Page 1

Features

■ Integrated high-voltage start-up

■ 4 drivers for PFC, half-bridge & pre-heating

MOSFETs

■ 3.3V microcontroller compatible

■ Fully integrate power management for all

operating modes

■ Internal two point V

■ Over-current protection with digital output

signal

■ Cross-conduction protection (interlocking)

■ Under voltage lock-out

■ Integrated bootstrap diode

regulator

CC

L6382D

Power management unit

for microcontrolled ballast

SO-20

Description

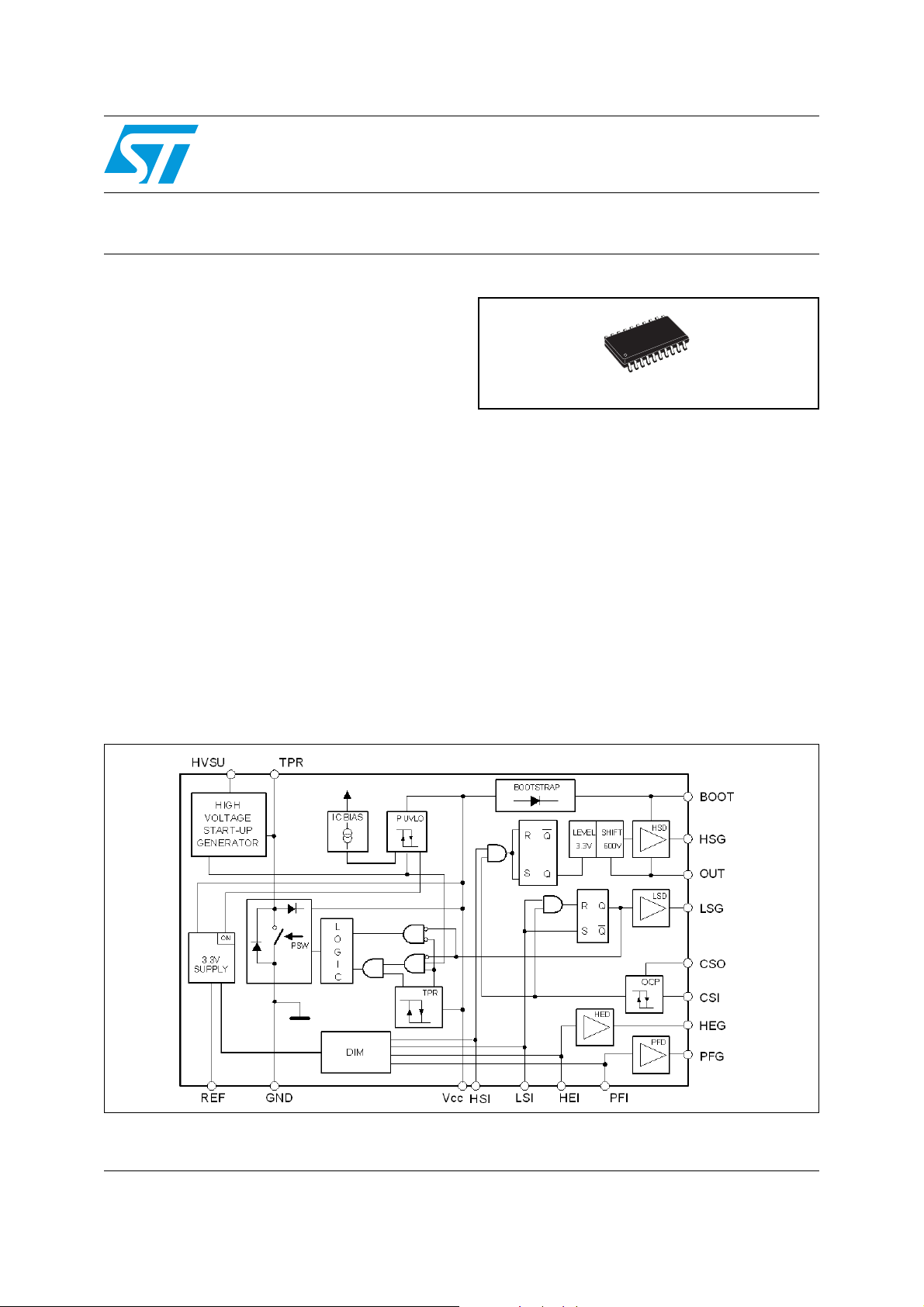

The L6382D is suitable for microcontrolled

electronic ballasts embedding a PFC stage and a

half-bridge stage. The L6382D includes 4

MOSFET driving stages (for the PFC, for the half

bridge, for the preheating MOSFET) plus a power

management unit (PMU) featuring also a

reference able to supply the microcontroller in any

condition.

Applications

■ Dimmable / non-dimmable ballast

Figure 1. Block diagram

Besides increasing the application efficiency, the

L6382D reduces the bill of materials because

different tasks (regarding drivers and power

management) are performed by a single IC, which

improves the application reliability.

µ

March 2007 Rev 6 1/22

www.st.com

22

Page 2

Contents L6382D

Contents

1 Device description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2 Pin settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.1 Pin connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.2 Pin description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3 Maximum ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3.1 Absolute maximum ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3.2 Thermal data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

4 Electrical characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

5 Typical electrical performance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

6 Application information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

6.1 Power management . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

6.1.1 START-UP mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

6.1.2 SAVE Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

6.1.3 OPERATING Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

6.1.4 Shut down . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

7 Block description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

7.1 Supply section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

7.2 3.3V reference voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

7.3 Drivers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

7.4 Internal logic, over current protection (OCP) and interlocking function . . 17

8 Package mechanical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

9 Order codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

10 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

2/22

Page 3

L6382D Device description

1 Device description

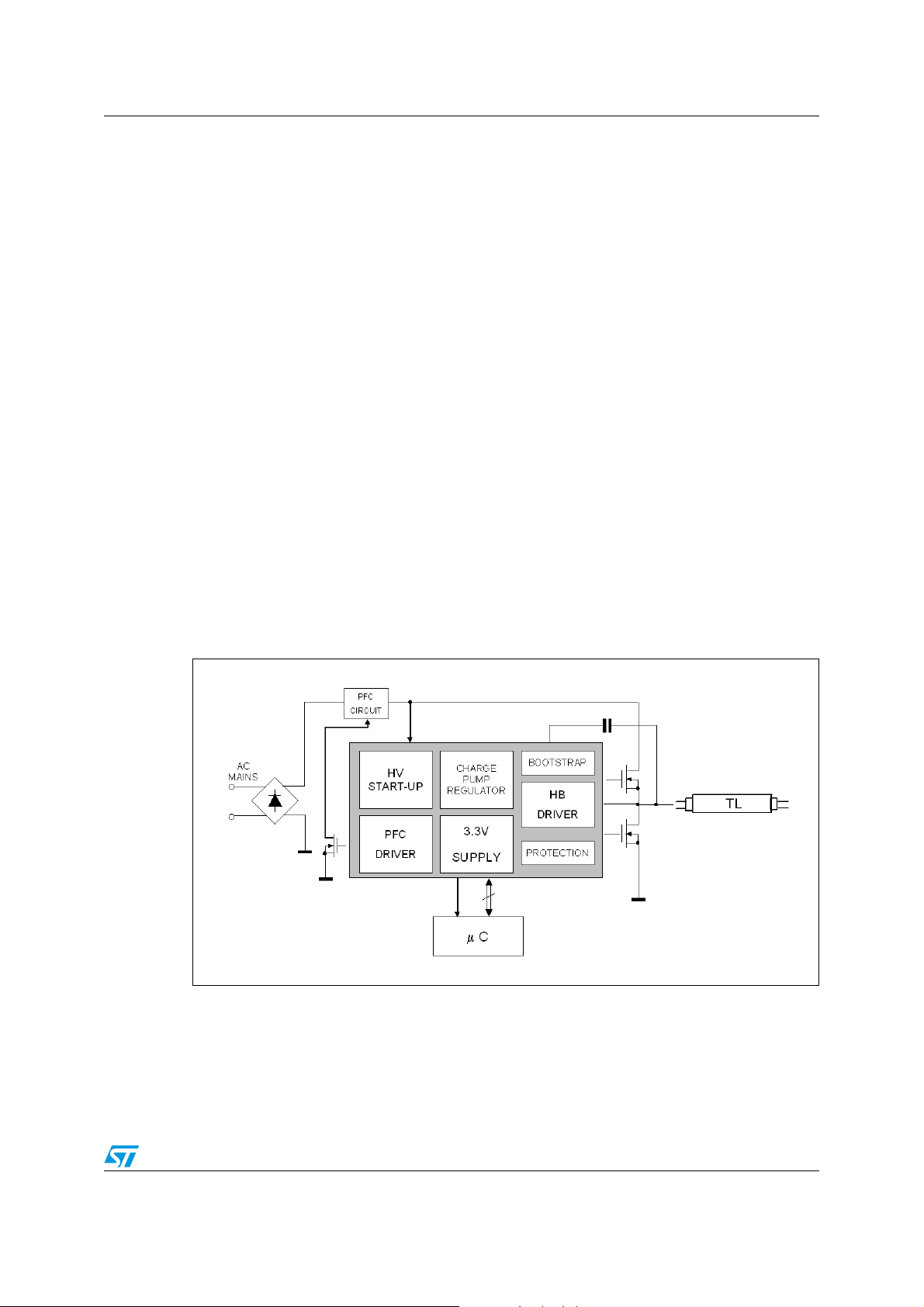

Designed in High-voltage BCD Off-line technology, the L6382D is a PFC and ballast

controller provided with 4 inputs pin and a high voltage start-up generator conceived for

applications managed by a microcontroller providing the maximum flexibility. It allows the

designer to use the same ballast circuit for different lamp wattage/type by simply changing

the µC software.

The digital input pins - able to receive signals up to 400KHz - are connected to level shifters

that provide the control signals to their relevant drivers; in particular the L6382D embeds

one driver for the PFC pre-regulator stage, two drivers for the ballast half-bridge stage (High

Voltage, including also the bootstrap function) and the last one to provide supplementary

features like preheating of filaments supplied through isolated windings in dimmable

applications.

A precise reference voltage (+3.3V ±1%) able to provide up to 30mA is available to supply

the µC: this current is obtained thanks to the on-chip high voltage start-up generator that,

moreover, keeps the consumption before start-up below 150µA.

The chip has been designed with advanced power management logic to minimize power

losses and increase the application reliability.

In the half-bridge section, a patented integrated bootstrap section replaces the external

bootstrap diode.

The L6382D integrates also a function that regulates the IC supply voltage (without the need

of any external charge pump) and optimizes the current consumption.

Figure 2. Typical system block diagram

3/22

Page 4

Pin settings L6382D

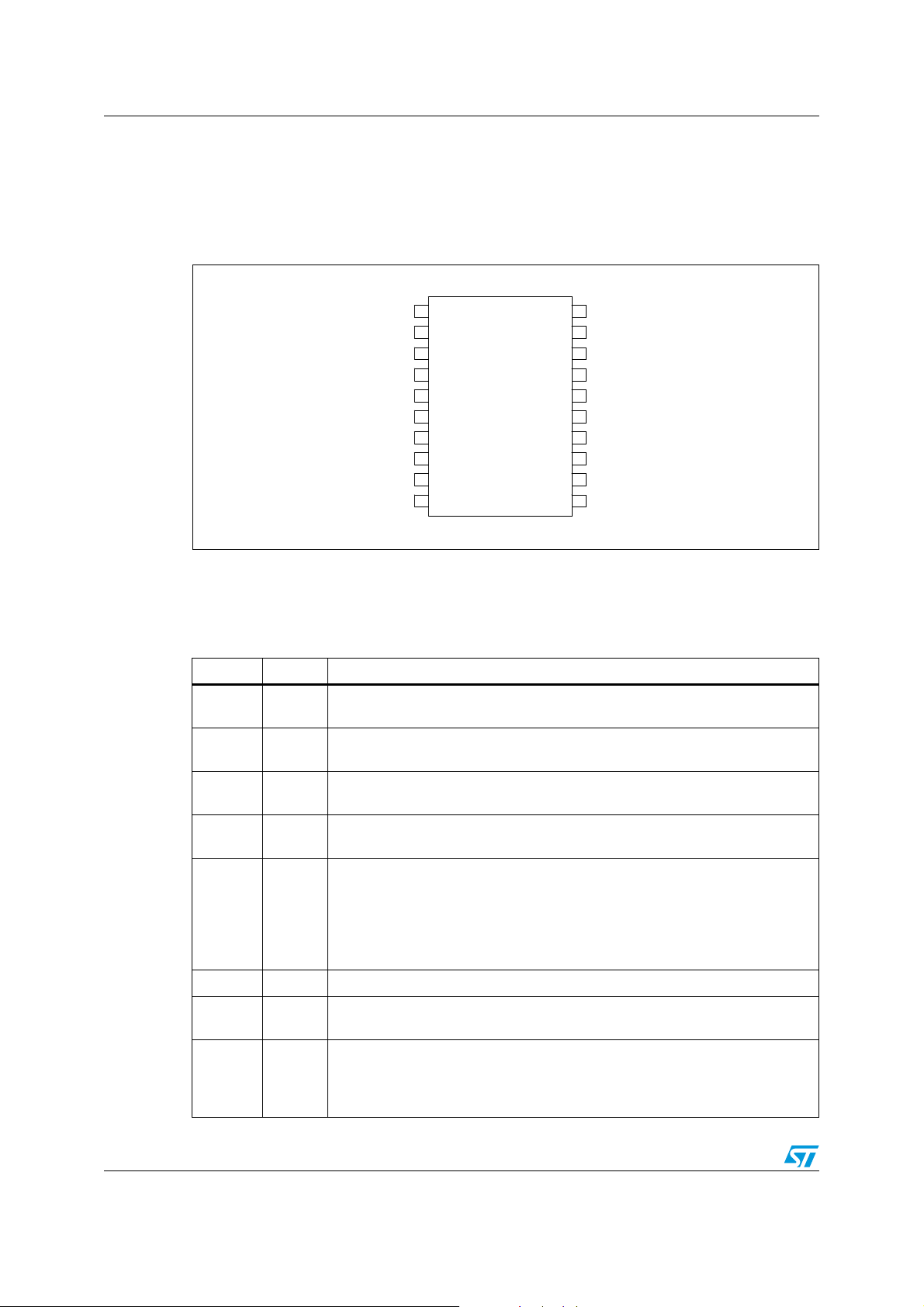

2 Pin settings

2.1 Pin connection

Figure 3. Pin connection (top view)

2.2 Pin description

Table 1. Pin description

Name Pin N° Description

1PFI

2LSI

3HSI

Digital input signal to control the PFC gate driver. This pin has to be connected

to a TTL compatible signal.

Digital input signal to control the half-bridge low side driver. This pin has to be

connected to a TTL compatible signal.

Digital input signal to control the half-bridge high side driver. This pin has to be

connected to a TTL compatible signal.

PFI

PFI

LSI

LSI

HSI

HSI

HEI

HEI

PFG

PFG

N.C.

N.C.

TPR

TPR

GND

GND

LSG

LSG

VCC

VCC

1

1

2

2

3

3

4

4

5

5

6

6

7

7

8

8

9

9

10

10

20

20

19

19

18

18

17

17

16

16

15

15

14

14

13

13

12

12

11

11

VREF

VREF

CSI

CSI

CSO

CSO

HEG

HEG

N.C.

N.C.

HVSU

HVSU

N.C.

N.C.

OUT

OUT

HSG

HSG

BOOT

BOOT

4HEI

5PFG

6 N.C. Not connected

7TPR

8GND

4/22

Digital input signal to control the HEG output. This pin has to be connected to a

TTL compatible signal.

PFC Driver Output. This pin is intended to be connected to the PFC power

MOSFET gate. A resistor connected between this pin and the power MOS gate

can be used to reduce the peak current. An internal 10KΩ resistor toward

ground avoids spurious and undesired MOSFET turn-on. The totem pole

output stage is able to drive the power MOS with a peak current of 120mA

source and 250mA sink.

Input for two point regulator; by coupling the pin with a capacitor to a switching

circuit, it is possible to implement a charge circuit for the Vcc.

Chip ground. Current return for both the low-side gate-drive currents and the

bias current of the IC. All of the ground connections of the bias components

should be tied to a trace going to this pin and kept separate from any pulsed

current return.

Page 5

L6382D Pin settings

Table 1. Pin description

Name Pin N° Description

Low Side Driver Output. This pin must be connected to the gate of the halfbridge low side power MOSFET. A resistor connected between this pin and the

power MOS gate can be used to reduce the peak current.

9LSG

10 Vcc Supply Voltage for the signal part of the IC and for the drivers.

11 BOOT

12 HSG

13 OUT

14 N.C. Not connected

An internal 20KΩ resistor toward ground avoids spurious and undesired

MOSFET turn-on.

The totem pole output stage is able to drive power with a peak current of

120mA source and 120mA sink.

High-side gate-drive floating supply Voltage. The bootstrap capacitor

connected between this pin and pin 13 (OUT) is fed by an internal

synchronous bootstrap diode driven in phase with the low-side gate-drive. This

patented structure normally replaces the external diode.

High Side Driver Output. This pin must be connected to the gate of the half

bridge high side power MOSFET . A resistor connected between this pin and

the power MOS gate can be used to reduce the peak current.

An internal 20KΩ resistor toward OUT pin avoids spurious and undesired

MOSFET turn-on

The totem pole output stage is able to drive the power MOS with a peak

current of 120mA source and 120mA sink.

High-side gate-drive floating ground. Current return for the high-side gate-drive

current. Layout carefully the connection of this pin to avoid too large spikes

below ground.

15 HVSU

16 N.C.

17 HEG

18 CSO

19 CSI

20 VREF

High-voltage start-up. The current flowing into this pin charges the capacitor

connected between pin Vcc and GND to start up the IC. Whilst the chip is in

mode, the generator is cycled on-off between turn-on and save mode

save

voltages. When the chip works in operating

and it is re-enabled when the Vcc voltage falls below the UVLO threshold.

According to the required V

rectified mains voltage either directly or through a resistor.

High-voltage spacer. The pin is not connected internally to isolate the highvoltage pin and comply with safety regulations (creepage distance) on the

PCB.

Output for the HEI block; this driver can be used to drive the MOS employed in

isolated filaments preheating. An internal 20KΩ resistor toward ground avoids

spurious and undesired MOSFET turn-on.

Output of current sense comparator, compatible with TTL logic signal; during

operating

triggered (CSI> 0.5V typ.) the pin latches high.

Input of current sense comparator, it is enabled only during operating mode;

when the pin voltage exceeds the internal threshold, the CSO pin is forced

high and the half bridge drivers are disabled. It exits from this condition by

either cycling the Vcc below the UVLO or with LGI=HGI=low simultaneously.

Voltage reference. During normal mode an internal generator provides an

accurate voltage reference that can be used to supply up to 30mA (during

operating mode) to an external circuit. A small film capacitor (0.22µF min.),

connected between this pin and GND is recommended to ensure the stability

of the generator and to prevent noise from affecting the reference.

mode, the pin is forced low whereas whenever the OC comparator is

pin current, this pin can be connected to the

REF

mode the generator is shut down

5/22

Page 6

Maximum ratings L6382D

3 Maximum ratings

3.1 Absolute maximum ratings

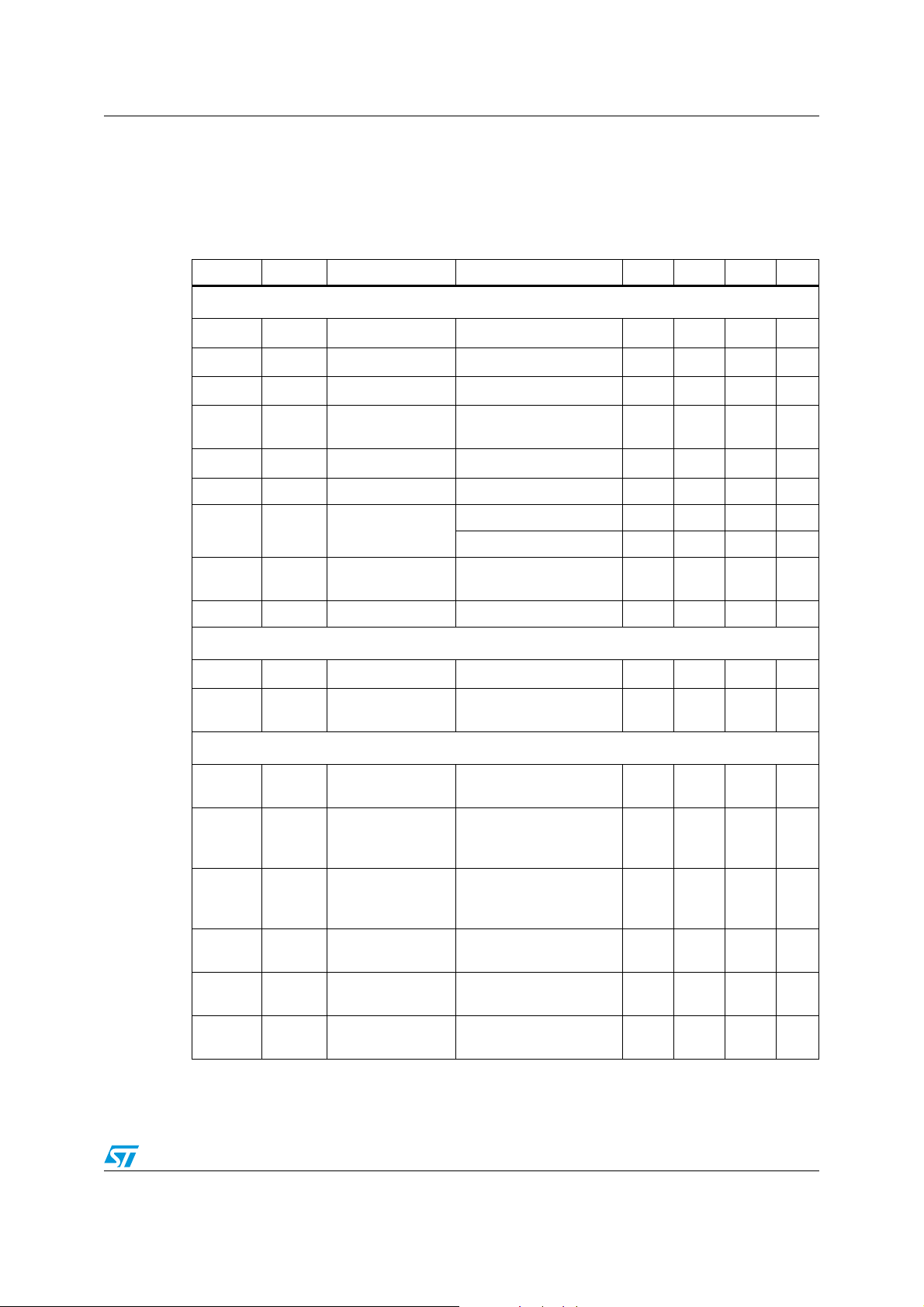

Table 2. Absolute maximum ratings

Symbol Pin Parameter Value Unit

V

CC

V

HVSU

V

BOOT

V

OUT

I

TPR(RMS)

I

TPR(PK)

V

TPR

10 IC supply voltage (ICC = 20mA) Self-limited

15 High voltage start-up generator voltage range -0.3 to 600 V

11 Floating supply voltage

-1 to V

HVSU+VCC

13 Floating ground voltage -1 to 600 V

7 Maximum TPR RMS current ±200 mA

7 Maximum TPR peak current ±600 mA

7

Maximum TPR voltage

(1)

14 V

19 CSI input voltage -0.3 to 7 V

1, 2,

Logic input voltage -0.3 to 7 V

3, 4

9, 12,

Operating frequency 15 to 400 KHz

17

V

5 Operating frequency 15 to 600 KHz

Tstg Storage temperature -40 to +150 °C

T

J

1. Excluding operating mode

3.2 Thermal data

Table 3. Thermal data

Symbol Parameter Value Unit

R

thJA

Maximum thermal resistance junction-ambient 120 °C/W

Ambient temperature operating range -40 to +125 °C

6/22

Page 7

L6382D Electrical characteristics

4 Electrical characteristics

Table 4. Electrical characteristcs (TJ = 25°C, VCC = 13V, C

unless otherwise specified)

DRIVER

= 1nF

Symbol Pin Parameter Test condition Min Typ Max Unit

Supply voltage

V

CCON

V

CCOFF

V

CCSM

VSMhys 10

V

REF(OFF)

10 Turn-on voltage 13 14 15 V

10 Turn-off voltage 7.5 8.25 9.2 V

10 Save mode voltage 12.75 13.8 14.85 V

Save mode

hysteresys

0.12 0.16 0.2 V

10 Reference turn-off 5.7 6 6.4 V

IvccON 10 Start-up current 150 µA

IvccSM 10

Ivcc 10

Save Mode current

consumption

Quiescent current

in operating mode

(1) 150 230 µA

LGI = HGI = high;

no load on VREF.

190 µA

2mA

Vz 10 Internal Zener 16.5 17 18 V

High voltage start-up

> 50V

IMSS 15 Maximum current

ILSS 15

Leakage current off

state

V

HVSU

V

HVSU

= 600V

20 mA

40 µA

Two point regulator (TPR) protection

T

PR

st

PR

T

(ON)

T

PR

(OFF)

Vcc Protection

10

level

10 Vcc Turn-on level

10 Vcc Turn-off level

Output voltage on

7

state

Forward voltage

7

drop Diode

Leakage current off

7

state

Operating mode 14.0 14.5 15.0 V

Operating mode; after

the first falling edge on

12.5 13 13.5 V

LSG

Operating mode; after

the first falling edge on

12.45 12.95 13.48 V

LSG

= 200mA

I

TPR

@ 600mA forward

current.

V

= 13V

TPR

2V

2.3 V

5µA

7/22

Page 8

Electrical characteristics L6382D

Table 4. Electrical characteristcs (TJ = 25°C, VCC = 13V, C

unless otherwise specified)

(continued)

DRIVER

= 1nF

Symbol Pin Parameter Test condition Min Typ Max Unit

LSG, HEG & PFG drivers

V

OH(LS

V

OL(LS)

5, 9

)

17 IHEG = 2.5mA

5, 9

17 IHEG = 2.5mA

HIGH Output

Voltage

LOW Output

Voltage

Source Current

Capability

ILSG = IPFG = 10mA

12.5 V

ILSG=IPFG=10mA

0.5 V

LSG and PFG 120 mA

HEG 50 mA

LSG 120 mA

Sink Current

Capability

HEG 70

PFG 250

LSG 115 ns

T

RISE

Rise time

HEG 300 ns

PFG 60 ns

LSG 75 ns

T

FAL L

Fall time

HEG 110 ns

PFG 40 ns

LSG; high to low and low

to high

300 ns

T

DELAY

R

B

Propagation delay

(input to output)

Pull down Resistor

HSG driver (voltages referred to OUT)

V

OH(HS)

V

OL(HS)

T

RISE

T

FAL L

HIGH Output

12

Voltage

LOW Output

12

Voltage

Sink Current

12

Capability

Source Current

12

Capability

12 Rise time Cload = 1nF 115 ns

12 Fall time Cload = 1nF 75 ns

HEG; high to low and low

to high

200 ns

PFG; high to low 250 ns

PFG; low to high 200 ns

LSG 20 KΩ

HEG 50 KΩ

PFG 10 KΩ

IHSG = 10 mA 12.5 V

IHSG = 10 mA 0.5 V

120 mA

120 mA

8/22

Page 9

L6382D Electrical characteristics

Table 4. Electrical characteristcs (TJ = 25°C, VCC = 13V, C

unless otherwise specified)

(continued)

DRIVER

= 1nF

Symbol Pin Parameter Test condition Min Typ Max Unit

T

DELAY

Propagation delay

12

(LGI to LSG)

R

B

12 Pull down Resistor to OUT 20 KΩ

high to low and low to

high

300 ns

High-side floating gate-driver supply

I

LKBOOT

I

LKOUT

11

current

OUT pin leakage

13

current

BOOT

V

BOOT

V

OUT

= 580V

= 562V

5µA

5µA

V

pin leakage

Synchronous

R

DS(on)

bootstrap

diode on-

V

LVG

= HIGH

150 W

resistance

V

REF

V

REF

Forward Voltage

Drop

Forward Current

20 Reference voltage 15mA load. 3.267 3.3 3.366 V

at 10 mA forward current 2.4 V

at 5V forward voltage

drop

20 mA

20 Load regulation IRef = -3 to +30 mA -20 2 mV

20 Voltage change

15mA load; Vcc = 9V to

15V

15 mV

V

REF

protection

V

REF

@3mA

Current Drive

Capability

I

REF

20

20

20

Overcurrent buffer stage

V

CSI

I

CSI

19 Comparator Level 0.537 0.56 0.582 V

19 Input Bias Current 500 nA

Propagation delay CSO turn off to LSG low 200 ns

18 High output voltage

18 Low output voltage

latched

Clamp

2V

from 0 to V

V

CC

during start-up;Vcc from

V

REF(OFF)

shut-down; V

to 0 during

ref

CCON

<2V

1.2 1.4 V

-3 +30 mA

Save mode -3 +10 mA

V

-

I

I

CSO

CSO

= 200µA

= -150µA

REF

0.5V

0.5 V

9/22

Page 10

Electrical characteristics L6382D

Table 4. Electrical characteristcs (TJ = 25°C, VCC = 13V, C

unless otherwise specified)

Symbol Pin Parameter Test condition Min Typ Max Unit

DIM

T

ED

Logic input

1 to 4

1 to 4

LGI Pull down resistor 100 KΩ

(continued)

Normal Mode Time

Out

Vref enabling

drivers

Time enabling

drivers

Low Level Logic

Input Voltage

High Level Logic

Input Voltage

DRIVER

= 1nF

70 100 130 µs

3.0 V

10 µs

0.8 V

2.2 V

10/22

Page 11

L6382D Typical electrical performance

5 Typical electrical performance

Figure 4. UVLO thresholds [V] vs. T

15

14

13

12

11

10

9

8

7

-40 -25 0 25 50 75 100 125

Figure 6. VREF [V] vs. T

3.5

3.5

3.45

3.45

3.4

3.4

3.35

3.35

3.3

3.3

3.25

3.25

3.2

3.2

3.15

3.15

3.1

3.1

-40 -25 0 25 50 75 100 125

-40 -25 0 25 50 75 100 125

Vcc(on)

Vcc(off)

J

J

Figure 5. VCC zener voltage [V] vs. T

21

21

20

20

19

19

18

18

17

17

16

16

15

15

14

14

-40 -25 0 25 50 75 100 125

-40 -25 0 25 50 75 100 125

Figure 7. Overcurrent protection

threshold [V] vs. T

600

580

560

540

520

500

-40-25 0 25 50 75100125

J

J

Figure 8. Propagation delays [ns] high

300

250

200

150

100

50

0

-40 - 25 0 25 5 0 75 100 125

to low vs. T

HS

J

LS

PF

11/22

Figure 9. Propagation delays [ns] low to

high vs. T

300

250

200

150

100

50

0

HS

-40 -25 0 25 50 75 100 125

J

LS

PF

Page 12

Application information L6382D

6 Application information

6.1 Power management

The L6382D has two stable states (SAVE MODE and OPERATING MODE) and two

additional states that manage the Start-up and fault conditions (Figure 10): the Over Current

Protection is a parallel asynchronous process enabled when in operating

Following paragraphs will describe each mode and the condition necessary to shift between

them.

Figure 10. State diagram

mode.

VCC>V

V

REF

>10µs

T

ED

6.1.1 START-UP mode

With reference to the timing diagram of figure 11, when power is first applied to the

converter, the voltage on the bulk capacitor builds up and the HV generator is enabled to

operate drawing about 10mA. This current, diminished by the IC consumption (less than

150µA), charges the bypass capacitor connected between pin Vcc and ground and makes

its voltage rise almost linear.

START-UP

CC(ON)

SAVE MODE

>3V

&

OPERATING

MODE

VCC<V

REF(OFF)

LGI low

for more

than 100µs

V

CC<VCC(ON)

VCC<V

V

REF(OFF)

SHUT DOWN

< V

CC

CC(OFF)

or

V

<2V

REF

During this phase, all IC's functions are disabled except for:

● the current sinking circuit on VREF pin that maintains low the voltage by keeping

disabled the microcontroller connected to this pin;

● the High-Voltage Start-Up (HVSU) that is ON (conductive) to charge the external

capacitor on pin Vcc.

As the Vcc voltage reaches the start-up threshold (14V typ.) the chip starts operating and

the HV generator is switched off.

12/22

Page 13

L6382D Application information

Summarizing:

– the high-voltage start-up generator is active;

–V

is disabled with additional sinking circuit on pin V

REF

enabled;

REF

– TPR is disabled;

– OCP is disabled;

– the drivers are disabled.

6.1.2 SAVE Mode

This mode is entered after the Vcc voltage reaches the turn-on threshold; the V

enabled in low current source mode to supply the µC connected to it, whose wake-up

required current must be less than 10mA: if no switching activity is detected at LGI input, the

high voltage start-up generator cycles ON-OFF keeping the Vcc voltage between VccON

and VccSM.

Summarizing:

– the high-voltage start-up generator is cycling;

–V

is enabled in low source current capability (I

REF

– TPR circuit is disabled;

– OCP is disabled;

– the drivers are disabled.

If the Vcc voltage falls below the V

6.1.3 OPERATING Mode

After 10µs in save mode and only if the voltage at V

edge on the HGI input, the drivers are enabled as well as all the IC's functions; this is the

mode correspondent to the proper lamp behavior.

Summarizing:

– HVSU is OFF

–V

– TPR circuit is enabled

– OCP is enabled

– the drivers are enabled

is enabled in high source current mode (I

REF

REF(OFF)

is

REF

≤ 10mA);

REF

threshold, the device enters the start-up mode.

is higher than 3.0V, on the falling

REF

< 30mA)

REF

If there is no switching activity on LGI for more than 100µs, the IC returns in save

6.1.4 Shut down

This state permits to manage the fault conditions in operating mode and it is entered by the

occurrence on one of the following conditions:

1. Vcc<VccOff (Under Voltage fault on Supply),

2. V

<2.0V (Under Voltage fault on V

REF

mode.

)

REF

13/22

Page 14

Application information L6382D

In this state the functions are:

– The HVSU generator is ON

–V

is enabled in low source current mode (I

REF

< 10mA)

REF

–TPR is disabled

– OCP is disabled

– the drivers are disabled

In this state if Vcc reaches VccOn, the device enters the save

Vcc<V

REF(OFF)

, also the µC is turned off and the device will be ready to execute the Start-up

sequence.

Figure 11. Timing sequences: TPR behavior

mode otherwise, if

14/22

Page 15

L6382D Application information

Figure 12. Timing sequences: save mode and operating mode

Vcc

Vcc

VCCon

VCCon

VccSM

VccSM

VccOFF

VccOFF

VREF

VREF

LGI

LGI

HGI

HGI

HVSU

HVSU

TPR Switching

TPR Switching

10ms

10ms

µ

OPERATING MODE

OPERATING MODE

15/22

Page 16

Block description L6382D

7 Block description

7.1 Supply section

● µPUVLO (µPower Under Voltage Lock Out): This block controls the power

management of the L6382D ensuring the right current consumption in each operating

state, the correct V

up generator switching.

During Start-up the device sinks the current necessary to charge the external capacitor

on pin V

from the high voltage bus; in this state the other IC's functions are disabled

CC

and the current consumption of the whole IC is less than 150µA.

When the voltage on V

µPUVLO block controls Vcc between VccON and VccSM by switching ON/OFF the

high voltage start-up generator.

● HVSU (High-Voltage Start-Up generator): a 600V internal MOS transistor structure

controls the Vcc supply voltage during start-up

reduces the power losses during operating

The transistor has a source current capability of up to 30mA.

current capability, the driver enabling and the high-voltage start-

REF

pin reaches VccON, the IC enters the save mode where the

CC

and save mode conditions and it

Mode by switching OFF the MOS transistor.

● TPR (Two Point Regulator) & PWS: during normal mode, the TPR block controls the

PSW switch in order to regulate the IC supply voltage (V

between TPR(ON) and TPR(OFF) by switching ON and OFF the PSW transistor

Figure 11.

– Vcc > TPRst: the PSW is switched ON immediately;

– TPR(ON) < Vcc < TPRst: the PSW is switched ON at the following falling edge of

LGI;

– Vcc < TPR(OFF): the PSW is switched OFF at the following falling edge on LGI.

When the PSW switch is OFF, the diodes build a charge pump structure so that, connecting

the TPR pin to a switching voltage (through a capacitor) it is possible to supply the low

voltage section of the chip without adding any further external component. The diodes and

the switch are designed to withstand a current of at least 200mA

7.2 3.3V reference voltage

This block is used to supply the microcontroller; this source is able to supply 10mA in save

mode and 30mA in operating

available, an additional circuit is ensures that, even sinking 3mA, the pin voltage doesn't

exceed 1.2V.

The reference is available until Vcc is above V

additional sinking circuit is enabled again.

mode; moreover, during start-up when V

REF(OFF)

) to a value in the range

CC

.

RMS

is not yet

REF

; below that it turns off and the

16/22

Page 17

L6382D Block description

7.3 Drivers

● LSD (Low Side Driver): it consists of a level shifter from 3.3V logic signal (LSI) to Vcc

MOS driving level; conceived for the half-bridge low-side power MOS, it is able to

source and sink 120mA (min).

● HSD (Level Shifter and High Side Driver): it consists of a level shifter from 3.3V logic

signal (HGI) to the high side gate driver input up to 600V. Conceived for the half-bridge

high-side power MOS, the HSG is able to source and sink 120mA.

● PFD (Power Factor Driver): it consists of a level shifter from 3.3V logic signal (PFI) to

Vcc MOS driving level: the driver is able to source 120mA from Vcc to PFG (turn-on)

and to sink 250mA to GND (turn-off); it is suitable to drive the MOS of the PFC preregulator stage.

● HED (Heat Driver): it consists of a level shifter from 3.3V logic signal (HEI) to Vcc MOS

driving level; the driver is able to source 30mA from Vcc to HEG and to sink 75mA to

GND and it is suitable for the filament heating when they are supplied by independent

winding.

● Bootstrap Circuit: it generates the supply voltage for the high side Driver (HSD).

A patented integrated bootstrap section replaces an external bootstrap diode. This

section together with a bootstrap capacitor provides the bootstrap voltage to drive the

high side power MOSFET. This function is achieved using a high voltage DMOS driver

which is driven synchronously with the low side external power MOSFET. For a safe

operation, current flow between BOOT pin and Vcc is always inhibited, even though

ZVS operation may not be ensured.

7.4 Internal logic, over current protection (OCP) and interlocking function

The DIM (Digital Input Monitor) block manages the input signals delivered to the drivers

ensuring that they are low during the described start-up procedure; the DIM block controls

the L6382D behaviour during both save

When the voltage on pin CSI overcomes the internal reference of 0.5V (typ.) the block

latches the fault condition: in this state the OCP block forces low both HSG and LSG signals

while CSO will be forced high. This condition remains latched until LSI and HSI are

simultaneously low and CSI is below 0.5V.

This function is suitable to implement an over current protection or hard-switching detection

by using an external sense resistor.

As the voltage on pin CSI can go negative, the current must be limited below 2mA by

external components.

Another feature of the DIM block is the internal interlocking that avoids cross-conduction in

the half-bridge FET's: if by chance both HGI and LGI input's are brought high at the same

time, then LSG and HSG are forced low as long as this critical condition persists.

and operating modes.

17/22

Page 18

Package mechanical data L6382D

8 Package mechanical data

In order to meet environmental requirements, ST offers these devices in ECOPACK®

packages. These packages have a Lead-free second level interconnect . The category of

second level interconnect is marked on the package and on the inner box label, in

compliance with JEDEC Standard JESD97. The maximum ratings related to soldering

conditions are also marked on the inner box label. ECOPACK is an ST trademark.

ECOPACK specifications are available at: www.st.com

18/22

Page 19

L6382D Package mechanical data

Table 5. SO-20 Mechanical data

Dim.

mm. inch

Min Typ Max Min Typ Max

A 2.35 2.65 0.093 0.104

A1 0.10 0.30 0.004 0.012

B 0.33 0.51 0.013 0.200

C 0.23 0.32 0.009 0.013

D (1)

12.60 13.00 0.496 0.512

E 7.40 7.60 0.291 0.299

e 1.27 0.050

H 10.0 10.65 0.394 0.419

h 0.25 0.75 0.010 0.030

L 0.40 1.27 0.016 0.050

k 0° (min.), 8° (max.)

ddd 0.10 0.004

Figure 13. Package dimensions

19/22

Page 20

Order codes L6382D

9 Order codes

Table 6. Order codes

Part number Package Packaging

L6382D SO-20 Tube

L6382DTR SO-20 Tape & Reel

20/22

Page 21

L6382D Revision history

10 Revision history

Table 7. Revision history

Date Revision Changes

15-Nov-2004 1 First Issue

03-Jan-2005 2 Changed from “Preliminary Data” to “Final Datasheet”

23-Oct-2005 3 Many modified

19-Apr-2006 4 New template

22-May-2006 5 Typo error in block diagram, updated values in electrical

charcteristics Ta b l e 4 .

21-Mar-2007 6 Typo on Ta b le 2

21/22

Page 22

L6382D

Please Read Carefully:

Information in this document is provided solely in connection with ST products. STMicroelectronics NV and its subsidiaries (“ST”) reserve the

right to make changes, corrections, modifications or improvements, to this document, and the products and services described herein at any

time, without notice.

All ST products are sold pursuant to ST’s terms and conditions of sale.

Purchasers are solely responsible for the choice, selection and use of the ST products and services described herein, and ST assumes no

liability whatsoever relating to the choice, selection or use of the ST products and services described herein.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted under this document. If any part of this

document refers to any third party products or services it shall not be deemed a license grant by ST for the use of such third party products

or services, or any intellectual property contained therein or considered as a warranty covering the use in any manner whatsoever of such

third party products or services or any intellectual property contained therein.

UNLESS OTHERWISE SET FORTH IN ST’S TERMS AND CONDITIONS OF SALE ST DISCLAIMS ANY EXPRESS OR IMPLIED

WARRANTY WITH RESPECT TO THE USE AND/OR SALE OF ST PRODUCTS INCLUDING WITHOUT LIMITATION IMPLIED

WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE (AND THEIR EQUIVALENTS UNDER THE LAWS

OF ANY JURISDICTION), OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY RIGHT.

UNLESS EXPRESSLY APPROVED IN WRITING BY AN AUTHORIZED ST REPRESENTATIVE, ST PRODUCTS ARE NOT

RECOMMENDED, AUTHORIZED OR WARRANTED FOR USE IN MILITARY, AIR CRAFT, SPACE, LIFE SAVING, OR LIFE SUSTAINING

APPLICATIONS, NOR IN PRODUCTS OR SYSTEMS WHERE FAILURE OR MALFUNCTION MAY RESULT IN PERSONAL INJURY,

DEATH, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE. ST PRODUCTS WHICH ARE NOT SPECIFIED AS "AUTOMOTIVE

GRADE" MAY ONLY BE USED IN AUTOMOTIVE APPLICATIONS AT USER’S OWN RISK.

Resale of ST products with provisions different from the statements and/or technical features set forth in this document shall immediately void

any warranty granted by ST for the ST product or service described herein and shall not create or extend in any manner whatsoever, any

liability of ST.

ST and the ST logo are trademarks or registered trademarks of ST in various countries.

Information in this document supersedes and replaces all information previously supplied.

The ST logo is a registered trademark of STMicroelectronics. All other names are the property of their respective owners.

© 2007 STMicroelectronics - All rights reserved

STMicroelectronics group of companies

Australia - Belgium - Brazil - Canada - China - Czech Republic - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan -

Malaysia - Malta - Morocco - Singapore - Spain - Sweden - Switzerland - United Kingdom - United States of America

www.st.com

22/22

Loading...

Loading...