Page 1

L6920

1V HIGH EFFICIENCY SYNCRONO US STEP UP CONVERTER

■ 0.6 TO 5.5V OPERATING IN PUT VOLTA GE

■ 1V START UP INPUT VOLTAGE

■ INTERNAL SYNCHRONOUS RECTIFIER

■ ZERO SHUT DOWN CURRENT

■ 3.3V AND 5V FIXED OR ADJUSTABLE

OUTPUT VOLTAGE (2V UP TO 5.2V)

■ 120mΩ INTERNAL ACTIVE SWITCH

■ LOW BATTERY VOLTAGE DETECTION

■ REVERSE BATTERY PROTECTION

ORDERING NUMBER: L6920D

TSSOP8

Applications

■ ONE TO THREE CELL BATTERY DEVICES

■ PDA AND HAND HELD INSTRUMENTS

■ CELLULAR PHONES - DIGITAL CORDLESS

PHONE

■ PAGERS

■ GPS

■ DIGITAL CAMERAS

APPLICATION CIRCUIT

L1

V

CC

2.5V 3.3V

C2

LX

SHDN

7

5

L6920

DESCRIPTION

The L6920 is a high efficiency step-up controller requiring only three external components to realize the

conversion from the battery voltage to the selected

output voltage.

The start up is guaranteed at 1V and the dev ice is operating down to 0.6V.

Internal synchronous rectifier is implemented with a

120m

Ω

P-channel MOSFET and, in order to i mpr ove

the efficiency, a variable frequency control is implemented.

OUT

8

V

OUT

FB

1

500mA

C3 C1

May 2003

LBI

REF

2

3

LBO

GND

4

6

D00IN1136C

1/12

Page 2

L6920

8

PIN DESCRIPTION

Pin Name Function

1FB

Output voltage selector. Connect FB to GND for Vout=5V or to OUT for Vout=3.3V. Connect FB to an

external resistor divider for adjustable output voltage (from 2V to 5.2V) [see R4 and R5, fig. 7].

2 LBI Battery low voltage detector input. The internal threshold is set to 1.23V.

A resistor divider is needed to adjust the desired low battery threshold:

R1

V

1.23V= 1

LBI

3

LBO

Battery low voltage detector output. If the voltage at the LBI pin drops below the internal

------- -+

⋅

[see R1 and R2, fig. 7]

R2

threshold typ. 1.23V, LBO goes low.

LBO is an open drain output and so a pull-up resistor (about 200KΩ) has to be added for

The

correct output setting [see R3, fig. 7].

4 REF 1.23V reference voltage. Bypass this output to GND with a 100nF capacitor for filtering high

frequency noise. No capacitor is required for stability

5

SHDN

Shutdown pin. When pin 5 is below 0.2V the device is in shutdown, when pin 5 is above 0.6V the

device is operating.

6 GND Ground pin

7 LX Step-up inductor connection

8 OUT Power OUTPUT pin

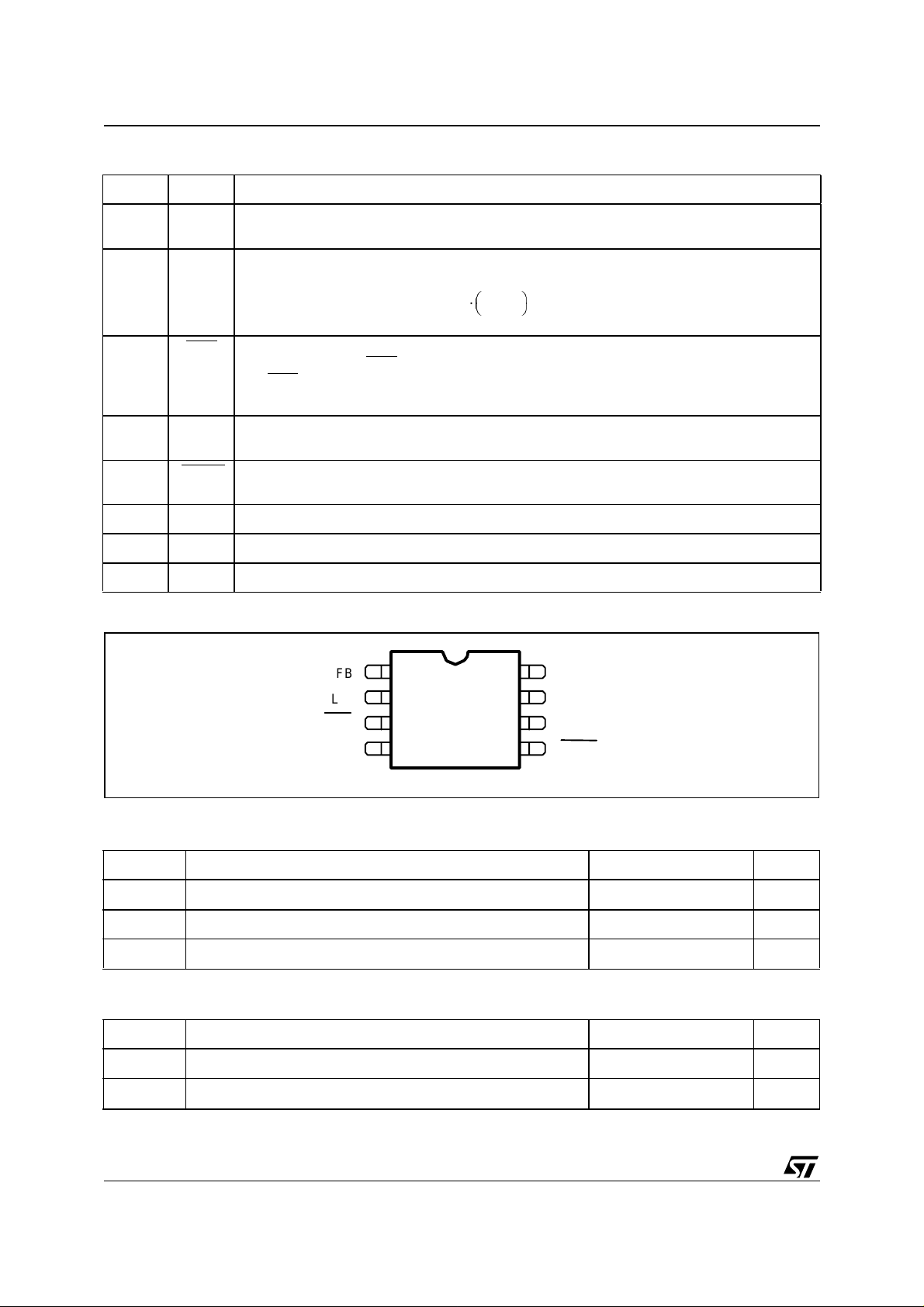

PIN CONNECTION (Top vi ew)

FB

LBI

LBO

REF

8

2

3

4

TSSOP

7

6

5

OUT1

LX

GND

SHDN

ABSOLUTE MAXIMUM RATINGS

Symbol Parameter Value Unit

V

ccmax

Vcc to GND 6 V

LBI, SHDN, FB to GND 6 V

V

out max

Vout to GND 6 V

THERMAL DATA

Symbol Parameter Value Unit

R

th j-amb

T

Thermal Resistance Junction to Ambient 250 °C/W

Maximum Junction Temperature 150 °C

j

2/12

Page 3

L6920

ELECTRICAL CHARACTERISTCS

(Vin = 2V, FB = GND, T

= -40°C to 85°C and Tj < 125°C unless other-

amb

wise specified))

Symbol Parameter Test Condition Min. Typ. Max. Unit

SECTION

V

CC

in

in

I

q

I

sd

on-N

on-P

Minimum operating Input Voltage 0.6 V

Minimum Start Up Input Voltage 1 V

Quiescent Current Il =0 mA, FB = 1.4V, V

LBI = SHDN = 2V, Tj = T

I

=0 mA, FB = 1.4V, V

l

LBI = SHDN = 2V, Tj = T

= 3.3V

out

amb

= 5V

out

amb

915µA

11 18 µA

Shut Down Current Vin = 5V, Il =0 mA 0.1 5 µA

amb

0.1 2 µA

Active switch ON resistance 120 250 mΩ

Synchronous switch ON

120 250 mΩ

resistance

V

V

Irev Reverse battery current Vin = -4V, Tj = T

POWER SECTION

R

R

CONTROL SECTION

Vout Output voltage FB = OUT, Il =0 mA 3.2 3.3 3.4 V

FB = GND, Il =0 mA 4.9 5 5.1 V

Output voltage range External divider 2 5.2 V

V

V

I

T

onmax

T

offmin

SHDN SHDN logic LOW

V

LBI threshold 1.18 1.23 1.27 V

LBI

0°C < T

LBO logic LOW

LBO

LX switch current limit 0.8 1 1.2 A

lim

I

Maximum on time V

Minimum off time V

SHDN logic HIGH

Reference Voltage 1.18 1.23 1.27 V

ref

< 70°C 1.205 1.23 1.255 V

j

< 250µA 0.2 0.4 V

sink

= 2V to 5.3V 3.75 5 6.25 µs

out

= 2V to 5.3V 0.75 1 1.25 µs

out

0.6 V

0.2 V

3/12

Page 4

L6920

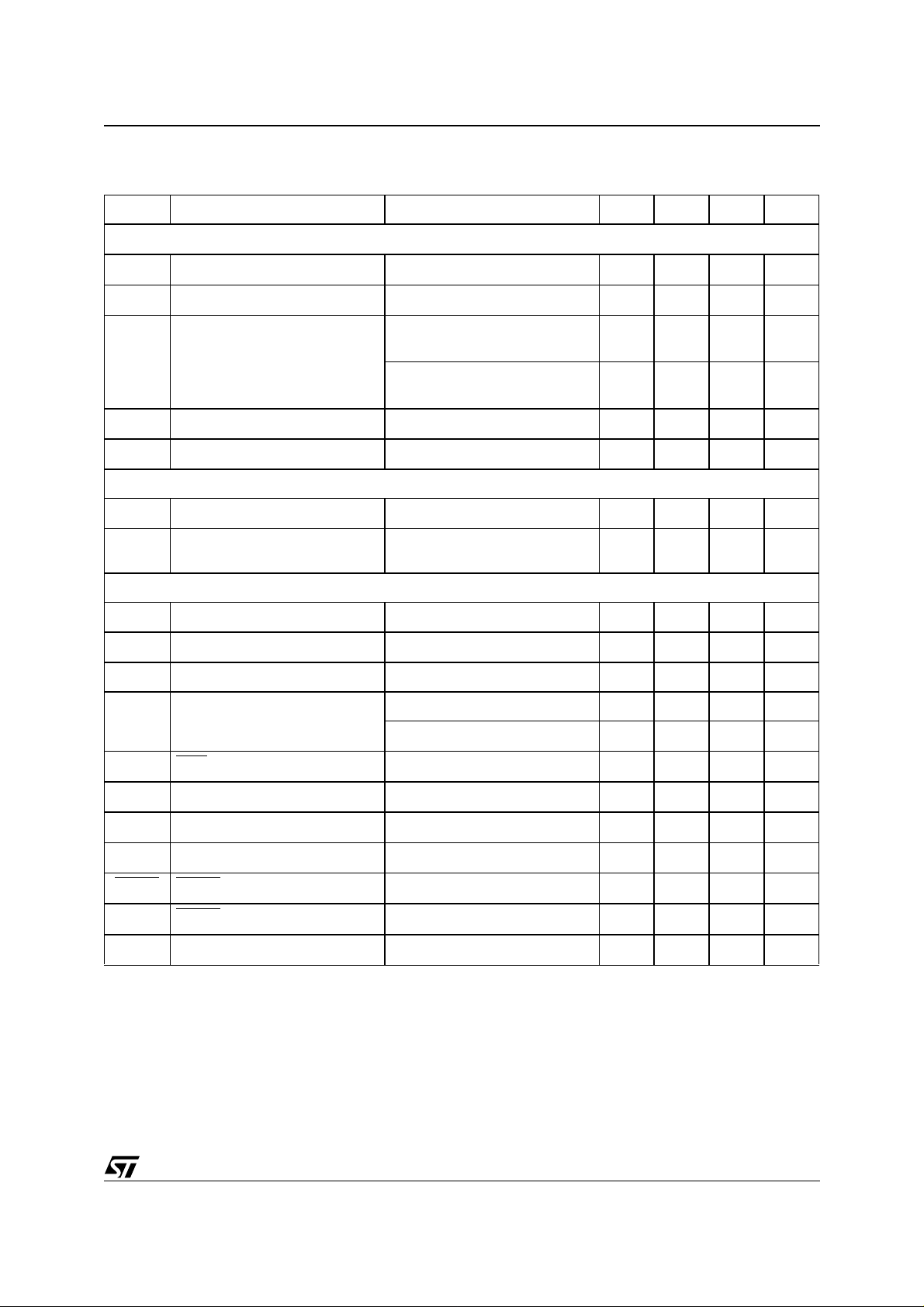

Figure 1.

Efficiency vs. Output Current

100

90

80

Vin = 1.2V

70

60

]

]

]

]

%

%

%

%

[

[

[

[

η

η

η

η

50

EFFICIENCY

40

30

20

10

0

0.01 0.1 1 10 100 1000

Figure 2.

Efficiency vs. Output Current

100

90

80

LOAD CURRENT [mA]

Vout = 3. 3V

L = 47µH

C = 100µF

Vin = 1.2V

70

Vin = 2.4V

Vin = 3.6V

Vin = 2.4V

Fig u re 3. Startup Vol tage v s Outpu t Curr ent

1.4

1.2

1

0.8

0.6

Startup voltage (V)

0.4

0.2

0

30 60 90 120 150 180

Output current (mA)

L = 47µH

C = 22µF

60

]

]

]

]

%

%

%

%

[

[

50

[

[

η

η

η

η

EFFICIENCY

40

30

20

10

0

0.01 0.1 1 10 100 1000

f

Vout = 5V

L = 47µH

C = 100µF

LOAD CURRENT [mA]

4/12

Page 5

L6920

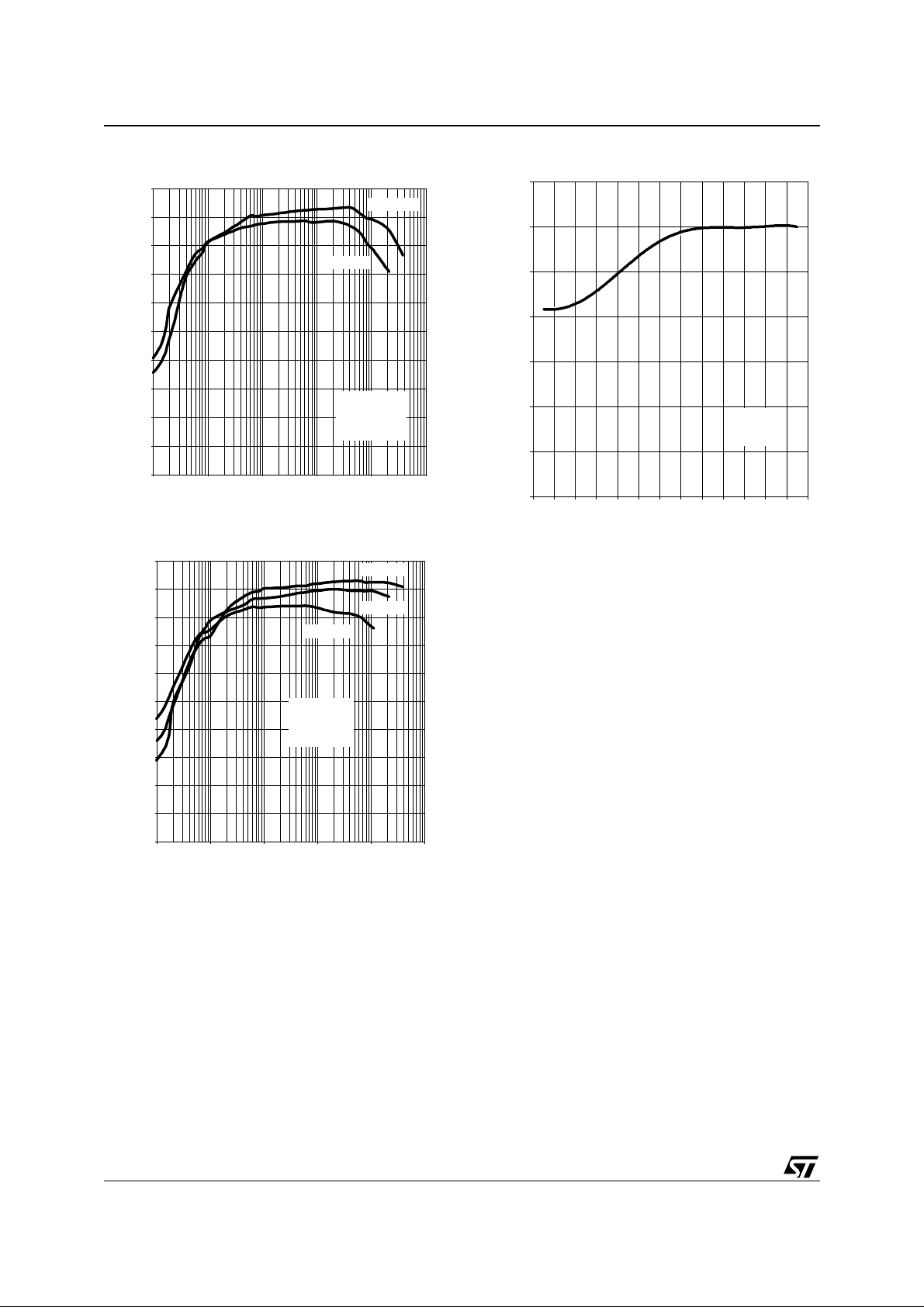

DETAILED DESCRIPTION

The L6920 is a high efficiency, low voltage step- up DC/DC conve rter partic ular ly su itable for 1 to 3 cell s (L i-Ion/

polymer, NiMH respectively) battery up conversion.

µ

These performances are achieved via a strong reduction of quiescent current (10

chronous rectification, that implies also a reduced cost in the application (no external diode required).

Operation is based on maximum ON time - minimum OFF time control, tailored by a current limit set to 1A. A

simplified block diagram is shown here below.

Figure 4. Simplified Block Diagram

A only) and adopting a syn-

V

REF

SHDN

LBO

OUT

LBI

A

B

C

(CR)

ZERO CROSSING

RQS

+

VBG

FB Y

V

OUT

GND

R1,R

Y

VBG

2

-

+

Toff min

1µsec

VBG

OPAMP

A

B

C

+

Ton max

5µsec

-

- +

+

CURRENT LIMIT

VOUT

LX

+

GND

FB

D99IN1041

V

OUT

V

IN

PRINCIPLE OF OPERATION

In L6920 the control is based on a comparator that continuously checks the status of output voltage.

If the output voltage is lower than the expected value, t he control function of the L6920 directs the energy stor ed

in the inductor to be transferred to the load. This is accomplished by alternating between two basic steps:

- TON phase: the energy is transfer red from the battery to the inductor by shor ting LX node to gr ound via the Nchannel power switch. The switch is turned off i f the curre nt flowing in the inductor r eaches 1A or after a maximum on time set to 5

µ

s.

- TOFF phase: the energy stored in the inductor is tr ansferred to the load thr ough the synchronous swi tch for at

least a minimum off time equal to 1

µ

s. After this, the synchronous switch is turned off as soon as the output

voltage goes lower than the regulated voltage or the current flowing in the inductor goes down to zero.

So, in case of light load, the device works in PFM mode, as shown in figure 5.

5/12

Page 6

L6920

Figure 5.1.

Figure 5.2.

PFM mode Condition: V

= 5V; Vin

out

=1.5V. Trace1: Vout (50mV~/div) Trace

4: IL (100mA/div) Time div.: 5µs/div

Heavier load - Train pulses overlapping.

Trace1: V

(100mV~/div) Trace 4: IL

out

(200mA /div) T ime div.: 10 µs/div

Figure 5.3.

Figure 5.4.

Heavy load - Inductor current ripples

below I

Trace1: V

lim

(100mV~/div)

out

Trace 4: IL (200mA/div) Time di v. : 20 µs/div

Heavy load and High ESR. Regulation

falls in continuous mode of operation.

Trace1: V

(100mV~/div) Trace 4: IL

out

(200mA/div). Time div.: 5 µs/div

When Iload is heavier, the pulse trains are overlapped. Figures 5.2 - 5.4 show some possible behaviors.

Considering that current in the inductor is limited to 1A, the maximum load current is defined by the following

relationship:

Where

η

is the efficiency and I

I

load _lim

lim

=1A.

V

in

-----------

V

I

–

limToff min

out

–

V

outVin

------------------------- -

⋅

2L⋅

eq. (1)

η⋅⋅=

Of course, if Iload is greater than Iload_lim the regulation is lost (figure 6).

6/12

Page 7

L6920

Figure 6. No regulation. I

V

(100mV~/div) Trace 4: IL (200mA/div).

out

load

> I

load_lim

Trace1:

Time div.: 5 µ s/div

Start-up

One of the key features of L6920 is the startup at supply voltage down to 1V (please see the diagram in

Figure 3. in case of heavy load).

The device leaves the startup mode of operation as

soon as VOUT goes over 1.4V. During startup, the

synchronous switch is off and the energy is transferred to the load through its intrinsic body diode.

The N-channel switches with a very low RDSon

thanks to an internal charge pump used to bias the

power mos gate. Because of this modified behavior,

TON/TOFF times are lengthened. Current limit and

zero crossing detection are still available.

The synchronous switch body diode causes a parasitic path between power supply and output that can't

be avoided also in shutdown.

Low battery detection

The L6920 includes a low battery detector comparator. Threshold is VREF voltage and a 1.3% hysteresis is added to avoid oscillations when input crosses

the threshold slowly. The

LBO

is an open drain out-

put so a pull up resistor is required for a proper use.

Reverse polarity

A protection circuit has been implemented to avoid

that L6920 and the battery are destroyed in case of

wrong battery insertion.

In addition, this circuit has been designed so that the

current required by the battery is zero also i n rever se

polarity.

APPLICATION INFORMATION

Output voltage selection

Output voltage must be selected acting on FB pin.

Three choices are av ailable : fixed 3.3V , 5V or a djustable output set via an external resistor divider.

OUTPUT VOLTAGE SELECTION

V

= 3.3V FB pin connected to OUT (see

OUT

= 5V FB pin connected to GND

V

OUT

application circui t)

Shutdown

In shutdown mode (

SHDN

pulled low) all internal circuitries are turned off, minimizing the current provided by the battery (I

< 100 nA, in typical case).

SHDN

Both switches are turned off, and the low battery

comparator output is forced in high impedance state.

2V ≤ V

≤ 5.2V FB pin connected to a resistive

OUT

divider

V

OUT

1.23V 1

=

R4

------- -+

R5

7/12

Page 8

L6920

Figure 7. Dem ob oard Circui t

+VBATT

R1

N.C.

LBI

2

R2

N.C.

VREF

C4

100nF

not mounted components

GND

4

6

VBATT

L6920

F.B.

Panasonic

ELL6RH100M

L1 10µH

7

VOUT

8

R3

N.C.

LBO

3

SHDN

5

1

J1

C3

N.C.

1

2

3

1

2

J2

3

C2

47µF

C1

47µF

R4 N.C.

R5 N.C.

Panasonic

EEFCDJ470R

Panasonic

EEFCDJ470R

D01IN1310

+VBATT

GND

VOUT

GND

LBO

SHDN

Jumper Position Function

1-2 Device enabled

J1

2-3 Device disabled

None Adjustable using R4 and R5 [not

mounted]

J2

1-2 3.3V output voltage

2-3 5V output voltage

R4, R5 should be s elected in the range of 100kΩ - 10MΩ to minimize c onsumption and error due to current s unk

by FB pin (few nA).

Output capacitor selection

The output capacitor affects both efficiency and output ripple so its choice has to be considered with particular

care.

The capacitance value should be in the range of about 10

µ

F-100µF.

An additional, smaller, low ESR capacitor can be in parallel for high frequency filtering. A typical value can be

µ

around 1

F.

If very high performances, in terms of efficiency and output voltage ripple, are required, a very low ESR capacitor has to be chosen.

Ceramic capacitors are the lowest ESR but they are very expensive.

Other possibilities are low-ESR tantalum capacit ors, available fr om KEMET, AVX and other sources. POSCAP

capacitors from SANYO and polymeric capacitors from PANASONIC are also good.

Below there is a l ist of some c apacitors supplier s . The cap values and rated v oltages a re only a suggested pos-

sibility

8/12

Page 9

Table 1. Capacitors distributors main list

Manufacturer Series Cap Value (µF) Rated Voltage (V) ESR (mΩ)

AVX TPS 15 to 470 6.3 50 to 1500

L6920

KEMET T510/T494/

T495

PANASONIC EEFCD 22 to 47 6.3 50 to 700

SANYO POSCAP TPA/B/C 22 to 230 6.3 40 to 80

SPRAGUE 595D 100 to 390 6.3 160 to 700

10 to 470 6 30 to 1000

Inductor selection

Usually, inductors ranging between 5µH to 40µH satisfy most of the applications.

Small value inductors have smaller phy sical size a nd guarantee a faster respons e to load transient but in s teady

state condition a bigger ripple on output voltage is generated. In fact the output ripple voltage is given by Ipeak

multiplied by ESR. Furthermore, as shown in equation (1), inductor size affects also the maximum current deliverable to the load. Lastl y, a low series resistanc e is s uggested if ver y high ef ficienc y values are needed. A nyway, the saturation current of the choke should be higher than the peak current limit of the device (1A).

Good surface mounting i nductors are availabl e fr om COILCRAFTS, COILTRONICS, MURATA and other souces. In the following table are listed some suggested components.

Table 2. Inductors distributors main list

Manufacture r Series Inductor Value (uH) Saturation Current (A)

Coilcraft DO1813HC 22 to 33 1 to 1.2

DO1608 4.7 to 15 0.9 to 1.5

Coiltronics UP1B 22 to 33 1 to 1.2

TP3 4.7 to 15 0.97 to 1.6

BI HM76-2 22 to 33 1 to 1.2

HM76-1 4.7 to 10 1 to 1.5

Murata LQN6C 10 to 22 1.2 to 1.7

Panasonic ELL6SH 10 to 22 0.9 to 1.5

ELL6RH 5.1 to10 11 to 1.55

Sumida CR43 4.7 to 10 0.84 to 1.15

Layout Guidelines

The board layout is very important in order to minimize noise, high frequency resonance problems and electromagnetic interference.

It is essential to keep as small as possible the high switching current circulating paths to reduce radiation and

resonance problems. So, the output and input cap should be very close to the device.

The external resistor dividers, if used, should be as cl ose as possibl e to the pi ns of the dev ice (F B and LBI) and

as far as possible from the high current circulating paths, to avoid pick up noise.

Large traces for high current paths and an extended groundplane, help to reduce the noise and increase the

efficiency.

For an example of recommended layout see the following evaluation board

9/12

Page 10

L6920

Figure 8. Figu re 8. De m o board Comp onents (Top s i de) .

Figure 9. Dem ob oard Layout (Top side).

4.5cm

4cm

Figure 10. Demoboard Layout (Bottom side).

4.5cm

4cm

4.5cm

4cm

10/12

Page 11

L6920

DIM.

mm inch

MIN. TYP. MAX. MIN. TYP. MAX.

A 1.20 0.047

A1 0.050 0.150 0.002 0.006

A2 0.800 1.0 00 1.050 0.031 0.039 0.041

b 0.190 0.300 0.007 0.0 12

c 0.090 0.200 0.003 0.008

D (1) 2.900 3.000 3.100 0.114 0.118 0.122

E 6.200 6.400 6.650 0.244 0.252 0.260

E1 (1) 4.300 4.400 4.500 0.169 0.173 0.177

e 0.650 0.026

L 0.450 0.600 0.750 0.018 0.024 0.027

L1 1.000 0.039

k 0˚ (min.) 8˚ (max.)

aaa 0.100 0.004

Note: 1. D and F doe s not include mold flash o r protru sions.

Mold flash or potrusions shall not exceed 0.15mm

(.006inch) per side.

OUTLINE AND

MECH ANICAL DA T A

TSSOP8

(Body 4.4mm)

0079397 (Jedec MO-153-AA)

11/12

Page 12

L6920

Information furnished is believed to be accurate and reliable. However, STMicroelectronics assumes no responsibility for the consequences

of use of such information nor for any infringement of patents or other rights of third parties which may result from its use. No license is granted

by implic ation or otherwise under any patent or patent ri ghts of STMicroelectronics . S pecificat i ons menti oned in th i s publicati on are subject

to change without notice. This publication supersedes and replaces all information previously supplied. STMicroelectronics products are not

authorized for use as cri tical comp onents in lif e support dev i ces or systems wi thout exp ress written approval of STMicroe l ectronics.

The ST logo is a registered trademark of STMicroelectronics

© 2003 STMic roelectroni cs - All Rig hts Reserved

Austra lia - Brazil - Canada - China - Finland - France - Germany - Hon g K ong - India - Israel - Italy - J apan -Mal aysia - Malta - Morocco -

Singap ore - Spain - Sw eden - Switzerland - Uni ted Kingdom - United St ates.

STMicroelectronics GROUP OF COMPANIES

http://www.s t. com

12/12

Loading...

Loading...