Page 1

Ordering number : ENN6329

32400RM (OT) No. 6329-1/40

Overview

The LC78628E CMOS IC implements signal processing

and servo control for compact disc players, laser disc

players, CD-V, CD-I, and similar products. It provides

functions for demodulation of the EFM signal from the

optical pickup, deinterleaving, error detection and

correction, and processing servo system commands issued

by the system microprocessor. In addition to this basic CD

functionality, it also provides HDCD (High Definition

Compatible Digital) decoding functions and CD text

functions. It also includes a built-in EFM PLL circuit.

Functions

• Full decoding and playback for discs encoded with the

HDCD technique developed by Pacific Microsonics,

Inc.

• Slices the high-frequency input signal at an accurate

level, converts it into the EFM signal, and generates a

PLL clock with an average frequency of 4.3218 MHz

performing a phase comparison with an internal VCO.

• Accurately generates a reference clock signal and all

necessary internal timings using an external 16.9344MHz crystal.

• Controls the disc motor speed using a frame phase

difference signal created based on the reproduced clock

signal and the reference clock.

• Performs detection, protection, and interpolation for the

frame synchronizing signal to assure stable data readout.

• Demodulates the EFM signal, converting it to 8-bit

symbol data.

• After applying a CRC check to the subcode Q signal,

outputs that data to the control microprocessor using

serial data transfer.

Continued on next page.

Package Dimensions

unit: mm

3174-QIP80E

0.15

1.6

14.0

17.2

0.8

124

25

40

41

64

65

80

21.6

0.8

3.0max

1.0

2.7

15.6

0.8

1.6

0.35

23.2

20.0

0.8 0.8

SANYO: QIP80E

[LC78628E]

LC78628E

SANYO Electric Co.,Ltd. Semiconductor Company

TOKYO OFFICE Tokyo Bldg., 1-10, 1 Chome, Ueno, Taito-ku, TOKYO, 110-8534 JAPAN

Compact Disc Player DSP with Built-in HDCD Decoder

CMOS IC

Any and all SANYO products described or contained herein do not have specifications that can handle

applications that require extremely high levels of reliability, such as life-support systems, aircraft’s

control systems, or other applications whose failure can be reasonably expected to result in serious

physical and/or material damage. Consult with your SANYO representative nearest you before using

any SANYO products described or contained herein in such applications.

SANYO assumes no responsibility for equipment failures that result from using products at values that

exceed, even momentarily, rated values (such as maximum ratings, operating condition ranges, or other

parameters) listed in products specifications of any and all SANYO products described or contained

herein.

HDCD® (High Definition Compatible Digital®) is a registered trademark of Pacific Microsonics, Inc.

in the US and other countries.

A license from Pacific Microsonics, Inc. is required to use this product.

Sanyo Electric Co., Ltd. has acquired license for the use of HDCD technology from Pacific Microsonics, Inc.

The following patents apply to the design of this product:

USA: 5479168, 5638074, 5640161, 5808574, 5838274, 5854600, and 5872531.

Australia: 669114

Other patents have also been applied for.

®

®

Page 2

Continued from preceding page.

• Buffers the demodulated EFM signal data in internal

RAM and compensates for ±4 frames of jitter due to

disc speed fluctuations.

• Performs unscrambling and deinterleaving by reordering

the demodulated EFM signal data to the stipulated order.

• Performs error detection and correction and flag

processing (C1: dual errors, C2: dual errors)

• The C2 flags are set based on the C1 flags and the result

of the C2 processing, and the signal is interpolated or

muted according to the C2 flags. Four-sample

interpolation is adopted in the interpolation circuit.

Linear (average value) interpolation is applied if up to

three consecutive errors are indicated by the C2 flags,

and muting at the zero level is applied if four or more

consecutive errors are indicated.

• Performs track jump, focus start, disc motor start/stop,

muting on/off, track count, and other operations by

executing 8- or 16-bit commands serially input from the

system microprocessor.

• Supports high-speed disc access operations based on

arbitrary track counts.

• Provides digital outputs.

• Built-in Σ∆ D/A converter based on a third-order noise

shaper.

• Zero-cross muting

• Digital attenuator and deemphasis filter

• Support 2 × speed playback

• Bilingual function

• Built-in text decoder

• Five general-purpose I/O ports

Features

• 80-pin QFP package

• Fabricated in a silicon gate CMOS process

• 3.3 and 5 V power supply voltages

No. 6329-2/40

LC78628E

EFMO

VVDDVVSSPDO

ISETFRPCK

TAI

TST11

TEST1

TEST2

TEST3

TEST4

TEST5

VDDVSSV

DD

3V

V

SS

LRSY

C2F

ROMXA

LRCKI

BCKI

DATAI

DOUT

GAIN

HDCD

DFOLO

DACKO

LRCKO

DFORO

RWC

COIN

CQCK

SQOUT

WRQ

CS

TEST6

V/P

Slice level

control

Synchronization

EFM demodulation

CLV

digital servo

Subcode

separation

Q CRC

Microprocessor

interface

Servo

commander

I/O ports

Text

decoder

Crystal oscillator

System timing generator

1-bit DAC

MUX

M

U

X

HDCD

decoder

Interpolation

mute

2k × 8bits

RAM

C1 and C2 error

detection and correction

flag processing

VCO

clock control

RAM address

generator

Bilingual

MUX, S–P

Digital

output

8·Fs HDCD

interpolation

filter

De-emphasis

attenuator

CLV–

CLV+

FSEQ

EFMIN

DEFI

MUTEL

LV

DD

LCHN

LCHP

RV

SS

LV

SS

RCHP

MUTER

RV

DD

XVDDXOUT

XIN

XV

SS

FSX

CK2

4.2M

16M

EFLG

SRDT

DQSY

SCLK

EMPH

P4

P3

P2

P1

P0

TGL

RES

JP+

JP–

TOFF

TES

PCCL

HFL

RCHN

A12795

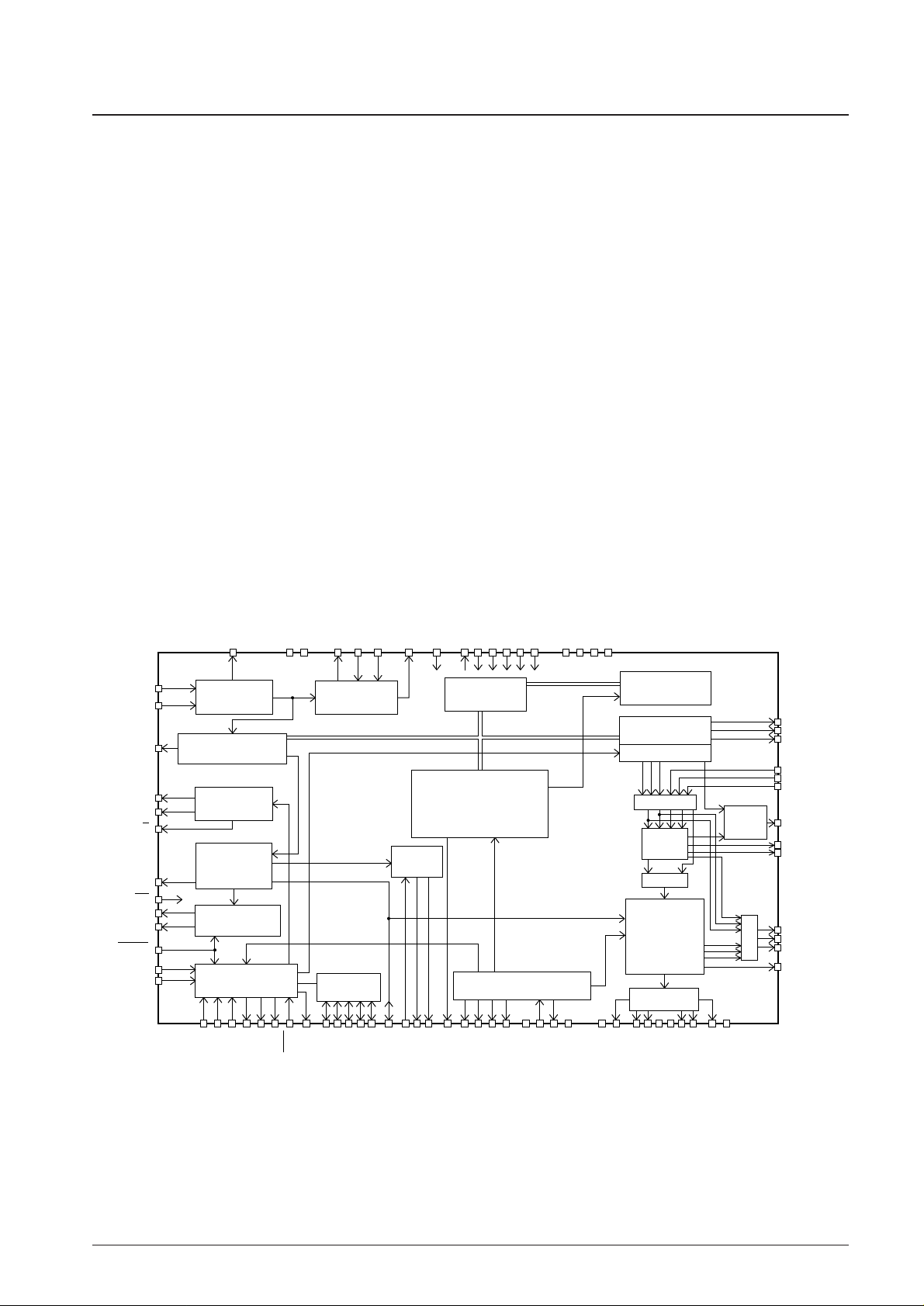

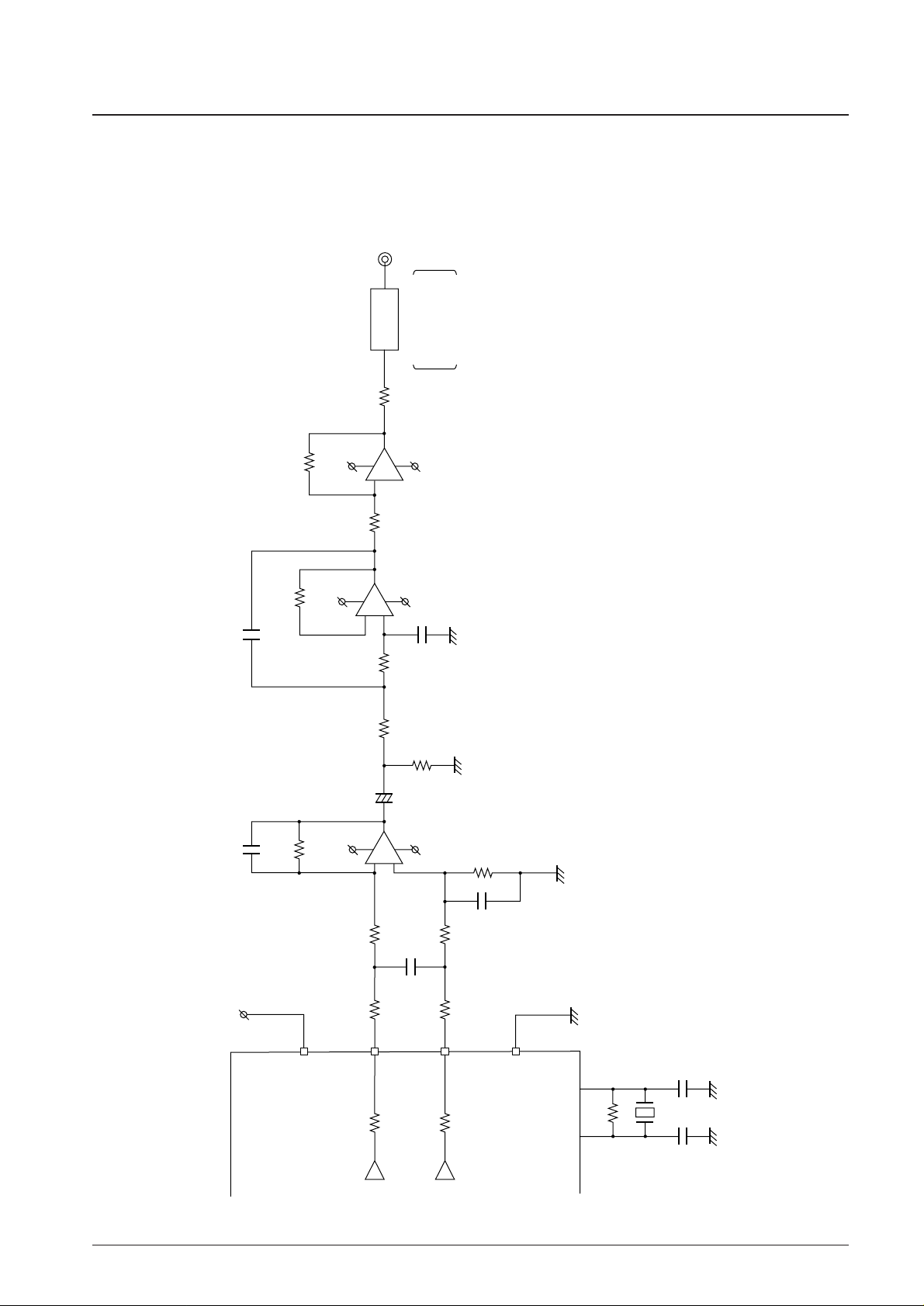

Block Diagram

Page 3

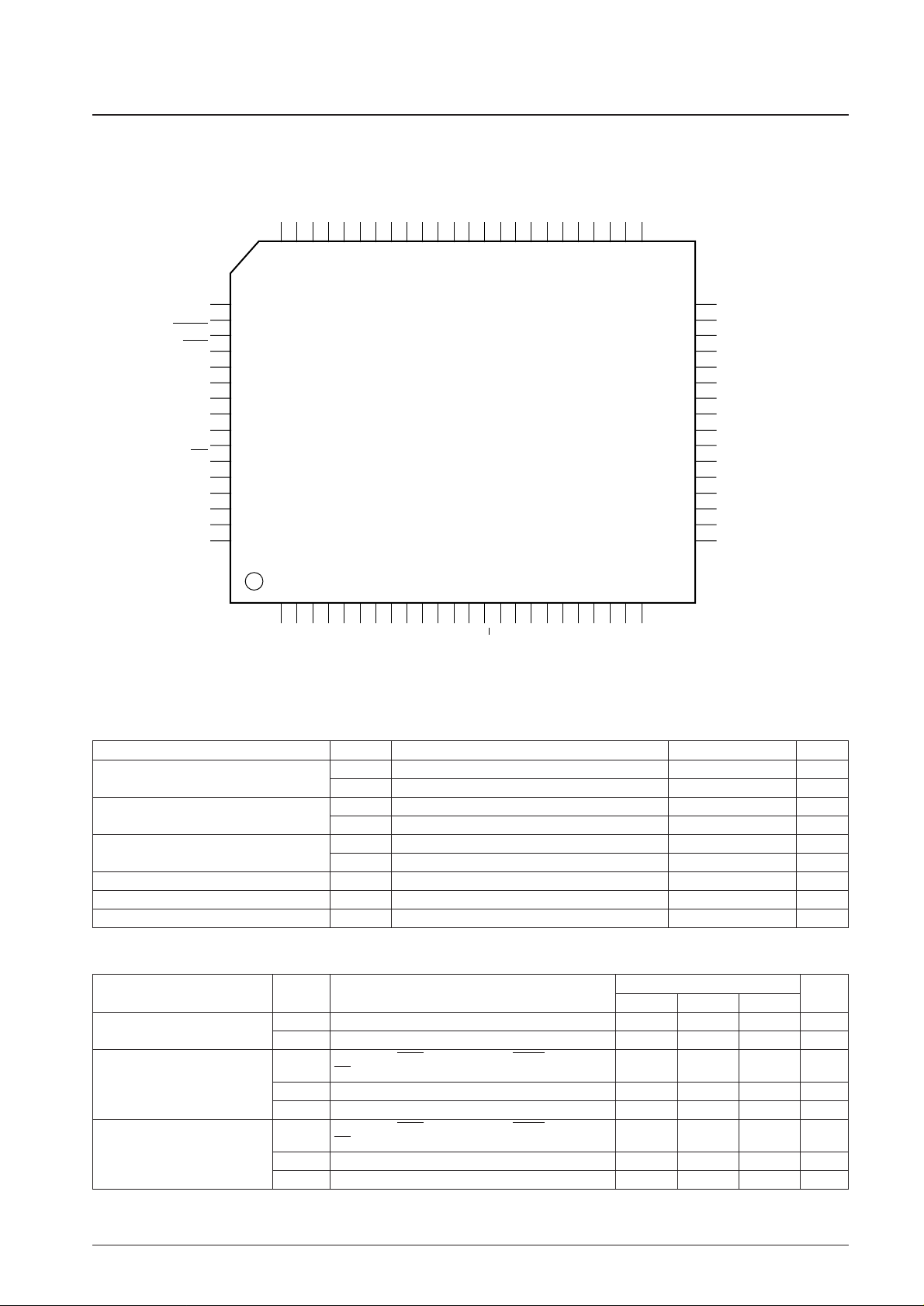

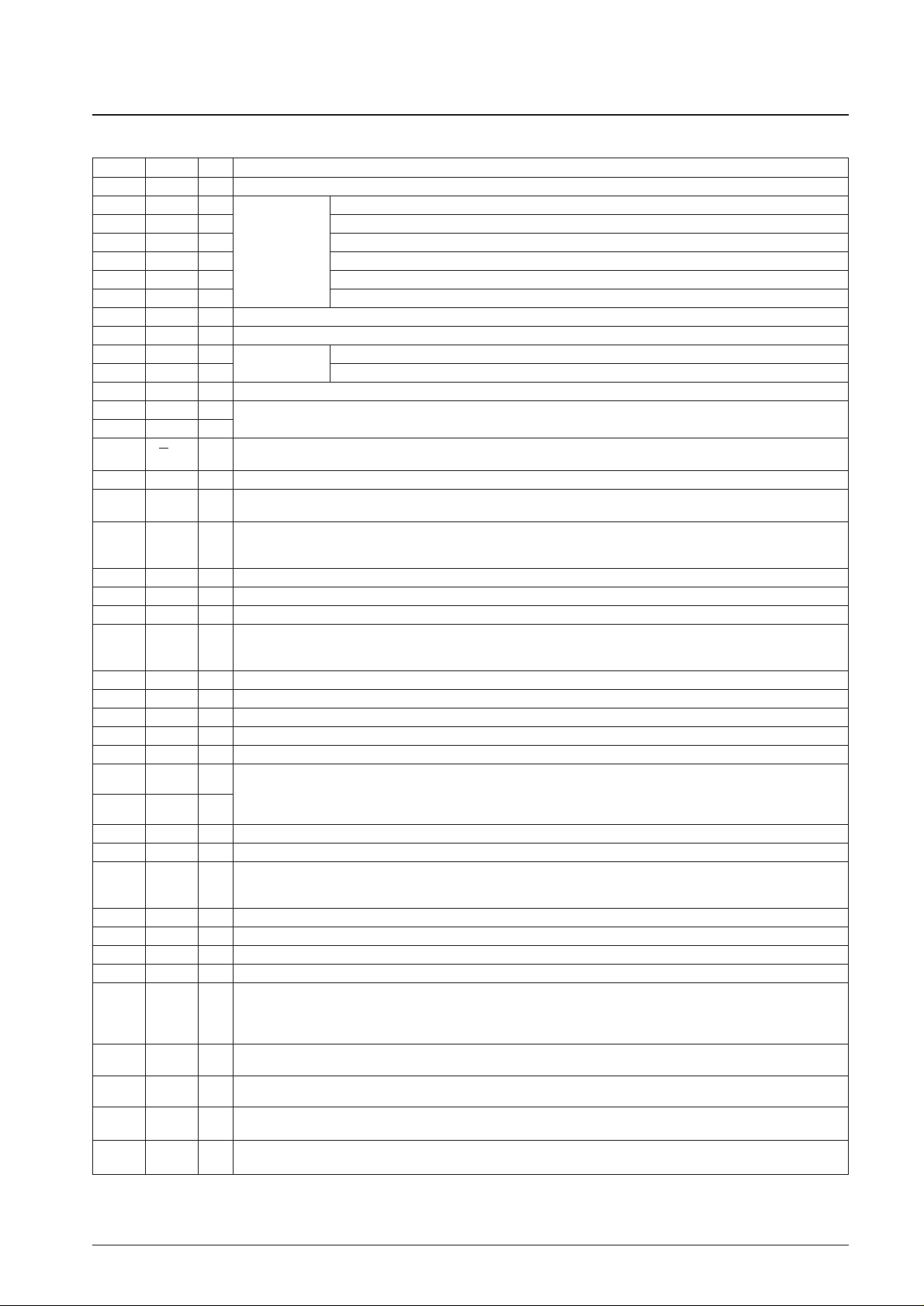

Pin Assignment

No. 6329-3/40

LC78628E

A12796

SQOUT

COIN

CQCK

RES

TST11

SCLK

DQSY

4.2M

LC78628E

SRDT

TEST5

CS

LRSY

CK2

ROMXA

C2F

TEST1

P2

P1

P0

GAIN

DACKO

DFOLO

DFORO

LRCKO

EMPH

TEST4

16M

JP–

JP+

VDD3V

TEST3

HDCD

40

39

38

37

36

35

34

33

32

31

30

29

28

27

26

25

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

RWC64

WRQ63

FSX62

BCKI61

TEST660

DATAI59

EFLG58

LRCKI57

DOUT56

MUTER55

RV

DD

54

RCHP53

RCHN52

RV

SS

51

LV

SS

50

LCHN49

LCHP48

LV

DD

47

MUTEL46

XV

SS

45

XOUT44

XIN43

XV

DD

42

P341

DEFI 1

TAI 2

PDO 3

VV

SS

4

ISET 5

VV

DD

6

FR 7

V

SS

8

V

SS

9

EFMO 10

EFMIN 11

TEST2 12

CLV+ 13

CLV– 14

V/P 15

V

DD

16

P4 17

PCCL 18

HFL 19

TES 20

PCK 21

FSEQ 22

TOFF 23

TGL 24

Parameter Symbol Conditions Ratings Unit

Maximum supply voltage

V

DD

max1 VDD, VVDD, XVDD, LVDD, RV

DD

VSS– 0.3 to VSS+ 6.0 V

V

DD

max2 VDD3V VSS– 0.3 to VSS+ 4.0 V

Input voltage

V

IN

5 max VSS– 0.3 to VDD1 + 0.3 V

V

IN

3 max VSS– 0.3 to VDD2 + 0.3 V

Output voltage

V

OUT

5 max VSS– 0.3 to VDD1 + 0.3 V

V

OUT

3 max VSS– 0.3 to VDD2 + 0.3 V

Allowable power dissipation Pd max 500 mW

Operating temperature Topr –20 to +75 °C

Storage temperature Tstg –40 to +125 °C

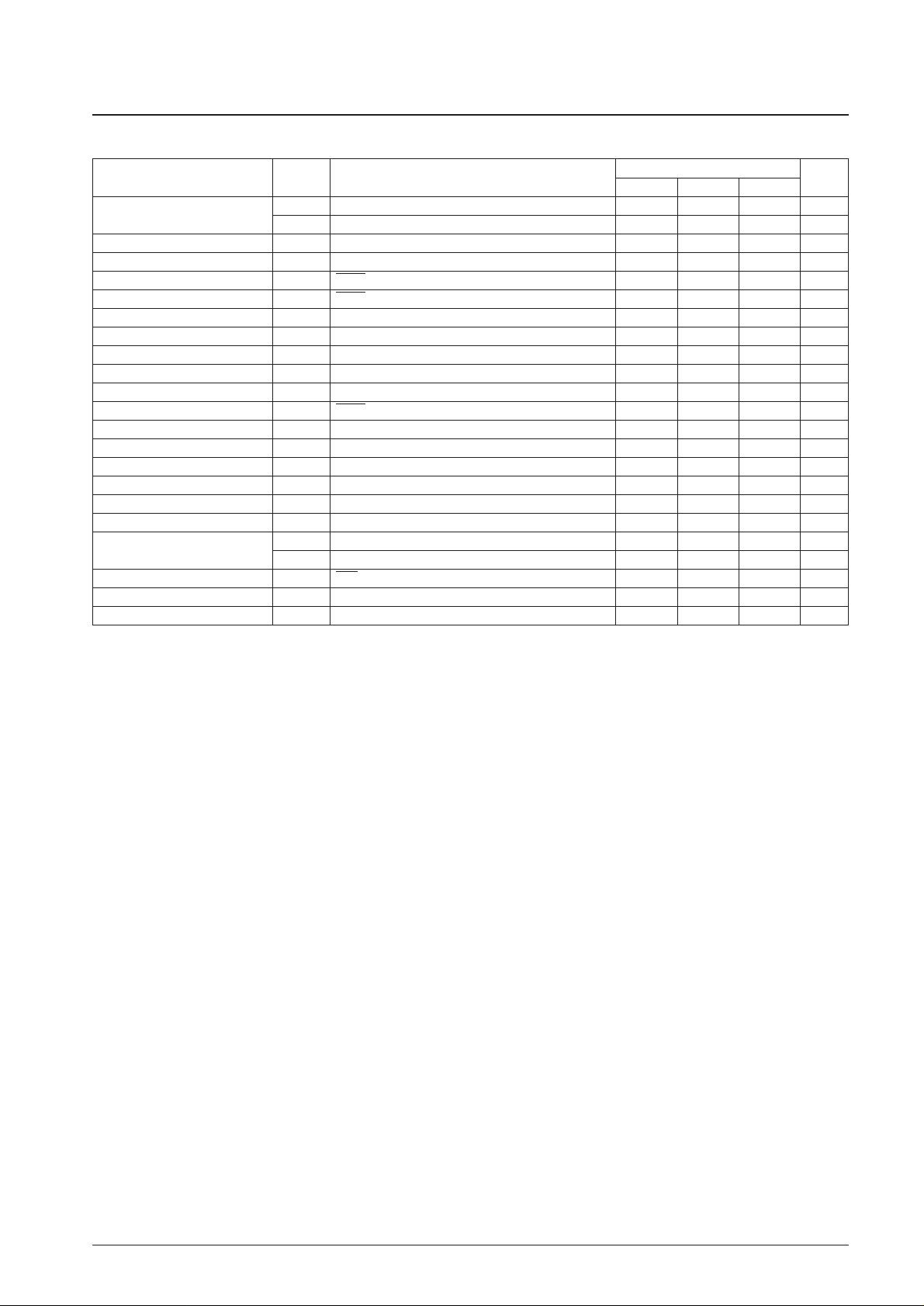

Specifications

Absolute Maximum Ratings at Ta = 25°C, VSS= 0 V

Parameter Symbol Conditions

Ratings

Unit

min typ max

Supply voltage

V

DD

1VDD, VVDD, XVDD, LVDD, RV

DD

4.5 5.0 5.5 V

V

DD

2VDD3V 3.0 3.3 3.6 V

V

IH

1

DEFI, COIN, RES, HFL, TES, RWC, CQCK, TAI, SCLK,

0.8 VDD1V

DD

1V

High-level input voltage

CS, PCCL, LRCKI, BCKI, DATAI

V

IH

2 P0 to P4, TEST1 to TEST5, EMPH 0.7 VDD1V

DD

1V

V

IH

3 EFMIN 0.6 VDD1V

DD

1V

V

IL

1

DEFI, COIN, RES, HFL, TES, RWC, CQCK, TAI, SCLK,

0 0.2 VDD1V

Low-level input voltage

CS, PCCL, LRCKI, BCKI, DATAI

V

IL

2 P0 to P4, TEST1 to TEST5, EMPH 0 0.3 VDD1V

V

IL

3 EFMIN 0 0.4 VDD1V

Allowable Operating Conditions at Ta = 25°C, VSS= 0 V

Continued on next page.

Page 4

No. 6329-4/40

LC78628E

Continued from preceding page.

Notes: The same voltage must be applied to all 5 V system power supply pins.

* When used in conjunction with an ASP that provides a command interface, the stricter ratings of the ASP shall be given priority.

Parameter Symbol Conditions

Ratings

Unit

min typ max

Input level

V

IN

1 EFMIN: Slice level control 1.0 Vp-p

V

IN

2 XIN: Capacitor coupled input 1.0 Vp-p

Data setup time t

SU

COIN, RWC, *: See figure 1. 400 ns

Data hold time t

HD

COIN, RWC, *: See figure 1. 400 ns

High-level clock pulse width t

WH

CQCK, *: See figures 1 and 2. 400 ns

Low-level clock pulse width t

WL

CQCK, *: See figures 1 and 2. 400 ns

Data read access time t

RAC

SQOUT: See figures 2. 0 400 ns

Command output time t

RWC

RWC, *: See figures 1. 1000 ns

Subcode Q readout enable time t

SQE

WRQ, normal speed: See figures 2, RWC = VIL1 11.2 ms

Port input setup time t

CSU

P0 to P4, RWC: See figures 3. 400 ns

Port input hold time t

CHD

P0 to P4, RWC: See figures 3. 400 ns

Port input clock setup time t

RCQ

CQCK, RWC, *: See figures 3. 100 ns

Port output data delay time t

CDD

P0 to P4, RWC: See figure 4. 1200 ns

Text readout period t

CW

DQSY, normal speed: See figure 5. 1.5 3.3 3.7 ms

DQSY pulse width t

W

DQSY, normal speed: See figure 5. 60 136 150 µs

SCLK high-level clock pulse width t

WTH

SCLK: See figure 5. 100 ns

SCLK low-level clock pulse width t

WTL

SCLK: See figure 5. 100 ns

SCLK clock delay time t

D

1 SCLK: See figure 5. 100 ns

Text data delay time

t

D

2 SRDT: See figure 5. 50 ns

t

D

3 SRDT: See figure 5. 50 ns

Reset time t

RES

RES 400 ns

Operating frequency range f

OP

EFMIN 10 MHz

Crystal oscillator frequency f

X

XIN, X

OUT

16.9344 MHz

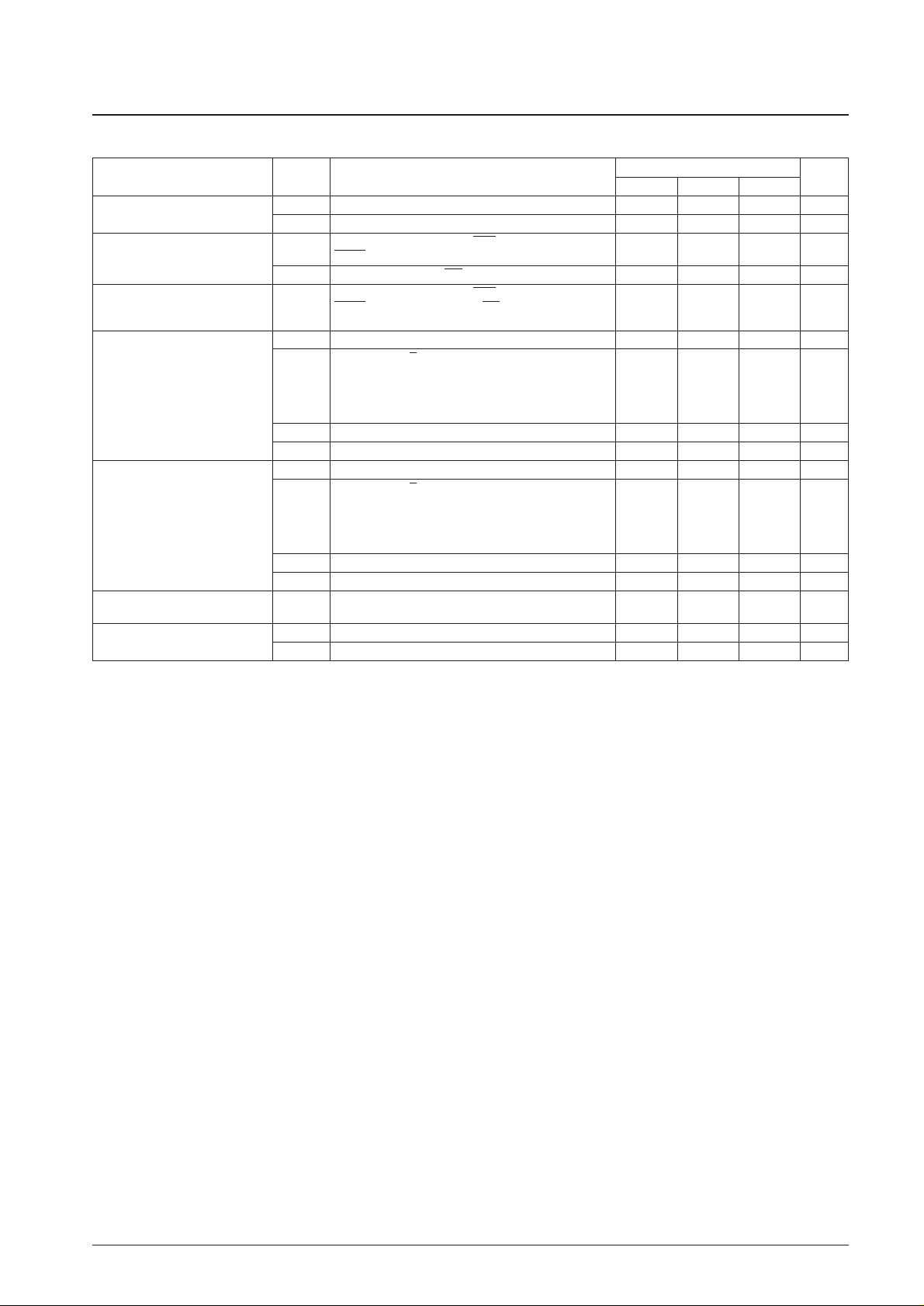

Page 5

No. 6329-5/40

LC78628E

Parameter Symbol Conditions

Ratings

Unit

min typ max

Current drain

I

DD

1VDD, VVDD, XVDD, LVDD, RVDD: 4.5 V to 5.5 V 17 24 mA

I

DD

2VDD3V: 3.0 V to 3.6 V 55 85 mA

I

IH

1

DEFI, EFMIN, SCLK, COIN, RES, HFL, TES, RWC, –10 +10 µA

High-level input current

CQCK, TEST1, LRCKI, BCKI, DATAI, XIN: V

IN

= VDD1

I

IH

2 TAI, TEST2 to TEST5, CS, PCCL: VIN= VDD1 10 200 µA

DEFI, EFMIN, SCLK, COIN, RES, HFL, TES, RWC,

Low-level input current I

IL

CQCK, TAI, TEST1 to TEST5, CS, PCCL, LRCKI, BCKI, –10 +10 µA

DATAI, XIN: V

IN

= 0 V

V

OH

1 EFMO: IOH= –1 mA 4 V

CLV

+

, CLV–, V/P, P0 to P4, PCK, FSEQ, TOFF, TGL,

JP

+

, JP–, 16M, EMPH, LRCKO, DACKO, DFOLO,

V

OH

2 DFORO, GAIN, MUTEL, MUTER, DOUT, EFLG, TEST6, VDD1 – 2.1 V

High-level output voltage FSX, WRQ, SQOUT, TST11, DQSY, 4.2M, SRDT, LRSY,

CK2, ROMXA, C2F: I

OH

= –4 mA

V

OH

3 HDCD: IOH= –12 mA VDD1 – 2.1 V

V

OH

4 LCHP, LCHN, RCHP, RCHN: IOH= –1 mA 3.0 4.5 V

V

OL

1 EFMO: IOL= 1 mA 1V

CLV

+

, CLV–, V/P, P0 to P4, PCK, FSEQ, TOFF, TGL,

JP

+

, JP–, 16M, EMPH, LRCKO, DACKO, DFOLO,

Low-level output voltage

V

OL

2 DFORO, GAIN, MUTEL, MUTER, DOUT, EFLG, TEST6, 0.4 V

FSX, WRQ, SQOUT, TST11, DQSY, 4.2M, SRDT, LRSY,

CK2, ROMXA, C2F: I

OL

= 4 mA

V

OL

3 HDCD: IOL= 12 mA 0.4 V

V

OL

4 LCHP, LCHN, RCHP, RCHN: IOH= 1 mA 0.5 2.0 V

Output off leakage current I

OFF

1

PDO, CLV

+

, CLV–, JP+, JP–, P0 to P4, EMPH, SQOUT,

–10 +10 µA

EFMO: In the high-impedance output state

Charge pump output current

I

PDOH

PDO: R

ISET

= 68 kΩ 64 80 96 µA

I

PDOL

PDO: R

ISET

= 68 kΩ –96 –80 –64 µA

Electrical Characteristics at Ta = 25°C, VDD1 = 5 V, VDD2 = 3.3 V, VSS= 0 V

Page 6

No. 6329-6/40

LC78628E

Parameter Symbol Conditions

Ratings

Unit

min typ max

LCHP, LCHN, RCHP RCHN;

Total harmonic distortion THD + N 1 kHz: 0 dB data input 0.009 0.012 %

With the 20 kHz low-pass filter (internal AD725D) used.

LCHP, LCHN, RCHP, RCHN;

Dynamic range DR

1 kHz: –60 dB data input

83 86 dB

With the 20 kHz low-pass and A filters (internal AD725D)

used.

LCHP, LCHN, RCHP, RCHN;

Signal-to-noise ratio S/N

1 kHz: 0 dB data input

98 103 dB

With the 20 kHz low-pass and A filters (internal AD725D)

used.

LCHP, LCHN, RCHP, RCHN;

Crosstalk (separation) CT 1 kHz: 0 dB data input 96 98 dB

With the 20 kHz low-pass filter (internal AD725D) used.

D/A Converter Block Analog Characteristics at Ta = 25°C, VDD= LVDD= RVDD= XVDD= VVDD= 5 V,

VDD3V = 3.3 V, VSS= LVSS= RVSS= XVSS= VVSS= 0 V.

Figure 1 Command Input

COIN

CQCK

RWC

t

SU

t

SU

t

WL

t

WH

t

HD

t

HD

t

RWC

A12797

Figure 2 Subcode Q Output

t

WH

t

SQE

t

WH

t

WL

WRQ

CQCK

SQOUT

RWC

t

RAC

A12798

Note: Measured in the normal speed playback of the Sanyo 1-bit D/A converter reference circuit.

Page 7

CQCK

RWC

P0 to P4

HDCD

GAIN

SQOUT

4.2M

RWC

t

CDD

P0 to P4

t

RA

P0 P1 P2 P3 P4

HDCD GAIN

t

CHD

t

RCQ

t

CW

t

CSU

t

D2

t

D3

t

D1

t

WTL

t

W

DQSY

SCLK

SRDT

t

WTL

Flag

D0 D1 D2 D127

A12799

A12800

A12801

No. 6329-7/40

LC78628E

Figure 3 General-Purpose Port Input Timing

Figure 4 General-Purpose Port Output Timing

Figure 5 Text Data Output Timing

Page 8

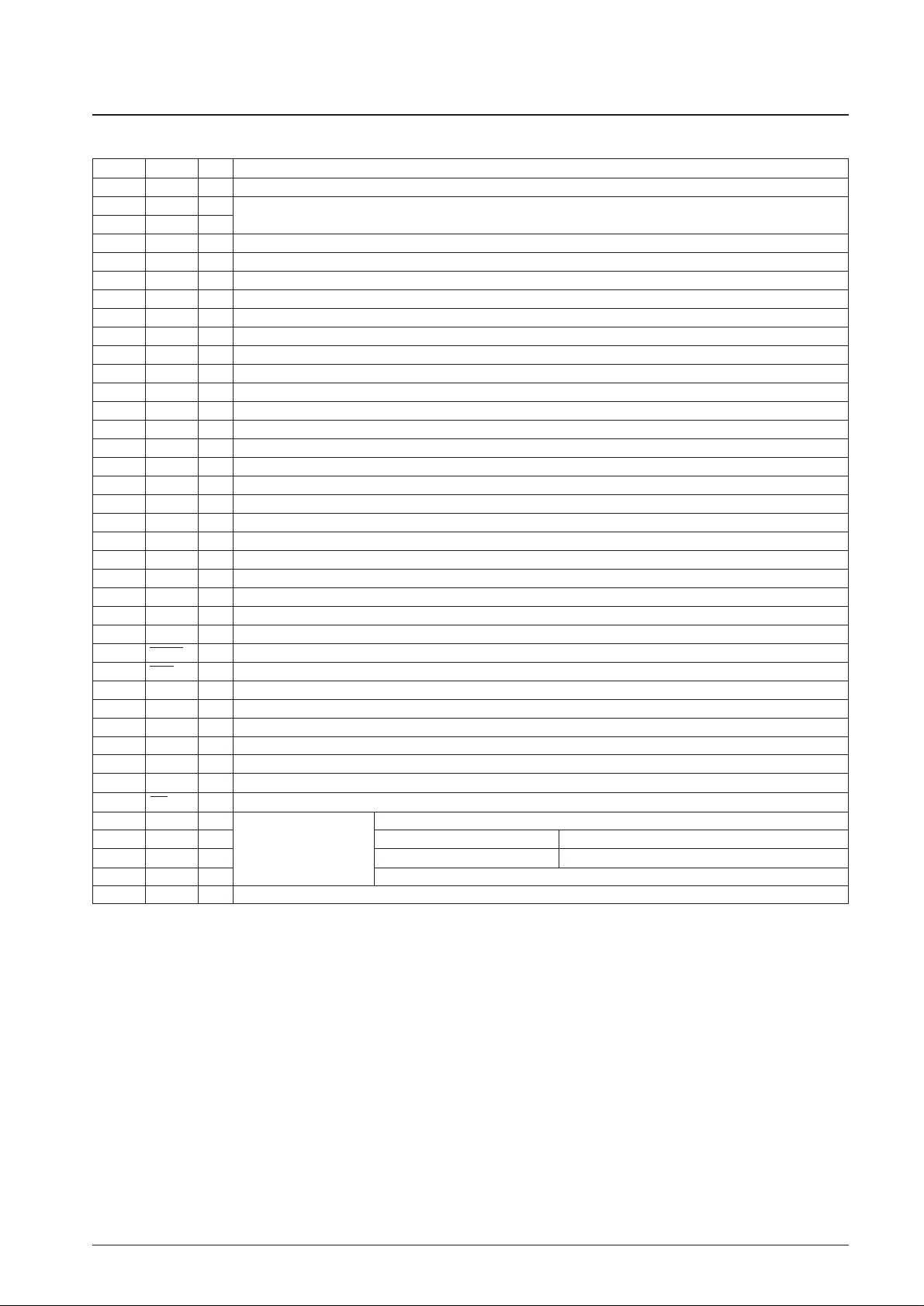

Reference Circuit for the 1-Bit D/A Converter Output Block

No. 6329-8/40

LC78628E

+

–

+

–

+

–

+

LC78628E

LV

DD

(RV

DD

)

LV

SS

(RV

SS

)

XOUT

8pF

X'tal:16.9344MHz

8pF

XIN

1MΩ

1kΩ

1kΩ

8.2kΩ

R1

+5V

+10V

–10V

R2

R3

R4

C1

360pF

C6

1200pF

C3

100pF

8.2kΩ

6.2kΩ

24kΩ

R5

C2

C4 R9

R10

47µF

100pF C5 4700pF

6.2kΩ

1.5kΩ

R8

1.5kΩ

10kΩ

100kΩ

LPF

Internal AD725D

manufactured

by Shibasoku.

LCH

(RCH)

Analog output

R11

R13

R12

OP2

OP1

OP3

13kΩ

+10V

10kΩ

+10V

–10V

–10V

R6

24kΩ

R7

10kΩ

LCHP

(RCHP)

LCHN

(RCHN)

A12802

Page 9

No. 6329-9/40

LC78628E

Pin Functions

Pin No. Pin I/O Function

1 DEFI I Defect detection signal (DEF) input (Must be connected to 0 V if unused.)

2 TAI I Test input. A pull-down resistor is built in. This pin must be connected to 0 V.

3 PDO O External VCO control phase comparator output

4VV

SS

—

PLL-related pins

Internal VCO ground. This pin must be connected to 0 V.

5I

SET

AI PDO output current adjustment resistor connection

6VV

DD

— Internal VCO power supply. 5 V system

7 FR AI VCO frequency range adjustment resistor connection

8V

SS

— Ground. This pin must be connected to 0 V.

9V

SS

— Ground. This pin must be connected to 0 V.

10 EFMO O

Slice level control

EFM signal output

11 EFMIN I EFM signal input

12 TEST2 I Test input. A pull-down resistor is built in. This pin must be connected to 0 V.

13 CLV

+

O

Spindle control servo outputs. CLV

+

outputs a high level for accelerate, and CLV–outputs a high level for decelerate.

14 CLV

–

O

A command is provided to set these pins to three-state output.

15 V/P O

Automatic rough servo/phase control switching monitor output. A high level indicates rough servo and a low level indicates

phase control.

16 V

DD

— 5 V system power supply

17 P4 I/O

General-purpose I/O port. If unused, this port must either be set to input mode and connected to the 0 V level, or be set to

output mode and left open.

General-purpose I/O command identification. A pull-down resistor is built in.

18 PCCL I High: Only general-purpose I/O port commands can be used for control

Low: All commands can be used for control.

19 HFL I Track detection signal input. This is a Schmitt input.

20 TES I Tracking error signal input. This is a Schmitt input.

21 PCK O EFM data reproduction clock monitor output. Outputs 4.3218 MHz when the phase is locked.

Synchronizing signal output.

22 FSEQ O Outputs a high level if the synchronizing signal detected from the EFM signal and the internally generated synchronizing

signal match.

23 TOFF O Tracking off state output

24 TGL O Tracking gain switching output. A low level output raises the gain.

25 HDCD O HDCD identification output. High: An HDCD disc is being played, Low: A normal disc is being played.

26 TEST3 I Test input. A pull-down resistor is built in. This pin must be connected to 0 V.

27 V

DD

3V — 3 V system power supply

28 JP

+

O

Track jump outputs.

JP

+

:

A high level indicates either acceleration during a jump towards outer tracks, or deceleration during a jump towards inner tracks.

29 JP

–

O

JP

–

:

A high level indicates either acceleration during a jump towards inner tracks, or deceleration during a jump towards outer tracks.

A command is provided to set these pins to three-state output.

30 16M O 16.9344 MHz clock output

31 TEST4 I Test input. A pull-down resistor is built in. This pin must be connected to 0 V.

Deemphasis monitor output/input. A high level is output during playback of a deemphasis disc. When external data is applied

32 EMPH I/O to the HDCD filter engine, this pin is used for deemphasis switching. After a reset, this pin goes to monitor output mode in the

high-impedance state.

33 LRCKO O HDCD filter engine output word clock (8fs) or L/R clock output from the HDCD decoder (1fs).

34 DFORO O HDCD filter engine output right channel data (8fs)

35 DFOLO O HDCD filter engine output left channel data (8fs) or L/R data output from the HDCD decoder (1fs).

36 DACKO O HDCD filter engine output bit clock (8fs) or HDCD decoder output bit clock (1fs).

Analog output stage gain indicator

37 GAIN O

In internal gain scaling mode, this pin always outputs a high level (unused). Gain scaling is performed internally. Normal discs

are –6 dB. When external gain scaling is used, peak extend should be turned on when this pin is high, and should be turned

off when this output is low.

38 P0 I/O

General-purpose I/O port. If unused, this port must either be set to input mode and connected to the 0 V level, or be set to

output mode and left open.

39 P1 I/O

General-purpose I/O port. If unused, this port must either be set to input mode and connected to the 0 V level, or be set to

output mode and left open.

40 P2 I/O

General-purpose I/O port. If unused, this port must either be set to input mode and connected to the 0 V level, or be set to

output mode and left open.

41 P3 I/O

General-purpose I/O port. If unused, this port must either be set to input mode and connected to the 0 V level, or be set to

output mode and left open.

Continued on next page.

Page 10

No. 6329-10/40

LC78628E

Continued from preceding page.

Pin No. Pin I/O Function

42 XV

DD

— Crystal oscillator power supply. 5 V system.

43 X

IN

I

Connections for the 16.9344 crystal element and capacitors. Since no feedback resistor is built in, an external feedback

44 X

OUT

O

resistor must be provided.

45 XV

SS

— Crystal oscillator ground. This pin must be connected to 0 V.

46 MUTEL O Left channel audio data mute detection output

47 LV

DD

— Power supply. 5 V system.

48 LCHP O Left channel audio data P output

49 LCHN O Left channel audio data N output

50 LV

SS

—

Ground. This pin must be connected to 0 V.

51 RV

SS

— Ground. This pin must be connected to 0 V.

52 RCHN O Right channel audio data N output

53 RCHP O Right channel audio data P output

54 RV

DD

— Power supply. 5 V system.

55 MUTER O Right channel audio data mute detection output

56 DOUT O Digital output

57 LRCKI I Left/right clock input for external data input to the HDCD filter engine (1fs)

58 EFLG O C1/C2 single/double error correction monitor output

59 DATAI I Data input for external data input to the HDCD filter engine (20 bits)

60 TEST6 O Test output. Outputs the subcode frame sync signal. This pin must be left open when used.

61 BCKI I Bit clock input for external data input to the HDCD filter engine (48fs)

62 FSX O Outputs the 7.35 kHz sync detection signal divided from the crystal oscillator clock.

63 WRQ O Subcode Q output standby (ready) state output

64 RWC I Read/write control input. This is a Schmitt input.

65 SQOUT O Subcode Q output

66 COIN I Input for commands from the microcontroller

67 CQCK I Command input acquisition clock input, or clock input for readout of subcode data from SQOUT. This is a Schmitt input.

68 RES I IC reset input. Applications must apply a low level to this pin after power is first applied.

69 TST11 O Test output. This pin must be left open (it normally outputs a low level).

70 SCLK I Text data shift clock input

71 DQSY O Text data readout permission output

72 4.2M O 4.2336 MHz output

73 SRDT O Text data output

74 TEST5 I Test input. A pull-down resistor is built in. This pin must be connected to 0 V.

75 CS I Chip select input. A pull-down resistor is built in. (This pin must be connected to 0 V when not controlled.)

76 LRSY O Left/right clock output

77 CK2 O

ROMXA support outputs

Bit clock output (at reset) Polarity inverted clock output (in CK2CON mode)

78 ROMXA O Interpolated data output (at reset) ROM data output (in ROMXA mode)

79 CF2 O C2 flag output

80 TEST1 I Test input. There is no built-in pull-down resistor. This pin must be connected to 0 V.

Note: The equal power-supply voltage must be applied to all the 5 V system power supply pins.

Page 11

No. 6329-11/40

LC78628E

Internal Functions

1. HF signal input circuit — Pin 11: EFMIN, pin 10: EFMO, pin 1: DEFI, pin 13: CLV

+

When an HF signal is input to the EFMIN pin, an

EFM signal (NRZ) sliced at the optimal level is

acquired. As a measure to handle defects, when the

DEFI pin (pin 1) goes high, the slice level

controller output from the EFMO pin (pin 10) goes

to the high-impedance state, and the slice level is

held. However, this is only valid when the CLV

circuit is in phase control mode, that is, when the

V/P pin (pin 15) is outputting a low level.

This function can be implemented in combination

with the DEF pin from an LA9230/9240 series

product.

*: If the EFMIN and CLV+lines are run close

together, the error rate may increase due to

spurious radiation. We recommend inserting

either a ground or VDDshield line between these

lines.

2. PLL clock regeneration circuit — Pin 3: PDO, pin 5: ISET, pin 7: FR, pin 21: PCK

The LC78628E includes a built-in VCO circuit,

and a PLL circuit is formed by adding external

resistors and capacitors. The ISET pin sets the

charge pump reference current, PDO sets the VCO

circuit loop filter, and FR sets the VCO frequency

range.

Sample values for reference purposes:

R1 = 68 kΩ, C1 = 0.1 µF

R2 = 680 Ω, C2 = 0.1 µF

R3 = 1.2 kΩ

+

–

SLC

SLI

VREF

1110EFMIN

EFMO

HF signal

A12803

V

DD

R1

C2

R2

R3

C1

5 ISET

EFM(NRZ)

PDO

FR

PCK

VCO 1/N

Charge pump

Frequency

and phase

comparator

3

21

7

A12804

Code Command Frequency divisor RES = low

$AC VCO × 2 SET 1

$AD VCO × 1 SET 2

$AE VCO × 0.5 SET 0.5

●●

The divisor used by the divider to create PCK from the VCO can be set using the VCO × 2, VCO ×1, and VCO × 0.5 SET instructions. Normally, the circuit

operates in the VCO × 0.5 SET state after a reset.

Page 12

3. VCO monitor — Pin 21: PCK

This pin monitors the 4.3218 MHz (on average) signal created by dividing the VCO frequency. In 2 × speed playback

mode, the frequency becomes 8.6436 MHz.

4. Sync detection monitor — Pin 22: FSEQ

When the frame sync (a positive sync signal) read from the EFM signal by PCK and the timing (interpolated sync

signal) generated with a counter match, this pin outputs a high level. Thus this pin functions as a sync detection

monitor. Note that it holds the high level for a single frame.

5. Servo command function — Pin 64: RWC, pin 66: COIN, pin 67: CQCK, pin 18: PCCL

The LC78628E instructions can be executed by setting RWC high and inputting the command to COIN in

synchronization with the CQCK clock. Note that the command is executed starting at the fall of the RWC signal.

Focus start

Track jump

Muting control - - - - - - One-byte commands

Disc motor control

Other control commands

Track check- - - - - - - - - - - - - - - - - - - - - - - - - - - - Two-byte command (RWC set twice)

General-purpose port I/O, E/D settings

Digital attenuator settings - - - - - - Two-byte commands (RWC set once)

HDCD control register settings

No. 6329-12/40

LC78628E

MSBLSB

MSB

LSB

Command ($F0, $F8) Data ($008 to $FE) or command ($FF)

MSB

LSB

RWC

CQCK

COIN

RWC

CQCK

COIN

A12805

A12806

• One-byte commands

• Two-byte command (RWC set twice)

Page 13

No. 6329-13/40

LC78628E

MSB

LSB

Data

Command ($81 to $87, $DB, $DC, $D8)

MSB

LSB

RWC

CQCK

COIN

A12807

• Two-byte commands (RWC set once)

Code Command RES = low

$FE Command input noise reduction mode

$EE Reset command input noise reduction mode ●●

This command reduces noise on the CQCK signal. Although this command is effective for noise pulses of less than 500 ns, the CQCK timing parameters tWL,

t

WH

, and tSUmust all be set to 1µs or longer.

• Command noise reduction

Code Command RES = low

$04 Disc motor start (accelerate)

$05 Disc motor CLV (CLV)

$06 Disc motor brake (decelerate)

$07 Disc motor stop (stop) ●●

The CLV+signal accelerates the disc in the forward direction, while the CLV–signal decelerates the disc. The corresponding mode, accelerate, decelerate,

CLV, or stop, is selected by the command sent from the microcontroller. The table below lists the CLV

+

and CLV–outputs in each of these modes.

6. CLV servo circuit — Pin 13: CLV+, pin 14: CLV–, pin 15: V/P

PCCL input level Command transfer during track check, track jump, and internal motor braking operations

L Incorrect operation occurs if a command is transferred (if a high level is applied to RWC).

H Transfer of only the port related ($DBXX and $DCXX) and HDCD register setting ($D8XX) commands is allowed.

Mode CLV

+

CLV

–

Accelerate H L

Decelerate L H

CLV Pulse output Pulse output

Stop L L

• PCCL

The PCCL control pin is provided to allow the use of certain commands for which command transfer is disabled during

track check, track jump, and internal motor braking operations.

A12808

1413CLV–

CLV+

+

–

+–

Disc motor

M

Note: The CLV servo control commands set the TOFF pin low during CLV mode, and high at all other times. The TOFF pin can only be controlled by

commands during CLV mode.

Page 14

• CLV mode

In CLV mode, the disc rotation is detected from the HF signal, and proper linear velocity rotation is achieved by

changing the DSP internal modes. The basic PWM period corresponds to a frequency of 7.35 kHz. The V/P pin outputs

a high level during rough servo operation and a low level during phase control.

No. 6329-14/40

LC78628E

Internal mode CLV

+

CLV

–

V/P

Rough servo (low-speed rotation recognized) H L H

Rough servo (high-speed rotation recognized) L H H

Phase control (PCK locked) PWM PWM L

Code Command RES = low

$A8 Disc 8 cm Set

$A9 Disc 12 cm Set ●●

The CLV control gain in rough servo mode can be set 8.5 dB lower for 8 cm discs that for 12 cm discs.

• Rough servo gain switching

Code Command RES = low

$B1 CLV phase comparator divided by 2

$B2 CLV phase comparator divided by 4

$B3 CLV phase comparator divided by 8

$B0 CLV No phase comparator division ●●

The phase control gain can be modified by switching the divisor provided by the divider circuit in the front end of the phase comparator.

• Phase control gain switching

13

CLV+

1/N

1/N

Phase

comparator

7.35 kHz

PCK/588

CLV–

14

A12809

CLV+

CLV+

CLV–

CLV–

Acceleration Deceleration

High-impedance output

3-value output

2-value output

A12810

Code Command RES = low

$B4 CLV 3-value output

$B5 CLV 2-value output (earlier technique) ●●

The CLV 3-value output command allows CLV control to be implemented using a single output pin. However, note that since the spindle gain is reduced by

6 dB, the servo side gain must be increased.

• CLV 3-value output

Page 15

No. 6329-15/40

LC78628E

Code Command RES = low

$C5 Internal braking: on

$C4 Internal braking: off ●●

$A3 Internal braking: control

$CB Internal braking continuous mode

$CA Reset continuous mode ●●

$CD Internal braking TON mode

$CC Reset TON mode ●●

• Issuing the internal braking on ($C5) command sets the LC78628E to internal brake mode. In this mode, the disc deceleration state can be monitored from

the WRQ pin when a brake command ($06) is executed.

• In this mode the disc deceleration state is determined by counting the EFM signal density in a single frame, and when the EFM signal count falls under four,

the CLV

–

pin is dropped to low. At the same time the WRQ signal, which functions as a brake completion monitor, goes high. When the microprocessor

detects a high level on the WRQ signal, it should issue a STOP command to fully stop the disc. In internal braking continuous mode, the CLV

–

pin highlevel output braking operation continues even after the WRQ brake completion monitor goes high. Note that if errors occur in deceleration state

determination due to noise in the EFM signal, the problem can be rectified by changing the EFM signal count from four to eight with the internal brake

control command ($A3).

• In internal braking TON mode ($CD), the TOFF pin is held low during internal braking operations. We recommend using this feature, since it is effective at

preventing incorrect detection at the disc mirror surface.

Notes: 1. If focus is lost during the execution of an internal brake command, the pickup must first be refocused and then the internal brake command must be

reissued.

2. Since incorrect state determination is possible depending on the EFM signal playback state (e.g., disc defects, access in progress), we recommend

using these functions in combination with a microprocessor.

• Internal brake modes

WRQ

CLV–

Disc motor

braking ($06)

EFM signal

CLV+

A12811

Code Command RES = low

$22 New track count mode (using the TES/HFL combination) ●●

$23 Previous track count mode (directly counts the TES signal)

The earlier track count function used the TES signal directly as the internal track counter clock.

To reduce counting errors resulting from noise on the rising and falling edges of the TES signal, the new track count function prevents noise induced errors

by using the combination of the TES and HFL signals, and implements a more reliable track count function. However, dirt and scratches on the disc can still

result in HFL signal dropouts that may result in missing track count pulses. Thus care is required when using this function.

7. Track jump — Pin 19: HFL, pin 20: TES, pin 23: TOFF, pin 24: TGL, pin 28: JP+, pin 29: JP

–

• Track counting types

The LC78628E supports the two track count modes listed below.

Page 16

No. 6329-16/40

LC78628E

Code Command RES = low

$A0 Previous Track Jump Mode ●●

$A1 New Track Jump Mode

$11 1 TRACK JUMP IN #1

$12 1 TRACK JUMP IN #2

$31 1 TRACK JUMP IN #3

$52 1 TRACK JUMP IN #4

$10 2 TRACK JUMP IN

$13 4 TRACK JUMP IN

$14 16 TRACK JUMP IN

$30 32 TRACK JUMP IN

$15 64 TRACK JUMP IN

$17 128 TRACK JUMP IN

$19 1 TRACK JUMP OUT #1

$1A 1 TRACK JUMP OUT #2

$39 1 TRACK JUMP OUT #3

$5A 1 TRACK JUMP OUT #4

$18 2 TRACK JUMP OUT

$1B 4 TRACK JUMP OUT

$1C 16 TRACK JUMP OUT

$38 32 TRACK JUMP OUT

$1D 64 TRACK JUMP OUT

$1F 128 TRACK JUMP OUT

$16 256 TRACK CHECK

$0F TOFF

$8F TON ●●

$8C TRACK JUMP BRAKE

$21 JP pulse period TOFF output mode

$20 Reset the JP pulse period TOFF output mode ●●

• Track jump commands

c

ba

JP–(+)

JP+(–)

(Braking period)

(JP pulse width)

TGL

A12812

When the LC78628E receives a track jump instruction as a servo command, it first generates accelerating pulses (period

a) and next generates deceleration pulses (period b). The passage of the braking period (period c) completes the specified

jump. During the braking period, the LC78628E detects the beam slip direction from the TES and HFL inputs. TOFF is

used to cut the components in the TES signal that aggravate slip. The jump destination track is captured by increasing the

servo gain with TGL. In JP pulse period TOFF output mode, TOFF goes high during the period that JP pulses are

generated.

Note: Of the modes related to disc motor control, the TOFF pin goes low only in CLV mode, and will be high during

start, stop, and brake operations. Note that the TOFF pin can be turned on and off independently by microprocessor

issued commands. However, this function is valid only when disc motor control is in CLV mode.

Page 17

No. 6329-17/40

LC78628E

• Track jump modes

The table lists the relationships between acceleration pulses (period a), deceleration pulses (period b), and the braking

period (period c).

Item

Previous track jump mode New track jump mode

abcabc

1 TRACK JUMP IN (OUT) #1 233 µs 233 µs 60 ms 233 µs 233 µs 60 ms

1 TRACK JUMP IN (OUT) #2

0.5 track

233 µs 60 ms

0.5 track The same time

60 ms

jump periods jump periods as a

1 TRACK JUMP IN (OUT) #3

0.5 track

233 µs

This period does 0.5 track The same time This period does

jump periods not exist. jump periods as a not exist.

1 TRACK JUMP IN (OUT) #4

0.5 track

233 µs

60 ms;

TOFF is low

0.5 track The same time 60 ms;

TOFF is low

jump periods

during the C period.

jump periods as a

during the C period.

2 TRACK JUMP IN (OUT) None

1 track The same time

60 ms

jump period as a

4 TRACK JUMP IN (OUT)

2 track

466 µs 60 ms

2 track The same time

60 ms

jump periods jump periods as a

16 TRACK JUMP IN (OUT)

9 track 7 track

60 ms

9 track The same time

60 ms

jump periods jump periods jump periods as a

32 TRACK JUMP IN (OUT)

18 track 14 track

60 ms

18 track 14 track

60 ms

jump periods jump periods jump periods jump periods

64 TRACK JUMP IN (OUT)

36 track 28 track

60 ms

36 track 28 track

60 ms

jump periods jump periods jump periods jump periods

128 TRACK JUMP IN (OUT)

72 track 56 track

60 ms

72 track 56 track

60 ms

jump periods jump periods jump periods jump periods

TOFF goes high during the period TOFF goes high during the period

256 TRACK JUMP IN (OUT)

when 256 tracks are passed over.

60 ms

when 256 tracks are passed over.

60 ms

The a and b period pulses are not The a and b period pulses are not

output. output.

TRACK JUMP BRAKE There are no a and b periods. 60 ms There are no a and b periods. 60 ms

Notes: 1. As indicated in the table, actuator signals are not output during the 256 TRACK CHECK function. This is a mode in which the TES signal is counted

in the tracking loop off state. Therefore, feed motor forwarding is required.

2. The servo command register is automatically reset after one cycle of the track jump sequence (a, b, c) completes.

3. If another track jump command is issued during a track jump operation, the track jump operation is immediately interrupted. Therefore, applications

must not issue a new command during a jump operation. However, port related commands and the HDCD register setting command can be used

by setting the PCCL pin.

4. The 1 TRACK JUMP #3 mode does not have a braking period (the C period). Since brake mode must be generated by an external circuit, care is

required when using this mode.

5. Although there was no braking period (period c) for the 2 TRACK JUMP IN/OUT new track jump mode in the LC78620/21/25 products, in this IC

(the LC78628E) the braking period for this mode has been modified to be 60 ms.

Page 18

No. 6329-18/40

LC78628E

A12813

+

–

HFL

19

24

TGL

23

TOFF

29

JP–

28

T.Coil

JP+

20

Slip detection

High during the braking period

TES

T.E.

(THLD)

TES (when moving out)

TES (when moving in)

HFL

TOFF output

A12814

JP+

JP+

JP–

JP–

Two-value output

Three-value output

High-impedance output

A12815

The THLD signal is generated by the LA9230/40 and the tracking error signal is held during the JP pulse period.

* Tracking brake

• The figure shows the relationships between the TES, HFL, and TOFF signals during the track jump c period. The

TOFF signal is extracted from the HFL signal by TES signal edges. When the HFL signal is high, the pickup is over

the mirror surface, and when low, the pickup is over pits region. Thus braking is applied based on the TOFF signal

being high when the pickup is moving from a mirror region to a pits region and on TOFF being low when the pickup

is moving from a data region to a mirror region in the increased gain state (TGL = low).

Code Command RES = low

$B6 JP three-value output

$B7 JP two-value output (earlier technique) ●●

The JP three value output command allows the track jump operation to be controlled from a single pin. However, the spindle gain is 6 dB lower when this pin

is used, so applications must increase the gain in the servo system.

• JP three-value output

Page 19

No. 6329-19/40

LC78628E

Code Command RES = low

$F0 Track check in

$F8 Track check out

$FF Two-byte command reset ●●

The LC78628E will count exactly one more than the specified number of tracks when the microprocessor sends an arbitrary binary value in the range 8 to

254 after issuing either a track check in or a track check out command.

Notes: 1. When the desired track count has been input in binary, the track check operation is started by the fall of RWC.

2. During a track check operation the TOFF pin goes high and the tracking loop is turned off. Therefore, feed motor forwarding is required.

3. When a track check in/out command is issued the function of the WRQ signal switches from the normal mode subcode Q standby monitor function

to the track check monitor function. This signal goes high when the track check is half completed, and goes low when the check finishes. The

control microprocessor should monitor this signal for a low level to determine when the track check completes.

4. If a two-byte reset command is not issued, the track check operation will repeat. That is, to skip over 20,000 tracks, issue a track check 199

command once, and then count the WRQ signal 100 times. This will check 20,000 tracks.

5. After performing a track check operation, use the brake command to have the pickup lock onto the track.

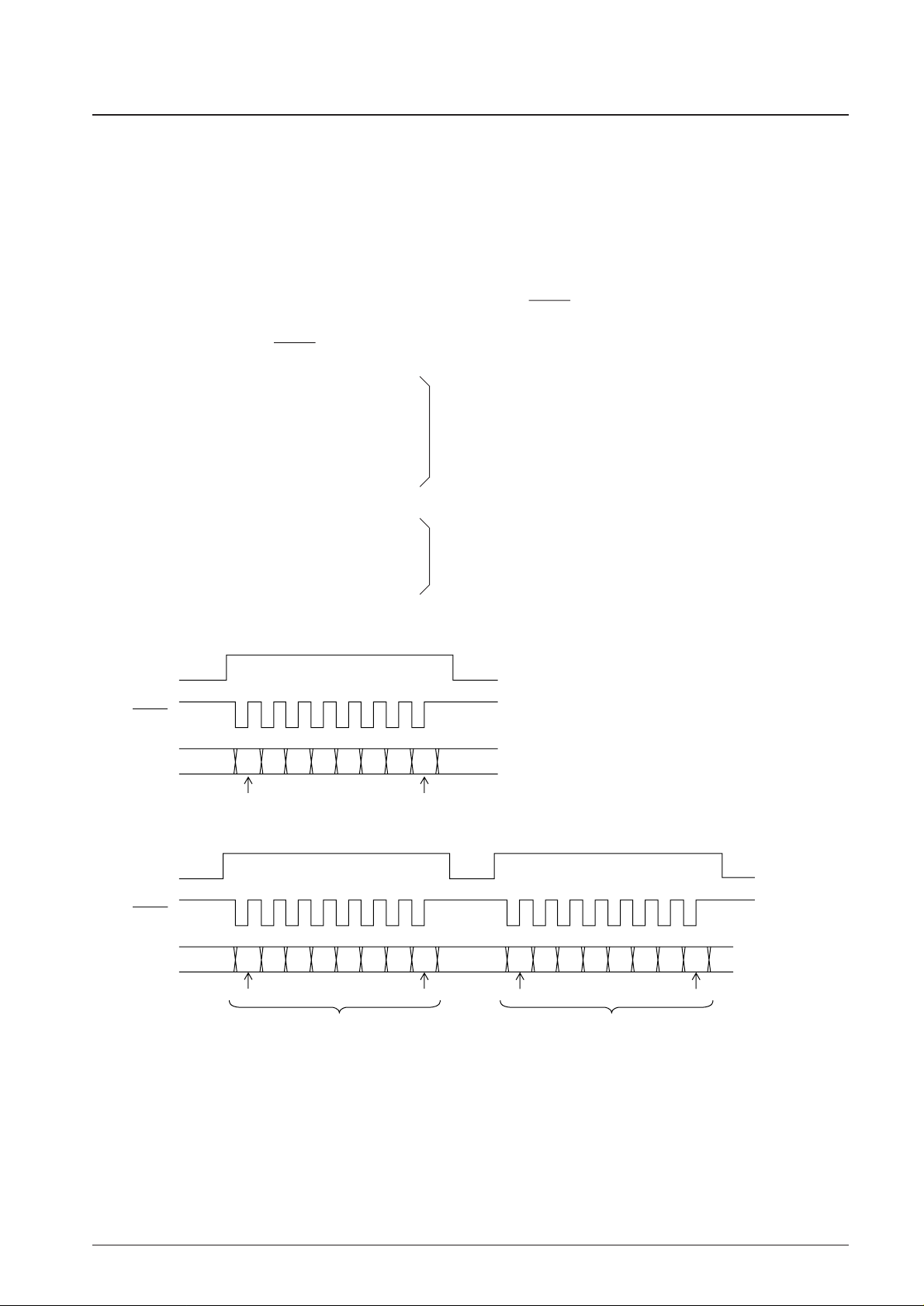

8. Error flag output — Pin 58: EFLG, pin 62: FSX

The FSX signal is a 7.35 kHz frame sync signal generated by dividing the crystal oscillator clock. The error correction

state for each frame is output from EFLG. While FSX is low, EFLG indicates the C1 correction and while FSX is high it

indicates the C2 correction. The playback OK/NG state can be easily determined from the number of high level pulses

that appear here.

The FSX and EFLG pins can be held at the low level by applying an FSX, TEST6, EFLG, LO command ($0A).

Applying an FSX, TEST6, EFLG, EN command ($0B) returns the IC to the original output mode.

• Track check mode

Two-byte command reset

($FF)

Falls to low when the track

check completes.

Rises at 1/2 the specified

track count

Input of the desired

number of tracks

minus 1 in binary

Track check in/out

command

($F0 or $F8)

RWC

WRQ

Track count

Command

Brake command

($8C)

A12816

C1

Single

correction

Double

correction

Correction

not possible

No errors

EFLG

FSX

C2

A12817

Page 20

No. 6329-20/40

LC78628E

Code Command RES = low

$09 ADDRESS FREE

$89 ADRESS = low ●●

Subcode Q can be read from the SQOUT pin by applying a clock to the CQCK pin.

Of the eight bits in the subcode, the Q signal is used for song (track) access and display. WRQ will be high only if the data passed the CRC error check and

the subcode Q format internal address is 1 *. The control microprocessor can read out data from SQOUT in the order shown below by detecting this high

level and applying CQCK. When CQCK is applied the DSP disables register update internally. The microprocessor gives update permission by setting RWC

high briefly after reading has completed. This causes WRQ to fall to low at this time. Since WRQ falls to low 11.2 ms after going high, CQCK must be applied

during the WRQ high period. Note that data is read out LSB first.

Note: * These conditions will be ignored if an address free command is sent. This is provided to handle CD-ROM applications.

9. Subcode Q output circuit — Pin 63: WRQ, pin 64: RWC, pin 65: SQOUT, pin 67: CQCK, pin 75: CS

ADR CONT AFRAME

80 bits

WRQ

CQCK

SQOUT

RWC

SUBQ data

A12818

CONT

TNO

INDEX (POINT)

MIN

SEC Note: Items in parentheses

refer to the read-in area.

FRAME

ZERO

AMIN (PMIN)

ASEC (PSEC)

AFRAME (PFRAME)

ADR

8 bits

Notes: 1. Normally, the WRQ pin indicates the subcode Q standby state. However, it is used for a different monitoring purpose in track check mode and

during internal braking. (See the items on track counting and internal braking for details.)

2. The LC78628E becomes active when the CS pin is low, and subcode Q data is output from the SQOUT pin. When the CS pin is high, the SQOUT

pin goes to the high-impedance state.

Page 21

10. Text circuit

The text function decodes and outputs the song titles and other text data written to the subcode R through W channels

in the compact disc read entry area.

A single pack, which is the subcode R through W data for 24 symbols (18 bytes = 144 (24 × 6 = 18 × 8) bits),

consists of 4 bytes of ID data, 12 bytes of text data, and 2 bytes of CRC data. The data that can be read out from the

LC78628E consists of a result flag for the CRC check (1 bit) and the 16 bytes of the ID and text data. When the IC is

in a state where the data can be read out, it outputs a low-level pulse (minimum: 60 µs, maximum: 150 µs) from the

DQSY pin and outputs, from the SRDT pin, the CRC check result flag (OK: high, NG: low) for the one pack of data

that can be read out. After the control microprocessor detects the low level on the DQSY pin, it can read out the data

serially from the SRDT by applying 128 transfer clock pulses to the SCLK pin. The application must complete the

readout of one pack of data within 3.3 ms in normal-speed playback mode, and within 1.5 ms in 2 × -speed playback

mode. Since the type and other information concerning the following text data is encoded in the ID data, the control

microprocessor must interpret the text data according to the ID data.

No. 6329-21/40

LC78628E

Data for one pack

1 packet = 4 packs

SBSY

DQSY

SCLK

SRDT

DQSY

SCLK

SRDT

CRC D0 D1 D2 D3 D4 D5 D6 D127 D0 D1 D2 D3 D4 D5

D126

••••••••••••••••••••••••••••••••••••

CRC

•••••••••

A12819

: Correct data

: Flagged data

: Linearly interpolated data

: Data converging

to the mute level

A12820

Code Command RES = low

$01 MUTE 0 dB

$02 MUTE –12 dB

$03 MUTE –∞ dB ●●

An attenuation of 12 dB (MUTE –12 dB) or full muting (MUTE –∞ dB) can be applied by issuing the appropriate command from the table. Since zero cross

muting is used, there is minimal noise associated with this function. Zero cross is defined for this function as the top seven bits being all ones or all zeros.

Caution: Note that it may become impossible to detect HDCD discs if either the $02 or $03 instruction is executed.

11. Muting control circuit

12. Interpolation circuit

The output of incorrect audio data that could not be corrected by the error detection and correction circuit would

result in loud noise in the output. To minimize this noise, the LC78628E replaces the incorrect data with linearly

interpolated data based on the correct data on either side of the incorrect data. More precisely, the LC78628E uses

this technique if C2 flags occurred up to three times in a row. If C2 flags occurred four or more times in a row, the

LC78628E converges the output level to the muting level. However, when correct data is finally output following

four or more C2 flag occurrences, the LC78628E replaces the 3 data items between the data actually output at the

fourth preceding item and the correct data with data linearly interpolated between those two values.

Page 22

No. 6329-22/40

LC78628E

Code Command RES = low

$28 STO CONT ●●

$29 Lch CONT

$2A Rch CONT

• Following a reset or when a stereo ($28) command has been issued, the left and right channel data is output to the left and right channels respectively.

• When an Lch set ($29) command is issued, the left and right channels both output the left channel data.

• When an Rch set ($2A) command is issued, the left and right channels both output the right channel data.

• This function applies to the 16-bit data output to the HDCD decoder and ROMXA pin. This means that it may become impossible to recognize HDCD discs

when either the Lch CONT or Rch CONT mode in this function has been set up.

13. Bilingual function

Code Command RES = low

$88 CD-ROMXA

$8B CD-ROM XA reset ●●

$C9 CK2 polarity inversion

14. CD-ROM outputs — Pin 76: LRSY, pin 77: CK2, pin 78: ROMXA, pin 79: C2F

Although the LC78628E is initially set up to output audio data from the interpolation circuit MSB first from the

ROMXA pin in synchronization with the LRSY signal, it can be switched to output CD-ROM data by issuing a CDROMXA command. Since this data has not been processed by the interpolation, muting, and other digital circuits, it

is appropriate for input to a CD-ROM encoder IC. CK2 is a 2.1168 MHz clock, and data is output on the CK2 falling

edge. However, this clock polarity can be inverted by issuing a CK2 polarity inversion command. C2F is the flag

information for the data in 8-bit units.

SPDHDCD ROMXA Data output from the DOUT pin RES = low

0 0 16-bit audio data after interpolation and muting processing ●●

0 1 16-bit data before interpolation and muting processing

10

20-bit audio data following HDCD processing.

11

15. Digital output circuit — Pin 56: DOUT

This output pin is provided for use with a digital audio interface. Data is output in the EIAJ format. The data output

from DOUT can be switched as listed below by the ROMXA flag set by the CD-ROMXA ($88) or CD-ROMXA

reset ($8B) commands and by the SPDHDCD flag in the HDCD control register.

CK2 positive

polarity mode

CK2 inverted

polarity mode

LRSY

ROMXA

0 “0” “0”

151413121110 9 8 7 6 5 4 3 2 1 0 151413121110 9 8 7 6 5 4 3 2 1 0

214847464544434241403938373635343332312625242322212019181716151413121110983214847

214847464544434241403938373635343332312625242322212019181716151413121110983214847

LSB

LRSY = 44.1 kHz (N times disc speed)

CK2 = 2.1168 MHz (N times disc speed)

Rch

MSBLSB

Lch

LSB C2 flags MSB C2 flags LSB C2 flagsMSB C2 flags

MSB

C2F

A12821

Page 23

No. 6329-23/40

LC78628E

Code Command Function RES = low

$42 DOUT ON Enabled state for output of the various data types from DOUT. ●●

$43 DOUT OFF Sets the DOUT output to be fixed at the low level.

$40 UBIT ON Of the DOUT data, the subcodes Q through W are output as the UBIT information. ●●

$41 UBIT OFF Of the DOUT data, the UBIT information is set to all zeros.

$88 CDROM-XA The ROMXA flag is set to 1.

$8B ROMXZ-RST The ROMXA flag is set to 0. ●●

The following table lists the DOUT related commands. See the item on the HDCD control register for details on the

method for setting the SPDHDCD flag.

16. One-bit D/A converter — Pin 48: LCHP, pin 49: LCHN, pin 52: RCHN, pin 53: RCHP, pin 46: MUTEL,

pin 55: MUTER

The LC78628E PWM block outputs a single data value in the range –3 to +3 once every 64 fs period. To reduce

carrier noise, this block adopts an output format in which each data switching block is adjusted so that the PWM

output level does not invert. This block outputs a positive phase signal to the LCHP (RCHP) pin and a reverse phase

signal to the LCHN (RCHN) pin. High-quality analog signals can be acquired by taking the differences of these two

output pairs using external low-pass filters. Note that the LC78628E includes built-in radiation suppression resistors

(1 kΩ) in each of the LCHP/N and RCHP/N pins.

Additionally, if the played back song data (source signal) goes to zero continuously for longer than a certain fixed

period (about 100 ms in normal-speed playback), the IC goes to D/A converter muting mode and outputs zero-valued

data (a 50/50 duty). Since this zero detection function operates independently for the left and right channels, when

zero is detected and muting mode is turned on, a high level is output from either the MUTEL or MUTER pin,

according to the channel in which zero was detected.

PWM output format

–3

+3)

–2

+2

–1

+1

0

0

+1

–1

+2

–2

+3

(–3

LCHP

(RCHP)

One data item

2.8224 MHz(64 fs)

LCHN

(RCHN)

+3

–3)

+2

–2

+1

–1

0

0

–1

+1

–2

+2

–3

(+3

–2–3+3 +1+1–10+2

Data value

LCHP

(RCHP)

LCHN

(RCHN)

A12823

A12822

PWM output example

Page 24

No. 6329-24/40

LC78628E

XDSEL Zero detection D/A converter muting circuit source signal RES = low

0 16-bit data read from the disc ●●

1 Data input from the LRCKI, BCKI, and DATAI pins

The source signal for the zero detection D/A converter muting circuit can be switched as shown below by the XDSEL

flag in the HDCD control register.

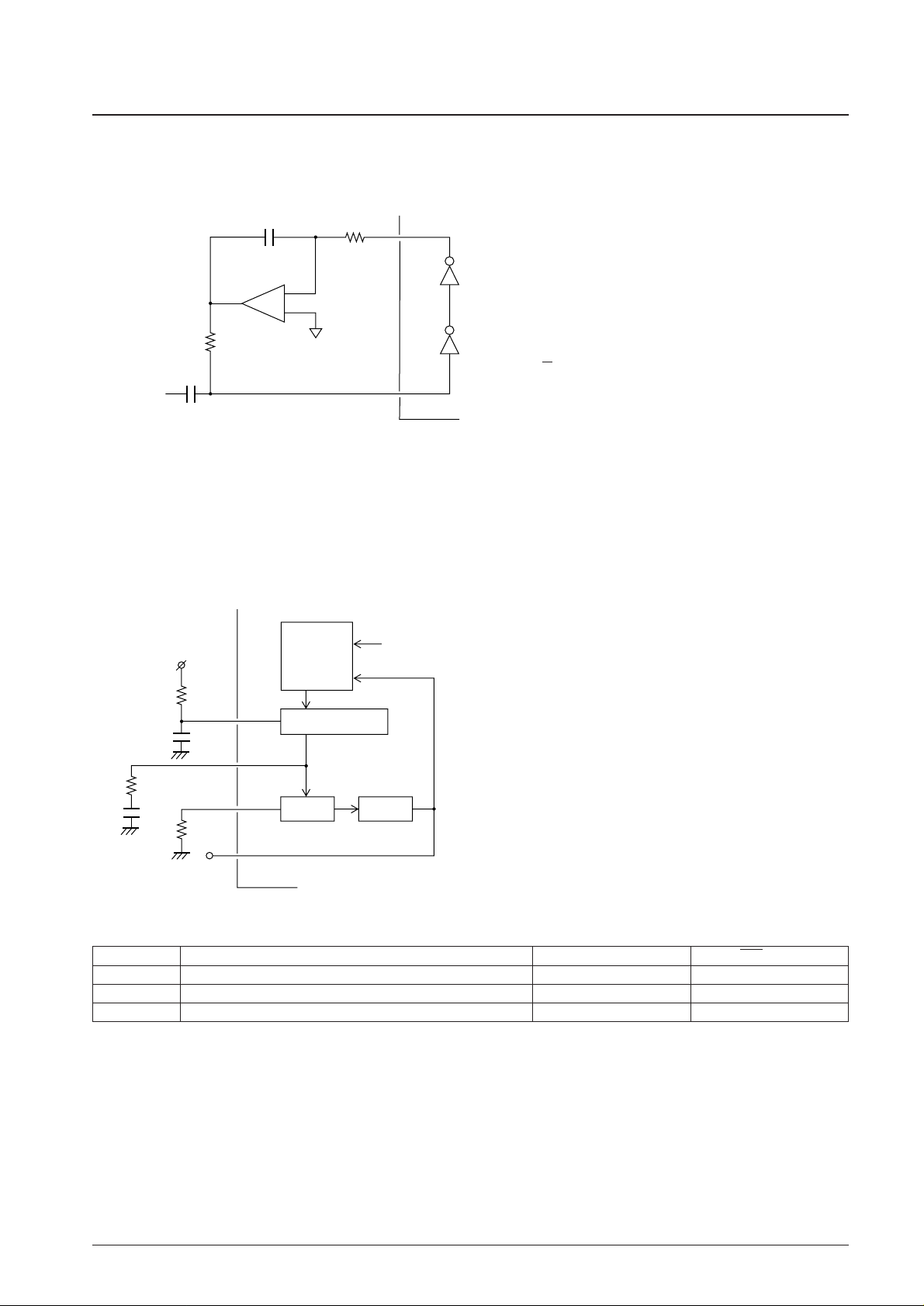

17. HDCD function

• Detailed block diagram of the HDCD function area

• HDCD block functions

— Automatic discrimination of HDCD encoded discs

— PE, GS, and LLE processing (HDCD decoder block)

— HDCD and GAIN signal output

—8 × oversampling HDCD filters, deemphasis, and attenuation (HDCD filter block)

— Output of HDCD decoded signals to the digital interface block

— Output of HDCD decoded signals to LRCKO, DACKO, and DFOLO

— Output of HDCD filtered signals from LRCKO, DACKO, DFOLO, and DFORO

— Output of HDCD filtered signals to the D/A converter block

— HDCD filter block source signal switching

When data with value other than zero is input as a source signal, the mute detection circuit immediately turns off and

the MUTEL or MUTER pin returns to the low level.

EMPH

LRCKI,BCKI,DATAI

MUTER

MUTEL

GAIN

HDCD

RCHP

RCHN

LCHN

LCHP

DAC

HDCD decoder

NS,

PWM

Zero

detection

muting

HDCD filter

attenuator,

8 fs HDCD

Interpolation

filter,

De-emphasis

LRCKO

DACKO

DFOLO

DFORO

DOUT

Digital output

interface

M

U

X

M

U

X

M

U

X

M

U

X

M

U

X

M

U

X

HDCD

detection

Deemphasis

control signal

Interpolation

and

muting

HDCD

control

register

PE,

LLE,

GS

PE: Peak extension

LLE: Low-level extension

GS: Gain scaling

A12824

Page 25

Peak Extension (PE)

HDCD includes a function called peak extension. Peak extension is an optional function that applies a digitally

implemented soft limit (6 dB) to rare peaks in the music signal before recording on the disc. HDCD discs include ones to

which peak extension has been applied, and ones to which peak extension has not been applied. The LC78628E HDCD

decoder block automatically detects this optional peak extension processing and restores the attenuated peaks to their

original shape.

Gain Scaling (GS)

After decoding, recordings to which peak extension was applied have peaks that are 6 dB higher, and the D/A converter

must reproduce these peaks. Therefore, the D/A converter input block average level is reduced by 6 dB. This average

level must be matched to the average level when recordings made without peak extension or non-HDCD recordings are

played back. This average level adjustment is called gain scaling (GS).

The LC78628E allows applications to switch between performing this gain scaling digitally within the IC or externally

using analog circuits. The EXSCA flag in the HDCD control register is used for this setting. The GAIN pin is used as the

control signal if gain scaling is performed in the analog domain.

Low-Level Extension (LLE)

HDCD includes a function called low-level extension. This is a function that compares the average level of a song to a

threshold level and raises that average level (i.e., it compresses the low levels). This is an optional function, and there are

both HDCD recordings that are made with low-level extension, and ones in which it is not used. The LC78628E

automatically recognizes low-level extension discs and returns compressed low levels to their original values.

HDCD Signal Output — Pin 25: HDCD

If the disc being played back was HDCD encoded, the HDCD output pin outputs a high level. At all other times it outputs

a low level. This pin output can be used in end products to provide an LED indicator that indicates when an HDCD disc

is being played. The HDCD signal can also be read by the control microprocessor using the port input instruction.

Gain Signal Output — Pin 37: GAIN

The GAIN pin is used when gain scaling is performed in the analog domain. This pin must be left open if gain scaling is

performed in the digital domain.

When analog gain scaling is used, a high level is output from the GAIN pin to indicate that peak extension processing

had been applied to the disc being played back. A low level is output from the GAIN pin for HDCD discs that did not

have peak extension applied and for non-HDCD discs. For analog domain gain scaling, the application must include an

external circuit that, when the GAIN pin output level is high, increases the output level by 6 dB over the level when the

pin output level is low. The GAIN signal can also be read out using the port input instruction.

Digital Attenuator

The HDCD filter block includes a digital attenuator that allows the attenuation level to be set in 0.5 dB steps with

commands. After a reset, the attenuation level goes to fully muted (the –∞ muted state with an attenuation code of $00).

This means that applications must set the attenuation code to $FF (the maximum setting value) to output the audio signal.

The attenuation code can be set to one of 256 values from $00 to $FF (0.5 dB steps) by applying commands from the

control microprocessor. The setting command is a 2-byte command. This command differs from the 2-byte command

used for track checking, and is the type where 16 bits of command data are transferred consecutively after setting RWC

high. There is no need to send the 2-byte command reset instruction ($FF) after using this command. (See the “Two-byte

commands (RWC set once)” section on page 13.)

No. 6329-25/40

LC78628E

EXSCA Gain scaling type RES = low

0 Digital gain scaling ●●

1 Analog gain scaling

Page 26

No. 6329-26/40

LC78628E

Code Command RES = low

$81xx ATT DIRECT SET DATA $00 SET (ATT –∞dB)

$82xx ATT 4-STEP UP

$83xx ATT 4-STEP DOWN

$84xx ATT 8-STEP UP

$85xx ATT 8-STEP DOWN

$86xx ATT 16-STEP UP

$87xx ATT 16-STEP DOWN

The attenuator STEP UP/DOWN commands ($82xx to $87xx) can be used to gradually change the attenuation level to

the target value in one code step (0.5 dB) at a time every 4, 8, or 16 samples. The target value can be loaded directly by

using the attenuator DIRECT SET command ($81xx).

When the attenuator STEP UP command is used, the target attenuation code must have a larger value than the code set at

that point. When the attenuator STEP DOWN command is used, inversely, the target attenuation code must have a

smaller value than the code set at that point. Also note that when either the attenuator STEP UP or DOWN command is

issued, the next attenuator setting command must not be issued until the preceding STEP UP/DOWN command has

completed, i.e. the circuit has reached the target value.

The following formula can be used to estimate the time required for the attenuation value to reach the target value set by

an attenuator STEP UP/DOWN command.

(target code – current code) × (4, 8, or 16)

———————————————————— [ms]

44.1 kHz (normal speed) or 88.2 kHz (2 × speed)

The attenuator can be set in 0.5 dB steps, and the amount of attenuation can be calculated from the following formula.

attenuation = (data value – 255) × 0.5 [dB]

Note that since this digital attenuator is located after the HDCD detection circuit, it will not affect HDCD discrimination,

no matter what attenuation level is set.

8 × Oversampling HDCD Interpolation Filters

The 20-bit 1 fs data processed in the HDCD decoder block is 8 × oversampled by the 8 × oversampling HDCD

interpolation filters in the HDCD filter block. However, 4 × oversampling is used in double-speed playback.

RWC

Command

LSB MSB

Attenuator setting commandAttenuation code

A12825

LR

Internal fs signal

Four steps down

ATT DATA

Start Stop

44.1 kHz (normal speed), 88.2 kHz (2 × speed)

A12826

Page 27

No. 6329-27/40

LC78628E

Deemphasis Filter — Pin 32: EMPH

The HDCD filter block includes a built-in deemphasis filter so that music that is recorded with preemphasis applied can

be played back with deemphasis. The HDCD filter block can operate with its input taken from either the audio signal

read from a disc or from the audio signal input to the LRCKI, BCKI, and DATAI pins.

The EMPH pin in an I/O pin that provides two functions:

• Monitor output for the preemphasis on/off bit for the audio signal being read out from the disc.

• Input for a signal that controls deemphasis on/off for the audio signal input to the pins.

These functions are switched by the XDSEL and EMPHOEN flags in the HDCD control register as listed below.

HDCD Decoded Signal Output to the Digital Interface Block

The 20-bit data processed by the HDCD decoder can be output as digital data from the DOUT pin. The average level of

the output data will differ depending on the digital/analog setting for the gain scaling mode and the type of the disc being

played back. The values shown in the table are levels relative to the average value of the source signal.

HDCD Decoded Signal Output from LRCKO, DACKO, DFOLO, and DFORO — Pin 33: LRCKO, pin 36: DACKO,

pin 35: DFOLO, pin 34: DFORO

HDCD decoded 1fs 20-bit data can be output digitally from the LRCKO, DACKO, DFOLO, and DFORO pins. The

output data is identical to that output from the DOUT pin.

It is also possible to output post-HDCD decoder processing HDCD processed 8 × oversampled 20-bit data (or 4 ×

oversampled 20-bit data in double-speed mode) from the LRCKO, DACKO, DFOLO, and DFORO pins. This 8 ×

oversampled signal has had internal deemphasis filtering and attenuator processing applied.

The 1FSOUT flag in the HDCD control register is used to switch between the above two types of data output.

The 16-bit data read out from the disc can also be output from the DOUT pin. That switching is controlled by the

SPDHDCD flag in the HDCD control register.

EMPOEN XDSEL EMPH pin state Deemphasis filter control signal source RES = low

0 0 Must be tied either high or low.

The subcode Q preemphasis on/off information

●●

High: on, low: off.

01

The deemphasis on/off signal must be applied. The signal applied to the EMH pin

High: on, low: off. High: on, low: off.

10

Outputs the subcode Q preemphasis on/off information The subcode Q preemphasis on/off information

High: on, low: off. High: on, low: off.

1 1 Do not set this mode. The IC may operate incorrectly.

GS mode Digital scaling Analog scaling

Disc type (EXSCA = 0) (EXSCA = 1)

PE processed HDCD disc –6 dB

When GAIN is low: 0 dB

When GAIN is high: –6 dB

HDCD disc that was not PE processed –6 dB 0 dB

Non-HDCD disc –6 dB 0 dB

SPDHDCD Data output from the DOUT pin RES = low

0 Pre-HDCD decoder processing 1 fs 16-bit data ●●

1 Post-HDCD decoder processing 1 fs 20-bit data

1FSOUT Data output from LRCKO, DACKO, DFOLO, and DFORO RES = low

0 Post-HDCD filter processing 8 fs data ●●

1 Pre-HDCD filter processing 1 fs data

Page 28

No. 6329-28/40

LC78628E

XDSEL DIN16 Input source signal to the HDCD filter block RES = low

00

HDCD decoder block 20-bit output data

●●

01

1 0 20-bit data input to the LRCKI, BCKI, DATAI, and EMPH pins

1 1 16-bit data input to the LRCKI, BCKI, DATAI, and EMPH pins

• Timing when 1FSOUT is 0

• Timing when 1FSOUT is 1

HDCD Filter Processed Signal Output to the D/A Converter Block

The 8 × oversampled data (4 × oversampled in double-speed playback) processed by the HDCD filter block is transferred

to the internal D/A converter block, converted to PWM data, and output from the LCHP, LCHN, RCHN, and RCHP pins.

This 8 × oversampling filter output signal has had internal deemphasis filtering and attenuator processing applied.

HDCD Filter Block Source Switching — Pin 57: LRCKI, pin 61: BCKI, pin 59: DATAI, pins 32: EMPH

The signal to be processed in the HDCD filter block can be set to be either the 20-bit data from the HDCD decoder block

or external data with the XDSETL flag in the HDCD control register. If data input from outside the IC is selected as the

HDCD filter block source signal, the bit length of that data (i.e. the serial input format) can be switched as shown in the

table below using the DIN16 flag in the HDCD control register.

LRCKO

LSB

DFOLO

DFORO

DACKO

2 1

LSB

2 1

LRCKO

LSB MSB

DFOLO

1716151413121110 9 8 7 6 5 4 3 2 1

18

1/352.8 kHz

MSB

18 17 16 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1

MSB

181716151413121110987654321

Normal speed: 1/44.1 kHz, 2 × speed: 1/88.2 kHz

LSB

MSB

18171615 1314 121110 9 8 7 6 5 4 3 2 1

LSB

LSB

MSB

MSB

A12827

LSB

DFORO

DACKO

Lch

Rch

A12828

Page 29

No. 6329-29/40

LC78628E

Normal speed: 1/44.1 kHz, 2 × speed: 1/88.2 kHz

Rch

18

LSB MSB

1716151413121110 9 8 7 6 5 4 3 2 1

LSB

MSB

18171615 1314 121110 9 8 7 6 5 4 3 2 1

LSB

Lch

DATAI

LRCKI

BCKI

A12829

Normal speed: 1/44.1 kHz, 2 × speed: 1/88.2 kHz

Rch

LSB

151413121110 9 8 7 6 5 4 3 2 1

LSB

MSB

1314 121110 9 8 7 6 5 4 3 2 1

LSB

Lch

DATAI

LRCKI

BCKI

A12830

01234567COIN

CQCK

RWC

A12831

• Timing when 20-bit data is input to IC pins

• Timing when 16-bit data is input to IC pins

• Use 20-bit input mode when inputting, to the LRCKI, BCKI, and DATAI pins, post-HDCD decoding 20-bit data that

was recorded on MD and using this IC’s internal D/A converter for playback.

• When the HDCD filter block input source is set to pin input by setting XDSEL flag to 1, do not set the IC to CD

playback state. In this case, if gain scaling is set to analog gain scaling mode, the GAIN pin will output a low level,

and if set to digital gain scaling mode, it will output a high level.

• Clocks applied to the LRCKI and BCKI pins must be synchronized with the LC78628E’s system clock.

HDCD Control Register (CRHDCD)

The HDCD control register consists of 6 flags used for setting the modes associated with HDCD operations. This section

presents the method for setting this register and the meanings of the flags.

• Setting procedure

The HDCD control register is set using the following 2-byte command.

Instruction code: $D8xx (2-byte command)

Here, xx corresponds to the flags in CRHDCD, and bits transferred as a high level are set to 1.

Page 30

No. 6329-30/40

LC78628E

• Flag bit allocation in the register

Flag Function After a reset

EXSCA

0 The 6 dB gain scaling operation is performed internally. ●●

(bit 0)

1 The 6 dB gain scaling operation is performed externally. The GAIN output pin is used.

XDSEL

0 Data from the HDCD decoder block is applied to the HDCD filter block. ●●

(bit 1)

1 Data input from the LRCKI, BCKI, and DATAI pins is applied to the HDCD filter block.

1FSOUT

0 Data from the HDCD filter block is output from the LRCKO, DACKO, DFOLO, and DFORO pins. (8 fs) ●●

(bit 2)

1 Data from the HDCD decoder block is output from the LRCKO, DACKO, DFOLO, and DFORO pins. (1 fs)

Reserved

— This flag must always be set to 0. —

(bit 3)

SPDHDCD

0 Pre-HDCD processing 16-bit data read out from the disc is output from the DOUT pin. ●●

(bit 4)

1 The 20-bit data from the HDCD decode block is output from the DOUT pin.

Reserved

— This flag must always be set to 0. —

(bit 5)

DIN16

0 The data input to the DATAI pin has a bit length of 20 bits. ●●

(bit 6)

1 The data input to the DATAI pin has a bit length of 16 bits.

EMPHONEN

0 The EMPH pin output is disabled (high impedance). ●●

(bit 7)

1 The EMPH pin output is enabled (monitor data is output).

18. General-purpose I/O ports — Pin 38: P0, pin 39: P1, pin 40: P2, pin 41: P3, pin 17: P4, pin 18: PCCL

The LC78628E provides 5 I/O ports. These are set to input mode after a reset. Unused I/O port pins must either be set

to input mode and conntected to ground or set to output mode and left open.

Applications can use the PORT READ command to read out the port information, the HDCD signal and the GAIN signal

in the order P0 to P4, HDCD, GAIN from the SQOUT pin in synchronization with the falling edge of the CQCK signal.

This command has a 1-byte command format.

Only those commands related to the general-purpose ports and the HDCD control register can be used during track

check, track jump, and internal motor braking operations by setting the PCCL pin. To use these commands during a track

check or other operation, the application must set the PCCL pin high. (When the PCCL pin is high, the LC78628E will

not accept commands other than those mentioned above.) The application must set the PCCL pin low before applying

any other command. However, note that if commands are applied during a track check or other operation when the PCCL

pin is low, that operation will be interrupted. These high and low levels must be applied to the PCCL pin when the RWC

pin is at the low level.

Code Command RES = low

$DD PORT READ

$DB PORT I/O SET PORT I SET

$DC PORT OUTPUT SET

RWC

CQCK

MSBLSB

COIN

10111011

SQOUT

P0 P1 P2 P3 P4

HDCD

GAIN

A12832

Page 31

Another point here is that these pins can be independently set to be used as control output pins with the PORT I/O set

command. The ports are selected with the lower 5 bits of the one byte of data. The one byte of data corresponds to

P0, P1, P2, P3, and P4 starting with the low order bit. This command has the two-byte command format (RWC set

once).

dn = 1 ... Sets Pn to be an output pin.

dn = 0 ... Sets Pn to be an input pin.

n = 0 to 4

No. 6329-31/40

LC78628E

One data byte + $DB PORT I/O SET

Ports set up to be output pins can independently output either a high or low level. The low order 5 bits of the one byte

of data correspond to those ports. The one byte of data corresponds to P0, P1, P2, P3, and P4 starting with the low

order bit. This command has the two-byte command format (RWC set once).

dn = 1 ... Outputs a high level from Pn, which is set up for output.

dn = 0 ... Outputs a low level from Pn, which is set up for output.

n = 0 to 4

One data byte + $DC PORT OUTPUT SET

19. Clock oscillator — Pin 43: XIN, pin 4: XOUT

20. 16M and 4.2M pins — Pin 30: 16M, pin 72: 4.2M

The 16M pin outputs the 16.9344 MHz clock which is output of the buffer for the 16.9344 MHz crystal oscillator.

The 4.2M pin outputs a 4.2336 MHz clock signal which can be used as the system clock for an LA9230/40 Series IC.

When the oscillator is turned off both these pins will be fixed at either high or low.

The clock that is used as the time base is generated by connecting a 16.9344

MHz oscillator element between these pins. The OSC OFF command turns

off both the VCO and crystal oscillators.

When implementing a system that supports double-speed playback, the

playback speed is set with either the double-speed playback command or

the normal speed playback command.

Recommended oscillator element: CSA-309 (Citizen Watch Co., Ltd.)

SCA16.93MXZ040 (Toyama Murata Mfg. Co., Ltd.)

The oscillator circuit should be located as close as possible to the IC. We

recommend evaluating oscillator performance on the printed circuit board

actually used to determine the values of the resistor (Rf) and capacitors (C)

used.

Code Command RES = low

$8E OSC ON ●●

$8D OSC OFF

$CE XTAL 16M ●●

$C2 Normal-speed playback ●●

$C1 Double-speed playback

XIN

Oscillator

element

XOUT

Rf

4443

CC

A12833

Page 32

21. Reset circuit — Pin 68: RES

When power is first applied, this pin should be briefly set low and then set high. This will set the muting to –∞ dB

and stop the disc motor.

22. Other pins — Pin 2:TAI, pin 80: TEST1, pin 12: TEST2, pin 26: TEST3, pin 31: TEST4, pin 74: TEST5, pin 69:

TST11, pin 60: TEST6

These pins are used for testing the IC’s internal circuits. The TAI and TEST1 to TEST5 pins must be connected to

ground (0 V). TST11 is an output pin, and should be left open in normal applications. TST11 normally outputs a low

level. TEST6 is an output pin, and should be left open in normal applications. TEST6 outputs a low level after an

FSX, TEST6, or EFLG LO instruction ($0A) has been applied.

23. Circuit Block Operating Descriptions

• RAM address control