Page 1

July 2007

LM27313

1.6 MHz Boost Converter With 30V Internal FET Switch in

SOT-23

LM27313 1.6 MHz Boost Converter With 30V Internal FET Switch in SOT-23

General Description

The LM27313 switching regulator is a current-mode boost

converter with a fixed operating frequency of 1.6 MHz.

The use of the SOT-23 package, made possible by the minimal losses of the 800 mA switch, and small inductors and

capacitors result in extremely high power density. The 30V

internal switch makes these solutions perfect for boosting to

voltages of 5V to 28V.

This part has a logic-level shutdown pin that can be used to

reduce quiescent current and extend battery life.

Protection is provided through cycle-by-cycle current limiting

and thermal shutdown. Internal compensation simplifies design and reduces component count.

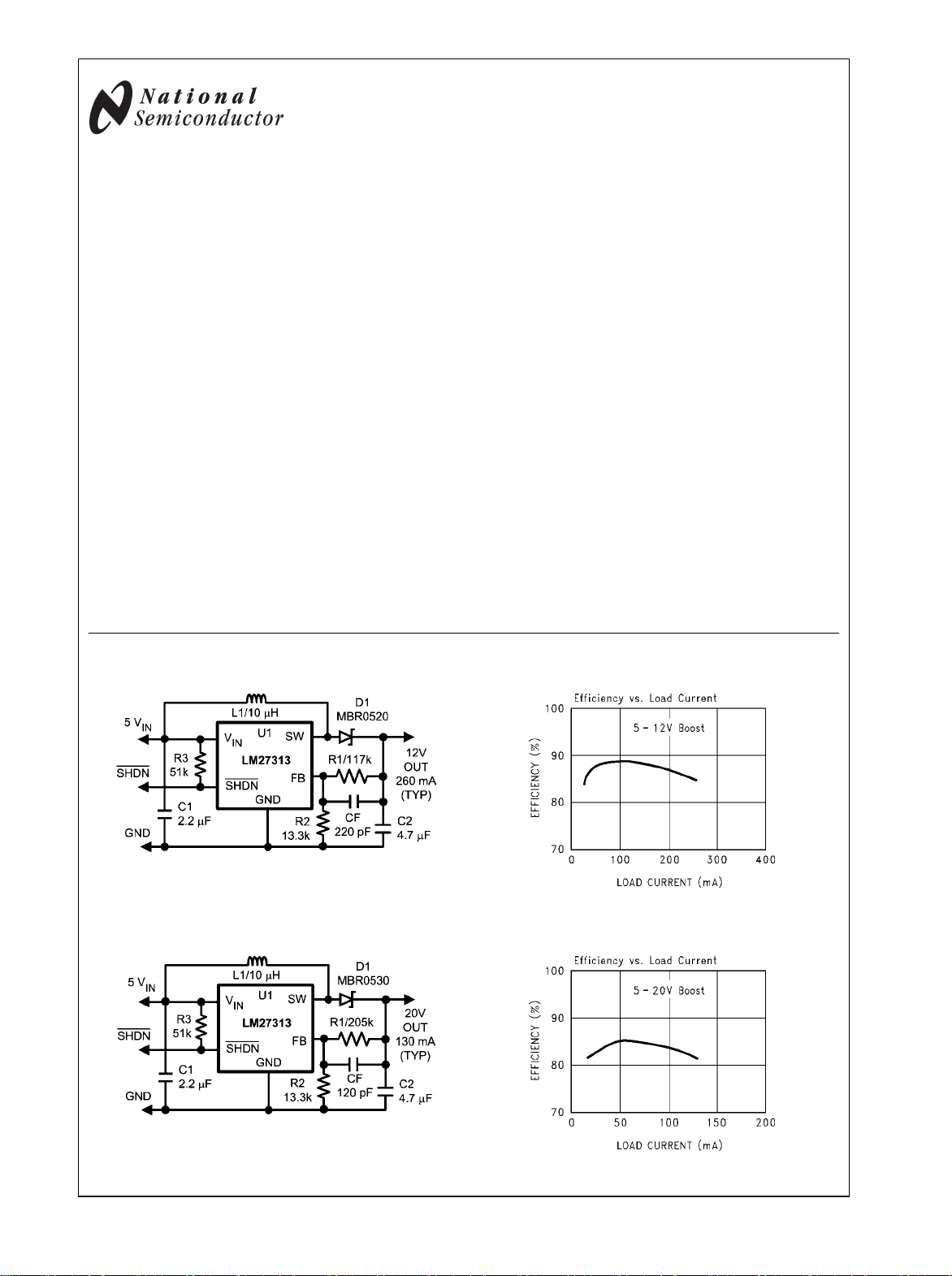

Typical Application Circuits

Features

30V DMOS FET switch

■

1.6 MHz switching frequency

■

Low RDS(ON) DMOS FET

■

Switch current up to 800 mA

■

Wide input voltage range (2.7V–14V)

■

Low shutdown current (<1 µA)

■

5-Lead SOT-23 package

■

Uses tiny capacitors and inductors

■

Cycle-by-cycle current limiting

■

Internally compensated

■

Applications

White LED Current Source

■

PDA’s and Palm-Top Computers

■

Digital Cameras

■

Portable Phones, Games and Media Players

■

GPS Devices

■

20216824

20216857

20216801

20216858

© 2007 National Semiconductor Corporation 202168 www.national.com

Page 2

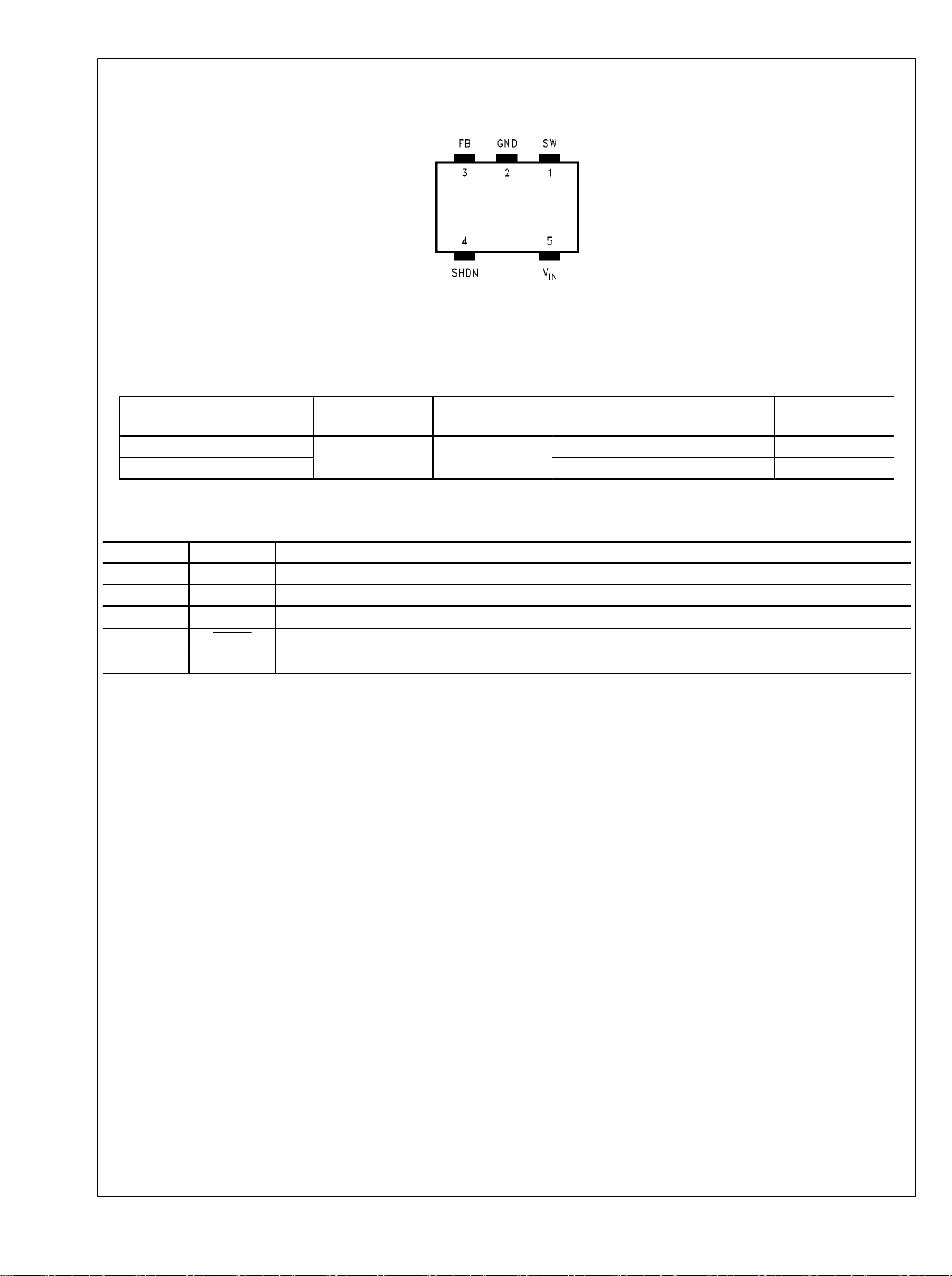

Connection Diagram

LM27313

Ordering Information

Order

Number

LM27313XMF

LM27313XMFX 3K Tape and Reel SRPB

Pin Descriptions

Pin Name Function

1 SW Drain of the internal FET switch.

2 GND Analog and power ground.

3 FB Feedback point that connects to external resistive divider to set V

4 SHDN Shutdown control input. Connect to VIN if this feature is not used.

5 V

IN

See NS Package Number MF05A

Package

Type

SOT23-5 MF05A

Analog and power input.

Top View

5-Lead SOT-23 Package

Package

Drawing

20216802

Supplied

As

1K Tape and Reel SRPB

.

OUT

Package

Marking

www.national.com 2

Page 3

LM27313

Absolute Maximum Ratings (Note 1)

If Military/Aerospace specified devices are required,

please contact the National Semiconductor Sales Office/

Distributors for availability and specifications.

Storage Temperature Range −65°C to +150°C

Lead Temp. (Soldering, 5 sec.) 300°C

Power Dissipation (Note 2) Internally Limited

FB Pin Voltage −0.4V to +6V

SW Pin Voltage −0.4V to +30V

Input Supply Voltage −0.4V to +14.5V

Shutdown Input Voltage

(Survival) −0.4V to +14.5V

ESD Rating (Note 3)

Human Body Model

±2 kV

Operating Ratings

V

IN

V

SW(MAX)

V

SHDN

Junction Temperature, T

(Note 2)

θ

(SOT23-5)

J-A

J

2.7V to 14V

0V to V

-40°C to 125°C

265°C/W

Electrical Characteristics

Unless otherwise specified: VIN = 5V, V

limits in boldface type apply over the full operating temperature range (−40°C ≤ TJ ≤ +125°C). Minimum and Maximum limits are

guaranteed through test, design, or statistical correlation. Typical values represent the most likely parametric norm at TJ = 25°C,

and are provided for reference purposes only.

Symbol Parameter Conditions Min Typical Max Units

V

I

SW

R

DS(ON)

V

SHDN(TH)

I

SHDN

V

I

FB

I

ΔVFB/ΔV

f

SW

D

MAX

I

Note 1: Absolute Maximum Ratings indicate limits beyond which damage to the device may occur. Operating Ratings indicate conditions for which the device is

to be functional, but does not guarantee specific limits. For guaranteed specifications and conditions see the Electrical Characteristic table.

Note 2: The maximum power dissipation which can be safely dissipated for any application is a function of the maximum junction temperature, T

the junction-to-ambient thermal resistance for the SOT-23 package, θ

at any ambient temperature for designs using this device can be calculated using the formula:

Input Voltage 2.7 14 V

IN

Switch Current Limit (Note 4) 0.80 1.25 A

Switch ON Resistance

Shutdown Threshold

Shutdown Pin Bias Current

Feedback Pin Reference

FB

Voltage

Feedback Pin Bias Current

Quiescent Current

Q

FB Voltage Line Regulation

IN

Switching Frequency 1.15 1.6 1.90 MHz

Maximum Duty Cycle 80 88 %

Switch Leakage

L

= 5V, IL = 0 mA, and TJ = 25°C. Limits in standard typeface are for TJ = 25°C, and

SHDN

ISW = 100 mA

500 650

Device ON 1.5

Device OFF 0.50

V

= 0

SHDN

V

= 5V

SHDN

VIN = 3V

VFB = 1.23V

V

= 5V, Switching

SHDN

V

= 5V, Not Switching

SHDN

V

= 0

SHDN

2.7V ≤ VIN ≤ 14V

Not Switching, VSW = 5V

= 265°C/W, and the ambient temperature, TA. The maximum allowable power dissipation

J-A

0

0 2

1.205 1.230 1.255 V

60 nA

2.1 3.0 mA

400 500

0.024 1

0.02 %/V

1 µA

J(MAX)

mΩ

µA

µA

= 125°C,

30V

IN

V

If power dissipation exceeds the maximum specified above, the internal thermal protection circuitry will protect the device by reducing the output voltage as

required to maintain a safe junction temperature.

Note 3: The human body model is a 100 pF capacitor discharged through a 1.5 kΩ resistor into each pin. Test method is per JESD22-A114.

Note 4: Switch current limit is dependent on duty cycle. Limits shown are for duty cycles ≤ 50%. See Figure 3 in Application Information – MAXIMUM SWITCH

CURRENT section.

3 www.national.com

Page 4

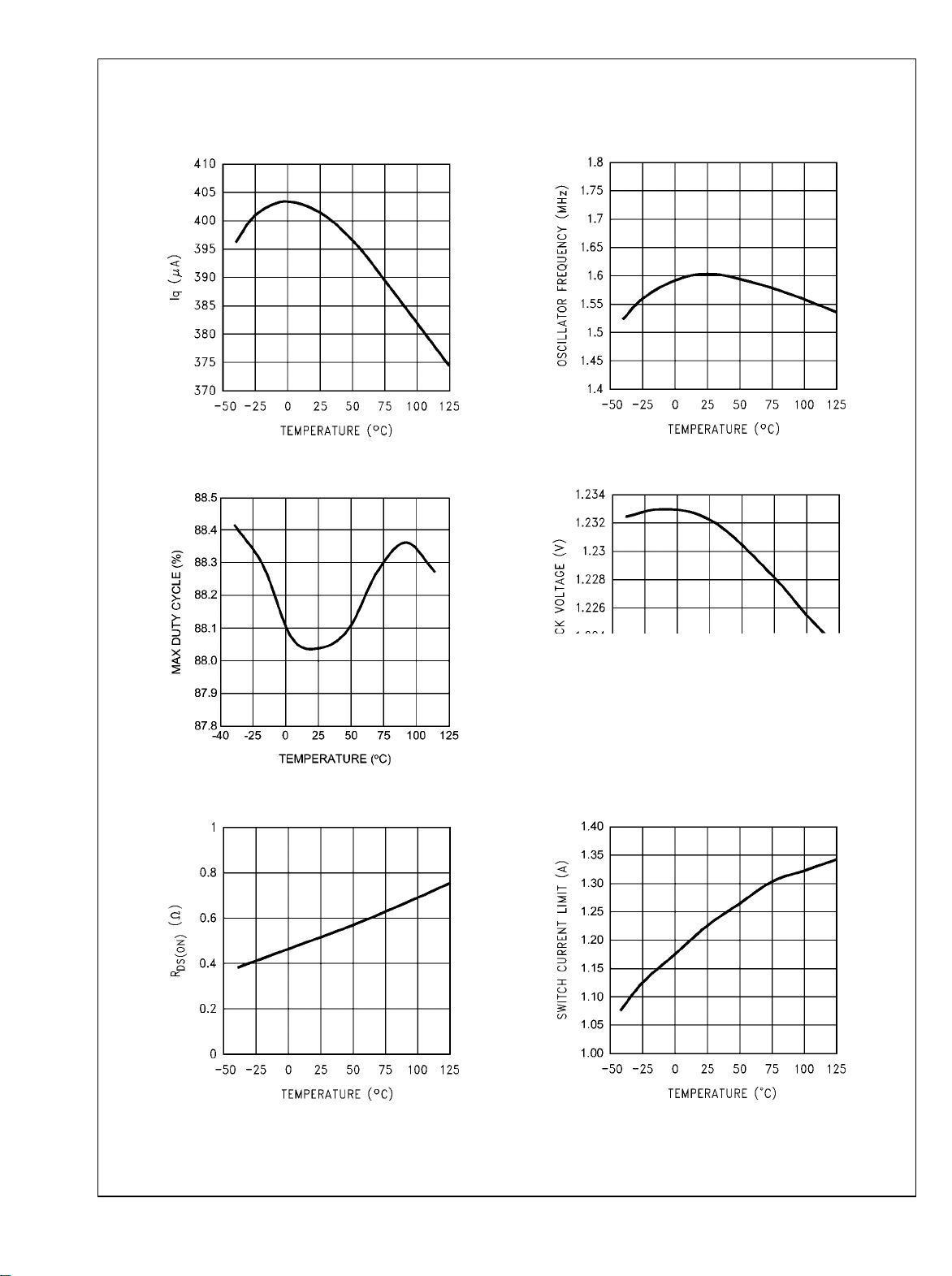

Typical Performance Characteristics Unless otherwise specified: V

TJ = 25°C.

LM27313

Iq VIN (Active) vs Temperature

Oscillator Frequency vs Temperature

= 5V, SHDN pin is tied to VIN,

IN

Max. Duty Cycle vs Temperature

RDS(ON) vs Temperature

20216810

20216855

20216808

Feedback Voltage vs Temperature

20216806

Current Limit vs Temperature

20216807

www.national.com 4

20216809

Page 5

R

DS(ON)

vs V

IN

Efficiency vs Load Current (V

OUT

= 12V)

Efficiency vs Load Current (V

Efficiency vs Load Current (V

OUT

OUT

20216823

= 15V)

20216845

= 25V)

Efficiency vs Load Current (V

OUT

20216814

= 20V)

20216846

20216847

5

Page 6

Block Diagram

LM27313

Theory of Operation

The LM27313 is a switching converter IC that operates at a

fixed frequency of 1.6 MHz using current-mode control for fast

transient response over a wide input voltage range and incorporate pulse-by-pulse current limiting protection. Because

this is current mode control, a 50 mΩ sense resistor in series

with the switch FET is used to provide a voltage (which is

proportional to the FET current) to both the input of the pulse

width modulation (PWM) comparator and the current limit

amplifier.

At the beginning of each cycle, the S-R latch turns on the FET.

As the current through the FET increases, a voltage (proportional to this current) is summed with the ramp coming from

the ramp generator and then fed into the input of the PWM

comparator. When this voltage exceeds the voltage on the

other input (coming from the Gm amplifier), the latch resets

and turns the FET off. Since the signal coming from the Gm

amplifier is derived from the feedback (which samples the

voltage at the output), the action of the PWM comparator

constantly sets the correct peak current through the FET to

keep the output voltage in regulation.

Q1 and Q2 along with R3 - R6 form a bandgap voltage reference used by the IC to hold the output in regulation. The

currents flowing through Q1 and Q2 will be equal, and the

feedback loop will adjust the regulated output to maintain this.

Because of this, the regulated output is always maintained at

a voltage level equal to the voltage at the FB node "multiplied

up" by the ratio of the output resistive divider.

The current limit comparator feeds directly into the flip-flop,

that drives the switch FET. If the FET current reaches the limit

threshold, the FET is turned off and the cycle terminated until

the next clock pulse. The current limit input terminates the

pulse regardless of the status of the output of the PWM comparator.

20216803

Application Information

SELECTING THE EXTERNAL CAPACITORS

The LM27313 requires ceramic capacitors at the input and

output to accommodate the peak switching currents the part

needs to operate. Electrolytic capacitors have resonant frequencies which are below the switching frequency of the

device, and therefore can not provide the currents needed to

operate. Electrolytics may be used in parallel with the ceramics for bulk charge storage which will improve transient response.

When selecting a ceramic capacitor, only X5R and X7R dielectric types should be used. Other types such as Z5U and

Y5F have such severe loss of capacitance due to effects of

temperature variation and applied voltage, they may provide

as little as 20% of rated capacitance in many typical applications. Always consult capacitor manufacturer’s data curves

before selecting a capacitor. High-quality ceramic capacitors

can be obtained from Taiyo-Yuden, AVX, and Murata.

SELECTING THE OUTPUT CAPACITOR

A single ceramic capacitor of value 4.7 µF to 10 µF will provide

sufficient output capacitance for most applications. For output

voltages below 10V, a 10 µF capacitance is required. If larger

amounts of capacitance are desired for improved line support

and transient response, tantalum capacitors can be used in

parallel with the ceramics. Aluminum electrolytics with ultra

low ESR such as Sanyo Oscon can be used, but are usually

prohibitively expensive. Typical AI electrolytic capacitors are

not suitable for switching frequencies above 500 kHz due to

significant ringing and temperature rise due to self-heating

from ripple current. An output capacitor with excessive ESR

can also reduce phase margin and cause instability.

SELECTING THE INPUT CAPACITOR

An input capacitor is required to serve as an energy reservoir

for the current which must flow into the inductor each time the

switch turns ON. This capacitor must have extremely low ESR

and ESL, so ceramic must be used. We recommend a nom-

www.national.com 6

Page 7

LM27313

inal value of 2.2 µF, but larger values can be used. Since this

capacitor reduces the amount of voltage ripple seen at the

input pin, it also reduces the amount of EMI passed back

along that line to other circuitry.

FEED-FORWARD COMPENSATION

Although internally compensated, the feed-forward capacitor

Cf is required for stability (see Typical Application Circuits).

Adding this capacitor puts a zero in the loop response of the

converter. Without it, the regulator loop can oscillate. The

recommended frequency for the zero fz should be approximately 8 kHz. Cf can be calculated using the formula:

Cf = 1 / (2 x π x R1 x fz)

SELECTING DIODES

The external diode used in the typical application should be

a Schottky diode. If the switch voltage is less than 15V, a 20V

diode such as the MBR0520 is recommended. If the switch

voltage is between 15V and 25V, a 30V diode such as the

MBR0530 is recommended. If the switch voltage exceeds

25V, a 40V diode such as the MBR0540 should be used.

The MBR05xx series of diodes are designed to handle a maximum average current of 500mA. For applications with load

currents to 800mA, a Microsemi UPS5817 can be used.

LAYOUT HINTS

High frequency switching regulators require very careful layout of components in order to get stable operation and low

noise. All components must be as close as possible to the

LM27313 device. It is recommended that a 4-layer PCB be

used so that internal ground planes are available.

As an example, a recommended layout of components is

shown:

3.

If internal ground planes are available (recommended)

use vias to connect directly to the LM27313 ground at

device pin 2, as well as the negative sides of capacitors

C1 and C2.

SETTING THE OUTPUT VOLTAGE

The output voltage is set using the external resistors R1 and

R2 (see Typical Application Circuits). A minimum value of

13.3 kΩ is recommended for R2 to establish a divider current

of approximately 92 µA. R1 is calculated using the formula:

R1 = R2 x ( (V

/ VFB) − 1 )

OUT

DUTY CYCLE

The maximum duty cycle of the switching regulator determines the maximum boost ratio of output-to-input voltage that

the converter can attain in continuous mode of operation. The

duty cycle for a given boost application is defined as:

This applies for continuous mode operation.

The equation shown for calculating duty cycle incorporates

terms for the FET switch voltage and diode forward voltage.

The actual duty cycle measured in operation will also be affected slightly by other power losses in the circuit such as wire

losses in the inductor, switching losses, and capacitor ripple

current losses from self-heating. Therefore, the actual (effective) duty cycle measured may be slightly higher than calculated to compensate for these power losses. A good

approximation for effective duty cycle is :

DC (eff) = (1 - Efficiency x (VIN / V

OUT

))

Where the efficiency can be approximated from the curves

provided.

FIGURE 1. Recommended PCB Component Layout

Some additional guidelines to be observed:

1.

Keep the path between L1, D1, and C2 extremely short.

Parasitic trace inductance in series with D1 and C2 will

increase noise and ringing.

2.

The feedback components R1, R2 and CF must be kept

close to the FB pin of the LM27313 to prevent noise

injection on the high impedance FB pin.

20216822

INDUCTANCE VALUE

The first question we are usually asked is: “How small can I

make the inductor?” (because they are the largest sized component and usually the most costly). The answer is not simple

and involves trade-offs in performance. More inductance

means less inductor ripple current and less output voltage

ripple (for a given size of output capacitor). More inductance

also means more load power can be delivered because the

energy stored during each switching cycle is:

E = L/2 x (lp)

2

Where “lp” is the peak inductor current. An important point to

observe is that the LM27313 will limit its switch current based

on peak current. This means that since lp(max) is fixed, increasing L will increase the maximum amount of power available to the load. Conversely, using too little inductance may

limit the amount of load current which can be drawn from the

output.

Best performance is usually obtained when the converter is

operated in “continuous” mode at the load current range of

interest, typically giving better load regulation and less output

ripple. Continuous operation is defined as not allowing the inductor current to drop to zero during the cycle. It should be

noted that all boost converters shift over to discontinuous operation as the output load is reduced far enough, but a larger

inductor stays “continuous” over a wider load current range.

To better understand these tradeoffs, a typical application circuit (5V to 12V boost with a 10 µH inductor) will be analyzed.

7 www.national.com

Page 8

Since the LM27313 typical switching frequency is 1.6 MHz,

the typical period is equal to 1/f

0.625 µs.

LM27313

We will assume: VIN = 5V, V

0.5V. The duty cycle is:

= 12V, V

OUT

, or approximately

SW(TYP)

DIODE

= 0.5V, VSW =

Duty Cycle = ((12V + 0.5V - 5V) / (12V + 0.5V - 0.5V)) = 62.5%

The typical ON time of the switch is:

(62.5% x 0.625 µs) = 0.390 µs

It should be noted that when the switch is ON, the voltage

across the inductor is approximately 4.5V.

Using the equation:

V = L (di/dt)

We can then calculate the di/dt rate of the inductor which is

found to be 0.45 A/µs during the ON time. Using these facts,

we can then show what the inductor current will look like during operation:

FIGURE 2. 10 µH Inductor Current, 5V–12V Boost

During the 0.390 µs ON time, the inductor current ramps up

0.176A and ramps down an equal amount during the OFF

time. This is defined as the inductor “ripple current”. It can also

be seen that if the load current drops to about 33 mA, the

inductor current will begin touching the zero axis which means

it will be in discontinuous mode. A similar analysis can be

performed on any boost converter, to make sure the ripple

current is reasonable and continuous operation will be maintained at the typical load current values.

MAXIMUM SWITCH CURRENT

The maximum FET switch current available before the current

limiter cuts in is dependent on duty cycle of the application.

This is illustrated in Figure 3 below which shows typical values

of switch current as a function of effective (actual) duty cycle:

20216812

20216825

FIGURE 3. Switch Current Limit vs Duty Cycle

CALCULATING LOAD CURRENT

As shown in the figure which depicts inductor current, the load

current is related to the average inductor current by the relation:

I

LOAD

= I

IND(AVG)

x (1 - DC)

Where "DC" is the duty cycle of the application. The switch

current can be found by:

ISW = I

IND(AVG)

+ ½ (I

RIPPLE

)

Inductor ripple current is dependent on inductance, duty cycle, input voltage and frequency:

I

= DC x (VIN - VSW) / (fSW x L)

RIPPLE

Combining all terms, we can develop an expression which

allows the maximum available load current to be calculated:

The equation shown to calculate maximum load current takes

into account the losses in the inductor or turn-OFF switching

losses of the FET and diode. For actual load current in typical

applications, we took bench data for various input and output

voltages and displayed the maximum load current available

for a typical device in graph form:

www.national.com 8

Page 9

20216834

In this example, the LM27313 nominal switching frequency is

1.6 MHz, and the minimum switching frequency is

1.15 MHz. This means the maximum cycle period is the reciprocal of the minimum frequency:

T

We will assume: VIN = 5V, V

V

= 0.3V. The duty cycle is:

DIODE

= 1/1.15M = 0.870 µs

ON(max)

= 12V, VSW = 0.2V, and

OUT

Duty Cycle = ((12V + 0.3V - 5V) / (12V + 0.3V - 0.2V)) = 60.3%

Therefore, the maximum switch ON time is:

(60.3% x 0.870 µs) = 0.524 µs

An inductor should be selected with enough inductance to

prevent the switch current from reaching 800 mA in the 0.524

µs ON time interval (see below):

LM27313

FIGURE 4. Max. Load Current vs V

DESIGN PARAMETERS VSW AND I

SW

IN

The value of the FET "ON" voltage (referred to as VSW in the

equations) is dependent on load current. A good approximation can be obtained by multiplying the "ON Resistance" of

the FET times the average inductor current.

FET on resistance increases at VIN values below 5V, since

the internal N-FET has less gate voltage in this input voltage

range (see Typical performance Characteristics curves).

Above VIN = 5V, the FET gate voltage is internally clamped to

5V.

The maximum peak switch current the device can deliver is

dependent on duty cycle. The minimum switch current value

(ISW) is guaranteed to be at least 800 mA at duty cycles below

50%. For higher duty cycles, see Typical performance Characteristics curves.

THERMAL CONSIDERATIONS

At higher duty cycles, the increased ON time of the FET

means the maximum output current will be determined by

power dissipation within the LM27313 FET switch. The switch

power dissipation from ON-state conduction is calculated by:

2

PSW = DC x I

IND(AVG)

x R

DS(ON)

There will be some switching losses as well, so some derating

needs to be applied when calculating IC power dissipation.

MINIMUM INDUCTANCE

In some applications where the maximum load current is relatively small, it may be advantageous to use the smallest

possible inductance value for cost and size savings. The converter will operate in discontinuous mode in such a case.

The minimum inductance should be selected such that the

inductor (switch) current peak on each cycle does not reach

the 800 mA current limit maximum. To understand how to do

this, an example will be presented.

20216813

FIGURE 5. Discontinuous Design, 5V–12V Boost

The voltage across the inductor during ON time is 4.8V. Minimum inductance value is found by:

L = V x (dt/dl)

L = 4.8V x (0.524 µs / 0.8 mA) = 3.144 µH

In this case, a 3.3 µH inductor could be used, assuming it

provided at least that much inductance up to the 800 mA current value. This same analysis can be used to find the minimum inductance for any boost application.

INDUCTOR SUPPLIERS

Some of the recommended suppliers of inductors for this

product include, but are not limited to, Sumida, Coilcraft,

Panasonic, TDK and Murata. When selecting an inductor,

make certain that the continuous current rating is high enough

to avoid saturation at peak currents. A suitable core type must

be used to minimize core (switching) losses, and wire power

losses must be considered when selecting the current rating.

SHUTDOWN PIN OPERATION

The device is turned off by pulling the shutdown pin low. If this

function is not going to be used, the pin should be tied directly

to VIN. If the SHDN function will be needed, a pull-up resistor

must be used to VIN (50kΩ to 100 kΩ is recommended), or

the pin must be actively driven high and low. The SHDN pin

must not be left unterminated.

9 www.national.com

Page 10

Physical Dimensions inches (millimeters) unless otherwise noted

LM27313

Order Number LM27313XMF, or LM27313XMFX

5-Lead SOT-23 Package

NS Package Number MF05A

www.national.com 10

Page 11

Notes

LM27313

11 www.national.com

Page 12

Notes

THE CONTENTS OF THIS DOCUMENT ARE PROVIDED IN CONNECTION WITH NATIONAL SEMICONDUCTOR CORPORATION

(“NATIONAL”) PRODUCTS. NATIONAL MAKES NO REPRESENTATIONS OR WARRANTIES WITH RESPECT TO THE ACCURACY

OR COMPLETENESS OF THE CONTENTS OF THIS PUBLICATION AND RESERVES THE RIGHT TO MAKE CHANGES TO

SPECIFICATIONS AND PRODUCT DESCRIPTIONS AT ANY TIME WITHOUT NOTICE. NO LICENSE, WHETHER EXPRESS,

IMPLIED, ARISING BY ESTOPPEL OR OTHERWISE, TO ANY INTELLECTUAL PROPERTY RIGHTS IS GRANTED BY THIS

DOCUMENT.

TESTING AND OTHER QUALITY CONTROLS ARE USED TO THE EXTENT NATIONAL DEEMS NECESSARY TO SUPPORT

NATIONAL’S PRODUCT WARRANTY. EXCEPT WHERE MANDATED BY GOVERNMENT REQUIREMENTS, TESTING OF ALL

PARAMETERS OF EACH PRODUCT IS NOT NECESSARILY PERFORMED. NATIONAL ASSUMES NO LIABILITY FOR

APPLICATIONS ASSISTANCE OR BUYER PRODUCT DESIGN. BUYERS ARE RESPONSIBLE FOR THEIR PRODUCTS AND

APPLICATIONS USING NATIONAL COMPONENTS. PRIOR TO USING OR DISTRIBUTING ANY PRODUCTS THAT INCLUDE

NATIONAL COMPONENTS, BUYERS SHOULD PROVIDE ADEQUATE DESIGN, TESTING AND OPERATING SAFEGUARDS.

EXCEPT AS PROVIDED IN NATIONAL’S TERMS AND CONDITIONS OF SALE FOR SUCH PRODUCTS, NATIONAL ASSUMES NO

LIABILITY WHATSOEVER, AND NATIONAL DISCLAIMS ANY EXPRESS OR IMPLIED WARRANTY RELATING TO THE SALE

AND/OR USE OF NATIONAL PRODUCTS INCLUDING LIABILITY OR WARRANTIES RELATING TO FITNESS FOR A PARTICULAR

PURPOSE, MERCHANTABILITY, OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY

RIGHT.

LIFE SUPPORT POLICY

NATIONAL’S PRODUCTS ARE NOT AUTHORIZED FOR USE AS CRITICAL COMPONENTS IN LIFE SUPPORT DEVICES OR

SYSTEMS WITHOUT THE EXPRESS PRIOR WRITTEN APPROVAL OF THE CHIEF EXECUTIVE OFFICER AND GENERAL

COUNSEL OF NATIONAL SEMICONDUCTOR CORPORATION. As used herein:

LM27313 1.6 MHz Boost Converter With 30V Internal FET Switch in SOT-23

Life support devices or systems are devices which (a) are intended for surgical implant into the body, or (b) support or sustain life and

whose failure to perform when properly used in accordance with instructions for use provided in the labeling can be reasonably expected

to result in a significant injury to the user. A critical component is any component in a life support device or system whose failure to perform

can be reasonably expected to cause the failure of the life support device or system or to affect its safety or effectiveness.

National Semiconductor and the National Semiconductor logo are registered trademarks of National Semiconductor Corporation. All other

brand or product names may be trademarks or registered trademarks of their respective holders.

Copyright© 2007 National Semiconductor Corporation

For the most current product information visit us at www.national.com

www.national.com

National Semiconductor

Americas Customer

Support Center

Email:

new.feedback@nsc.com

Tel: 1-800-272-9959

National Semiconductor Europe

Customer Support Center

Fax: +49 (0) 180-530-85-86

Email: europe.support@nsc.com

Deutsch Tel: +49 (0) 69 9508 6208

English Tel: +49 (0) 870 24 0 2171

Français Tel: +33 (0) 1 41 91 8790

National Semiconductor Asia

Pacific Customer Support Center

Email: ap.support@nsc.com

National Semiconductor Japan

Customer Support Center

Fax: 81-3-5639-7507

Email: jpn.feedback@nsc.com

Tel: 81-3-5639-7560

Loading...

Loading...