®

www.BDTIC.com/Intersil

ISL90461

Digitally Controlled Potentiometer (XDCP™)

Data Sheet October 14, 2005

Single Volatile 32-Tap XDCP

The Intersil ISL90461 is a digitally controlled potentiometer

(XDCP). Configured as a variable resistor, the device

consists of a resistor array, wiper switches, a control section,

and volatile memory. The wiper position is controlled by a 2pin Up /Down interface.

The potentiometer is implemented by a resistor array

composed of 31 resistive elements and a wiper switching

network. Between each element and at either end are tap

points accessible to the wiper terminal. The position of the

wiper element is controlled by the CS

The device can be used in a wide variety of applications

including:

• LCD contrast control

• Parameter and bias adjustments

• Industrial and Automotive Control

• Transducer adjustment of pressure, temperature, position,

chemical, and optical sensors

• Laser Diode driver biasing

• Gain control and offset adjustment

and U/D inputs.

FN8229.3

Features

• Volatile solid-state potentiometer

• 2-pin UP/DN interface

• DCP terminal voltage, 2.7V to 5.5V

• Tempco 35 ppm/

°C typical

• 32 wiper tap points

• Low power CMOS

- Active current, 25µA max.

- Supply current 0.3µA

• Available R

• Temperature Range

values = 10kΩ, 50kΩ, 100kΩ

TOTAL

-40°C to +85°C

• Packages

- 6 Ld SC-70, SOT-23

• Pb-Free Plus Anneal Available (RoHS Compliant)

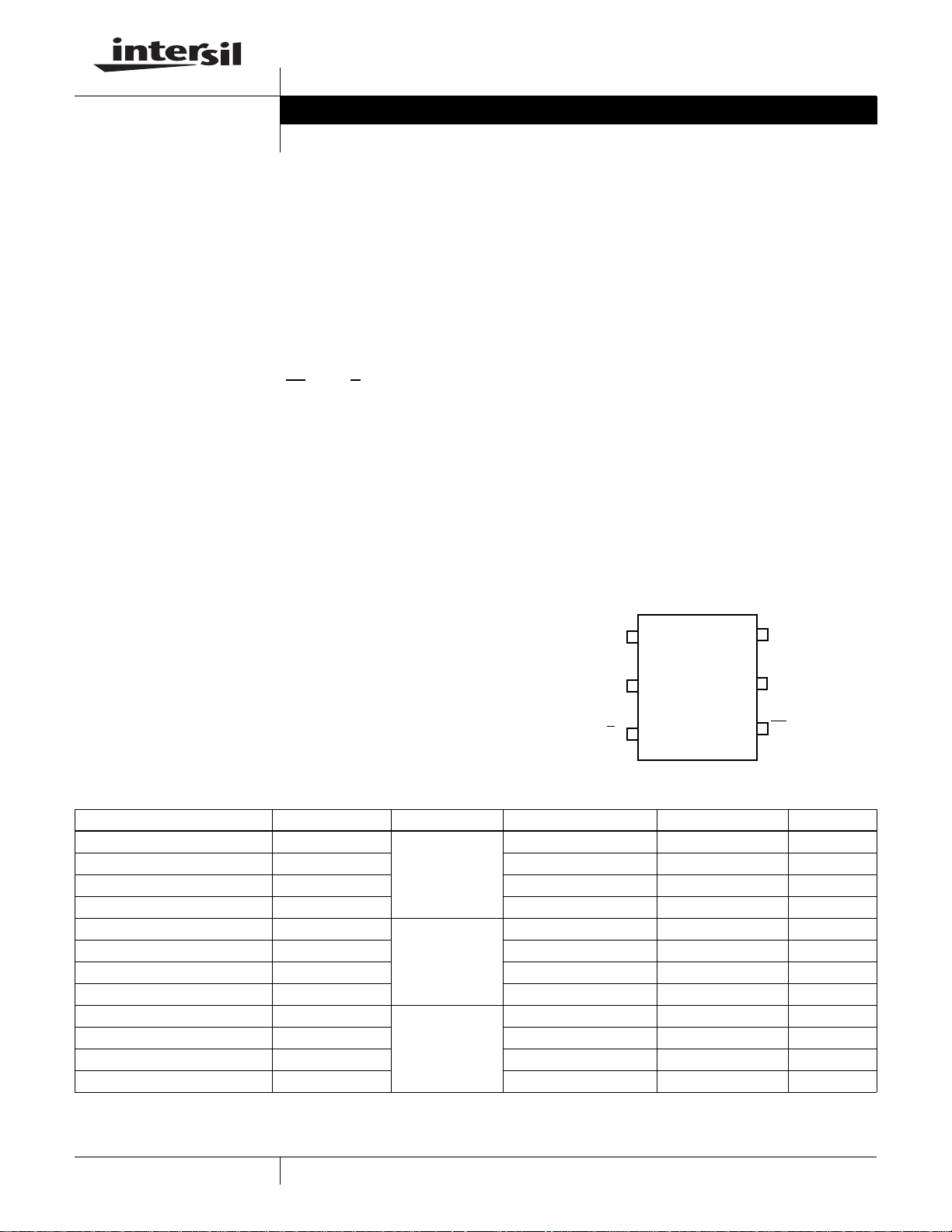

Pinout

ISL90461

(SOT-23, SC-70)

TOP VIEW

VDD

RH

GND

U/D

RL

CS

Ordering Information

PAR T N UM BE R PAR T M AR KI NG R

ISL90461WIE627-TK AJP 10 -40 to +85 6 Ld SC-70 P6.049

ISL90461WIE627Z-TK (See Note) DEE -40 to +85 6 Ld SC-70 (Pb-free) P6.049

ISL90461WIH627-TK AJY -40 to +85 6 Ld SOT-23 P6.064

ISL90461WIH627Z-TK (See Note) DEF -40 to +85 6 Ld SOT-23 (Pb-free) P6.064

ISL90461UIE627-TK AJR 50 -40 to +85 6 Ld SC-70 P6.049

ISL90461UIE627Z-TK (See Note) DEC -40 to +85 6 Ld SC-70 (Pb-free) P6.049

ISL90461UIH627-TK AKA -40 to +85 6 Ld SOT-23 P6.064

ISL90461UIH627Z-TK (See Note) DED -40 to +85 6 Ld SOT-23 (Pb-free) P6.064

ISL90461TIE627-TK AJQ 100 -40 to +85 6 Ld SC-70 P6.049

ISL90461TIE627Z-TK (See Note) DEA -40 to +85 6 Ld SC-70 (Pb-free) P6.049

ISL90461TIH627-TK AJZ -40 to +85 6 Ld SOT-23 P6.064

ISL90461TIH627Z-TK (See Note) DEB -40 to +85 6 Ld SOT-23 (Pb-free) P6.064

NOTE: Intersil Pb-free plus anneal products employ special Pb-free material sets; molding compounds/die attach materials and 100% matte tin plate termination finish, which are

RoHS compliant and compatible with both SnPb and Pb-free soldering operations. Intersil Pb-free products are MSL classified at Pb-free peak reflow temperatures that meet or exceed

the Pb-free requirements of IPC/JEDEC J STD-020

(K) TEMP RANGE (°C) PACKAGE PKG. DWG. #

TOTAL

1

CAUTION: These devices are sensitive to electrostatic discharge; follow proper IC Handling Procedures.

1-888-INTERSIL or 1-888-468-3774

XDCP is a trademark of Intersil Americas Inc. Copyright Intersil Americas Inc. 2005. All Rights Reserved

| Intersil (and design) is a registered trademark of Intersil Americas Inc.

All other trademarks mentioned are the property of their respective owners.

ISL90461

www.BDTIC.com/Intersil

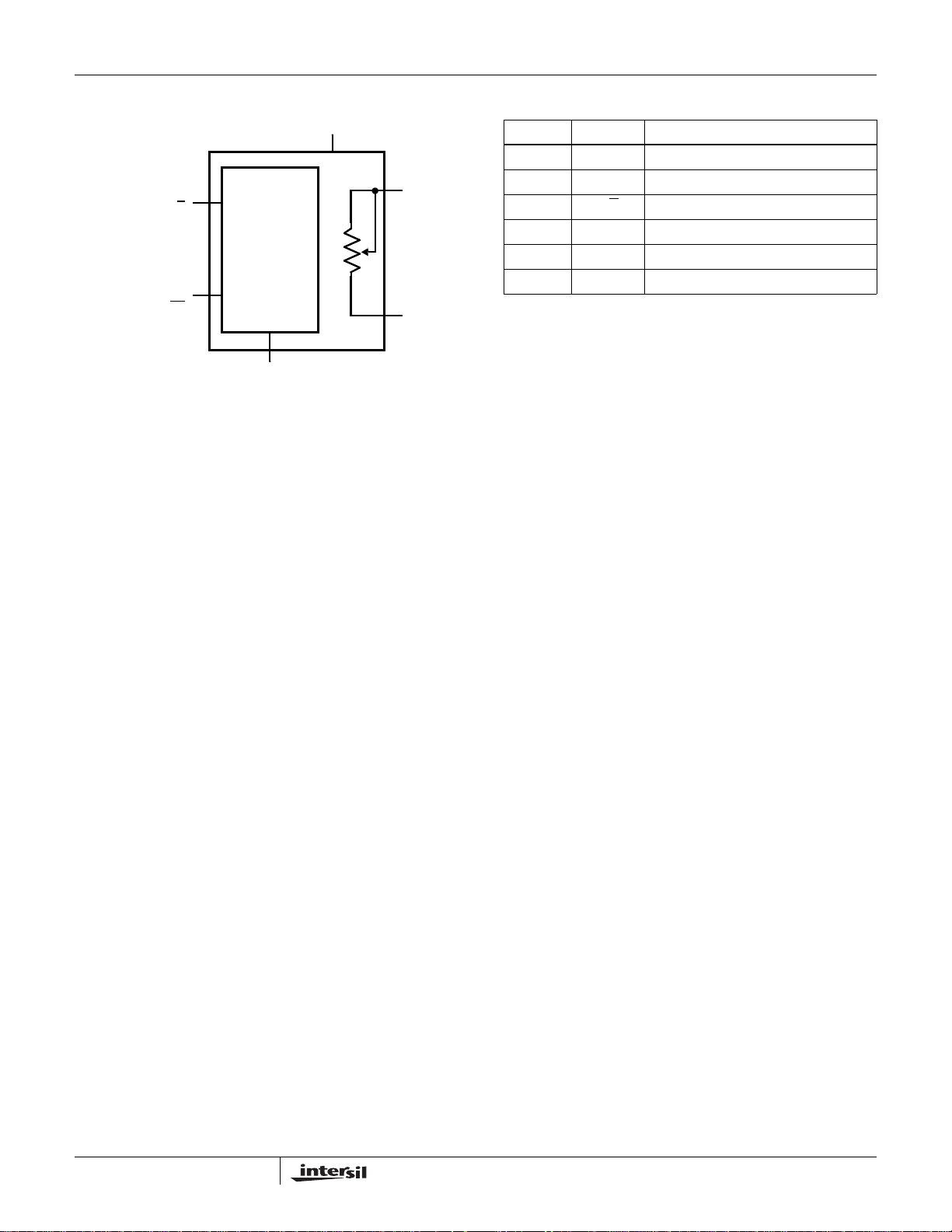

Block Diagram

UP/DOWN

(U/D

)

DEVICE SELECT

)

(CS

CONTROL

AND

MEMORY

GND (GROUND)

GENERAL

VCC

RH

RL

Pin Descriptions

6-PIN SYMBOL DESCRIPTION

1 VDD Supply voltage

2 GND Ground

3U/D

4 CS Chip select

5 RL Low terminal

6 RH High terminal/ Wiper terminal

Up - Down

2

FN8229.3

October 14, 2005

ISL90461

www.BDTIC.com/Intersil

Absolute Maximum Ratings Recommended Operating Conditions

Storage temperature . . . . . . . . . . . . . . . . . . . . . . . .-65°C to +150°C

Voltage on CS

, U/D and VCC

with respect to GND . . . . . . . . . . . . . . . . . . . . . . . . . . . -1V to +7V

Lead temperature (soldering 10s) . . . . . . . . . . . . . . . . . . . . . .300°C

(10s) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ±6mA

I

W

Power rating. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1mW

CAUTION: Stresses above those listed in “Absolute Maximum Ratings” may cause permanent damage to the device. This is a stress only rating and operation of the

device at these or any other conditions above those indicated in the operational sections of this specification is not implied.

Potentiometer Specifications Over recommended operating conditions unless otherwise stated.

SYMBOL PARAMETER TEST CONDITIONS/NOTES MIN

R

TOT

V

R

R

W

I

W

CH/CL/C

NOTES:

1. Absolute linearity is utilized to determine actual wiper voltage versus expected voltage = (R

n = 1 .. 29 only

2. Relative linearity is a measure of the error in step size between taps = R

3. 1 Ml = Minimum Increment = R

4. Typical values are for T

End to end resistance W version 8 10 12 kΩ

U version 405060kΩ

T version 80 100 120 kΩ

RH, RL terminal voltages 0 V

Noise Ref: 1kHz -120 dBV

Wiper Resistance 600 Ω

Wiper Current 0.6 mA

Resolution 132Taps

Absolute linearity (Note 1) R

Relative linearity (Note 2) R

temperature coefficient ±35 ppm/°C

R

TOTAL

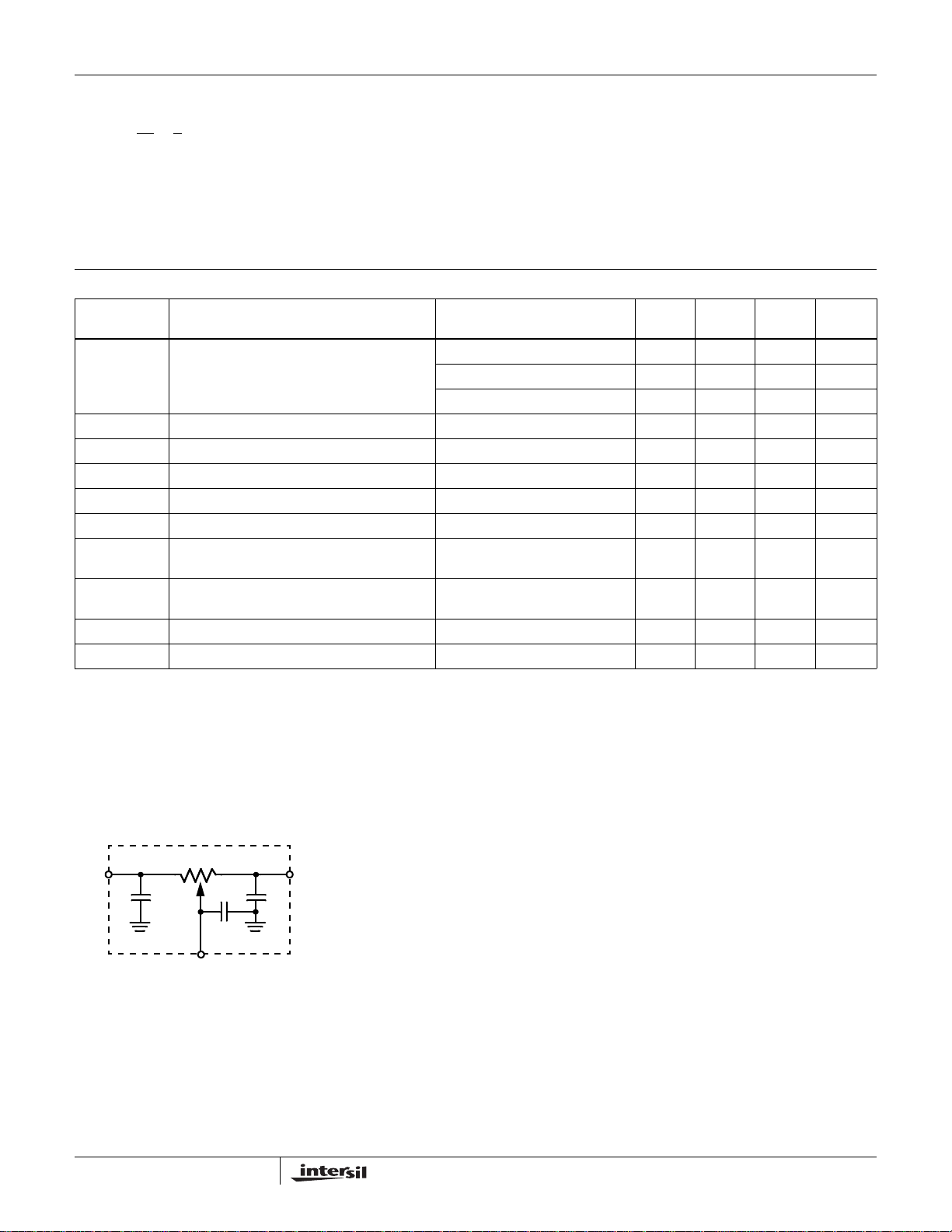

Potentiometer capacitances See equivalent circuit 10/10/25 pF

W

/31.

TOT

= 25°C and nominal supply voltage.

A

H(n)(actual)-RH(n)(expected)

H(n+1)

Temperature Range (Industrial) . . . . . . . . . . . . . . . . .-40°C to +85°C

Supply Voltage (V

) . . . . . . . . . . . . . . . . . . . . . . . . . . 2.7V to 5.5V

CC

TYP

(Note 4) MAX UNIT

CC

±1 MI

(Note 3)

-[R

H

]±0.5MI

H(n)+MI

(n+1)

(actual) - R

(n)

H

-[R

+ Ml] = ±0.5 Ml, n = 1 .. 29 only.

(n)

H

(expected)) = ±1 Ml Maximum.

(n)

H

(Note 3)

V

Equivalent Circuit

R

TOTAL

R

H

C

H

C

W

R

W

R

L

C

L

3

FN8229.3

October 14, 2005

ISL90461

www.BDTIC.com/Intersil

DC Electrical Specifications Over recommended operating conditions unless otherwise specified.

TYP

SYMBOL PARAMETER TEST CONDITIONS MIN

I

CC

I

SB

I

LI

V

V

C

VCC active current (Increment) CS = 0V, U/D = f

Standby supply current CS = VCC, U/D = GND or V

CS input leakage current VIN = GND to V

CS, U/D input HIGH voltage V

IH

CS, U/D input LOW voltage V

IL

CS, U/D input capacitance VCC = 3V, VIN = VSS, TA= 25°C, f = 1MHz 10 pF

IN

= 1MHz and VCC=3V 25 µA

clock

= 3V 0.3 1 µA

CC

CC

CC

Timing Specifications (Over recommended operating conditions unless otherwise specified)

SYMBOL PARAMETER MIN TYP (Note 4) MAX UNIT

t

CU

t

CI

t

IC

t

lL

t

lH

f

TOGGLE

t

SETTLE

U/D to CS setup 25 ns

CS to U/D setup 50 ns

CS to U/D hold 25 ns

U/D LOW period 300 ns

U/D HIGH period 300 ns

Up/Down toggle Rate 1 MHz

Output settling time 1 µs

(Note 4) MAX UNIT

x 0.7 V

±1 µA

x 0.3 V

CC

CS

U/D

RH - RL

t

CU

t

IL

t

t

CI

IH

FIGURE 1. SERIAL INTERFACE TIMING DIAGRAM, INCREMENT

t

IC

t

SETTLE

4

FN8229.3

October 14, 2005

CS

www.BDTIC.com/Intersil

U/D

RH - RL

ISL90461

t

CU

t

IH

t

t

CI

FIGURE 2. SERIAL INTERFACE TIMING DIAGRAM, DECREMENT

IL

t

SETTLE

t

IC

Pin Descriptions

RH and RL

The ISL90461 contains a digital potentiometer configured as

a variable resistor. The wiper of the potentiometer is tied to

one end of the potentiometer at terminal RH, and the RL pin

is the other terminal of the potentiometer. The resistance

from the RH pin to the RL pin will vary with the potentiometer

setting. At the highest setting the resistance will be

maximum (Rtot) and at the lowest setting it will be minimum.

As the wiper position is incremented, the wiper will move

from the Low terminal to the High terminal.

Up/Down (U/D)

The U/D input controls the direction of the wiper movement

and whether the counter is incremented or decremented.

Chip Select (CS)

The device is selected when the CS input is LOW. The

current counter value is stored in volatile memory when CS

is returned HIGH. When CS

low power standby mode.

is high, the device is placed in

Principles of Operation

There are two sections of the ISL90461: the input control,

counter and decode section; and the resistor array. The input

control section operates just like an up/down counter. The

output of this counter is decoded to turn on a single

electronic switch connecting a point on the resistor array to

the wiper output. The resistor array is comprised of 31

individual resistors connected in series. At either end of the

array and between each resistor is an electronic switch that

transfers the connection at that point to the wiper. The wiper

is connected to the RH terminal, forming a variable resistor

from RH to RL.

The direction of the wiper movement is defined when the

device is selected. If during CS

the U/D

rising edge of U/D

input is LOW, the wiper will move down on each

toggling. Similarly, the wiper will move up

on each rising edge of U/D

from High to Low, the U/D

The wiper, when at either fixed terminal, acts like its

mechanical equivalent and does not move beyond the last

position. That is, the counter does not wrap around when

clocked to either extreme.

If the wiper is moved several positions, multiple taps are

connected to the wiper for t

2-terminal resistance value for the device can temporarily

change by a significant amount if the wiper is moved several

positions.

transition from High to Low

toggling if, during CS transition

input is High.

SETTLE

(U/D to RH change). The

5

FN8229.3

October 14, 2005

ISL90461

www.BDTIC.com/Intersil

Small Outline Transistor Plastic Packages (SC70-6)

C

L

A2

A

SEATING

PLANE

0.20 (0.008)

C

L

b

123

e1

D

C

L

WITH

PLATING

4X θ1

C

4X θ1

M

e

456

0.10 (0.004) C

c

BASE METAL

L1

C

VIEW C

P6.049

6 LEAD SMALL OUTLINE TRANSISTOR PLASTIC PACKAGE

INCHES MILLIMETERS

SYMBOL

NOTESMIN MAX MIN MAX

A 0.031 0.043 0.80 1.10 -

C

L

E

E1

A1 0.000 0.004 0.00 0.10 A2 0.031 0.039 0.00 1.00 -

b 0.006 0.012 0.15 0.30 -

b1 0.006 0.010 0.15 0.25

c 0.003 0.009 0.08 0.22 6

C

c1 0.003 0.009 0.08 0.20 6

D 0.073 0.085 1.85 2.15 3

E 0.071 0.094 1.80 2.40 -

E1 0.045 0.053 1.15 1.35 3

A1

SEATING

PLANE

-C-

e 0.0256 Ref 0.65 Ref -

e1 0.0512 Ref 1.30 Ref -

L 0.010 0.018 0.26 0.46 4

L1 0.017 Ref. 0.420 Ref.

L2 0.006 BSC 0.15 BSC

b

b1

N6 65

R 0.004 - 0.10 -

R1 0.004 0.010 0.15 0.25

c1

α

o

0

o

8

o

0

o

8

-

Rev. 2 9/03

NOTES:

1. Dimensioning and tolerance per ASME Y14.5M-1994.

2. Package conforms to EIAJ SC70 and JEDEC MO203AB.

3. Dimensions D and E1 are exclusive of mold flash, protrusions,

R1

R

GAUGE PLANE

L

α

L2

or gate burrs.

4. Footlength L measured at reference to gauge plane.

5. “N” is the number of terminal positions.

6. These Dimensions apply to the flat section of the lead between

0.08mm and 0.15mm from the lead tip.

7. Controlling dimension: MILLIMETER. Converted inch dimensions are for reference only

VIEW C

6

FN8229.3

October 14, 2005

ISL90461

www.BDTIC.com/Intersil

Small Outline Transistor Plastic Packages (SOT23-6)

C

L

A2

A

SEATING

PLANE

0.20 (0.008)

C

L

b

123

e1

D

C

L

WITH

PLATING

4X θ1

C

4X θ1

M

e

456

0.10 (0.004) C

c

BASE METAL

L1

C

VIEW C

P6.064

6 LEAD SMALL OUTLINE TRANSISTOR PLASTIC PACKAGE

INCHES MILLIMETERS

SYMBOL

NOTESMIN MAX MIN MAX

A 0.036 0.057 0.90 1.45 -

C

L

E

E1

A1 0.000 0.0059 0.00 0.15 A2 0.036 0.051 0.90 1.30 -

b 0.012 0.020 0.30 0.50 -

b1 0.012 0.018 0.30 0.45

c 0.003 0.009 0.08 0.22 6

C

c1 0.003 0.008 0.08 0.20 6

D 0.111 0.118 2.80 3.00 3

E 0.103 0.118 2.60 3.00 -

E1 0.060 0.068 1.50 1.75 3

A1

SEATING

PLANE

-C-

e 0.0374 Ref 0.95 Ref -

e1 0.0748 Ref 1.90 Ref -

L 0.014 0.022 0.35 0.55 4

L1 0.024 Ref. 0.60 Ref.

L2 0.010 Ref. 0.25 Ref.

b

b1

N6 65

R 0.004 - 0.10 -

R1 0.004 0.010 0.10 0.25

c1

α

o

0

o

8

o

0

o

8

-

Rev. 3 9/03

NOTES:

1. Dimensioning and tolerance per ASME Y14.5M-1994.

2. Package conforms to EIAJ SC-74 and JEDEC MO178AB.

3. Dimensions D and E1 are exclusive of mold flash, protrusions,

R1

or gate burrs.

4. Footlength L measured at reference to gauge plane.

R

GAUGE PLANE

L

α

L2

5. “N” is the number of terminal positions.

6. These Dimensions apply to the flat section of the lead between

0.08mm and 0.15mm from the lead tip.

7. Controlling dimension: MILLIMETER. Converted inch dimensions are for reference only

VIEW C

All Intersil U.S. products are manufactured, assembled and tested utilizing ISO9000 quality systems.

Intersil Corporation’s quality certifications can be viewed at www.intersil.com/design/quality

Intersil products are sold by description only. Intersil Corporation reserves the right to make changes in circuit design, software and/or specifications at any time without

notice. Accordingly, the reader is cautioned to verify that data sheets are current before placing orders. Information furnished by Intersil is believed to be accurate and

reliable. However, no responsibility is assumed by Intersil or its subsidiaries for its use; nor for any infringements of patents or other rights of third parties which may result

from its use. No license is granted by implication or otherwise under any patent or patent rights of Intersil or its subsidiaries.

For information regarding Intersil Corporation and its products, see www.intersil.com

7

FN8229.3

October 14, 2005

Loading...

Loading...