Page 1

LM1921 1 Amp Industrial Switch

LM1921 1 Amp Industrial Switch

February 1995

General Description

The LM1921 Relay Driver incorporates an integrated power

PNP transistor as the main driving element. The advantages

of this over previous integrated circuits employing NPN

power elements are several. Greater output voltages are

available off the same supply for driving grounded loads;

typically 4.5 volts for a 500 mA load from a 5.0 volt supply.

The output can swing below ground potential up to 57 volts

negative with respect to the positive power supply. This can

be used to facilitate rapid decay times in inductive loads.

Also, the IC is immune to negative supply voltages or transients. The inherent Safe Operating Area of the lateral PNP

allows use of the IC as a bulb driver or for capacitive loads.

Familiar integrated circuit features such as short circuit protection and thermal shutdown are also provided. The input

voltage threshold levels are designed to be TTL, CMOS,

and LSTTL compatible over the entire operating temperature range. If several drivers are used in a system, their

inputs and/or outputs may be combined and wired together

if their supply voltages are also common.

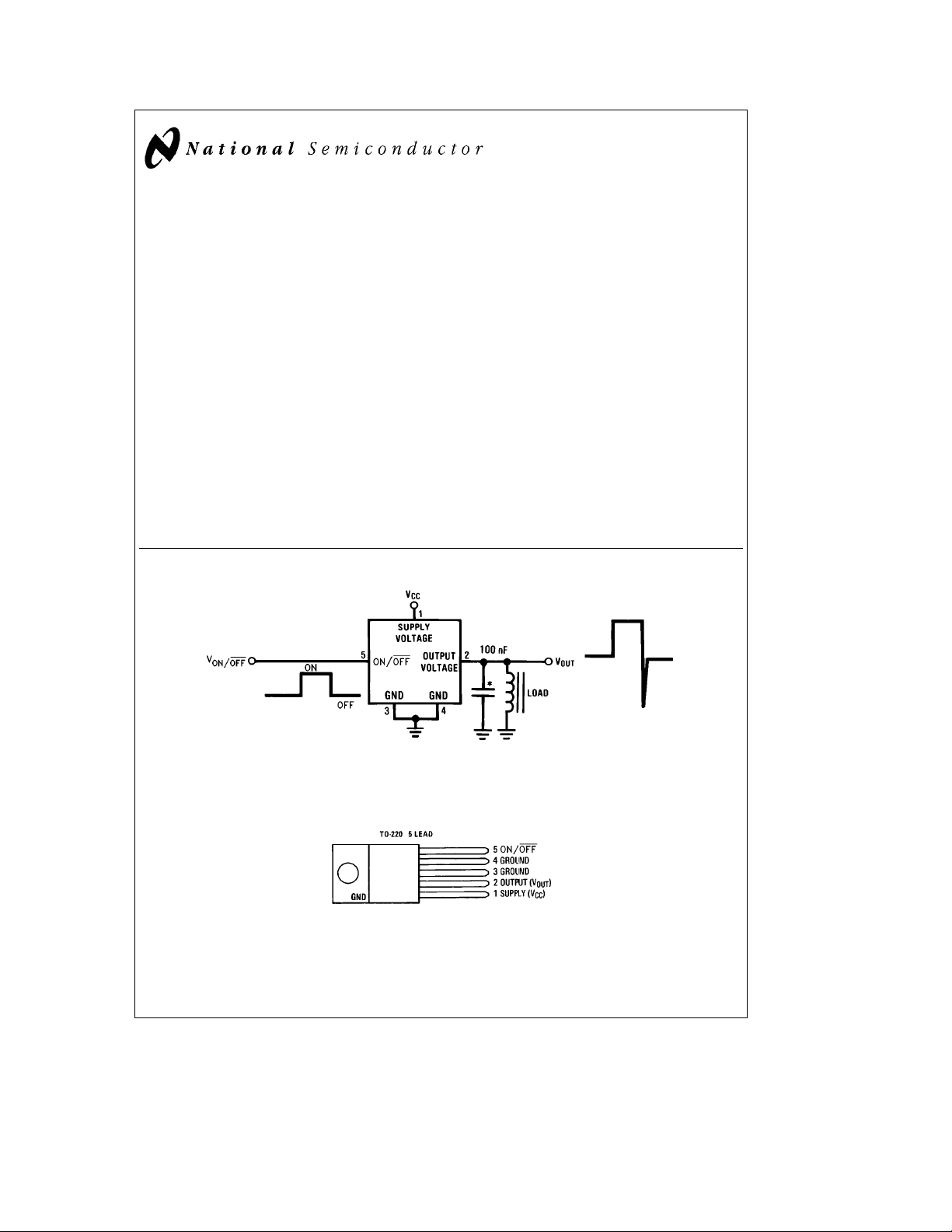

Typical Application Circuit

Features

Y

1 Amp output drive

Y

Load connected to ground

Y

Low input-output voltage differential

Y

a

60 volt positive transient protection

Y

b

50 volt negative transient protection

Y

Automotive reverse battery protection

Y

Short circuit proof

Y

Internal thermal overload protection

Y

Unclamped output for fast decay times

Y

TTL, LSTTL, CMOS compatible input

Y

Plastic TO-220 package

Y

100% electrical burn-in

Applications

Y

Relays

Y

Solenoids

Y

Valves

Y

Motors

Y

Lamps

Y

Heaters

*Required for stability

TL/H/5271– 1

FIGURE 1. Test and Application Circuit

Connection Diagram

Front View

Order Number LM1921T

See NS Package Number T05A

C

1995 National Semiconductor Corporation RRD-B30M115/Printed in U. S. A.

TL/H/5271

TL/H/5271– 2

Page 2

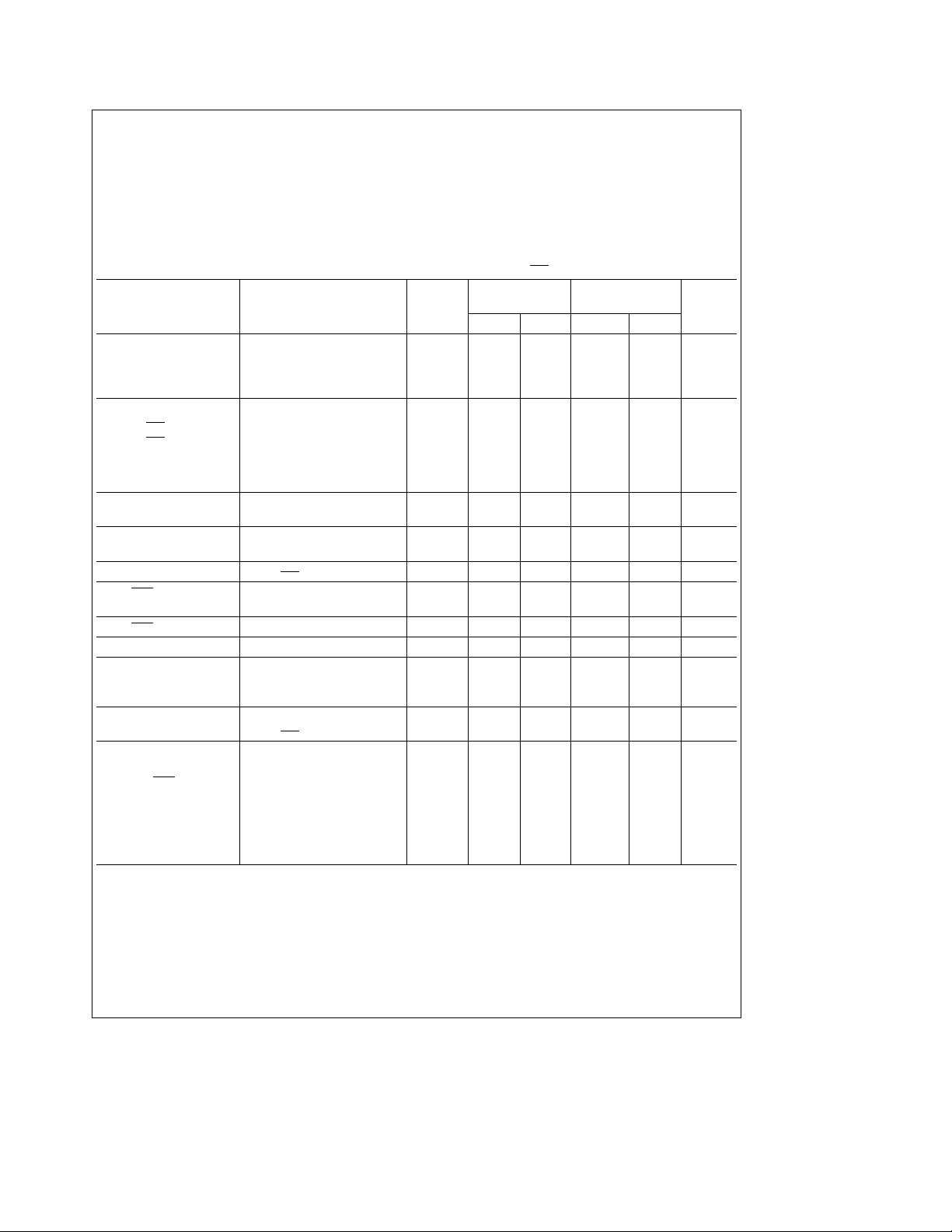

Absolute Maximum Ratings

If Military/Aerospace specified devices are required,

please contact the National Semiconductor Sales

Office/Distributors for availability and specifications.

Supply Voltage

Operating Range 4.75V to 26V

Overvoltage Protection (100 ms)

b

50V toa60V

Internal Power Dissipation Internally Limited

b

Operating Temperature Range

40§Ctoa125§C

Maximum Junction Temperature 150§C

Storage Temperature Range

b

65§Ctoa150§C

Lead Temp. (Soldering, 10 seconds) 230§C

Electrical Characteristics (V

CC

e

12V, I

OUT

e

500 mA, T

e

J

25§C, V

ON/OFF

e

2V, unless otherwise specified.)

Tested Limits Design Limits

Parameter Conditions Typ

(Note 1) (Note 2)

Units

Min Max Min Max

Supply Voltage

Operational 4.75 26 6 24 V

Survival

Transient 100 ms, 1% Duty Cycle

b

15 60 V

b

50 V

Supply Current

e

V

ON/OFF

V

ON/OFF

Input to Output I

Voltage Drop I

0 0.6 1.5 mA

e

2V I

e

0 mA 6 10 mA

OUT

e

I

250 mA 285 350 mA

OUT

e

I

500 mA 575 700 mA

OUT

e

I

1A 1.3 1.5 A

OUT

e

500 mA 0.5 0.8 V

OUT

e

1A 1.0 V

OUT

Short Circuit Current 1.4 1.0 2.0 A

s

s

6V

V

24V .75 3.0 A

CC

Output Leakage Current V

ON/OFF

e

0 0.1 50 mA

ON/OFF Voltage 1.3 0.8 2.0 V

Threshhold 6VsV

s

24V 0.8 2.0 V

CC

ON/OFF Current 15 10 30 mA

Overvoltage Shutdown 32 26 36 V

Thermal Resistance

junction-case ijc 3

case-ambient ica 50

C/W

§

C/W

§

Inductive Clamp

Output Voltage V

ON/OFF

0, I

OUT

e

100 mA

b

60

b

120

b

45 V

e

Fault Conditions

Output Current

ON/OFF

Floating Pin 5 Open 0.1 50 mA

Ground Floating Pin 3 & Pin 4 Open 0.1 50 mA

Reverse Voltage V

Reverse Transient V

Overvoltage V

Supply Current Pin 1 & Pin 2 Short, No load 10 40 mA

Note 1: Guaranteed and 100% production tested.

Note 2: Guaranteed, not necessarily 100% production tested. Not used to calculate outgoing AQL . Limits are for the temperature range of

eb

15V

CC

eb

50V

CC

ea

60V 0.01 1 mA

CC

b

0.01

b

100 mA

b

1mA

b

40§CsT

j

s

150§C.

DC

2

Page 3

Typical Performance Characteristics

Output Voltage Drop

Device Operating Current

Peak Output Current (V

OUT

)

TL/H/5271– 3

Output Voltage Drop

TL/H/5271– 6

ON/OFF Current vs.

Junction Temperature

TL/H/5271– 13

Equivalent Block Diagram

Output Voltage (V

OUT

Threshold Voltage vs.

Supply Voltage

TL/H/5271– 4

)

TL/H/5271– 7

TL/H/5271– 14

Maximum Power

Dissipation (TO-220)

ON/OFF Current vs.

ON/OFF

Voltage

TL/H/5271– 5

TL/H/5271– 8

TL/H/5271– 15

FIGURE 1

3

TL/H/5271– 12

Page 4

Circuit Schematic

TL/H/5271– 9

4

Page 5

Application Hints

HIGH CURRENT OUTPUT

The 1 Amp output is fault protected against overvoltage. If

the supply voltage rises above approximately 30 volts, the

output will automatically shut down. This protects the internal circuitry and enables the IC to survive higher voltage

transients than would otherwise be expected. The 1921 will

survive transients and DC voltages up to 60 volts on the

supply. The output remains off during this time, independent

of the state of the input logic voltage. This protects the load.

The high current output is also protected against short circuits to either ground or supply voltage. Standard thermal

shutdown circuits are employed to protect the 1921 from

over heating.

FLYBACK RESPONSE

Since the 1921 is designed to drive inductive as well as any

other type of load, inductive kickback can be expected

whenever the output changes state from on to off (see

waveforms on

clamped since it is often desirable in many systems to

achieve a very rapid decay in the load current. In applications where this is not true, such as in

external diode clamp will suffice. In this application, the integrated current in the inductive load is controlled by varying

the duty cycle of the input to the driver IC. This technique

achieves response characteristics that are desirable for certain automotive transmission solenoids, for example.

For applications requiring a rapid controlled decay in the

solenoid current, such as fuel injector drivers, an external

zener and diode can be used as in

rating of the zener should be such that it breaks down before the output of the LM1921. The minimum output breakdown voltage of the IC output is rated at

respect to the supply voltage. Thus, on a 12 volt supply, the

Figure 1

). The driver output was left un-

Figure 3

Figure 2

. The voltage

b

57 volts with

, a simple

combined zener and diode breakdown should be less than

45 volts.

The LM1921 can be used alone as a simple relay or solenoid driver where a rapid decay of the load current is desired, but the exact rate of decay is not critical to the system. If the output is unclamped as in

Figure 1

, and the load

is inductive enough, the negative flyback transient will cause

the output of the IC to breakdown and behave similarly to a

zener clamp. Relying upon the IC breakdown is practical,

and will not damage or degrade the IC in any way. There are

two considerations that must be accounted for when the

driver is operated in this mode. The IC breakdown voltage is

process and lot dependent. Clamp voltages ranging from

b

60 tob120 volts (with respect to the supply voltage) will

be encountered over time on different devices. This is not at

all critical in most applications. An important consideration,

however, is the additional heat dissipated in the IC as a

result. This must be added to normal device dissipation

when considering junction temperatures and heat sinking

requirements. Worst case for the additional dissipation can

be approximated as:

e

I2xLxf(Watts)

D

where: I

Additional P

e

peak solenoid current (Amps)

Lesolenoid inductance (Henries)

femaximum frequency input signal (Hz)

For solenoids where the inductance is less than ten millihenries, the additional power dissipation can be ignored.

Overshoot, undershoot, and ringing can occur on certain

loads. The simple solution is to lower the Q of the load by

the addition of a resistor in parallel or series with the load. A

value that draws one tenth of the current or DC voltage of

the load is usually sufficient.

FIGURE 2. Diode Clamp

TL/H/5271– 10

FIGURE 3

TL/H/5271– 11

Zener clamp for rapid controlled current decay

5

Page 6

Physical Dimensions inches (millimeters)

LM1921 1 Amp Industrial Switch

5-Lead TO-220 Power Package (T)

Order Number LM1921T

NS Package Number T05A

LIFE SUPPORT POLICY

NATIONAL’S PRODUCTS ARE NOT AUTHORIZED FOR USE AS CRITICAL COMPONENTS IN LIFE SUPPORT

DEVICES OR SYSTEMS WITHOUT THE EXPRESS WRITTEN APPROVAL OF THE PRESIDENT OF NATIONAL

SEMICONDUCTOR CORPORATION. As used herein:

1. Life support devices or systems are devices or 2. A critical component is any component of a life

systems which, (a) are intended for surgical implant support device or system whose failure to perform can

into the body, or (b) support or sustain life, and whose be reasonably expected to cause the failure of the life

failure to perform, when properly used in accordance support device or system, or to affect its safety or

with instructions for use provided in the labeling, can effectiveness.

be reasonably expected to result in a significant injury

to the user.

National Semiconductor National Semiconductor National Semiconductor National Semiconductor

Corporation Europe Hong Kong Ltd. Japan Ltd.

1111 West Bardin Road Fax: (

Arlington, TX 76017 Email: cnjwge@tevm2.nsc.com Ocean Centre, 5 Canton Rd. Fax: 81-043-299-2408

Tel: 1(800) 272-9959 Deutsch Tel: (

Fax: 1(800) 737-7018 English Tel: (

National does not assume any responsibility for use of any circuitry described, no circuit patent licenses are implied and National reserves the right at any time without notice to change said circuitry and specifications.

Fran3ais Tel: (

Italiano Tel: (

a

49) 0-180-530 85 86 13th Floor, Straight Block, Tel: 81-043-299-2309

a

49) 0-180-530 85 85 Tsimshatsui, Kowloon

a

49) 0-180-532 78 32 Hong Kong

a

49) 0-180-532 93 58 Tel: (852) 2737-1600

a

49) 0-180-534 16 80 Fax: (852) 2736-9960

Loading...

Loading...