Page 1

LM2698

SIMPLE SWITCHER

®

1.35A Boost Regulator

General Description

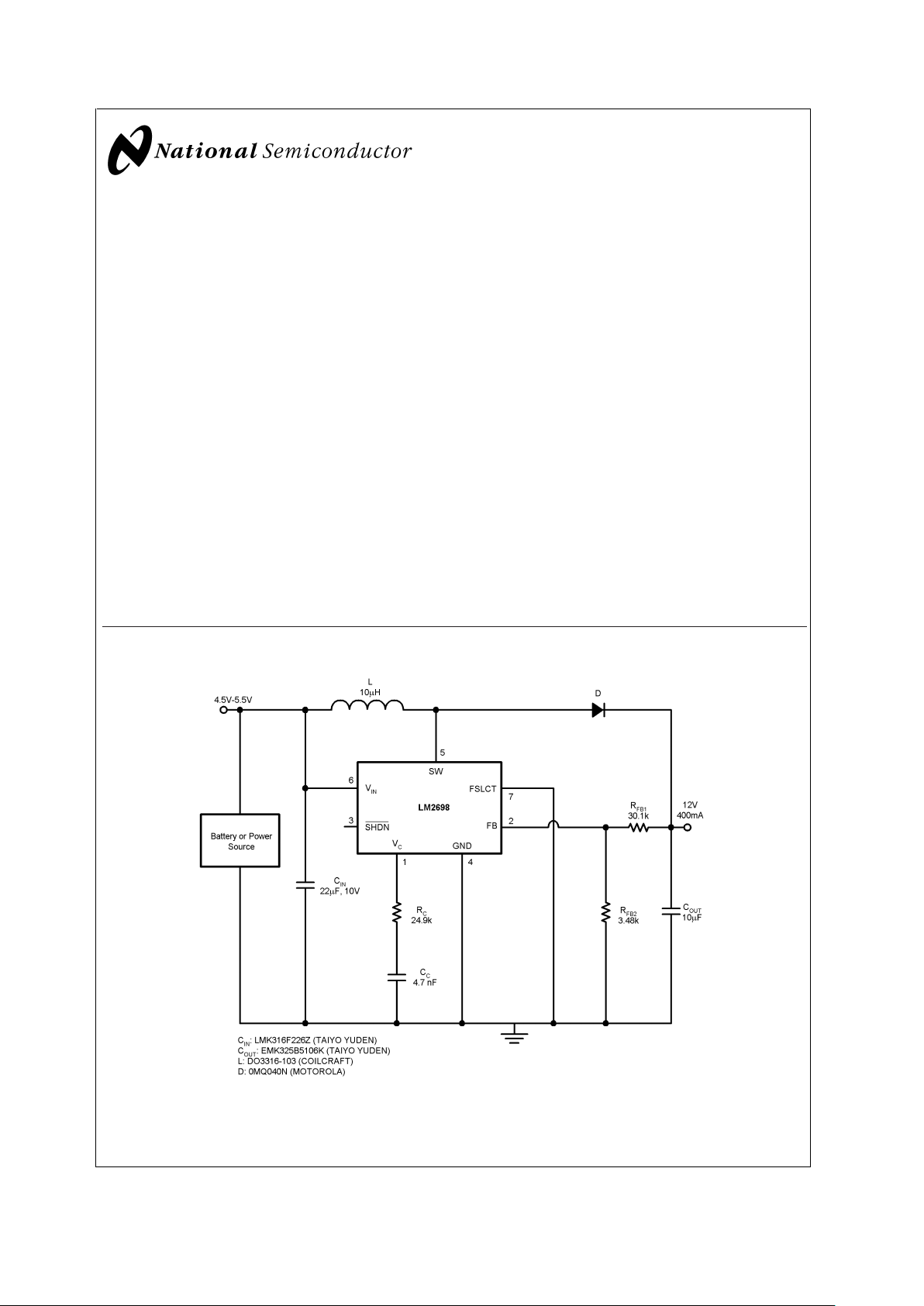

The LM2698 is a general purpose PWM boost converter.

The 1.9A, 18V, 0.2ohm internal switch enables the LM2698

to provide efficient power conversion to outputs ranging from

2.2V to 17V.Itcanoperate with input voltages as low as 2.2V

and as high as 12V. Current-mode architecture provides

superior line and load regulation and simple frequency compensation over the device’s 2.2V to 12V input voltagerange.

The LM2698 sets the standard in power density and is

capable of supplying 12V at 400mA from a 5V input. The

LM2698 can also be used in flyback or SEPIC topologies.

The LM2698 SIMPLE SWITCHER

®

features a pin selectable

switching frequency of either 600kHz or 1.25MHz. This promotes flexibility in component selection and filtering techniques. A shutdown pin is available to suspend the device

and decrease the quiescent current to 5µA. An external

compensation pin gives the user flexibility in setting frequency compensation, which makes possible the use of

small, low ESR ceramic capacitors at the output. Switchers

Made Simple

®

software is available to insure a quick, easy

and guaranteed design. The LM2698 is available in a low

profile 8-lead MSOP package.

Features

n 1.9A, 0.2Ω, internal switch (typical)

n Operating voltage as low as 2.2V

n 600kHz/1.25MHz adjustable frequency operation

n Switchers Made Simple

®

software

n 8-Lead MSOP package

Applications

n 3.3V to 5V, 5V to 12V conversion

n Distributed Power

n Set-Top Boxes

n DSL Modems

n Diagnostic Medical Instrumentation

n Boost Converters

n Flyback Converters

n SEPIC Converters

Typical Application Circuit

20012658

SIMPLE SWITCHER®is a registered trademark of National Semiconductor Corporation.

October 2001

LM2698 SIMPLE SWITCHER

®

1.35A Boost Regulator

© 2001 National Semiconductor Corporation DS200126 www.national.com

Page 2

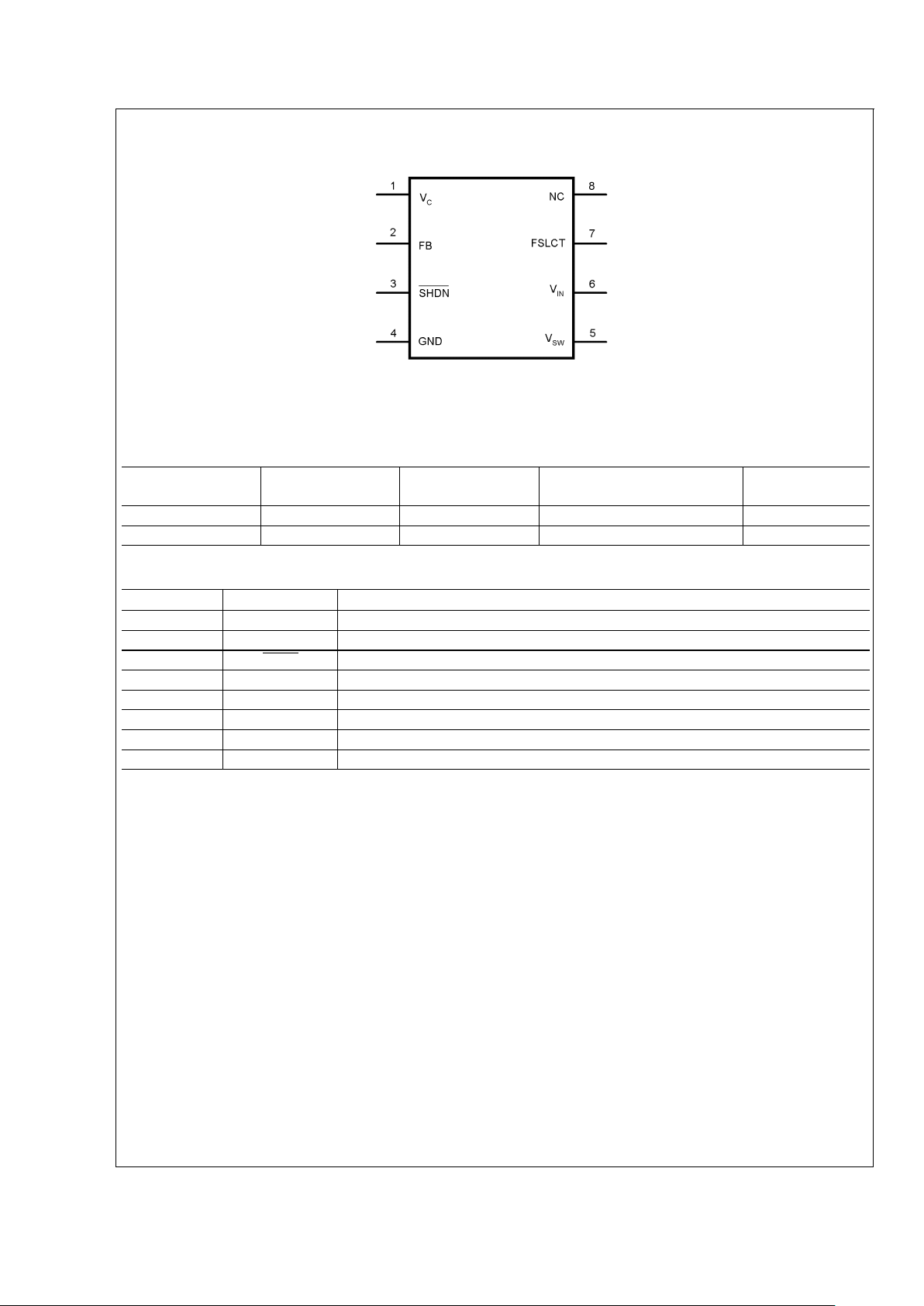

Connection Diagram

Top View

20012604

8-Lead Plastic MSOP

NS Package Number MUA08A

Ordering Information

Order Number Package Type NSC Package

Drawing

Supplied As Package ID

LM2698MM-ADJ MSOP-8 MUA08A 1000 Units, Tape and Reel S22B

LM2698MMX-ADJ MSOP-8 MUA08A 3500 Units, Tape and Reel S22B

Pin Description

Pin Name Function

1V

C

Compensation network connection. Connected to the output of the voltage error amplifier.

2 FB Output voltage feedback input.

3 SHDN

Shutdown control input, active low.

4 GND Analog and power ground.

5V

SW

Power switch input. Switch connected between SW pin and GND pin.

6V

IN

Analog power input.

7 FSLCT Switching frequency select input. V

IN

= 1.25MHz. Ground = 600kHz.

8 NC Connect to ground.

LM2698

www.national.com 2

Page 3

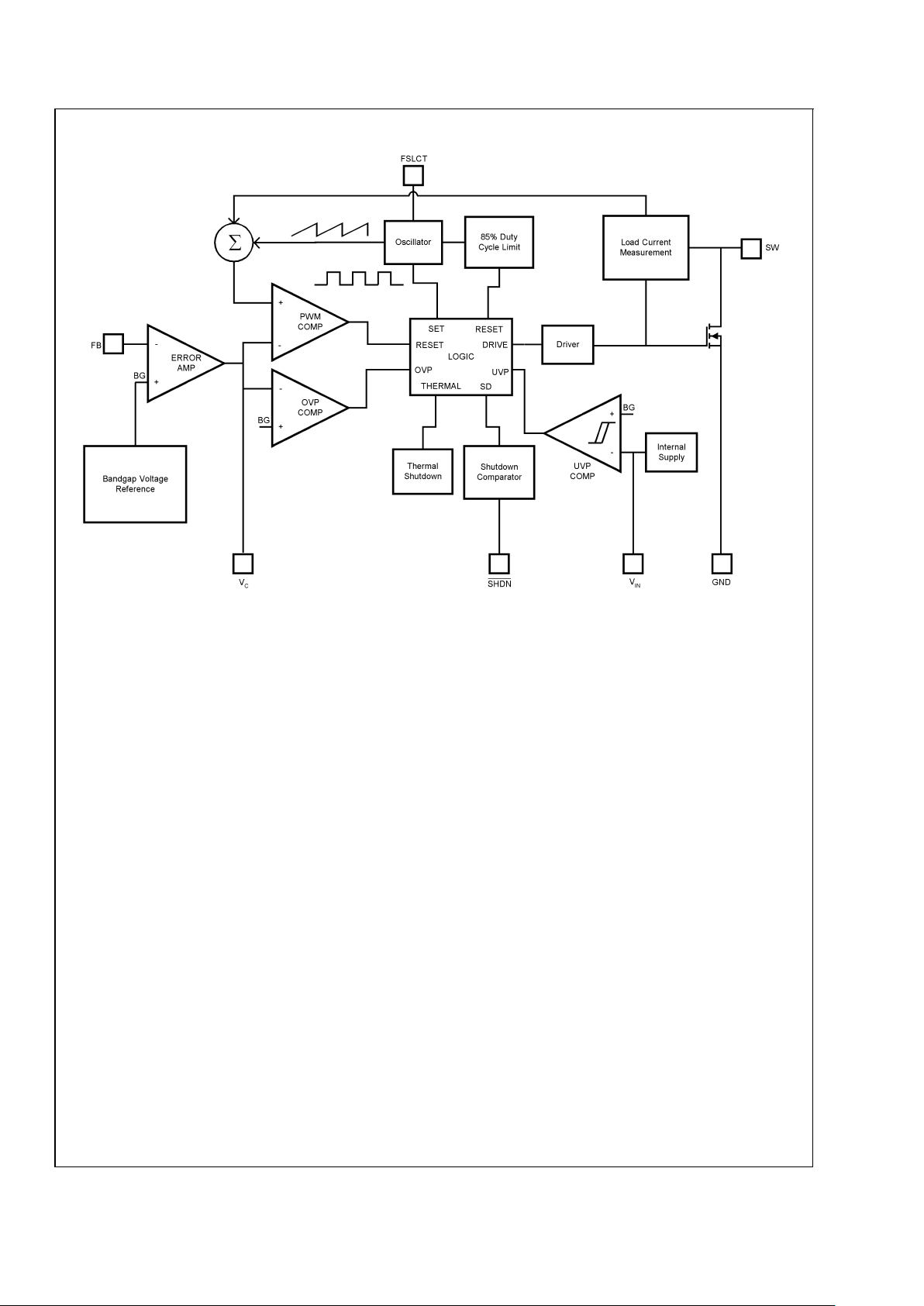

Block Diagram

20012603

LM2698

www.national.com3

Page 4

Absolute Maximum Ratings (Note 1)

If Military/Aerospace specified devices are required,

please contact the National Semiconductor Sales Office/

Distributors for availability and specifications.

V

IN

−0.3V ≤ VIN≤ 12V

SW Voltage −0.3V ≤ V

SW

≤ 18V

FB Voltage −0.3V ≤ V

FB

≤ 7V

V

C

Voltage 0.965<V

C

<

1.565

SHDN Voltage

(Note 2) −0.3V ≤ V

SHDN

≤ 7V

FSLCT

(Note 2) −0.3V ≤ V

FSLCT

≤ 12V

Maximum Junction

Temperature

150˚C

Power Dissipation (Note 3) Internally Limited

Lead Temperature 300˚C

Vapor Phase (60 sec.) 215˚C

Infrared (15 sec.) 220˚C

ESD Susceptibility

(Note 4)

Human Body Model

(Note 5) 2kV

Machine Model 200V

Operating Conditions

Operating Junction

Temperature Range

(Note 6) −40˚C to +125˚C

Storage Temperature −65˚C to +150˚C

Supply Voltage 2.2V to 12V

SW Voltage 0 ≤ V

SW

≤ 17.5V

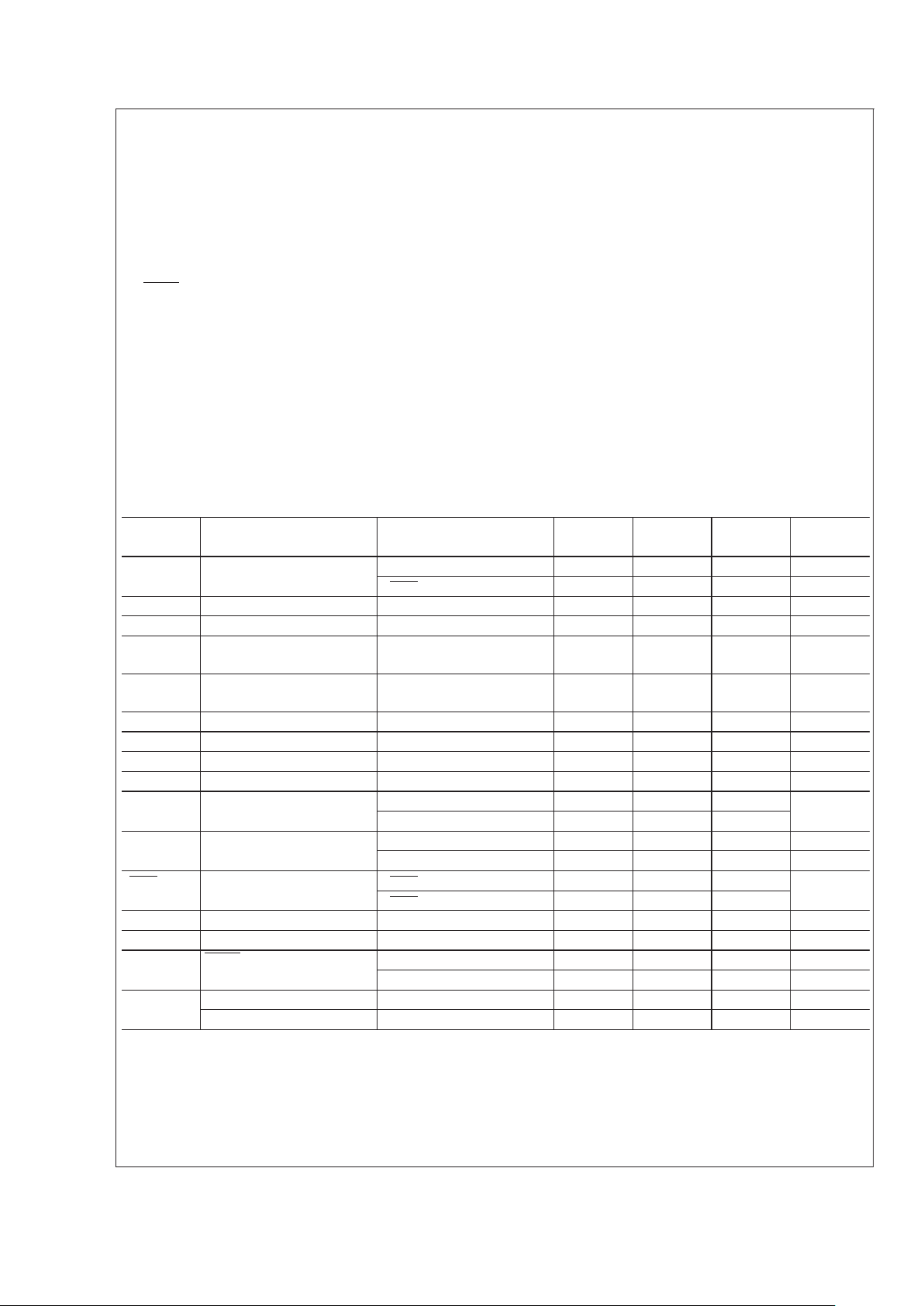

Electrical Characteristics

Specifications in standard type face are for TJ= 25˚C and those with boldface type apply over the full Operating Temperature Range (T

J

= −40˚C to +125˚C)Unless otherwise specified. VIN=2.2V and IL= 0A, unless otherwise specified.

Symbol Parameter Conditions

Min

(Note 6)

Typ

(Note 7)

Max

(Note 6)

Units

I

Q

Quiescent Current FB = 0V (Not Switching) 1.3 2.0 mA

V

SHDN

=0V 5 10 µA

V

FB

Feedback Voltage 1.2285 1.26 1.2915 V

I

CL

Switch Current Limit VIN= 2.7V (Note 8) 1.35 1.9 2.4 A

%V

FB

/∆VINFeedback Voltage Line

Regulation

2.2V ≤ VIN≤ 12.0V 0.013 0.1 %/V

I

B

FB Pin Bias Current

(Note 9)

0.5 20 nA

V

IN

Input Voltage Range 2.2 12 V

g

m

Error Amp Transconductance ∆I = 5µA 40 135 290 µmho

A

V

Error Amp Voltage Gain 120 V/V

D

MAX

Maximum Duty Cycle FSLCT = Ground 78 85 %

D

MIN

Minimum Duty Cycle FSLCT = Ground 15 %

FSLCT = V

IN

30

f

S

Switching Frequency FSLCT = Ground 480 600 720 kHz

FSLCT = V

IN

1 1.25 1.5 MHz

I

SHDN

Shutdown Pin Current V

SHDN

=V

IN

0.01 0.1 µA

V

SHDN

=0V −0.5 -1

I

L

Switch Leakage Current VSW= 18V 0.01 3 µA

R

DS(ON)

Switch R

DS(ON)

VIN= 2.7V, ISW= 1A 0.2 0.4 Ω

TH

SHDN

SHDN Threshold Voltage Output High 0.6 0.9 V

Output Low 0.3 0.6 V

UVP On Threshold 1.95 2.05 2.2 V

Off Threshold 1.85 1.95 2.1 V

LM2698

www.national.com 4

Page 5

Electrical Characteristics (Continued)

Specifications in standard type face are for TJ= 25˚C and those with boldface type apply over the full Operating Temperature Range (T

J

= −40˚C to +125˚C)Unless otherwise specified. VIN=2.2V and IL= 0A, unless otherwise specified.

Symbol Parameter Conditions

Min

(Note 6)

Typ

(Note 7)

Max

(Note 6)

Units

θ

JA

Thermal Resistance Junction to Ambient

(Note 10)

235 ˚C/W

Junction to Ambient

(Note 11)

225

Junction to Ambient

(Note 12)

220

Junction to Ambient

(Note 13)

200

Junction to Ambient

(Note 14)

195

Note 1: Absolute maximum ratings are limits beyond which damage to the device may occur. Operating Ratings are conditions for which the device is intended to

be functional, but device parameter specifications may not be guaranteed. For guaranteed specifications and test conditions, see the Electrical Characteristics.

Note 2: Shutdown and voltage frequency select should not exceed V

IN

.

Note 3: The maximum allowable power dissipation is a function of the maximum junction temperature, T

J

(MAX), the junction-to-ambient thermal resistance, θJA,

and the ambient temperature, T

A

. See the Electrical Characteristics table for the thermal resistance of various layouts. The maximum allowable power dissipation

at any ambient temperature is calculated using: P

D

(MAX) = (T

J(MAX)−TA

)/θJA. Exceeding the maximum allowable power dissipation will cause excessive die

temperature, and the regulator will go into thermal shutdown.

Note 4: The human body model is a 100 pF capacitor discharged through a 1.5kΩ resistor into each pin. The machine model is a 200pF capacitor discharged

directly into each pin.

Note 5: ESD susceptibility using the human body model is 500V for V

C

.

Note 6: All limits guaranteed at room temperature (standard typeface) and at temperature extremes (bold typeface). All room temperature limits are 100% tested

or guaranteed through statistical analysis.All limits at temperature extremes are guaranteed via correlation using standard Statistical Quality Control (SQC) methods.

All limits are used to calculate Average Outgoing Quality Level (AOQL).

Note 7: Typical numbers are at 25˚C and represent the most likely norm.

Note 8: This is the switch current limit at 0% duty cycle. The switch current limit will change as a function of duty cycle. See Typical performance Characteristics

section for I

CL

vs. V

IN

Note 9: Bias current flows into FB pin.

Note 10: Junction to ambient thermal resistance (no external heat sink) for the MSO8 package with minimal trace widths (0.010 inches) from the pins to the circuit.

See ’Scenario ’A’’ in the Power Dissipation section.

Note 11: Junction to ambient thermal resistance for the MSO8 package with minimal trace widths (0.010 inches) from the pins to the circuit and approximately

0.0191 sq. in. of copper heat sinking. See ’Scenario ’B’’ in the Power Dissipation section.

Note 12: Junction to ambient thermal resistance for the MSO8 package with minimal trace widths (0.010 inches) from the pins to the circuit and approximately

0.0465 sq. in. of copper heat sinking. See ’Scenario ’C’’ in the Power Dissipation section.

Note 13: Junction to ambient thermal resistance for the MSO8 package with minimal trace widths (0.010 inches) from the pins to the circuit and approximately

0.2523 sq. in. of copper heat sinking. See ’Scenario ’D’’ in the Power Dissipation section.

Note 14: Junction to ambient thermal resistance for the MSO8 package with minimal trace widths (0.010 inches) from the pins to the circuit and approximately

0.0098 sq. in. of copper heat sinking on the top layer and 0.0760 sq. in. of copper heat sinking on the bottom layer, with three 0.020 in. vias connecting the planes.

See ’Scenario ’E’’ in the Power Dissipation section.

LM2698

www.national.com5

Page 6

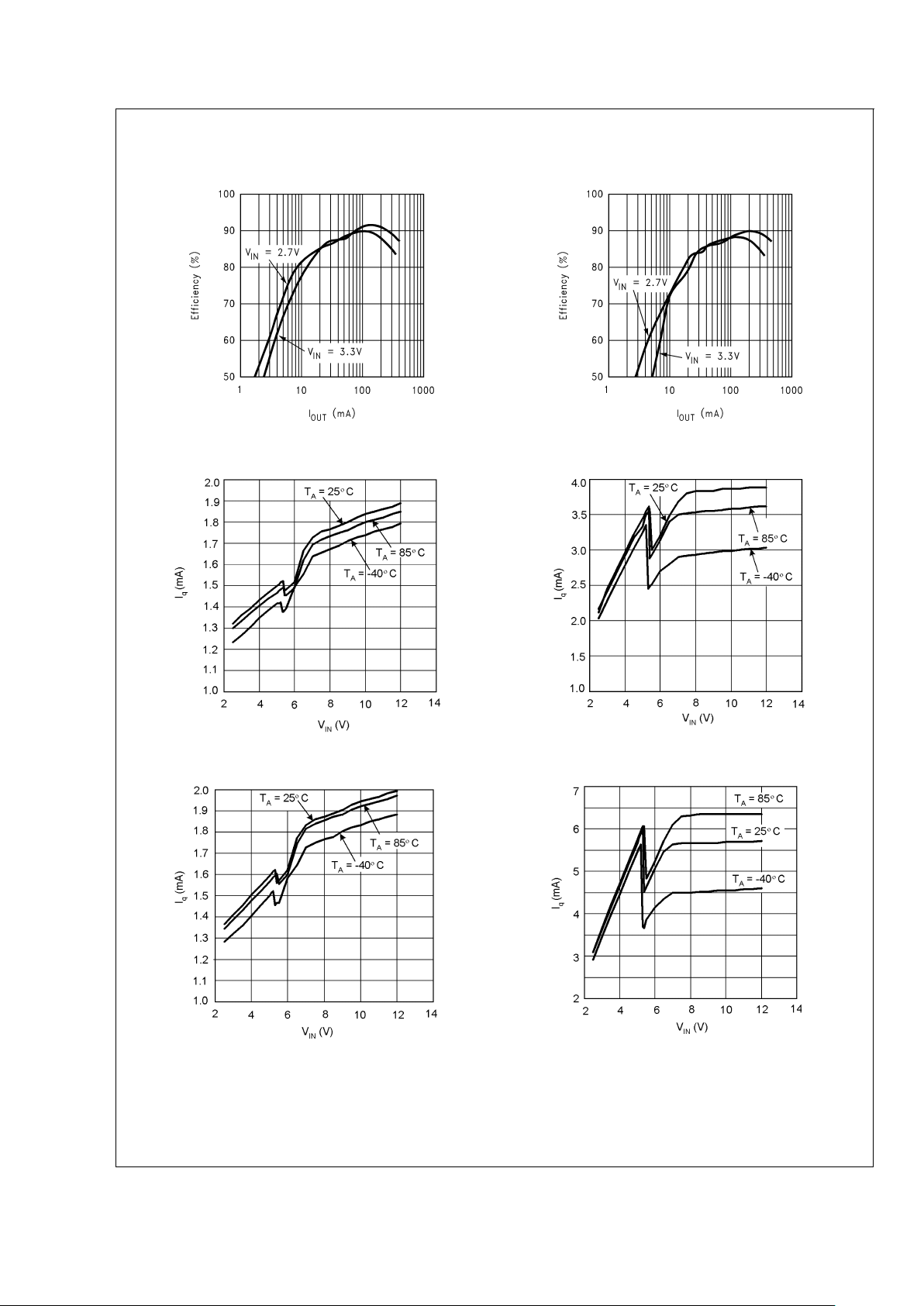

Typical Performance Characteristics

Efficiency vs Load Current

(V

OUT

= 8V, fS= 600kHz)

Efficiency vs Load Current

(V

OUT

= 8V, fS= 1.25MHz)

20012667 20012666

Iqvs VIN(600 kHz, non-switching) Iqvs VIN(600 kHz, switching)

20012618

20012619

Iqvs. VIN(1.25MHz, non-switching) Iqvs VIN(1.25MHz, switching)

20012622

20012617

LM2698

www.national.com 6

Page 7

Typical Performance Characteristics (Continued)

I

q(SHDN)

vs V

IN

R

DS(ON)

vs V

IN

20012616 20012621

Switching Frequency vs VIN(600kHz) Switching Frequency vs VIN(1.25MHz)

20012620 20012623

ICLvs. Ambient Temperature

V

IN

= 3.3V, V

OUT

=8V ICLvs. V

IN

20012641 20012642

LM2698

www.national.com7

Page 8

Operation

Continuous Conduction Mode

The LM2698 is a current-mode, PWM boost regulator. A

boost regulator steps the input voltage up to a higher output

voltage. In continuous conduction mode (when the inductor

current never reaches zero at steady state), the boost regulator operates in two cycles.

In the first cycle of operation, shown in

Figure 1

(a), the

transistor is closed and the diode is reverse biased. Energy

is collected in the inductor and the load current is supplied by

C

OUT

.

The second cycle is shown in

Figure 1

(b). During this cycle,

the transistor is open and the diode is forward biased. The

energy stored in the inductor is transferred to the load and

output capacitor.

The ratio of these two cycles determines the output voltage.

The output voltage is defined as:

where D is the duty cycle of the switch.

Inductor

The inductor is one of the two energy storage elements in a

boost converter.

Figure 2

shows how the inductor current

varies during a switching cycle. The current through an

inductor is quantified as:

20012602

FIGURE 1. Simplified Boost Converter Diagram

(a) First Cycle of Operation (b) Second Cycle Of Operation

20012605

FIGURE 2. (a) Inductor Current (b) Diode Current

LM2698

www.national.com 8

Page 9

Operation (Continued)

If V

L(t)

is constant, diL/ dt must be constant, thus the current

in the inductor changes at a constant rate. This is the case in

DC/DC converters since the voltages atthe input andoutput

can be approximated as a constant. The current through the

inductor of the LM2698 boost converter is shown in

Figure

2

(a). The important quantities in determininga proper induc-

tance value are I

L(AVG)

(the average inductor current) and ∆i

L

(the inductor current ripple). If ∆iLis larger than I

L(AVG)

, the

inductor current will drop to zero for a portion of the cycle and

the converter will operate in discontinuous conduction mode.

If ∆i

L

is smaller than I

L(AVG)

, the inductor current will stay

above zero and the converter will operate in continuous

conduction mode (CCM). All the analysis in this datasheet

assumes operation in continuous conduction mode. To operate in CCM:

I

L(AVG)

>

∆i

L

Choose the minimum I

OUT

to determine the minimum L for

CCM operation. A common choice is to set ∆i

L

to 30% of

I

L(AVG)

.

The inductance value will also affect the stability of the

converter. Because the LM2698 utilizes current mode control, the inductor value must be carefully chosen. See the

COMPENSATIONsection for recommended inductance values.

Choosing an appropriate core size for the inductor involves

calculating the average and peak currents expected through

the inductor. In a boost converter,

and

I

L(Peak)=IL(AVG)

+ ∆iL,

where

A core size with ratings higher than these values should be

chosen. If the core is not properly rated, saturation will

dramatically reduce overall efficiency.

Current Limit

The current limit in the LM2698 is referenced to the peak

switch current. The peak currents in the switch of a boost

converter will always be higher than the average current

supplied to the load. To determine the maximum average

output current that the LM2698 can supply, use:

I

OUT(MAX)

=(ICL− ∆iL)*(1−D) = (ICL− ∆iL)*VIN/V

OUT

Where ICLis the switch current limit (see Electrical Charateristics table and Typical Performance Curves). Hence, as

V

IN

increases, the maximum current that can be supplied to

the load increases, as shown in

Figure 3

.

Diode

The diode in a boost converter such as the LM2698 acts as

a switch to the output. During the first cycle, when the

transistor is closed, the diode is reverse biased and current

is blocked; the load current is supplied by the output capacitor. In the second cycle, the transistor is open and the diode

is forward biased; the load current is supplied by the inductor.

Observation of the boost converter circuit shows that the

average current through the diode is the average load current, and the peak current through the diode is the peak

current through the inductor. The diode should be rated to

handle more than its peak current. To improve efficiency, a

low forward drop Schottky diode is recommended.

Input Capacitor

Due to the presence of an inductor at the input of a boost

converter, the input current waveform is continuous and

triangular.The inductor ensures that the input capacitor sees

fairly low ripple currents. However, as the inductor gets

smaller, the input ripple increases. The rms current in the

input capacitor is given by:

The input capacitor should be capable of handling the rms

current.Although the input capacitor is not so critical in boost

applications, a 10 µF or higher value, good quality capacitor

prevents any impedance interactions with the input supply.

A 0.1µF or 1µF ceramic bypass capacitor is also recommended on the V

IN

pin (pin 6) of the IC. This capacitor must

20012673

FIGURE 3. Maximum Output Current vs Input Voltage

LM2698

www.national.com9

Page 10

Operation (Continued)

be connected very close to pin 6 to effectively filter high

frequency noise. When operating at 1.25 MHz switching

frequency, a minimum bypass capacitance of 0.22 µF is

recommended.

Output Capacitor

The output capacitor in a boost converter provides all the

output current when the switch is closed and the inductor is

charging. As a result, it sees very large ripple currents. The

output capacitor should be capable of handling the maximum RMS current. The RMS current in the output capacitor

is:

where,

and

D=(V

OUT-VIN

)/V

OUT

The ESR and ESL of the output capacitor directly control the

output ripple. Use capacitors with low ESR and ESL at the

output for high efficiency and low ripple voltage. Surface

mount tantalums, surface mount polymer electrolytic, and

polymer tantalum, Sanyo OS-CON, or multi-layer ceramic

capacitors are recommended at the output.

Compensation

This section presents a step-by-step procedure to design the

compensation network at pin 1 (V

c

) of the LM2698. These

design methods will produce a conservative and stable control loop.

There is a minimum inductance requirement in any current

mode converter. This is a function of V

OUT

, duty cycle, and

switching frequency, among other things. The graphs below

plot the recommended inductance range vs. duty cycle for

V

OUT

= 12V. The two lines represent the upper and lower

bounds of the recommended inductance range. The simplified compensation procedure that follows assumes that the

inductance never drops below the Q = 5 line.

Figure 4

plots

the equation:

(1)

where,

R

DSON

= 0.15,

Se = 0.072

*

fS,

and Q = 0.5 and 5

Use Q = 5 to calculate the minimum inductance recom-

mended for a stable design. Choosing an inductor between

the Q = 0.5 and Q = 5 values provides a good tradeoff

between size and stability. Note that as V

IN

drops less than

5V, R

DS(ON)

increases, as shown in the Typical Performance

Characteristics section (R

DS(ON)

vs.VINcurve). The worst

case R

DS(ON)

should be used when choosing the inductance. To view plots for different Vout, multiply the Y axis by

a factor of V

OUT

/12, or plot

Equation (1)

for the respective

output voltage.

20012654

20012653

FIGURE 4. Minimum Inductance Requirements for (a) fS= 600kHz and (b) fS= 1.25MHz

LM2698

www.national.com 10

Page 11

Operation (Continued)

The goal of the compensation network is to provide the best

static and dynamic performance while insuring stability over

line and load variations. The relationship of stability and

performance can be best analyzed by plotting the magnitude

and phase of the open loop frequency response in the form

of a bode plot. A typical bode plot of the LM2698 open loop

frequency response is shown in

Figure 5

.

Poles are marked with an ’X’, and zeros are marked with a

’O’. The bolded ’O’ labeled ’f

RHP

’ is a right-half plane zero.

Right half plane zeros act like normal zeros to the magnitude

(+20dB/decade slope influence) and like poles to the phase

(−90˚ shift). Three curves are shown. The powerstage curve

is the frequency response of the powerstage, which includes

the switch, diode, inductor, output capacitor, and load. The

compensator curve is the frequency response of the compensator,which is the error amp combined with thecompensation network. T is the product of the powerstage and the

compensator and is the complete open loop frequency response. The power stage response is fixed by line and load

constraints, while the compensator is set by the external

compensation network at pin 1. The compensator can be

designed in a few simple steps as follows.

Quick Compensator Design

Calculate:

where,

where R

OUT

= 875kΩ

Choose C

C1

= 4.7nF

Choose

Where,

20012657

FIGURE 5. Bode plot of the LM2698 Frequency Response using the Typical Application Circuit

LM2698

www.national.com11

Page 12

Operation (Continued)

If the output capacitor is of high ESR (0.1Ω or higher), it may

be necessary to use C

C2

. A rule of thumb is that if

1/(2πC

OUT

ESR) (Hz) is lower than fS/2 (Hz), CC2should be

used. Choose C

C2

such that:

(R

C+ROUT

)(C

OUT

ESR) / (RCR

OUT

) (F)

where R

OUT

= output impedance of the error amp (875 kΩ).

Improving Transient Response Time

The above compensator design provides a loop gain with

high phase margin for a large stability margin. The transient

response time of this loop is limited by the lower

mid-frequency gain necessary to achieve a high phase margin. If it is desired to increase the transient response time,

C

C1

may be decreased. Decreasing CC1by 2x, 4x, and 6x

will yield increasingly shorter transient response times, how-

ever the loop phase margin will become progressively lower

as C

C1

is decreased. When optimizing the loop gain for

transient response time, it is recommended to keep the

phase margin above 40˚.

LM2698

www.national.com 12

Page 13

Operation (Continued)

Additional Comments on the Open Loop Frequency Response

The procedure used here to pick the compensation network

will provide a good starting point. In most cases, these

values will be sufficient for a stable design. It is always

recommended to check the design in a real test setup. This

is easy to do with the aid of a dynamic load. Set the high and

low load values to your system requirements and switch

between the two at about 1kHz. View the output voltage with

an oscilloscope using AC coupling, and zoom in enough to

see the waveform react to the load change. Use the follow-

ing table to determine if your design is stable. Remember to

use worst case conditions (V

IN(MIN),ROUT(MIN),ROUT(MAX)

).

Response Conclusion What to

Change

Underdamped,

weak attenuation

Nearing instability Make C

C1

larger

Underdamped,

strong attenuation

Stable Nothing

Critically damped Stable Nothing

Overdamped Stable Nothing

Application Information

1.25MHz Boost Converter

Figure 6

shows the LM2698 boosting 3.3V to 10V at 300mA.

As discussed in the COMPENSATION section, the R

DS(ON)

of the internal FET in the LM2698 raises as the inputvoltage

drops below 5V (see Typical Performance Characteristics).

The minimum input voltage for this application is 2.5V, at

which point the R

DS(ON)

is approximately 200mΩ. Substitut-

ing these values in for

Equation (1)

, it is found that either a

10 µH (1.25MHz operation) or a 22 µH (600kHz operation) is

necessary for a stable design. The circuit is operated at

1.25MHz to allow for a smaller inductance. From the Compensator Design equations, R

C

is calculated to be 18.6kΩ,

and a 20kΩ resistor is used.

20012668

FIGURE 6. 3.3V to 10V Boost Converter

LM2698

www.national.com13

Page 14

Application Information (Continued)

3.3V SEPIC

The LM2698 can be used to implement a SEPIC technology.

The advantages of the SEPIC topology are that it can step

up or step down an input voltage, and it has low input current

ripple.

The conversion ratio for the SEPIC is :

where

D’ = 1−D

Solving for D yeilds:

To avoid subharmonic oscillations, it is recommended that

inductors L1 and L2 be the same inductance. Currents conducted by the inductors are:

I

1=IOUT(VOUT/VIN

)

∆i

1=VIN

D/(2*L1*fs)

I

2=IOUT

∆i1=VIND/(2*L2*fs)

The switch sees a maximum current of I

1+I2

+∆i1+∆i2.If

L1 = L2 = L, the maximum switch current is given by:

I

OUT

(1+V

OUT/VIN

)+VIND/(L*fs)

The maximum load current is limited by this relationship to

the switch current.

The polarity of C

SEPIC

will change between each cycle, so a

ceramic capacitor should be used here. A high quality, low

ESR capacitor will directly improve efficiency because all the

load current passes through C

SEPIC

.

C

IN

should be chosen using the same relationship as in the

boost converter (see the C

IN

section). CINmust be able to

provide the necessary RMS current.

20012631

FIGURE 7. 3.3V SEPIC Converter

LM2698

www.national.com 14

Page 15

Application Information (Continued)

Level-Shifted SEPIC

The circuit shown in

Figure 8

is similar to the SEPIC shown

in

Figure 7

, except that it is level shifted to provide a negative

output voltage. This is achieved by connecting the ground of

the LM2698 to the output. The circuit analysis for the

level-shifted SEPIC is the same as the SEPIC. The voltage

at the input of the LM2698 will need to be clamped if the

absolute value of the output voltage plus the input voltage

exceeds 12V, the absolute maximum rating for the V

IN

pin.

The simplest way to do this is with a zener diode, as shown

in

Figure 8

. Likewise, if the FSLCT pin is pulled high to

operate at 1.25 MHz, its voltage must not exceed 12V. To

prevent any high frequency noise from entering the

LM2698’s internal circuitry, a high frequency bypass capacitor must be placed as close to pin 6 as possible. A good

choice for this capacitor is a 0.1µF ceramic capacitor.

Power Dissipation

The output power of the LM2698 is limited by its maximum

power dissipation. The maximum power dissipation is determined by the formula

P

D

=(T

jmax-TA

)/θ

JA

where T

jmax

is the maximum specified junction temperature

(125˚C), T

A

is the ambient temperature, and θJAis the ther-

mal resistance of the package. θ

JA

is dependant on the

layout of the board as shown below.

20012611

20012612

20012643

FIGURE 8. Level-Shifted SEPIC Converter

LM2698

www.national.com15

Page 16

Application Information (Continued)

20012613

20012614

20012615

LM2698

www.national.com 16

Page 17

Physical Dimensions inches (millimeters)

unless otherwise noted

8-Lead Plastic MSOP

NS Package Number MUA08A

LIFE SUPPORT POLICY

NATIONAL’S PRODUCTS ARE NOT AUTHORIZED FOR USE AS CRITICAL COMPONENTS IN LIFE SUPPORT

DEVICES OR SYSTEMS WITHOUT THE EXPRESS WRITTEN APPROVAL OF THE PRESIDENT AND GENERAL

COUNSEL OF NATIONAL SEMICONDUCTOR CORPORATION. As used herein:

1. Life support devices or systems are devices or

systems which, (a) are intended for surgical implant

into the body, or (b) support or sustain life, and

whose failure to perform when properly used in

accordance with instructions for use provided in the

labeling, can be reasonably expected to result in a

significant injury to the user.

2. A critical component is any component of a life

support device or system whose failure to perform

can be reasonably expected to cause the failure of

the life support device or system, or to affect its

safety or effectiveness.

National Semiconductor

Corporation

Americas

Email: support@nsc.com

National Semiconductor

Europe

Fax: +49 (0) 180-530 85 86

Email: europe.support@nsc.com

Deutsch Tel: +49 (0) 69 9508 6208

English Tel: +44 (0) 870 24 0 2171

Français Tel: +33 (0) 1 41 91 8790

National Semiconductor

Asia Pacific Customer

Response Group

Tel: 65-2544466

Fax: 65-2504466

Email: ap.support@nsc.com

National Semiconductor

Japan Ltd.

Tel: 81-3-5639-7560

Fax: 81-3-5639-7507

www.national.com

LM2698 SIMPLE SWITCHER

®

1.35A Boost Regulator

National does not assume any responsibility for use of any circuitry described, no circuit patent licenses are implied and National reserves the right at any time without notice to change said circuitry and specifications.

Loading...

Loading...