (dBc)

–70

–80

–90

–100

1 100 1k

LOAD RESISTANCE (Ω)

2nd

3rd

10

Harmonic Distortion vs Output

Swing, AV = 10, V

0

TA = 25°C

–10

f = 1MHz

–20

–30

–40

–50

–60

DISTORTION (dBc)

–70

–80

–90

–100

0

1

RL = 25Ω

2nd

3rd

2nd

3rd

OUTPUT VOLTAGE (V

= ±2.5V

S

RL = 100Ω

2 3 4 5

P-P

1886 G24

)

1886 G27

Harmonic Distortion vs Output

Swing, AV = 2, V

0

TA = 25°C

–10

= RG = 1k

R

F

–20

= 124Ω

R

C

= 100pF

C

C

–30

f = 1MHz

SEE FIGURE 3

–40

–50

–60

DISTORTION (dBc)

–70

–80

–90

–100

024681012

2nd

2nd

3rd

3rd

OUTPUT VOLTAGE (V

= ±6V

S

RL = 25Ω RL = 100Ω

)

P-P

1886 G28

Harmonic Distortion vs Output

Swing, AV = 2, V

0

TA = 25°C

–10

= RG = 1k

R

F

–20

= 124Ω

R

C

= 100pF

C

C

–30

f = 1MHz

SEE FIGURE 3

–40

–50

–60

DISTORTION (dBc)

–70

2nd

–80

3rd

2nd

–90

–100

3rd

0

1

RL = 25Ω

OUTPUT VOLTAGE (V

= ±2.5V

S

2 3 4 5

RL = 100Ω

)

P-P

1886 G29

Harmonic Distortion vs Output

Current, V

= ±6V

S

7

Page 8

LT1886

UW

TYPICAL PERFOR A CE CHARACTERISTICS

Harmonic Distortion vs Output

Current, V

–30

TA = 25°C

= 10

A

V

–40

f = 1MHz

–50

–60

–70

HIGHEST HARMONIC DISTORTION (dBc)

–80

0

= ±2.5V

S

RL = 5Ω

RL = 10Ω

RL = 25Ω

100 150 200 250

50

PEAK OUTPUT CURRENT (mA)

)

P-P

OUTPUT VOLTAGE SWING (V

1886 G30

Small-Signal Transient, AV = 10 Small-Signal Transient, AV = –10

Undistorted Output Swing vs

Frequency

12

10

8

TA = 25°C

A

6

R

1% DISTORTION

4

2

0

100k

= 10

V

= 100Ω

L

FREQUENCY (Hz)

VS = ±6V

VS = ±2.5V

1M 10M

Small-Signal Transient, AV = 10,

CL = 1000pF

1886 G32

1886 G33 1886 G34 1886 G35

Large-Signal Transient, AV = 10 Large-Signal Transient, AV = –10

1886 G36 1886 G37 1886 G38

Large-Signal Transient, AV = 10,

CL = 1000pF

8

Page 9

LT1886

U

WUU

APPLICATIO S I FOR ATIO

Input Considerations

The inputs of the LT1886 are an NPN differential pair

protected by back-to-back diodes (see the Simplified

Schematic). There are no series protection resistors

onboard which would degrade the input voltage noise. If

the inputs can have a voltage difference of more than 0.7V,

the input current should be limited to less than 10mA with

external resistance (usually the feedback resistor or source

resistor). Each input also has two ESD clamp diodes—one

to each supply. If an input drive exceeds the supply, limit

the current with an external resistor to less than 10mA.

The LT1886 design is a true operational amplifier with high

impedance inputs and low input bias currents. The input

offset current is a factor of ten lower than the input bias

current. To minimize offsets due to input bias currents,

match the equivalent DC resistance seen by both inputs.

The low input noise current can significantly reduce total

noise compared to a current feedback amplifier, especially

for higher source resistances.

Layout and Passive Components

With a gain bandwidth product of 700MHz the LT1886

requires attention to detail in order to extract maximum

performance. Use a ground plane, short lead lengths and

a combination of RF-quality supply bypass capacitors

(i.e., 470pF and 0.1µF). As the primary applications have

high drive current, use low ESR supply bypass capacitors

(1µF to 10µF). For best distortion performance with high

drive current a capacitor with the shortest possible trace

lengths should be placed between Pins 4 and 8. The

optimum location for this capacitor is on the back side of

the PC board. The DSL driver demo board (DC304) for this

part uses a Taiyo Yuden 10µF ceramic (TMK432BJ106MM).

The parallel combination of the feedback resistor and gain

setting resistor on the inverting input can combine with

the input capacitance to form a pole which can cause

frequency peaking. In general, use feedback resistors of

1kΩ or less.

Thermal Issues

The LT1886 enhanced θJA SO-8 package has the V– pin

fused to the lead frame. This thermal connection increases

the efficiency of the PC board as a heat sink. The PCB

material can be very effective at transmitting heat between

the pad area attached to the V– pin and a ground or power

plane layer. Copper board stiffeners and plated throughholes can also be used to spread the heat generated by the

device. Table 1 lists the thermal resistance for several

different board sizes and copper areas. All measurements

were taken in still air on 3/32" FR-4 board with 2oz copper.

This data can be used as a rough guideline in estimating

thermal resistance. The thermal resistance for each application will be affected by thermal interactions with other

components as well as board size and shape.

Table 1. Fused 8-Lead SO Package

COPPER AREA (2oz) TOTAL

TOPSIDE BACKSIDE COPPER AREA θJA

2500 sq. mm 2500 sq. mm 5000 sq. mm 80°C/W

1000 sq. mm 2500 sq. mm 3500 sq. mm 92°C/W

600 sq. mm 2500 sq. mm 3100 sq. mm 96°C/W

180 sq. mm 2500 sq. mm 2680 sq. mm 98°C/W

180 sq. mm 1000 sq. mm 1180 sq. mm 112°C/W

180 sq. mm 600 sq. mm 780 sq. mm 116°C/W

180 sq. mm 300 sq. mm 480 sq. mm 118°C/W

180 sq. mm 100 sq. mm 280 sq. mm 120°C/W

180 sq. mm 0 sq. mm 180 sq. mm 122°C/W

Calculating Junction Temperature

The junction temperature can be calculated from the

equation:

TJ = (PD)(θJA) + T

TJ = Junction Temperature

TA = Ambient Temperature

PD = Device Dissipation

θJA = Thermal Resistance (Junction-to-Ambient)

As an example, calculate the junction temperature for the

circuit in Figure 1 assuming an 85°C ambient temperature.

The device dissipation can be found by measuring the

supply currents, calculating the total dissipation and then

subtracting the dissipation in the load.

A

9

Page 10

LT1886

R

G

R

C

V

o

V

i

C

C

(OPTIONAL)

–

+

1886 F02

R

F

=

–R

F

R

G

V

o

V

i

< 15MHz

1

2πR

CCC

(RC || RG) ≤ RF/9

U

WUU

APPLICATIO S I FOR ATIO

6V

+

–

909Ω

100Ω

1K

100Ω

Figure 1. Thermal Calculation Example

–

+

–6V

50Ω

f = 1MHz

The dissipation for the amplifiers is:

PD = (63.5mA)(12V) – (4V/√2)2/(50) = 0.6W

The total package power dissipation is 0.6W. When a 2500

sq. mm PC board with 2oz copper on top and bottom is

used, the thermal resistance is 80°C/W. The junction

temperature TJ is:

TJ = (0.6W)(80°C/W) + 85°C = 133°C

The maximum junction temperature for the LT1886 is

150°C so the heat sinking capability of the board is

adequate for the application.

4V

–4V

1886 F01

Typical Performance Curve of Frequency Response vs

Capacitive Load shows the peaking for various capacitive

loads.

This stability is useful in the case of directly driving a

coaxial cable or twisted pair that is inadvertently

unterminated. For best pulse fidelity, however, a termination resistor of value equal to the characteristic impedance

of the cable or twisted pair (i.e., 50Ω/75Ω/100Ω/135Ω)

should be placed in series with the output. The other end

of the cable or twisted pair should be terminated with the

same value resistor to ground.

Compensation

The LT1886 is stable in a gain 10 or higher for any supply

and resistive load. It is easily compensated for lower gains

with a single resistor or a resistor plus a capacitor.

Figure␣ 2 shows that for inverting gains, a resistor from the

inverting node to AC ground guarantees stability if the

parallel combination of RC and RG is less than or equal to

RF/9. For lowest distortion and DC output offset, a series

capacitor, CC, can be used to reduce the noise gain at lower

frequencies. The break frequency produced by RC and C

C

should be less than 15MHz to minimize peaking. The

Typical Curve of Frequency Response vs Supply Voltage,

AV = –1 shows less than 1dB of peaking for a break

frequency of 12.8MHz.

If the copper area on the PC board is reduced to 180 sq.

mm the thermal resistance increases to 122°C/W and the

junction temperature becomes:

TJ = (0.6W)(122°C/W) + 85°C = 158°C

which is above the maximum junction temperature indicating that the heat sinking capability of the board is

inadequate and should be increased.

Capacitive Loading

The LT1886 is stable with a 1000pF capacitive load. The

photo of the small-signal response with 1000pF load in a

gain of 10 shows 50% overshoot. The photo of the largesignal response with a 1000pF load shows that the output

slew rate is not limited by the short-circuit current. The

10

Figure 2. Compensation for Inverting Gains

Figure 3 shows compensation in the noninverting configuration. The RC, CC network acts similarly to the inverting

case. The input impedance is not reduced because the

network is bootstrapped. This network can also be placed

between the inverting input and an AC ground.

Another compensation scheme for noninverting circuits is

shown in Figure 4. The circuit is unity gain at low frequency

and a gain of 1 + RF/RG at high frequency. The DC output

offset is reduced by a factor of ten. The techniques of

Page 11

LT1886

U

WUU

APPLICATIO S I FOR ATIO

Figures 3 and 4 can be combined as shown in Figure 5. The

gain is unity at low frequencies, 1 + RF/RG at mid-band and

for stability, a gain of 10 or greater at high frequencies.

V

o

V

V

(RC || RG) ≤ RF/9

2πR

V

(OPTIONAL)

i

R

C

C

C

R

G

+

–

R

F

Figure 3. Compensation for Noninverting Gains

V

+

V

i

–

R

F

R

G

C

C

o

= 1 (LOW FREQUENCIES)

V

i

= 1 +

V

O

RG ≤ RF/9

1

2πR

GCC

R

F

(HIGH FREQUENCIES)

R

G

< 15MHz

Figure 4. Alternate Noninverting Compensation

V

i

R

C

C

C

R

G

C

BIG

+

V

–

R

F

o

V

o

= 1 AT LOW FREQUENCIES

V

i

R

F

= 1 + AT MEDIUM FREQUENCIES

R

G

R

= 1 + AT HIGH FREQUENCIES

F

(RC || RG)

Figure 5. Combination Compensation

Output Loading

The LT1886 output stage is very wide bandwidth and able

to source and sink large currents. Reactive loading, even

isolated with a back-termination resistor, can cause ringing at frequencies of hundreds of MHz. For this reason, any

design should be evaluated over a wide range of output

conditions. To reduce the effects of reactive loading, an

optional snubber network consisting of a series RC across

the load can provide a resistive load at high frequency.

Another option is to filter the drive to the load. If a back-

R

1

= 1 +

CCC

F

R

G

< 15MHz

1886 F03

1886 F04

1886 F05

o

i

termination resistor is used, a capacitor to ground at the

load can eliminate ringing.

Line Driving Back-Termination

The standard method of cable or line back-termination is

shown in Figure 6. The cable/line is terminated in its

characteristic impedance (50Ω, 75Ω, 100Ω, 135Ω, etc.).

A back-termination resistor also equal to to the

chararacteristic impedance should be used for maximum

pulse fidelity of outgoing signals, and to terminate the line

for incoming signals in a full-duplex application. There are

three main drawbacks to this approach. First, the power

dissipated in the load and back-termination resistors is

equal so half of the power delivered by the amplifier is

wasted in the termination resistor. Second, the signal is

halved so the gain of the amplifer must be doubled to have

the same overall gain to the load. The increase in gain

increases noise and decreases bandwidth (which can also

increase distortion). Third, the output swing of the amplifier is doubled which can limit the power it can deliver to

the load for a given power supply voltage.

CABLE OR LINE WITH

+

V

i

CHARACTERISTIC IMPEDANCE R

R

BT

–

R

F

R

G

L

V

O

R

L

RBT = R

L

1

V

o

V

(1 + RF/RG)

=

2

i

1886 F06

Figure 6. Standard Cable/Line Back-Termination

An alternate method of back-termination is shown in

Figure 7. Positive feedback increases the effective backtermination resistance so RBT can be reduced by a factor

of n. To analyze this circuit, first ground the input. As RBT␣=

RL/n, and assuming RP2>>RL we require that:

Va = Vo (1 – 1/n) to increase the effective value of

RBT by n.

Vp = Vo (1 – 1/n)/(1 + RF/RG)

Vo = Vp (1 + RP2/RP1)

Eliminating Vp, we get the following:

(1 + RP2/RP1) = (1 + RF/RG)/(1 – 1/n)

11

Page 12

LT1886

U

WUU

APPLICATIO S I FOR ATIO

For example, reducing RBT by a factor of n = 4, and with an

amplifer gain of (1 + RF/RG) = 10 requires that RP2/R

=␣ 12.3.

Note that the overall gain is increased:

RRR

V

o

=

V

i

[]

nRRRRR

+

11 1

// / /

()

()

/

221

PPP

+

FG P P P

+

()

−+

()

[]

121

A simpler method of using positive feedback to reduce the

back-termination is shown in Figure 8. In this case, the

drivers are driven differentially and provide complementary outputs. Grounding the inputs, we see there is inverting gain of –RF/RP from –Vo to V

a

Va = Vo (RF/RP)

and assuming RP >> RL, we require

Va = Vo (1 – 1/n)

solving

RF/RP = 1 – 1/n

P1

modems. The key advantages are: ±200mA output drive

with only 1.7V worst-case total supply voltage headroom,

high bandwidth, which helps achieve low distortion, low

quiescent supply current of 7mA per amplifier and a

space-saving, thermally enhanced SO-8 package.

An ADSL remote terminal driver must deliver an average

power of 13dBm (20mW) into a 100Ω line. This corresponds to 1.41V

into the line. The DMT-ADSL peak-to-

RMS

average ratio of 5.33 implies voltage peaks of 7.53V into

the line. Using a differential drive configuration and transformer coupling with standard back-termination, a transformer ratio of 1:2 is well suited. This is shown on the front

page of this data sheet along with the distortion performance vs line voltage at 200kHz, which is beyond ADSL

requirements. Note that the distortion is better than

–73dBc for all swings up to 16V

into the line. The gain

P-P

of this circuit from the differential inputs to the line voltage

is 10. Lower gains are easy to implement using the

compensation techniques of Figure 5. Table 2 shows the

drive requirements for this standard circuit.

So to reduce the back-termination by a factor of 3 choose

RF/RP = 2/3. Note that the overall gain is increased to:

Vo/Vi = (1 + RF/RG + RF/RP)/[2(1 – RF/RP)]

ADSL Driver Requirements

The LT1886 is an ideal choice for ADSL upstream (CPE)

R

P2

R

P1

V

i

+

R

V

V

P

a

–

R

F

R

G

FOR RBT =

1 +

()

V

o

V

i

V

BT

o

R

L

R

L

n

R

R

F

P1

()

R

RP1 + R

G

=

P2

RP2/(RP2 + RP1)

1 + 1/n

R

F

1 +

()

R

G

= 1 –

–

1

n

R

P1

RP2 + R

P1

1886 F07

The above design is an excellent choice for desktop

applications and draws typically 550mW of power. For

portable applications, power savings can be achieved by

reducing the back-termination resistor using positive feedback as shown in Figure 9. The overall gain of this circuit

is also 10, but the power consumption has been reduced

to 350mW, a savings of 36% over the previous design.

Note that the reduction of the back-termination resistor

has allowed use of a 1:1 transformer ratio.

V

+

–V

i

–

R

G

R

P

R

P

R

G

–

+

i

V

R

a

BT

R

F

R

F

R

BT

–V

a

V

o

R

L

=

FOR R

BT

n

1

n =

R

L

R

L

–V

o

R

F

1 –

R

P

R

R

F

F

+

1 +

V

o

=

V

i

R

R

P

G

R

F

1 –2

()

R

P

1886 F08

Figure 7. Back-Termination Using Positive Feedback

12

Figure 8. Back-Termination Using Differential Positive Feedback

Page 13

LT1886

U

WUU

APPLICATIO S I FOR ATIO

Table 2. ADSL Upstream Driver Designs

STANDARD LOW POWER

Line Impedance 100Ω 100Ω

Line Power 13dBm 13dBm

Peak-to-Average Ratio 5.33 5.33

Transformer Turns Ratio 2 1

Reflected Impedance 25Ω 100Ω

Back-Termination Resistors 12.5Ω 8.35Ω

Transformer Insertion Loss 1dB 0.5dB

Average Amplifier Swing 0.79V

Average Amplifier Current 31.7mA

RMS

RMS

Peak Amplifier Swing 4.21V Peak 4.65V Peak

Peak Amplifier Current 169mA Peak 80mA Peak

Total Average Power Consumption 550mW 350mW

Supply Voltage Single 12V Single 12V

Table 2 compares the two approaches. It may seem that

the low power design is a clear choice, but there are further

system issues to consider. In addition to driving the line,

the amplifiers provide back-termination for signals that

are received simultaneously from the line. In order to

reject the drive signal, a receiver circuit is used such as

shown in Figure 10. Taking advantage of the differential

nature of the signals, the receiver can subtract out the

drive signal and amplify the received signal. This method

works well for standard back-termination. If the backtermination resistors are reduced by positive feedback, a

portion of the received signal also appears at the amplifier

outputs. The result is that the received signal is attenuated

0.87V

15mA

RMS

RMS

by the same amount as the reduction in the back-termination resistor. Taking into account the different transformer

turns ratios, the received signal of the low power design

will be one third of the standard design received signal.

The reduced signal has system implications for the sensitivity of the receiver. The power reduction may, or may not,

be an acceptable system tradeoff for a given design.

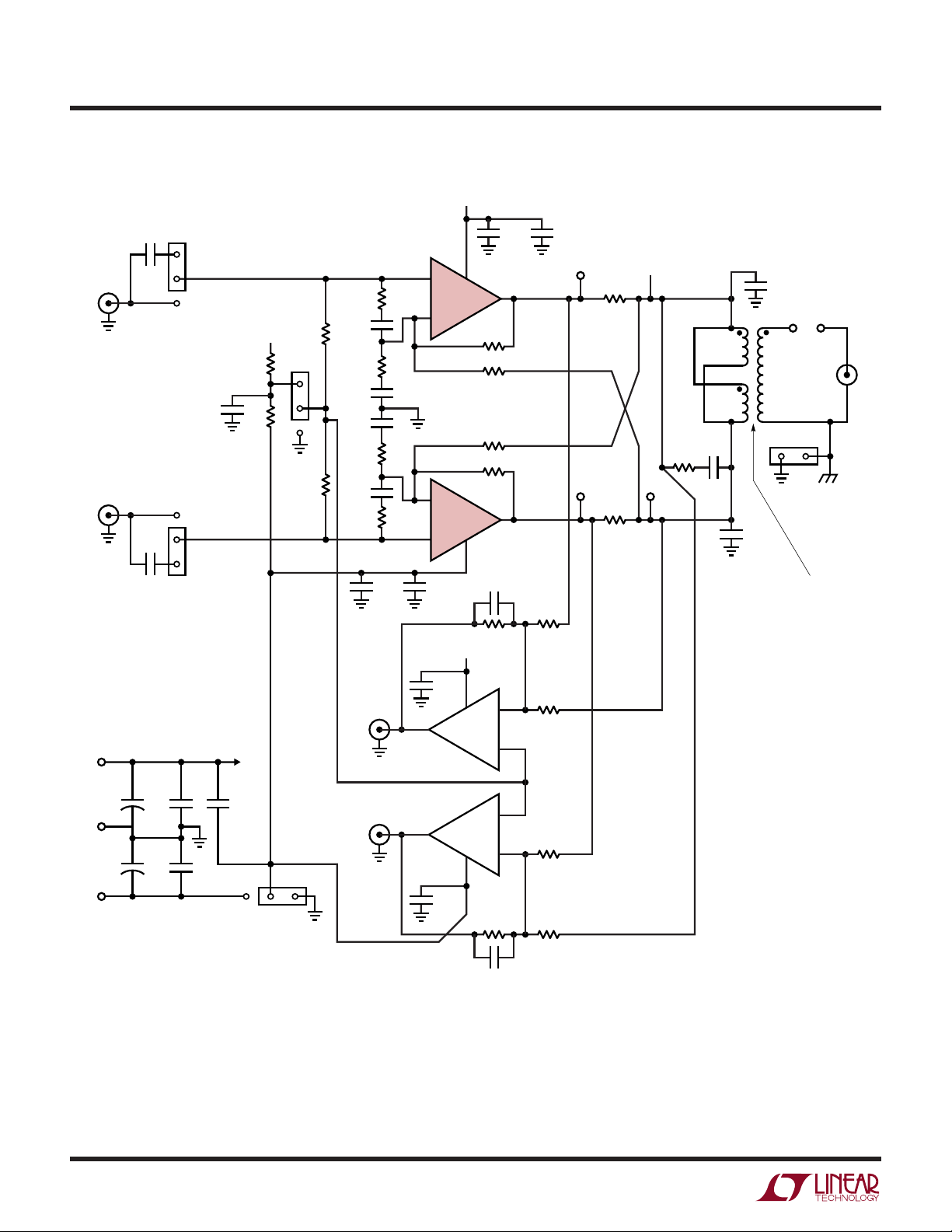

Demo Board

Demo board DC304 has been created to provide a versatile

platform for a line driver/receiver design. (Figure 11 shows

a complete schematic.) The board is set up for either single

or dual supply designs with Jumpers 1–4. The LT1886 is

set up for differential, noninverting gain of 3. Each amp is

configured as in Figure 5 for maximum flexibility. The

amplifiers drive a 1:2 transformer through back-termination resistors that can be reduced with optional positive

feedback. The secondary of the transformer can be isolated from the primary with Jumper 5.

A differential receiver is included using the LT1813, a dual

100MHz, 750V/µs operational amplifier. The receiver gain

from the transformer secondary is 2, and the drive signals

are rejected by approximately a factor of 14dB. Other

optional components include filter capacitors and an RC

snubber network at the transformer primary.

R

V

a

BT

V

L

1:n

R

BT

D

G

V

BIAS

1µF

–V

a

V

+

i

–

523Ω

523Ω

8.45Ω

1k

1:1

1.21k

100Ω

1.21k

1k

+

V

RX

R

F

LT1813

R

R

–

+

+

–

8.45Ω

+

–V

i

AV = 10

1886 F09

–

R

F

LT1813

R

D

–

R

G

Figure 9. Power Saving ADSL Modem Driver Figure 10. Receiver Configuration

–V

L

R

L

2

n

R

2n

R

L

= REFLECTED IMPEDANCE

R

L

2

2n

= ATTENUATION OF V

L

+ R

BT

2

R

L

2

2n

R

G

=SET

R

R

L

D

+ R

BT

2

2n

13

a

1886 F10

Page 14

LT1886

U

WUU

APPLICATIO S I FOR ATIO

C1

0.1µF

JP1

+DRV

–DRV

C2

0.1µF

JP2

1µF

R3

+

V

20k

R1

JP3

10k

C3

R2

10k

–

V

R4

20k

130Ω

C19

100pF

499Ω

1µF

1µF

499Ω

C20

100pF

130Ω

C4

C5

R20

R6

R8

R4

C10

470pF

3

2

6

5

+

–

–

+

C11

0.1µF

V

LT1886

LT1886

+

C8

0.1µF

8

1

R5

1k

R18

R19

R7

1k

7

4

C6

10pF

C9

470pF

TP1

TP3

R9

12.4Ω

R10

12.4Ω

TP2

TP4

R7

12.4Ω

C23

470pF

6

9

7

10

C22

470pF

C21

470pF

TP5

TP6

4

2

JP5

SEPARATE

SECONDARY

GROUND

COILCRAFT X8390-A

OR EQUIVALENT

LINE

OUT

GND

R11

+

4.02k

V

C12

0.1µF

8

–RCV

+

V

+

C14

10µF

C16

10µF

–

V

C15

1µF

+

C17

1µF

C18

10µF

+

V

+RCV

JP4

1

7

C13

0.1µF

LT1813

LT1813

4

V

–

4.02k

10pF

R14

C7

R12

2k

R13

1k

2

–

3

+

5

+

R15

2k

6

–

R16

1k

1886 F11

Figure 11. LT1886, LT1813 DSL Demo Board (DC304)

14

Page 15

WW

SI PLIFIED

SCHE ATIC

V

–IN

V

PACKAGE DESCRIPTIO

+

I

4

Q3

Q1

–

Q4

Q5

D1

Q2

D2

I

1

Q6

C1

+IN

I

I

2

3

Q8

OUT

Q7

Q9

1886 SS

U

Dimensions in inches (millimeters) unless otherwise noted.

LT1886

S8 Package

8-Lead Plastic Small Outline (Narrow 0.150)

(LTC DWG # 05-08-1610)

0.228 – 0.244

(5.791 – 6.197)

0.010 – 0.020

(0.254 – 0.508)

0.008 – 0.010

(0.203 – 0.254)

*

DIMENSION DOES NOT INCLUDE MOLD FLASH. MOLD FLASH

SHALL NOT EXCEED 0.006" (0.152mm) PER SIDE

**

DIMENSION DOES NOT INCLUDE INTERLEAD FLASH. INTERLEAD

FLASH SHALL NOT EXCEED 0.010" (0.254mm) PER SIDE

×

°

45

0.016 – 0.050

(0.406 – 1.270)

0°– 8° TYP

0.053 – 0.069

(1.346 – 1.752)

0.014 – 0.019

(0.355 – 0.483)

TYP

0.189 – 0.197*

(4.801 – 5.004)

7

8

1

2

5

6

0.150 – 0.157**

(3.810 – 3.988)

3

4

0.004 – 0.010

(0.101 – 0.254)

0.050

(1.270)

BSC

SO8 1298

Information furnished by Linear Technology Corporation is believed to be accurate and reliable.

However, no responsibility is assumed for its use. Linear Technology Corporation makes no representation that the interconnection of its circuits as described herein will not infringe on existing patent rights.

15

Page 16

LT1886

TYPICAL APPLICATIO

+

V

IN

–

130Ω

100pF

100pF

130Ω

U

Split Supply ±5V ADSL CPE Line Driver

5V

3

2

866Ω

866Ω

6

5

+

1/2 LT1886

–

–

1/2 LT1886

+

–5V

8

6.19Ω

1

1k

1:2*

2k

1k

4

2k

6.19Ω

7

*COILCRAFT X8390-A

OR EQUIVALENT

100Ω

+

V

L

–

V

L

= 5 (ASSUME 0.5dB TRANSFORMER POWER LOSS)

V

IN

2kΩ

1kΩ

RMS

2

= 25Ω

= 24.8Ω

1886 TA02

REFLECTED LINE IMPEDANCE = 100Ω / 2

EFFECTIVE TERMINATION = 2 • 6.19 •

EACH AMPLIFIER: 0.56V

, 29.9mA

RMS

±3V PEAK, ±160mA PEAK

RELATED PARTS

PART NUMBER DESCRIPTION COMMENTS

LT1207 Dual 250mA, 60MHz Current Feedback Amplifier Shutdown/Current Set Function

LT1361 Dual 50MHz, 800V/µs Op Amp ±15V Operation, 1mV VOS, 1µA I

LT1396 Dual 400MHz, 800V/µs Current Feedback Amplifier 4.6mA Supply Current Set, 80mA I

LT1497 Dual 125mA, 50MHz Current Feedback Amplifier 900V/µs Slew Rate

LT1795 Dual 500mA, 50MHz Current Feedback Amplifier Shutdown/Current Set Function, ADSL CO Driver

LT1813 Dual 100MHz, 750V/µs, 8nV/√Hz Op Amp Low Noise, Low Power Differential Receiver

B

OUT

16

Linear Technology Corporation

1630 McCarthy Blvd., Milpitas, CA 95035-7417

(408) 432-1900 ● FAX: (408) 434-0507

●

www.linear-tech.com

1886f LT/TP 0400 4K • PRINTED IN USA

LINEAR TECHNOLOGY CORPORATION 1999

Loading...

Loading...