Page 1

INTELLIGENT QUAD (2X5A/2X2.5A) LOW-SIDE SWITCH

■

Quad low-side switch

■

2 x 5A designed as conventional switch

■

2 x 2.5A designed as switched current-regulator

■

Low ON-resistance 2 x 0.2Ω, 2 x 0.35Ω (typ.)

■

Power SO-36 - package with integrated

cooling area

■

Integrated free-wheeling and clamping Z-diodes

■

Output slope control

■

Short circuit protection

■

Selective overtemperature shutdown

■

Open load detection

■

Ground and supply loss detection

■

External clock control

■

Recirculation control

■

Regulator drift detection

■

Regulator error control

■

Regulator resolution 5mA

■

Status monitoring

■

Status push-pull stages

■

Electrostatic discharge (ESD) protection

L9347

PowerSO-36 BARE DIE

ORDERING NUMB ERS :

L9347PD L9347DIE1

DESCRIPTION

The L9347 is an integrated quad low-side power

switch to drive inductive loads like valves used in

ABS systems. Two of the four channels are current

regulators with current range from 250mA to 2.25A

and an accuracy of 10%.

All channels are protected against fail functions.

They are monitored by a status output.

Figure 1. Pin Connection

99AT0060

June 2002

GND 1

PGND3

PGND3

Q3

Q3

D3

D3

Q1

Q1

Q2

Q2

D4

D4

Q4

Q4

PGND4

PGND4

N.C.

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

36

35

34

33

32

31

30

29

28

27

26

25

24

23

22

21

20

19

CLK

ST3

IN1

IN3

ST1

PGND1

PGND1

VS

PGND2

PGND2

TEST

EN

ST2

IN4

IN2

ST4

VDD

VCC

1/21

Page 2

L9347

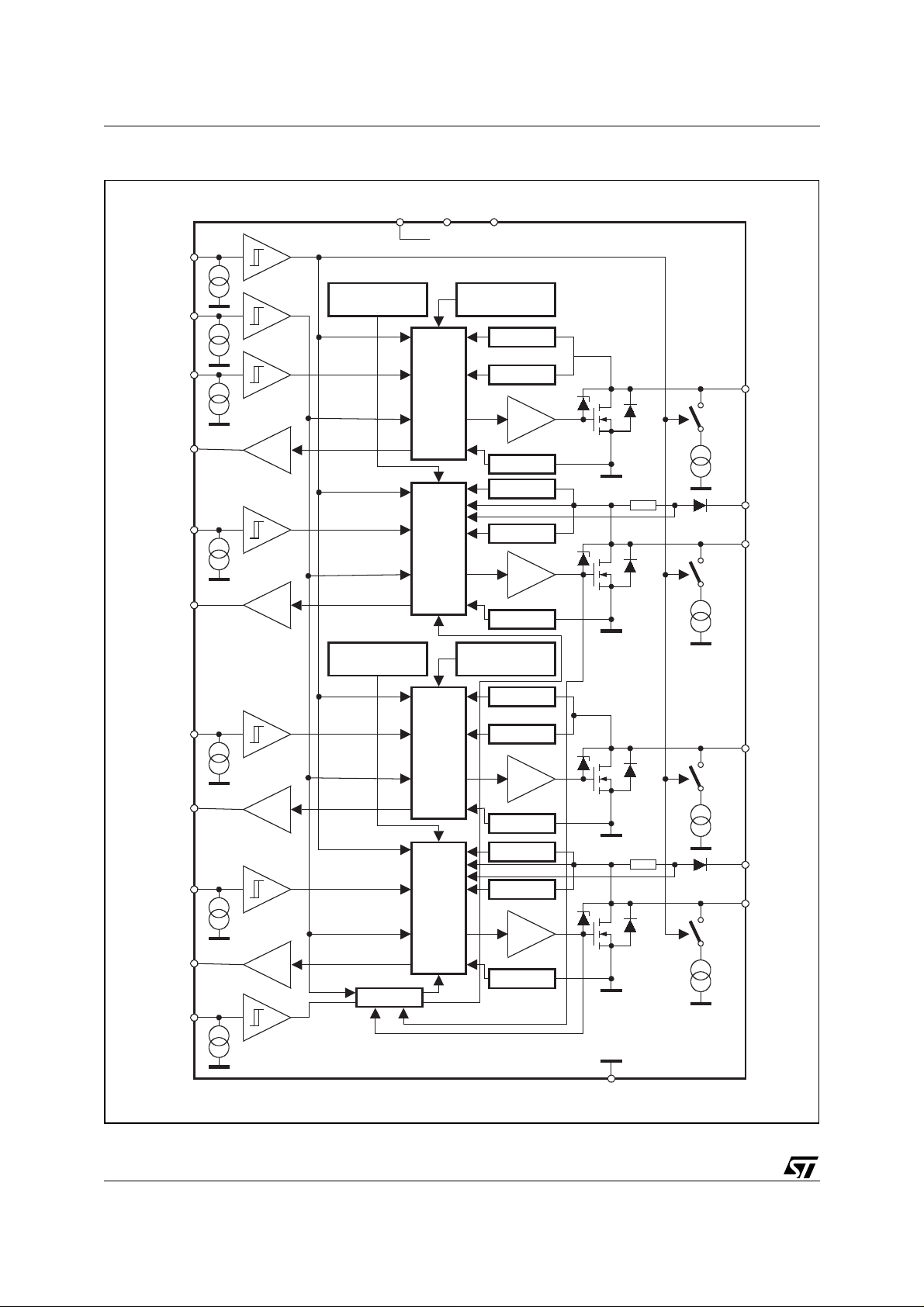

Figure 2. Block Diagram

EN

VS VCC VDD

Internal Supply

CLK

IN1

ST1

IN4

ST4

IN2

Overtemperature

Channel 4

Overtemperature

Channel 3

LOGIC

LOGIC

&

DA

LOGIC

Overtemperature

Channel 1

Open Load

Overload

GND-det.

Open Load

Overload

GND-det.

Overtemperature

Channel 2

Open Load

Overload

Q1

IPD

D4

Q4

IPD

Q2

2/21

ST2

IN3

ST3

TEST

99AT0059

drift-det.

LOGIC

&

DA

GND-det.

Open Load

Overload

GND-det.

IPD

D3

Q3

IPD

GND

Page 3

PIN DESCRIPTION

N° Pin Function

1 GND Logic Ground

2, 3 PGND 3 Power Ground Channel 3

4, 5 Q 3 Power Output Channel 3

6, 7 D 3 Free-Wheeling Diode Channel 3

8, 9 Q 1 Power Output Channel 1

10, 11 Q 2 Power Output Channel 2

12, 13 D 4 Free-Wheeling Diode Channel 4

14, 15 Q 4 Power Output Channel 4

16, 17 PGND 4 Power Ground Channel 4

18 NC Not Connected

19 VCC 5V Supply

20 VDD 5V Supply

L9347

21 ST 4 Status Output Channel 4

22 IN 2 Control Input Channel 2

23 IN 4 Control Input Channel 4

24 ST 2 Status Output Channel 2

25 EN Enable Input for all four Channels

26 TEST Enable Input for Drift detection

27, 28 PGND 2 Power Ground Channel 2

29 VS Supply Voltage

30, 31 PGND 1 Power Ground Channel 1

32 ST 1 Status Output Channel 1

33 IN 3 Control Input Channel 3

34 IN 1 Control Input Channel 1

35 ST 3 Status Output Channel 3

36 CLK Clock Input

3/21

Page 4

L9347

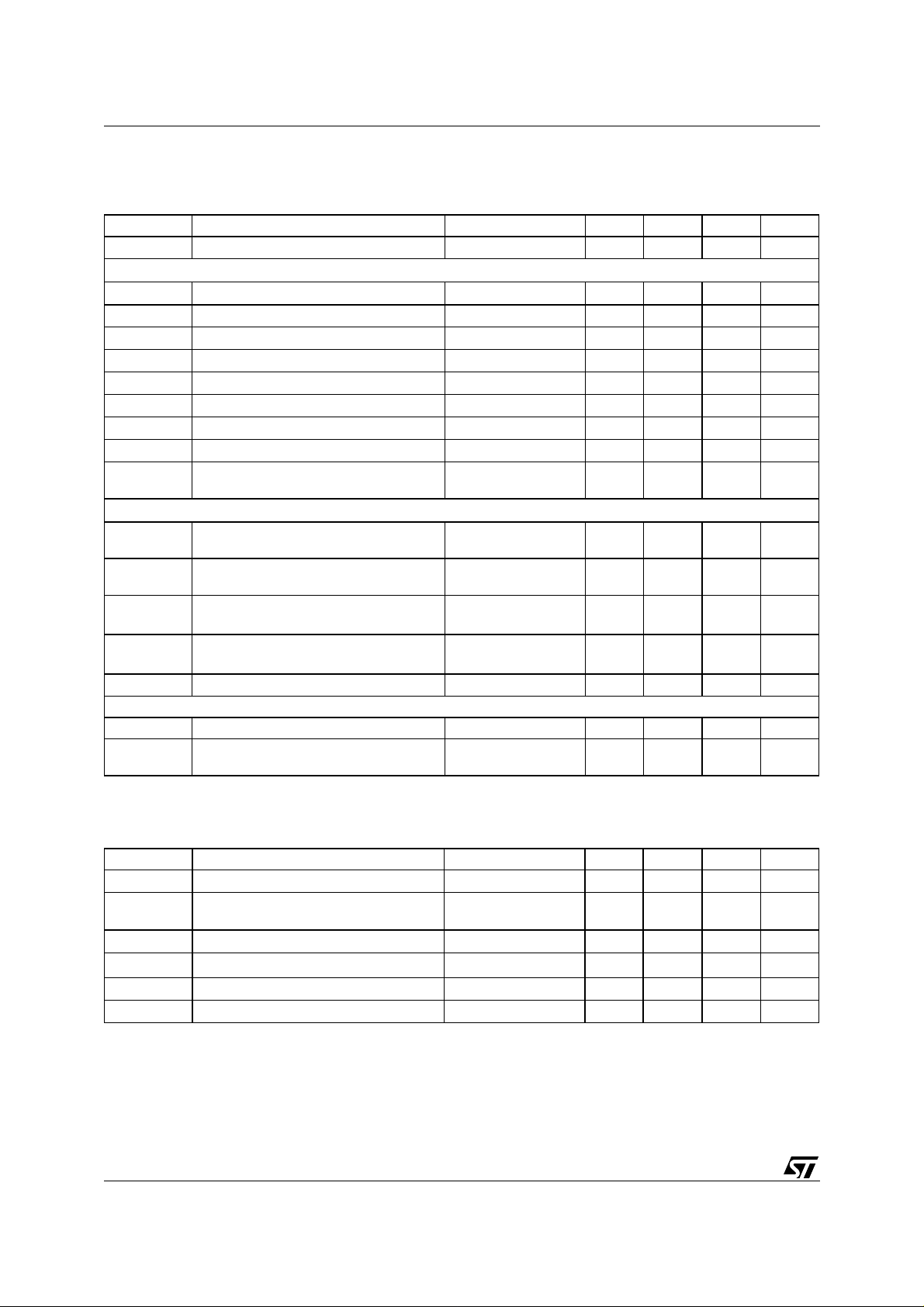

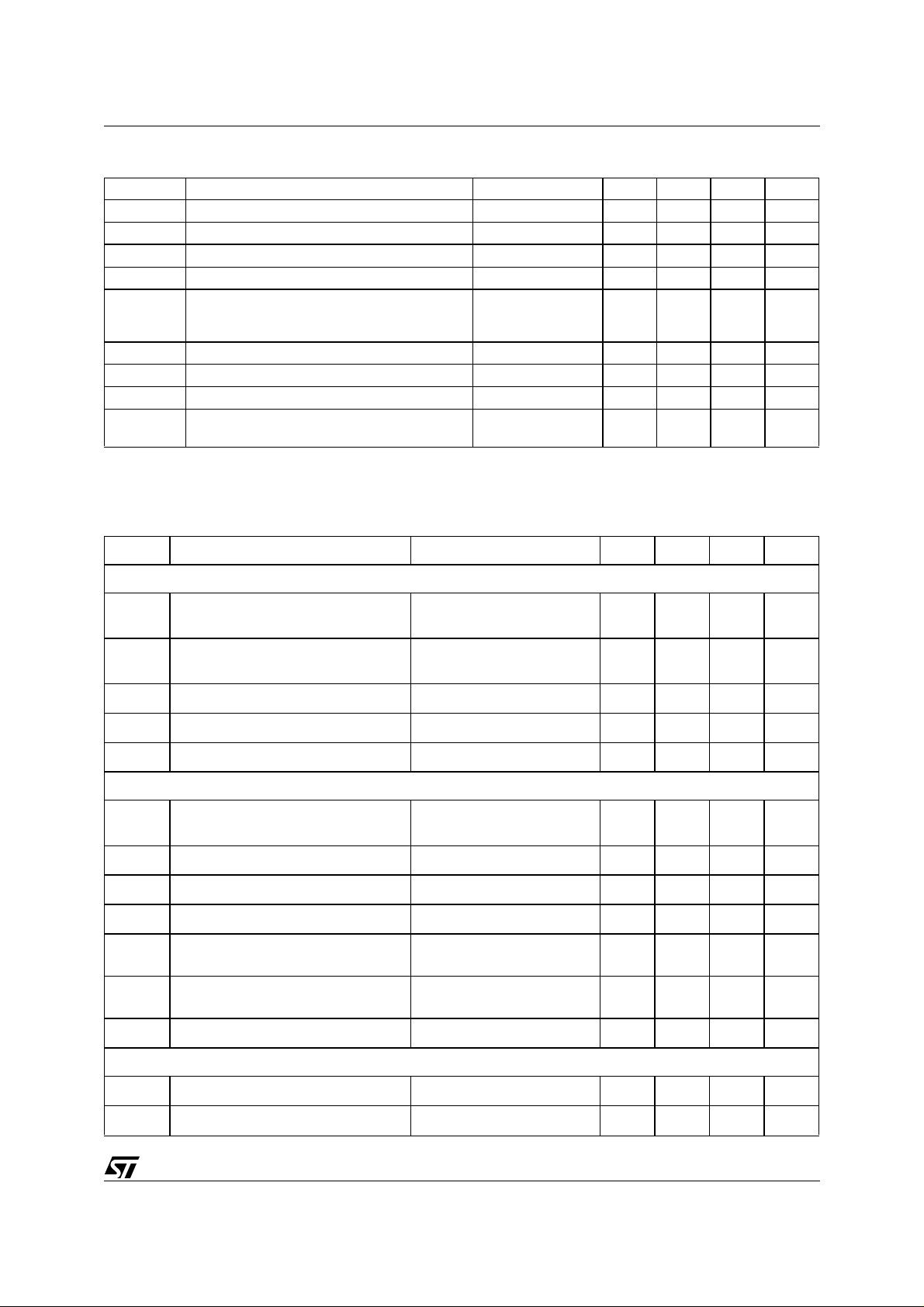

ABSOLUTE MAXIMUM RATINGS

The absolute maximum ratings are the limiting values for this device. Damage may occur if this device is subjected to conditions which are beyond these values.

Symbol Parameter Test Conditions Min Typ Max Unit

E

Q

Voltages

V

S

V

, V

CC

V

Q

V

Q

V

, V

IN

V

CLK

V

ST

V

D

V

DRmax

Currents

I

Q1/2

I

Q3/4

I

Q1/2

I

PGND1/2

I

Q3/4

I

PGND3/4

I

ST

ESD Protection

ESD Elec trost atical Disch argin g MIL883C ±2kV

ESD Output Pins (Qx, Dx) vs. Common GND

Switch off energy for inductive loads 50 mJ

Supply voltage -0.3 40 V

Supply voltage -0.3 6 V

DD

Output voltage static 40 V

Output voltage during clamping t < 1ms 60 V

Input voltage IN1 to IN4, EN II < |10|mA -1.5 6 V

EN

Input Voltage CLK -1.5 6 V

Output voltage status -0.3 6 V

Recirculation circuits D3, D4 40 V

max. reverse breakdown voltage of free

wheeling diodes D3, D4

Output current for Q1 and Q2 >5

Output current for Q3 and Q4 >3

,

Output current at reversal supply for Q1

-4 A

and Q2

,

Output current at reversal supply for

-2 A

Q3 and Q4

Output current status pin -5 5 mA

±4kV

(PGND1-4 + GND)

55 V

internal

limited

internal

limited

A

A

THERMAL DATA

Symbol Parameter Test Conditions Min Typ Max Unit

T

j

T

jc

Junction temperature T

Junction temperature during clamping

(life time)

T

stg

T

th

T

hy

R

thJC

(1) This parameter will not be tested but assured by design.

Storage temperature T

Overtemperature shutdown threshold

Overtemperature shutdown hysteresis

Thermal resistance junction to case R

4/21

j

t = 30min

Σ

t = 15min

Σ

stg

(1)

(1)

thJC

-40 150 °C

175

190

-55 150 °C

175 200 °C

10 °C

2 K/W

°C

Page 5

L9347

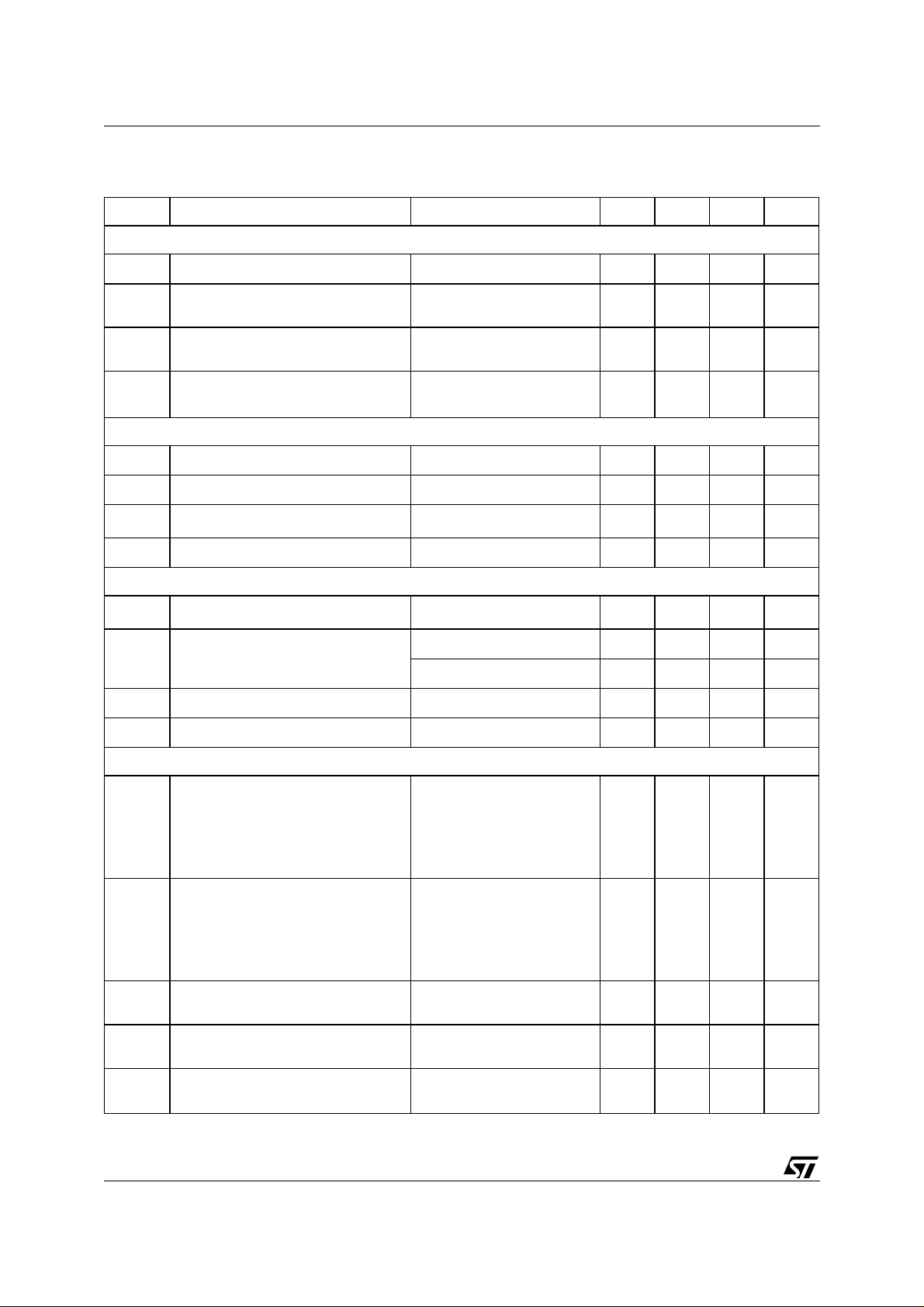

OPERATING RANGE

Symbol Parameter Test Conditions Min. Typ. Max. Unit

V

, V

V

CC

dV

S

V

V

V

ST

I

ST

T

T

jc

.

ELECTRICAL CHARACTERISTCS

(Vs = 4.8 to 18V; T

Symbol Parameter Test Condition Min. Typ. Max. Unit

Supply voltage 4.8 18 V

S

Supply voltage 4.5 5.5 V

DD

/dt Supply voltage transient time -1 1

Output voltage static -0.3 40 V

Q

Output voltage induced by inductive switching Voltage will be

Q

limited by internal

Z-diode clamping

Output voltage status -0.3 6 V

Output current status -1 1 mA

Junction temperature -40 150 °C

j

Junction temperature during clamping

= 30min

Σ

= 15min

Σ

:

= -40 to 150°C unless otherwise specified)

j

60 V

175

190

V/

°C

s

µ

Power Supply

I

SON

I

SOFF

Supply current

Quiescent current

I

Supply current VCC (analog supply) VCC =5V 5 mA

cc

I

Supply current VDD (digital supply) VDD =5V f

dd

I

Supply current VDD (digital supply) VDD =5V f

dd

General Diagnostic Functions

V

V

thGND

V

thPGL

f

CLK,min

DC

DC

high

Open load voltage

QU

Signal-GND-loss threshold VCC= 5V 0.1 1 V

Power-GND-loss thresh old VCC = 5V 1.5 2.5 3.5 V

Clock frequency error 10 100 kHz

Clock duty cycle error detection low f

CLKe_l

ow

Clock duty cycle error detection high f

CLKe_

V

S

≤ 18V

5mA

(outputs ON)

V

S

≤ 18V

5mA

(outputs OFF)

=0Hz 5 uA

CLK

=250kHz 5 mA

CLK

V

S

≥ 6.5V

0.3 0.33 0.36 x V

(outputs OFF)

= 250 kHz 33,3 45 %

CLK

= 250 kHz 55 66,6 %

CLK

Q

VS

Supply detection VCC = VDD = 5V 2 4.5 V

loss

Additional Diagnostic Functions channel 1 and channel 2 (non regulated channels)

I

QU1,2

I

QO1,2

Open-load current channel 1, 2

Over-load current channel 1, 2

V

S

V

S

≥ 6.5V

≥ 6.5V

50 140 mA

57.59 A

5/21

Page 6

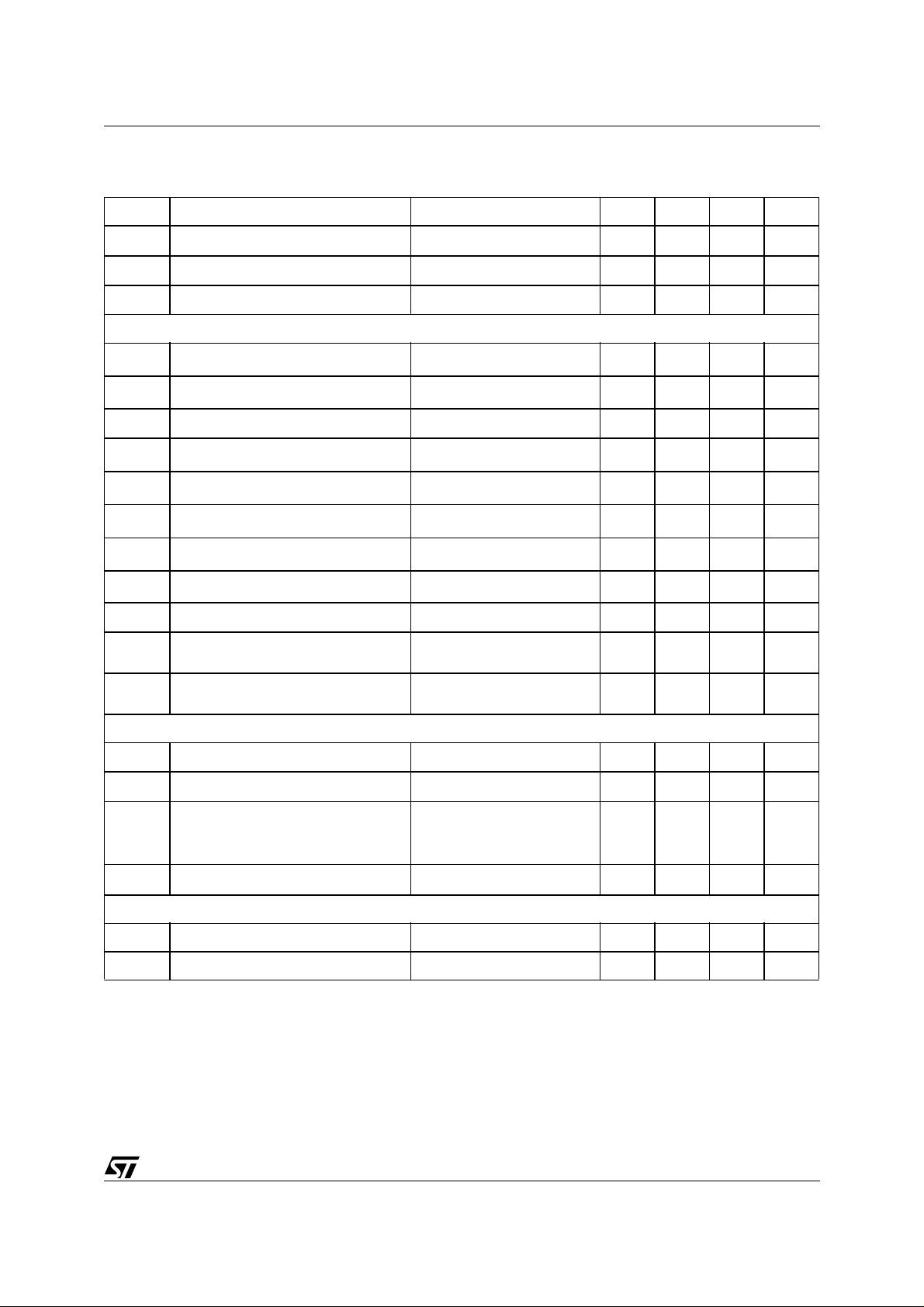

L9347

ELECTRICAL CHARACTERISTCS

:

(continued)

(Vs = 4.8 to 18V; Tj = -40 to 150°C unless otherwise specified)

Symbol Parameter Test Condition Min. Typ. Max. Unit

Additional Diagnostic Functions channel 3 and channel 4 (regulated channels)

DC

I

QO3,4

V

PWM

Digital Inputs (IN1 to IN4, ENA, CLK, TEST). The valid PWM-Ratio for IN3/IN4 is 10% to 90%

V

V

Digital Outputs (ST1 to ST4)

V

Output duty cycle range filtered with 10ms 10 90 %

OUT

Overload current

V

S

≥ 6.5V

2.5 5 8 A

channel 3,4

Recirculation error shutdown

rerr

Iout > 50mA 45 50 60 V

threshold (open D3/D4)

Output PWM ratio during drift

dOU

T

comparison

Input low voltage -0.3 1 V

V

IL

Input high voltage 2 6 V

IH

IHy

Input voltage hysteresis

I

Input pull down current

I

STL

Status output voltage in low state

(1)

(2)

V

= V

IN3

V

V

IN4

= H

TEST

= 5V, VS ≥ 6.5V

IN

IST ≤ 40µA

= PWM

IN

-14.3 +14.3 %

20 500 mV

82040

0 0.4 V

A

µ

V

STH

Status output voltage in high state

R

DIAGLROUT

R

DIAGHROUT

+ R

+ R

DSON

DSON

Power Outputs (Q1 to Q4)

R

DSON1,2

Static drain-source ON-resistance

Q1 and Q2

(non-reg. channels)

R

DSON3,4

Static drain-source ON-resistance

Q3 and Q4

(reg. channels)

V

F_250mA

Forward voltage of free wheeling path

D3, D4 @250mA

V

F_2.25A

Forward voltage of free wheeling path

D3, D4 @2.25A

R

Sense resistor = (V

sens

2A

2)

IST ≥ -40µA

I

≥ -120µA

ST

2.5 3.45 V

23.45V

in low state 0.3 0.64 1.5

in high state 1.5 3.2 7.0

= 1A; VS ≥ 9.5V

I

Q

0.2

0.5

0.5

0.35

0.75

0.75

1

F_2.25A-VF_250mA

= 25°C

T

j

Tj = 125°C

Tj = 150°C

= 1A; VS ≥ 9.5V

I

Q

= 25°C

T

j

= 125°C

T

j

Tj = 150°C

I

D3/4

I

D3/4

)/

(3)

(4)

3)

4)

= -250mA 0.5 1.5 V

= -2.25A 2.0 4.5 V

k

Ω

k

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

6/21

Page 7

L9347

ELECTRICAL CHARACTERISTCS

:

(continued)

(Vs = 4.8 to 18V; Tj = -40 to 150°C unless otherwise specified)

Symbol Parameter Test Condition Min. Typ. Max. Unit

V

Z-diode clamping voltage

Z

I

Output pull down current VEN = H, VIN = L 10 150

PD

I

Output leakage current VEN = L; VQ = 20V 5

Qlk

Timing

t

t

t

OFFREG

t

Output ON delay time

ON

Output OFF delay time channel

OFF

Output OFF delay time regulator

Output rise time

t

r

Output fall time

t

f

t

sf

Short error detection filter time f

t

lf

Long error detection filter time f

Short circuit switch-OFF delay time

SCP

t

Status delay time

D

t

Regulation error status delay time

RE

≥ 100mA

I

Q

= 1A

I

Q

IQ = 1A

(5)

IQ = 1A

= 1A

I

Q

= 250kHz DC = 50%

CLK

= 250kHz DC = 50%

CLK

(5)

(5)

(5)

(reg. channels only)

(5)

(5)

45 60 V

0520

01030

528

0.5 1.5 8

0.5 1.5 8

48

16 32

430

896 1024 us

10 ms

A

µ

A

µ

s

µ

s

µ

s

µ

s

µ

s

µ

s

µ

s

µ

s

µ

t

Dreg

Output off status delay time

(5)

(reg. channels only

528

Reg. Current Accuracy (reg. channels only)

I

Q3/Q4

I

Q3/Q4

I

I

∆

REG

Minimum current DC = 10% 200 250 300 mA

Maximum current DC = 90% 2 2.25 2.5 A

Max. regulation deviation @

DC 10% - 90%

Min. quant. step 5 mA

Q3/Q4

250mA < I

400mA ≤ I

800mA < I

Q3/Q4

Q3/Q4

Q3/Q4

< 400mA

≤ 800mA

< 2.25A

Frequencies

CLK frequency crystal-controlled 250 kHz

Input PWM frequency (reg. channels only) 2 kHz

(1) This parameter will not be tested but assured by design

(2) Short circuit between two digital outputs (one in high the other in low state) will lead to the defined result "LOW"

(3) Measured chip, bond wires not i ncluded

(4) Measured on Power SO-36 devices

(5) Digital filtered with external clock, only functional test

±10

±6

±10

s

µ

%

%

%

7/21

Page 8

L9347

1.0 Functional Description

1.1 Overv iew

The L9347 is designed to drive inductive loads (relays, electromagnetic valves) in low side configuration. Integrated active Zener-clamp (for channel1 and 2) or free wheeling diodes (for channel 3 and 4) allow the recirculation of the inductive loads. All four channels are monitored with a status output. All wiring to the loads and

supply pins of the device are controlled. The device is self-protected against shor t circuit at the outputs and overtemperature. For each channel one independent push-pull status output is used for a parallel diagnostic function.

Channel 3 and 4 work as current regulator. A PWM signal on the input defines the target output current. The

output current is controlled through the output PWM of the power stage. The regulator limits of 10% or 90% are

detected and monitored with the status signal. The current is measured during recirculation phase of the load.

A test mode compares the differences between the two regulators. This “drift” test compares the output PWM

of the regulators. By this feature a drift of the load during lifetime can be detected.

1.2 In put Ci rc ui ts

The INput, CLK, TEST and ENable inputs, are active high, consist of Schmidt triggers with hysteresis. All inputs

are connected to pull-down current sources.

1.3 O utput Stages (not regulated) C hannel 1 and 2

The two power outputs (5A) consist of DMOS-power transistors with open drain output. The output stages are

protected against short circuit. Via integrated Zener-clamp-diodes the overvoltage of the inductive loads due to

recirculation are clamped to typ. 52V for fast shut off of the valves. Parallel to the DMOS transistors there are

internal pull-down current sources. They are provided to assure an open load condition in the OFF-state. With

EN=low this current source is switched off, but the open load comparator is still active.

1.4 Current-Regulator-Stages Channel 3 and 4

The current-regulator channel s ar e des igned to drive i nductive loads. The target val ue of the current is given by

the duty cycle (DC) of the 2kHz PWM input signal. The following figure shows the relation between the input

PWM and the output current and the specified

accuracy

.

Figure 3. Input PWM to output current range

2250

ion

s

t preci

n

Curre

90

400

250

800

OUTPUT Current [mA]

+- 6%

±10%

10

+-10%

INPUT PWM[%]

8/21

Page 9

L9347

The ON period of the input signal is measured with a 1MHz clock, synchronized with the external 250kHz clock.

For requested precision of the output current the ratio between the frequencies of the input signal and the external 250kHz clock has to be fixed according to the graph shown in Fig.

Figure 4. Current accuracy according to the input and clock frequency ratio

current accuracy

5.6%

112.5

125

132

0%

-10%

Regulator

switched off

f

CLK

/ f

IN

The theoretical error is zero for f

/ fIN = 125.

CLK

If the period of the input signal is longer than 132 times the period of the clock the regulator is switched off. For

a clock frequency lower than 100kHz the clock control will also disable the regulator. For high precision applications the clock frequency and the input frequency have to be correlated.

The output current is measu red during the recir culati on of the load. The c urrent sense resistor is in series to the

free wheeling diode. If this recircul ation path is inter rupted the regulator stops immed iately and the status output

remains low for the rest of the input cycle.

The output period is 64 times the clock period. With a clock frequency of 250kHz the output PWM frequency is

3.9kHz. The output PWM is synchronized with the first negative edge of the input signal. After that the output

and the input are asynchronous. The first period is used to measure the current. This means the first turn-on of

the power is 256µs after the first negative edge of the input signal.

As regulator a digital PI-regulator with the Transfer function for:

KI: and KP: 0.96

0.126

-------------- -

z1–

for a sampling time of 256us is realised.

To speed up the current settling time the regulator output is locked to 90% output PWM untill the target current

value is reached. This happens alsowhen the target current value changes and the output PWM reaches 90%

during the regulation. The status output gets low if the target current value is not reached within the regulation

t

error delay time of

=10ms. The output PWM is than out of the regulation range from 10% to 90%.

RE

1.5 Protective Circuits

The outputs are protected against cur rent over lo ad, overtemperatur e, and power -GND-loss. The ex ternal cloc k

is monitored by a clock watchdog. This clock watchdog detects a minimal frequency

f

and wrong clock

CLK,min

duty cycles. The allowed clock duty cycle range is 45% to 55%. The current-regulator stages are protected

9/21

Page 10

L9347

against recirculation er rors, w hen D3 or D4 is not connecte d. All these er ror conditions shut off the power stage

and invert the status output information.

1.6 Error Detection

The status outputs indicat e the switching state under normal conditions ( status LOW = OFF; stat us HIGH = ON).

If an error occurs, the logic level of the status output is inverted, as listed in the diagnostic table below. All external errors, for example open load, are filtered internally. The following table shows the detected errors, the

filter times and the detection mode (on/off).

Short circuit of the load

Open load

(under voltage detection)

Open load

(under current detection)

Overtemperature

Power-GND-loss

Signal-GND-loss

Supply-VS-loss

Clock control

Output voltage clamp active

ON State

EN &IN = HIGH

Xt

Xt

Xt

XXt

XXt

XXt

X X no in on: EN & IN = “LOW”

X

(regulated

channels)

OFF State

EN &IN = LOW

Xt

Filter time Reset done by

sf

lf

sf

sf

lf

lf

lf

no in on: EN & IN = “LOW”

EN & IN = “LOW”

for

or

T

T

D

Dreg

timer

T

D

timer

T

D

EN & IN = “LOW”

for

or

T

T

D

Dreg

in on: EN & IN = “LOW”

for

or

T

T

D

Dreg

in off: timer

timer

timer

or

for

T

D

in off: timer

or

for

T

D

in off: timer

T

T

T

T

D

D

Dreg

Dreg

T

D

T

D

T

D

EN&IN=low means that at least one between enable and input is low. For the inputs IN=low means also no input

PWM. For the regulator input period l onger than T

A detected error is stored in an error register. The reset of this register is made with a timer T

proach all errors are present at the status output at least for the time T

and for the standard channel input perio d longer thanTD.

Dreg

. With this ap-

D

.

D

All protection functions like short circuit of the output, overtemperature, clock failure or power-GND-loss in ON

condition are stored into an internal “fail” register. The output is then shut off. The register must be reset with a

low signal at the input. A “low signal” means that the input is low for a time longer than T

or T

D

DReg

for the re-

ulated channel, otherwise it is interpreted as a PWM input signal and the register is left in set mode.

Signal-GND-loss and VS-loss are detected in the active on mode, but they do not set the fail r egis ter. This type

t

of error is only delayed with the standard timer

function.

lf

Open load is detected for all four channels in on- and off-state.

Open load in off condition detects the voltage on the output pin. If this voltage is below 0.33 * VS the error reg-

ister is set and delayed with T

. A sink current stage pull the output down to ground, with EN high. With EN low

D

the output is floating in case of openload and the detection is not assured. In the ON state the load current is

monitored by the non-regulated channels. If it drops below the specified threshold value I

detected and the error register is set and delayed with T

. A regulated channel detects the open load in the on

D

state with the current regulator error detection. If the output PWM reaches 90% for a time longer than t

an open load is

QU

RE

than

an error occurs. This c ould happen when no load is c onnected, the resistivi ty of the l oad is too high or the suppl y

voltage too low. The same error is shown if the regulator is not able to reduce the current in the load in the time

, so the output PWM falls below 10%.

t

RE

A clock failure (clock loss) is detected when the frequency becomes lower than

f

. All status outputs are

CLK,min

10/21

Page 11

L9347

set on error and all power outputs are shut off. The status signals remain in their state until the clock signal is

present again. A clock failure during power on of VCC is detected only on the regulated channels. The status

outputs of the channel 1 and 2 are low in this case.

1.7 Drift Detection (regulated channels only)

The drift detection is used to compare the two regulated channels during regulation. This “Drift” test compares

the output PWM of the regulators. The resistivity of the load influences the output PWM. The approximated formula for the output current below shows the depen dency of the load resi stor to the output PWM. In this formula

the energy reduction dur ing the recirculati on is not taken into account. The real output PWM i s high er. The testmode is enabled with IN,EN and TEST high. With an identical 2kH z PWM-Si gnal c onnected to the I N-inputs the

output PWM must be in a range of +-14.3%. If the difference between the two on-times is more than ±14.3% of

the expected value an error is detected and monitored by the status outputs, in the same way as described

above, but a drift error will not be registered and also not delayed with T

IOUT

----------------------------

RL RON+

PWM⋅=

VBAT

Drift Definition:

Drift = PWM(1+E) - PWM (1-E) = 2PWM E

Drift * 4 < PWM (1+E)

with E >14.3% a drift is detected

as other errors

D

E.. not correlated Error of the channels

%PWM ... Corresponding ideal output PWM to a given input PWM

A 7bit output-PWM-register is used for the comparison. The register with the lower val ue is subtracted from the

higher one. This result is multiplied by four and compared with the higher value.

1.8 Other Test modes

The test pin is also used to test the regulated channels in the production. With a special sequence on this pin

the power stages of the regulated channels can be controlled direct from the input. No status feedback of the

regulated channels is given. The status output is clocked by the regulator logic. The output sequence is a indication of a proper logic functionality. The following table shows the functionality of this special test mode

EN IN TEST OUT STATUS Note

1

1

0

0

0

0

0

X X X X disable test mode

1 1 on 1 Drift mode

X off test pattern test condition one

X off test pattern test condition two

X off test pattern test condition three

0 off test pattern test condition four

1 on test pattern test condition four

For more details about the test condition four see timing diagram.

11/21

Page 12

L9347

Diagnostic Table

The status follows the input signal in normal operating conditions.

If any error is detected the status is inverted.

Operating Condition Test

Input

TEST

Normal function L

L

L

L

Open load or short to ground L

L

L

L

Overload or short to supply

Latched overload

Reset latch

Reset latch

Overtemperature

Latched overtemperature

Reset latch

Reset latch

Recirculation error (reg.chn.)

Latched error

Reset latch

Reset latch

Clock failure (clock loss)

Drift

Failure

No failure

(1)

(2)

L

L

L

L

L

L

L

L

L

L

L

L

L

L

L

L

H

H

H

H

Enable

Input

ENA

L

L

H

H

L

L

H

H

H

H

H –> L

H

H

H

H –> L

H

H

H

H –> L

H

L

L

H

H

L

L

H

H

Control Input

non-reg./reg.

IN

L

H/PWM

L

H/PWM

L

H/PWM

L

H/PWM

H/PWM

H/PWM

X

H/PWM –> L

H/PWM

H/PWM

X

H/PWM –> L

PWM

PWM

X

PWM –> L

L

H/PWM

L

H/PWM

L

H/PWM

H/PWM

H/PWM

Powe r Outp u t/

Current reg.

Q

OFF

OFF

OFF

ON

OFF

OFF

OFF

ON

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

ON

ON

Status

Output

ST

L

L

L

H

X

X

H

L

L

L

L

L

L

L

L

L

L

L

L

L

H

H

H

L

X

X

L

H

(1) during power on sequence only detected on channel 3 and 4 (see description).

(2) This in put combina tion is also us ed for an internal chip- test and mus t not be used.

12/21

Page 13

2.0 Timing Diagrams

2.1 Non Re gu lated Chan nel s

Figure 5. Out put S lo pe, Re s is tive Load

V

I

V

IH

V

IL

t

ONtf

85% V

15% V

V

Q

V

S

S

S

t

OFFtr

L9347

t

99AT0061

Figure 6. Overload Switch-OFF Delay

I

Q

I

QO

I

QU

V

ST

t

t

t

D

t

SCP

t

sf

00RS0001

t

13/21

Page 14

L9347

Figure 7. Normal Condition, Resistive Load, Pulsed Input Signal

V

IN

V

Q

I

Q

t

D

V

ST

99A T0063

Figure 8. Current Overload

V

IN

V

Q

Set Fail

register

I

QU

t

D

t

D

Reset Fail

register

14/21

I

Q

V

ST

99A T0064

I

QO

t

D

Page 15

Figure 9. Diagnostic Status Output at Different OPEN Load Current Conditions

Under current condition followed by normal operation

t

D

V

IN

V

Q

L9347

I

Q

t

D

V

ST

99AT0065

Open load condition in the case of pulsed input signal followed by normal operation

V

IN

V

Q

I

QU

t

D

I

Q

V

ST

99AT0066

I

QU

t

D

15/21

Page 16

L9347

Figure 10. Pulsed Open Load Conditions (regulated and non-regulated channels)

V

IN

V

Q

I

Q

V

ST

99AT0067

t

lf

t

D

0.33 x V

S

t

lf

2.2 Regulated Channels (timing diagrams of diagnostic with 2kHz PWM input signal)

Figure 11. Normal Condi t io n, In ductive Load

500µs

t

DREG

16/21

V

IN

V

Q

I

Q

V

ST

99AT0068

Target Current

256µs

256µs

Page 17

Figure 12. Current Overload

L9347

500µs

V

IN

V

Q

I

QO

I

Q

V

ST

99AT0069

Figure 13. Recirculation Error

t

DREG

Reset Fail

register

Set fail

registor

t

sf

V

IN

V

Q

I

Q

V

ST

99AT0070

500µs

target current

t

DREG

Set Fail

register

Reset Fail

register

17/21

Page 18

L9347

Figure 14. Current Regulation Error (e.g. as a result of voltage reduction)

500µs

V

IN

V

Q

target current

I

Q

V

ST

99AT0071

Figure 15. Overtemperature

500µs

V

IN

Overtemperature

Condition

t

DREG

t

RE

PWM

= 90%

ratio

Reset Fail

register

18/21

V

Q

I

Q

V

ST

99AT0072

Set Fail

register

target current

Page 19

Figure 16.

Test mode 4 VEN low

V

TEST

V

IN3/4

V

Q3/4

99A T0073

L9347

19/21

Page 20

L9347

DIM.

MIN. TYP. MAX. MIN. TYP. MAX.

mm inch

A 3.60 0.141

a1 0.10 0.30 0.004 0.012

a2 3.30 0.130

a3 0 0.10 0 0.004

b 0.22 0.38 0.008 0.015

c 0.23 0.32 0.009 0.012

D (1) 15.80 16.00 0.622 0.630

D1 9.40 9.80 0.370 0.385

E 13.90 14.50 0.547 0.570

e 0.65 0.0256

e3 11.05 0.435

E1 (1) 10.90 11.10 0.429 0.437

E2 2.90 0.114

E3 5.80 6.20 0.228 0.244

E4 2.90 3.20 0.114 0.126

G 0 0.10 0 0.004

H 15.50 15.90 0.610 0.626

h 1.10 0.043

L 0.80 1.10 0.031 0.043

N10°(max.)

S8°(max.)

(1): "D" and "E1" do not include mold flash or protrusions

- Mold flash or protrusions shall not exceed 0.15mm (0.006 inch)

- Critical dimensions are "a3", "E" and "G".

OUTLINE AND

MECHANICAL DATA

PowerSO36

E2

h x 45˚

NN

a2

A

1936

0.12 AB

⊕

e

a3

B

E1

Gage Plane

M

PSO36MEC

DETAIL A

118

A

e3

H

D

b

DETAIL B

lead

BOTTOM VIEW

DETAIL B

0.35

S

DETAIL A

L

a1

E

slug

D1

SEATING PLANE

(COPLANARITY)

c

- C -

GC

E3

20/21

Page 21

L9347

Information furnished is believed to be accurate and reliable. However, STMicroelectronics assumes no responsibility for the consequences

of use of such information nor for any infringement of patents or other rights of third parties which may result from its use. No license is granted

by implic ation or o th erwise un der any pat ent or patent right s of STMi croelectr oni cs. Specifications menti oned in th i s publication are s ubj ect

to change without notice. This publication supersedes and replaces all information previously supplied. STMicroelectronics products are not

authorized for use as c ritical components in li fe support devices or syst em s without express wri t ten approval of STMic roelectronics.

The ST logo is a registered trademark of STMicroelectronics

2002 STMi croelectronics - All Ri ghts Reserved

Australi a - Brazil - China - Finland - Fr ance - Germany - Hong Kong - India - Italy - Japan - Malaysia - Malta - Morocco - Singapore - Spain

STMicroelectronics GROUP OF COMPANIES

- Sweden - Sw itzerland - United Kingdom - U. S.A.

http://www.s t. com

21/21

Loading...

Loading...