Page 1

LM3916

Dot/Bar Display Driver

General Description

The LM3916 is a monolithic integrated circuit that senses

analog voltage levels and drives ten LEDs, LCDs or vacuum

fluorescent displays, providing an electronic version of the

popular VU meter. One pin changes the display from a bar

graph to a moving dot display. LED current drive is regulated

and programmable, eliminating the need for current limiting

resistors. The whole display system can operate from a

single supply as low as 3V or as high as 25V.

The IC contains an adjustable voltage reference and an

accurate ten-step voltage divider. The high-impedance input

buffer accepts signals down to ground and up to within 1.5V

of the positive supply. Further, it needs no protection against

inputs of

parators referenced to the precision divider. Accuracy is

typically better than 0.2 dB.

Audio applications include average or peak level indicators,

and power meters. Replacing conventional meters with an

LED bar graph results in a faster responding, more rugged

display with high visibility that retains the ease of interpretation of an analog display.

The LM3916 is extremely easy to apply. A 1.2V full-scale

meter requires only one resistor in addition to the ten LEDs.

One more resistor programs the full-scale anywhere from

1.2V to 12V independent of supply voltage. LED brightness

is easily controlled with a single pot.

±

35V. The input buffer drives 10 individual com-

January 2000

The LM3916 is very versatile. The outputs can drive LCDs,

vacuum fluorescents and incandescent bulbs as well as

LEDs of any color. Multiple devices can be cascaded for a

dot or bar mode display for increased range and/or resolution. Useful in other applications are the linear LM3914 and

the logarithmic LM3915.

Features

n Fast responding electronic VU meter

n Drivers LEDs, LCDs, or vacuum fluorescents

n Bar or dot display mode externally selectable by user

n Expandable to displays of 70 dB

n Internal voltage reference from 1.2V to 12V

n Operates with single supply of 3V to 25V

n Inputs operate down to ground

n Output current programmable from 1 mA to 30 mA

n Input withstands

n Outputs are current regulated, open collectors

n Directly drives TTL or CMOS

n The internal 10-step divider is floating and can be

referenced to a wide range of voltages

The LM3916 is rated for operation from 0˚C to +70˚C. The

LM3916N-1 is available in an 18-lead molded DIP package.

±

35V without damage or false outputs

LM3916 Dot/Bar Display Driver

© 2004 National Semiconductor Corporation DS007971 www.national.com

Page 2

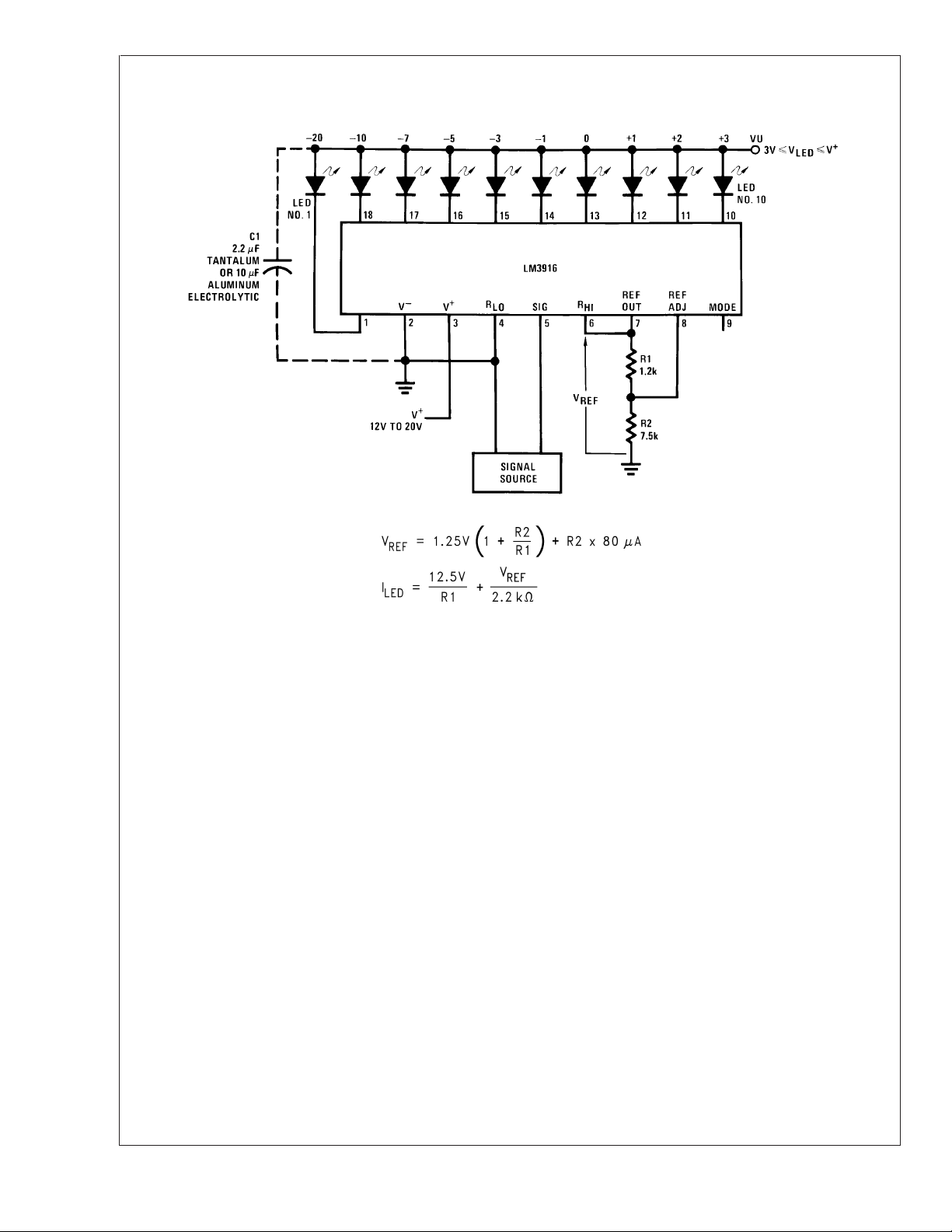

Typical Applications

LM3916

0V to 10V VU Meter

00797101

Notes: Capacitor C1 is required if leads to the LED supply are 6" or longer.

Circuit as shown is wired for dot mode. For bar mode, connect pin 9 to pin 3. V

dissipation.

must be kept below 7V or dropping resistor should be used to limit IC power

LED

www.national.com 2

Page 3

LM3916

Absolute Maximum Ratings (Note 1)

If Military/Aerospace specified devices are required,

please contact the National Semiconductor Sales Office/

Distributors for availability and specifications.

Power Dissipation (Note 6)

Molded DIP (N) 1365 mW

Input Signal Overvoltage (Note 4)

Divider Voltage −100 mV to V

Reference Load Current 10 mA

Storage Temperature Range −55˚C to +150˚C

Lead Temperature

(Soldering, 10 seconds) 260˚C

±

35V

Supply Voltage 25V

Voltage on Output Drivers 25V

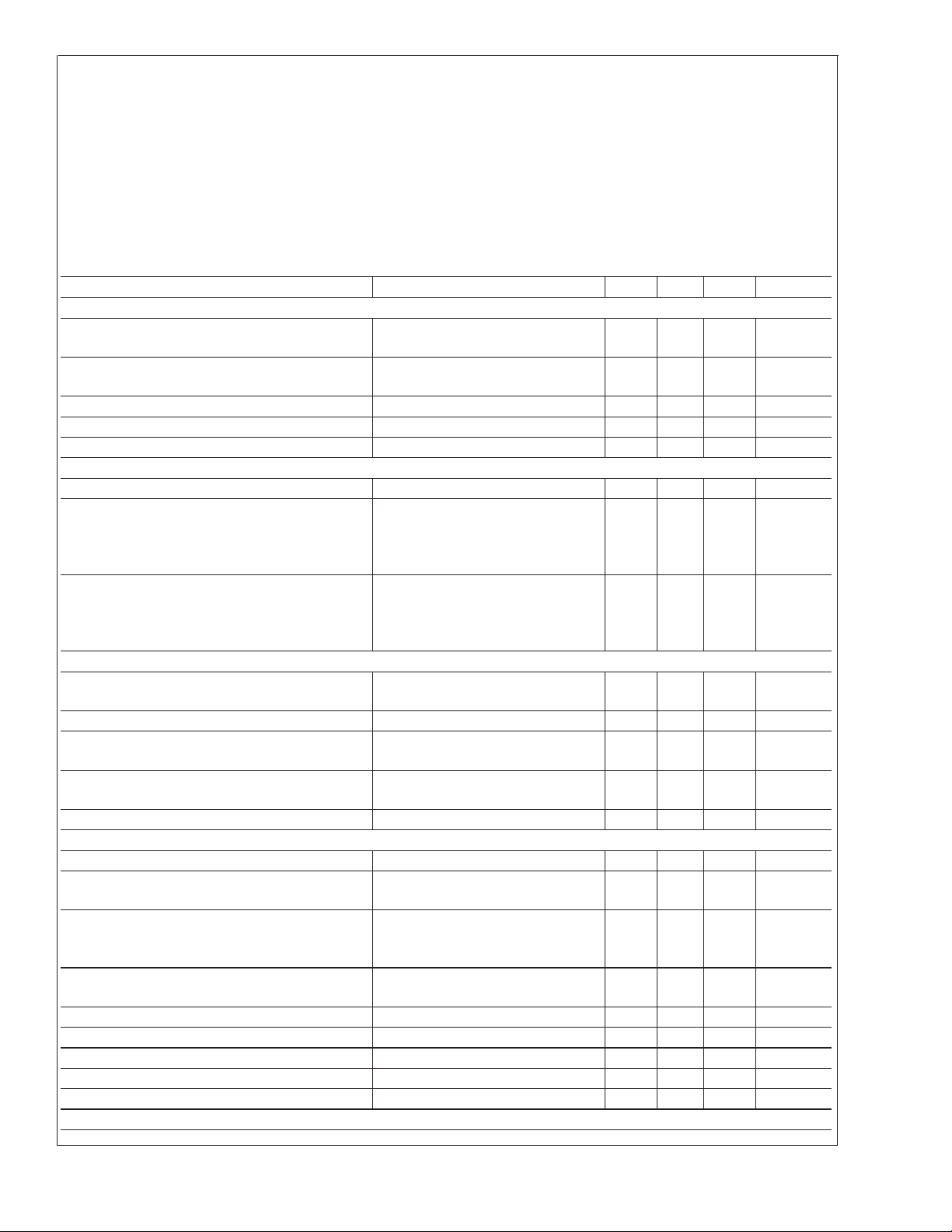

Electrical Characteristics (Notes 2, 4)

Parameter Conditions (Note 2) Min Typ Max Units

COMPARATORS

Offset Voltage, Buffer and First Comparator 0V ≤ V

Offset Voltage, Buffer and Any Other Comparator 0V ≤ V

Gain (∆I

/ ∆VIN)I

LED

Input Bias Current (at Pin 5) 0V ≤ V

I

LED

I

LED

(REF)

RLO=VRHI

=1mA

RLO=VRHI

=1mA

= 2 mA, I

≤ (V+−1.5V) 25 100 nA

IN

Input Signal Overvoltage No Change in Display −35 35 V

VOLTAGE DIVIDER

Divider Resistance Total, Pin 6 to 4 8 12 17 kΩ

Relative Accuracy (Input Change

Between Any Two Threshold Points)

(Note 3)

−1 dB ≤ V

−7 dB ≤ V

IN

IN

−10 dB ≤ V

Absolute Accuracy (Note 3)

=2,1,0,−1dB

V

IN

= −3, −5 dB

V

IN

= −7, −10, −20 dB

V

IN

VOLTAGE REFERENCE

Output Voltage 0.1 mA ≤ I

+

V

Line Regulation 3V ≤ V

Load Regulation 0.1 mA ≤ I

+

V

Output Voltage Change with Temperature 0˚C ≤ T

+

V

L(REF)

=V

LED

+

≤ 18V 0.01 0.03 %/V

L(REF)

=V

LED

≤ +70˚C, I

A

=V

LED

Adjust Pin Current 75 120 µA

OUTPUT DRIVERS

LED Current V

LED Current Difference (Between Largest and

Smallest LED Currents)

LED Current Regulation 2V ≤ V

Dropout Voltage I

Saturation Voltage I

+

V

LED

V

LED

I

LED

I

LED

LED(ON)

∆I

LED

LED

=V

LED

= 5V, I

= 5V, I

LED

2mA

=20mA

=20mA@V

=2mA

= 2.0 mA, I

Output Leakage, Each Collector Bar Mode (Note 5) 0.1 100 µA

Output Leakage Dot Mode (Note 5)

Pins 10– 18 0.1 100 µA

Pin 1 60 150 450 µA

SUPPLY CURRENT

LED

≤ 3dB

≤ −1 dB

≤ −7 dB

IN

= 5Vg

=5V

=5V

= 5V, I

LED

LED

≤ 17V

≤ 12V,

≤ 12V,

310 mV

315 mV

= 10 mA 3 8 mA/mV

0.75

1.5

2.5

−0.25

−0.5

−1

≤ 4 mA,

1.2 1.28 1.34 V

≤ 4 mA,

= 1 mA,

L(REF)

= 1 mA 7 10 13 mA

L(REF)

=2mA

=20mA

1.0

1.25

2.0

3.0

2.5

2.5

+0.25

+0.5

+1

0.4 2 %

1%

0.12

1.2

0.4

3

0.110.25

3

= 5V,

LED

= 0.4 mA 0.15 0.4 V

L(REF)

1.5 V

dB

dB

dB

dB

dB

dB

mA

mA

mA

mA

+

www.national.com3

Page 4

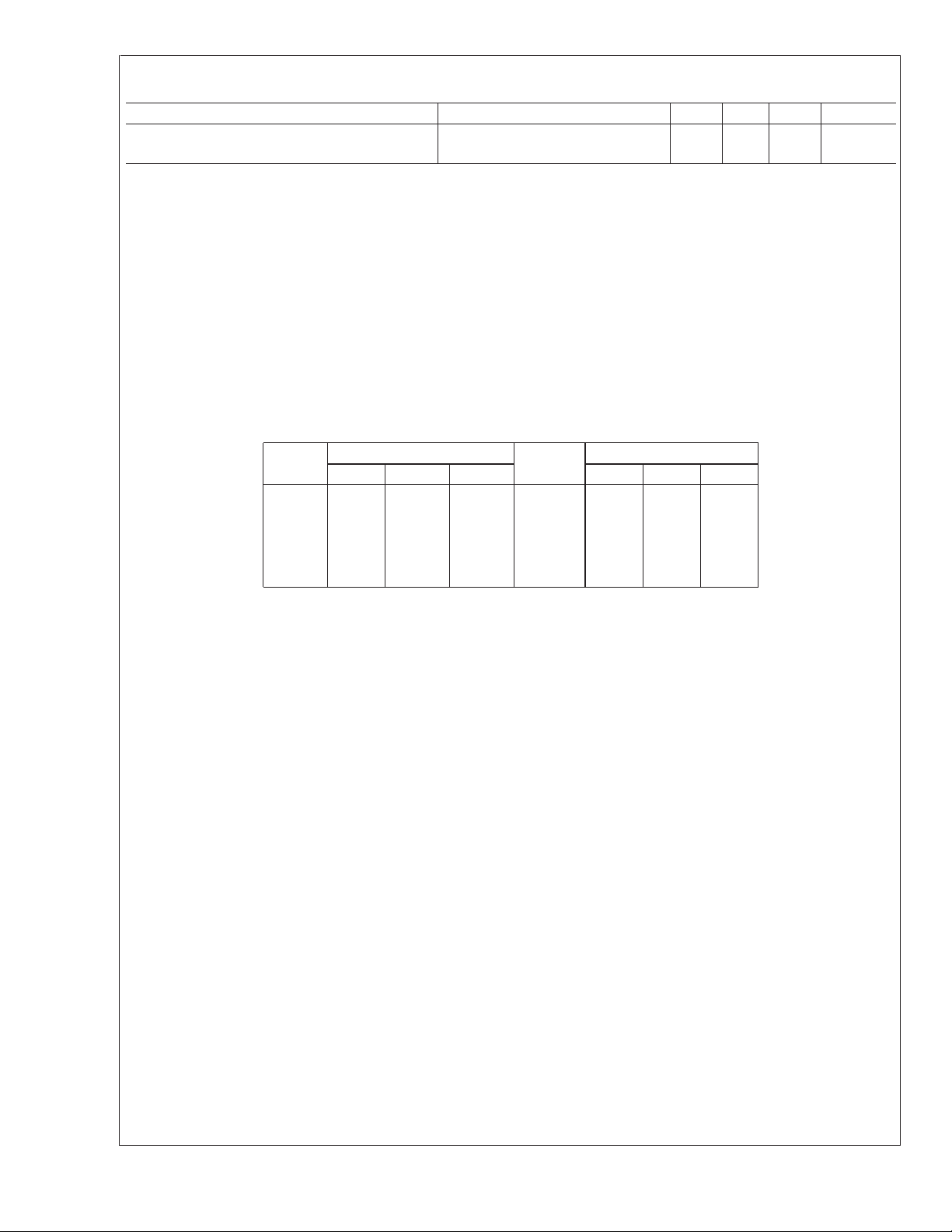

Electrical Characteristics (Notes 2, 4) (Continued)

LM3916

Parameter Conditions (Note 2) Min Typ Max Units

Standby Supply Current

(All Outputs Off)

Note 1: Absolute Maximum Ratings indicate limits beyond which damage to the device may occur. Operating ratings indicate conditions for which the device is

functional, but do not guarantee specific performance limits. Electrical Characteristics state DC and AC electrical specifications under particular test conditions which

guarantee specific performance limits. This assumes that the device is within the Operating Ratings. Specifications are not guaranteed for parameters where no limit

is given, however, the typical value is a good indication of device performance.

Note 2: Unless otherwise stated, all specifications apply with the following conditions:

3V

≤ V+≤ 20 V

DC

≤ V

3V

DC

−0.015V ≤ V

Note 3: Accuracy is measured referred to +3 dB = +10.000 V

comparator offset voltage may add significant error. See table for threshold voltages.

Note 4: Pin 5 input current must be limited to

Note 5: Bar mode results when pin 9 is within 20 mV of V

disabled if pin 9 is pulled 0.9V or more below V

Note 6: The maximum junction temperature of the LM3916 is 100˚C. Devices must be derated for operation at elevated temperatures. Junction to ambient thermal

resistance is 55˚C/W for the molded DIP (N package).

LED

RHI

≤ V

≤ 12 V

DC

+

−0.015V ≤ V

V

REF,VRHI,VRLO

0V ≤ VIN≤ V+− 1.5V

DC

≤ 12 V

RLO

DC

≤ (V+− 1.5V) For higher power dissipations, pulse testing is used.

±

3 mA. The addition of a 39k resistor in series with pin 5 allows±100V signals without damage.

.

LED

+

V

= + 5V, I

+

= + 20V, I

V

TA= 25˚C, I

at pin 5, with +10.000 VDCat pin 6, and 0.000 VDCat pin 4. At lower full-scale voltages, buffer and

DC

+

. Dot mode results when pin 9 is pulled at least 200 mV below V+. LED #10 (pin 10 output current) is

L(REF)

= 0.2 mA

L(REF)

= 1.0 mA

L(REF)

= 0.2 mA, pin 9 connected to pin 3 (bar mode).

2.4

6.1

4.2

9.2

LM3916 Threshold Voltage (Note 3)

dB

Min Typ Max Min Typ Max

3 9.985 10.000 10.015 −3

1

±

2

⁄48.660 8.913 9.173 −5

1

±

1

⁄47.718 7.943 8.175 −7±1 2.818 3.162 3.548

1

±

0

⁄46.879 7.079 7.286 −10±1 1.995 2.239 2.512

1

±

−1

⁄25.957 6.310 6.683 −20±1 0.631 0.708 0.794

Volts

dB

1

±

⁄24.732 5.012 5.309

1

±

⁄23.548 3.981 4.467

Volts

mA

mA

www.national.com 4

Page 5

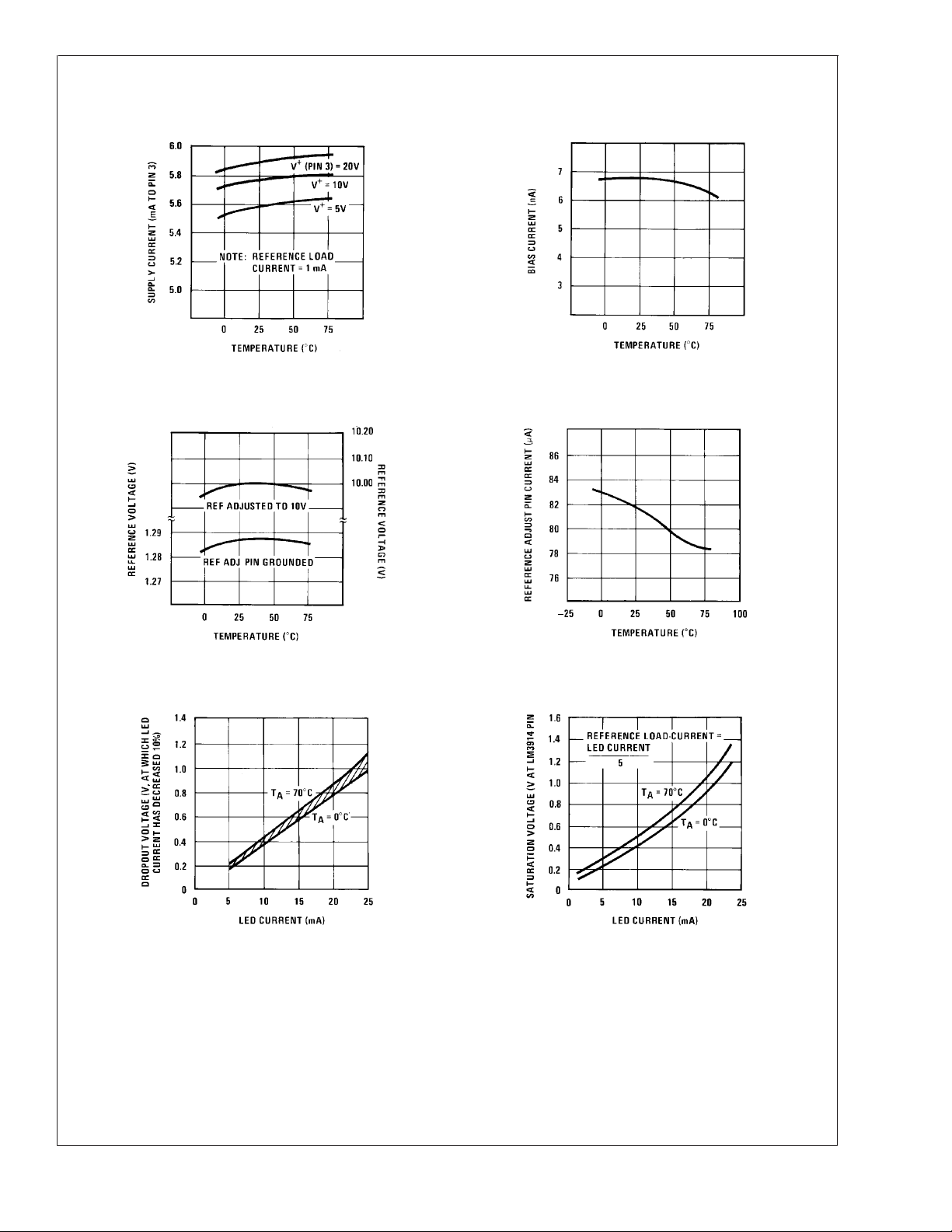

Typical Performance Characteristics

LM3916

Supply Current vs

Temperature

Reference Voltage vs

Temperature

00797135

Operating Input Bias

Current vs Temperature

00797136

Reference Adjust Pin

Current vs Temperature

LED Current-Regulation

Dropout

00797137

00797139

00797138

LED Driver Saturation

Voltage

00797140

www.national.com5

Page 6

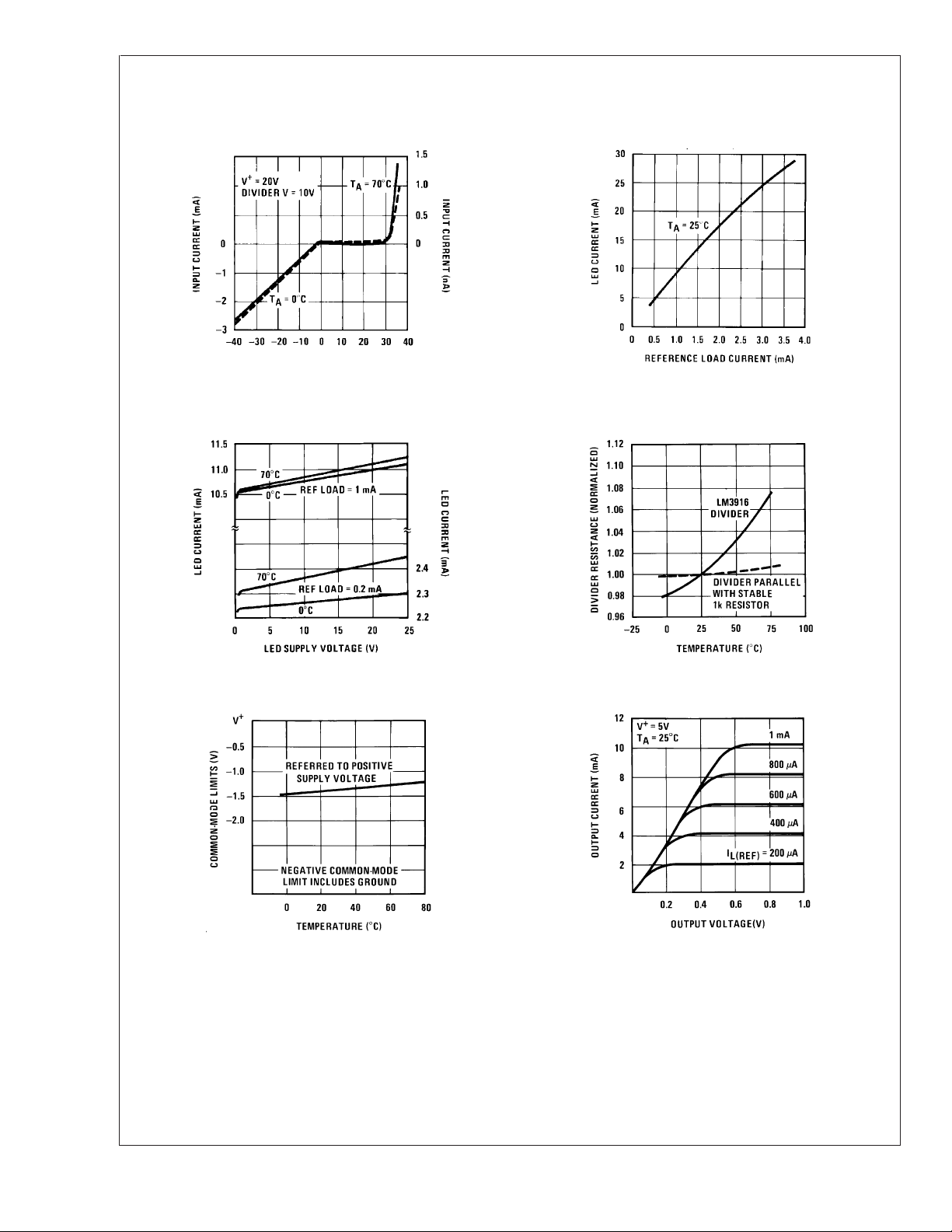

Typical Performance Characteristics (Continued)

LM3916

Input Current Beyond

Signal Range (Pin 5)

LED Driver Current

Regulation

LED Current vs

Referenced Loading

00797141

00797142

Total Divider Resistance

vs Temperature

00797143

Common-Mode Limits Output Characteristics

00797145

00797144

00797146

www.national.com 6

Page 7

Block Diagram (Showing Simplest Application)

LM3916

00797104

www.national.com7

Page 8

Functional Description

The simplified LM3916 block diagram is included to give the

LM3916

general idea of the circuit’s operation. A high input impedance buffer operates with signals from ground to 12V, and is

protected against reverse and overvoltage signals. The signal is then applied to a series of 10 comparators; each of

which is biased to a different comparison level by the resistor

string.

In the example illustrated, the resistor string is connected to

the internal 1.25V reference voltage. As the input voltage

varies from 0 to 1.25, the comparator outputs are driven low

one by one, switching on the LED indicators. The resistor

divider can be connected between any 2 voltages, providing

that they are at least 1.5V below V

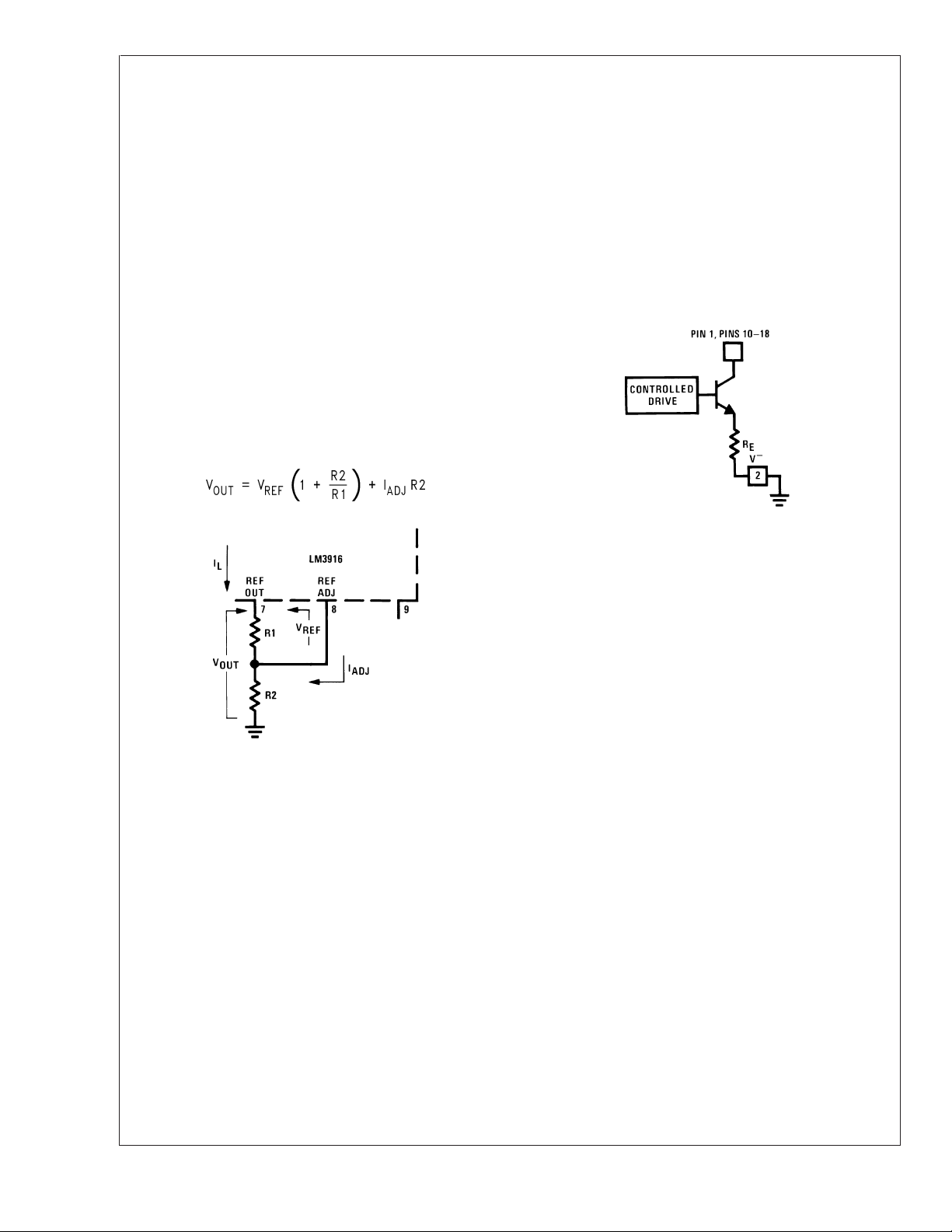

INTERNAL VOLTAGE REFERENCE

The reference is designed to be adjustable and develops a

nominal 1.25V between the REF OUT (pin 7) and REF ADJ

(pin 8) terminals. The reference voltage is impressed across

program resistor R1 and, since the voltage is constant, a

constant current I

then flows through the output set resistor

1

R2 giving an output voltage of:

+

and no lower than V−.

lighted LED, and this current will be relatively constant despite supply voltage and temperature changes. Current

drawn by the internal 10-resistor divider, as well as by the

external current and voltage-setting divider should be included in calculating LED drive current. The ability to modulate LED brightness with time, or in proportion to input voltage and other signals can lead to a number of novel displays

or ways of indicating input overvoltages, alarms, etc.

The LM3916 outputs are current-limited NPN transistors as

shown below. An internal feedback loop regulates the transistor drive. Output current is held at about 10 times the

reference load current, independent of output voltage and

processing variables, as long as the transistor is not saturated.

LM3916 Output Circuit

00797106

00797105

Since the 120 µA current (max) from the adjust terminal

represents an error term, the reference was designed to

minimize changes of this current with V

+

and load changes.

For correct operation, reference load current should be between 80 µA and 5 mA. Load capacitance should be less

than 0.05 µF.

CURRENT PROGRAMMING

A feature not completely illustrated by the block diagram is

the LED brightness control. The current drawn out of the

reference voltage pin (pin 7) determines LED current. Approximately 10 times this current will be drawn through each

Outputs may be run in saturation with no adverse effects,

making it possible to directly drive logic. The effective saturation resistance of the output transistors, equal to R

plus

E

the transistors’ collector resistance, is about 50Ω. It’s also

possible to drive LEDs from rectified AC with no filtering. To

avoid oscillations, the LED supply should be bypassed with a

2.2 µF tantalum or 10 µF aluminum electrolytic capacitor.

MODE PIN USE

Pin 9, the Mode Select input, permits chaining of multiple

devices, and controls bar or dot mode operation. The following tabulation shows the basic ways of using this input. Other

more complex uses will be illustrated in the applications.

Bar Graph Display: Wire Mode Select (pin 9) directly to pin

+

pin).

3(V

Dot Display, Single LM3916 Driver: Leave the Mode Select

pin open circuit.

Dot Display, 20 or More LEDs: Connect pin 9 of the first

drivers in the series (i.e., the one with the lowest input

voltage comparison points) to pin 1 of the next higher

LM3916 driver. Continue connecting pin 9 of lower input

drivers to pin 1 of higher input drivers for 30 or more LED

displays. The last LM3916 driver in the chain will have pin 9

left open. All previous drivers should have a 20k resistor in

parallel with LED #9 (pin 11 to V

LED

).

www.national.com 8

Page 9

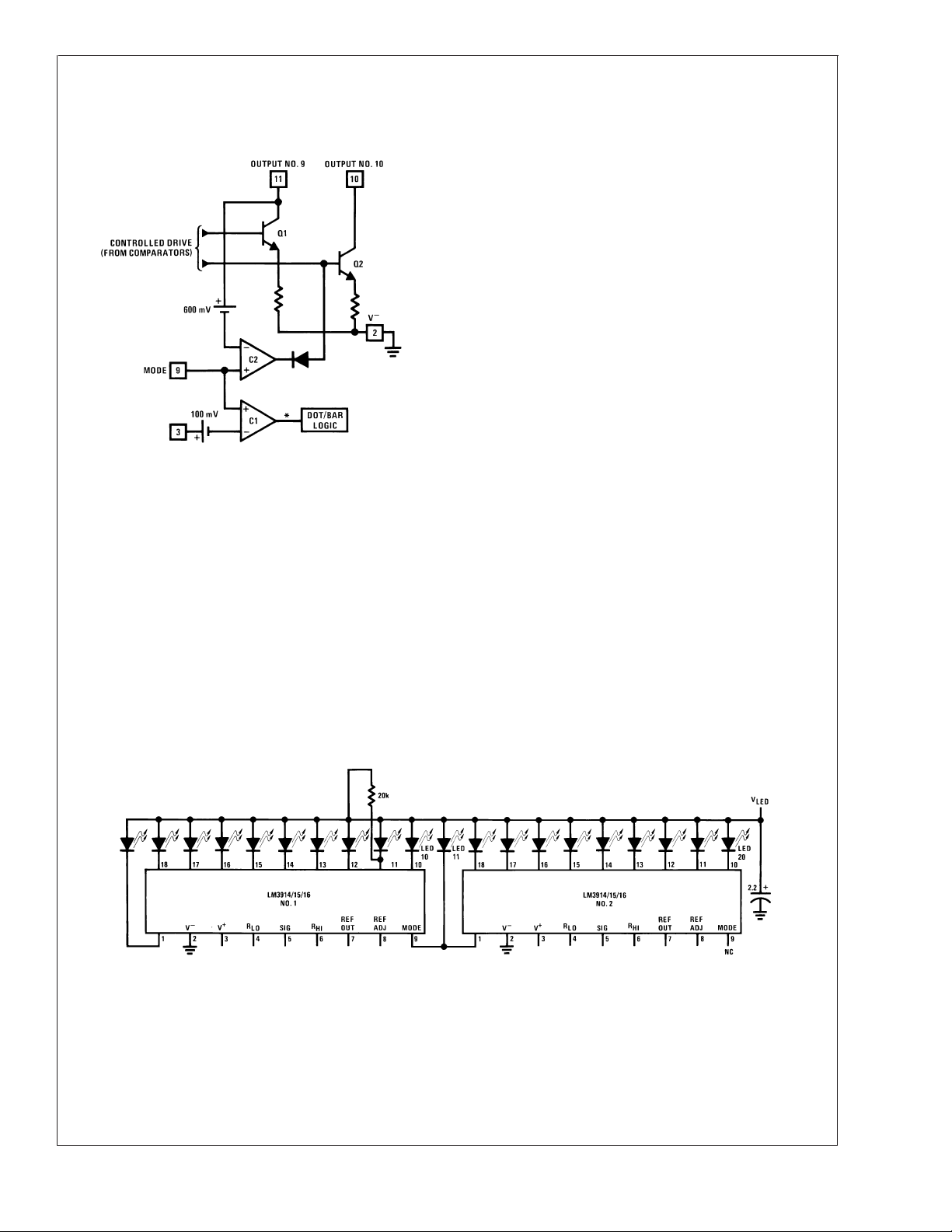

Mode Pin Functional Description

This pin actually performs two functions. Refer to the simplified block diagram below.

Block Diagram of Mode Pin Function

*High for bar

DOT OR BAR MODE SELECTION

The voltage at pin 9 is sensed by comparator C1, nominally

referenced to (V

+

−100 mV). The chip is in bar mode when

pin 9 is above this level; otherwise it’s in dot mode. The

comparator is designed so that pin 9 can be left open circuit

for dot mode.

Taking into account comparator gain and variation in the

100 mV reference level, pin 9 should be no more than 20 mV

below V

open circuit) for dot mode. In most applications, pin 9 is

either open (dot mode) or tied to V

+

for bar mode and more than 200 mV below V+(or

+

(bar mode). In bar mode,

pin 9 should be connected directly to pin 3. Large currents

drawn from the power supply (LED current, for example)

should not share this path so that large IR drops are avoided.

00797107

DOT MODE CARRY

In order for display to make sense when multiple drivers are

cascaded in dot mode, special circuitry has been included to

shut off LED #10 of the first device when LED #1 of the

second device comes on. The connection for cascading in

dot mode has already been described and is depicted in

Figure 1.

As long as the input signal voltage is below the threshold of

the second driver, LED #11 is off. Pin 9 of driver #1 thus sees

effectively an open circuit so the chip is in dot mode. As soon

as the input voltage reaches the threshold of LED #11, pin 9

of driver #1 is pulled an LED drop (1.5V or more) below

. This condition is sensed by comparator C2, refer-

V

LED

enced 600 mV below V

. This forces the output of C2 low,

LED

which shuts off output transistor Q2, extinguishing LED #10.

is sensed via the 20k resistor connected to pin 11. The

V

LED

very small current (less than 100 µA) that is diverted from

LED #9 does not noticeably affect its intensity.

An auxiliary current source at pin 1 keeps at least 100 µA

flowing through LED #11 even if the input voltage rises high

enough to extinguish the LED. This ensures that pin 9 of

driver #1 is held low enough to force LED #10 off when any

higher LED is illuminated. While 100 µA does not normally

produce significant LED illumination, it may be noticeable

when using high-efficiency LEDs in a dark environment. If

this is bothersome, the simple cure is to shunt LED #11 (and

LED #1) with a 10k resistor. The 1V 1R drop is more than the

900 mV worst case required to hold off LED #10 yet small

enough that LED #11 does not conduct significantly.

In some circuits a number of outputs on the higher device

are not used. Examples include the high resolution VU meter

and the expanded range VU meter circuits (see Typical

Applications). To provide the proper carry sense voltage in

dot mode, the LEDs of the higher driver IC are tied to V

LED

through two series-connected diodes as shown in Figure 2.

Shunting the diodes with a 1k resistor provides a path for

driver leakage current.

LM3916

FIGURE 1. Cascading LM3914/15/16 Series in Dot Mode

00797108

www.national.com9

Page 10

Mode Pin Functional Description (Continued)

LM3916

FIGURE 2. Cascading Drivers in Dot Mode with Pin 1 of Driver #2 Unused

00797109

OTHER DEVICE CHARACTERISTICS

The LM3915 is relatively low-powered itself, and since any

number of LEDs can be powered from about 3V, it is a very

efficient display driver. Typical standby supply current (all

LEDs OFF) is 1.6 mA. However, any reference loading adds

4 times that current drain to the V

+

(pin 3) supply input. For

example, an LM3915 witha1mAreference pin load (1.3k)

would supply almost 10 mA to every LED while drawing only

10 mA from its V

+

pin supply. At full-scale, the IC is typically

drawing less than 10% of the current supplied to the display.

The display driver does not have built-in hysteresis so that

the display does not jump instantly from one LED to the next.

Under rapidly changing signal conditions, this cuts down

high frequency noise and often an annoying flicker. An “overlap” is built in so that at no time are all segments completely

off the dot mode. Generally one LED fades in while the other

fades out over a 1 mV range. The change may be much

more rapid between LED #10 of one device and LED #1 of a

second device cascaded.

Application Hints

The most difficult problem occurs when large LED currents

are being drawn, especially in bar graph mode. These currents flowing out of the ground pin cause voltage drops in

external wiring, and thus errors and oscillations. Bringing the

return wires from signal sources, reference ground and bottom of the resistor string to a single point very near pin 2 is

the best solution.

Long wires from V

oscillations. The usual cure is bypassing the LED anodes

with a 2.2 µF tantalum or 10 µF aluminum electrolytic capacitor. If the LED anode line wiring is inaccessible, often a

0.1 µF capacitor from pin 1 to pin 2 will be sufficient.

If there is a large amount of LED overlap in the bar mode,

oscillation or excessive noise is usually the problem. In

cases where proper wiring and bypassing fail to stop oscillations, V

+

voltage at pin 3 is usually below suggested limits.

When several LEDs are lit in dot mode, the problem is

usually an AC component of the input signal which should be

filtered out. Expanded scale meter applications may have

one or both ends of the internal voltage divider terminated at

relatively high value resistors. These high-impedance ends

should be bypassed to pin 2 with 0.1 µF.

to LED anode common can cause

LED

Power dissipation, especially in bar mode should be given

consideration. For example, with a 5V supply and all LEDs

programmed to 20 mA the driver will dissipate over 600 mW.

In this case a 7.5Ω resistor in series with the LED supply will

cut device heating in half. The negative end of the resistor

should be bypassed with a 2.2 µF solid tantalum or 10 µF

aluminum electrolytic capacitor to pin 2.

TIPS ON RECTIFIER CIRCUITS

The simplest way to display an AC signal using the LM3916

is to apply it right to pin 5 unrectified. Since the LED illuminated represents the instantaneous value of the AC waveform, one can readily discern both peak and average values

of audio signals in this manner. The LM3916 will respond to

positive half-cycles only but will not be damaged by signals

±

35V (or up to±100V if a 39k resistor is in series with

up to

the input). A smear or bar type display results even though

the LM3916 is connected for dot mode. The LEDs should be

run at 20 mA to 30 mA for high enough average intensity.

True average or peak detection requires rectification. If an

LM3916 is set up with 10V full scale across its voltage

divider, the turn-on point for the first LED is only 450 mV. A

simple silicon diode rectifier won’t work well at the low end

due to the 600 mV diode threshold. The half-wave peak

detector in Figure 3 uses a PNP emitter-follower in front of

the diode. Now, the transistor’s base-emitter voltage cancels

out the diode offset, within about 100 mV. This approach is

usually satisfactory when a single LM3916 is used for a 23

dB display.

Display circuits such as the extended range VU meter using

two or more drivers for a dynamic range of 40 dB or greater

require more accurate detection. In the precision half-wave

rectifier of Figure 4 the effective diode offset is reduced by a

factor equal to the open-loop gain of the op amp. Filter

capacitor C2 charges through R3 and discharges through

R2 and R3, so that appropriate selection of these values

results in either a peak or an average detector. The circuit

has a gain equal to R2/R1.

It’s best to capacitively couple the input. Audio sources

frequently have a small DC offset that can cause significant

error at the low end of the log display. Op amps that slew

quickly, such as the LF351, LF353 or LF356, are needed to

faithfully respond to sudden transients. It may be necessary

to trim out the op amp DC offset voltage to accurately cover

a 60 dB range. Best results are obtained if the circuit is

www.national.com 10

Page 11

Application Hints (Continued)

adjusted for the correct output when a low-level AC signal

(10 to 20 mV) is applied, rather than adjusting for zero output

with zero input.

LM3916

*DC Couple

00797110

FIGURE 3. Half-Wave Peak Detector

D1, D2: 1N914 or 1N4148

00797111

Average Peak

R2 1k 100k

R3 100k 1k

R1 = R2 for AV=1

R1 = R2/10 for A

C1 = 10/R1

V

=10

FIGURE 4. Precision Half-Wave Rectifier

For precision full-wave averaging use the circuit in Figure 5.

Using 1% resistors for R1 through R4, gain for positive and

negative signal differs by only 0.5 dB worst case. Substituting 5% resistors increases this to 2 dB worst case. (A 2 dB

±

gain difference means that the display may have a

1dB

error when the input is a nonsymmetrical transient). The

averaging time constant is R5

C2. A simple modification

•

results in the precision full-wave detector of Figure 6. Since

the filter capacitor is not buffered, this circuit can drive only

high impedance loads such as the input of an LM3916.

D1, D2: 1N914 or 1N4148

00797112

FIGURE 5. Precision Full-Wave Average Detector

00797113

D1, D2, D3, D4: 1N914 OR 1N4148

Attack and decay time to DIN PPM spec. Response down 1 dB for 10 ms

tone burst. Decays 20 dB in 1.5s.

FIGURE 6. Precision Full-Wave Peak Detector

AUDIO METER STANDARDS

VU Meter

The audio level meter most frequently encountered is the VU

meter. Its characteristics are defined as the ANSI specification C165. The LM3916’s outputs correspond to the meter

indications specified with the omission of the −2 VU indication. The VU scale divisions differ slightly from a linear scale

in order to obtain whole numbers in dB.

Some of the most important specifications for an AC meter

are its dynamic characteristics. These define how the meter

responds to transients and how fast the reading decays. The

VU meter is a relatively slow full-wave averaging type, specified to reach 99% deflection in 300 ms and overshoot by 1 to

1.5%. In engineering terms this means a slightly under-

www.national.com11

Page 12

Application Hints (Continued)

damped second order response with a resonant frequency

LM3916

of2.1HzandaQof0.62. Figure 7 depicts a simple rectifier/

filter circuit that meets these criteria.

Design Equations

GAIN R5 R6 C2 C3

1 100k 43k 2.0 0.56 µF

10 1M 100k 1.0 0.056 µF

FIGURE 7. Full-Wave Average Detector to VU Meter Specifications*

Peak Program Meter

The VU meter, originally intended for signals sent via telephone lines, has shortcomings when used in high fidelity

systems. Due to its slow response time, a VU meter will not

accurately display transients that can saturate a magnetic

tape or drive an amplifier into clipping. The fast-attack peak

program meter (PPM) which does not have this problem is

becoming increasingly popular.

While several European organizations have specifications

for peak program meters, the German DIN specification

45406 is becoming a de facto standard. Rather than respond

instantaneously to peak, however, PPM specifications require a finite “integration time” so that only peaks wide

enough to be audible are displayed. DIN 45406 calls for a

response of 1 dB down from steady-state for a 10 ms tone

burst and 4 dB down fora3mstone burst. These requirements are consistent with the other frequently encountered

spec of 2 dB down fora5msburst and are met by an attack

time constant of 1.7 ms.

00797114

The specified return time of 1.5s to −20 dB requires a

650 ms decay time constant. The full-wave peak detector of

Figure 6 satisfies both the attack and decay time criteria.

Cascading The LM3916

The LM3916 by itself covers the 23 dB range of the conventional VU meter. To display signals of 40 dB or 70 dB

dynamic range, the LM3916 may be cascaded with the 3

dB/step LM3915s. Alternatively, two LM3916s may be cascaded for increased resolution over a 28 dB range. Refer to

the Extended Range VU Meter and High Resolution VU

Meter in the Typical Applications section for the complete

circuits for both dot and bar mode displays.

To obtain a display that makes sense when an LM3915 and

an LM3916 are cascaded, the −20 dB output from the

LM3916 is dropped. The full-scale display for the LM3915 is

set at 3 dB below the LM3916’s −10 dB output and the rest

of the thresholds continue the 3 dB/step spacing. A simple,

low cost approach is to set the reference voltage of the two

chips 16 dB apart as in Figure 5. The LM3915, with pin 8

grounded, runs at 1.25V full-scale. R1 and R2 set the

www.national.com 12

Page 13

Application Hints (Continued)

LM3916’s reference 16 dB higher or 7.89V. Variation in the

two on-chip references and resistor tolerance may cause a

±

1 dB error in the −10 dB to −13 dB transition. If this is

objectionable, R2 can be trimmed.

The drawback of the aforementioned approach is that the

threshold of LED #1 on the LM3915 is only 56 mV. Since

LM3916

comparator offset voltage may be as high as 10 mV, large

errors can occur at the first few thresholds. A better approach, as shown in Figure 9, is to keep the reference the

same for both drivers (10V in the example) and amplify the

input signal by 16 dB ahead of the LM3915. Alternatively,

instead of amplifying, input signals of sufficient amplitude

can be fed directly to the LM3916 and attenuated by 16 dB to

drive the LM3915.

V

REF2

. 7.89V

00797115

FIGURE 8. Low Cost Circuit for 40 dB Display

FIGURE 9. Improved Circuit for 40 dB Display

00797116

www.national.com13

Page 14

Application Hints (Continued)

To extend this approach to get a 70 dB display, another

LM3916

30 dB of amplification must be placed in the signal path

ahead of the lowest LM3915. Extreme care is required as the

lowest LM3915 displays input signals down to 2 mV! Several

offset nulls may be required. High currents should not share

the same path as the low level signal. Also power line wiring

should be kept away from signal lines.

TIPS ON REFERENCE VOLTAGE AND LED CURRENT PROGRAMMING

Single Driver

The equations in Figure 10 illustrate how to choose resistor

values to set reference voltage for the simple case where no

LED intensity adjustment is required. A LED current of

10 mA to 20 mA generally produces adequate illumination.

Having 10V full-scale across the internal voltage divider

gives best accuracy by keeping signal level high relative to

the offset voltage of the internal comparators. However, this

causes 1 mA to flow from pin 7 into the divider which means

that the LED current will be at least 10 mA. R1 will typically

be between 1 kΩ and5kΩ. To trim the reference voltage,

vary R2.

The current in Figure 11 shows how to add a LED intensity

control which can vary LED current from 5 mA to 28 mA.

Choosing V

increasing the intensity adjustment range. The reference

adjustment has some effect on LED intensity but the reverse

is not true.

= 5V lowers the current drawn by the ladder,

REF

00797117

5mA≤ I

≤ 28 mA@V

LED

REF

=5V

00797118

FIGURE 11. Varying LED Intensity

Multiple Drivers

Figure 12 shows how to obtain a common reference trim and

intensity control for two drivers. The two ICs may be connected in cascade or may be handling separate channels for

stereo. This technique can be extended for larger numbers

of drivers by varying the values of R1, R2 and R3. Because

the LM3915 has a greater ladder resistance, R5 was picked

less than R7 in such a way as to provide equal reference

load currents. The ICs’ internal references track within

100 mV so that worst case error from chip to chip is only 0.2

dB for V

REF

=5V.

The scheme in Figure 13 is useful when the reference and

LED intensity must be adjusted independently over a wide

range. The R

voltage can be adjusted from 1.2V to 10V

HI

with no effect on LED current. Since the internal divider here

does not load down the reference, minimum LED current is

much lower. At the minimum recommended reference load

of 80 µA, LED current is about 0.8 mA. The resistor values

shown give a LED current range from 1.5 mA to 25 mA.

At the low end of the intensity adjustment, the voltage drop

across the 510Ω current-sharing resistors is so small that

chip to chip variation in reference voltage may yield a visible

variation in LED intensity. The optional approach shown of

connecting the bottom end of the intensity control pot to a

negative supply overcomes this problem by allowing a larger

voltage drop across the (larger) current-sharing resistors.

FIGURE 10. Design Equations for Fixed LED Intensity

www.national.com 14

Page 15

Application Hints (Continued)

LM3916

5mA≤ I

=5V

V

REF

LED

≤ 28 mA

00797119

FIGURE 12. Independent Adjustment of Reference Voltage and LED Intensity for Multiple Drivers

1.25V ≤ V

1.5 mA ≤ I

Optional circuit for improved intensity matching at low currents. See text.

REF

LED

≤ 10V

≤ 25 mA

FIGURE 13. Wide-Range Adjustment of Reference Voltage and LED intensity for Multiple Drivers

Other Applications

For increased resolution, it’s possible to obtain a display with

a smooth transition between LEDs. This is accomplished by

superimposing an AC waveform on top of the input level as

00797120

shown in Figure 14. The signal can be a triangle, sawtooth or

sine wave from 60 Hz to 1 kHz. The display can be run in

either dot or bar mode.

www.national.com15

Page 16

Other Applications (Continued)

LM3916

00797121

FIGURE 14. 0V to 10V VU Meter with Smooth Transitions

www.national.com 16

Page 17

00797122

LM3916

Extended Range VU Meter (Dot Mode)

Typical Applications

This application shows that the LED supply requires minimal filtering.

*See Application Hints for optional Peak or Average Detector.

Adjust R3 for 3 dB difference between LED #11 and LED #12

†

www.national.com17

Page 18

LM3916

00797123

Extended Range VU Meter (Dot Mode)

Typical Applications (Continued)

www.national.com 18

D1, D2: 1N914 or 1N4148

*OPTIONAL SHUNTS 100 µA auxiliary sink current away from LED #1.

See Application Hints for optional peak or average detector.

†

Page 19

Typical Applications (Continued)

Driving Vacuum Fluorescent Display

LM3916

R7 thru R15: 10k±10%

D1, D2: 1N914 or 1N4148

*Half-wave peak detector.

See Application Hints.

00797124

www.national.com19

Page 20

Typical Applications (Continued)

LM3916

*The input to the Dot-Bar switch may be taken from cathodes of other LEDs. Display will change to bar as soon as the LED so selected begins to light.

**Optional. Shunts 100 µA auxiliary sink current away from LED #1.

Indicator and Alarm, Full-Scale Changes Display From Dot to Bar

00797125

www.national.com 20

Page 21

00797126

LM3916

High Resolution VU Meter (Bar Mode)

Typical Applications (Continued)

*See Application Hints for optional peak or average detector.

www.national.com21

Page 22

LM3916

00797127

High Resolution VU Meter (Dot Mode)

Typical Applications (Continued)

www.national.com 22

*Optional shunts 100 µA auxiliary sink current away from LED #1.

See Application Hints for optional peak or average detector.

†

Page 23

Typical Applications (Continued)

LM3916

Displaying Additional Levels

00797128

www.national.com23

Page 24

Typical Applications (Continued)

LM3916

The LED currents are approximately 10 mA, and LM3916 outputs operate in saturation for minimum dissipation.

*This point is partially regulated and decreases in voltage with temperature. Voltage requirements of the LM3916 also decrease with temperature.

Operating with a High Voltage Supply (Dot Mode Only)

00797129

Low Current Bar Mode Display

Supply current drain is only 20 mA with ten LEDs illuminated@16 mA.

00797130

www.national.com 24

Page 25

Typical Applications (Continued)

LM3916

Driving Liquid Crystal Display

00797131

Bar Display with Alarm Flasher

Full-scale causes the full bar display to flash. If the junction of R1 and C1 is connected to a different LED cathode, the display will flash when that LED lights,

and at any higher input signal.

00797132

www.national.com25

Page 26

Connection Diagram

LM3916

Dual-In-Line Package

Order Number LM3916N-1

See NS Package Number NA18A

Order Number LM3916N *

See NS Package Number N18A

*Discontinued, Life Time Buy date 12/20/99

Definition of Terms

Absolute Accuracy: The difference between the observed

threshold voltage and the ideal threshold voltage for each

comparator. Specified and tested with 10V across the internal voltage divider so that resistor ratio matching error predominates over comparator offset voltage.

Adjust Pin Current: Current flowing out of the reference

amplifier pin when the reference amplifier is in the linear

region.

Comparator Gain: The ratio of the change in output current

) to the change in input voltage (VIN) required to pro-

(I

LED

duce it for a comparator in the linear region.

Dropout Voltage: The voltage measured at the current

source outputs required to make the output current fall by

10%.

Input Bias Current: Current flowing out of the signal input

when the input buffer is in the linear region.

LED Current Regulation: The change in output current

over the specified range of LED supply voltage (V

LED

)as

Top View

00797133

measured at the current source outputs. As the forward

voltage of an LED does not change significantly with a small

change in forward current, this is equivalent to changing the

voltage at the LED anodes by the same amount.

Line Regulation: The average change in reference output

voltage (V

+

).

(V

) over the specified range of supply voltage

REF

Load Regulation: The change in reference output voltage

over the specified range of load current (I

L(REF)

).

Offset Voltage: The differential input voltage which must be

applied to each comparator to bias the output in the linear

region. Most significant error when the voltage across the

internal voltage divider is small. Specified and tested with pin

6 voltage (V

) equal to pin 4 voltage (V

RHI

RLO

).

Relative Accuracy: The difference between any two adjacent threshold points. Specified and tested with 10V across

the internal voltage divider so that resistor ratio matching

error predominates over comparator offset voltage.

www.national.com 26

Page 27

Physical Dimensions inches (millimeters) unless otherwise noted

LM3916

Note: Unless otherwise specified.

1. Standard Lead Finish:

200 microinches /5.08 micrometer minimum

lead/tin 37/63 or 15/85 on alloy 42 or equivalent or copper

2. Reference JEDEC registration MS-001, Variation AC, dated May 1993.

Molded Dual-In-Line Package (N)

Order Number LM3916N-1

NS Package Number NA18A

www.national.com27

Page 28

Physical Dimensions inches (millimeters) unless otherwise noted (Continued)

LM3916 Dot/Bar Display Driver

Molded Dual-In-Line Package (N)

Order Number LM3916N *

NS Package Number N18A

*Discontinued, Life Time Buy date 12/20/99

National does not assume any responsibility for use of any circuitry described, no circuit patent licenses are implied and National reserves

the right at any time without notice to change said circuitry and specifications.

For the most current product information visit us at www.national.com.

LIFE SUPPORT POLICY

NATIONAL’S PRODUCTS ARE NOT AUTHORIZED FOR USE AS CRITICAL COMPONENTS IN LIFE SUPPORT DEVICES OR SYSTEMS

WITHOUT THE EXPRESS WRITTEN APPROVAL OF THE PRESIDENT AND GENERAL COUNSEL OF NATIONAL SEMICONDUCTOR

CORPORATION. As used herein:

1. Life support devices or systems are devices or systems

which, (a) are intended for surgical implant into the body, or

(b) support or sustain life, and whose failure to perform when

properly used in accordance with instructions for use

2. A critical component is any component of a life support

device or system whose failure to perform can be reasonably

expected to cause the failure of the life support device or

system, or to affect its safety or effectiveness.

provided in the labeling, can be reasonably expected to result

in a significant injury to the user.

BANNED SUBSTANCE COMPLIANCE

National Semiconductor certifies that the products and packing materials meet the provisions of the Customer Products Stewardship

Specification (CSP-9-111C2) and the Banned Substances and Materials of Interest Specification (CSP-9-111S2) and contain no ‘‘Banned

Substances’’ as defined in CSP-9-111S2.

National Semiconductor

Americas Customer

Support Center

Email: new.feedback@nsc.com

Tel: 1-800-272-9959

www.national.com

National Semiconductor

Europe Customer Support Center

Fax: +49 (0) 180-530 85 86

Email: europe.support@nsc.com

Deutsch Tel: +49 (0) 69 9508 6208

English Tel: +44 (0) 870 24 0 2171

Français Tel: +33 (0) 1 41 91 8790

National Semiconductor

Asia Pacific Customer

Support Center

Email: ap.support@nsc.com

National Semiconductor

Japan Customer Support Center

Fax: 81-3-5639-7507

Email: jpn.feedback@nsc.com

Tel: 81-3-5639-7560

Loading...

Loading...