Page 1

FEATURES

LT1777

Low Noise Step-Down

Switching Regulator

U

DESCRIPTIO

■

Programmable dI/dt Limit

■

Internally Limited dV/dt

■

High Input Voltage: 48V Max

■

700mA Peak Switch Rating

■

True Current Mode Control

■

100kHz Fixed Operating Frequency

■

Synchronizable to 250kHz

■

Low Supply Current in Shutdown: 30µA

■

Low Thermal Resistance 16-Pin SO Package

U

APPLICATIO S

■

Automotive Cellular and GPS Receivers

■

Telecom Power Supplies

■

Industrial Instrument Power Supplies

U

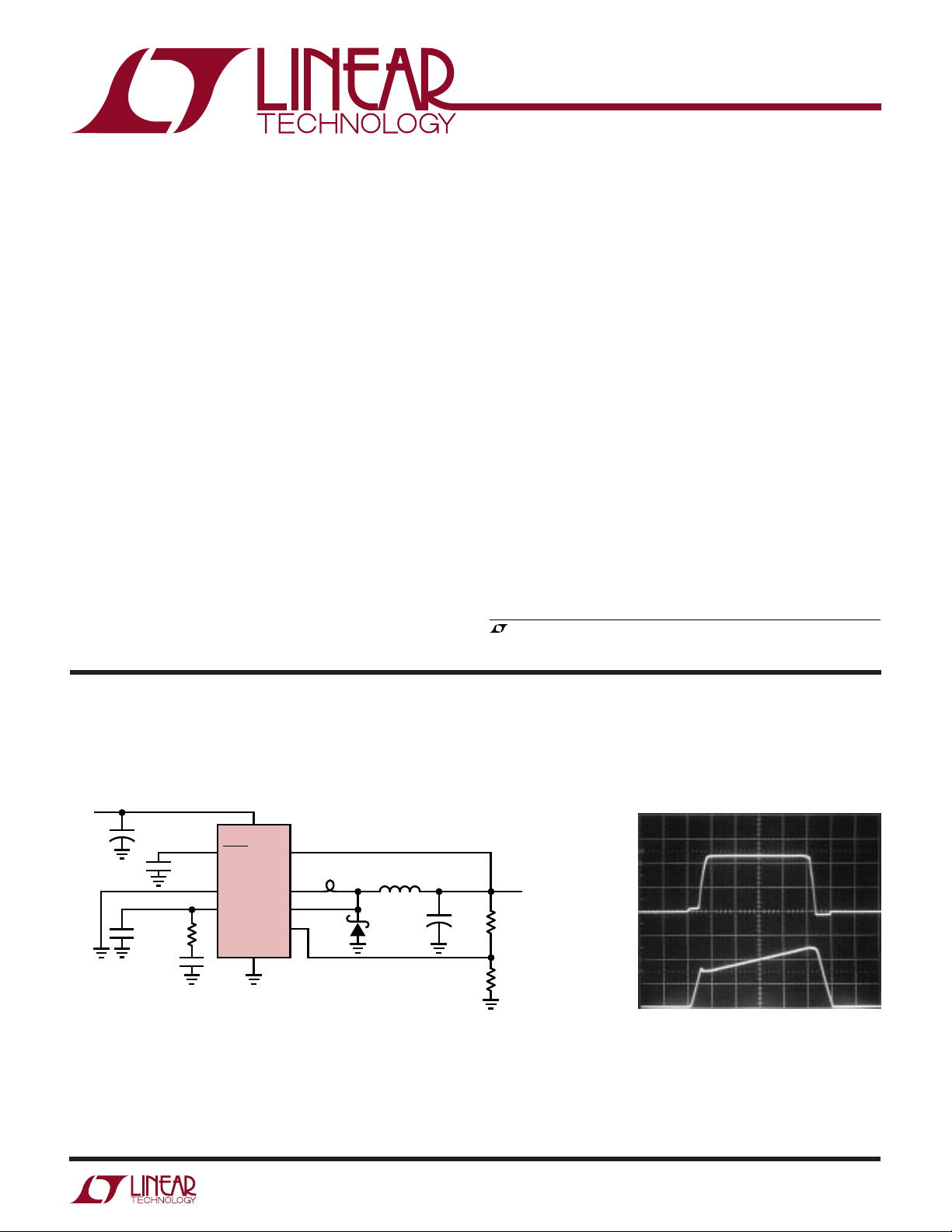

TYPICAL APPLICATIO

The LT®1777 is a Buck (step-down) regulator designed for

noise sensitive applications. It contains a dI/dt limiting

circuit programmed via a small external inductor in the

switching path. Internal circuitry also generates controlled

dV/dt ramp rates.

The monolithic die includes all oscillator, control and

protection circuitry. The part can accept operating input

voltages as high as 48V, and contains an output switch

rated at 700mA peak current. Current mode control offers

excellent dynamic input supply rejection and short-circuit

protection. The internal control circuitry is normally powered via the VCC pin, thereby minimizing power drawn

directly from the VIN supply (see Applications Information). The fused-lead SO16 package and 100kHz switching frequency allow for minimal PC board area

requirements.

, LTC and LT are registered trademarks of Linear Technology Corporation.

V

IN

24V

+

*PROGRAMS dI/dT

39µF

63V

100pF

2200pF

100pF

12k

VSW Switching WaveformsLow Noise 5V Step-Down Supply

10

V

IN

3

SHDN

LT1777

12

SYNC

14

V

C

SGND

4

V

CC

1µH*

6

V

SW

5

V

D

13

FB

7

220µH

MBRS1100

V

OUT

5V

+

100µF

10V

36.5k

1%

12.1k

1%

1777 TA01

400mA

V

SW

VOLTAGE

10V/DIV

V

SW

CURRENT

200mA/DIV

500ns/DIV

1777 TA02

1

Page 2

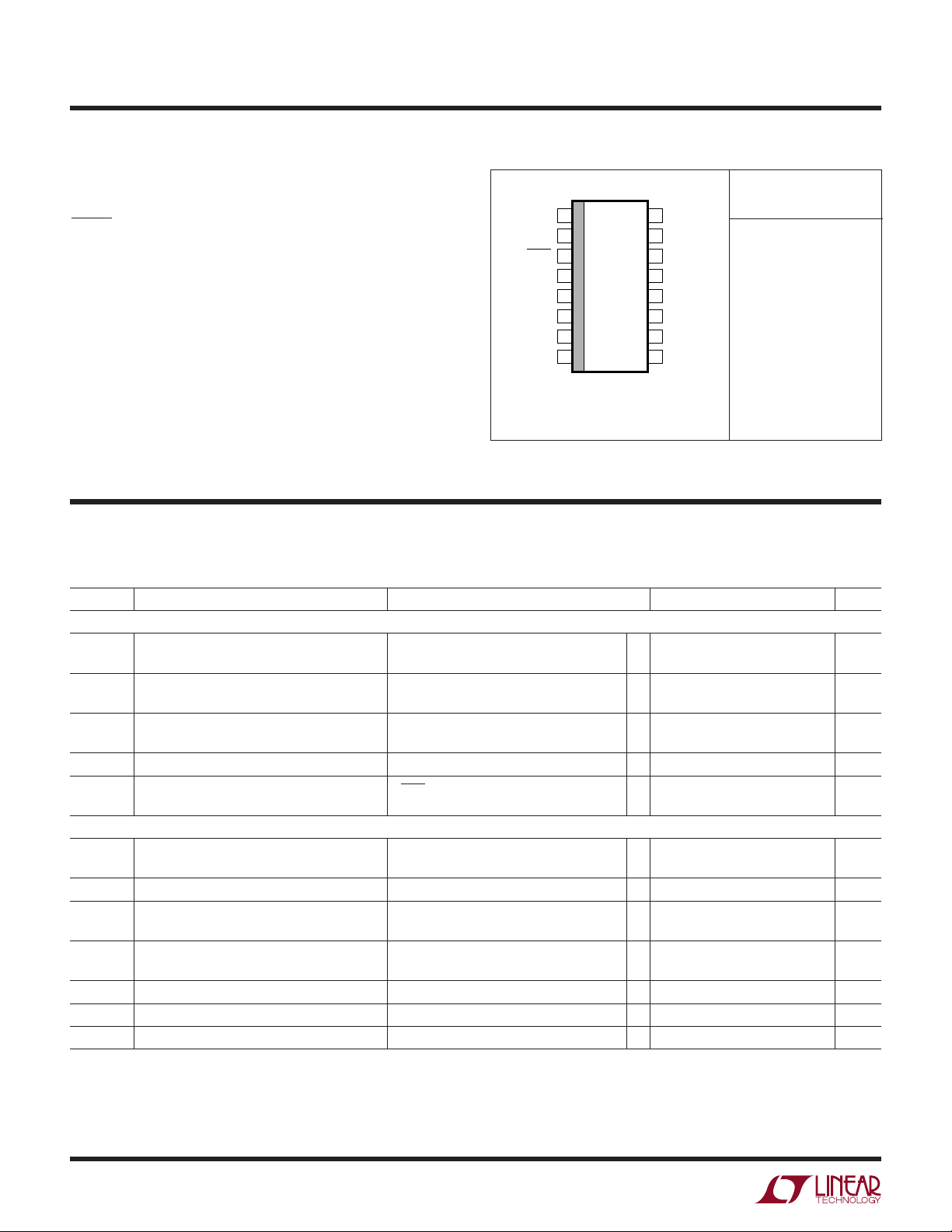

LT1777

TOP VIEW

S PACKAGE

16-LEAD PLASTIC SO

1

2

3

4

5

6

7

8

16

15

14

13

12

11

10

9

GND*

NC

SHDN

V

CC

V

D

V

SW

SGND

GND*

GND*

NC

V

C

FB

SYNC

NC

V

IN

GND*

WW

W

ABSOLUTE MAXIMUM RATINGS

U

PACKAGE

/

O

RDER I FOR ATIO

WU

(Note 1)

Supply Voltage ....................................................... 48V

Switch Voltage (VIN – VSW) (Note 4) ...................... 51V

ORDER PART

NUMBER

SHDN, SYNC Pin Voltage.......................................... 7V

VCC Pin Voltage ...................................................... 30V

FB Pin Voltage ........................................................ 3.0V

LT1777CS

LT1777IS

Operating Junction Temperature Range

LT1777C............................................... 0°C to 125°C

LT1777I ........................................... –40°C to 125°C

Storage Temperature Range ................ –65°C to 150°C

Lead Temperature (Soldering, 10 sec)................. 300°C

T

= 125°C, θJA = 50°C/W*

JMAX

Consult factory for Military grade parts.

*FOUR CORNER PINS ARE

FUSED TO INTERNAL DIE

ATTACH PADDLE FOR HEAT

SINKING. CONNECT THESE

FOUR PINS TO EXPANDED PC

LANDS FOR PROPER HEAT

SINKING.

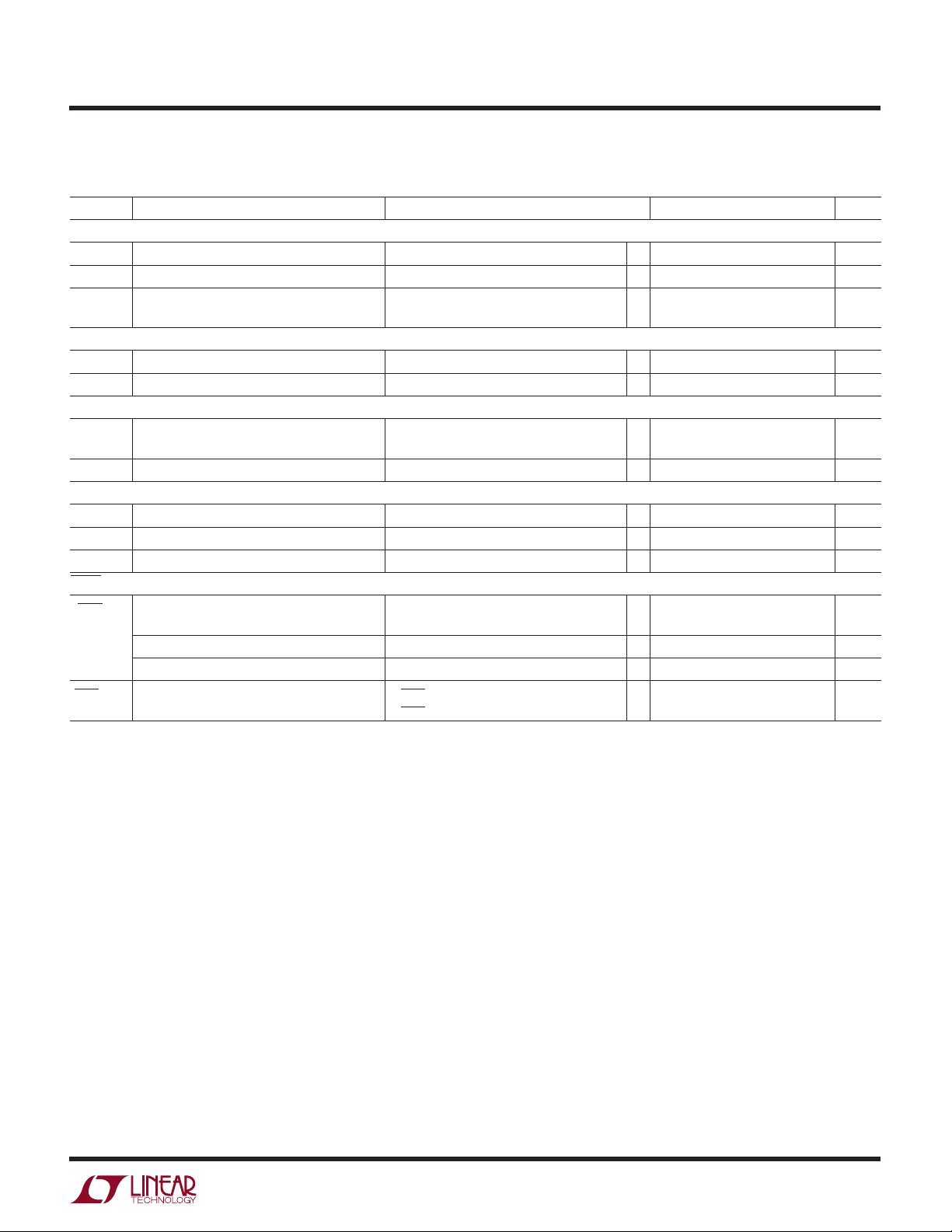

ELECTRICAL CHARACTERISTICS

The ● denotes specifications which apply over the full operating temperature range, otherwise specifications are at TJ = 25°C.

VIN = 24V, VSW Open, VCC = 5V, VC = 1.4V unless otherwise noted.

U

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

Power Supplies

V

IN(MIN)

I

VIN

I

VCC

V

VCC

Feedback Amplifier

V

REF

I

IN

g

m

I

, I

SRC

V

CL

2

Minimum Input Voltage 6.7 7.0 V

● 7.4 V

VIN Supply Current VC = 0V 620 800 µA

● 900 µA

VCC Supply Current VC = 0V 2.5 3.5 mA

● 4.5 mA

VCC Dropout Voltage (Note 2) ● 2.8 3.1 V

Shutdown Mode I

Reference Voltage 1.225 1.240 1.255 V

FB Pin Input Bias Current 600 1500 nA

Feedback Amplifier Transconductance ∆IC = ±10µA 400 650 1000 µmho

Feedback Amplifier Source or Sink Current 60 100 170 µA

SNK

Feedback Amplifier Clamp Voltage 2.0 V

Reference Voltage Line Regulation 12V ≤ VIN ≤ 48V ● 0.01 %/V

Voltage Gain 200 600 V/V

VIN

V

= 0V 30 50 µA

SHDN

● 75 µA

● 1.215 1.265 V

● 200 1500 µmho

● 45 220 µA

Page 3

LT1777

ELECTRICAL CHARACTERISTICS

The ● denotes specifications which apply over the full operating temperature range, otherwise specifications are at TJ = 25°C.

VIN = 24V, VSW Open, VCC = 5V, VC = 1.4V unless otherwise noted.

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

Output Switch

R

ON

I

LIM

Current Amplifier

Timing

f Switching Frequency 90 100 110 kHz

Sync Function

SHDN Pin Function

V

SHDN

I

SHDN

Output Switch On Voltage ISW = 0.5A 1.0 1.5 V

Switch Current Limit (Note 3) ● 0.55 0.70 1.0 A

Output dl/dt Sense Voltage 1.3 V

● 0.6 2.0 V

Control Pin Threshold Duty Cycle = 0% 0.9 1.1 1.25 V

Control Voltage to Switch Transconductance 2 A/V

● 85 115 kHz

Maximum Switch Duty Cycle ● 85 90 %

Minimum Sync Amplitude ● 1.5 2.2 V

Synchronization Range ● 130 250 kHz

SYNC Pin Input R 40 kΩ

Shutdown Mode Threshold 0.5 V

● 0.2 0.8 V

Upper Lockout Threshold Switching Action On 1.260 V

Lower Lockout Threshold Switching Action Off 1.245 V

Shutdown Pin Current V

= 0V 12 20 µA

SHDN

V

= 1.25V 2.5 10 µA

SHDN

Note 1: Absolute Maximum Ratings are those values beyond which the life

of a device may be impaired.

Note 2: Control circuitry powered from V

Note 3: Switch current limit is DC trimmed and tested in production.

Inductor dI/dt rate will cause a somewhat higher current limit in actual

application.

CC

.

Note 4: During normal operation the V

below ground. However, the LT1777 may not be used in an inverting

DC/DC configuration.

pin may fly as much as 3V

SW

3

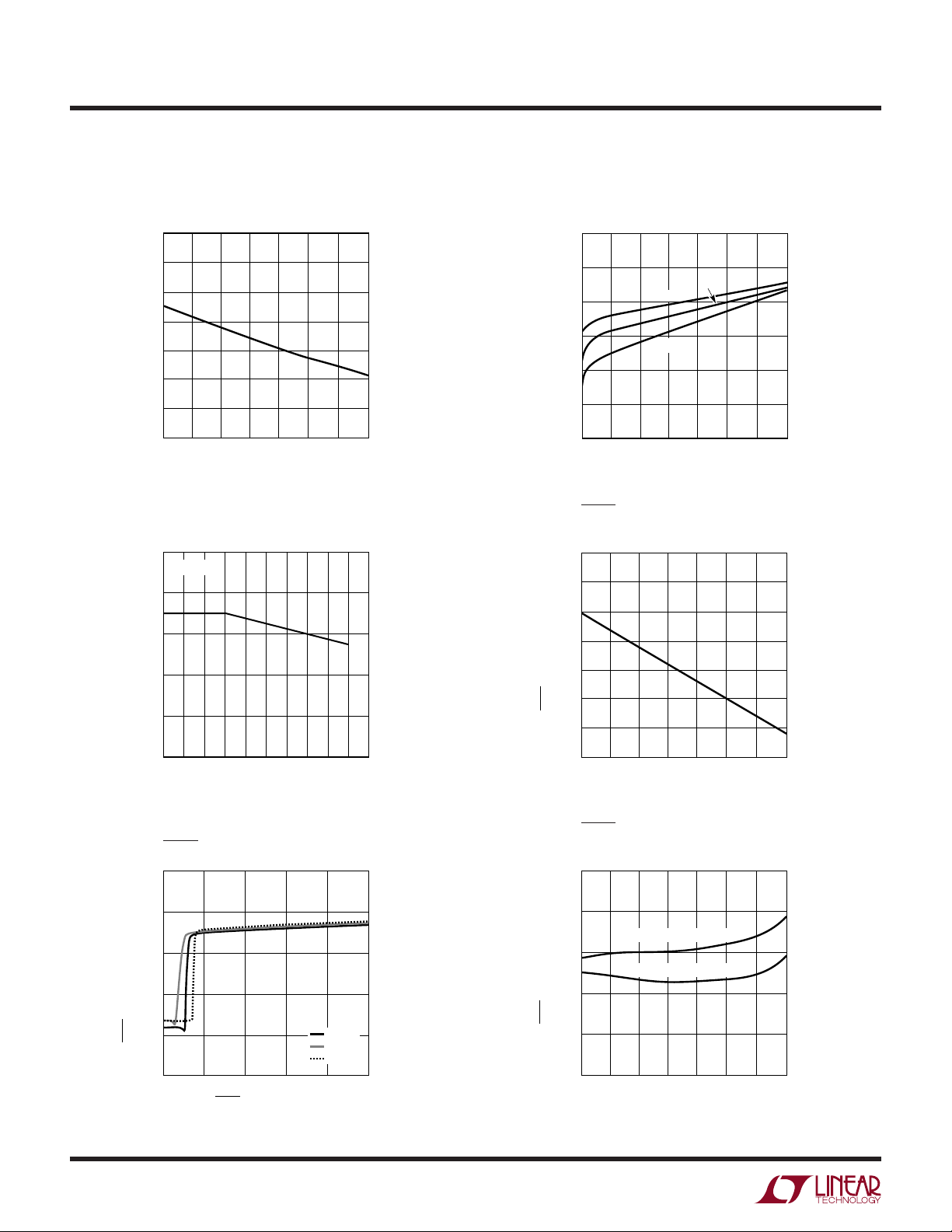

Page 4

LT1777

UW

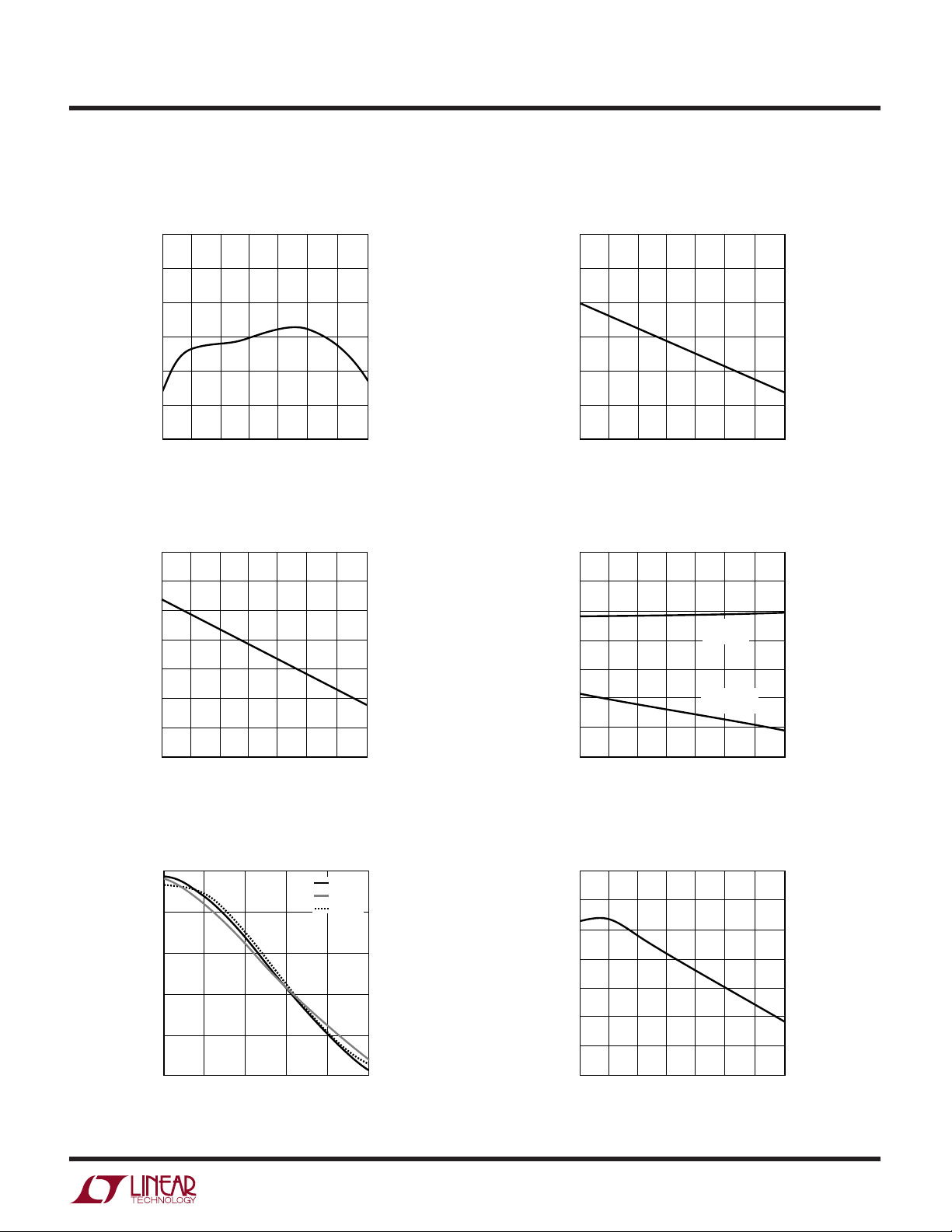

TYPICAL PERFOR A CE CHARACTERISTICS

Minimum Input Voltage

vs Temperature

7.4

7.2

7.0

6.8

6.6

INPUT VOLTAGE (V)

6.4

6.2

6.0

–50

–25 0

TEMPERATURE (°C)

Switch Current Limit

vs Duty Cycle

1000

TA = 25°C

800

600

50 100 125

25 75

1777 G01

Switch On Voltage

vs Switch Current

1.50

1.25

1.00

0.75

0.50

SWITCH VOLTAGE (V)

0.25

0

0

100 200

SWITCH CURRENT (mA)

–55°C

125°C

25°C

400 600 700

300 500

SHDN Pin Shutdown Threshold

vs Temperature

900

800

700

600

1777 G02

400

200

SWITCH CURRENT LIMIT (mA)

0

2010 30 50 70 90

0

40

DUTY CYCLE (%)

SHDN Pin Current vs Voltage

5

0

–5

–10

–15

SHDN PIN INPUT CURRENT (µA)

–20

1

0

2

SHDN PIN VOLTAGE (V)

500

400

SHDN PIN VOLTAGE (mV)

300

60

80

100

1777 G03

200

–50

–25 0

50 100 125

25 75

TEMPERATURE (°C)

1777 G04

SHDN Pin Lockout Thresholds

vs Temperature

1.30

1.28

UPPER THRESHOLD

1.26

LOWER THRESHOLD

1.24

25°C

125°C

–55°C

3

4

5

1777 G05

SHDN PIN VOLTAGE (V)

1.22

1.20

–50

–25 0

TEMPERATURE (°C)

50 100 125

25 75

1777 G06

4

Page 5

UW

TYPICAL PERFOR A CE CHARACTERISTICS

LT1777

Switching Frequency

vs Temperature

106

104

102

100

98

SWITCHING FREQUENCY (kHz)

96

94

–50 25 75

–25 0

TEMPERATURE (°C)

Output dI/dt Sense Voltage

vs Temperature

2.0

1.8

1.6

1.4

50 100 125

1777 G07

Minimum Synchronization

Voltage vs Temperature

2.25

2.00

1.75

1.50

1.25

1.00

MINIMUM SYNCHRONIZATION VOLTAGE (V)

0.75

–50 25 75

–25 0

TEMPERATURE (°C)

50 100 125

VC Pin Switching Threshold,

Clamp Voltage vs Temperature

2.2

2.0

1.8

1.6

CLAMP

VOLTAGE

1777 G08

1.2

1.0

dI/dt SENSE VOLTAGE (V)

0.8

0.6

–50 25 75

–25 0

TEMPERATURE (°C)

Feedback Amplifier Output

Current vs FB Pin Voltage

100

50

0

–50

–100

FEEDBACK AMPLIFIER OUTPUT CURRENT (µA)

–150

1.0

1.1

1.2

FB PIN VOLTAGE (V)

50 100 125

1777 G09

25°C

125°C

–55°C

1.3

1.4

1777 G11

1.5

1.4

PIN VOLTAGE (V)

C

V

1.2

1.0

0.8

–50

–25 0

TEMPERATURE (°C)

SWITCHING

THRESHOLD

50 100 125

25 75

Error Amplifier Transconductance

vs Temperature

750

700

650

600

550

500

TRANSCONDUCTANCE (µmho)

450

400

–50

–25 0

TEMPERATURE (°C)

50 100 125

25 75

1777 G10

1777 G12

5

Page 6

LT1777

PIN FUNCTIONS

UUU

GND (Pins 1, 8, 9, 16): These corner package pins are

mechanically connected to the die paddle and thus aid in

conducting away internally generated heat. As these are

electrically connected to the die substrate, they must be

held at ground potential. A direct connection to the local

ground plane is recommended.

NC (Pins 2, 11, 15): Package Pins 2, 11 and 15 are

unconnected.

SHDN (Pin 3): When pulled below the shutdown mode

threshold, nominally 0.5V, this pin turns off the regulator

and reduces VIN input current to a few tens of microamperes (shutdown mode).

When this pin is held above the shutdown mode threshold,

but below the lockout threshold, the part will be operational with the exception that output switching action will

be inhibited (lockout mode). A user-adjustable undervoltage lockout can be implemented by driving this pin from

an external resistor divider to VIN. This action is logically

“ANDed” with the internal UVLO, nominally set at 6.7V,

such that minimum VIN can be increased above 6.7V, but

not decreased (see Applications Information).

If unused, this pin should be left open. However, the high

impedance nature of this pin renders it susceptible to

coupling from the VSW node, so a small capacitor to

ground, typically 100pF or so is recommended when the

pin is left open.

VCC: (Pin 4): Pin to power the internal control circuitry

from the switching supply output. Proper use of this pin

enhances overall power supply efficiency. During start-up

conditions, internal control circuitry is powered directly

from VIN. If the output capacitor is located more than an

inch from the VCC pin, a separate 0.1µF bypass capacitor

to ground may be required right at the pin.

VD (Pin 5): This pin is used in conjunction with a small

external sense inductor to limit power path dI/dt. The

sense inductor is placed between the VSW output node and

the cathode of the freewheeling (power) diode, and the V

pin is connected to the diode. As the voltage across the

inductor reaches ±2VBE, drive to the output transistor is

D

removed or supplied accordingly to limit dI/dt (see Applications Information).

VSW (Pin 6): This is the emitter node of the output switch

and has large currents flowing through it. Keep the traces

to the switching components as short as possible to

minimize electromagnetic radiation and voltage spikes.

SGND (Pin 7): This is the device signal ground pin. The

internal reference and feedback amplifier are referred to it.

Keep the ground path connection to the FB divider and the

VC compensation capacitor free of large ground currents.

VIN (Pin 10): This is the high voltage supply pin for the

output switch. It also supplies power to the internal control

circuitry during start-up conditions or if the VCC pin is left

open. A high quality bypass capacitor which meets the

input ripple current requirements is needed here (see

Applications Information).

SYNC (Pin 12): Pin to synchronize internal oscillator to

external frequency reference. It is directly logic compatible and can be driven with any signal between 10% and

90% duty cycle. The sync function is internally disabled if

the FB pin voltage is low enough to cause oscillator

slowdown. If unused, this pin should be grounded.

FB (Pin 13): This is the inverting input to the feedback

amplifier. The noninverting input of this amplifier is internally tied to the 1.24V reference. This pin also slows down

the frequency of the internal oscillator when its voltage is

abnormally low, e.g. 2/3 of normal or less. This feature

helps maintain proper short-circuit protection. Coupling

from high speed noise to this pin can cause irregular

operation. (See Switch Node Considerations section.)

VC (Pin 14): This is the control voltage pin which is the

output of the feedback amplifier and the input of the

current comparator. Frequency compensation of the overall loop is effected by placing a capacitor (or in most cases

a series R/C combination) between this node and ground.

Coupling from high speed noise to this pin can cause

irregular operation. (See Switch Node Considerations

section.)

6

Page 7

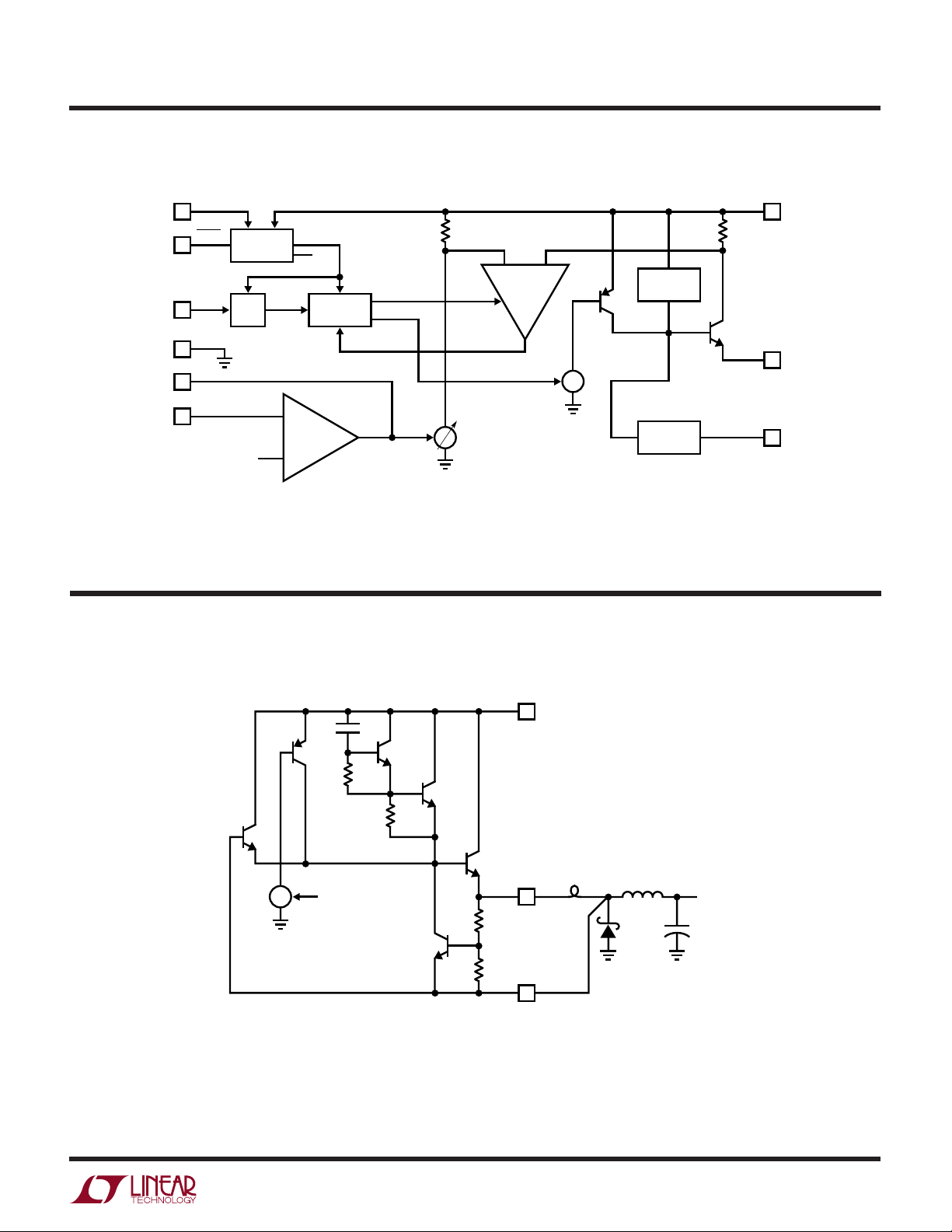

BLOCK DIAGRA

LT1777

W

V

CC

4

V

V

BG

LOGIC

FEEDBACK

AMP

g

m

B

SWDR

SWON

SHDN

3

SYNC

12

SGND

7

V

C

14

FB

13

OSC

V

BG

BIAS

R1

I

I

2

WW

OUTPUT STAGE SI PLIFIED SCHE ATIC

I

COMP

V

IN

10

R

SENSE

–dV/dt

LIMITER

Q2

Q1

V

SW

6

I

1

I

V

±dI/dt

LIMITER

1777 BD

D

5

V

C1

Q3Q2

R1

Q4

R2

Q6

Q1

I

1

SWITCH ON

I

SIGNAL

R3

Q5

R4

IN

L

V

SW

SENSE

L

MAIN

V

OUT

+

V

D

1777 SS

NOTE: R3 = R4

7

Page 8

LT1777

OPERATIO

U

The LT1777 is a current mode step-down switcher regulator IC designed for low noise operation. The Block

Diagram shows an overall view of the system. The individual blocks are straightforward and similar to those

found in traditional designs, including: Internal Bias Regulator, Oscillator, Logic, and Feedback Amplifier. The novel

portion includes a specialized Output Switch section including circuits to limit the dI/dt and dV/dt switching rates.

The LT1777 operates much the same as traditional current

mode switchers, the major difference being its specialized

output switch section. Due to space constraints, this

discussion will not reiterate the basics of current mode

switcher/controllers and the “buck” topology. A good

source of information on these topics is Application Note

AN19.

A straightforward output stage is provided by current

source I1 driving the base of PNP transistor Q2. The

collector of Q2 in turn drives the base of NPN output device

Q1. The considerable base/collector capacitance of PNP

Q2 acts to limit dV/dt rate during switch turn-on. However,

when the switch is to be turned off, the only natural limit

to voltage slew rate would be the collector/base capacitance of Q1 providing drive for the same device. While

dependent upon output load level and Q1’s β, the turn-off

voltage slew rate would be typically much faster than the

turn-on rate. To limit the voltage slew rate on switch turnoff, an extra function is supplied. This is denoted by the

block labeled “–dV/dt Limiter.”

The details of the – dV/dt Limiter can be seen in the Output

Stage Simplified Schematic. Transistors Q3 and Q4 are

connected in a Darlington configuration whose input is

coupled with small-valued capacitor C1 to the VIN supply

rail. The product of negative voltage slew rate times this

capacitor value equals current, and when this current

through emitter/base resistor R1 exceeds a diode drop, Q3

and then Q4 turn on supplying base drive to output device

Q1 to limit –dV/dt rate.

In addition to voltage rates, the current slew rate also

needs to be controlled for reduced noise behavior. This is

provided by the section in the Block Diagram labeled

“±dI/dt Limiter.” The details of this circuit can be seen in

the Output Stage Simplified Schematic. Note that an extra,

small-valued inductor, termed the “sense inductor” has

been added to the classic buck topology. As this inductor

is external to the LT1777, its value can be chosen by the

user allowing for optimization on a per application basis.

Operation of the current slew limiter is as follows: The

product of the sense inductor times the dI/dt through it

generates a voltage according to the well known formula

V = (L)(dI/dt). The remainder of the circuit is configured

such that when the voltage across the sense inductor

reaches ±2VBE, drive current will be supplied or removed

as necessary to limit current slew rate. The actual sensing

is performed between the output node labeled VSW and a

new node labeled VD.

In the case of switch turn-on, current drive is provided by

PNP Q2. If the voltage at VSW reaches 2VBE above that at

VD, transistor Q5 turns on and removes a portion of Q2’s

drive from Q1’s base. Similarly for turn-off, as the V

node goes 2VBE below VD, transistor Q6 then turns on to

drive Q1’s base as needed. The net effect is that of limiting

the switch node dI/dt in both directions at a rate inversely

proportional to the external sense inductor value.

SW

8

Page 9

LT1777

+

+

LT1777

V

IN

C1

D1

V

OUT

1777 F01

C2

L

SENSE

L

MAIN

U

WUU

APPLICATIONS INFORMATION

Basics of Low Noise Operation

Switching power supply circuits are often preferred over

linear topologies for their improved efficiency (P

However, their typically rapid voltage and current slew

rates often cause “radio frequency” interference problems, commonly referred to as “RFI”. The LT1777 is

designed to provide a less aggressive voltage slew rate

and a user-programmable current slew rate to eliminate

the highest frequency harmonics of RFI emissions. These

highest frequency components are typically the most

troublesome. Optimum behavior is obtained by a combination of proper circuit design, which includes passive

component selection, and proper printed circuit board

layout technique.

There are two types of RFI emissions, i.e.,

radiated

. Conducted interference travels directly through

conducted

“wires”, as opposed to radiated interference, which travels

through the air. Conducted RFI can be created by a

switching power supply at its input voltage supply node,

its output node(s) or both. It is typically caused by pulsatile

current flow through the residual high frequency impedance (ESR) of bypass capacitors.

Radiated interference can be of two types: electric (E field)

or magnetic (B field). E field interference is caused by stray

capacitance coupling of the node(s) which swing rapidly

over a large voltage excursion. In the LT1777, this includes the VSW and VD nodes. E field radiation is kept low

by minimizing the length and area of all traces connected

to these nodes. A ground plane should always be used

under the switcher circuitry to prevent interplane coupling. Although these nodes swing over a voltage range

roughly equal to the input voltage, the limited dV/dt rate of

the LT1777 reduces the highest frequency components of

the generated E field RFI.

OUT

/ PIN).

and

external sense inductor to set a maximum allowed dI/dt

rate. This attenuates the highest frequency components of

generated B field RFI. Minimal lead length in the path is

also essential to minimize generated RFI.

A second potential source of magnetic RFI is the main

(power) inductor. Fortunately, the natural triangular behavior of the current waveform in the main inductor tends

to generate magnetic field energy concentrated in the

fundamental and lower harmonics. Nevertheless, the relatively intense magnetic field present in the main inductor

can cause coupling problems, especially if the main inductor is of an open construction type. So called rod or barrel

inductors may be the physically smallest and most effective types, but their magnetic field extends far beyond the

device itself. Closed type inductors, toroids for example,

contain the magnetic field nearly completely. These are

generally preferred for low noise behavior.

The sense inductor sees a much more rapid current slew

rate than does the main inductor. However the sense

inductor is physically smaller and of much lower inductance than the main inductor. These factors tend to reduce

its propensity to generate magnetic interference problems. Nevertheless, more sensitive applications can opt

for a closed type magnetic construction on the sense

inductor.

Figure 1. High Speed Current Switching Paths

B field RFI is simply coupling of high frequency magnetic

fields generated by the offending circuitry. High frequency

magnetic fields are created by relatively rapidly changing

currents, and the high speed current switching path in the

LT1777 is shown schematically in Figure 1. This includes

the input capacitor, output switch, sense inductor and

output diode. Normal switching supply operation requires

a rapid switching of current back and forth between the

output switch and output diode. The LT1777 uses the

Selecting Sense Inductor

The LT1777 uses an external sense inductor to set a

theoretical limit for current ramp rate according to the

formula:

V

2

L

SENSE

BE

Max dI dt

/ =

9

Page 10

LT1777

U

WUU

APPLICATIONS INFORMATION

Deciding upon a value for the sense inductor involves

evaluating the trade-off between overall efficiency (P

PIN) and switch current slew rate. Larger sense inductors

yield lower current slew rates which offer reduced high

frequency RFI emissions, but at the expense of poorer

efficiency.

The question is “What is the allowed range of values for a

sense inductor in a given application?” There is really no

minimum

limit to the sense inductor, i.e., its value is

allowed to be zero. (In other words, the physical sense

inductor ceases to exist and is replaced by a short circuit.)

This will yield the highest efficiency possible in a given

situation. Although an explicit current slew rate no longer

exists, the naturally less aggressive nature of the LT1777

will often yield quieter supply operation than other standard switching regulators.

As far as the

maximum

allowable value for the sense

inductor, this is dictated by the current ramp rate in the

main inductor during the conventional part of the switching cycle. It is generally overconservative to limit the

switch current slew rate to that exhibited by the main

inductor. This would potentially yield a triangular current

waveform. Efficiency would be greatly reduced at little

further gain in noise performance. Stated mathematically,

maximum slew rate in the main inductor occurs at maximum input voltage as:

OUT

/

As an example, a maximum input voltage of 36V, an output

voltage of 5V and a main inductor value of 220µH yields a

maximum suggested sense inductor value of 3.5µH.

Circuit behavior versus sense inductor value is shown in

the oscilloscope photos in Figure 2. The circuit and operating conditions are similar to the Typical Application on

the first page of this data sheet with the exception that the

sense inductor is allowed to assume the series of values:

0µH, 0.47µH, 1µH and 2.2µH. Figure 2a shows a close-up

of the leading edge (turn-on) of the current waveform.

Values of 0µH and 0.47µH are found to yield a dI/dt of

about 2.2A/µs, while 1µH yields 1.4A/µs and 2.2µH yields

0.6A/µs. Figure 2b shows the trailing edge (turn-off) of the

100mA/DIV

200ns/DIV

(a) Leading Edge

1777 F02a

Max V V

dI

=

dt

–

IN OUT

L

MAIN

The sense inductor experiences 2VBE of applied voltage.

This is perhaps 1.0V at a maximum hot condition. If we use

an additional factor of two to be conservative, this yields

a maximum sense inductor value as follows:

L

=

–

IN OUT

MAIN

Max V V

,

or

.

V

–

IN OUT

0505.

L

SENSE

Max L L

Max V V

V

=

SENSE MAIN

10

100mA/DIV

200ns/DIV

(b) Trailing Edge

Figure 2. VSW Node Current Behavior vs L

L

= 0µH, 0.47µH, 1.0µH and 2.2µH

SENSE

1777 F02b

SENSE

Value.

Page 11

LT1777

U

WUU

APPLICATIONS INFORMATION

current waveform. The four sense inductor values of 0µH,

0.47µH, 1µH and 2.2µH yield dI/dt rates of roughly

4.5A/µs, 2.2A/µs, 1.4A/µs and 0.6A/µs, respectively.

These photos show that there is a minimum effective value

for sense inductance, which is 0.47µH for a typical part at

room temperature as shown. This value inductor has a

small effect on the trailing edge rate, but essentially no

effect on the rising edge. Minimum effective sense inductance value means that inductors much smaller than this

value will have substantially the same performance as zero

inductance, such that these inductors serve no useful

purpose.

In summary,

1. The LT1777 uses an external sense inductor to set a

theoretical limit for current ramp rate according to the

formula:

V

2

L

=

BE

SENSE

05.

Max V V

IN OUT

V

–

Max dI dt

/ =

2. Allowable range for the sense inductor runs from a

minimum of 0 to a maximum of:

Max L L

SENSE MAIN

3. The minimum effective inductor size is typically 0.47µH.

Harmonic Behavior

The LT1676 is a high efficiency “cousin” to the LT1777. An

additional set of oscilloscope photographs in Figure 3

show the leading edge and trailing edge of the current

waveform when this part is substituted for the LT1777.

(No sense inductor is used with the LT1676.) The leading

and trailing edges of the LT1676 current waveform are

much faster than that of the LT1777, even when the

LT1777 uses a sense inductor of 0µH. The 10% to 90%

rise time/fall time is on the order of 10ns to 20ns, too fast

to measure accurately at the horizontal sweep rate of

200ns/DIV.

While this time-based analysis demonstrates that the

current waveform of the LT1777 is quieter than standard

high efficiency buck converters, some users may prefer to

see a direct comparison on a frequency domain basis.

Figures 4a, 4b, and 4c show a spectral analysis of the

current waveforms. The horizontal axis is 2MHz/DIV (0MHz

to 20MHz), and the vertical axis is 10dB/DIV. All photos

were taken with VIN = 24V and V

= 5V at 400mA. Figure

OUT

4a is of the LT1676 and is for comparison purposes.

Figures 4b and 4c are of the LT1777 with a sense inductor

of 0µH and 2.2µH, respectively. A decrease in high fre-

quency energy is seen when going from the LT1676 to the

LT1777 with no sense inductor, and a further improvement with a 2.2µH sense inductor. For example, at 10MHz,

the LT1777 shows an improvement of about –10dB with

0µH and perhaps –25dB with 2.2µH.

100mA/DIV

200ns/DIV

(a) Leading Edge

Figure 3. LT1676 Current Behavior for Comparison Purposes Only

1777 F03a

100mA/DIV

200ns/DIV

(b) Trailing Edge

1777 F03b

11

Page 12

LT1777

U

WUU

APPLICATIONS INFORMATION

10dB/DIV

0MHz to 20MHz (2MHz/DIV)

(a) LT1676 for Comparison

10dB/DIV

1777 F04a

voltage of 12V, and then 36V. Once again the circuit is the

Typical Application shown on the first page of this data

sheet, with an output load of 400mA.

Figure 5a, with VIN of 12V, shows a relatively rectangular

voltage waveform. The limited voltage slew rate still allows

for nearly vertical switching edges, so little power is

wasted. A positive-going step before the leading edge and

a negative-going step after the trailing edge can be seen.

These are evidence of the internal current limiting circuitry

at work.

Figure 5b, with VIN of 36V, shows a substantially

nonrectangular waveform. The limited voltage slew rate is

clearly evident as transitions take a few hundred nanoseconds. Efficiency (P

OUT/PIN

) is reduced as a result of the

slower transitions. For comparison purposes, the oscilloscope photo in Figure 6 shows the performance of the high

efficiency LT1676. Voltage transitions are well under

100ns and the waveform appears quite rectangular.

0MHz to 20MHz (2MHz/DIV)

(b) LT1777 with L

10dB/DIV

0MHz to 20MHz (2MHz/DIV)

(c) LT1777 with L

Figure 4. Spectral Analysis of Current Waveforms in

Figures 2 and 3. (VIN = 24V, V

SENSE

SENSE

OUT

= 0µH

= 2.2µH

= 5V, I

1777 F04b

1777 F04c

= 400mA)

OUT

Voltage Waveform Behavior

Unlike current behavior, voltage slew rate of the LT1777 is

not adjustable by the user. No component selection or

other action is required. Nevertheless, it is instructive to

examine typical behavior. The oscilloscope photos in

Figure 5 show the VSW voltage waveform with an input

2V/DIV

GND

1µs/DIV

(a) VIN = 12V

10V/DIV

GND

500ns/DIV

(b) VIN = 36V

Figure 5. VSW Node Voltage Behavior

1777 F05a

1777 F05b

12

Page 13

LT1777

U

WUU

APPLICATIONS INFORMATION

10V/DIV

GND

500ns/DIV

Figure 6. LT1676 VSW Node Voltage Behavior

for Comparison Purposes Only, VIN = 36V

Selecting Main Inductor

There are several parameters to consider when selecting

a main inductor. These include inductance value, peak

current rating (to avoid core saturation), DC resistance,

construction type, physical size, and of course, cost.

Once the inductance value is decided, inductor peak

current rating and resistance need to be considered. Here,

the inductor peak current rating refers to the onset of

saturation in the core material, although manufacturers

sometimes specify a “peak current rating” which is derived from a worst-case combination of core saturation

and self-heating effects. Inductor winding resistance alone

limits the inductor’s current carrying capability as the I2R

power threatens to overheat the inductor. Remember to

include the condition of output short circuit, if applicable.

Although the peak current rating of the inductor can be

exceeded in short-circuit operation, as core saturation per

se is not destructive to the core, excess resistive selfheating is still a potential problem.

The final inductor selection is generally based on cost,

which usually translates into choosing the smallest physical size part which meets the desired inductance value,

resistance and current carrying capability. An additional

factor to consider is that of physical construction. Briefly

stated, “open” inductors built on a rod- or barrel-shaped

core generally offer the smallest physical size and lowest

cost. However their open construction does not contain

the resulting magnetic field, and they may not be acceptable in RFI-sensitive applications. (A mitigating factor is

that, as mentioned previously, the AC current passing

1777 F06

through the main inductor has most of its energy concentrated in the fundamental and lower harmonics.) Toroidal

style inductors, many available in surface mount configuration, offer a reduced external magnetic field, generally at

an increase in cost and physical size. Although custom

design is always a possibility, most potential LT1777 applications can be handled by the array of standard, off-theshelf inductor products offered by the major suppliers.

Selecting Bypass Capacitors

The basic topology as shown in the Typical Application on

the first page uses two bypass capacitors, one for the V

input supply and one for the V

User selection of an appropriate output capacitor is relatively easy, as this capacitor sees only the AC ripple current

in the inductor L1. As the LT1777 is designed for buck or

step-down applications, output voltage will nearly always

be compatible with tantalum type capacitors, which are

generally available in ratings up to 35V or so. These

tantalum types offer good volumetric efficiency, and many

are available with specified ESR performance. The product

of inductor AC ripple current and output capacitor ESR will

manifest itself as peak-to-peak voltage ripple on the output

node. (Note: If this ripple becomes too large, heavier

control loop compensation, at least at the switching frequency, may be required on the VC pin.)

The input bypass capacitor can present a more difficult

choice. In a typical application e.g., 24VIN to 5V

relatively heavy VIN current is drawn by the power switch

for only a small portion of the oscillator period (low ON

duty cycle). The resulting RMS ripple current, for which

the capacitor must be rated, can be several times the DC

average VIN current. The straightforward choice for a low

volume, surface mountable electrolytic capacitor with

good ESR/ripple current ratings is a tantalum type. However, worst-case (high) input voltage coupled with standard capacitor voltage derating may exceed the 35V or so

for which tantalum capacitors are generally available.

Relatively bulky “high frequency” aluminum electrolytic

types, specifically constructed and rated for switching

supply applications, may then be the only choice.

Additionally, it may be advantageous to parallel the input

and output capacitors with 0.1µF ceramic bypass capaci-

output supply.

OUT

OUT

IN

,

13

Page 14

LT1777

FB DIVIDER THEVENIN VOLTAGE (V)

0

0

f

OSC

(kHz)

20

40

60

80

100

120

0.25 0.50 0.75 1.00

1777 F07

1.25

R

TH

LT1777

FB

RTH = 10k RTH = 4.7k

R

TH

= 22k

U

WUU

APPLICATIONS INFORMATION

tors. Their relatively low ESR in the mid-MHz region can

further attenuate high speed glitches.

Maximum Load/Short-Circuit Considerations

The LT1777 is a current mode controller. It uses the V

node voltage as an input to a current comparator, which

turns off the output switch on a cycle-by-cycle basis as

this peak current is reached. The internal clamp on the V

node, nominally 2.0V, then acts as an output switch peak

current limit. This action becomes the switch current limit

specification. The maximum available output power is

then determined by the switch current limit.

A potential controllability problem could occur under

short-circuit conditions. If the power supply output is

short circuited, the feedback amplifier responds to the low

output voltage by raising the control voltage, VC, to its

peak current limit value. Ideally, the output switch would

be turned on, and then turned off as its current exceeded

the value indicated by VC. However, there is finite response

time involved in both the current comparator and turn-off

of the output switch. These result in a minimum on time

t

ON(MIN)

. When combined with the large ratio of VIN to

(VF + I • R), the diode forward voltage plus inductor I • R

voltage drop, the potential exists for a loss of control.

Expressed mathematically the requirement to maintain

control is:

C

C

The solution to this dilemma is to slow down the oscillator

when the FB pin voltage is abnormally low thereby indicating some sort of short-circuit condition. Figure 7 shows

the typical response of oscillator frequency vs FB pin

voltage. Oscillator frequency is normal until FB voltage

drops to about half of its normal value. Below this point the

oscillator frequency decreases linearly down to a limit of

about 25kHz. This lower oscillator frequency during shortcircuit conditions can then maintain control with the

effective minimum on time.

A further potential problem with short-circuit operation

might occur if the user were operating the part with its

oscillator slaved to an external frequency source via the

SYNC pin. However, the LT1777 has circuitry to automatically disable the sync function when the oscillator is

slowed down due to abnormally low FB voltage.

ft

()( )

where:

f = switching frequency

tON = switch on time

VF = diode forward voltage

VIN = Input voltage

I • R = inductor I • R voltage drop

If this condition is not observed, the current will not be

limited at IPK, but will cycle-by-cycle ratchet up to some

higher value. Using the nominal LT1777 clock frequency

of 100kHz, a VIN of 48V and a (VF + I • R) of say, 0.7V, the

maximum tON to maintain control would be approximately

140ns, an unacceptably short time.

14

ON

VIR

+ •

F

≤

V

IN

Figure 7. Oscillator Frequency vs FB Divider

Thevenin Voltage and Impedance

Feedback Divider Considerations

An LT1777 application typically includes a resistive divider

between V

the FB pin to the reference voltage V

and ground, the center node of which drives

OUT

. This establishes

REF

a fixed ratio between the two resistors, but a second

degree of freedom is offered by the overall impedance

level of the resistor pair. The most obvious effect this has

is one of efficiency—a higher resistance feedback divider

will waste less power and offer somewhat higher efficiency, especially at light load.

Page 15

LT1777

U

WUU

APPLICATIONS INFORMATION

However, remember that oscillator slowdown to achieve

short-circuit protection (discussed above) is dependent

on FB pin behavior, and this in turn, is sensitive to FB node

external impedance. The graph in Figure 7 shows the

typical relationship between FB pin voltage, driving impedance and oscillator frequency. This shows that as

feedback network impedance increases beyond 10k, complete oscillator slowdown is not achieved, and shortcircuit protection may be compromised. And as a practical

matter, the product of FB pin bias current and larger FB

network impedances will cause increasing output voltage

error. (Nominal cancellation for 10k of FB Thevenin impedance is included internally.)

Thermal Considerations

Care should be taken to ensure that the worst-case input

voltage and load current conditions do not cause excessive die temperatures. The SO16 package is rated at

50°C/W when the four corner package pins are connected

to a good ground plane. (These corner pins are internally

fused to the die paddle for improved thermal performance.) Die junction temperature is then a function of

ambient temperature and internal dissipation as follows:

TJ = TA + θ

Total internally dissipated power is composed of three

parts, quiescent power, DC switch loss and AC switch

loss. The AC switch loss will often dominate the total

dissipation, and this is unfortunately difficult to estimate

accurately.

Two options are suggested to the potential user. The first

is to observe the graphical data presented in the Typical

Applications section. Internal LT1777 dissipation vs load

current is given for output voltages of 5V and 3.3V, with

input voltages of 12V, 24V and 36V, and with sense

inductors of 0µH, 1µH, and 2.2µH (Figures 9 and 11).

While it is true that the user’s ultimate circuit may use

somewhat different passive components than the examples given, it turns out that internal IC dissipation is not

very sensitive to these changes.

In cases where the user’s potential circuit differs significantly from the examples given, an empirical method is

JA

• P

INT

suggested. Operate the proposed power supply over the

applicable input voltage and load current ranges. Measure

the input power and output power, and calculate the

difference as “lost power.” This measured lost power

minus estimated inductor and diode dissipation yields a

figure for internal LT1777 dissipation. Fortunately, as

LT1777 internal dissipation dominates total lost power,

inductor and diode power need not be estimated very

accurately. Inductor power may be estimated as I2R where

I is the load current and R is the DC resistance of the

inductor. (Loss in the sense inductor is usually so small

that only the main inductor must be considered.) Diode

power may be estimated as 1/2 • VF • I • DC, where VF is the

diode forward voltage, I is the load current and DC is the

duty cycle percentage when the diode is conducting.

Frequency Compensation

Loop frequency compensation is performed by connecting a capacitor, or in most cases a series R/C, from the

output of the error amplifier (VC pin) to ground. Proper

loop compensation may be obtained by empirical methods as described in detail in Application Note AN19.

Briefly, this involves applying a load transient and observing the dynamic response over the expected range of V

and I

As a practical matter, a second small capacitor, directly

from the VC pin to ground is generally recommended to

attenuate capacitive coupling from the VSW and VD pins. A

typical value for this capacitor is 100pF. (See Switch Node

Considerations).

Switch Node Considerations

In spite of the fact that the LT1777 is a low noise converter,

it is still possible for the part to cause problems by

“coupling to itself.” Specifically, this can occur if the V

pin is allowed to capacitively couple in an uncontrolled

manner to the part’s high impedance nodes, i.e., SHDN,

SYNC, VC and FB. This can cause erratic operation such as

odd/even cycle behavior, pulse width “nervousness”, improper output voltage and/or premature current limit

action.

LOAD

values.

IN

SW

15

Page 16

LT1777

U

WUU

APPLICATIONS INFORMATION

As an example, assume that the capacitance between the

VSW node and a high impedance pin node is 0.1pF, and that

the high impedance node in question exhibits a capacitance of 1pF to ground. Also assume a “typical” 36VIN to

5V

application. Due to the large voltage excursion at

OUT

the VSW node, this will couple a 3.5V(!) transient to the

high impedance pin, causing abnormal operation. An

explicit 100pF capacitor added to the node will reduce the

amplitude of the disturbance to more like 35mV (although

settling

time

will increase).

Specific pin recommendations are as follows:

SHDN: If unused, add a 100pF capacitor to ground.

SYNC: Ground if unused.

VC: Add a capacitor directly to ground in addition to the

explicit compensation network. A value of one-tenth of

the main compensation capacitor is recommended, up

to a maximum of 100pF.

FB: Assuming the VC pin is handled properly, this pin

usually requires no explicit capacitor of its own, but

keep this node physically small to minimize stray

capacitance.

16

Page 17

U

TYPICAL APPLICATIONS

LT1777

Basic 5V Output Application

Figure 8 shows a basic application that produces 5V at up

to 500mA I

. Efficiency and Internal Power Dissipation

OUT

graphs are shown in Figure 9 for input voltages of 12V,

24V and 36V, and for sense inductor values of 0µH, 1µH

and 2.2µH. Be aware that continuous operation at the

combination of high input voltage, large sense inductor

and high output current may not be possible due to

thermal constraints. (Brief transients in input voltage or

V

10V TO 40V

IN

+

C1

39µF

63V

C1: PANASONIC HFQ ELECTROLYTIC

C2: AVX D CASE TPSD107M010R0080

C3, C4, C5: NPO OR X7R

C6, C7: Z5U

D1: MOTOROLA 100V, 1A SMD SCHOTTKY

MBRS1100

C6

0.1µF

C4

100pF

C5

100pF

R3

12k

C3

2200pF

3

12

14

10

V

IN

V

SHDN

SYNC

V

CC

LT1777

V

SW

V

C

D

FB

SGND

7

L1: SENSE INDUCTOR CAN VARY FROM 0µH TO 2.2µH

AS PER APPLICATION. GRAPHICAL DATA TAKEN WITH:

1µH = D01608C-102, COILCRAFT OR SIMILAR

2.2µH = D01608C-222, COILCRAFT OR SIMILAR (SEE TEXT)

L2: COILCRAFT D03316-224 OR SIMILAR (SEE TEXT)

output current should not present a problem, though.) As

shown, the SHDN and SYNC pins are unused, however

either (or both) can be optionally driven by external signals

as desired.

The data as shown were performed using an off-the-shelf

Coilcraft DO3316-224 as the main inductor. This is a

cost-effective inductor using an open style of construction. For a toroidal style inductor, the Coiltronics

CTX250-4 or similar may be substituted.

4

L1

0µH TO 2.2µH

(SEE BELOW)

6

5

13

220µH

D1

L2

V

OUT

+

C2

100µF

10V

C7

0.1µF

R1

36.5k

1%

R2

12.1k

1%

1777 F08

5V

Figure 8. Basic 5V Output Application

17

Page 18

LT1777

I

OUT

(mA)

0

0.6

0.4

0.2

1.4

1.2

1.0

0.8

1777 F09b

INTERNAL DISSIPATION (W)

10

1000

100

1µH

0µH

L

SENSE

=

2.2µH

VIN = 12V

V

OUT

= 5V

T

A

= 25°C

I

OUT

(mA)

0

0.6

0.4

0.2

1.4

1.2

1.0

0.8

1777 F09d

INTERNAL DISSIPATION (W)

10

1000

100

1µH

0µH

L

SENSE

=

2.2µH

VIN = 24V

V

OUT

= 5V

T

A

= 25°C

I

OUT

(mA)

0

0.6

0.4

0.2

1.4

1.2

1.0

0.8

1777 F09f

INTERNAL DISSIPATION (W)

10

1000

100

1µH

0µH

L

SENSE

=

2.2µH

VIN = 36V

V

OUT

= 5V

T

A

= 25°C

U

TYPICAL APPLICATIONS

VIN = 12V

VIN = 24V

90

VIN = 12V

V

OUT

80

= 25°C

T

A

70

60

50

EFFICIENCY (%)

40

30

20

1

90

VIN = 24V

V

OUT

80

T

= 25°C

A

70

60

50

EFFICIENCY (%)

40

Efficiency

= 5V

10 100 1000

I

(mA)

LOAD

= 5V

L

L

SENSE

SENSE

0µH

0µH

Internal Dissipation

=

1µH

2.2µH

1777 F09a

=

1µH

2.2µH

VIN = 36V

30

20

90

80

70

60

50

EFFICIENCY (%)

40

30

20

1

1

VIN = 36V

V

OUT

= 25°C

T

A

Figure 9. Efficiency and LT1777 Internal Dissipation for the Basic 5V Output Application

10 100 1000

I

(mA)

LOAD

= 5V

10 100 1000

I

(mA)

LOAD

L

SENSE

0µH

1777 F09c

=

1µH

2.2µH

1777 F09e

18

Page 19

U

TYPICAL APPLICATIONS

LT1777

Basic 3.3V Output Application

Figure 10 shows a circuit similar to the previous example,

but modified for a 3.3V output. Once again, Efficiency and

Internal Power Dissipation graphs are shown in Figure 11

for input voltages of 12V, 24V and 36V, and for sense

inductor values of 0µH, 1µH and 2.2µH. It is interesting to

note that internal LT1777 dissipation is very close to the

5V example. This confirms the fact that internal LT1777

V

10V TO 40V

IN

+

C1

39µF

63V

C1: PANASONIC HFQ ELECTROLYTIC

C2: AVX D CASE TPSD107M010R0080

C3, C4, C5: NPO OR X7R

C6, C7: Z5U

D1: MOTOROLA 100V, 1A SMD SCHOTTKY

MBRS1100

C4

100pF

C6

0.1µF

C5

100pF

R3

12k

C3

2200pF

3

12

14

10

V

IN

V

SHDN

SYNC

V

CC

LT1777

V

SW

V

C

D

FB

SGND

7

L1: SENSE INDUCTOR CAN VARY FROM 0µH TO 2.2µH

AS PER APPLICATION. GRAPHICAL DATA TAKEN WITH:

1µH = D01608C-102, COILCRAFT OR SIMILAR

2.2µH = D01608C-222, COILCRAFT OR SIMILAR (SEE TEXT)

L2: COILCRAFT D03316-154 OR SIMILAR (SEE TEXT)

dissipation is largely determined by input voltage, load

current and sense inductor, and is only a weak function of

output voltage.

The data as shown were performed using an off-the-shelf

Coilcraft DO3316-154 as the main inductor. This is a costeffective inductor using an open style of construction. For

a toroidal style inductor, the Coiltronics CTX150-4 or

similar may be substituted.

4

L1

0µH TO 2.2µH

(SEE BELOW)

6

5

13

L2

150µH

D1

V

OUT

+

C2

100µF

10V

C7

0.1µF

R1

20k

1%

R2

12.1k

1%

1777 F10

3.3V

Figure 10. Basic 3.3V Output Application

19

Page 20

LT1777

I

OUT

(mA)

0

0.6

0.4

0.2

1.4

1.2

1.0

0.8

1777 F11b

INTERNAL DISSIPATION (W)

10

1000

100

1µH

0µH

L

SENSE

=

2.2µH

VIN = 12V

V

OUT

= 3.3V

T

A

= 25°C

I

OUT

(mA)

0

0.6

0.4

0.2

1.4

1.2

1.0

0.8

1777 F11d

INTERNAL DISSIPATION (W)

10

1000

100

1µH

0µH

L

SENSE

=

2.2µH

VIN = 24V

V

OUT

= 3.3V

T

A

= 25°C

I

OUT

(mA)

0

0.6

0.4

0.2

1.4

1.2

1.0

0.8

1777 F11f

INTERNAL DISSIPATION (W)

10

1000

100

1µH

0µH

L

SENSE

=

2.2µH

VIN = 36V

V

OUT

= 3.3V

T

A

= 25°C

U

TYPICAL APPLICATIONS

VIN = 12V

VIN = 24V

90

VIN = 12V

V

OUT

80

= 25°C

T

A

70

60

50

EFFICIENCY (%)

40

30

20

1

90

VIN = 24V

V

OUT

80

= 25°C

T

A

70

60

50

EFFICIENCY (%)

40

Efficiency

= 3.3V

10 100 1000

I

(mA)

LOAD

= 3.3V

L

SENSE

L

SENSE

0µH

0µH

Internal Dissipation

=

1µH

2.2µH

1777 F11a

=

1µH

2.2µH

VIN = 36V

30

20

1

90

80

70

60

50

EFFICIENCY (%)

40

30

20

1

10 100 1000

I

(mA)

LOAD

VIN = 36V

= 3.3V

V

OUT

= 25°C

T

A

10 100 1000

I

(mA)

LOAD

Figure 11. Efficiency and LT1777 Internal Dissipation for the Basic 3.3V Output Application

L

SENSE

0µH

1777 F11c

=

1µH

2.2µH

1777 F11e

20

Page 21

U

TYPICAL APPLICATIONS

LT1777

Optional Input/Output Filtering

When minimum

conducted

noise is required, it is often

advantageous to add an explicit input and/or output filter

to the topology. This can be a cost-effective way to reduce

conducted noise on the input or output node by an order

of magnitude or more. The exact details involved are a bit

lengthy, so the user is referred to the thorough treatments

in Application Notes AN19 and AN44. However, an example will be given to illustrate the principles involved.

Figure 12 shows the previous “Basic 5V Output Application” modified with an additional input inductor and an

output L/C combination. The dramatic improvement in

noise performance is seen in the accompanying oscilloscope photos shown in Figures 13 and 14. Operating

conditions are VIN = 24V, I

= 400mA. The pair of scope

OUT

photos in Figure 13 show the response at the input node,

before and after the additional 33µH inductor is added. The

upper waveform shows an AC-coupled version of the

L3

33µH

V

IN

+

3

12

14

Figure 12. Basic 5V Application with Optional Input/Output Filters

SHDN

SYNC

V

C

V

IN

LT1777

SGND

10

4

V

CC

6

V

SW

5

V

D

13

FB

7

output voltage at 50mV/DIV, and the lower waveform is a

DC-coupled representation of current into the node at

50mA/DIV. Input voltage ripple is seen to decrease from

100mV

to perhaps 10mV

P-P

. Ripple current is also seen

P-P

to decrease dramatically. (This improvement in AC ripple

current actually affects

radiated

magnetic noise.)

The next pair of scope photos in Figure 14 show an

AC-coupled version of the output node at 2mV/DIV.

Voltage ripple is seen to be originally about 12mV

P-P

, with

most of the energy in the lowest harmonics. After the

addition of a 4.7µH inductor and a second 100µF output

capacitor, ripple is about 200µV

P-P

.

These input and output inductor requirements are typically

not very difficult to achieve, and inexpensive open style

DO1608C types were used in this example. Once again,

more costly closed-construction style inductors may be

employed, but these are usually not necessary, as the AC

fields generated by these inductors are typically small.

L4

4.7µH

+

D1

ADDITIONAL FILTER COMPONENTS

L3: COILCRAFT D01608C-333 OR SIMILAR

L4: COILCRAFT D01608C-472 OR SIMILAR

C8: AVX D CASE TPSD107M010R0080

1777 F12

V

OUT

+

C8

100µF

10V

VIN NODE VOLTAGE

AC COUPLED

50mV/DIV

VIN NODE CURRENT

DC COUPLED

50mA/DIV

GND, CH2

2µs/DIV

(a) Before Input Inductor

VIN NODE VOLTAGE

V

NODE CURRENT

IN

1777 F13a

Figure 13. Input Node Ripple

AC COUPLED

50mV/DIV

DC COUPLED

50mA/DIV

GND, CH2

2µs/DIV

(b) After Input Inductor

1777 F13b

21

Page 22

LT1777

U

TYPICAL APPLICATIONS

V

NODE

OUT

AC COUPLED

2mV/DIV

V

NODE

OUT

AC COUPLED

2mV/DIV

2µs/DIV

(a) Before Output Filter

1777 F13a

Figure 14. Output Node Ripple

User Programmable Undervoltage Lockout

Figure 15 uses a resistor divider between VIN and ground

to drive the SHDN node. This is a simple, cost-effective

way to add a user-programmable undervoltage lockout

(UVLO) function. Resistor R5 is chosen to have approximately 200µA through it at the nominal SHDN pin lockout

threshold of roughly 1.25V. The somewhat arbitrary value

of 200µA was chosen to be significantly above the SHDN

pin input current to minimize its error contribution, but

significantly below the typical 2.5mA the LT1777 draws in

lockout mode. Resistor R4 is then chosen to yield this

same 200µA, less 2.5µA, with the desired VIN UVLO voltage minus 1.25V across it. (The 2.5mA factor is an allowance to minimize error due to SHDN pin input current.)

2µs/DIV

(b) After Output Filter

1777 F14b

Behavior is as follows: Normal operation is observed at the

nominal input voltage of 24V. As the input voltage is

decreased to roughly 18V, switching action will stop, V

will drop to zero, and the LT1777 will draw its VIN and V

OUT

CC

quiescent currents from the VIN supply. At a lower input

voltage, typically 10V or so at 25°C, the voltage on the

SHDN pin will drop to the shutdown threshold, and the part

will draw its shutdown current only from the VIN rail. The

resistive divider of R4 and R5 will continue to draw power

from VIN. (The user should be aware that while the SHDN

pin

lockout

threshold is relatively accurate including

temperature effects, the SHDN pin shutdown threshold is

more coarse, and exhibits considerably more temperature

drift. Nevertheless the

shutdown

threshold will always be

well below the lockout threshold.)

22

V

IN

R4

84.5k

1%

R5

6.19k

1%

Figure 15. User Programmable UVLO

C5

100pF

LT1777

SHDN

1777 F15

Page 23

PACKAGE DESCRIPTION

U

Dimensions in inches (millimeters) unless otherwise noted.

S Package

16-Lead Plastic Small Outline (Narrow 0.150)

(LTC DWG # 05-08-1610)

0.386 – 0.394*

(9.804 – 10.008)

13

16

14

15

12

11

LT1777

10

9

0.010 – 0.020

(0.254 – 0.508)

0.008 – 0.010

(0.203 – 0.254)

*

DIMENSION DOES NOT INCLUDE MOLD FLASH. MOLD FLASH

SHALL NOT EXCEED 0.006" (0.152mm) PER SIDE

**

DIMENSION DOES NOT INCLUDE INTERLEAD FLASH. INTERLEAD

FLASH SHALL NOT EXCEED 0.010" (0.254mm) PER SIDE

×

°

45

0.016 – 0.050

(0.406 – 1.270)

0° – 8° TYP

0.228 – 0.244

(5.791 – 6.197)

0.053 – 0.069

(1.346 – 1.752)

0.014 – 0.019

(0.355 – 0.483)

TYP

0.150 – 0.157**

(3.810 – 3.988)

4

5

0.050

(1.270)

BSC

3

2

1

7

6

8

0.004 – 0.010

(0.101 – 0.254)

S16 1098

Information furnished by Linear Technology Corporation is believed to be accurate and reliable.

However, no responsibility is assumed for its use. Linear Technology Corporation makes no representation that the interconnection of its circuits as described herein will not infringe on existing patent rights.

23

Page 24

LT1777

TYPICAL APPLICATION

U

Minimum PC Board Size Application

The previously described basic applications employ power

path parts which are capable of delivering the full rated

input supply voltage and output current capabilities of the

LT1777. A substantial improvement in printed circuit

board area requirements can be achieved with the circuit

shown below. This uses a physically smaller and less

costly power inductor and a tantalum input capacitor. This

Minimum PC Board Area Application

V

10V TO 28V

IN

+

C1

22µF

35V

C1: AVX E CASE TPSE226M035R0300

C2: AVX D CASE TPSD107M010R0080

C3, C4, C5: NPO OR X7R

C6, C7: Z5U

D1: MOTOROLA 100V, 1A SMD SCHOTTKY

MBRS1100

C4

100pF

C6

0.1µF

C5

100pF

R3

12k

C3

2200pF

3

12

14

10

V

IN

V

SHDN

SYNC

V

CC

LT1777

V

SW

V

C

D

FB

SGND

7

L1: SENSE INDUCTOR CAN VARY FROM 0µH TO 2.2µH

AS PER APPLICATION. SEE PREVIOUS SCHEMATICS

FOR EXAMPLES

L2: COILCRAFT CTX200-1 OR SIMILAR

circuit is capable of delivering up to 300mA at 5V, from

input voltages as high as 28V. The only disadvantage is

that due to the increased resistance in the inductor, the

circuit is no longer capable of withstanding indefinite short

circuits to ground. The LT1777 will still current limit at its

nominal I

value, but this will overheat the inductor.

LIM

Momentary short circuits of a few seconds or less can still

be tolerated.

4

L1

0µH TO 2.2µH

(SEE BELOW)

6

5

13

200µH

D1

L2

V

OUT

+

C2

100µF

10V

C7

0.1µF

R1

36.5k

1%

R2

12.1k

1%

1777 TA03

5V

RELATED PARTS

PART NUMBER DESCRIPTION COMMENTS

LT1076 100kHz, 2A Step-Down Switching Regulator Integrated 2A Switch, VIN Up to 46V

LT1533 Ultralow Noise 1A Switching Regulator Push-Pull Design for Low Noise Isolated Supplies

LT1534 Ultralow Noise 2A Switching Regulator Ultralow Noise Regulator for Boost Topologies

LT1576 200kHz, 1.5A Step-Down Switching Regulator Output Up to 1.25A, Integrated Switch, SO-8 Package

LTC1622 Low VIN Step-Down DC/DC Controller Fixed Frequency 550kHz Operation, MSOP Package

LTC1624 High Efficiency SO-8 DC/DC Controller 200kHz Operation, VIN from 3.5V to 36V, SO-8 Package

LT1676/LT1776 Wide Input Range, High Efficiency, Step-Down Voltage Regulator 7.4V to 60V Input, 100/200kHz Operation, 700mA Internal Switch

1777f LT/TP 0899 4K • PRINTED IN USA

LINEAR TECHNOLOGY CORPORATION 1999

24

Linear Technology Corporation

1630 McCarthy Blvd., Milpitas, CA 95035-7417

(408) 432-1900 ● FAX: (408) 434-0507

●

www.linear-tech.com

Loading...

Loading...