Page 1

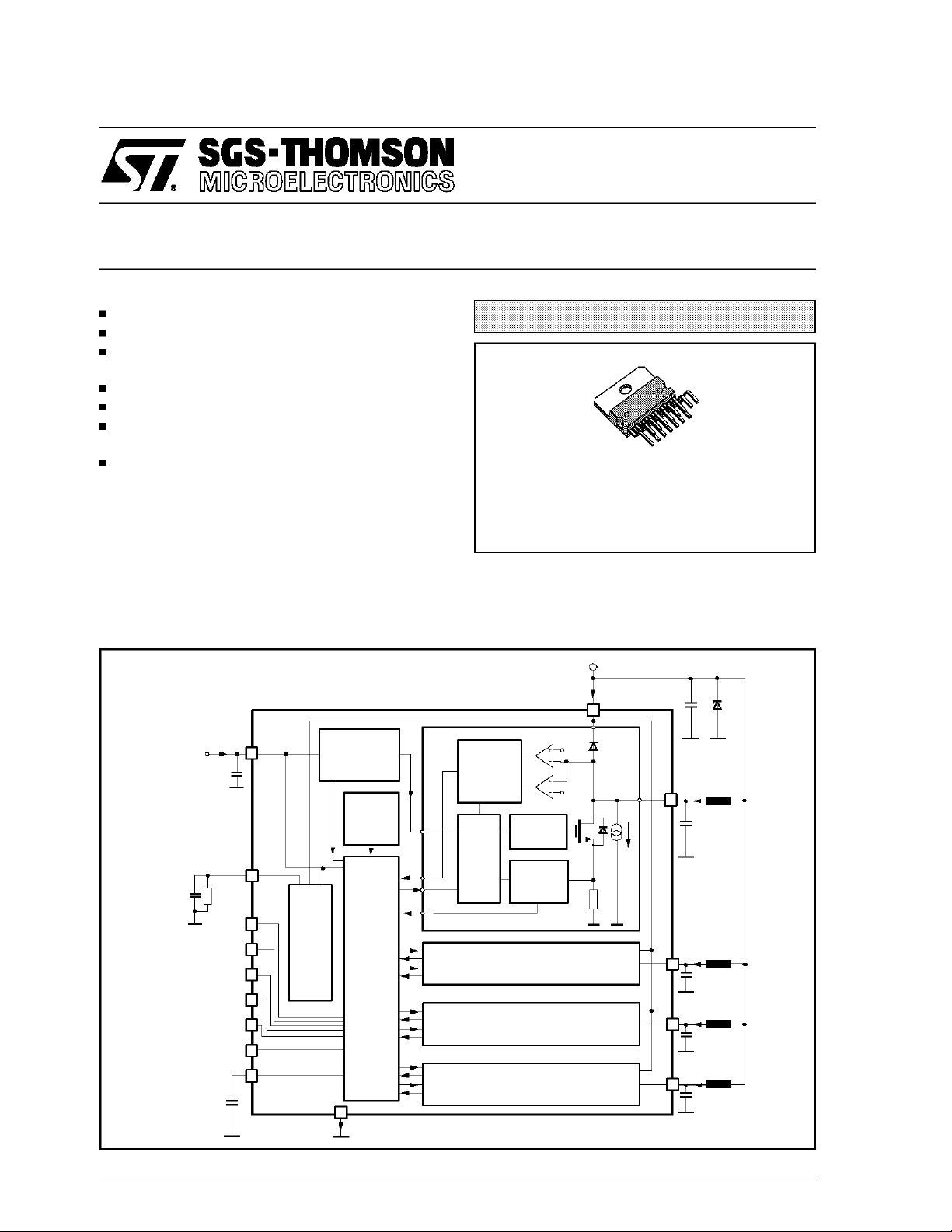

L9341

QUAD LOW SIDE DRIVER

AVANCE DATA

DU/DTAND DI/DTCONTROL

PWM CONTROLLEDOUTPUT CURRENT

SHORT CURRENT PROTECTION AND DI-

AGNOSTIC

INTEGRATEDFLYBACKDIODE

UNDERVOLTAGESHUTDOWN

OVERVOLTAGE AND UNDERVOLTAGE DI-

AGNOSTIC

OVERTEMPERATUREDIAGNOSTIC

DESCRIPTION

The L9341 is a monolithic integrated circuit realized in Multipower BCD-II mixed technology. The

driver is intended for inductive loads in synchronous PWM applications, especially for valve driv-

BLOCK & APPLICATION DIAGRAM

VCC

10nF

Vcc

10uF

R

12.4k

4

I

cc

REXT

12

ext

Ω

RES1

9

RES2

10

CS

3

SCLK

11

SDI

5

SDO

13

OSC

6

C

OSC

BIAS

GND

UNDERVOLTAGE

SHUTDOWN

THERMAL

FLAG

SERIAL

INTERFACE

&

PWM

CONTROLL

8

I

GND

MULTIPOWERBCD TECHNOLOGY

Multiwatt 15

ORDERING NUMBERS: L9341V

L9341H

ers. The output voltage and current rise and fall

slopesdu/dt and di/dt are controlled.

V

s

I

CHANNEL 1

DIAGNOSTIC

DRIVER

COMP1

COMP2

di / dt & du / dt

CONTROL

SHORT

CURRENT

PROTECTION

CHANNEL 2

CHANNEL 3

CHANNEL 4

s

VS

7

V

flyth

V

offth

I

220nF

C

BATDBAT

OUT1

2

I

OUT1

10nF

C

outs

O1

OUT2

1

I

OUT2

C

O2

10nF

OUT3

15

I

OUT3

C

O3

10nF

OUT4

14

I

OUT4

C

O4

10nF

March 1994

1/10

This is advanced information on a new productnow in development or undergoing evaluation. Details aresubject to change withoutnotice.

Page 2

L9341

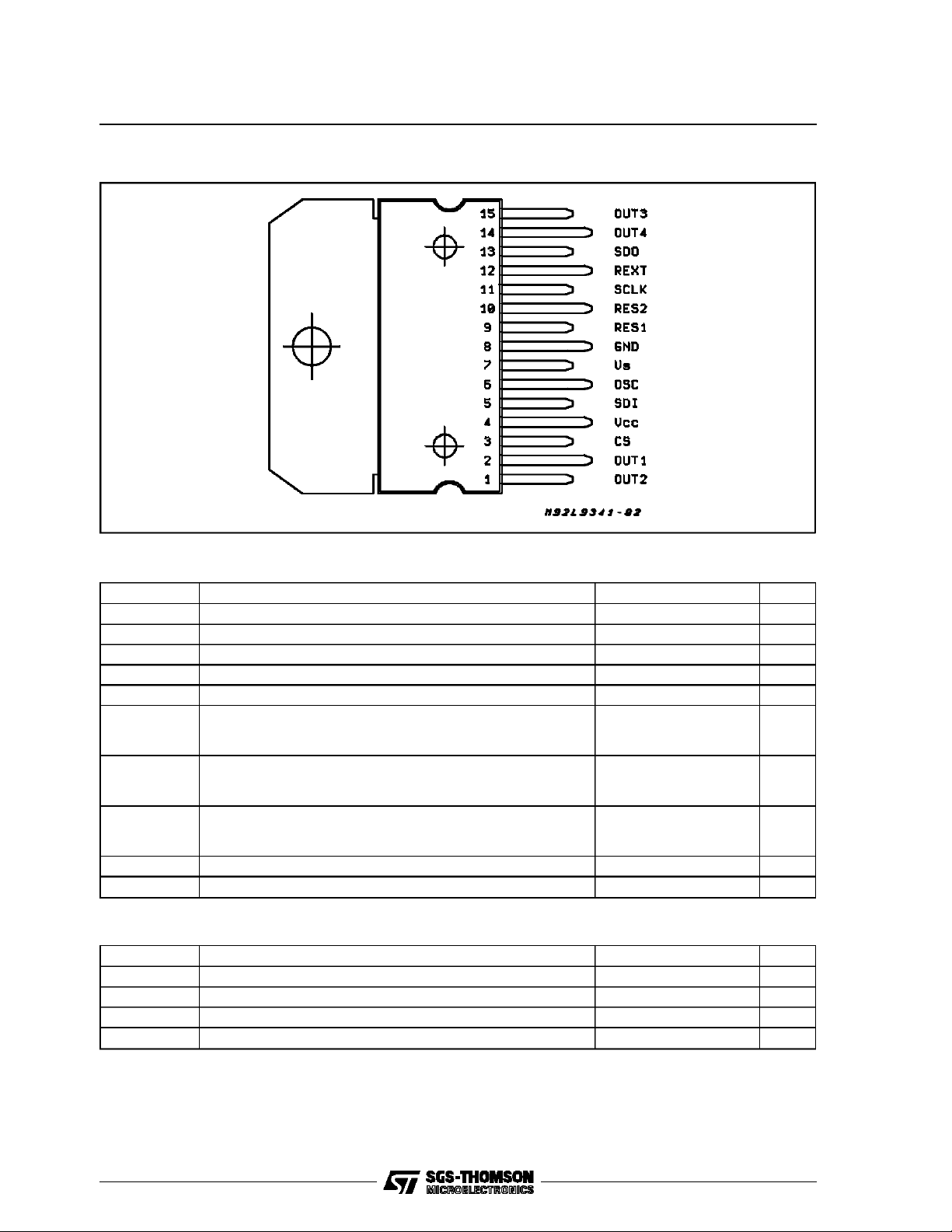

PIN CONNECTION (Top view)

ABSOLUTE MAXIMUMRATINGS

Symbol Parameter Value Unit

V

CC

V

S

V

spmax

V

st

Vin InputVoltage Range for SDI; SCLK;CS;RES1;RES2 -0.3to V

V

out

I

out

VCCVoltageRange -0.3 to 6 V

VSVoltage Range -0.3 to 24 V

VS Voltage Range for t ≤ 400ms -2 to 40 V

Schaffner Transient Pulses on V

S

see note1 V

+0.3

CC

Output Voltage Range for all Outputs:

Negative

Positive

intern. clamped to V

– 0.3

S

Output Current for all Outputs:

Negative

Positive

–2

+2

for Transient witht < 10ms

Negative

Positive

–5

5

Schaffner Transient Pulses on Output see note2

V

ESD

ESD Voltage Capability (MIL 883 C) 1500 V

THERMAL DATA

Symbol Parameter Value Unit

R

th j-case

R

th j-amb

T

sdh

T

sd

Notes:

1. Schaffner transient specification: DIN 40839 testwaveforms of the following type: 1, 2, 3a, 3b, 5 and 6.

The pulses are applied to the application circuit according to fig. 3.

2. The maximum output current results from theSchaffner pulses specified in note 1.

Thermal Resistance Junction to Case 3 °C/W

Thermal Resistance Junction to Ambient mountedon PC Board 35 °C/W

Thermal Hysteresis 20 °C

Thermal Diagnostic Tj> 150 °C

V

V

A

A

A

A

2/10

Page 3

L9341

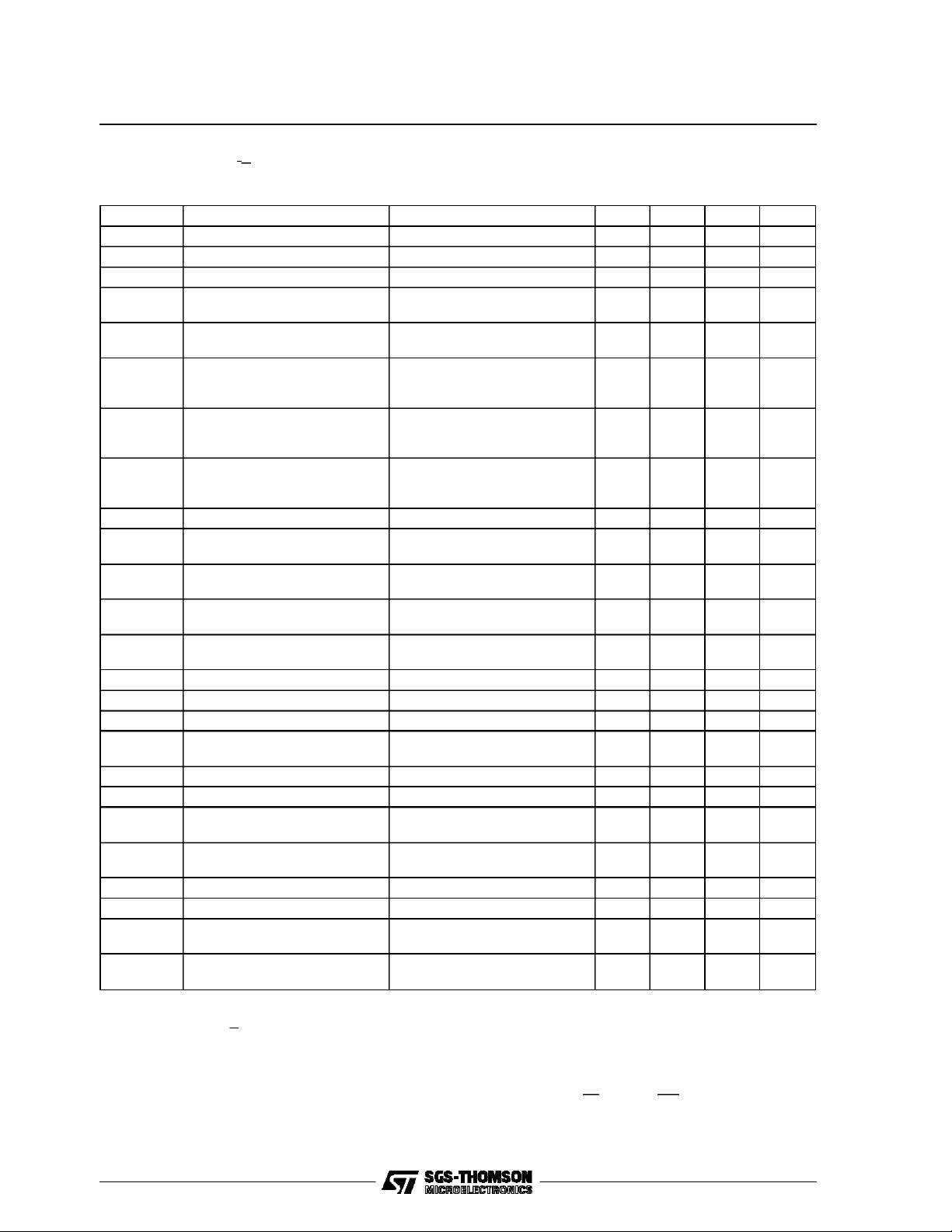

ELECTRICAL CHARACTERISTICS (Unless otherwise specified: 8V ≤ VS≤ 24V; 4.7V ≤ VCC≤ 5.3V; –

40 °C ≤ Tj ≤ 150°C;I

R

=12.4KΩ ± 1%).

ext

≤ 1A(note 3); IO≤ 1.5A;Vsp=VSfor t ≤ 400ms; V

O

OUTP=VOUT

Symbol Parameter Test Condition Min. Typ. Max. Unit

I

ccq

I

sq

V

ccu

V

ccr

VccQuiescent Current All Outputs Off 1 3 mA

VsQuiescent Current All Outputs Off 14 25 mA

VccUndervoltage Threshold See Note 4 3 4 4.7 V

VccRange for RES1 and RES2

3V

Operation

R

on

I

o off

V

outf

I

gndf

I

outr

V

inH

On Resistance Io=1A Tj= 125°C

T

=25°C

j

Off State Output Current Outputs Off

1.4V ≤ V

V

outp=Vsp

≤ V

o

s

= 40V

1

1

Output Voltage During Flyback Io= 1A Output Off

T

=25°C

j

T

= 125°C

j

Current to GND during Flyback

(see note 5)

Io= 1A Output Off

V

= 24V

s

V

= 40V

sp

Reverse Leakage Current Vsp-Vo= 40V 500 µA

High Input Level of SCLK,

0.7*V

cc

SDI, CS, RES1, RES2

V

inL

Low Input Level of SCLK,

– 0.3 0.3*Vcc V

SDI, CS, RES1, RES2

V

REShys

Hysteresis of Reset Inputs

0.3 1 V

RES1, RES2

I

inRESH

I

V

SDOH

V

SDOL

I

SDOZ

PWM

K

V

V

in

f

flyth

offth

Input Current on RES1,RES2 RESi= H; -2V ≤ Vsp≤ 8V

RES

=H;8V≤Vsp≤ 40V

i

–10

5

Input Current on SCLK,SDI,CS – 2V ≤ Vsp ≤ 40V – 10 10 µA

High Level SDO Output Voltage I

Low Level SDO Output Voltage I

SDO TristateHigh-Z Leakage

Current

PWM Duty Cycle 1/16 15/16

duty

= -1mA -2V≤ Vsp≤ 40V 0.9*V

SDO

= 1mA -2V≤ Vsp≤ 40V 0 0.4 V

SDO

0 ≤ V

SDO

≤ V

cc

cc

–10 10 µA

–2V≤Vsp≤ 40V

Frequency Accuracy Constant See Note 6 0.93*KfnK

Flyback Diagnostic Comparator

Threshold

Off State Diagnostic

40 ≥ Vsp≥ 8V

V

≤ 8V

s

–1

V

s

1.5

1.5 2 V

Comparator Threshold

I

outl

t

dpo

S

ov

OutputCurrentLimitationThreshold see Note 7 1.5 2.5 A

Delay Time PWM Signal to Out. 5 15 µs

Output Voltage Rise andFall

(from 10 to 90% of Vo) Fig. 2 1.0 10 V/µs

Slope | du/dt |

S

oc

Notes:

3. The mean value is Io=

4. The outputs are switced off for Vcc ≤ Vccu. The logic is notreseted. Fora reset,RES1 or RES2 must be used.

5. This currentismeasured in the GND - terminal when one single output is in flybackand consistsof the supply current added to the value

ofthe output current source and the leakage currentof the flyback diode. This leakage current is less than 1% of the nominal flyback current.

6. The PWMfrequency isdefined by an external capacitor.The PWMoscillator frequency is: f

therange is: 300Hz ≤ f

7. For I

out

Output Current Rise and Fall

Slope |di/dt|

T

1

Io(t) dt

∫

0

T

≤ 3000Hz. The OSC Pin can be alternatively driven by an external TTL / CMOS signal.

≥ I

an internal comparator switches the corresponding output off for the currentPWM cycle.

outl

pwm

;

0.1 ≤ Io ≤ 1.5A

(from 10 to 90% of I

)

o

pwm

25 125 mA/µs

f

osc

withf

=

32

osc

for t ≤ 400ms;

750

450

2.5 4

V

s

V

s

17

20

Vcc+0.3 V

1.07*K

fn

Vs– 0.4 V

K

f

=

⋅1A/V and kin=15⋅10-6;

C

osc

10

+1.3

+1.1VV

44

52

10

10

V

cc

fn

mΩ

mΩ

mA

mA

mA

mA

µA

µA

V

V

3/10

Page 4

L9341

Figure1: LogicDiagramof PWMGeneration.

INTERNAL

CLOCK

CLK

15

14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

PWM1

PWM2

PWM3

PWM4

Figure2: Output Switching Diagram.

+12V

220 nF

f

OUT

5

20 mH

I

10 nF

out

V

out

Internal PWM Signal

Output Voltage V

Current through

Low Side Switch

Current through

Flyback Diode

DMOS

GND

I

s

V

s

D

I

f

I

D

I

s

Figure3: Test Circuit for SchaffnerPulses.

+12V

220 nF

Vs

OUT1

out

I

D

I

f

D1

-2V to 40 V

12V

t

dpo

t

dpo

di/dt

5%

di/dt

5%

du/dtdu/dt

0

1A

di/dt

0

1A

di/dt

0

Schaffner

Generator

4/10

+5V

10 uF

VCC

GND

OUT2

OUT3

OUT4

4x1nF

4 x 10 nF

Page 5

Figure4: SynchronousSerial Interface Protocol.

CS

SCLK

L9341

f

clock

t

t

t

t

chch

t

t

t

SDI

SDO

MSB 14 13 12 11 3 2 1 LSB

MSB 14 13 12 11 3 2 1 LSB

CS

t

t

clcl

chcl t

ch

t

cl

t

clch

SCLK

t

suth

SDI

SDO

t

t

clz

d

t

oh

15 14 0

015

Clock Frequency min. DC max. 2MHz

Width of Clock Input High Puls min. 200ns

t

ch

Widh of Clock Input Low Puls min. 200ns

t

cl

Clock Low Before CS Low min. 200ns

cicl

Clock High After CS Low min. 200ns

chcl

Clock Low Before CS High min. 200ns

clch

Clock High After CS High min. 200ns

SDO Low-Z CS Low min. 0ns max.400ns

ciz

SDO High-Z CS High max. 400ns

zch

SDI Input Setup Time min. 80ns

t

su

SDI Input Hold Time min. 80ns

t

h

SDO Output Delay Time (CL= 50pF) max. 100ns

t

d

SDO Output Hold Time min. 0ns

oh

t

chch

t

zch

5/10

Page 6

L9341

Figure5: PWM GenerationFunction Table.

Bit 3 - 0 PWM1 PWM2 PWM3 PWM4 OUTPUT

0000 15/16 15/16 15/16 15/16 OFF

0001 1/16 15/16 1/16 15/16 ON

0010 2/16 14/16 2/16 14/16 ON

0011 3/16 13/16 3/16 13/16 ON

0100 4/16 12/16 4/16 12/16 ON

0101 5/16 11/16 5/16 11/16 ON

0110 6/16 10/16 6/16 10/16 ON

0111 7/16 9/16 7/16 9/16 ON

1000 8/16 8/16 8/16 8/16 ON

1001 9/16 7/16 9/16 7/16 ON

1010 10/16 6/16 10/16 6/16 ON

1011 11/16 5/16 11/16 5/16 ON

1100 12/16 4/16 12/16 4/16 ON

1101 13/16 3/16 13/16 3/16 ON

1110 14/16 2/16 14/16 2/16 ON

1111 15/16 1/16 15/16 1/16 ON

Figure6: PWM Information From Microcontrollerto QLSD.

Bit. Nr. Name Contents

0 P10 PWM Duty Cycle for Channel 1 / Bit 0: LSB

1 P11 PWM Duty Cycle for Channel 1 / Bit 1

2 P12 PWM Duty Cycle for Channel 1 / Bit 2

3 P13 PWM Duty Cycle for Channel 1 / Bit 3 : MSB

4 P20 PWM Duty Cycle for Channel 2 / Bit 0 : LSB

5 P21 PWM Duty Cycle for Channel 2 / Bit 1 :

6 P22 PWM Duty Cycle for Channel 2 / Bit 2 :

7 P23 PWM Duty Cycle for Channel 2 / Bit 3 : MSB

8 P30 PWM Duty Cycle for Channel 3 / Bit 0 : LSB

9 P31 PWM Duty Cycle for Channel 3 / Bit 1 :

10 P32 PWM Duty Cycle for Channel 3 / Bit 2 :

11 P33 PWM Duty Cycle for Channel 3 / Bit 3 : MSB

12 P40 PWM Duty Cycle for Channel 4 / Bit 0 : LSB

13 P41 PWM Duty Cycle for Channel 4 / Bit 1:

14 P42 PWM Duty Cycle for Channel 4 / Bit 2 :

15 P43 PWM Duty Cycle for Channel 4 / Bit 3 : MSB

6/10

Page 7

Figure7: DiagnosticInformationfrom QLSD to Microcontroller.

Bit Nr. Name Contents

0 F11 COMP1 State at Positive Edge of PWM1 (0: V

1 F12 COMP2 State at Negative Edge of PWM1 (1: V

2 F21 COMP1 State at Positive Edge of PWM2 (0: V

3 F22 COMP2 State at Negative Edge of PWM2 (1: V

4 F31 COMP1 State at Positive Edge of PWM3 (0: V

5 F32 COMP2 State at Negative Edge of PWM3 (1: V

6 F41 COMP1 State at Positive Edge of PWM4 (0: V

7 F42 COMP2 State at Negative Edge of PWM4 (1: V

8 RES1 Logic State of RES1 Input (0: RES1 = L ; 1: RES1 = H)

9 RES2 Logic State of RES2 Input (0: RES2 = L ; 1: RES2 = H)

10 TSDF Thermal Diagnostic Flag ( 0: Overtemperature; 1:Normal )

11 C1 Current at Negative Edge of PWM1 ( 0: I

12 C2 Current at Negative Edge of PWM2 ( 0: I

13 C3 Current at Negative Edge of PWM3 ( 0: I

14 C4 Current at Negative Edge of PWM4 ( 0: I

15 1 Framing Information (always 1)

out1>Vflyth

out2>Vflyth

out3>Vflyth

out4>Vflyth

out>Ioutl

out>Ioutl

out>Ioutl

out>Ioutl

out1>Voffth

out2>Vofth

out3>Voffth

out4 > Voffth

;1:I

out<Ioutl

;1:I

out<Ioutl

;1:I

out<Ioutl

;1:I

out<Ioutl

;1:V

;0:V

;1:V

;0:V

;1:V

;0:V

;1:V

;0:V

out1<Vflyth

out1<Vofth

out2<Vflyth

out2<Vofth

out3<Vflyth

out3<Vofth

out4<Vflyth

out4<Vofth

)

)

)

)

L9341

)

)

)

)

)

)

)

)

Figure8.

PWM

I

D

V

OUT

PWM

t

C

t

dPO

t

V

t

PWMON

min

Sample point COMP2

Sample point COMP1

Fig.1 Fig.2

Fig. A Fig. B

V

OUT

t

t

dPO

PWMOFF

min

Sample point COMP2

t

V

Sample point COMP1

Note:

For safty diagnostic take notice of the following conditions:

t

PWMON

t

PWMOFF

≥ t

dPOMAX+tC+tV

≥ t

dPOMAX+tV

(see Fig. A) tC=

(see Fig. B)

S

I

D

OCMIN

tV=

V

outfmax

S

OVMIN

7/10

Page 8

L9341

FUNCTIONAL DESCRIPTION

The U511 is a PWM quad low side driver for inductive loads. The duty cycle of the internal generated PWM signal is set by a microcontrollervia

a serial interface for each output. An output slope

limitation for both dv/dt and di /dt is implemented

to reduce RFI. The PWM generation is realized

avoiding a simultaneous output switching. As a

result, di/dt becomes smaller. Integrated flyback

diodes clamp the output voltage during the flyback phase of thelow side switches.

The driver is protected against short circuit. An

undervoltageshutdown circuit switchesoff all outputs if V

is less then V

cc

. Below the shutdown

ccu

voltage all outputs remain in off state regardless

of the input state. After each malfunction which

resets the driver,only the serial link interface can

reactivatethe normal function.In case of overcurrent (I

out=Iout1

), an internal comparator switches

the output off. The overcurrent informationcan be

read via the serial link for each driver separately

at the negative edge of the corresponding PWM

signal.

The interface to the microcontroller is realized

with a 16 bit synchronous serial peripheral interface (SPI). If CS is switched low, the serial link

becomesactive and SDO goes to lowimpedance.

At the rising edge of the SCLK signal, one of the

16 bit of data stored in a shift register appear sequencely at SDO. These data contain the 8 error

flags, the statusof thermaldiagnostic flag and the

external reset sourcesRES1, RES2 and the overcurrent flgs c1...c4. The last bit is framing information (see fig. 7). At each falling edge of SCLK,

one of the 16 bits of data sent by the microcontrolleris transferredvia the SDI input to the driver.

These data contain the duty-cycle information for

the internal PWM generation (4 times 4 bit).

On the rising edge of CS the previouslystored information is transferred to the circuits. SDO become now high impedance and SDI is inactive.

The serial interface of the QLSD is cascadable

with the serial link interface of another QLSD,

thus obtaininga 32 bit serial link information wich

can control eight inductive loads. For a safety

data transfer the takeoverof data bits is only realized when the number of SCLK - clocks is n x 16

(n ≥ 1).

The PWM duty cycle is set by 4 bit for each output independentlyvia the serial link. If all four bits

for an output are zero, theoutput is turned off, but

the error diagnosis will work correctly (see fig. 5

and 6). The PWM frequencyis defined by an external capacitor on the OSC pin. Rext defines

through the reference current the output current

slope, the diagnostic current sink and the internal

oscillatorfrequency(togetherwith C

osc

).

For error diagnosis the voltage on the output is

measured during the on and off state of the particular output driver. Upon the rising edge of the

PWM signal (at this moment the power output is

off and will be switched on) the status of COMP1

is stored into an internal latch. On the fallingedge

of the PWM signal ( the power output is on and

will be switched off) the status of COMP2 is

stored into another internal latch. This information

can be read via the serial link for each output

driverseparately(see fig. 7).

The thermal diagnostic switch the thermal flag to

0 in case of overtemperature T ≥ T

switched to 1 with the hysteresis T

T<T

sd-Tsdh

.

.Itwillbe

sd

in case of

sdth

To avoid male functions due to extensivenoise or

spikes at the supply pins V

CC,VS

and R

ext

must

be blocked externally via capacitors.

8/10

Page 9

MULTIWATT15 PACKAGE MECHANICAL DATA

L9341

DIM.

MIN. TYP. MAX. MIN. TYP. MAX.

A 5 0.197

B 2.65 0.104

C 1.6 0.063

D 1 0.039

E 0.49 0.55 0.019 0.022

F 0.66 0.75 0.026 0.030

G 1.02 1.27 1.52 0.040 0.050 0.060

G1 17.53 17.78 18.03 0.690 0.700 0.710

H1 19.6 0.772

H2 20.2 0.795

L 21.9 22.2 22.5 0.862 0.874 0.886

L1 21.7 22.1 22.5 0.854 0.870 0.886

L2 17.65 18.1 0.695 0.713

L3 17.25 17.5 17.75 0.679 0.689 0.699

L4 10.3 10.7 10.9 0.406 0.421 0.429

L7 2.65 2.9 0.104 0.114

M 4.25 4.55 4.85 0.167 0.179 0.191

M1 4.63 5.08 5.53 0.182 0.200 0.218

S 1.9 2.6 0.075 0.102

S1 1.9 2.6 0.075 0.102

Dia1 3.65 3.85 0.144 0.152

mm inch

9/10

Page 10

L9341

Information furnished is believed to be accurate and reliable. However, SGS-THOMSON Microelectronics assumes no responsibility for the

consequences of use of such information nor for any infringement ofpatents or other rights ofthird parties whichmay result from itsuse. No

license is granted by implication or otherwise under any patent or patent rights of SGS-THOMSON Microelectronics. Specifications mentioned in this publication are subject to change without notice. This publication supersedes and replaces all information previously supplied.

SGS-THOMSON Microelectronics products are not authorized for use as critical components in life support devices or systems without express writtenapproval of SGS-THOMSON Microelectronics.

1994 SGS-THOMSON Microelectronics - All RightsReserved

Australia - Brazil - France -Germany - Hong Kong - Italy - Japan- Korea -Malaysia - Malta - Morocco - The Netherlands - Singapore-

SGS-THOMSON Microelectronics GROUPOF COMPANIES

Spain - Sweden - Switzerland - Taiwan - Thaliand - United Kingdom - U.S.A.

10/10

Loading...

Loading...