®

www.BDTIC.com/Intersil

ISL97634

Data Sheet March 7, 2008

White LED Driver with Wide PWM

Dimming Range

The ISL97634 represents an efficient and highly integrated

PWM boost LED driver that is suitable for 1.8” to 3.5” LCDs

that employ 2 to 7 white LEDs for backligh ti n g. With

integrated Schottky diode, OVP, and wide range of PWM

dimming capability , the ISL97634 provides a simple, reliable,

and flexible solution to the backlight designers.

The ISL97634 features a wide range of PWM dimming

control capability. It allows dimming frequency as low as DC

to 32kHz beyond audible spectrum. The ISL97634 also

features a feedback disconnect switch to prevent the output

from being modulated by the PWM dimming signal that

minimizes system disturbance.

The ISL97634 is available in the 8 Ld TDFN (2mmx3mm)

package. There are 14V , 18V, and 26V OVP options that are

suitable for 3 LEDS, 4 LEDs, and 7 LEDs (3.5V/20mA type)

backlight applications respectively. The ISL97634 is

specified for operation over the -40°C to +85°C ambient

temperature at input voltage from 2.4V to 5.5V.

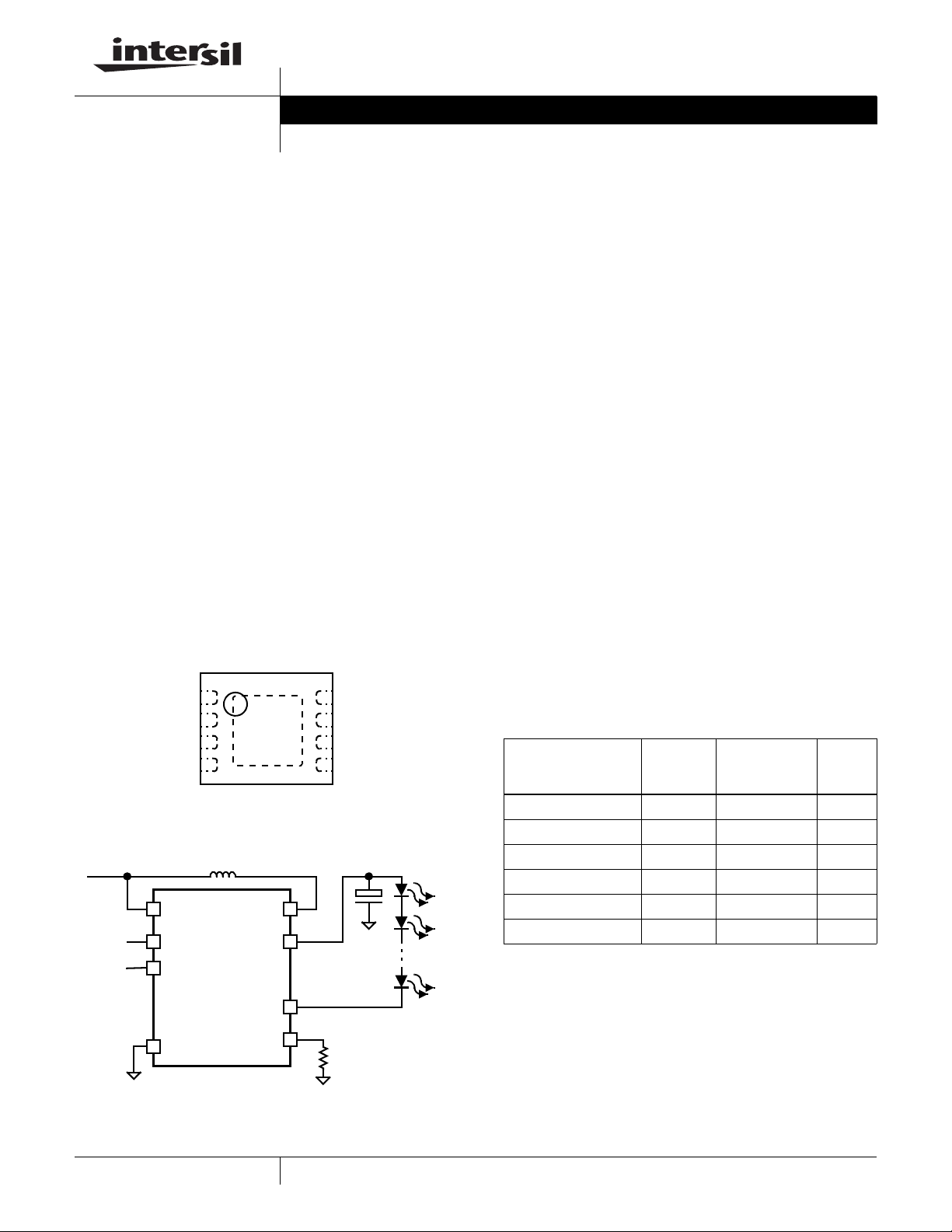

Pinout

ISL97634

(8 LD TDFN)

TOP VIEW

GND

VIN

PWM/EN

NC

1

2

3

4

8

7

6

5

LX

VOUT

FBSW

FB

Typical Application Circuit

VIN

PWM/EN

NC

GND

10µH or 22µH

LX

VOUT

FBSW

FB

VIN

FN6264.3

Features

• Drives Up to 7 LEDs in Series (3.5V/20mA type)

• OVP (14V , 18V, and 26V for 3, 4 and 7 LEDs Applications)

• PWM Dimming Control From DC to 32kHz

• Output Disconnect Switch

• Integrated Schottky Diode

• 2.4V to 5.5V Input

• 85% Efficiency

• 1.4MHz Switching Frequency Allows Small LC

• 1µA Shutdown Current

• Internally Compensated

• 8 Ld TDFN (2mmx3mm)

• Pb-Free (RoHS Compliant)

Applications

• LED Backlighting for:

- Cell phones

- Smartphones

-MP3

-PMP

- Automotive Navigation Panel

- Portable GPS

Ordering Information

PART

NUMBER

(Note)

ISL97634IRT14Z-T ELE 8 Ld 2x3 TDFN L8.2x3A

ISL97634IRT14Z-TK ELE 8 Ld 2x3 TDFN L8.2x3A

ISL97634IRT18Z-T ELF 8 Ld 2x3 TDFN L8.2x3A

ISL97634IRT18Z-TK ELF 8 Ld 2x3 TDFN L8.2x3A

ISL97634IRT26Z-T ELG 8 Ld 2x3 TDFN L8.2x3A

ISL97634IRT26Z-TK ELG 8 Ld 2x3 TDFN L8.2x3A

*Please refer to TB347 for details on reel specifications

NOTE: These Intersil Pb-free plastic packaged products employ

special Pb-free material sets; molding compounds/die attach

materials and 100% matte tin plate PLUS ANNEAL - e3 termination

finish, which is RoHS compliant and compatible with both SnPb and

Pb-free soldering operations. Intersil Pb-free products are MSL

classified at Pb-free peak reflow temperatures that meet or exceed

the Pb-free requirements of IPC/JEDEC J STD-020..

PART

MARKING

PACKAGE

(Pb-free)

Tape & Reel

PKG.

DWG.

#

1

CAUTION: These devices are sensitive to electrostatic discharge; follow proper IC Handling Procedures.

1-888-INTERSIL or 1-888-468-3774

| Intersil (and design) is a registered trademark of Intersil Americas Inc.

All other trademarks mentioned are the property of their respective owners.

Copyright Intersil Americas Inc. 2006-2008. All Rights Reserved

ISL97634

www.BDTIC.com/Intersil

Absolute Maximum Ratings (T

Input Voltage (V

LX Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .-0.3V to 28V

FBSW Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .-0.3V to 28V

All Other Pins. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .-0.3V to 6V

) . . . . . . . . . . . . . . . . . . . . . . . . . . . . .-0.3V to 6V

IN

Operating Conditions

Temperature Range . . . . . . . . . . . . . . . . . . . . . . . . . .-40°C to +85°C

CAUTION: Do not operate at or near the maximum ratings listed for extended periods of time. Exposure to such conditions may adversely impact product reliability and

result in failures not covered by warranty.

IMPORTANT NOTE: All parameters having Min/Max specifications are guaranteed over temperature of -40°C to +85°C unless otherwise stated. Typ values are for

information purposes only at TJ = TC = TA = +25°C.

NOTE:

1. θ

is measured in free air with the component mounted on a high effective thermal conductivity test board with “direct attach” features. See

JA

Tech Brief TB379.

2. For θ

, the “case temp” location is the center of the exposed metal pad on the package underside.

JC

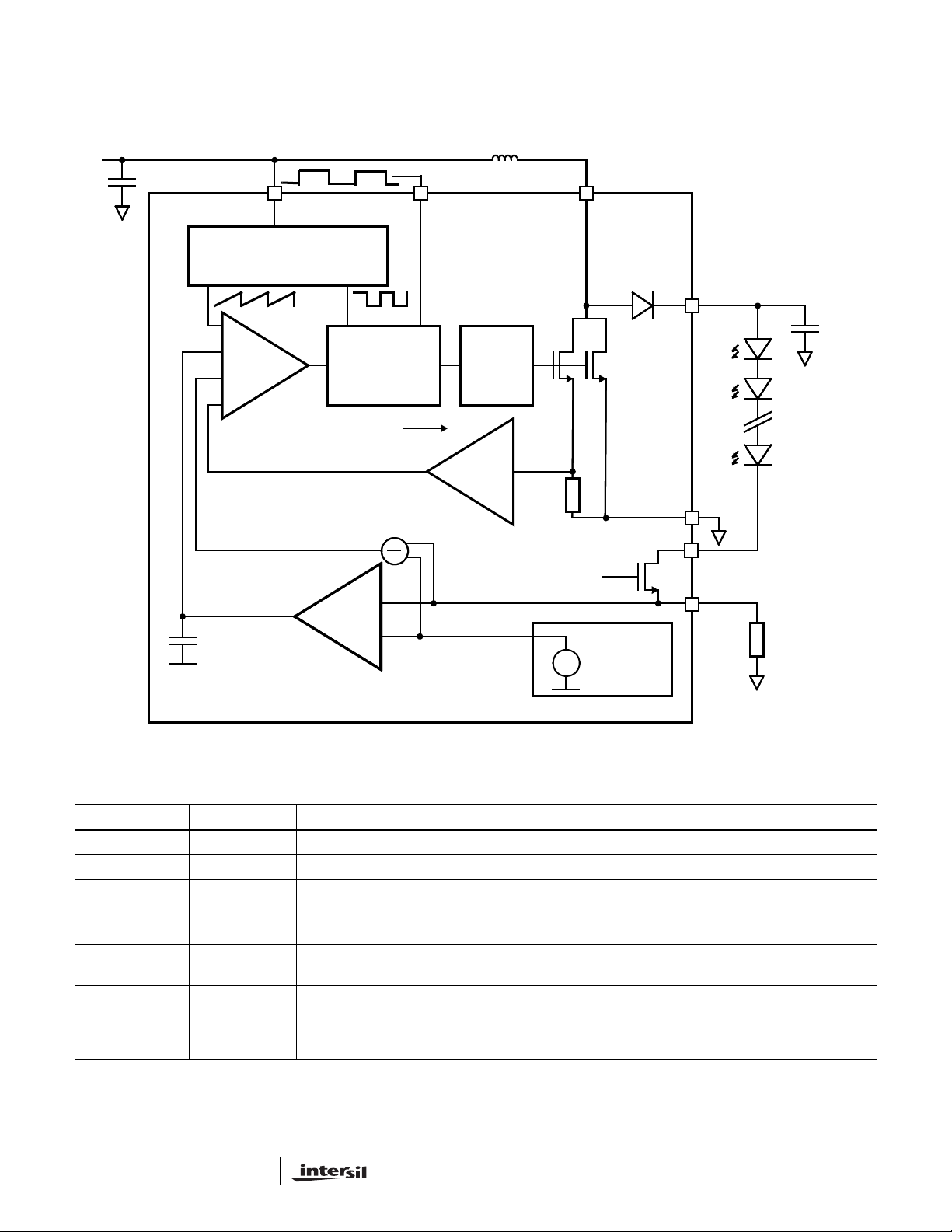

Electrical Specifications V

PARAMETER DESCRIPTION CONDITION MIN TYP MAX UNIT

V

IN

I

IN

f

SW

DMAX Maximum Switching Duty

I

LIM

R

SW(LX)

ILEAK LX Switch Leakage Current VLX = 28V 0.01 1 µA

VFB Feedback Voltage 90 95 100 mV

IFB FB Pin Bias Current VFB = 95mV 1 µA

R

SW(FBSW)

V

DIODE

OVP Overvoltage Protection ISL97634IRT14Z 14 V

VIL Logic Low Voltage of

VIH Logic High Voltage of

PWM_on Minimum PWM On-Time 1.5 µs

EN_delay EN to Vout Delay 200 µs

Supply Voltage 2.4 5.5 V

Supply Current PWM/EN = 3V, enabled, not switching 0.8 1.5 mA

Switching Frequency 1,300 1,450 1,600 kHz

Cycle

LX Current 400 470 mA

LX Switch ON-Resistance ILX = 100mA 900 mΩ

FBSW Switch ON-Resistance 10 Ω

Schottky Diode Forward

Voltage

PWM/EN

PWM/EN

= +25°C) Thermal Information

A

Thermal Resistance θ

8 Ld TDFN Package (Notes 1, 2). . . . . 77 12

Maximum Junction Temperature . . . . . . . . . . . . . . . . . . . . . .+125°C

Storage Temperature . . . . . . . . . . . . . . . . . . . . . . .-65°C to +150°C

Pb-free reflow profile . . . . . . . . . . . . . . . . . . . . . . . . . .see link below

http://www.intersil.com/pbfree/Pb-FreeReflow.asp

= V

IN

= 3V

PWM/EN

PWM/EN = 0V, disabled 1 µA

IDIODE = 100mA, TA = +25°C 600 850 mV

ISL97634IRT18Z 18 V

ISL97634IRT26Z 26 28 V

(°C/W) θ

JA

90 95 %

0.6 V

1.5 V

JC

(°C/W)

2

FN6264.3

March 7, 2008

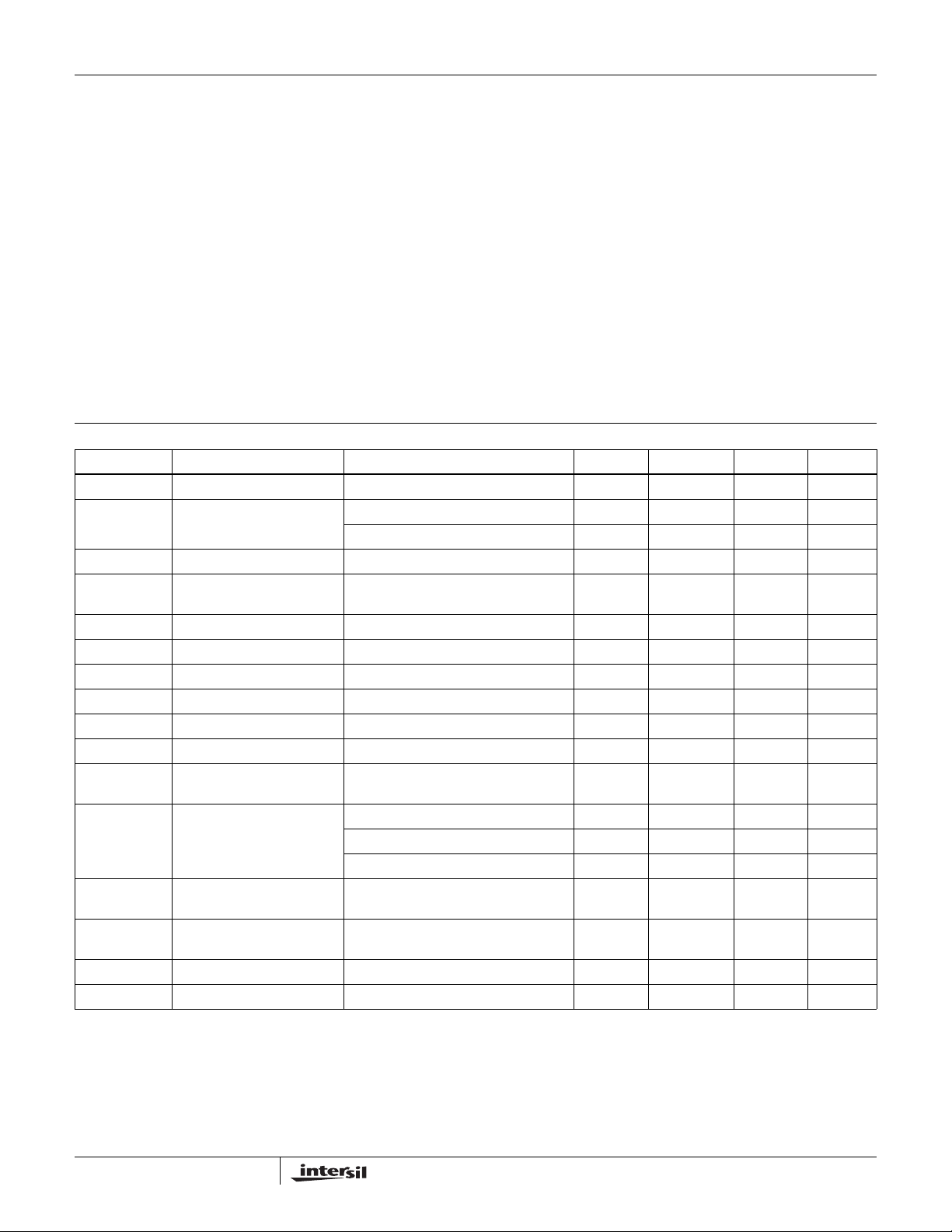

Block Diagram

www.BDTIC.com/Intersil

VIN (2.4V TO 5.5V)

CIN

ISL97634

L

VIN PWM/EN LX

1.4MHZ OSCILLATOR AND RAMP

GENERATOR

PWM

COMPARATOR

GM AMP

GM AMP

COMPENSATION

COMPENSATION

CONTROLLER

GM

AMPLIFIER

ISL97634

DRIVER

CURRENT

SENSE

95mV

VOUT

COUT

FET PWM LOGIC

2 LEDs to 7 LEDS

GND

FBSW

PWM/EN

FB

BANDGAP

REFERENCE

GENERATOR

RSET

Pin Description

PIN NUMBER PIN NAME DESCRIPTION

1 GND Ground Pin. Conn ect to local grou nd.

2 VIN In put Supply Pin. Connect to the input supply voltage, the inductor and the input supply de coupling capacitor .

3 PWM/EN PWM or Enable Pin. Connect external PWM signal allows pulse width modulation current operation. Enable

signal allows peak current operation or disable signal shuts dow n th e de vice.

4 NC No Connect

5 FB Feedback Pin. Connect the sense resistor between FB and ground. The cathode of bot tom LED ca n also

be connected at this pin if the output current is not to b e P WMed.

6 FBSW FB Disconnect Switch. Connect to the cathode of the bottom LED if the output current to be PWMed.

7 VOUT Output Pin. Connect to the anode of the top LED and the output filter capacitor.

8 LX Switching Pin. Connect to inductor.

3

FN6264.3

March 7, 2008

Typical Performance Curves

www.BDTIC.com/Intersil

ISL97634

90

85

80

75

70

65

EFFICIENCY (%)

60

55

50

7 LEDs, 22µH

0 20406080100

3 LEDs, 10µH

3 LEDs, 22µH

PWM DUTY CYCLE (%)

4 LEDs, 10µH

7 LEDs, 10µH

ILED_peak = 25mA

VIN = 4V

RSET = 4Ω

= 1kHz

f

PWM

1.0

0.8

0.6

0.4

(mA)

q

I

0.2

0.0

-0.2

0246

135

V

(V)

IN

FIGURE 1. EFFICIENCY vs PWM DUTY CYCLE FIGURE 2. QUIESCENT CURRENT vs VIN (PWM/EN = HI)

(mA)

O

I

20.08

20.04

20.00

19.76

19.74

19.72

19.70

(mA)

O

I

19.68

19.96

19.92

0 5 10 15 20 25 30

FIGURE 3. LOAD REGULATION (V

100

7 LEDs

90

V

= 4V

IN

80

RSET = 4Ω

L = 10µH

70

60

50

40

FB VOLTAGE (mV)

30

20

10

0

0 20 40 60 80 100 120

V

(V)

OUT

1kHz

20kHz

32kHz

DUTY CYCLE (%)

= 4V) FIGURE 4. LINE REGULATION

IN

19.66

19.64

19.62

2.5 3.0 3.5 4.0 4.5 5.0 5.5

V

(V)

IN

V

OUT

LX

PWM/EN

ILED

VIN = 4V

R

L

= 4Ω

1

= 22µH

1

FIGURE 5. DIMMNG LINEARITY (FB VOLT AGE) vs DUTY

FIGURE 6. PWM DIMMING AT 1kHz, D = 1%

CYCLE

4

FN6264.3

March 7, 2008

V

www.BDTIC.com/Intersil

OUT

LX

ISL97634

V

OUT

LX

PWM/EN

VIN = 4V

= 4

Ω

R

1

ILED

FIGURE 7. PWM DIMMING AT 1kHz, D = 1% ZOOM IN FIGURE 8. PWM DIMMING AT 1kHz, D = 99%

L1 = 22µH

V

R1 = 4

Ω

VIN = 4V

L1 = 22µH

PWM/EN

OUT

LX

ILED

PWM/EN

ILED

VIN = 4V

= 4

Ω

R

1

L1 = 22µH

FIGURE 9. PWM DIMMING AT 20kHz, D = 50%

Detailed Description

The ISL97634 uses a constant frequency, current mode

control scheme to provide excellent line and load

regula tion. There are three OVP models for driving 3, 4

and 7 LEDs (3.5V/20mA type) and their OVP thresholds

are set at 14V, 18V and 26V respectively. The ISL97634

operates from an input voltage of 2.4V to 5.5V and ambient

temperature from -40°C to +85°C. The switching frequency

is around 1.45MHz and allows the driver circuit to employ

small LC components. The peak forward current of the LED

is set using the R

LED peak current is given by Equation1:

V

FB

---------------

=

I

LED

R

SET

PWM Dimming

The ISL97634’s PWM/EN pin can be tied permanently to

high for a fixed current operation. On the other hand, the

ISL97634 can be applied with an external PWM signal to

resistor. In the steady state mode, the

SET

5

(EQ. 1)

pulse width modulated output current. It is well understood

that the LED brightness is a linear function of the LED

current. In addition, the average LED current corresponds to

the duty cycle “D” of the PWM signal as shown in

Equation 2:

V

FB

I

LED-AVG

---------------

R

SET

D⋅=

(EQ. 2)

As a result, PWM signal provides a means to dim the LED

brightness. PWM dimming offers the best LEDs matching

over DC dimming. It is because the LED peak current

operating point is far away from the knee of the diode I-V

curve where part to part variations are high. The PWM

dimming test results are shown in Figure 6 with two PWM

frequencies, 1kHz and 20kHz. The vertical scale parameter

FB is proportional to the current and therefore the

brightness.

For the ISL97634, PWM dimming provides linear dimming

adjustment with low frequency signal, such as 1kHz and

FN6264.3

March 7, 2008

ISL97634

www.BDTIC.com/Intersil

below. The applied PWM dimming signal can be up to

32kHz; however, the dimming linearity is compromised at

low duty cycles as their durations are too short for the

ISL97634’s control loop to respond properly. This

non-ideality behavior does not cause any functional

problem. The PWM dimming linear responses in Figure 5

are expanded in Figure 10. At 1kHz PWM dimming, the duty

cycle can virtually vary from below 1% to DC. On the other

hand, at 20kHz PWM dimming, the linearity range is from

5% to DC only.

10

7 LEDs

9

V

= 4V

IN

RSET = 4Ω

8

L = 10µH

7

6

5

4

FB VOLTAGE (mV)

3

2

1

0

024681012

FIGURE 10. DIMMING LINEARITY vs DUTY CYCLES ZOOM IN

1kHz

20kHz

32kHz

DUTY CYCLE (%)

The low level non-linearity effects at high frequency PWM

dimming is also reflected in the efficiency measurements in

Figure 11.

90

85

80

75

70

65

EFFICIENCY (%)

60

55

50

0 5 10 15 20 25 30

FIGURE 11. EFFICIENCY vs PWM DIMMING FREQUENCIES

ILED (mA)

3 LEDs

V

= 4V

IN

RSET = 4

L = 22µH

Ω

Feedback Disconnect Switch

The ISL97634 functions properly without using the FBSW.

However, the output cap a citor will disch arge during the PWM

off time resulting in poor dimming linearity at low duty cycles.

The output discharge effect can be seen in Figure 12.

Moreover, the output is modulated by the PWM signal that

may create interference to other systems.

.

V

OUT

LX

PWM/EN

VIN = 4V

ILED

FIGURE 12. PWM DIMMING AT 1kHz WITHOUT USING FBSW

R1 = 4Ω

L1 = 22µH

The FBSW should be used for PWM dimming as illustrated

in “Typical Application Circuit” on page 1. During the PWM

off time, the FBSW is opened. The LEDs are floating and

therefore the output capacitor has no path to discharge. The

LED current responds accurately with the PWM signal (see

Figure 13). The output switches very quickly to the target

current with minimal settling ringing and without being

modulated by the PWM signal, and therefore minimizes any

system disturbance.

V

OUT

LX

PWM/EN

ILED

FIGURE 13. PWM DIMMING AT 1kHz USING FBSW

VIN = 4V

Ω

R1 = 4

L1 = 22µH

Overvoltage Protection

The ISL97634 comes with overvoltage protection. The OVP

trip points are at 14V, 18V and 26V for ISL97634IRT14Z,

ISL97634IRT18Z and ISL97634IRT26Z respectively. The

maximum numbers of LEDs and OVP threshold are shown in

Table 1. When the device reaches the OVP, the LX stops

switching, disabling the boost circuit until V

below the OVP threshold. At this point, LX will be allowed to

switch again. The OVP event will not cause the device to

shutdown.

There are three OVP options so that the 3 LEDs application

should use the 14V OVP device and the 7 LEDs application

should use the 26V OVP device. An output capacitor that is

falls about 7%

OUT

6

FN6264.3

March 7, 2008

ISL97634

www.BDTIC.com/Intersil

only rated for the required voltage range can therefore be

used, which will optimize the component costs in so me cases.

TABLE 1.

PART NO. OVP

ISL97634IRT14Z 14V 3 70mA

ISL97634IRT18Z 18V 4 50mA

ISL97634IRT26Z 26V 7 30mA

MAX NO. OF

LEDS MAX ILED

Shutdown

When PWM/EN is taken low the ISL97634 enters into the

power-down mode where the supply current is reduced to

less than 1µA. The device resumes normal when the

PWM/EN goes high.

Components Selection

The input capacitance is typically 0.22µF. The output

capacitor should be in the range of 0.22µF to 1µF. X5R or

X7R type of ceramic capacitors of the appropriate voltage

rating are recommended.

When choosing an inductor, make sure the average and

peak current ratings are adequate by using Equations 3, 4 and

5 (80% efficiency assumed):

I

⋅

LEDVOUT

I

LAVG

I

LPKILAVG

---------------------------------

=

0.8 V

⋅

IN

1

-- -

Δ⋅+=

I

L

2

(EQ. 3)

(EQ. 4)

Compensation

The product of the output capacitor and the load create a

pole while the inductor creates a right half plane zero. Both

of these attributes degrade the phase margin but the

ISL97634 has internal compensation network that ensures

the device operates reliably under the specified conditions.

The internal compensation and the highly integrated

functions of the ISL97634 make it a design friendly device to

be used in high volume, high reliability applications.

Applications

Analog Dimming

Analog dimming is usually not recommended because of the

brightness non-linearity at low levels dimming. However,

some systems are EMI or noise sensitive that analog

dimming may be more suitable than PWM dimming under

those situations. The ISL97632 is part of the same family as

the ISL97634 and has been designed with a serial interface

to give access to 32 separate dimming levels. Alternatively

analog dimming can be achieved by applying a variable DC

voltage (V

current. As the DC dimming signal voltage increases above

VFB, the voltages drop on R

voltage drop on RSET decreases. Thus, the LED current

decreases as shown in Equation 6:

=

I

LED

If V

DIM

brightness will increase.

) at FB pin (see Figure 14) to adjust the LED

Dim

and R2 increase and the

1

VFBR1R2+()V

------------------------------------------------------------------------- -

R⋅

R

2

SET

⋅–⋅

DimR1

(EQ. 6)

is taken below FB, the inverse will happen and the

V

INVOUTVIN

---------------------------------------------------

Δ

I

=

L

LV

⋅⋅

–()⋅

OUTfOSC

(EQ. 5)

Where:

• ΔI

is the peak-to-peak inductor current ripple in Amps

L

• L is the inductance in H

is the switching frequency, typically 1.45MHz

•f

OSC

The ISL97634 supports a wide range of inductance values

(10µH to ~82µH). For lower inductor values or lighter loads,

the boost inductor current may become discontinuous. For

high boost inductor values, the boost inductor current will be

in continuous mode.

In addition to the inductor value and switching frequency, the

input voltage, number of LEDs and the LED current also

affects whether the converter operates in continuous

conduction or discontinuous conduction mode.

Both operating modes are allowed and normal. The

discontinuous conduction mode yields lower efficiency due

to higher peak current.

The DC dimming signal voltage can be a variable DC voltage

from a POT, a DCP (Digitally Controlled Potentiometer), or a

DC voltage generated by filtering a high frequency PWM

control signal.

L1

22µH

V

IN

3.3V

C1

1µF

FIGURE 14. ANALOG DIMMING CONTROL APPLICATION

CIRCUIT

V

LX

LX

IN

V

OUT

ISL97634

PWM FB

GND

R2

As brightness is directly proportional to LED currents, V

R1

3.3k

LEDs

C2

0.22µF

R

SET

4.75Ω

V

Dim

Dim

may be calculated for any desired “relative brightness” (F)

using Equation 7:

R

2

Dim

-------

R

1

V

Where F = I

⋅⋅=

V

LED

FB

R

⎛⎞

1

-------

1

⎜⎟

⎝⎠

(dimmed)/I

F–+

R

2

(undimmed).

LED

(EQ. 7)

7

FN6264.3

March 7, 2008

ISL97634

www.BDTIC.com/Intersil

These equations are valid for values of R1 and R2 such that

both R

>>RSET and R2>>RSET.

1

The analog dimming circuit can be tailored to a desired

relative brightness for different V

ranges using

Dim

Equation 8.

V

Dim_maxVFB

-------------------------------------------------------------------

R

=

2

Where V

V

Dim_max

–()R1•[]

1F

–()•[]

FB

min

is the maximum V

voltage and F

Dim

(EQ. 8)

min

the minimum relative brightness (i.e., the brightness with

V

Dim_max

i.e., V

i.e., V

applied).

Dim_max

Dim_max

= 5V, F

= 1V, F

= 10% (i.e., 0.1), R2 = 189k

min

= 10% (i.e., 0.1), R2 = 35k

min

Efficiency Improvement

Figure 1 shows the efficiency measurement s during PWM

operation. The choice of the inductor has a significant impact

on the power efficiency. As shown in Equation 4, the higher

the inductance, the lower the peak current, therefore, the

lower the conduction and switching losses. On the other hand,

it has also a higher series resistance. Neverthe less, the

efficiency improvement effect by lowering the peak current is

greater than the resistance increases with larger value of

inductor. Effi ciency can also be improved for systems that

have high supply voltages. Since the ISL97634 can only

supply from 2.4V to 5.5V, V

high supply voltage for the boost circuit as shown in Figure 15

and the efficiency improvement is shown in Figure 16.

Vs = 12V

C1

1µF

VIN = 2.7V TO 5.5V

0.1µF

C2

FIGURE 15. SEPARATE HIGH INPUT VOLT AGE FOR HIGHER

L1

1 2

22µH

VIN

ISL97634

PWM/EN

EFFICIENCY OPERATION

must be separated from the

IN

LX

VOUT

FBSW

FB

GND

C3

0.22µF

R1

D1

D2

D3

D4

D5

D6

4Ω

is

.

90

85

80

EFFICIENCY (%)

75

70

0 5 10 15 20 25 30

FIGURE 16. EFFICIENCY IMPROVEMENT WITH 9 AND 12V

VS = 12V

INPUTS

ILED (mA)

VS = 9V

VIN = 4V

7 LEDs

L1 = 22µH

R1 = 4Ω

f

PWM

8 LEDs Operation

For medium size LCDs that need more than 7 low power LEDs

for backlighting, such as a portable media player or automotive

navigation panel displays, the voltage range of the ISL97634 is

not sufficient. However, the ISL97634 can be used as an LED

controller with an external protection MOSFET connected in

cascode fashion to achieve higher output voltage. A conceptual

8 LEDs driver circuit is shown in Figure 17. A 60V logic level NChannel MOSFET is configured such that its drain ties between

the inductor and the anode of Schottky diode, its gate ties to the

input, and its source ties to the ISL97634 LX node connecting

to the drain of the internal switch. When the internal switch

turns on, it pulls the source of M1 down to ground and LX

conducts as normal. When the internal switch turns off, the

source of M1 will be pulled up by the follower action of M1,

limiting the maximum voltage on the ISL97634 LX pin to below

V

, but allowing the output voltage to go much higher than the

IN

breakdown limit on the LX pin. The switch current limit and

maximum duty cycle will not be changed by this setup, so input

voltage will need to be carefully considered to make sure that

the required output voltage and current levels are achievable.

Because the source of M1 is effectively floating when the

internal LX switch is off, the drain-to-source capacitance of M1

may be sufficient to capacitively pull the node high enough to

break down the gate oxide of M1. To prevent this, V

be connected to V

, allowing the internal Schottky diode to

IN

limit the peak voltage. This will also hold the VOUT pin at a

known low voltage, preventing the built in OVP function from

causing problems. This OVP function is effectively useless in

this mode as the real output voltage is outside its intended

range. If the user wants to implement their own OVP protection

(to prevent damage to the output capacitor), they should insert

a zener diode from VOUT to the FB pin. In this setup, it would

be wise not to use the FBSW to FB switch, as otherwise, the

zener diode will have to be a high power one capable of

dissipating the entire LED load power. Then the LED stack can

then be connected directly to the sense resistor via a 10kΩ

resistor to FB. A zener can be placed from VOUT to the FB pin

allowing an overvoltage event to pull-up on FB with a low

breakdown current (and thus low power zener diode) as a

result of the 10kΩ resistor.

OUT

should

8

FN6264.3

March 7, 2008

ISL97634

www.BDTIC.com/Intersil

V

= 2.7V TO 5.5V

IN

C1

1µF

C2

0.1µF

FIGURE 17. CONCEPTUAL 8 LEDs HIGH VOLTAGE DRIVER

L1

12

2.2µ

VOUT

VIN

PWM/EN

ISL97634

FBSW

GND

LX

FB

M1

R1

D0

10BQ100

FQT13N06L

SK011C226KAR

6.3Ω

C3

4.7µF

D1

D2

D3

D4

D5

D6

D7

D8

SEPIC Operation

For applications where the output voltage is not always

above the input voltage, a buck or boost regulation is

needed. A SEPIC (Single Ended Primary Inductance

Converter) topology, shown in Figure 18, can be considered

for such an application. A single cell Li-ion battery operating

a cellular phone backlight or flashlight is one example. The

battery voltage is between 2.5V and 4.2V, depending on the

state of charge. On the other hand, the output may require

only one 3V to 4V medium power LED for illumination

because the light guard of the backlight assembly is

optimized for cost efficiency trade-off reason.

In fact, a SEPIC configured LED driver is flexible enough to

allow the output to be well above or below the input voltage,

unlike the previous example. Another example is when the

number of LEDs and input requirements are different from

platform to platform, a common circuit and PCB that fit all the

platforms in some cases may be beneficial enough that it

outweighs the disadvantage of adding additional component

cost. L

The simplest way to understand SEPIC topology is to think

about it as a boost regulator where the input voltage is level

shifted downward at the same magnitude and the lowest

reference level starts at -V

and L2 can be a coupled inductor in one p ackage.

1

VIN = 2.7V TO 5.5V

C1

1µF

C2

0.1µF

L1

1

2

22µH

VOUT

ISL97634

FBSW

LX

FB

GND

VIN

SDIN

FIGURE 18. SEPIC LED DRIVER

IN

C3

V

A

1µF

R1

rather than 0V.

V

1Ω

B

D0

L2

22µH

C4 0.22µF

D1

The SEPIC works as follows; assume the circuit in Figure 18

operates normally when the ISL97634 internal switch opens

and it is in the PWM off state. After a short duration where few

LC time constants elapsed, the circuit is considere d in the

steady-state within the PWM off period that L

shorted. V

charged to V

is therefore shorted to the ground and C3 is

B

with VA = VIN. When the ISL97634 internal

IN

switch closes and the circuit is in the PWM on-state, V

pulled to ground. Since the voltage in C

instantaneously, V

is shifted downward and becomes -VIN.

B

The next cycle when the ISL97634 switch opens, V

and L2 are

1

is now

cannot be changed

3

A

boosts

B

up to the targeted output like the standard boost regulator

operation, except the lowest reference point is at -V

. The

IN

output is approximated in Equation 9:

=

------------------

1D–()

(EQ. 9)

V

OUTVIN

D

where D is the on-time of the PWM duty cycle.

The convenience of SEPIC comes with some trade-off in

addition to the additional L and C costs. The effi cie ncy is

usually lowered because of the relatively large efficien cy loss

through the Schottky diode if the output voltage is low. The L

series resistance also contributes additional loss. Figure 19

shows the efficiency measurement of a single LED application

as the input varies between 2.7V and 4.2V.

Note V

is considered the level-shifted LX node of a standard

B

boost regulator. The higher the input volt age, the lower the V

voltage will be during PWM on period. The result is that the

efficiency will be lower at higher input voltages be cause the

SEPIC has to work harder to boost up to the required level.

This behavior is the opposite to the standard boost regulator’s

and the comparison is shown in Figure 19.

76

72

68

EFFICIENCY (%)

64

60

0

FIGURE 19. EFFICIENCY MEASUREMENT OF A SINGLE LED

VIN = 2.7V

VIN = 4.2V

1 LED

L

= L2 = 22µH

1

C

= 1µF

3

= 4.7Ω

R

1

5101520

SEPIC DRIVER

ILED (mA)

PCB Layout Considerations

The layout is very import ant for the converter to function

properly. R

and GND pins. Longer traces to the LEDs are acceptable.

Similarly, the supply decoupling cap and the output filter cap

should be as close as possible to the VIN and VOUT pins.

The heat of the IC is mainly dissipated through the thermal pad

of the package. Maximizing the copper area connected to this

pad if possible. In addition, a solid ground plane is always

helpful for the EMI performance.

must be located as close as possible to the FB

SET

2

B

9

FN6264.3

March 7, 2008

ISL97634

www.BDTIC.com/Intersil

Thin Dual Flat No-Lead Plastic Package (TDFN)

(DATUM A)

NX (b)

5

INDEX

AREA

SEATING

(DATUM B)

6

INDEX

AREA

NX L

8

A

6

C

PLANE

(A1)

D

TOP VIEW

SIDE VIEW

D2

D2/2

12

N

N-1

e

(Nd-1)Xe

REF.

BOTTOM VIEW

2X

A3

NX b

L8.2x3A

ABC0.15

2X

0.15

CB

E

//

A

87

NX k

E2

E2/2

5

0.10

C

L

0.10

0.08

L

C

C

BAMC

8 LEAD THIN DUAL FLAT NO-LEAD PLASTIC PACKAGE

MILLIMETERS

SYMBOL

NOTESMIN NOMINAL MAX

A 0.70 0.75 0.80 A1 - - 0.05 A3 0.20 REF -

b 0.20 0.25 0.32 5,8

D 2.00 BSC -

D2 1.50 1.65 1.75 7,8

E 3.00 BSC E2 1.65 1.80 1.90 7,8

e 0.50 BSC -

k0.20 - - L 0.30 0.40 0.50 8

N 8 2

Nd 4 3

Rev. 0 6/04

NOTES:

1. Dimensioning and tolerancing conform to ASME Y14.5-1994.

2. N is the number of terminals.

3. Nd refers to the number of terminals on D.

4. All dimensions are in millimeters. Angles are in degrees.

5. Dimension b applies to the metallized terminal and is measured

between 0.25mm and 0.30mm from the terminal tip.

6. The configuration of the pin #1 identifier is optional, but must be

located within the zone indicated. The pin #1 identifier may be

either a mold or mark feature.

7. Dimensions D2 and E2 are for the exposed p ads which provide

improved electrical and thermal performance.

8. Nominal dimensions are provided to assist with PCB Land

Pattern Design efforts, see Intersil Technical Brief TB389.

SECTION "C-C"

FOR EVEN TERMINAL/SIDE

CC

e

TERMINAL TIP

All Intersil U.S. products are manufactured, assembled and tested utilizing ISO9000 quality systems.

Intersil Corporation’s quality certifications can be viewed at www.intersil.com/design/quality

Intersil products are sold by description only. Intersil Corporation reserves the right to make changes in circuit design, software and/or specifications at any time without

notice. Accordingly, the reader is cautioned to verify that data sheets are current before placing orders. Information furnished by Intersil is believed to be accurate and

reliable. However, no responsibility is assumed by Intersil or its subsidiaries for its use; nor for any infringements of patents or other rights of third parties which may result

from its use. No license is granted by implic atio n or other wise u nde r any p a tent or patent rights of Intersil or its subsidiaries.

For information regarding Intersil Corporation and its products, see www.intersil.com

10

FN6264.3

March 7, 2008

Loading...

Loading...