Page 1

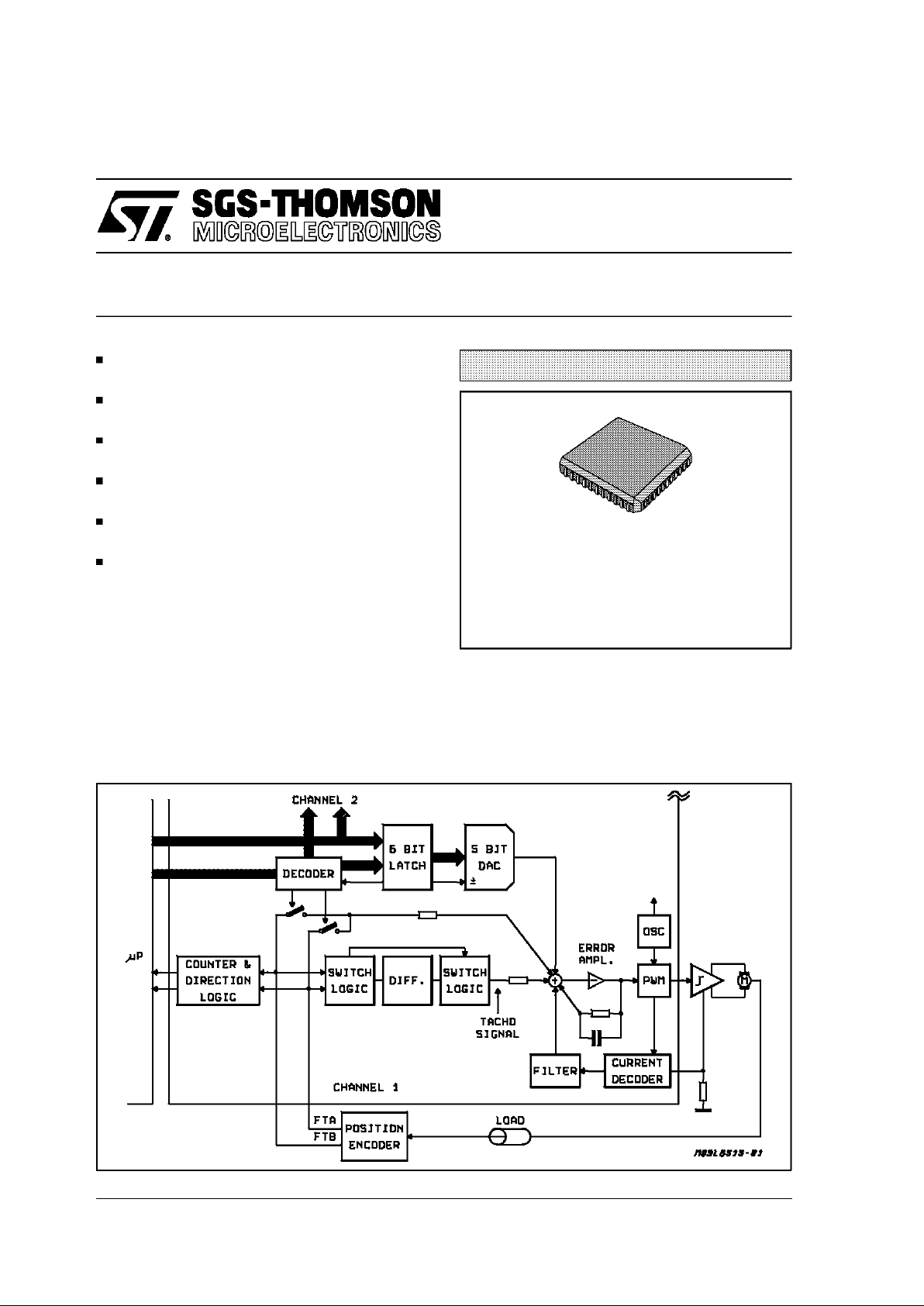

L6515

DUAL DC-MOTOR POSITIONING SYSTEM

ADVANCE DATA

PRECISE OPERATION ALSO WITH LOW

COST OPTICALENCODER

PWM - OUTPUT FOR DIGITAL SWITCHED

POWERBRIDGES

DIRECTION INDICATOR FOR EASY POSITIONCOUNTING WITH µP

EXTERNAL LOOP GAIN AND TRANSFER

FUNCTIONALADJUSTMENT

PARALLEL ADDRESSED INPUTS WITH

LATCH

44 LEAD PLCC PACKAGE

DESCRIPTION

The L6515 is a monolithic integrated circuit in

BCD-Technologyassembledina PLCC-44plastic

chipcarrier.

The device contains all functions for a complete

dual DC-Motor positioning system. For the motor

driver stage only digital switched bridges are

needed.

Useful are L293E, L298, L6203 and L6202. The

device is intended to drive DC-Motors in typewriters, printers, plotters and general purpose industrialapplications.

This isadvanced information on anew product now in development or undergoing evaluation. Details are subject tochange without notice.

May 1994

SYSTEM BLOCK DIAGRAM (ONECHANNEL)

PLCC44

ORDERING NUMBER: L6515

MULTIPOWERBCD TECHNOLOGY

1/13

Page 2

SYSTEM DESCRIPTION

The L6515 is intended to be used as a microprocessorcontrolledpositioningsystem.

For the motor driver stage only digital operating

bridgesareneededl ikeL293E,L298,L6203,L6202.

The system operates in two modes to achieve

high-speed,high-accurancy positioning.

Speed commands for the system originate in the

microprocessor. It is continuouslyupdated on the

motor position by means of pulses from the controller chip, which in turn gets its information from

the encoder. From this basic input, the microprocessor computes a 6-bit control word that sets the

systemspeed anddirectiondependenton the distance to travel.

When the motor is stopped and the microprocessor orders it to a new position, the system oper-

ates initially in an open-loop configuration as

there is no feedback from the tachometer generator.Therefore maximumcurrentis fed to themotor. As maximum speed is reached, the tachometer chip output backs off the processors signal

thus reducing acceleratingtorque.Themotor continues to run at top speed but under closed-loop

control.

As a target position is approached,the microprocessor lowers the value of the speed-demand

word; this reduces the voltage at the main summing point, in effect braking the motor. The braking is appliedprogressively until the motor is running at minimum speed.

At that time, the microprocessor orders a switch

to the position mode, and within 3 to 4ms the

power stage drives the motor to a null position,

whereit is held by electronic ”detening”.

Symbol Parameter Value Unit

V

S

Supply Voltage 12 V

V

IA

Analog Inputs Voltage -0.3 to 7 V

V

IL

Logic Inputs Voltage -0.3 to 7 V

V

O

Open Collector Output Current 12 V

I

O

Open Collector Current 10 mA

I

Z

Zener Current 20 mA

T

stg

, Tj Storage Temperature -40to 150 °C

T

amb

Operative Ambient Temperature 0 to 70 °C

ABSOLUTE MAXIMUMRATINGS

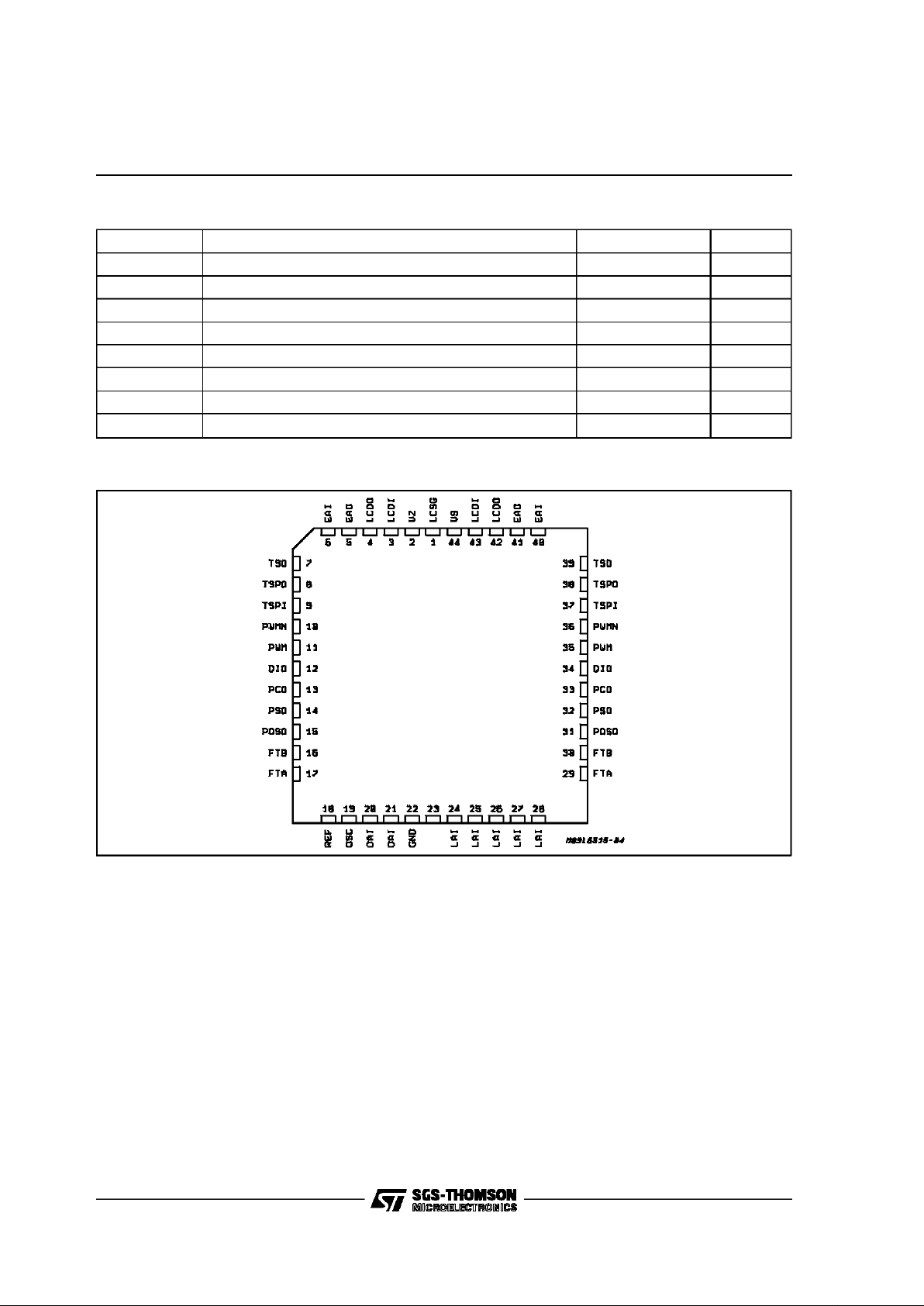

PIN CONNECTION (top view)

LAI

L6515

2/13

Page 3

Pin Name Description

1 LCSG Load Current Decoder Sens Reference Ground

2V

Z

Zener Clamp

3,43 LCDI Load Current Decoder Input

4,42 LCDO Load Current Decoder Output

5,41 EAO Error AmplifierOutput for Current Mode PWM Modulator

6,40 EAI Error Amplifier Input for Current Mode PWM Modulator

7,39 TSO Tacho Signal Output

8,38 TSPO Tacho SignalProcessor Output

9,37 TSPI Tacho Signal Processor Input

10,36 PWMN Current Mode PWM Output Inverted

11,35 PWM Current Mode PWM Output non Inverted

12,34 DIO Direction Indicator Digital Open Collector Output. A Low Level is cw,

A High Level is ccw Operation ofthe Motor

13,33 PCO Position Counter Digital Open Collector Output

14,32 PSO Phase Selector Output for Signal Differentation

15,31 POSO Positioning Output. The Output Becomes Activated via Position

Adress Decoder.

16,30 FTB Analog Input from PositionEncoder Phase B. Proposed Operation

Range is 2.8V + 1V.

17,29 FTA Analog Input from PositionEncoder Phase A. Proposed Operation

Range is 2.8V + 1V

18 REF Master Current Reference

19 OSC Oscillator

20,21 DAI Decoder Logic Input for Latch Select + Reset

22 GND Major and Logic Ground

23 to 28 LAI Latch Adress Input

44 V

S

Supply Voltage

PIN FUNCTIONS

L6515

3/13

Page 4

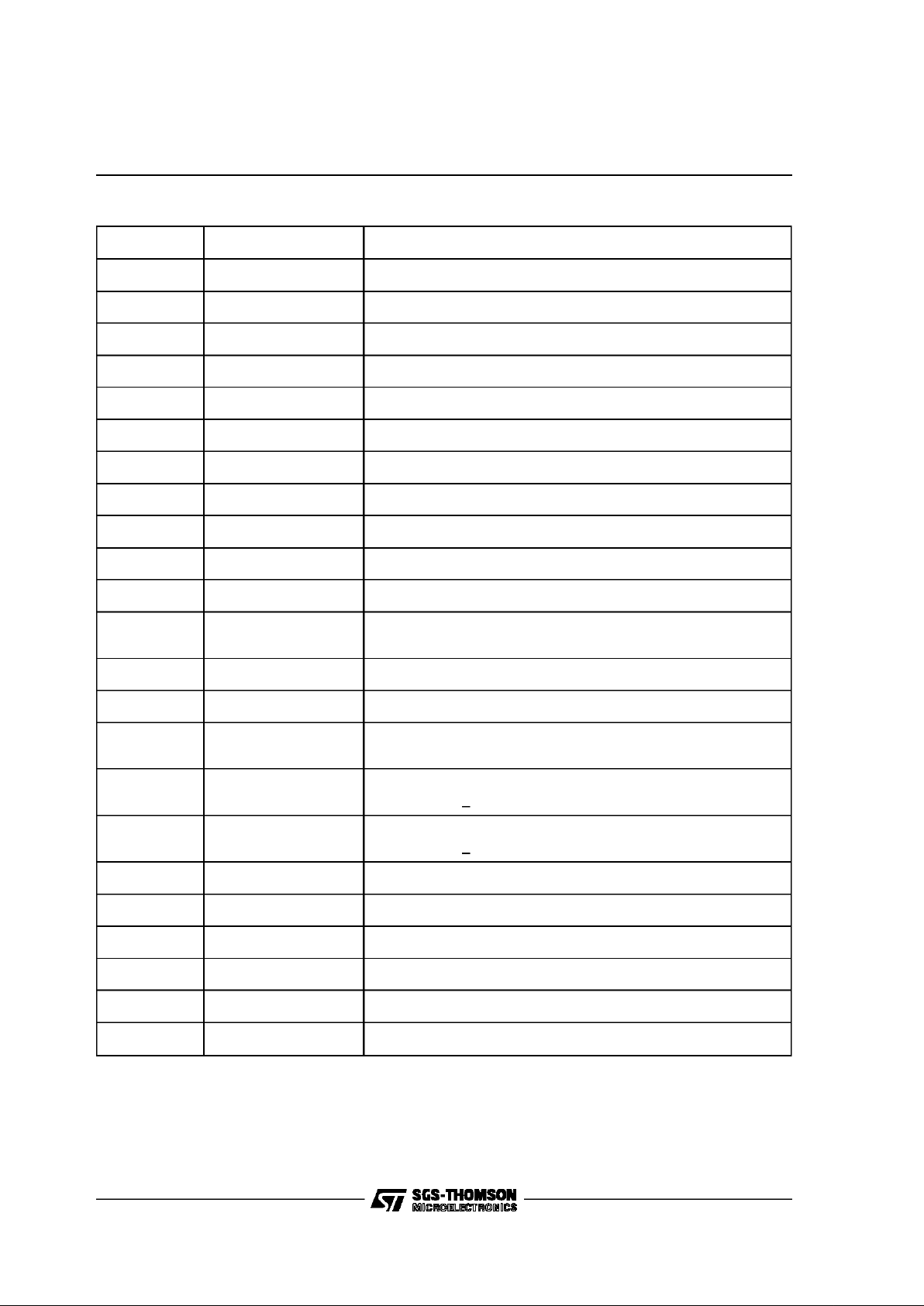

SCHEMATICDIAGRAM

L6515

4/13

Page 5

APPLICATIONCIRCUIT

L6515

5/13

Page 6

Symbol Parameter Pin Test Condition Min. Typ. Max. Unit

V

S

Operating Supply VoltageRange 7 11 V

I

S

Quiescent supply current 50 mA

V

Z

Zener Voltage Iz=1mA 8,5 9.9 11,4 V

I

Z

Operating Zener Current 1 mA

ELECTRICAL CHARACTERISTICS (refer to test circuit, VS=10V, I

REF

=300µA, T

amb

=25 °C unless

otherwisespecified)

V

I

Operating Input Voltage Range A/D/1/2 referredto V

REF

-1,65 +1,65 V

I

I

Input Bias Current 1 µA

V

OS

INput-output Offset Voltage Between

A/D/1/2 and F/1/2

S3 or S4

closed

I

o

=0

±15 mV

S1 or S2

closed

I

o

=0

V

IN=VREF

±20 mV

V

SAT

Output Saturation Voltage B/C/1/2 Io=1.4mA 0.4 V

I

OH

Output Leakage Current 10 µA

V

TH

ThresholdHysteresis

voltageBetween

A/1/2 and B/1/2

D/1/2 and C/1/2

80 150 mV

R

ON

Output Resistance ON State E/F/1/2 One of S1 to

S6 closed

150 300 Ω

V

OL

Output Operating Low Voltage E/F/1/2 referred

to V

REF

IO=1mA

-1.2 V

V

OH

OutpUt Operating High Voltage +1.2 V

POSITIONENCODER SECTION

L6515

6/13

Page 7

Symbol Parameter Pin Test Condition Min. Typ. Max. Unit

V

I

Input Voltage G/1/2 gain=1

referred

to V

REF

-1.65 +1.65 V

I

I

Input Bias Current 1 µA

V

OL

Output Operating Low Voltage H/1/2 referred to V

REF

-1.62

V

I/1/2

Io=1mAS7closed

-1.3

V

OH

Output Operating

low Voltage

I/1/2 +1.3

H/1/2 +1.62

R

ON

Output Resistance

On State

I1/2 S7 or S7

closed

150 260 Ω

V

OS

Input Offset Voltage H1/2 VIN=V

REF

S7 closed

I

o

=0

±20 mV

V

OS

Input Offset Voltage G1/2 referred to V

REF

g1/2 shorted

to H1/2

±20 mV

R

MO

Output Matching

Resistance

I1/2 S7 or S7

closed

0.8 1.2 Ω

TACHOSIGNALPROCESSINGSECTION

V

I

Input Voltage J1/2 gain=1 1 4.6 V

I

I

Input Bias Current 1 µA

V

O

L Lower Clamping Voltage K1/2 Io=1ma

refered to V

REF

-1.45 -1.22 V

V

OH

Higher Clamping Voltage +1.06 +1.56 V

V

OS

Input Offset Voltage J1/2 referred to V

REF

K1/2 J1/2 shorted

±20 mV

ERRORAMPLIFIERSECTION

V

OS

Output Offset Voltage L1/2 N1/2=0

referred to V

REF

±140 mV

R

OUT

Output Resistance 0.5 1.7 KΩ

V

CLH

Current Limit Threshold O1/2

P1/2

referred to V

REF

±0.5 V

V

CDO

Differential Output Offset Voltage L1/2 V

off(+)-Voff(-)

±20 mV

CURRENT DECODERSECTION

L6515

7/13

Page 8

Symbol Parameter Pin Test Condition Min. Typ. Max. Unit

V

H

Upper Triangle Threshold Referred to V

REF

+1.2 +1.8 V

V

L

Lower Triangle Threshold -1.6 -1.3 V

I

CD

Charge/Discharge Current I

REF

=500µA ±160 ±180 µA

V

O

PWM Output Voltage O1/2 Io=1.4mA 0.4 V

P1/2 2.7

OSCILLATOR-PWM SECTIONS

I

REF

Current Reference Input Range Z 0.3 0.7 mA

I

O

Sink and Source Output Current J1/2 I

REF

=0.5 mA 918 968 1018 µA

V

REF

Reference Voltage Z I

REF

=20 µa 2.7 2.8 2.9 V

I

O

LinearityError J1/2 I

REF

=0.5 mA 1.61 /FS

DACSECTION

V

INL

Input lOw Voltage R

S

-0.3 0.8 V

V

INH

Input High Voltage T

U

27V

I

L

Input V

W

-10 µA

I

H

Input High Current High Voltage X

Y

30 µA

INPUTLOGIC SECTION

L6515

8/13

Page 9

TRUTH TABLETACHO-ENCODER LOGIC

PDIB > PDIA C 1 = HIGH

PDIB < PDIA C 1 = LOW

PDIB > PDIA C2 = HIGH

PDIB < PDIA C2 = LOW

INPUTSIGNAL

C1 C2 CLOSED S2 POSITION

L H S1 TSPO

H H S2 TSPO

H L S3 TSPO

L L S4 TSPO

SWITCHSIGNAL

APPLICATIONCIRCUIT

L6515

9/13

Page 10

TRUTH TABLELOGICSELECTION CHIP ADDRESS

Terminals

Functions

RS

L L NO ACTION

H L STROBE LATCH 1

L H STROBE LATCH 2

H H RESET LATCH 1/2

DECODER ADDRESS

LATCH ADDRESS

TIMING DIAGRAM OF COUNTER AND DIRECTIONINDICATION LOGIC

L6515

10/13

Page 11

POSITIONENCODER

Main advantage of the operation principle of the

positioningsystem is that a high performancepositionencoder is not required.

The system accepts several phases and amplitude errors of the encoder output signal without

affectingthe systemperformance.

Two positionsensorsare useful.

1) Optical-Encoderwith IR-LED and Phototransistor

2) Magnetic Encoder with hall-effect sensors

The allowedspreadof theencoderoutput signal refer to referencelevel is shown in Fig.3.

Figure3.

Figure2.

Figure1.

L6515

11/13

Page 12

PLCC44PACKAGE MECHANICAL DATA

DIM.

mm inch

MIN. TYP. MAX. MIN. TYP. MAX.

A 17.4 17.65 0.685 0.695

B 16.51 16.65 0.650 0.656

C 3.65 3.7 0.144 0.146

D 4.2 4.57 0.165 0.180

d1 2.59 2.74 0.102 0.108

d2 0.68 0.027

E 14.99 16 0.590 0.630

e 1.27 0.050

e3 12.7 0.500

F 0.46 0.018

F1 0.71 0.028

G 0.101 0.004

M 1.16 0.046

M1 1.14 0.045

L6515

12/13

Page 13

Information furnished is believed to be accurate and reliable. However, SGS-THOMSON Microelectronics assumes no responsibility for the

consequences of use of such information nor for any infringement ofpatents or other rights of third parties whichmay result from itsuse. No

license is granted by implication or otherwise under any patent or patent rights of SGS-THOMSON Microelectronics. Specifications mentioned in this publication are subject to change without notice. This publication supersedes and replaces all information previously supplied.

SGS-THOMSON Microelectronics products are not authorized for use as critical components in life support devices or systems without express writtenapproval of SGS-THOMSON Microelectronics.

1994 SGS-THOMSON Microelectronics - All RightsReserved

SGS-THOMSON Microelectronics GROUP OF COMPANIES

Australia - Brazil- France -Germany - Hong Kong -Italy - Japan - Korea -Malaysia - Malta - Morocco -The Netherlands- Singapore -

Spain - Sweden - Switzerland- Taiwan - Thaliand - United Kingdom- U.S.A.

L6515

13/13

Loading...

Loading...