Page 1

FEATURES

LT1795

Dual 500mA/50MHz

Current Feedback Line Driver

Amplifier

U

DESCRIPTIO

■

500mA Output Drive Current

■

50MHz Bandwidth, AV = 2, RL = 25

■

900V/µs Slew Rate, AV = 2, RL = 25

■

Low Distortion: –75dBc at 1MHz

■

High Input Impedance, 10MΩ

■

Wide Supply Range, ±5V to ±15V

■

Full Rate, Downstream ADSL Supported

■

Power Enhanced Small Footprint Packages

Ω

Ω

TSSOP-20, S0-20 Wide

■

Low Power Shutdown Mode

■

Power Saving Adjustable Supply Current

■

Stable with CL = 10,000pF

U

APPLICATIO S

■

ADSL HDSL2, G.lite Drivers

■

Buffers

■

Test Equipment Amplifiers

■

Video Amplifiers

■

Cable Drivers

U

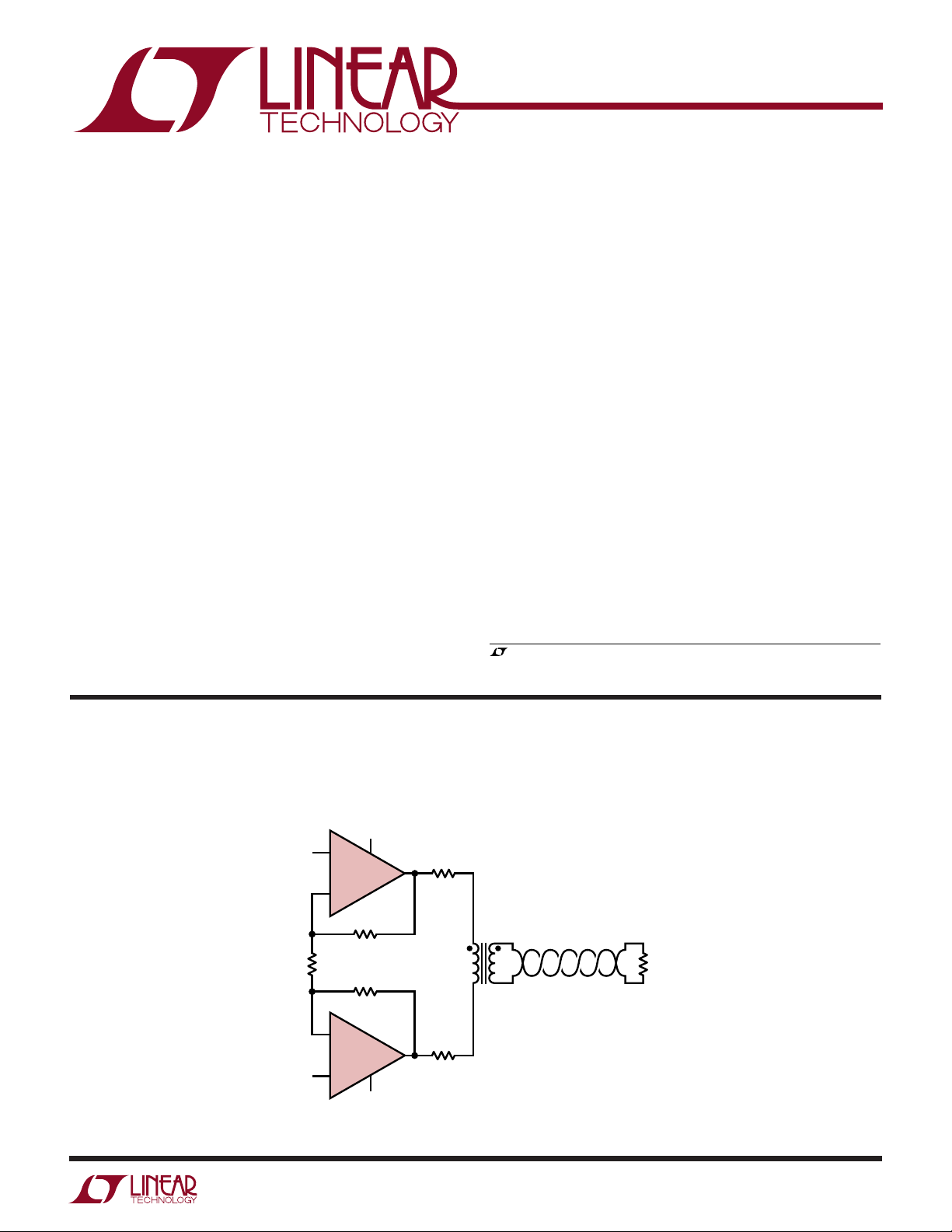

TYPICAL APPLICATION

The LT®1795 is a dual current feedback amplifier with high

output current and excellent large signal characteristics.

The combination of high slew rate, 500mA output drive

and up to ±15V operation enables the device to deliver

significant power at frequencies in the 1MHz to 2MHz

range. Short-circuit protection and thermal shutdown

insure the device’s ruggedness. The LT1795 is stable with

large capacitive loads and can easily supply the large

currents required by the capacitive loading. A shutdown

feature switches the device into a high impedance, low

current mode, reducing power dissipation when the device is not in use. For lower bandwidth applications, the

supply current can be reduced with a single external

resistor.

The LT1795 comes in the very small, thermally enhanced,

20-lead TSSOP package for maximum port density in line

driver applications.

, LTC and LT are registered trademarks of Linear Technology Corporation.

Low Loss, High Power Central Office ADSL Line Driver

+

V

+IN

+

1/2

LT1795

–

1k

165Ω

1k

–

1/2

–IN

* MIDCOM 50215 OR EQUIVALENT

LT1795

+

–

V

12.5Ω

1:2*

12.5Ω

100Ω

1795 TA01

1

Page 2

LT1795

WW

W

ABSOLUTE AXI U RATI GS

U

(Note 1)

Supply Voltage ...................................................... ±18V

Input Current ...................................................... ±15mA

Output Short-Circuit Duration (Note 2)............ Indefinite

Operating Temperature Range ................ –40°C to 85°C

UUW

PACKAGE/ORDER I FOR ATIO

–IN

+IN

SHDN

SHDNREF

+IN

–IN

TOP VIEW

–

1

V

2

NC

3

4

5

6

7

8

9

NC

–

10

V

FE PACKAGE

20-LEAD PLASTIC TSSOP

T

= 150° C, θJA = 40°C/W (Note 4)

JMAX

–

20

V

19

NC

18

OUT

+

17

V

16

COMP

15

COMP

+

14

V

13

OUT

12

NC

–

11

V

ORDER PART

NUMBER

LT1795CFE

LT1795IFE

Specified Temperature Range (Note 3)... – 40°C to 85°C

Junction Temperature........................................... 150°C

Storage Temperature Range ................. –65°C to 150°C

Lead Temperature (Soldering, 10 sec).................. 300°C

TOP VIEW

1

COMP

+

2

V

3

OUT

–

4

V

–

5

V

–

6

V

–

7

V

8

–IN

9

+IN

10

SHDN

S PACKAGE

20-LEAD PLASTIC SW

T

= 150° C, θJA ≈ 40°C/W (Note 4)

JMAX

20

19

18

17

16

15

14

13

12

11

COMP

+

V

OUT

–

V

–

V

–

V

–

V

–IN

+IN

SHDNREF

ORDER PART

NUMBER

LT1795CSW

LT1795ISW

Consult factory for Military grade parts.

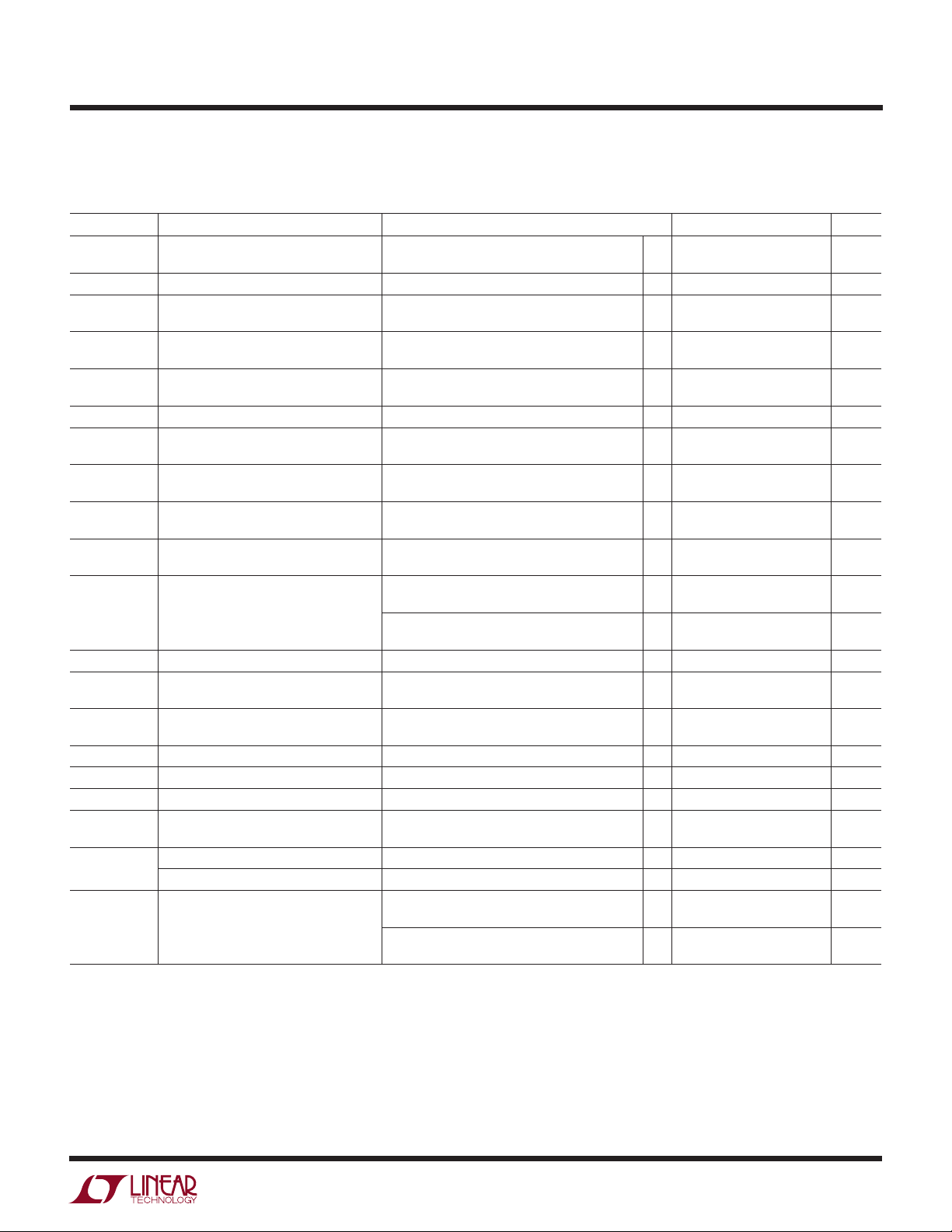

ELECTRICAL CHARACTERISTICS

The ● denotes the specifications which apply over the full specified temperature range, otherwise specifications are at TA = 25°C.

VCM = 0V, ±5V ≤ VS ≤ ±15V, pulse tested, V

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

V

I

I

e

+i

–i

OS

+

IN

–

IN

n

n

n

Input Offset Voltage ±3 ±13 mV

Input Offset Voltage Matching ±1 ±3.5 mV

Input Offset Voltage Drift ● 10 µV/°C

Noninverting Input Current ±2 ±5 µA

Noninverting Input Current Matching ±0.5 ±2 µA

Inverting Input Current ±10 ±70 µA

Inverting Input Current Matching ±10 ±30 µA

Input Noise Voltage Density f = 10kHz, RF =1k, RG = 10Ω, RS = 0Ω 3.6 nV/√Hz

Input Noise Current Density f = 10kHz, RF =1k, RG = 10Ω, RS = 10kΩ 2 pA/√Hz

Input Noise Current Density f = 10kHz, RF =1k, RG = 10Ω, RS = 10kΩ 30 pA/√Hz

SHDN

= 2.5V, V

SHDNREF

= 0V unless otherwise noted. (Note 3)

● ±4.5 ±17 mV

● ±1.5 ±5.0 mV

● ±8 ±20 µA

● ±1.5 ±7 µA

● ±20 ±100 µA

● ±20 ±50 µA

2

Page 3

LT1795

ELECTRICAL CHARACTERISTICS

The ● denotes the specifications which apply over the full specified temperature range, otherwise specifications are at TA = 25°C.

VCM = 0V, ±5V ≤ VS ≤ ±15V, pulse tested, V

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

+

R

IN

+

C

IN

CMRR Common Mode Rejection Ratio VS = ±15V, VCM = ±12V ● 55 62 dB

PSRR Power Supply Rejection Ratio VS = ±5V to ±15V ● 60 77 dB

A

V

R

OL

V

OUT

I

OUT

I

S

HD2, HD

3

SR Slew Rate (Note 7) AV = 4, RL = 400Ω 400 900 V/µs

BW Small-Signal BW AV = 2, VS = ±15V, Peaking ≤ 1.5dB 65 MHz

Input Resistance VIN = ±12V, VS = ±15V ● 1.5 10 MΩ

Input Capacitance VIN = ±15V 2 pF

Input Voltage Range (Note 5) VS = ±15V ● ±12 ±13.5 V

Inverting Input Current VS = ±15V, VCM = ±12V ● 110µA/V

Common Mode Rejection V

Noninverting Input Current VS = ±5V to ±15V ● 30 500 nA/V

Power Supply Rejection

Inverting Input Current VS = ±5V to ±15V ● 15µA/V

Power Supply Rejection

Large-Signal Voltage Gain VS = ±15V, V

Transresistance, ∆V

OUT

/∆I

–

IN

Maximum Output Voltage Swing VS = ±15V, RL = 25Ω±11.5 ±12.5 V

Maximum Output Current VS = ±15V, RL = 1Ω ● 0.5 1 A

Supply Current Per Amplifier VS = ±15V, V

Supply Current Per Amplifier, VS = ±15V 15 20 mA

= 51k, (Note 6) ● 25 mA

R

SHDN

Positive Supply Current, Shutdown VS = ±15V, V

Output Leakage Current, Shutdown VS = ±15V, V

Channel Separation VS = ±15V, V

2nd and 3rd Harmonic Distortion f = 1MHz, VO = 20V

Differential Mode

Slew Rate AV = 4, RL = 25Ω 900 V/µs

SHDN

= 2.5V, V

SHDNREF

= 0V unless otherwise noted. (Note 3)

V = ±2V, VS = ±5V ● 0.5 5 MΩ

VS = ±5V ● ±2 ±3.5 V

VS = ±5V, VCM = ±2V ● 50 60 dB

= ±5V, VCM = ±2V ● 110µA/V

S

= ±10V, RL = 25Ω ● 55 68 dB

= ±5V, V

V

S

VS = ±15V, V

VS = ±5V, V

OUT

= ±2V, RL = 12Ω ● 55 68 dB

OUT

= ±10V, RL = 25Ω ● 75 200 kΩ

OUT

= ±2V, RL = 12Ω ● 75 200 kΩ

OUT

● ±10.0 ±11.5 V

VS = ±5V, RL = 12Ω±2.5 ±3V

● ±2.0 ±3V

= 2.5V 29 34 mA

SHDN

= 0.4V ● 1 200 µA

SHDN

= 0.4V 1 10 µA

SHDN

= ±10V, RL = 25Ω 80 110 dB

OUT

, RL = 50, AV = 2 –75 dBc

P-P

● 42 mA

RF = RG = 910Ω, RL = 100Ω

AV = 2, VS = ±15V, Peaking ≤ 1.5dB 50 MHz

= RG = 820Ω, RL = 25Ω

R

F

Note 1: Absolute Maximum Ratings are those values beyond which the life

of a device may be impaired.

Note 2: Applies to short-circuits to ground only. A short-circuit between

the output and either supply may permanently damage the part when

operated on supplies greater than ±10V.

Note 3: The LT1795C is guaranteed to meet specified performance from

0°C to 70°C and is designed, characterized and expected to meet these

extended temperature limits, but is not tested at –40°C and 85°C. The

LT1795I is guaranteed to meet the extended temperature limits.

Note 4: Thermal resistance varies depending upon the amount of PC board

metal attached to the device. If the maximum dissipation of the package is

exceeded, the device will go into thermal shutdown and be protected.

Note 5: Guaranteed by the CMRR tests.

Note 6: R

is connected between the SHDN pin and V+.

SHDN

Note 7: Slew rate is measured at ±5V on a ±10V output signal while

operating on ±15V supplies with R

R

= 400Ω.

L

= 1k, RG = 333Ω (AV = +4) and

F

3

Page 4

LT1795

W

UU

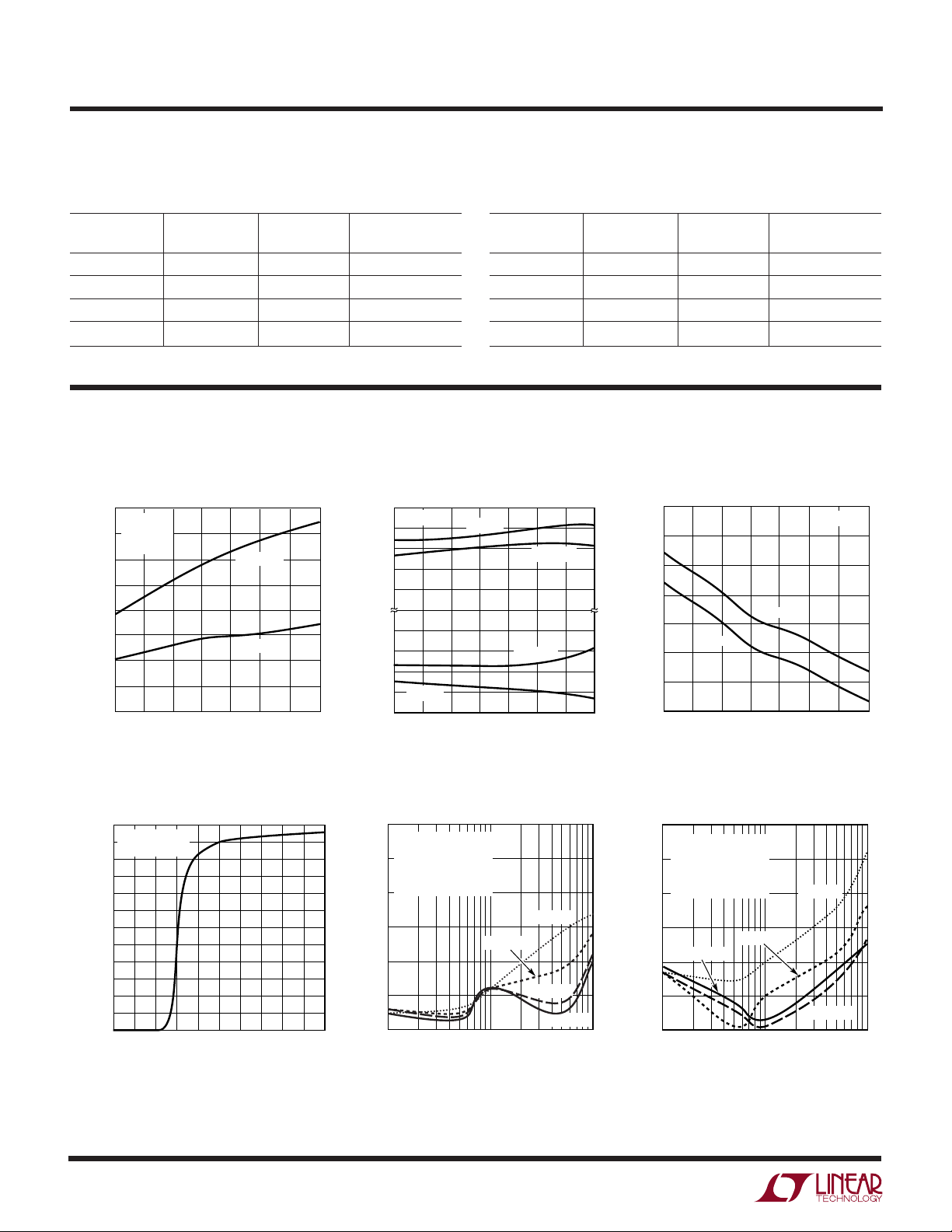

SMALL-SIGNAL BANDWIDTH

RSD = 0Ω, IS = 30mA per Amplifer, VS = ±15V,

Peaking ≤ 1dB, RL = 25Ω

A

V

R

F

–1 976 976 44

1 1.15k — 53

2 976 976 48

10 649 72 46

R

G

–3dB BW

(MHz)

RSD = 51kΩ, IS = 15mA per Amplifer, VS = ±15V,

Peaking ≤ 1dB, RL = 25Ω

A

V

–1 976 976 30

1 1.15k — 32

2 976 976 32

10 649 72 27

UW

TYPICAL PERFOR A CE CHARACTERISTICS

Supply Current vs Ambient

Temperature

40

VS = ±15V

= 1

A

35

V

= ∞

R

L

30

25

20

15

10

5

SUPPLY CURRENT PER AMPLIFIER (mA)

0

–50

–25 0

TEMPERATURE (°C)

RSD = 0Ω

RSD = 51kΩ

50 100 125

25 75

LT1795 G01

Output Saturation Voltage vs

Junction Temperature

+

V

VS = ±15V

–1

–2

–3

–4

4

3

2

OUTPUT SATURATION VOLTAGE (V)

1

RL = 2k

–

V

–50

–25

RL = 2k

50

25

0

TEMPERATURE (°C)

RL = 25Ω

RL = 25Ω

75

100

LT1795 G02

125

R

F

R

G

Output Short-Circuit Current vs

Junction Temperature

2.0

1.8

1.6

1.4

1.2

–50

SINKING

–25 0

1.0

0.8

OUTPUT SHORT-CIRCUIT CURRENT (A)

0.6

SOURCING

25 75

TEMPERATURE (°C)

–3dB BW

(MHz)

VS = ±15V

50 100 125

LT1795 G03

SHDN Pin Current vs Voltage

0.6

VS = ±15V

= 0V

V

SHDNREF

0.5

0.4

0.3

0.2

CURRENT INTO SHDN PIN (mA)

0.1

0

0

1 2 3 4 5

VOLTAGE APPLIED AT SHDN PIN (V)

4

1795 G04

Second Harmonic Distortion vs

Frequency

–40

AV = 2 DIFFERENTIAL

= 20V

V

OUT

–50

VS = ±15V

R

I

Q

–60

–70

–80

DISTORTION (dBc)

–90

–100

10k

P-P

= 50Ω

LOAD

PER AMPLIFIER

FREQUENCY (Hz)

IQ = 10mA

100k 1M

IQ = 5mA

IQ = 15mA

IQ = 20mA

LT1795 G05

Third Harmonic Distortion vs

Frequency

–40

AV = 2 DIFFERENTIAL

V

= 20V

OUT

–50

VS = ±15V

R

I

Q

–60

–70

–80

DISTORTION (dBc)

–90

–100

10k

P-P

= 50Ω

LOAD

PER AMPLIFIER

IQ = 20mA

FREQUENCY (Hz)

IQ = 10mA

100k 1M

IQ = 5mA

IQ = 15mA

LT1795 G06

Page 5

UW

TYPICAL PERFOR A CE CHARACTERISTICS

LT1795

Second Harmonic Distortion vs

Frequency

–40

AV = 10 DIFFERENTIAL

= 20V

V

OUT

–50

VS = ±15V

R

I

Q

–60

–70

–80

DISTORTION (dBc)

–90

–100

10k

P-P

= 50Ω

LOAD

PER AMPLIFIER

IQ = 15mA

IQ = 20mA

IQ = 5mA

100k 1M

FREQUENCY (Hz)

Third Harmonic Distortion vs

Frequency

–40

AV = 2 DIFFERENTIAL

V

= 20V

OUT

–50

VS = ±12V

R

I

–60

–70

–80

DISTORTION (dBc)

–90

IQ = 10mA

–100

10k

P-P

= 50Ω

LOAD

PER AMPLIFIER

Q

IQ = 20mA

100k 1M

FREQUENCY (Hz)

IQ = 5mA

IQ = 10mA

LT1795 G07

IQ = 15mA

LT1795 G10

Third Harmonic Distortion vs

Frequency

–40

AV = 10 DIFFERENTIAL

= 20V

V

OUT

–50

VS = ±15V

R

I

Q

–60

–70

–80

DISTORTION (dBc)

–90

–100

10k

P-P

= 50Ω

LOAD

PER AMPLIFIER

IQ = 5mA

FREQUENCY (Hz)

IQ = 10mA

IQ = 15mA

100k 1M

Second Harmonic Distortion vs

Frequency

–40

AV = 10 DIFFERENTIAL

= 20V

V

OUT

–50

VS = ±12V

R

I

Q

–60

–70

–80

DISTORTION (dBc)

–90

–100

10k

P-P

= 50Ω

LOAD

PER AMPLIFIER

IQ = 15mA

FREQUENCY (Hz)

IQ = 20mA

IQ = 5mA

100k 1M

IQ = 20mA

IQ = 10mA

LT1795 G08

LT1795 G11

Second Harmonic Distortion vs

Frequency

–40

AV = 2 DIFFERENTIAL

V

= 20V

OUT

–50

VS = ±12V

R

I

Q

–60

–70

–80

DISTORTION (dBc)

–90

–100

10k

P-P

= 50Ω

LOAD

PER AMPLIFIER

FREQUENCY (Hz)

IQ = 10mA

100k 1M

Third Harmonic Distortion vs

Frequency

–40

AV = 10 DIFFERENTIAL

V

= 20V

OUT

–50

VS = ±12V

R

I

Q

–60

–70

–80

DISTORTION (dBc)

–90

–100

10k

P-P

= 50Ω

LOAD

PER AMPLIFIER

IQ = 10mA

FREQUENCY (Hz)

IQ = 5mA

IQ = 15mA

100k 1M

IQ = 5mA

IQ = 15mA

IQ = 20mA

LT1795 G09

IQ = 20mA

LT1795 G12

Second Harmonic Distortion vs

Frequency

–40

AV = 2 DIFFERENTIAL

= 4V

V

OUT

–50

–60

–70

–80

DISTORTION (dBc)

–90

–100

10k

P-P

VS = ±12V

R

= 50Ω

LOAD

PER AMPLIFIER

I

Q

IQ = 20mA

IQ = 10mA

IQ = 15mA

100k 1M

FREQUENCY (Hz)

IQ = 5mA

LT1795 G13

Third Harmonic Distortion vs

Frequency

–40

AV = 2 DIFFERENTIAL

= 4V

V

OUT

VS = ±12V

R

= 50Ω

LOAD

PER AMPLIFIER

I

Q

P-P

100k 1M

FREQUENCY (Hz)

–50

–60

–70

–80

DISTORTION (dBc)

–90

–100

10k

IQ = 5mA

IQ = 10mA

IQ = 15mA

IQ = 20mA

LT1795 G14

Second Harmonic Distortion vs

Frequency

–40

AV = 10 DIFFERENTIAL

V

= 4V

OUT

–50

–60

–70

–80

DISTORTION (dBc)

–90

–100

10k

P-P

VS = ±12V

R

= 50Ω

LOAD

I

PER AMPLIFIER

Q

IQ = 5mA

IQ = 20mA

100k 1M

FREQUENCY (Hz)

IQ = 10mA

IQ = 15mA

LT1795 G15

5

Page 6

LT1795

UW

TYPICAL PERFOR A CE CHARACTERISTICS

Third Harmonic Distortion vs

Frequency

–40

AV = 10 DIFFERENTIAL

V

= 4V

OUT

–50

–60

–70

–80

DISTORTION (dBc)

–90

–100

–110

10k

P-P

VS = ±12V

R

= 50Ω

LOAD

PER AMPLIFIER

I

Q

100k 1M

FREQUENCY (Hz)

–40

–50

–60

–70

–80

DISTORTION (dBc)

Second Harmonic Distortion vs

Frequency

–40

AV = 2 DIFFERENTIAL

IQ = 5mA

IQ = 10mA

IQ = 15mA

IQ = 20mA

LT1795 G16

V

–50

VS = ±5V

R

I

–60

–70

–80

DISTORTION (dBc)

–90

–100

10k

Second Harmonic Distortion vs

Frequency

AV = 10 DIFFERENTIAL

= 4V

V

OUT

P-P

VS = ±5V

= 50Ω

R

LOAD

PER AMPLIFIER

I

Q

IQ = 20mA

IQ = 15mA

IQ = 10mA

= 4V

OUT

P-P

= 50Ω

LOAD

PER AMPLIFIER

Q

IQ = 20mA

IQ = 10mA

IQ = 15mA

100k 1M

FREQUENCY (Hz)

Third Harmonic Distortion vs

Frequency

–40

AV = 2 DIFFERENTIAL

V

–50

VS = ±5V

R

I

–60

IQ = 5mA

LT1795 G17

–70

–80

DISTORTION (dBc)

–90

–100

10k

Third Harmonic Distortion vs

Frequency

–40

AV = 10 DIFFERENTIAL

= 4V

V

OUT

–50

–60

–70

–80

DISTORTION (dBc)

P-P

VS = ±5V

R

= 50Ω

LOAD

PER AMPLIFIER

I

Q

= 4V

OUT

P-P

= 50Ω

LOAD

PER AMPLIFIER

Q

IQ = 5mA

IQ = 10mA

IQ = 15mA

IQ = 5mA

IQ = 10mA

IQ = 15mA

IQ = 20mA

100k 1M

FREQUENCY (Hz)

LT1795 G18

10k

IQ = 5mA

100k 1M

FREQUENCY (Hz)

–90

–100

Slew Rate vs Supply Current

1200

1000

800

600

400

SLEW RATE (V/µs)

200

0

10 15

7.5

SUPPLY CURRENT PER AMPLIFIER (mA)

RISING

20 30

LT1795 G19

FALLING

VS = ±15V

=25°C

T

A

= 4

A

V

R

LOAD

= 1k

R

F

25

= 25Ω

1795 • G21

–90

–100

10k

100k 1M

FREQUENCY (Hz)

–3dB Bandwidth vs

Supply Current

50

45

40

35

–3dB BANDWIDTH (MHz)

30

25

10 15

7.5

SUPPLY CURRENT PER AMPLIFIER (mA)

IQ = 20mA

LT1795 G20

VS = ±15V

=25°C

T

A

= 4

A

V

= 25Ω

R

LOAD

= 1k

R

F

20 30

25

1795 • G22

6

Page 7

LT1795

10 SHDN

V

+

11 SHDNREF

1795 F03

R

SHDNREF

U

WUU

APPLICATIO S I FOR ATIO

The LT1795 is a dual current feedback amplifier with high

output current drive capability. The amplifier is designed

to drive low impedance loads such as twisted-pair transmission lines with excellent linearity.

SHUTDOWN/CURRENT SET

If the shutdown/current set feature is not used, connect

SHDN to V+ and SHDNREF to ground.

The SHDN and SHDNREF pins control the biasing of the

two amplifiers. The pins can be used to either turn off the

amplifiers completely, reducing the quiescent current to

less then 200µA, or to control the quiescent current in

normal operation.

+

V

R

SHDN

10 SHDN

When V

SHDN

= V

SHDNREF

, the device is shut down. The

device will interface directly with 3V or 5V CMOS logic

when SHDNREF is grounded and the control signal is

applied to the SHDN pin. Switching time between the

active and shutdown states is about 1.5µs.

Figures 1 to 4 illustrate how the SHDN and SHDNREF pins

can be used to reduce the amplifier quiescent current. In

both cases, an external resistor is used to set the current.

The two approaches are equivalent, however the required

resistor values are different. The quiescent current will be

approximately 115 times the current in the SHDN pin and

230 times the current in the SHDNREF pin. The voltage

across the resistor in either condition is V+ – 1.5V. For

example, a 50k resistor between V+ and SHDN will set the

11 SHDNREF

1795 F01

Figure 1. R

Connected Between V+ and SHDN (Pin 10);

SHDN

SHDNREF (Pin 11) = GND. See Figure 2

80

70

60

50

40

30

– mA (BOTH AMPLIFIERS)

20

SY

I

AMPLIFIER SUPPLY CURRENT,

10

0

0 25 50 75 100 125 150 175 200 225

R

SHDN

(kΩ)

Figure 2. LT1795 Amplifier Supply Current vs R

TA = 25°C

= ±15V

V

S

1795 F02

SHDN

. R

SHDN

Connected Between V+ and SHDN, SHDNREF = GND (See

Figure 1)

Figure 3. R

SHDNREF

Connected Between SHDNREF (Pin 11)

and GND; SHDN (Pin 10) = V+. See Figure 4

80

70

60

50

40

30

– mA (BOTH AMPLIFIERS)

20

SY

I

AMPLIFIER SUPPLY CURRENT,

10

0

50 100 150 200 250 300 350 400 450 500

R

SHDNREF

(kΩ)

TA = 25°C

= ±15V

V

S

1795 F04

Figure 4. LT1795 Amplifier Supply Current vs R

R

SHDNREF

Connected Between SHDNREF and GND,

SHDN = V+ (See Figure 3)

SHDNREF

.

7

Page 8

LT1795

U

WUU

APPLICATIO S I FOR ATIO

quiescent current to 33mA with VS = ±15V. If ON/OFF

control is desired in addition to reduced quiescent current,

then the circuits in Figures 5 to 7 can be employed.

+

V

R

SHDN

R

OFF

ON

(0V)

(3.3V/5V)

Q1: 2N3904 OR EQUIVALENT

10k

B

Q1

Figure 5. Setting Amplifier Supply Current

Level with ON/OFF Control, Version 1

R

SHDN1

R

B1

ON

OFF

10k

(0V) (0V)

Q1A, Q1B: ROHM IMX1 or FMG4A (W/INTERNAL R

Q1A

Figure 6. Setting Multiple Amplifier Supply

Current Levels with ON/OFF Control, Version 2

OFF

10 SHDN

11 SHDNREF

ON

(3.3V/5V)(3.3V/5V)

R

PULLUP

R

R

B2

10k

B

1795 F05

>500k

SHDN2

)

INTERNAL

LOGIC THRESHOLD

~1.4V

+

V

10 SHDN

11 SHDNREF

Q1B

1795 F06

Figure 8 illustrates a partial shutdown with direct logic

control. By keeping the output stage slightly biased on, the

output impedance remains low, preserving the line termination. The design equations are:

•

V

R

1

R

2

115

=

II

S

() ()

ON

=

VVI I I

SHDN H S

( ) () ()

H

–

S

OFF

•–

VV

115

/• –

CC SHDN

()

ON

OFF

+

S

()

OFF

S

where

VH = Logic High Level

(IS)ON = Supply Current Fully On

(IS)

V

= Supply Current Partially On

OFF

= Shutdown Pin Voltage ≈1.4V

SHDN

VCC = Positive Supply Voltage

V

CC

R2

10

SHDN

11

SHDNREF

I

SY

CONTROL

1795 F08

INTERNAL

LOGIC THRESHOLD

~ 1.4V

OFF

(0V)

ON

(3.3V/5V)

R1

ON

OFF

(0V)

(3.3V/5V)

≅ 0.5mA

I

PROG

= 0Ω

FOR R

EXT

(SEE SHDN PIN

CURRENT vs

VOLTAGE

CHARACTERISTIC)

R

I

PROG

EXT

SHDN

10

SHDNREF

11

I

SY

CONTROL

Figure 7. Setting Amplifier Supply Current Level

with ON/OFF Control, Version 3

8

INTERNAL

LOGIC THRESHOLD

~ 1.4V

1795 F07

Figure 8. Partial Shutdown

THERMAL CONSIDERATIONS

The LT1795 contains a thermal shutdown feature that

protects against excessive internal (junction) temperature.

If the junction temperature of the device exceeds the

protection threshold, the device will begin cycling between

normal operation and an off state. The cycling is not

harmful to the part. The thermal cycling occurs at a slow

rate, typically 10ms to several seconds, which depends on

the power dissipation and the thermal time constants of the

package and heat sinking. Raising the ambient tempera-

Page 9

LT1795

U

WUU

APPLICATIO S I FOR ATIO

ture until the device begins thermal shutdown gives a

good indication of how much margin there is in the

thermal design.

For surface mount devices, heat sinking is accomplished

by using the heat spreading capabilities of the PC board

and its copper traces. For the TSSOP package, power is

dissipated through the exposed heatsink. For the SO

package, power is dissipated from the package primarily

through the V– pins (4 to 7 and 14 to 17). These pins

should have a good thermal connection to a copper plane,

either by direct contact or by plated through holes. The

copper plane may be an internal or external layer. The

thermal resistance, junction-to-ambient will depend on

the total copper area connected to the device. For example,

the thermal resistance of the LT1795 connected to a 2 × 2

inch, double sided 2 oz copper plane is 40°C/W.

CALCULATING JUNCTION TEMPERATURE

The junction temperature can be calculated from the

equation:

TJ = (PD)(θJA) + T

where

TJ = Junction Temperature

TA = Ambient Temperature

PD = Device Dissipation

θJA = Thermal Resistance (Junction-to-Ambient)

Differential Input Signal Swing

The differential input swing is limited to about ±5V by an

ESD protection device connected between the inputs. In

normal operation, the differential voltage between the

input pins is small, so this clamp has no effect. However,

in the shutdown mode, the differential swing can be the

same as the input swing. The clamp voltage will then set

the maximum allowable input voltage.

A

ing 0.5A current peaks into the load, a 1Ω power supply

impedance will cause a droop of 0.5V, reducing the

available output swing by that amount. Surface mount

tantalum and ceramic capacitors make excellent low ESR

bypass elements when placed close to the chip. For

frequencies above 100kHz, use 1µF and 100nF ceramic

capacitors. If significant power must be delivered below

100kHz, capacitive reactance becomes the limiting factor.

Larger ceramic or tantalum capacitors, such as 4.7µF, are

recommended in place of the 1µF unit mentioned above.

Inadequate bypassing is evidenced by reduced output

swing and “distorted” clipping effects when the output is

driven to the rails. If this is observed, check the supply pins

of the device for ripple directly related to the output

waveform. Significant supply modulation indicates poor

bypassing.

Capacitance on the Inverting Input

Current feedback amplifiers require resistive feedback

from the output to the inverting input for stable operation.

Take care to minimize the stray capacitance between the

output and the inverting input. Capacitance on the inverting input to ground will cause peaking in the frequency

response (and overshoot in the transient response), but it

does not degrade the stability of the amplifier.

Feedback Resistor Selection

The optimum value for the feedback resistors is a function

of the operating conditions of the device, the load impedance and the desired flatness of response. The Typical AC

Performance tables give the values which result in less

than 1dB of peaking for various resistive loads and operating conditions. If this level of flatness is not required, a

higher bandwidth can be obtained by use of a lower

feedback resistor.

For resistive loads, the COMP pin should be left open (see

Capacitive Loads section).

POWER SUPPLY BYPASSING

To obtain the maximum output and the minimum distortion from the LT1795, the power supply rails should be

well bypassed. For example, with the output stage supply-

Capacitive Loads

The LT1795 includes an optional compensation network

for driving capacitive loads. This network eliminates most

of the output stage peaking associated with capacitive

loads, allowing the frequency response to be flattened.

9

Page 10

LT1795

U

WUU

APPLICATIONS INFORMATION

Figure 9 shows the effect of the network on a 200pF load.

Without the optional compensation, there is a 6dB peak at

85MHz caused by the effect of the capacitance on the

output stage. Adding a 0.01µF bypass capacitor between

the output and the COMP pins connects the compensation

14

VS = ±15V

12

= 200pF

C

L

10

RF = 1k

8

COMPENSATION

6

4

2

VOLTAGE GAIN (dB)

0

–2

–4

–6

1

FREQUENCY (MHz)

Figure 9.

RF = 3.4k

NO

COMPENSATION

RF = 3.4k

COMPENSATION

10 100

1795 F09

and greatly reduces the peaking. A lower value feedback

resistor can now be used, resulting in a response which is

flat to ±1dB to 45MHz. The network has the greatest effect

for CL in the range of 0pF to 1000pF.

Although the optional compensation works well with

capacitive loads, it simply reduces the bandwidth when it

is connected with resistive loads. For instance, with a 25Ω

load, the bandwidth drops from 48MHz to 32MHz when

the compensation is connected. Hence, the compensation

was made optional. To disconnect the optional compensation, leave the COMP pin open.

DEMO BOARD

A demo board (DC261A) is available for evaluating the

performence of the LT1795. The board is configured as a

differential line driver/receiver suitable for xDSL applications. For details, consult your local sales representative.

PACKAGE DESCRIPTIO

0.291 – 0.299**

(7.391 – 7.595)

0.010 – 0.029

(0.254 – 0.737)

0.009 – 0.013

(0.229 – 0.330)

NOTE:

1. PIN 1 IDENT, NOTCH ON TOP AND CAVITIES ON THE BOTTOM OF PACKAGES ARE THE MANUFACTURING OPTIONS.

THE PART MAY BE SUPPLIED WITH OR WITHOUT ANY OF THE OPTIONS

DIMENSION DOES NOT INCLUDE MOLD FLASH. MOLD FLASH SHALL NOT EXCEED 0.006" (0.152mm) PER SIDE

*

DIMENSION DOES NOT INCLUDE INTERLEAD FLASH. INTERLEAD FLASH SHALL NOT EXCEED 0.010" (0.254mm) PER SIDE

**

NOTE 1

0.016 – 0.050

(0.406 – 1.270)

U

Dimensions in inches (millimeters) unless otherwise noted.

SW Package

20-Lead Plastic Small Outline (Wide 0.300)

(LTC DWG # 05-08-1620)

0.496 – 0.512*

(12.598 – 13.005)

× 45°

° – 8° TYP

0

NOTE 1

0.093 – 0.104

(2.362 – 2.642)

19 1817161514 13

20

2345

1

0.050

(1.270)

TYP

0.014 – 0.019

(0.356 – 0.482)

TYP

6

78

1112

910

(0.940 – 1.143)

0.037 – 0.045

0.004 – 0.012

(0.102 – 0.305)

0.394 – 0.419

(10.007 – 10.643)

S20 (WIDE) 0396

10

Page 11

PACKAGE DESCRIPTIO

U

Dimensions in millimeters (inches) unless otherwise noted.

FE Package

20-Lead Plastic TSSOP (4.4mm)

(LTC DWG # 05-08-1663)

6.40 – 6.60*

(0.252 – 0.260)

20 19 18 17 16 15

111214 13

LT1795

4.30 – 4.48**

(0.169 – 0.176)

° – 8°

0

0.09 – 0.18

(0.0035 – 0.0071)

NOTE: DIMENSIONS ARE IN MILLIMETERS

*

DIMENSIONS DO NOT INCLUDE MOLD FLASH. MOLD FLASH

SHALL NOT EXCEED 0.152mm (0.006") PER SIDE

**

DIMENSIONS DO NOT INCLUDE INTERLEAD FLASH. INTERLEAD

FLASH SHALL NOT EXCEED 0.254mm (0.010") PER SIDE

0.50 – 0.70

(0.020 – 0.028)

3.0

(0.118)

(0.0256)

0.65

BSC

0.18 – 0.30

(0.0071 – 0.0118)

345678

2

5.12

(0.202)

6.25 – 6.50

(0.246 – 0.256)

9 101

1.15

(0.453)

MAX

0.05 – 0.15

(0.002 – 0.006)

FE20 TSSOP 0200

Information furnished by Linear Technology Corporation is believed to be accurate and reliable.

However, no responsibility is assumed for its use. Linear Technology Corporation makes no representation that the interconnection of its circuits as described herein will not infringe on existing patent rights.

11

Page 12

LT1795

SI PLIFIED

WW

SCHEMATIC

SHDN

SHDNREF

TO ALL

CURRENT

SOURCES

+

V

Q5

Q2

Q1

–

V

+

V

Q3

Q4

Q6

Q8

Q7

D1

Q9

–

V

C

C

R

C

+

V

Q12

D2

Q15

Q16

50Ω

Q10

Q11

COMP–IN+IN

OUTPUT

Q14

Q13

–

V

1795 SS

RELATED PARTS

PART NUMBER DESCRIPTION COMMENTS

LT1497 Dual 125mA, 50MHz Current Feedback Amplifier 900V/µs Slew Rate

LT1207 Dual 250mA, 60MHz Current Feedback Amplifier Shutdown/Current Set Function

LT1886 Dual 200mA, 700MHz Voltage Feedback Amplifier Low Distortion: –72dBc at 200kHz

1795f LT/TP 4K 0200 • PRINTED IN USA

LINEAR TECHNOLOGY CORPORATION 1999

12

Linear Technology Corporation

1630 McCarthy Blvd., Milpitas, CA 95035-7417

(408) 432-1900 ● FAX: (408) 434-0507

●

www.linear-tech.com

Loading...

Loading...