Page 1

LM2679

SIMPLE SWITCHER

®

5A Step-Down Voltage Regulator

with Adjustable Current Limit

LM2679 SIMPLE SWITCHER 5A Step-Down Voltage Regulator with Adjustable Current Limit

April 2005

General Description

The LM2679 series of regulators are monolithic integrated

circuits which provide all of the active functions for a stepdown (buck) switching regulator capable of driving up to 5A

loads with excellent line and load regulation characteristics.

High efficiency (

ON-resistance DMOS power switch. The series consists of

fixed output voltages of 3.3V, 5V and 12V and an adjustable

output version.

The SIMPLE SWITCHER concept provides for a complete

design using a minimum number of external components. A

high fixed frequency oscillator (260KHz) allows the use of

physically smaller sized components. A family of standard

inductors for use with the LM2679 are available from several

manufacturers to greatly simplify the design process.

Other features include the ability to reduce the input surge

current at power-ON by adding a softstart timing capacitor to

gradually turn on the regulator. The LM2679 series also has

built in thermal shutdown and resistor programmable current

limit of the power MOSFET switch to protect the device and

load circuitry under fault conditions. The output voltage is

guaranteed to a

controlled to within a

>

90%) is obtained through the use of a low

±

2% tolerance. The clock frequency is

±

11% tolerance.

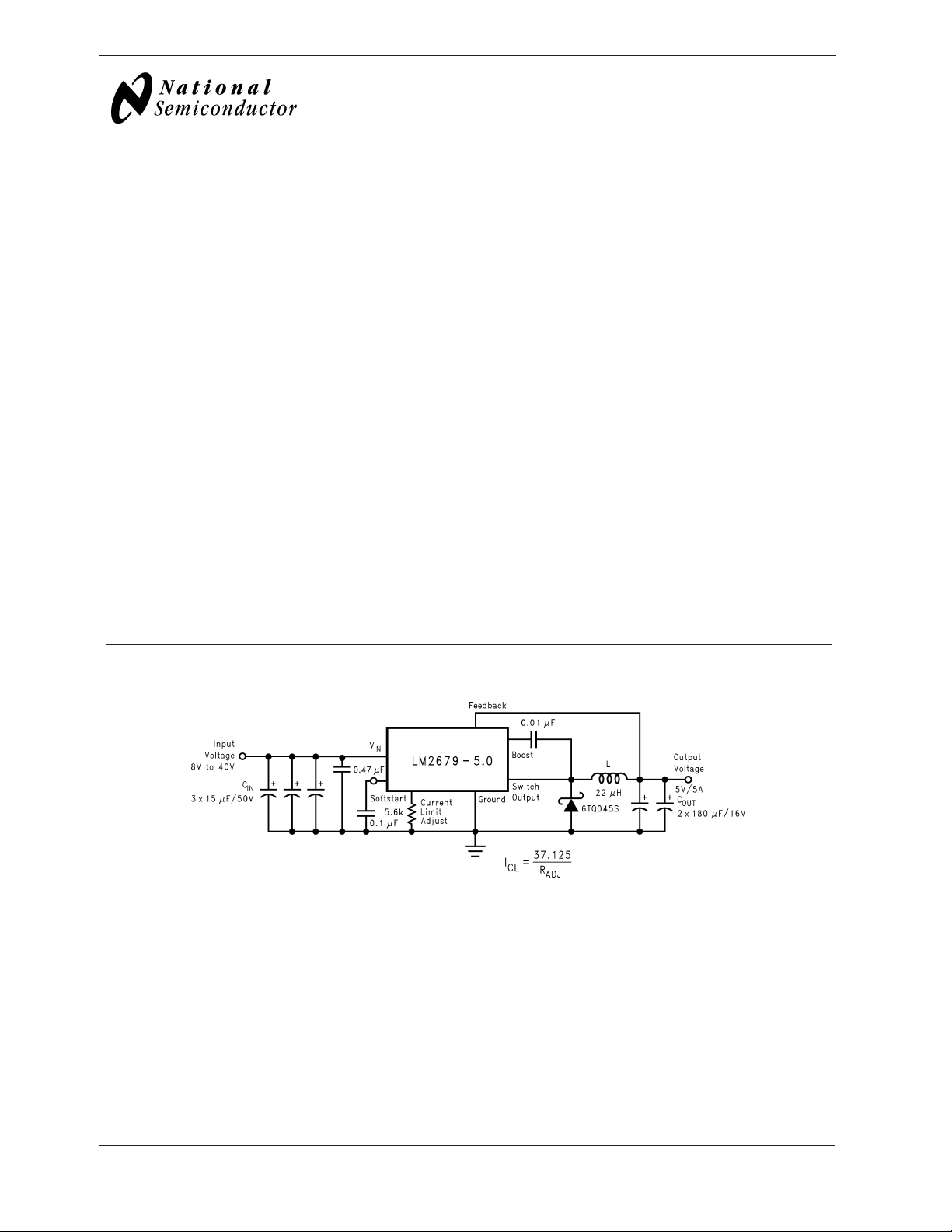

Typical Application

Features

n Efficiency up to 92%

n Simple and easy to design with (using off-the-shelf

external components)

n Resistor programmable peak current limit over a range

of 3A to 7A.

n 120 mΩ DMOS output switch

n 3.3V, 5V and 12V fixed output and adjustable (1.2V to

37V ) versions

±

n

2%maximum output tolerance over full line and load

conditions

n Wide input voltage range: 8V to 40V

n 260 KHz fixed frequency internal oscillator

n Softstart capability

n −40 to +125˚C operating junction temperature range

Applications

n Simple to design, high efficiency (>90%) step-down

switching regulators

n Efficient system pre-regulator for linear voltage

regulators

n Battery chargers

10084703

SIMPLE SWITCHER®is a registered trademark of National Semiconductor Corporation.

© 2005 National Semiconductor Corporation DS100847 www.national.com

Page 2

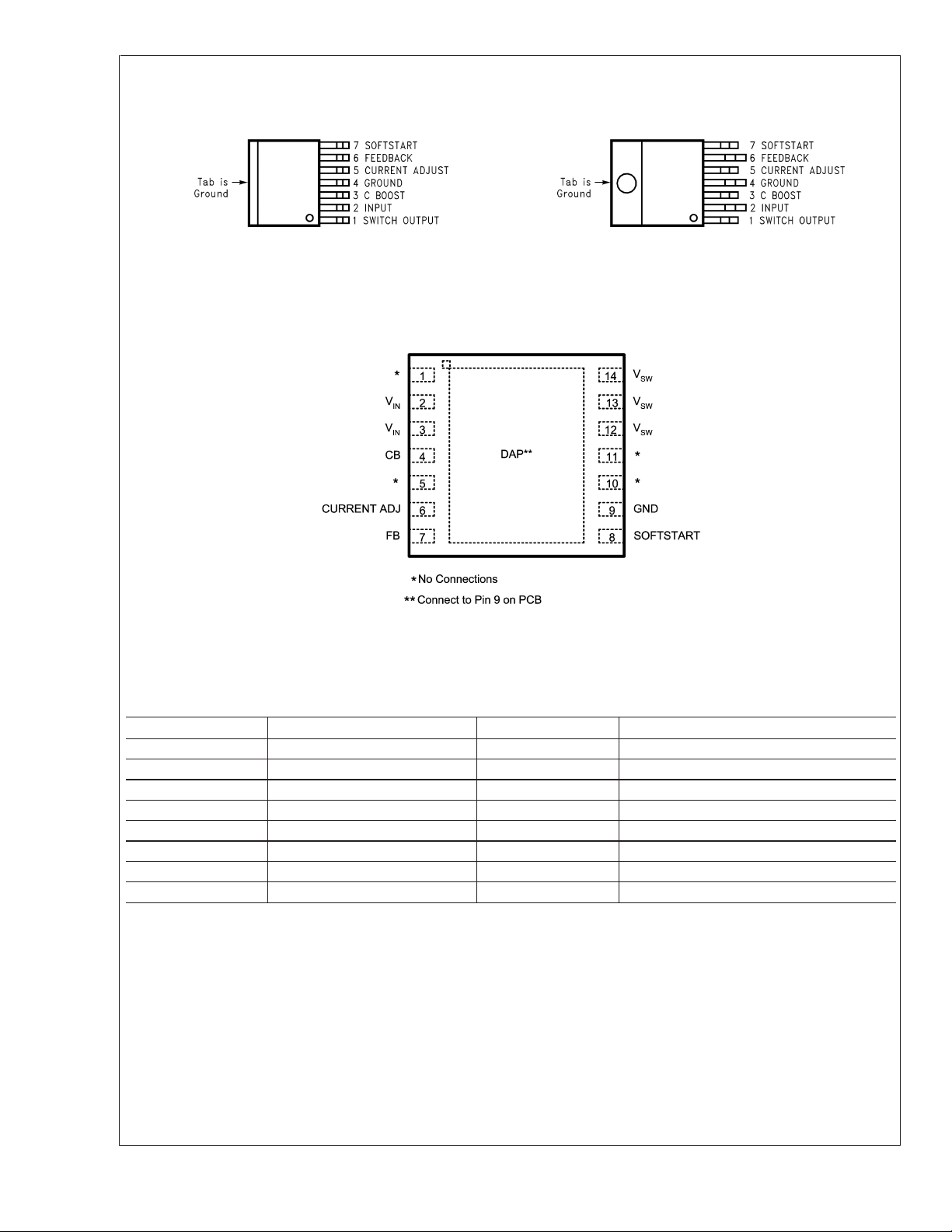

Connection Diagrams and Ordering Information

LM2679

TO-263 Package

Top View

TO-220 Package

Top View

Order Number

LM2679S-3.3, LM2679S-5.0,

LM2679S-12 or LM2679S-ADJ

See NSC Package Number TS7B

See NS package Number SRC14A

10084701

Order Number

10084702

LM2679T-3.3, LM2679T-5.0,

LM2679T-12 or LM2679T-ADJ

See NSC Package Number TA07B

Top View

10084735

LLP-14

Ordering Information for LLP Package

Output Voltage Order Information Package Marking Supplied As

12 LM2679SD-12 S0003FB 250 Units on Tape and Reel

12 LM2679SDX-12 S0003FB 2500 Units on Tape and Reel

3.3 LM2679SD-3.3 S0003HB 250 Units on Tape and Reel

3.3 LM2679SDX-3.3 S0003HB 2500 Units on Tape and Reel

5.0 LM2679SD-5.0 S0003JB 250 Units on Tape and Reel

5.0 LM2679SDX-5.0 S0003JB 2500 Units on Tape and Reel

ADJ LM2679SD-ADJ S0003KB 250 Units on Tape and Reel

ADJ LM2679SDX-ADJ S0003KB 2500 Units on Tape and Reel

www.national.com 2

Page 3

LM2679

Absolute Maximum Ratings (Note 1)

If Military/Aerospace specified devices are required,

please contact the National Semiconductor Sales Office/

Distributors for availability and specifications.

Input Supply Voltage 45V

Storage Temperature Range −65˚C to 150˚C

Soldering Temperature

Wave 4 sec, 260˚C

Infrared 10 sec, 240˚C

Vapor Phase 75 sec, 219˚C

Softstart Pin Voltage −0.1V to 6V

Switch Voltage to Ground −1V to V

IN

Operating Ratings

Boost Pin Voltage VSW+8V

Feedback Pin Voltage −0.3V to 14V

Power Dissipation Internally Limited

Supply Voltage 8V to 40V

Junction Temperature Range (T

) −40˚C to 125˚C

J

ESD (Note 2) 2 kV

Electrical Characteristics Limits appearing in bold type face apply over the entire junction temperature

range of operation, −40˚C to 125˚C. Specifications appearing in normal type apply for T

A=TJ

= 25˚C. R

ADJ

= 5.6KΩ

LM2679-3.3

Symbol Parameter Conditions Typical Min Max Units

(Note 3) (Note 4) (Note 4)

V

OUT

η Efficiency V

Output Voltage VIN= 8V to 40V, 100mA ≤ I

= 12V, I

IN

=5A 82 %

LOAD

≤ 5A 3.3 3.234/3.201 3.366/3.399 V

OUT

LM2679-5.0

Symbol Parameter Conditions Typical Min Max Units

(Note 3) (Note 4) (Note 4)

V

OUT

η Efficiency V

Output Voltage VIN= 8V to 40V, 100mA ≤ I

= 12V, I

IN

=5A 84 %

LOAD

≤ 5A 5.0 4.900/4.850 5.100/5.150 V

OUT

LM2679-12

Symbol Parameter Conditions Typical Min Max Units

(Note 3) (Note 4) (Note 4)

V

OUT

η Efficiency V

Output Voltage VIN= 15V to 40V, 100mA ≤ I

= 24V, I

IN

=5A 92 %

LOAD

≤ 5A 12 11.76/11.64 12.24/12.36 V

OUT

LM2679-ADJ

Symbol Parameter Conditions Typ Min Max Units

(Note 3) (Note 4) (Note 4)

V

FB

η Efficiency V

Feedback

Voltage

VIN= 8V to 40V, 100mA ≤ I

Programmed for 5V

V

OUT

= 12V, I

IN

=5A 84 %

LOAD

OUT

≤ 5A

1.21 1.186/1.174 1.234/1.246 V

www.national.com3

Page 4

All Output Voltage Versions Electrical Characteristics

LM2679

Limits appearing in bold type face apply over the entire junction temperature range of operation, −40˚C to 125˚C. Specifications appearing in normal type apply for T

versions and V

=24V for the 12V version.

IN

Symbol Parameter Conditions Typ Min Max Units

DEVICE PARAMETERS

I

Q

Quiescent

V

FEEDBACK

= 8V 4.2 6 mA

Current

For 3.3V, 5.0V, and ADJ Versions

V

FEEDBACK

= 15V

For 12V Versions

V

ADJ

Current Limit

Adjust Voltage

I

CL

I

L

R

DS(ON)

Current Limit R

Output Leakage

Current

Switch

= 5.6KΩ, (Note 5) 6.3 5.5/5.3 7.6/8.1 A

ADJ

VIN= 40V, Softstart Pin = 0V

V

V

I

SWITCH

=0V

SWITCH

= −1V

SWITCH

= 5A 0.12 0.14/0.225 Ω

On-Resistance

f

O

Oscillator

Measured at Switch Pin 260 225 280 kHz

Frequency

D Duty Cycle Maximum Duty Cycle 91 %

Minimum Duty Cycle 0 %

I

V

BIAS

SFST

Feedback Bias

Current

Softstart

V

FEEDBACK

= 1.3V

ADJ Version Only

Threshold

Voltage

I

SFST

Softstart Pin

Softstart Pin = 0V

Current

θ

JA

θ

JA

Thermal

Resistance

T Package, Junction to Ambient 65

(Note 6)

T Package, Junction to Ambient 45

(Note 7)

θ

JC

θ

JA

T Package, Junction to Case 2

S Package, Junction to Ambient 56 ˚C/W

(Note 8)

θ

JA

S Package, Junction to Ambient 35

(Note 9)

θ

JA

S Package, Junction to Ambient 26

(Note 10)

θ

JC

θ

JA

S Package, Junction to Case 2 ++

SD Package, Junction to Ambient 55

(Note 11)

θ

JA

SD Package, Junction to Ambient 29

(Note 12)

= 25˚C. Unless otherwise specified VIN=12V for the 3.3V, 5V and Adjustable

A=TJ

1.21 1.181/1.169 1.229/1.246 V

1.0

6

85 nA

0.63 0.53 0.74 V

3.7 6.9 µA

1.5

15

mA

mA

˚C/W

www.national.com 4

Page 5

All Output Voltage Versions

Electrical Characteristics

Note 1: Absolute Maximum Ratings are limits beyond which damage to the device may occur. Operating Ratings indicate conditions under which of the device is

guaranteed. Operating Ratings do not imply guaranteed performance limits. For guaranteed performance limits and associated test condition, see the electrical

Characteristics tables.

Note 2: ESD was applied using the human-body model, a 100pF capacitor discharged through a 1.5 kΩ resistor into each pin.

Note 3: Typical values are determined with T

Note 4: All limits are guaranteed at room temperature (standard type face) and at temperature extremes (bold type face). All room temperature limits are 100%

tested during production with T

methods. All limits are used to calculate Average Outgoing Quality Level (AOQL).

Note 5: The peak switch current limit is determined by the following relationship: I

Note 6: Junction to ambient thermal resistance (no external heat sink) for the 7 lead TO-220 package mounted vertically, with

board with minimum copper area.

Note 7: Junction to ambient thermal resistance (no external heat sink) for the 7 lead TO-220 package mounted vertically, with

containing approximately 4 square inches of (1 oz.) copper area surrounding the leads.

Note 8: Junction to ambient thermal resistance for the 7 lead TO-263 mounted horizontally against a PC board area of 0.136 square inches (the same size as the

TO-263 package) of 1 oz. (0.0014 in. thick) copper.

Note 9: Junction to ambient thermal resistance for the 7 lead TO-263 mounted horizontally against a PC board area of 0.4896 square inches (3.6 times the area

of the TO-263 package) of 1 oz. (0.0014 in. thick) copper.

Note 10: Junction to ambient thermal resistance for the 7 lead TO-263 mounted horizontally against a PC board copper area of 1.0064 square inches (7.4 times

the area of the TO-263 package) of 1 oz. (0.0014 in. thick) copper. Additional copper area will reduce thermal resistance further. See the thermal model in Switchers

Made Simple

Note 11: Junction to ambient thermal resistance for the 14-lead LLP mounted on a PC board copper area equal to the die attach paddle.

Note 12: Junction to ambient thermal resistance for the 14-lead LLP mounted on a PC board copper area using 12 vias to a second layer of copper equal to die

attach paddle. Additional copper area will reduce thermal resistance further. For layout recommendations, refer to Application Note AN-1187.

®

software.

A=TJ

A=TJ

= 25˚C. All limits at temperature extremes are guaranteed via correlation using standard standard Quality Control (SQC)

(Continued)

= 25˚C and represent the most likely norm.

=37,125/ R

CL

ADJ

.

1

⁄2inch leads in a socket, or on a PC

1

⁄2inch leads soldered to a PC board

LM2679

www.national.com5

Page 6

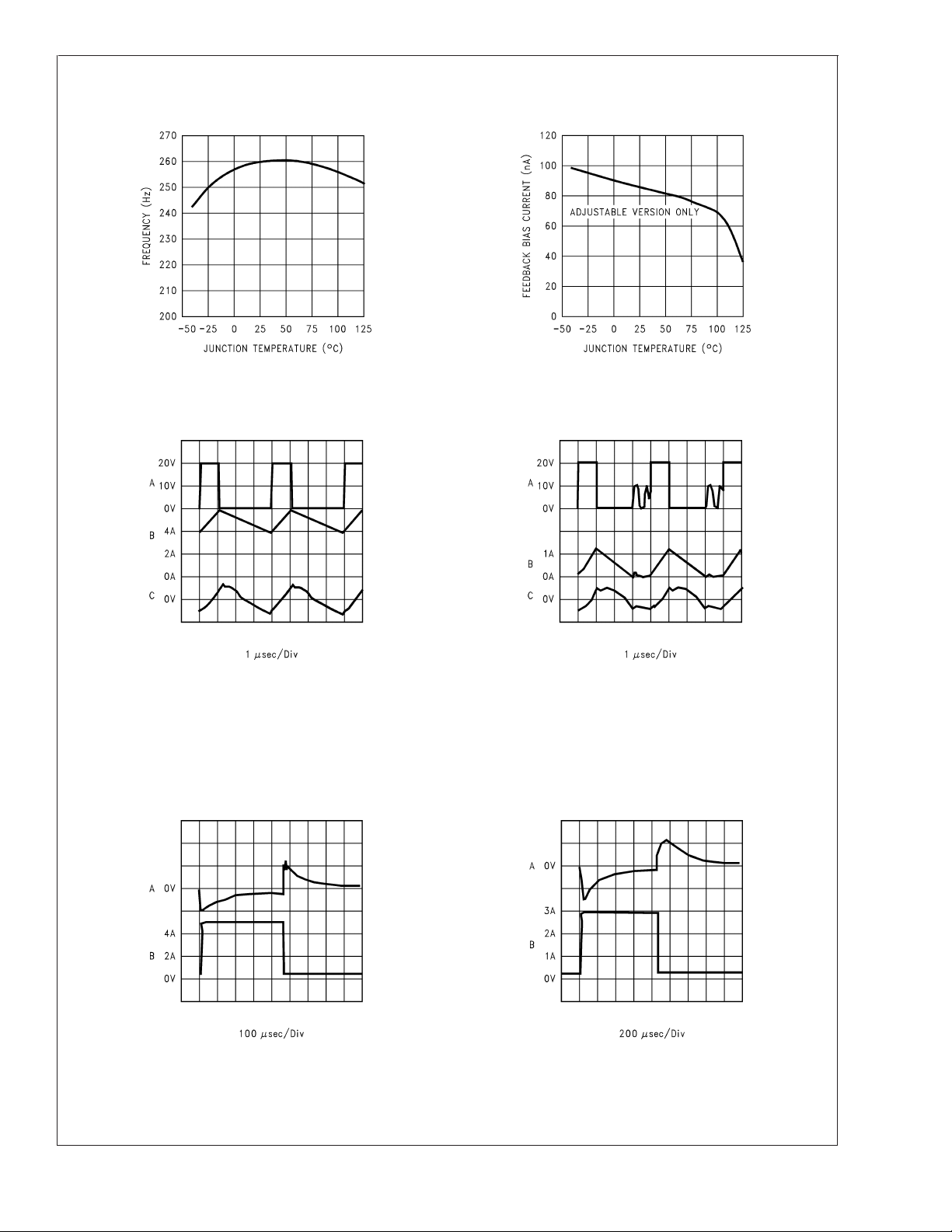

Typical Performance Characteristics

LM2679

Normalized

Output Voltage Line Regulation

10084704

Efficiency vs Input Voltage Efficiency vs I

10084706 10084707

LOAD

Switch Current Limit Operating Quiescent Current

10084705

10084708 10084709

www.national.com 6

Page 7

Typical Performance Characteristics (Continued)

Switching Frequency Feedback Pin Bias Current

LM2679

Continuous Mode Switching Waveforms

= 20V, V

V

L=10µH,C

A: VSWPin Voltage, 10 V/div.

B: Inductor Current, 2 A/div

C: Output Ripple Voltage, 20 mV/div AC-Coupled

IN

OUT

= 5V, I

OUT

= 400 µF, C

=5A

LOAD

ESR=13mΩ

OUT

10084715

Horizontal Time Base: 1 µs/div

Load Transient Response for Continuous Mode

L=10µH,C

= 20V, V

V

IN

= 400 µF, C

OUT

OUT

OUT

=5V

ESR=13mΩ

10084712

10084713

Discontinuous Mode Switching Waveforms

V

= 20V, V

IN

L=10µH,C

A: VSWPin Voltage, 10 V/div.

B: Inductor Current, 1 A/div

C: Output Ripple Voltage, 20 mV/div AC-Coupled

OUT

= 400 µF, C

OUT

= 5V, I

= 500 mA

LOAD

ESR=13mΩ

OUT

10084716

Horizontal Time Base: 1 µs//iv

Load Transient Response for Discontinuous Mode

V

L=10µH,C

= 20V, V

IN

= 400 µF, C

OUT

OUT

= 5V,

ESR=13mΩ

OUT

A: Output Voltage, 100 mV//div, AC-Coupled.

B: Load Current: 500 mA to 5A Load Pulse

Horizontal Time Base: 100 µs/div

10084717

A: Output Voltage, 100 mV/div, AC-Coupled.

10084718

B: Load Current: 200 mA to 3A Load Pulse

Horizontal Time Base: 200 µs/div

www.national.com7

Page 8

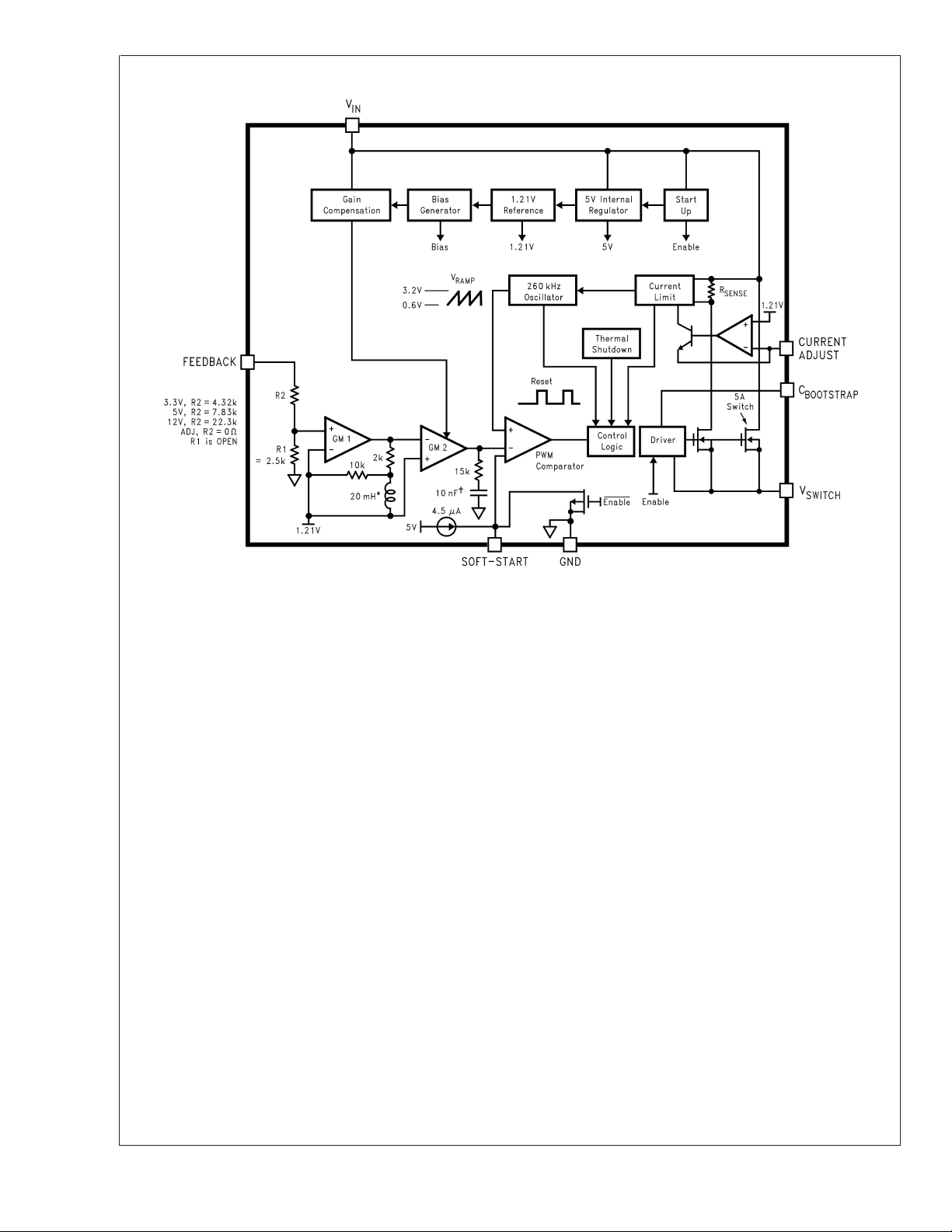

Block Diagram

LM2679

* Active Inductor Patent Number 5,514,947

†

Active Capacitor Patent Number 5,382,918

10084714

www.national.com 8

Page 9

Application Hints

The LM2679 provides all of the active functions required for

a step-down (buck) switching regulator. The internal power

switch is a DMOS power MOSFET to provide power supply

designs with high current capability, up to 5A, and highly

efficient operation.

The LM2679 is part of the SIMPLE SWITCHER family of

power converters. A complete design uses a minimum number of external components, which have been predetermined from a variety of manufacturers. Using either this

data sheet or a design software program called LM267X

Made Simple (version 2.0) a complete switching power

supply can be designed quickly. The software is provided

free of charge and can be downloaded from National Semiconductor’s Internet site located at http://www.national.com.

SWITCH OUTPUT

This is the output of a power MOSFET switch connected

directly to the input voltage. The switch provides energy to

an inductor, an output capacitor and the load circuitry under

control of an internal pulse-width-modulator (PWM). The

PWM controller is internally clocked by a fixed 260KHz

oscillator. In a standard step-down application the duty cycle

(Time ON/Time OFF) of the power switch is proportional to

the ratio of the power supply output voltage to the input

voltage. The voltage on pin 1 switches between Vin (switch

ON) and below ground by the voltage drop of the external

Schottky diode (switch OFF).

INPUT

The input voltage for the power supply is connected to pin 2.

In addition to providing energy to the load the input voltage

also provides bias for the internal circuitry of the LM2679.

For guaranteed performance the input voltage must be in the

range of 8V to 40V. For best performance of the power

supply the input pin should always be bypassed with an input

capacitor located close to pin 2.

C BOOST

A capacitor must be connected from pin 3 to the switch

output, pin 1. This capacitor boosts the gate drive to the

internal MOSFET above Vin to fully turn it ON. This minimizes conduction losses in the power switch to maintain high

efficiency. The recommended value for C Boost is 0.01µF.

CURRENT ADJUST

A key feature of the LM2679 is the ability to tailor the peak

switch current limit to a level required by a particular application. This alleviates the need to use external components

that must be physically sized to accommodate current levels

(under shorted output conditions for example) that may be

much higher than the normal circuit operating current requirements.

A resistor connected from pin 5 to ground establishes a

current (I

(pin 5)

=1.2V/R

) that sets the peak current

ADJ

through the power switch. The maximum switch current is

fixed at a level of 37,125 / R

ADJ

.

FEEDBACK

This is the input to a two-stage high gain amplifier, which

drives the PWM controller. It is necessary to connect pin 6 to

the actual output of the power supply to set the dc output

voltage. For the fixed output devices (3.3V, 5V and 12V

outputs), a direct wire connection to the output is all that is

required as internal gain setting resistors are provided inside

the LM2679. For the adjustable output version two external

resistors are required to set the dc output voltage. For stable

operation of the power supply it is important to prevent

coupling of any inductor flux to the feedback input.

SOFTSTART

A capacitor connected from pin 7 to ground allows for a slow

turn-on of the switching regulator. The capacitor sets a time

delay to gradually increase the duty cycle of the internal

power switch. This can significantly reduce the amount of

surge current required from the input supply during an abrupt

application of the input voltage. If softstart is not required this

pin should be left open circuited.

DAP (LLP PACKAGE)

The Die Attach Pad (DAP) can and should be connected to

PCB Ground plane/island. For CAD and assembly guidelines refer to Application Note AN-1187 at http://

power.national.com.

LM2679

GROUND

This is the ground reference connection for all components

in the power supply. In fast-switching, high-current applications such as those implemented with the LM2679, it is

recommended that a broad ground plane be used to minimize signal coupling throughout the circuit

www.national.com9

Page 10

Application Hints (Continued)

DESIGN CONSIDERATIONS

LM2679

10084723

FIGURE 1. Basic circuit for fixed output voltage applications.

FIGURE 2. Basic circuit for adjustable output voltage applications

Power supply design using the LM2679 is greatly simplified

by using recommended external components. A wide range

of inductors, capacitors and Schottky diodes from several

manufacturers have been evaluated for use in designs that

cover the full range of capabilities (input voltage, output

voltage and load current) of the LM2679. A simple design

procedure using nomographs and component tables provided in this data sheet leads to a working design with very

little effort. Alternatively, the design software, LM267X Made

Simple (version 6.0), can also be used to provide instant

component selection, circuit performance calculations for

evaluation, a bill of materials component list and a circuit

schematic.

The individual components from the various manufacturers

called out for use are still just a small sample of the vast

array of components available in the industry. While these

components are recommended, they are not exclusively the

only components for use in a design. After a close compari-

www.national.com 10

10084724

son of component specifications, equivalent devices from

other manufacturers could be substituted for use in an application.

Important considerations for each external component and

an explanation of how the nomographs and selection tables

were developed follows.

INDUCTOR

The inductor is the key component in a switching regulator.

For efficiency the inductor stores energy during the switch

ON time and then transfers energy to the load while the

switch is OFF.

Nomographs are used to select the inductance value required for a given set of operating conditions. The nomographs assume that the circuit is operating in continuous

mode (the current flowing through the inductor never falls to

zero). The magnitude of inductance is selected to maintain a

Page 11

Application Hints (Continued)

maximum ripple current of 30% of the maximum load current. If the ripple current exceeds this 30% limit the next

larger value is selected.

The inductors offered have been specifically manufactured

to provide proper operation under all operating conditions of

input and output voltage and load current. Several part types

are offered for a given amount of inductance. Both surface

mount and through-hole devices are available. The inductors

from each of the three manufacturers have unique characteristics.

Renco: ferrite stick core inductors; benefits are typically

lowest cost and can withstand ripple and transient peak

currents above the rated value. These inductors have an

external magnetic field, which may generate EMI.

Pulse Engineering: powdered iron toroid core inductors;

these also can withstand higher than rated currents and,

being toroid inductors, will have low EMI.

Coilcraft: ferrite drum core inductors; these are the smallest

physical size inductors and are available only as surface

mount components. These inductors also generate EMI but

less than stick inductors.

OUTPUT CAPACITOR

The output capacitor acts to smooth the dc output voltage

and also provides energy storage. Selection of an output

capacitor, with an associated equivalent series resistance

(ESR), impacts both the amount of output ripple voltage and

stability of the control loop.

The output ripple voltage of the power supply is the product

of the capacitor ESR and the inductor ripple current. The

capacitor types recommended in the tables were selected

for having low ESR ratings.

In addition, both surface mount tantalum capacitors and

through-hole aluminum electrolytic capacitors are offered as

solutions.

Impacting frequency stability of the overall control loop, the

output capacitance, in conjunction with the inductor, creates

a double pole inside the feedback loop. In addition the

capacitance and the ESR value create a zero. These frequency response effects together with the internal frequency

compensation circuitry of the LM2679 modify the gain and

phase shift of the closed loop system.

As a general rule for stable switching regulator circuits it is

desired to have the unity gain bandwidth of the circuit to be

limited to no more than one-sixth of the controller switching

frequency. With the fixed 260KHz switching frequency of the

LM2679, the output capacitor is selected to provide a unity

gain bandwidth of 40KHz maximum. Each recommended

capacitor value has been chosen to achieve this result.

In some cases multiple capacitors are required either to

reduce the ESR of the output capacitor, to minimize output

ripple (a ripple voltage of 1% of Vout or less is the assumed

performance condition), or to increase the output capacitance to reduce the closed loop unity gain bandwidth (to less

than 40KHz). When parallel combinations of capacitors are

required it has been assumed that each capacitor is the

exact same part type.

The RMS current and working voltage (WV) ratings of the

output capacitor are also important considerations. In a typical step-down switching regulator, the inductor ripple current

(set to be no more than 30% of the maximum load current by

the inductor selection) is the current that flows through the

output capacitor. The capacitor RMS current rating must be

greater than this ripple current. The voltage rating of the

output capacitor should be greater than 1.3 times the maximum output voltage of the power supply. If operation of the

system at elevated temperatures is required, the capacitor

voltage rating may be de-rated to less than the nominal room

temperature rating. Careful inspection of the manufacturer’s

specification for de-rating of working voltage with temperature is important.

INPUT CAPACITOR

Fast changing currents in high current switching regulators

place a significant dynamic load on the unregulated power

source. An input capacitor helps to provide additional current

to the power supply as well as smooth out input voltage

variations.

Like the output capacitor, the key specifications for the input

capacitor are RMS current rating and working voltage. The

RMS current flowing through the input capacitor is equal to

one-half of the maximum dc load current so the capacitor

should be rated to handle this. Paralleling multiple capacitors

proportionally increases the current rating of the total capacitance. The voltage rating should also be selected to be 1.3

times the maximum input voltage. Depending on the unregulated input power source, under light load conditions the

maximum input voltage could be significantly higher than

normal operation and should be considered when selecting

an input capacitor.

The input capacitor should be placed very close to the input

pin of the LM2679. Due to relative high current operation

with fast transient changes, the series inductance of input

connecting wires or PCB traces can create ringing signals at

the input terminal which could possibly propagate to the

output or other parts of the circuitry. It may be necessary in

some designs to add a small valued (0.1µF to 0.47µF)

ceramic type capacitor in parallel with the input capacitor to

prevent or minimize any ringing.

CATCH DIODE

When the power switch in the LM2679 turns OFF, the current

through the inductor continues to flow. The path for this

current is through the diode connected between the switch

output and ground. This forward biased diode clamps the

switch output to a voltage less than ground. This negative

voltage must be greater than −1V so a low voltage drop

(particularly at high current levels) Schottky diode is recommended. Total efficiency of the entire power supply is significantly impacted by the power lost in the output catch diode.

The average current through the catch diode is dependent

on the switch duty cycle (D) and is equal to the load current

times (1-D). Use of a diode rated for much higher current

than is required by the actual application helps to minimize

the voltage drop and power loss in the diode.

During the switch ON time the diode will be reversed biased

by the input voltage. The reverse voltage rating of the diode

should be at least 1.3 times greater than the maximum input

voltage.

BOOST CAPACITOR

The boost capacitor creates a voltage used to overdrive the

gate of the internal power MOSFET. This improves efficiency

by minimizing the on resistance of the switch and associated

power loss. For all applications it is recommended to use a

0.01µF/50V ceramic capacitor.

, ADJUSTABLE CURRENT LIMIT

R

ADJ

A key feature of the LM2679 is the ability to control the peak

switch current. Without this feature the peak switch current

would be internally set to 7A or higher to accommodate 5A

load current designs. This requires that both the inductor

LM2679

www.national.com11

Page 12

Application Hints (Continued)

(which could saturate with excessively high currents) and the

LM2679

catch diode be able to safely handle up to 7Awhich would be

conducted under load fault conditions.

If an application only requires a load current of 3A or 4A the

peak switch current can be set to a limit just over the maximum load current with the addition of a single programming

resistor. This allows the use of less powerful and more cost

effective inductors and diodes.

The peak switch current is equal to a factor of 37,125 divided

by R

typically 6.3A and an R

current to approximately 4.4A. For predictable control of the

current limit it is recommended to keep the peak switch

current greater than 3A. For lower current applications a 3A

switching regulator with adjustable current limit, the LM2673,

is available.

When the power switch reaches the current limit threshold it

is immediately turned OFF and the internal switching frequency is reduced. This extends the OFF time of the switch

to prevent a steady state high current condition. As the

switch current falls below the current limit threshold, the

switch will turn back ON. If a load fault continues, the switch

will again exceed the threshold and switch back OFF. This

will result in a low duty cycle pulsing of the power switch to

minimize the overall fault condition power dissipation.

Css SOFTSTART CAPACITOR

This optional capacitor controls the rate at which the LM2679

starts up at power on. The capacitor is charged linearly by an

internal current source. This voltage ramp gradually increases the duty cycle of the power switch until it reaches

the normal operating duty cycle defined primarily by the ratio

of the output voltage to the input voltage. The softstart

turn-on time is programmable by the selection of Css.

The formula for selecting a softstart capacitor is:

Where:

I

t

V

V

V

V

If this feature is not desired, leave the Softstart pin (pin 7)

open circuited

ADDITIONAL APPLICATION INFORMATION

When the output voltage is greater than approximately 6V,

and the duty cycle at minimum input voltage is greater than

approximately 50%, the designer should exercise caution in

selection of the output filter components. When an application designed to these specific operating conditions is subjected to a current limit fault condition, it may be possible to

observe a large hysteresis in the current limit. This can affect

the output voltage of the device until the load current is

reduced sufficiently to allow the current limit protection circuit

to reset itself.

Under current limiting conditions, the LM267x is designed to

respond in the following manner:

. A resistance of 5.6KΩ sets the current limit to

ADJ

= Softstart Current, 3.7µA typical

SST

= Softstart time, from design requirements

SS

= Softstart Threshold Voltage, 0.63V typical

SST

= Output Voltage, from design requirements

OUT

SCHOTTKY

IN

= Schottky Diode Voltage Drop, typically 0.5V

= Maximum Input Voltage, from design requirements

of 8.25KΩ reduces the maximum

ADJ

1. At the moment when the inductor current reaches the

current limit threshold, the ON-pulse is immediately terminated. This happens for any application condition.

2. However, the current limit block is also designed to

momentarily reduce the duty cycle to below 50% to

avoid subharmonic oscillations, which could cause the

inductor to saturate.

3. Thereafter, once the inductor current falls below the

current limit threshold, there is a small relaxation time

during which the duty cycle progressively rises back

above 50% to the value required to achieve regulation.

If the output capacitance is sufficiently ‘large’, it may be

possible that as the output tries to recover, the output capacitor charging current is large enough to repeatedly retrigger the current limit circuit before the output has fully

settled. This condition is exacerbated with higher output

voltage settings because the energy requirement of the output capacitor varies as the square of the output voltage

1

⁄2CV2), thus requiring an increased charging current.

(

A simple test to determine if this condition might exist for a

suspect application is to apply a short circuit across the

output of the converter, and then remove the shorted output

condition. In an application with properly selected external

components, the output will recover smoothly.

Practical values of external components that have been

experimentally found to work well under these specific operating conditions are C

= 47µF, L = 22µH. It should be

OUT

noted that even with these components, for a device’s current limit of I

, the maximum load current under which the

CLIM

possibility of the large current limit hysteresis can be minimized is I

/2. For example, if the input is 24V and the set

CLIM

output voltage is 18V, then for a desired maximum current of

1.5A, the current limit of the chosen switcher must be con-

firmed to be at least 3A.

SIMPLE DESIGN PROCEDURE

Using the nomographs and tables in this data sheet (or use

the available design software at http://www.national.com) a

complete step-down regulator can be designed in a few

simple steps.

Step 1: Define the power supply operating conditions:

Required output voltage

Maximum DC input voltage

Maximum output load current

Step 2: Set the output voltage by selecting a fixed output

LM2679 (3.3V, 5V or 12V applications) or determine the

required feedback resistors for use with the adjustable

LM2679−ADJ

Step 3: Determine the inductor required by using one of the

four nomographs, Figure 3 through Figure 6. Table 1 provides a specific manufacturer and part number for the inductor.

Step 4: Using Table 3 (fixed output voltage) or Table 6

(adjustable output voltage), determine the output capacitance required for stable operation. Table 2 provides the

specific capacitor type from the manufacturer of choice.

Step 5: Determine an input capacitor from Table 4 for fixed

output voltage applications. Use Table 2 to find the specific

capacitor type. For adjustable output circuits select a capacitor from Table 2 with a sufficient working voltage (WV) rating

greater than Vin max, and an rms current rating greater than

one-half the maximum load current (2 or more capacitors in

parallel may be required).

www.national.com 12

Page 13

Application Hints (Continued)

Step 6: Select a diode from Table 5. The current rating of the

diode must be greater than I load max and the Reverse

Voltage rating must be greater than Vin max.

Step 7: Include a 0.01µF/50V capacitor for Cboost in the

design and then determine the value of a softstart capacitor

if desired.

Step 8: Define a value for R

current limit to be at least 20% greater than Iout max to allow

for at least 30% inductor ripple current (

designs that must operate over the full temperature range

the switch current limit should be set to at least 50% greater

than Iout max (1.5 x I

out

max).

FIXED OUTPUT VOLTAGE DESIGN EXAMPLE

A system logic power supply bus of 3.3V is to be generated

from a wall adapter which provides an unregulated DC voltage of 13V to 16V. The maximum load current is 4A. A

softstart delay time of 50mS is desired. Through-hole components are preferred.

Step 1: Operating conditions are:

Vout = 3.3V

Vin max = 16V

Iload max = 4A

Step 2: Select an LM2679T-3.3. The output voltage will have

a tolerance of

±

2% at room temperature and±3% over the full operating

temperature range.

Step 3: Use the nomograph for the 3.3V device ,Figure 3.

The intersection of the 16V horizontal line (V

4A vertical line (I

max) indicates that L46, a 15µH induc-

load

tor, is required.

From Table 1, L46 in a through-hole component is available

from Renco with part number RL-1283-15-43.

Step 4: Use Table 3 to determine an output capacitor. With a

3.3V output and a 15µH inductor there are four through-hole

output capacitor solutions with the number of same type

capacitors to be paralleled and an identifying capacitor code

given. Table 2 provides the actual capacitor characteristics.

Any of the following choices will work in the circuit:

2 x 220µF/10V Sanyo OS-CON (code C5)

2 x 820µF/16V Sanyo MV-GX (code C5)

1 x 3900µF/10V Nichicon PL (code C7)

2 x 560µF/35V Panasonic HFQ (code C5)

Step 5: Use Table 4 to select an input capacitor. With 3.3V

output and 15µH there are three through-hole solutions.

These capacitors provide a sufficient voltage rating and an

rms current rating greater than 2A (1/2 I

using Table 2 for specific component characteristics the

following choices are suitable:

2 x 680µF/63V Sanyo MV-GX (code C13)

1 x 1200µF/63V Nichicon PL (code C25)

1 x 1500µF/63V Panasonic HFQ (code C16)

Step 6: From Table5a5Aormore Schottky diode must be

selected. For through-hole components only 40V rated diodes are indicated and 4 part types are suitable:

1N5825

MBR745

80SQ045

6TQ045

to set the peak switch

ADJ

±

15% of Iout). For

max) and the

in

max). Again

load

Step 7: A 0.01µF capacitor will be used for Cboost. For the

50mS softstart delay the following parameters are to be

used:

I

: 3.7µA

SST

: 50mS

t

SS

V

: 0.63V

SST

: 3.3V

V

OUT

V

SCHOTTKY

V

IN

: 0.5V

: 16V

Using Vin max ensures that the softstart delay time will be at

least the desired 50mS.

Using the formula for Css a value of 0.148µF is determined

to be required. Use of a standard value 0.22µF capacitor will

produce more than sufficient softstart delay.

Step 8: Determine a value for R

to provide a peak switch

ADJ

current limit of at least 4A plus 50% or 6A.

Use a value of 6.2KΩ.

ADJUSTABLE OUTPUT DESIGN EXAMPLE

In this example it is desired to convert the voltage from a two

battery automotive power supply (voltage range of 20V to

28V, typical in large truck applications) to the 14.8VDC alternator supply typically used to power electronic equipment

from single battery 12V vehicle systems. The load current

required is 3.5A maximum. It is also desired to implement the

power supply with all surface mount components. Softstart is

not required.

Step 1: Operating conditions are:

Vout = 14.8V

Vin max = 28V

Iload max = 3.5A

Step 2: Select an LM2679S-ADJ. To set the output voltage

to 14.9V two resistors need to be chosen (R1 and R2 in

Figure 2). For the adjustable device the output voltage is set

by the following relationship:

Where VFBis the feedback voltage of typically 1.21V.

A recommended value to use for R1 is 1K. In this example

then R2 is determined to be:

R2 = 11.23KΩ

The closest standard 1% tolerance value to use is 11.3KΩ

This will set the nominal output voltage to 14.88V which is

within 0.5% of the target value.

Step 3: To use the nomograph for the adjustable device,

Figure 6, requires a calculation of the inductor

microsecond constant (E•T expressed in V•µS) from

Volt

•

the following formula:

LM2679

www.national.com13

Page 14

Application Hints (Continued)

where V

LM2679

switch which is R

be typically 0.12Ω x 3.5A or 0.42V and V

across the forward bisased Schottky diode, typically 0.5V.

The switching frequency of 260KHz is the nominal value to

use to estimate the ON time of the switch during which

energy is stored in the inductor.

For this example E

Using Figure 6, the intersection of 27V•µS horizontally and

the 3.5A vertical line (I

inductor, or L49, a 33µH inductor could be used. Either

inductor will be suitable, but for this example selecting the

larger inductance will result in lower ripple current.

From Table 1, L48 in a surface mount component is available

from Pulse Engineering with part number P0848.

Step 4: Use Table 6 to determine an output capacitor. With a

14.8V output the 12.5 to 15V row is used and with a 47µH

inductor there are three surface mount output capacitor solutions. Table 2 provides the actual capacitor characteristics

based on the C Code number. Any of the following choices

can be used:

1 x 33µF/20V AVX TPS (code C6)

1 x 47µF/20V Sprague 594 (code C8)

1 x 47µF/20V Kemet T495 (code C8)

Important Note: When using the adjustable device in low

voltage applications (less than 3V output), if the nomograph,

Figure 6, selects an inductance of 22µH or less, Table 6 does

is the voltage drop across the internal power

SAT

times I

ds(ON)

T is found to be:

•

max) indicates that L48 , a 47µH

load

. In this example this would

load

is the voltage drop

D

not provide an output capacitor solution. With these conditions the number of output capacitors required for stable

operation becomes impractical. It is recommended to use

either a 33µH or 47µH inductor and the output capacitors

from Table 6.

Step 5: An input capacitor for this example will require at

least a 35V WV rating with an rms current rating of 1.75A

(1/2 Iout max). From Table 2 it can be seen that C12, a

33µF/35V capacitor from Sprague, has the highest voltage/

current rating of the surface mount components and that two

of these capacitor in parallel will be adquate.

Step 6: From Table5a5Aormore Schottky diode must be

selected. For surface mount diodes with a margin of safety

on the voltage rating one of two diodes can be used:

MBRD1545CT

6TQ045S

Step 7: A 0.01µF capacitor will be used for Cboost.

The softstart pin will be left open circuited.

Step 8: Determine a value for R

to provide a peak switch

ADJ

current limit of at least 3.5A plus 50% or 5.25A.

Use a value of 7.15KΩ.

LLP PACKAGE DEVICES

The LM2679 is offered in the 14 lead LLP surface mount

package to allow for a significantly decreased footprint with

equivalent power dissipation compared to the TO-263.

The Die Attach Pad (DAP) can and should be connected to

PCB Ground plane/island. For CAD and assembly guidelines refer to Application Note AN-1187 at http://

power.national.com.

www.national.com 14

Page 15

Inductor Selection Guides For Continuous Mode Operation

LM2679

FIGURE 3. LM2679-3.3

FIGURE 5. LM2679-12

10084719

10084721

10084720

FIGURE 4. LM2679-5.0

10084722

FIGURE 6. LM2679-ADJ

www.national.com15

Page 16

Inductor Selection Guides For Continuous Mode Operation (Continued)

LM2679

Table 1. Inductor Manufacturer Part Numbers

Inductor

Reference

Number

L23 33 1.35 RL-5471-7 RL1500-33 PE-53823 PE-53823S DO3316-333

L24 22 1.65 RL-1283-22-43 RL1500-22 PE-53824 PE-53824S DO3316-223

L25 15 2.00 RL-1283-15-43 RL1500-15 PE-53825 PE-53825S DO3316-153

L29 100 1.41 RL-5471-4 RL-6050-100 PE-53829 PE-53829S DO5022P-104

L30 68 1.71 RL-5471-5 RL6050-68 PE-53830 PE-53830S DO5022P-683

L31 47 2.06 RL-5471-6 RL6050-47 PE-53831 PE-53831S DO5022P-473

L32 33 2.46 RL-5471-7 RL6050-33 PE-53932 PE-53932S DO5022P-333

L33 22 3.02 RL-1283-22-43 RL6050-22 PE-53933 PE-53933S DO5022P-223

L34 15 3.65 RL-1283-15-43 — PE-53934 PE-53934S DO5022P-153

L38 68 2.97 RL-5472-2 — PE-54038 PE-54038S —

L39 47 3.57 RL-5472-3 — PE-54039 PE-54039S —

L40 33 4.26 RL-1283-33-43 — PE-54040 PE-54040S —

L41 22 5.22 RL-1283-22-43 — PE-54041 P0841 —

L44 68 3.45 RL-5473-3 — PE-54044 — —

L45 10 4.47 RL-1283-10-43 — — P0845 DO5022P-103HC

L46 15 5.60 RL-1283-15-43 — — P0846 DO5022P-153HC

L47 10 5.66 RL-1283-10-43 — — P0847 DO5022P-103HC

L48 47 5.61 RL-1282-47-43 — — P0848 —

L49 33 5.61 RL-1282-33-43 — — P0849 —

Inductance

(µH)

Current

(A)

Through Hole Surface

Renco Pulse Engineering Coilcraft

Mount

Through

Hole

Surface

Mount

Surface Mount

Inductor Manufacturer Contact Numbers

Coilcraft Phone (800) 322-2645

FAX (708) 639-1469

Coilcraft, Europe Phone +44 1236 730 595

FAX +44 1236 730 627

Pulse Engineering Phone (619) 674-8100

FAX (619) 674-8262

Pulse Engineering, Phone +353 93 24 107

Europe FAX +353 93 24 459

Renco Electronics Phone (800) 645-5828

FAX (516) 586-5562

www.national.com 16

Page 17

Capacitor Selection Guides

Table 2. Input and Output Capacitor Codes

Capacitor

Reference

Code

C1 330 6.3 1.15 120 6.3 1.1 100 6.3 0.82

C2 100 10 1.1 220 6.3 1.4 220 6.3 1.1

C3 220 10 1.15 68 10 1.05 330 6.3 1.1

C4 47 16 0.89 150 10 1.35 100 10 1.1

C5 100 16 1.15 47 16 1 150 10 1.1

C6 33 20 0.77 100 16 1.3 220 10 1.1

C7 68 20 0.94 180 16 1.95 33 20 0.78

C8 22 25 0.77 47 20 1.15 47 20 0.94

C9 10 35 0.63 33 25 1.05 68 20 0.94

C10 22 35 0.66 68 25 1.6 10 35 0.63

C11 15 35 0.75 22 35 0.63

C12 33 35 1 4.7 50 0.66

C13 15 50 0.9

AVX TPS Series Sprague 594D Series Kemet T495 Series

C (µF) WV (V)

Surface Mount

Irms

(A) C (µF) WV (V)

Irms

(A) C (µF) WV (V)

LM2679

Irms

(A)

www.national.com17

Page 18

Capacitor Selection Guides (Continued)

LM2679

Input and Output Capacitor Codes (continued)

Capacitor

Reference

Code

C1 47 6.3 1 1000 6.3 0.8 680 10 0.8 82 35 0.4

C2 150 6.3 1.95 270 16 0.6 820 10 0.98 120 35 0.44

C3 330 6.3 2.45 470 16 0.75 1000 10 1.06 220 35 0.76

C4 100 10 1.87 560 16 0.95 1200 10 1.28 330 35 1.01

C5 220 10 2.36 820 16 1.25 2200 10 1.71 560 35 1.4

C6 33 16 0.96 1000 16 1.3 3300 10 2.18 820 35 1.62

C7 100 16 1.92 150 35 0.65 3900 10 2.36 1000 35 1.73

C8 150 16 2.28 470 35 1.3 6800 10 2.68 2200 35 2.8

C9 100 20 2.25 680 35 1.4 180 16 0.41 56 50 0.36

C10 47 25 2.09 1000 35 1.7 270 16 0.55 100 50 0.5

C11 220 63 0.76 470 16 0.77 220 50 0.92

C12 470 63 1.2 680 16 1.02 470 50 1.44

C13 680 63 1.5 820 16 1.22 560 50 1.68

C14 1000 63 1.75 1800 16 1.88 1200 50 2.22

C15 220 25 0.63 330 63 1.42

C16 220 35 0.79 1500 63 2.51

C17 560 35 1.43

C18 2200 35 2.68

C19 150 50 0.82

C20 220 50 1.04

C21 330 50 1.3

C22 100 63 0.75

C23 390 63 1.62

C24 820 63 2.22

C25 1200 63 2.51

Sanyo OS-CON SA Series Sanyo MV-GX Series Nichicon PL Series Panasonic HFQ Series

Irms

C (µF) WV (V)

(A) C (µF) WV (V)

Through Hole

Irms

(A) C (µF) WV (V)

Irms

(A) C (µF) WV (V)

Irms

(A)

Capacitor Manufacturer Contact Numbers

Nichicon Phone (847) 843-7500

FAX (847) 843-2798

Panasonic Phone (714) 373-7857

FAX (714) 373-7102

AVX Phone (845) 448-9411

FAX (845) 448-1943

Sprague/Vishay Phone (207) 324-4140

FAX (207) 324-7223

Sanyo Phone (619) 661-6322

FAX (619) 661-1055

Kemet Phone (864) 963-6300

FAX (864) 963-6521

www.national.com 18

Page 19

Capacitor Selection Guides (Continued)

Table 3. Output Capacitors for Fixed Output Voltage Application

Output

Voltage (V)

3.3

5

12

Inductance

(µH)

10 5 C1 5 C1 5 C2

15 4 C1 4 C1 4 C3

22 3 C2 2 C7 3 C4

33 1 C1 2 C7 3 C4

10 4 C2 4 C6 4 C4

15 3 C3 2 C7 3 C5

22 3 C2 2 C7 3 C4

33 2 C2 2 C3 2 C4

47 2 C2 1 C7 2 C4

10 4 C5 3 C6 5 C9

15 3 C5 2 C7 4 C9

22 2 C5 2 C6 3 C8

33 2 C5 1 C7 3 C8

47 2 C4 1 C6 2 C8

68 1 C5 1 C5 2 C7

100 1 C4 1 C5 1 C8

AVX TPS Series Sprague 594D

No. C Code No. C Code No. C Code

Surface Mount

Series

LM2679

Kemet T495 Series

Through Hole

Output

Voltage (V)

3.3

5

12

No. represents the number of identical capacitor types to be connected in parallel

C Code indicates the Capacitor Reference number in Table 2 for identifying the specific component from the manufacturer.

Inductance

(µH)

10 2 C5 2 C6 1 C8 2 C6

15 2 C5 2 C5 1 C7 2 C5

22 1 C5 1 C10 1 C5 1 C7

33 1 C5 1 C10 1 C5 1 C7

10 2 C4 2 C5 1 C6 2 C5

15 1 C5 1 C10 1 C5 1 C7

22 1 C5 1 C9 1 C5 1 C5

33 1 C4 1 C5 1 C4 1 C4

47 1 C4 1 C4 1 C2 2 C4

10 2 C7 1 C10 1 C14 2 C4

15 1 C8 1 C6 1 C17 1 C5

22 1 C7 1 C5 1 C13 1 C5

33 1 C7 1 C4 1 C12 1 C4

47 1 C7 1 C3 1 C11 1 C3

68 1 C6 1 C2 1 C10 1 C3

100 1 C6 1 C2 1 C9 1 C1

Sanyo OS-CON SA

Series

No. C Code No. C Code No. C Code No. C Code

Sanyo MV-GX Series Nichicon PL Series

Panasonic HFQ

Series

www.national.com19

Page 20

Capacitor Selection Guides (Continued)

LM2679

Table 4. Input Capacitors for Fixed Output Voltage Application

(Assumes worst case maximum input voltage and load current for a given inductance value)

Surface Mount

Output

Voltage (V)

3.3

5

12

Inductance

(µH)

10 3 C7 2 C10 3 C9

15 * * 3 C13 4 C12

22 * * 2 C13 3 C12

33 * * 2 C13 3 C12

10 3 C4 2 C6 3 C9

15 4 C9 3 C12 4 C10

22 * * 3 C13 4 C12

33 * * 2 C13 3 C12

47 * * 1 C13 2 C12

10 4 C9 2 C10 4 C10

15 4 C8 2 C10 4 C10

22 4 C9 3 C12 4 C10

33 * * 3 C13 4 C12

47 * * 2 C13 3 C12

68 * * 2 C13 2 C12

100 * * 1 C13 2 C12

AVX TPS Series Sprague 594D

Series

No. C Code No. C Code No. C Code

Kemet T495 Series

Through Hole

Output

Voltage (V)

3.3

5

12

* Check voltage rating of capacitors to be greater than application input voltage.

No. represents the number of identical capacitor types to be connected in parallel

C Code indicates the Capacitor Reference number in Table 2 for identifying the specific component from the manufacturer.

Inductance

(µH)

10 2 C9 2 C8 1 C18 1 C8

15 * * 2 C13 1 C25 1 C16

22 * * 1 C14 1 C24 1 C16

33 * * 1 C14 1 C24 1 C16

10 2 C7 2 C8 1 C25 1 C8

15 * * 2 C8 1 C25 1 C8

22 * * 2 C13 1 C25 1 C16

33 * * 1 C14 1 C23 1 C13

47 * * 1 C12 1 C19 1 C11

10 2 C10 2 C8 1 C18 1 C8

15 2 C10 2 C8 1 C18 1 C8

22 * * 2 C8 1 C18 1 C8

33 * * 2 C12 1 C24 1 C14

47 * * 1 C14 1 C23 1 C13

68 * * 1 C13 1 C21 1 C15

100 * * 1 C11 1 C22 1 C11

Sanyo OS-CON SA

Series

No. C Code No. C Code No. C Code No. C Code

Sanyo MV-GX Series Nichicon PL Series

Panasonic HFQ

Series

www.national.com 20

Page 21

Capacitor Selection Guides (Continued)

Table 5. Schottky Diode Selection Table

Reverse

Voltage

(V)

20V SK32 1N5820

30V SK33 MBRD835L 1N5821

40V SK34 MBRD1545CT 1N5822 1N5825

50V or

More

International Rectifier Phone (310) 322-3331

Motorola Phone (800) 521-6274

General

Semiconductor

Diodes, Inc. Phone (805) 446-4800

Surface Mount Through Hole

3A 5A or More 3A 5A or

30WQ03F 31DQ03

30BQ040 6TQ045S MBR340 MBR745

30WQ04F 31DQ04 80SQ045

MBRS340 SR403 6TQ045

MBRD340

SK35 MBR350

30WQ05F 31DQ05

Diode Manufacturer Contact Numbers

LM2679

More

SR302

SR305

FAX (310) 322-3332

FAX (602) 244-6609

Phone (516) 847-3000

FAX (516) 847-3236

FAX (805) 446-4850

www.national.com21

Page 22

Capacitor Selection Guides (Continued)

LM2679

Table 6. Output Capacitors for Adjustable Output Voltage Applications

Output Voltage

(V)

1.21 to 2.50

2.5 to 3.75

3.75 to 5

5 to 6.25

6.25 to 7.5

7.5 to 10

10 to 12.5

12.5 to 15

15 to 20

20 to 30

30 to 37

Surface Mount

Inductance

(µH)

33* 7 C1 6 C2 7 C3

47* 5 C1 4 C2 5 C3

33* 4 C1 3 C2 4 C3

47* 3 C1 2 C2 3 C3

22 4 C1 3 C2 4 C3

33 3 C1 2 C2 3 C3

47 2 C1 2 C2 2 C3

22 3 C2 3 C3 3 C4

33 2 C2 2 C3 2 C4

47 2 C2 2 C3 2 C4

68 1 C2 1 C3 1 C4

22 3 C2 1 C4 3 C4

33 2 C2 1 C3 2 C4

47 1 C3 1 C4 1 C6

68 1 C2 1 C3 1 C4

33 2 C5 1 C6 2 C8

47 1 C5 1 C6 2 C8

68 1 C5 1 C6 1 C8

100 1 C4 1 C5 1 C8

33 1 C5 1 C6 2 C8

47 1 C5 1 C6 2 C8

68 1 C5 1 C6 1 C8

100 1 C5 1 C6 1 C8

33 1 C6 1 C8 1 C8

47 1 C6 1 C8 1 C8

68 1 C6 1 C8 1 C8

100 1 C6 1 C8 1 C8

33 1 C8 1 C10 2 C10

47 1 C8 1 C9 2 C10

68 1 C8 1 C9 2 C10

100 1 C8 1 C9 1 C10

33 2 C9 2 C11 2 C11

47 1 C10 1 C12 1 C11

68 1 C9 1 C12 1 C11

100 1 C9 1 C12 1 C11

10 4 C13 8 C12

15 3 C13 5 C12

22 No Values Available 2 C13 4 C12

33 1 C13 3 C12

47 1 C13 2 C12

68 1 C13 2 C12

AVX TPS Series Sprague 594D

Series

No. C Code No. C Code No. C Code

Kemet T495 Series

www.national.com 22

Page 23

Capacitor Selection Guides (Continued)

Output Capacitors for Adjustable Output Voltage Applications (continued)

Through Hole

Output Voltage

(V)

1.21 to 2.50

2.5 to 3.75

3.75 to 5

5 to 6.25

6.25 to 7.5

7.5 to 10

10 to 12.5

12.5 to 15

15 to 20

20 to 30

30 to 37

* Set to a higher value for a practical design solution. See Applications Hints section

No. represents the number of identical capacitor types to be connected in parallel

C Code indicates the Capacitor Reference number in Table 2 for identifying the specific component from the manufacturer.

Inductance

(µH)

33* 2 C3 5 C1 5 C3 3 C

47* 2 C2 4 C1 3 C3 2 C5

33* 1 C3 3 C1 3 C1 2 C5

47* 1 C2 2 C1 2 C3 1 C5

22 1 C3 3 C1 3 C1 2 C5

33 1 C2 2 C1 2 C1 1 C5

47 1 C2 2 C1 1 C3 1 C5

22 1 C5 2 C6 2 C3 2 C5

33 1 C4 1 C6 2 C1 1 C5

47 1 C4 1 C6 1 C3 1 C5

68 1 C4 1 C6 1 C1 1 C5

22 1 C5 1 C6 2 C1 1 C5

33 1 C4 1 C6 1 C3 1 C5

47 1 C4 1 C6 1 C1 1 C5

68 1 C4 1 C2 1 C1 1 C5

33 1 C7 1 C6 1 C14 1 C5

47 1 C7 1 C6 1 C14 1 C5

68 1 C7 1 C2 1 C14 1 C2

100 1 C7 1 C2 1 C14 1 C2

33 1 C7 1 C6 1 C14 1 C5

47 1 C7 1 C2 1 C14 1 C5

68 1 C7 1 C2 1 C9 1 C2

100 1 C7 1 C2 1 C9 1 C2

33 1 C9 1 C10 1 C15 1 C2

47 1 C9 1 C10 1 C15 1 C2

68 1 C9 1 C10 1 C15 1 C2

100 1 C9 1 C10 1 C15 1 C2

33 1 C10 1 C7 1 C15 1 C2

47 1 C10 1 C7 1 C15 1 C2

68 1 C10 1 C7 1 C15 1 C2

100 1 C10 1 C7 1 C15 1 C2

33 1 C7 1 C16 1 C2

47 No Values 1 C7 1 C16 1 C2

68 Available 1 C7 1 C16 1 C2

100 1 C7 1 C16 1 C2

10 1 C12 1 C20 1 C10

15 1 C11 1 C20 1 C11

22 No Values 1 C11 1 C20 1 C10

33 Available 1 C11 1 C20 1 C10

47 1 C11 1 C20 1 C10

68 1 C11 1 C20 1 C10

Sanyo OS-CON SA

Series

No. C Code No. C Code No. C Code No. C Code

Sanyo MV-GX Series Nichicon PL Series

LM2679

Panasonic HFQ

Series

www.national.com23

Page 24

Physical Dimensions inches (millimeters)

unless otherwise noted

LM2679

TO-263 Surface Mount Power Package

Order Number LM2679S-3.3, LM2679S-5.0,

LM2679S-12 or LM2679S-ADJ

NS Package Number TS7B

www.national.com 24

Page 25

Physical Dimensions inches (millimeters) unless otherwise noted (Continued)

LM2679

TO-220 Power Package

Order Number LM2679T-3.3, LM2679T-5.0,

LM2679T-12 or LM2679T-ADJ

NS Package Number TA07B

14-Lead LLP Package

NS Package Number SRC14A

www.national.com25

Page 26

Notes

National does not assume any responsibility for use of any circuitry described, no circuit patent licenses are implied and National reserves

the right at any time without notice to change said circuitry and specifications.

For the most current product information visit us at www.national.com.

LIFE SUPPORT POLICY

NATIONAL’S PRODUCTS ARE NOT AUTHORIZED FOR USE AS CRITICAL COMPONENTS IN LIFE SUPPORT DEVICES OR SYSTEMS

WITHOUT THE EXPRESS WRITTEN APPROVAL OF THE PRESIDENT AND GENERAL COUNSEL OF NATIONAL SEMICONDUCTOR

CORPORATION. As used herein:

1. Life support devices or systems are devices or systems

which, (a) are intended for surgical implant into the body, or

(b) support or sustain life, and whose failure to perform when

properly used in accordance with instructions for use

2. A critical component is any component of a life support

device or system whose failure to perform can be reasonably

expected to cause the failure of the life support device or

system, or to affect its safety or effectiveness.

provided in the labeling, can be reasonably expected to result

in a significant injury to the user.

BANNED SUBSTANCE COMPLIANCE

National Semiconductor manufactures products and uses packing materials that meet the provisions of the Customer Products

Stewardship Specification (CSP-9-111C2) and the Banned Substances and Materials of Interest Specification (CSP-9-111S2) and contain

no ‘‘Banned Substances’’ as defined in CSP-9-111S2.

LM2679 SIMPLE SWITCHER 5A Step-Down Voltage Regulator with Adjustable Current Limit

www.national.com

National Semiconductor

Americas Customer

Support Center

Email: new.feedback@nsc.com

Tel: 1-800-272-9959

National Semiconductor

Europe Customer Support Center

Fax: +49 (0) 180-530 85 86

Email: europe.support@nsc.com

Deutsch Tel: +49 (0) 69 9508 6208

English Tel: +44 (0) 870 24 0 2171

Français Tel: +33 (0) 1 41 91 8790

National Semiconductor

Asia Pacific Customer

Support Center

Email: ap.support@nsc.com

National Semiconductor

Japan Customer Support Center

Fax: 81-3-5639-7507

Email: jpn.feedback@nsc.com

Tel: 81-3-5639-7560

Loading...

Loading...