®

www.BDTIC.com/Intersil

ISL8840A, ISL8841A, ISL8842A,

ISL8843A, ISL8844A, ISL8845A

Data Sheet April 18, 2007

High Performance Industry Standard

Single-Ended Current Mode PWM

Controller

The ISL884xA is a high performance drop-in replacement for

the popular 28C4x and 18C4x PWM controllers suitable for a

wide range of power conversion applications including

boost, flyback, and isolated output configurations. Its fast

signal propagation and output switching characteristics

make this an ideal product for existing and new designs.

Features include 30V operation, low operating current, 90μA

start-up current, adjustable operating frequency to 2MHz,

and high peak current drive capability with 20ns rise and fall

times.

PART NUMBER RISING UVLO MAX. DUTY CYCLE

ISL8840A 7.0 100%

ISL8841A 7.0 50%

ISL8842A 14.4V 100%

ISL8843A 8.4V 100%

ISL8844A 14.4V 50%

ISL8845A 8.4V 50%

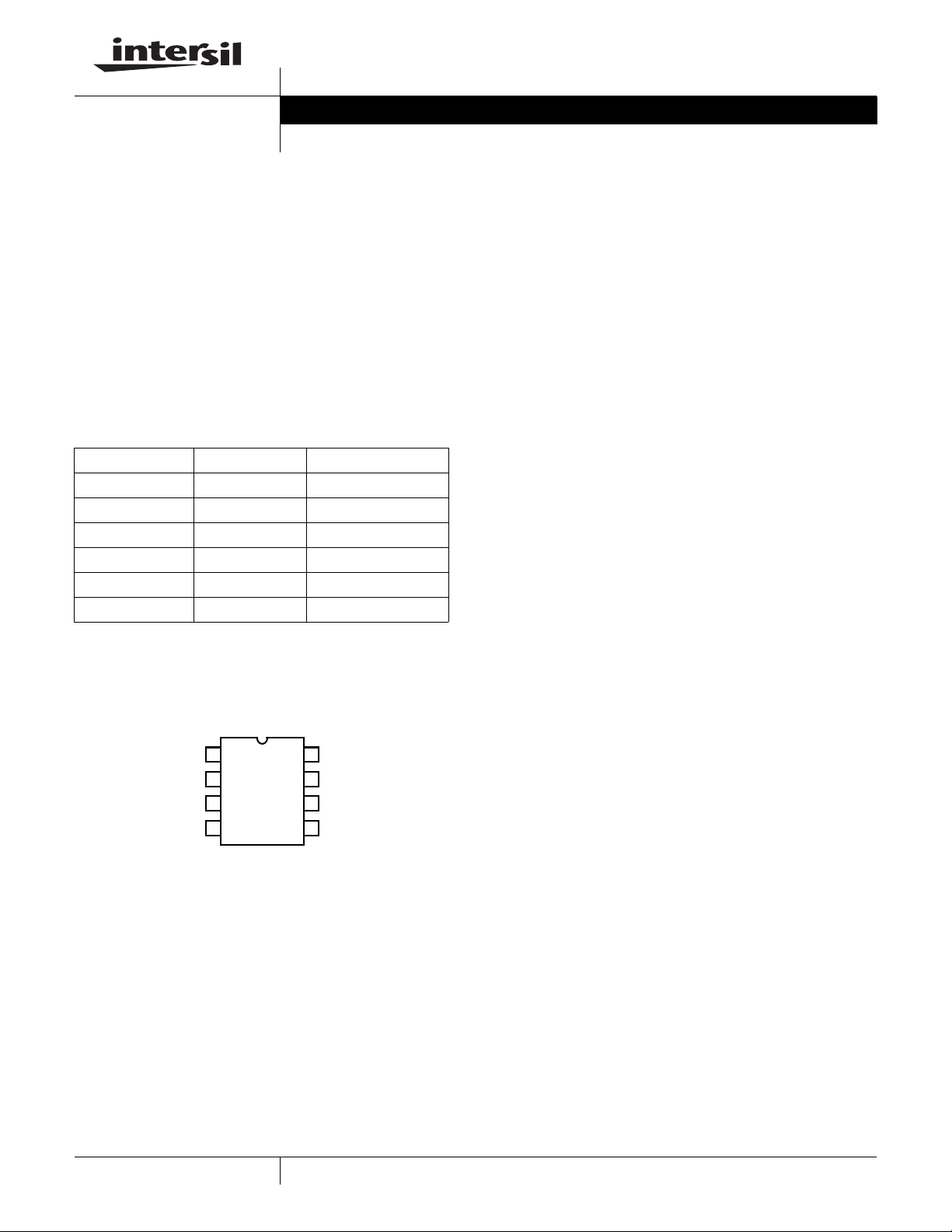

Pinout

ISL8840A, ISL8841A, ISL8842A, ISL8843A, ISL8844A, ISL8845A

(8 LD SOIC, MSOP)

TOP VIEW

COMP

FB

CS

RTCT

1

2

3

4

8

7

5

6

VREF

VDD

OUT

GND

FN6320.3

Features

• 1A MOSFET gate driver

•90μA start-up current, 125μA maximum

• 35ns propagation delay current sense to output

• Fast transient response with peak current mode control

• 30V operation

• Adjustable switching frequency to 2MHz

• 20ns rise and fall times with 1nF output load

• Trimmed timing capacitor discharge current for accurate

deadtime/maximum duty cycle control

• 1.5MHz bandwidth error amplifier

• Tight tolerance voltage reference over line, load and

temperature

• ±3% current limit threshold

• Pb-free plus anneal available and ELV, WEEE, RoHS

Compliant

Applications

• Telecom and datacom power

• Wireless base station power

• File server power

• Industrial power systems

• PC power supplies

• Isolated buck and flyback regulators

• Boost regulators

1

CAUTION: These devices are sensitive to electrostatic discharge; follow proper IC Handling Procedures.

1-888-INTERSIL or 1-888-468-3774

| Intersil (and design) is a registered trademark of Intersil Americas Inc.

Copyright © Intersil Americas Inc. 2005, 2006, 2007. All Rights Reserved.

All other trademarks mentioned are the property of their respective owners.

ISL8840A, ISL8841A, ISL8842A, ISL8843A, ISL8844A, ISL8845A

www.BDTIC.com/Intersil

Ordering Information

PART

NUMBER*

ISL8840AABZ

(See Note)

ISL8840AAUZ

(See Note)

ISL8840AMBZ

(See Note)

ISL8840AMUZ

(See Note)

ISL8841AABZ

(See Note)

ISL8841AAUZ

(See Note)

ISL8841AMBZ

(See Note)

ISL8841AMUZ

(See Note)

ISL8842AABZ

(See Note)

ISL8842AAUZ

(See Note)

ISL8842AMBZ

(See Note)

ISL8842AMUZ

(See Note)

ISL8843AABZ

(See Note)

ISL8843AAUZ

(See Note)

PART

MARKING

8840 AABZ -40 to +105 8 Ld SOIC M8.15

40AAZ -40 to +105 8 Ld MSOP M8.118

8840 AMBZ -55 to +125 8 Ld SOIC M8.15

40AMZ -55 to +125 8 Ld MSOP M8.118

8841 AABZ -40 to +105 8 Ld SOIC M8.15

41AAZ -40 to +105 8 Ld MSOP M8.118

8841 AMBZ -55 to +125 8 Ld SOIC M8.15

41AMZ -55 to +125 8 Ld MSOP M8.118

8842 AABZ -40 to +105 8 Ld SOIC M8.15

42AAZ -40 to +105 8 Ld MSOP M8.118

8842 AMBZ -55 to +125 8 Ld SOIC M8.15

42AMZ -55 to +125 8 Ld MSOP M8.118

8843 AABZ -40 to +105 8 Ld SOIC M8.15

43AAZ -40 to +105 8 Ld MSOP M8.118

TEMP.

RANGE (°C)

PACKAGE

(Pb-free)

PKG.

DWG. #

Ordering Information (Continued)

PART

NUMBER*

ISL8843AMBZ

(See Note)

ISL8843AMUZ

(See Note)

ISL8844AABZ

(See Note)

ISL8844AAUZ

(See Note)

ISL8844AMBZ

(See Note)

ISL8844AMUZ

(See Note)

ISL8845AABZ

(See Note)

ISL8845AAUZ

(See Note)

ISL8845AMBZ

(See Note)

ISL8845AMUZ

(See Note)

*Add “-T” suffix for tape and reel.

NOTE: Intersil Pb-free plus anneal products employ special Pb-free

material sets; molding compounds/die attach materials and 100%

matte tin plate termination finish, which are RoHS compliant and

compatible with both SnPb and Pb-free soldering operations. Intersil

Pb-free products are MSL classified at Pb-free peak reflow

temperatures that meet or exceed the Pb-free requirements of

IPC/JEDEC J STD-020.

PART

MARKING

8843 AMBZ -55 to +125 8 Ld SOIC M8.15

43AMZ -55 to +125 8 Ld MSOP M8.118

8844 AABZ -40 to +105 8 Ld SOIC M8.15

44AAZ -40 to +105 8 Ld MSOP M8.118

8844 AMBZ -55 to +125 8 Ld SOIC M8.15

44AMZ -55 to +125 8 Ld MSOP M8.118

8845 AABZ -40 to +105 8 Ld SOIC M8.15

45AAZ -40 to +105 8 Ld MSOP M8.118

8845 AMBZ -55 to +125 8 Ld SOIC M8.15

45AMZ -55 to +125 8 Ld MSOP M8.118

TEMP.

RANGE (°C)

PACKAGE

(Pb-free)

PKG.

DWG. #

2

FN6320.3

April 18, 2007

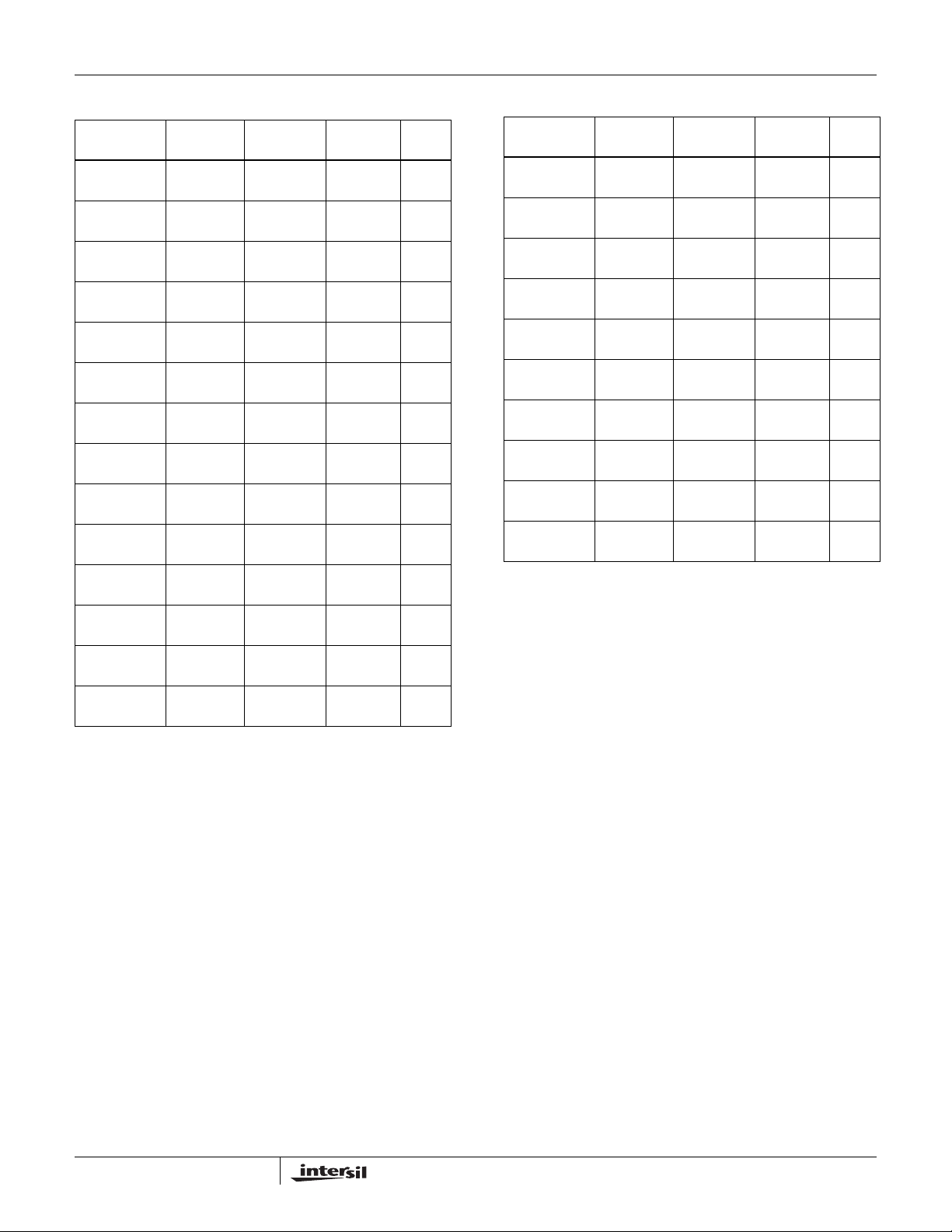

Functional Block Diagram

www.BDTIC.com/Intersil

V

DD

3

GND

CS

FB

COMP

ERROR

AMPLIFIER

VREF

START/STOP

UV COMPARATOR

+

-

+

-

2.5V

+

-

A

A = 0.5

VF TOTAL = 1.15V

DD

OKV

ENABLE

+

-

100mV

2R

COMPARATOR

R

V

REF

5.00V

PWM

+

-

1.1V

CLAMP

ONLY

ISL8841A/

ISL8844A/

ISL8845A

Q

T

Q

SRQ

Q

RESET

DOMINANT

VREF FAULT

VREF

UV COMPARATOR

4.65V 4.80V

-

+

-

+

36k

VREF

ISL8840A, ISL8841A, ISL8842A, ISL8843A, ISL8844A, ISL8845A

OUT

100k

150k

RTCT

April 18, 2007

FN6320.3

2.9V

1.0V

OSCILLATOR

COMPARATOR

8.4mA

ON

<10ns

+

ON

CLOCK

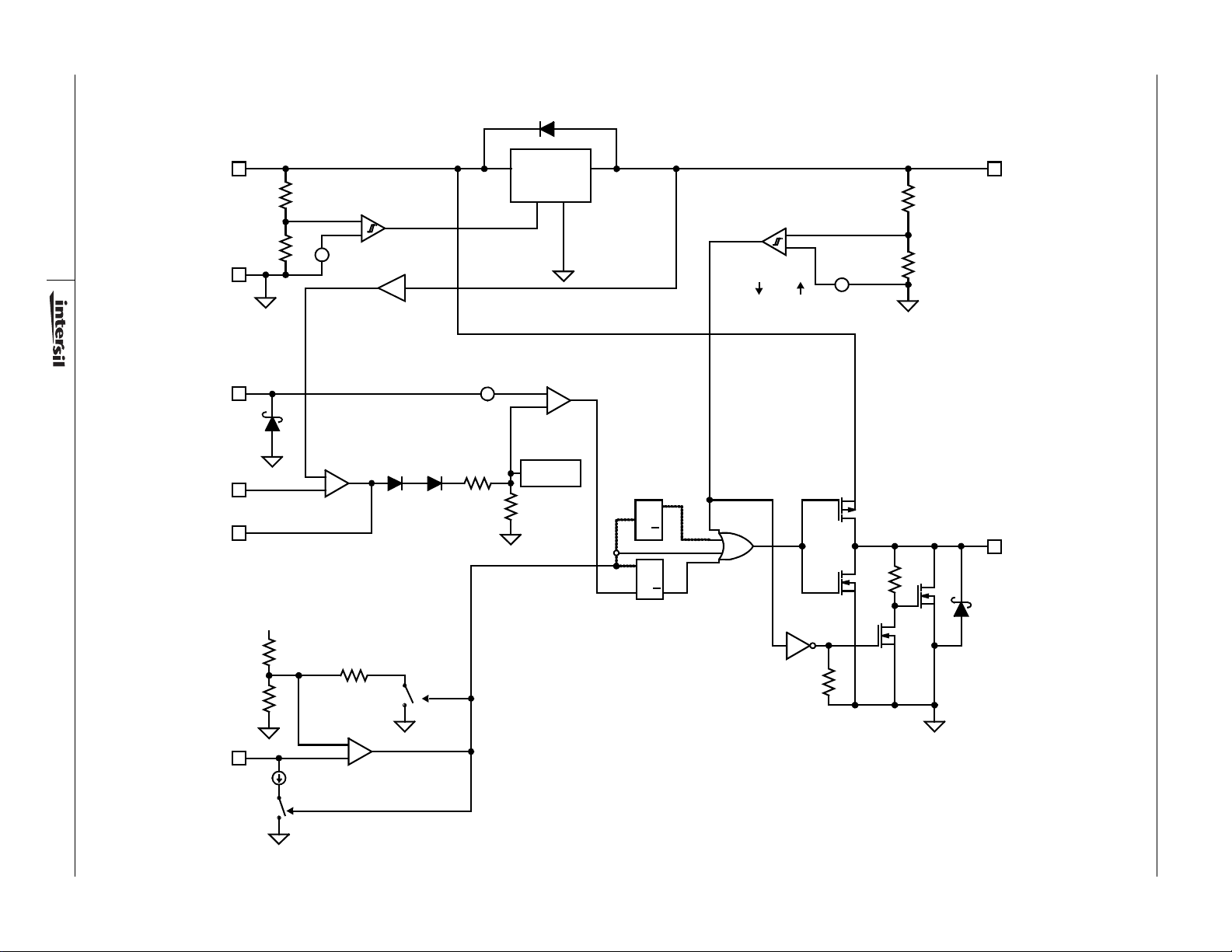

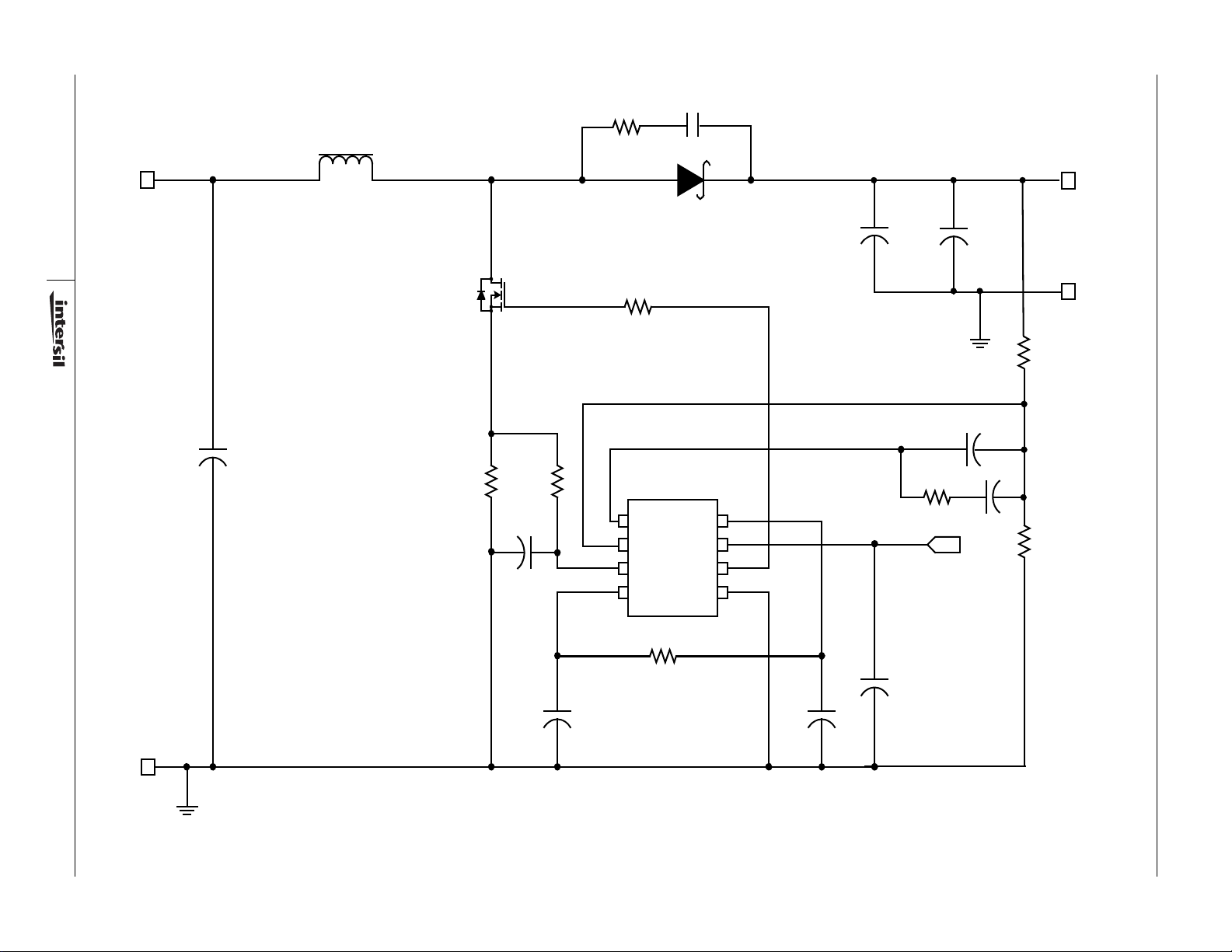

Typical Application - 48V Input Dual Output Flyback

www.BDTIC.com/Intersil

VIN+

4

R1

36V TO 75V

C1

C2

C3

R3

C4

CR6

Q1

C5

CR2

T1

C17

C6

R21

CR5

CR4

C19

+

R16

U2

C21

C15 C16

+

C22

+

C20

R17

R19

C14

R18

+3.3V

+

+1.8V

RETURN

ISL8840A, ISL8841A, ISL8842A, ISL8843A, ISL8844A, ISL8845A

R4

-

V

IN

R6

CR1

Q3

VR1

April 18, 2007

FN6320.3

C8

R26

R22

COMP

CS

FB

RTCT

R27

U4

VREF

ISL884xA

R10

V

DD

OUT

GND

R13

U3

C13

R15

R20

C12

C11

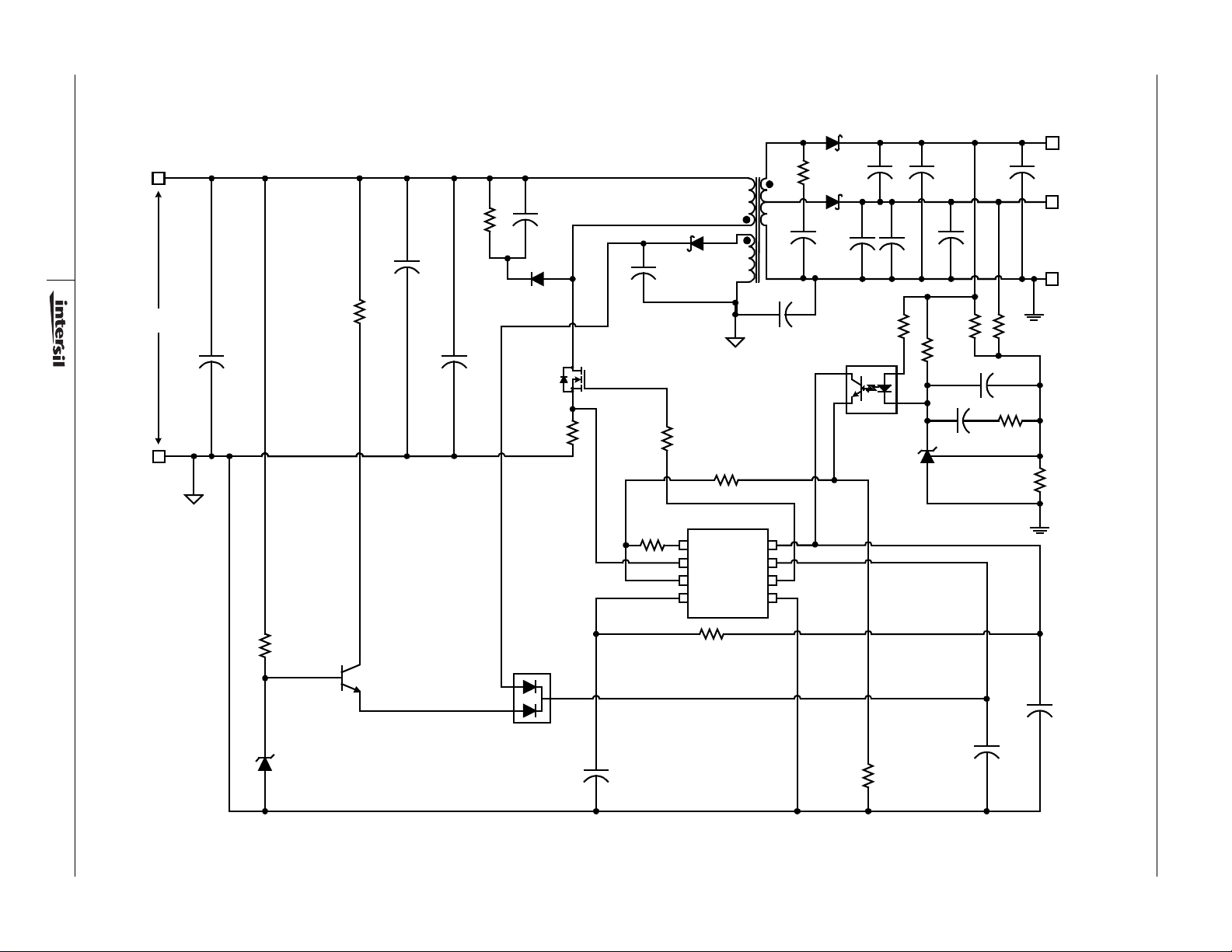

Typical Application - Boost Converter

www.BDTIC.com/Intersil

VIN+

R8

L1

CR1

C10

+VOUT

+

C2

C3

ISL8840A, ISL8841A, ISL8842A, ISL8843A, ISL8844A, ISL8845A

5

RETURN

R5

R6

C1

Q1

R1

C4

R2

R4

COMP

FB

CS

RTCT

U1

ISL884xA

VREF

VDD

OUT

GND

R7

VIN+

C9

C8

C7

VIN-

April 18, 2007

FN6320.3

R3

C5

C6

ISL8840A, ISL8841A, ISL8842A, ISL8843A, ISL8844A, ISL8845A

www.BDTIC.com/Intersil

Absolute Maximum Ratings Thermal Information

Supply Voltage, VDD . . . . . . . . . . . . . . . . . . . . . GND -0.3V to +30V

OUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . GND -0.3V to V

Signal Pins . . . . . . . . . . . . . . . . . . . . . . . . . . . . . GND -0.3V to 6.0V

Peak GATE Current. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1A

ESD Classification

Human Body Model (Per JESD22-A114C.01) . . . . . . . . . . .2000V

Machine Model (Per EIA/JESD22-A115-A) . . . . . . . . . . . . . .200V

Charged Device Model (Per JESD22-C191-A) . . . . . . . . . .1000V

DD

+ 0.3V

Thermal Resistance (Typical, Note 1) θ

SOIC Package . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

MSOP Package . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

Maximum Junction Temperature . . . . . . . . . . . . . . .-55°C to +150°C

Maximum Storage Temperature Range. . . . . . . . . .-65°C to +150°C

Maximum Lead Temperature (Soldering 10s) . . . . . . . . . . . . +300°C

(SOIC, MSOP - Lead Tips Only)

Operating Conditions

Temperature Range

ISL884xAAxZ . . . . . . . . . . . . . . . . . . . . . . . . . . . .-40°C to +105°C

ISL884xAMxZ. . . . . . . . . . . . . . . . . . . . . . . . . . . .-55°C to +125°C

Supply Voltage Range (Typical, Note 2)

ISL884xA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9V to 30V

CAUTION: Stresses above those listed in “Absolute Maximum Ratings” may cause permanent damage to the device. This is a stress only rating and operation of the

device at these or any other conditions above those indicated in the operational sections of this specification is not implied.

+150°C max junction temperature is intended for short periods of time to prevent shortening the lifetime. Constantly operated at +150° C may shorten the life of the part.

NOTES:

is measured with the component mounted on a high effective thermal conductivity test board in free air. See Technical Brief TB379 for details.

1. θ

JA

2. All voltages are with respect to GND.

(°C/W)

JA

Electrical Specifications ISL884xAA - Recommended operating conditions unless otherwise noted. Refer to Block Diagram and

Typical Application schematic onpage 3 and page 4. V

(Note 3). Typical values are at T

PARAMETER TEST CONDITIONS MIN TYP MAX UNITS

UNDERVOLTAGE LOCKOUT

START Threshold (ISL8840A, ISL8841A) 6.5 7.0 7.5 V

START Threshold (ISL8843A, ISL8845A) 8.0 8.4 9.0 V

START Threshold (ISL8842A, ISL8844A) (Note 6) 13.3 14.3 15.3 V

STOP Threshold (ISL8840A, ISL8841A) 6.1 6.6 6.9 V

STOP Threshold (ISL8843A, ISL8845A) 7.3 7.6 8.0 V

STOP Threshold (ISL8842A, ISL8844A) 8.0 8.8 9.6 V

Hysteresis (ISL8840A, ISL8841A) - 0.4 - V

Hysteresis (ISL8843A, ISL8845A) - 0.8 - V

Hysteresis (ISL8842A, ISL8844A) - 5.4 - V

Startup Current, I

Operating Current, I

Operating Supply Current, I

REFERENCE VOLTAGE

Overall Accuracy Over line (V

Long Term Stability T

Current Limit, Sourcing -20 - - mA

Current Limit, Sinking 5--mA

CURRENT SENSE

Input Bias Current V

CS Offset Voltage V

COMP to PWM Comparator Offset Voltage V

DD

DD

D

VDD < START Threshold - 90 125 μA

(Note 4) - 2.9 4.0 mA

Includes 1nF GATE loading - 4.75 5.5 mA

temperature

= +125°C, 1000 hours (Note 5) - 5 - mV

A

= 1V -1.0 - 1.0 μA

CS

= 0V (Note 5) 95 100 105 mV

CS

= 0V (Note 5) 0.80 1.15 1.30 V

CS

= +25°C

A

= 12V to 30V), load,

DD

= 15V, RT = 10kΩ, CT = 3.3nF, TA = -40 to +105°C

DD

4.925 5.000 5.050 V

6

FN6320.3

April 18, 2007

ISL8840A, ISL8841A, ISL8842A, ISL8843A, ISL8844A, ISL8845A

www.BDTIC.com/Intersil

Electrical Specifications ISL884xAA - Recommended operating conditions unless otherwise noted. Refer to Block Diagram and

Typical Application schematic onpage 3 and page 4. V

(Note 3). Typical values are at T

PARAMETER TEST CONDITIONS MIN TYP MAX UNITS

Input Signal, Maximum 0.97 1.00 1.03 V

CS

= ΔV

DD

Gain, A

CS to OUT Delay -3555ns

ERROR AMPLIFIER

Open Loop Voltage Gain (Note 5) 60 90 - dB

Unity Gain Bandwidth (Note 5) 1.0 1.5 - MHz

Reference Voltage V

FB Input Bias Current V

COMP Sink Current V

COMP Source Current V

COMP VOH V

COMP VOL V

PSRR Frequency = 120Hz, V

OSCILLATOR

Frequency Accuracy Initial, T

Frequency Variation with V

Temperature Stability (Note 5) - - 5 %

Amplitude, Peak to Peak Static Test - 1.75 - V

RTCT Discharge Voltage (Valley Voltage) Static Test - 1.0 - V

Discharge Current RTCT = 2.0V 6.5 7.8 8.5 mA

OUTPUT

Gate VOH V

Gate VOL OUT to GND, I

Peak Output Current C

Rise Time C

Fall Time C

GATE VOL UVLO Clamp Voltage VDD = 5V, I

PWM

Maximum Duty Cycle

(ISL8840A, ISL8842A, ISL8843A)

Maximum Duty Cycle

(ISL8841A, ISL8844A, ISL8845A)

Minimum Duty Cycle COMP = GND - - 0 %

NOTES:

3. Specifications at -40°C and +105°C are guaranteed by +25°C test with margin limits.

4. This is the V

5. These parameters, although guaranteed, are not 100% tested in production.

6. Adjust V

/ΔVCS 0 < VCS < 910mV, VFB = 0V 2.5 3.0 3.5 V/V

COMP

= V

FB

= 0V -1.0 -0.2 1.0 μA

FB

COMP

COMP

= 2.3V 4.80 - VREF V

FB

= 2.7V 0.4 - 1.0 V

FB

30V (Note 5)

DD

current consumed when the device is active but not switching. Does not include gate drive current.

DD

above the start threshold and then lower to 15V.

TA= +25°C, (f

to OUT, I

DD

OUT

OUT

OUT

COMP = VREF 94.0 96.0 - %

COMP = VREF 47.0 48.0 - %

= +25°C (Continued)

A

COMP

= 1.5V, VFB = 2.7V 1.0 - - mA

= 1.5V, VFB = 2.3V -0.4 - - mA

= 12V to

DD

= +25°C 48 51 53 kHz

A

- f

30V

OUT

OUT

= 1nF (Note 5) - 1.0 - A

= 1nF (Note 5) - 20 40 ns

= 1nF (Note 5) - 20 40 ns

LOAD

)/f

10V

30V

= -200mA - 1.0 2.0 V

= 200mA - 1.0 2.0 V

= 1mA - - 1.2 V

= 15V, RT = 10kΩ, CT = 3.3nF, TA = -40 to +105°C

DD

2.475 2.500 2.530 V

60 80 - dB

-0.21.0%

7

FN6320.3

April 18, 2007

ISL8840A, ISL8841A, ISL8842A, ISL8843A, ISL8844A, ISL8845A

www.BDTIC.com/Intersil

Electrical Specifications ISL884xAM - Recommended operating conditions unless otherwise noted. Refer to Block Diagram and

Typical Applicati on schematic. V

are at T

PARAMETER TEST CONDITIONS MIN TYP MAX UNITS

UNDERVOLTAGE LOCKOUT

START Threshold (ISL8840A, ISL8841A) 6.5 7.0 7.5 V

START Threshold (ISL8843A, ISL8845A) 8.0 8.4 9.0 V

START Threshold (ISL8842A, ISL8844A) (Note 10) 13.3 14.3 15.3 V

STOP Threshold (ISL8840A, ISL8841A) 6.1 6.6 6.9 V

STOP Threshold (ISL8843A, ISL8845A) 7.3 7.6 8.0 V

STOP Threshold (ISL8842A, ISL8844A) 8.0 8.8 9.6 V

Hysteresis (ISL8840A, ISL8841A) - 0.4 - V

Hysteresis (ISL8843A, ISL8845A) - 0.8 - V

Hysteresis (ISL8842A, ISL8844A) - 5.4 - V

Startup Current, I

Operating Current, I

Operating Supply Current, I

REFERENCE VOLTAGE

Overall Accuracy Over line (V

Long Term Stability T

Current Limit, Sourcing -20 - - mA

Current Limit, Sinking 5--mA

CURRENT SENSE

Input Bias Current V

CS Offset Voltage V

COMP to PWM Comparator Offset Voltage V

Input Signal, Maximum 0.97 1.00 1.03 V

Gain, A

CS

CS to OUT Delay -3560ns

ERROR AMPLIFIER

Open Loop Voltage Gain (Note 9) 60 90 - dB

Unity Gain Bandwidth (Note 9) 1.0 1.5 - MHz

Reference Voltage V

FB Input Bias Current V

COMP Sink Current V

COMP Source Current V

COMP VOH V

COMP VOL V

PSRR Frequency = 120Hz, V

OSCILLATOR

Frequency Accuracy Initial, T

Frequency Variation with V

Temperature Stability (Note 9) - - 5 %

= ΔV

DD

DD

D

/ΔVCS 0 < VCS < 910mV, VFB = 0V 2.5 3.0 3.5 V/V

COMP

DD

= +25°C

A

VDD < START Threshold - 90 125 μA

(Note 8) - 2.9 4.0 mA

Includes 1nF GATE loading - 4.75 5.5 mA

temperature

= +125°C, 1000 hours (Note 9) - 5 - mV

A

= 1V -1.0 - 1.0 μA

CS

= 0V (Note 9) 95 100 105 mV

CS

= 0V (Note 9) 0.80 1.15 1.30 V

CS

= V

FB

= 0V -1.0 -0.2 1.0 μA

FB

COMP

COMP

= 2.3V 4.80 - VREF V

FB

= 2.7V 0.4 - 1.0 V

FB

30V (Note 9)

TA = +25°C, (f

= 15V , R T = 10kΩ, CT = 3.3nF , TA = -55 to +125°C (Note 7), Typical values

DD

= 12V to 30V), load,

DD

COMP

= 1.5V, VFB = 2.7V 1.0 - - mA

= 1.5V, VFB = 2.3V -0.4 - - mA

= 12V to

DD

= +25°C 485153kHz

A

- f

10V

)/f

30V

30V

4.900 5.000 5.050 V

2.460 2.500 2.535 V

60 80 - dB

-0.21.0%

8

FN6320.3

April 18, 2007

ISL8840A, ISL8841A, ISL8842A, ISL8843A, ISL8844A, ISL8845A

www.BDTIC.com/Intersil

Electrical Specifications ISL884xAM - Recommended operating conditions unless otherwise noted. Refer to Block Diagram and

Typical Applicati on schematic. V

are at T

PARAMETER TEST CONDITIONS MIN TYP MAX UNITS

Amplitude, Peak to Peak Static Test - 1.75 - V

RTCT Discharge Voltage (Valley Voltage) Static Test - 1.0 - V

Discharge Current RTCT = 2.0V 6.2 8.0 8.5 mA

OUTPUT

Gate VOH V

Gate VOL OUT - GND, I

Peak Output Current C

Rise Time C

Fall Time C

GATE VOL UVLO Clamp Voltage V

PWM

Maximum Duty Cycle

(ISL8840A, ISL8842A, ISL8843A)

Maximum Duty Cycle

(ISL8841A, ISL8844A, ISL8845A)

Minimum Duty Cycle COMP = GND - - 0 %

NOTES:

7. Specifications at -55°C and +125°C are guaranteed by +25°C test with margin limits.

8. This is the V

9. These parameters, although guaranteed, are not 100% tested in production.

10. Adjust V

current consumed when the device is active but not switching. Does not include gate drive current.

DD

above the start threshold and then lower to 15V.

DD

= +25°C (Continued )

A

- OUT, I

DD

OUT

OUT

OUT

= 5V, I

DD

COMP = VREF 94.0 96.0 - %

COMP = VREF 47.0 48.0 - %

= 15V , R T = 10kΩ, CT = 3.3nF , TA = -55 to +125°C (Note 7), Typical values

DD

= -200mA - 1.0 2.0 V

OUT

= 200mA - 1.0 2.0 V

OUT

= 1nF (Note 9) - 1.0 - A

= 1nF (Note 9) - 20 40 ns

= 1nF (Note 9) - 20 40 ns

= 1mA - - 1.2 V

LOAD

Typical Performance Curves

1.01

1.00

0.99

NORMALIZED FREQUENCY

0.98

-60 -40 -20 0 20 40 60 80 100 120 140

TEMPERATURE (°C)

FIGURE 1. FREQUENCY vs TEMPERATURE FIGURE 2. REFERENCE VOLTAGE vs TEMPERATURE

1.001

1.000

0.999

0.998

0.997

NORMALIZED VREF

0.996

0.995

-60 -40 -20 0 20 40 60 80 100

TEMPERATURE (°C)

140120

9

FN6320.3

April 18, 2007

ISL8840A, ISL8841A, ISL8842A, ISL8843A, ISL8844A, ISL8845A

www.BDTIC.com/Intersil

Typical Performance Curves (Continued)

1.001

3

10

1.000

0.998

0.997

NORMALIZED EA REFERENCE

0.996

-60 -40 -20 0 20 40 60 80 100 120 140

TEMPERATURE (°C)

FIGURE 3. EA REFERENCE vs TEMPERATURE

Pin Descriptions

RTCT - This is the oscillator timing control pin. The

operational frequency and maximum duty cycle are set by

connecting a resistor, RT, between VREF and this pin and a

timing capacitor, CT, from this pin to GND. The oscillator

produces a sawtooth waveform with a programmable

frequency range up to 2.0MHz. The charge time, t

discharge time, t

, the switching frequency, f, and the

D

maximum duty cycle, Dmax, can be approximated from the

following equations:

tC0.533 RT CT⋅⋅≈

t

RT– CT In

D

f 1t

Dt

C

⋅⋅≈

+()⁄=

CtD

f⋅=

0.008 RT 3.83–⋅

⎛

---------------------------------------------

⎝

0.008 RT 1.71–⋅

⎞

⎠

The formulae have increased error at higher frequencies due

to propagation delays. Figure 4 may be used as a guideline

in selecting the capacitor and resistor values required for a

given frequency.

COMP - COMP is the output of the error amplifier and the

input of the PWM comparator. The control loop frequency

compensation network is connected between the COMP and

FB pins.

FB - The output voltage feedback is connected to the

inverting input of the error amplifier through this pin. The

non-inverting input of the error amplifier is internally tied to a

reference voltage.

CS - This is the current sense input to the PWM comparator.

The range of the input signal is nominally 0V to 1.0V and has

an internal offset of 100mV.

GND - GND is the power and small signal reference ground

for all functions.

, the

C

(EQ. 1)

(EQ. 2)

(EQ. 3)

(EQ. 4)

100

10

FREQUENCY (Hz)

1

1 10 100

FIGURE 4. RESISTANCE FOR CT CAPACITOR VALUES GIVEN

RT (kΩ)

100pF

220pF

330pF

470pF

1.0nF

2.2nF

3.3nF

4.7nF

6.8nF

OUT - This is the drive output to the power switching device.

It is a high current output capable of driving the gate of a

power MOSFET with peak currents of 1.0A. This GATE

output is actively held low when V

is below the UVLO

DD

threshold.

V

- VDD is the power connection for the device. The total

DD

supply current will depend on the load applied to OUT. Total

I

current is the sum of the operating current and the

DD

average output current. Knowing the operating frequency, f,

and the MOSFET gate charge, Qg, the average output

current can be calculated from:

I

OUT

Qg f×=

To optimize noise immunity, bypass V

ceramic capacitor as close to the V

DD

to GND with a

DD

and GND pins as

(EQ. 5)

possible.

VREF - The 5.00V reference voltage output. +1.0/-1.5%

tolerance over line, load and operating temperature. Bypass

to GND with a 0.1μF to 3.3μF capacitor to filter this output as

needed.

Functional Description

Features

The ISL884xA current mode PWM makes an ideal choice for

low-cost flyback and forward topology applications. With its

greatly improved performance over industry standard parts,

it is the obvious choice for new designs or existing designs

which require updating.

Oscillator

The ISL884xA has a sawtooth oscillator with a

programmable frequency range to 2MHz, which can be

programmed with a resistor from VREF and a capacitor to

GND on the RTCT pin. (Please refer to Figure 4 for the

resistor and capacitance required for a given frequency.)

10

FN6320.3

April 18, 2007

ISL8840A, ISL8841A, ISL8842A, ISL8843A, ISL8844A, ISL8845A

www.BDTIC.com/Intersil

Soft-Start Operation

Soft-start must be implemented externally. One method,

illustrated below, clamps the voltage on COMP.

D1 R1

C1

FIGURE 5. SOFT-START

VREF

COMP

Q1

GND

ISL884xA

The COMP pin is clamped to the voltage on capacitor C1

plus a base-emitter junction by transistor Q1. C1 is charged

from VREF through resistor R1 and the base current of Q1.

At power-up C1 is fully discharged, COMP is at ~0.7V, and

the duty cycle is zero. As C1 charges, the voltage on COMP

increases, and the duty cycle increases in proportion to the

voltage on C1. When COMP reaches the steady state

operating point, the control loop takes over and soft start is

complete. C1 continues to charge up to VREF and no longer

affects COMP. During power down, diode D1 quickly

discharges C1 so that the soft start circuit is properly

initialized prior to the next power on sequence.

Gate Drive

The ISL884xA is capable of sourcing and sinking 1A peak

current. To limit the peak current through the IC, an optional

external resistor may be placed between the totem-pole

output of the IC (OUT pin) and the gate of the MOSFET. This

small series resistor also damps any oscillations caused by

the resonant tank of the parasitic inductances in the traces of

the board and the FET’s input capacitance.

From the small signal current-mode model [1] it can be

shown that the naturally-sampled modulator gain, Fm,

without slope compensation, is in Equation 6.

1

------------------- -

Fm

=

SnTsw

(EQ. 6)

where Sn is the slope of the sawtooth signal and Tsw is the

duration of the half-cycle. When an external ramp is added,

the modulator gain becomes:

1

---------------------------------------

==

Fm

Sn Se+()Tsw

1

----------------------------

SnTsw

m

c

(EQ. 7)

where Se is slope of the external ramp and

Se

m

-------

1

+=

c

Sn

(EQ. 8)

The criteria for determining the correct amount of external

ramp can be determined by appropriately setting the

damping factor of the double-pole located at the switching

frequency. The double-pole will be critically damped if the

Q-factor is set to 1, over-damped for Q < 1, and

under-damped for Q > 1. An under-damped condition may

result in current loop instability.

-------------------------------------------------

=

Q

π m

c

1

1D–()0.5–()

(EQ. 9)

where D is the percent of on time during a switching cycle.

Setting Q = 1 and solving for Se yields

S

eSn

1

⎛⎞

⎛⎞

-- -

=

⎝⎠

⎝⎠

π

1

-------------

0.5+

1D–

1–

(EQ. 10)

Since Sn and Se are the on time slopes of the current ramp

and the external ramp, respectively , they can be multiplied

by t

to obtain the voltage change that occurs during tON.

ON

V

eVn

1

⎛⎞

⎛⎞

-- -

=

⎝⎠

⎝⎠

π

1

-------------

0.5+

1D–

1–

(EQ. 11)

Slope Compensation

For applications where the maximum duty cycle is less than

50%, slope compensation may be used to improve noise

immunity, particularly at lighter loads. The amount of slope

compensation required for noise immunity is determined

empirically, but is generally about 10% of the full scale

current feedback signal. For applications where the duty

cycle is greater than 50%, slope compensation is required to

prevent instability.

where Vn is the change in the current feedback signal (ΔI)

during the on time and Ve is the voltage that must be added

by the external ramp.

For a flyback converter, Vn can be solved for in terms of

input voltage, current transducer components, and primary

inductance, yielding

DT⋅

SWVINRCS

----------------------------------------------------

V

= V

e

Slope compensation may be accomplished by summing an

external ramp with the current feedback signal or by

subtracting the external ramp from the voltage feedback

error signal. Adding the external ramp to the current

feedback signal is the more popular method.

where R

frequency, L

is the current sense resistor, f

CS

p

input voltage, and D is the maximum duty cycle.

11

⋅⋅

L

p

1

⎛⎞

⎛⎞

-- -

⎝⎠

⎝⎠

π

1

-------------

0.5+

1D–

1–

is the switching

sw

(EQ. 12)

is the primary inductance, VIN is the minimum

FN6320.3

April 18, 2007

ISL8840A, ISL8841A, ISL8842A, ISL8843A, ISL8844A, ISL8845A

www.BDTIC.com/Intersil

The current sense signal at the end of the ON time for CCM

operation is:

NSRCS⋅

------------------------

V

= V (EQ. 13)

CS

where V

L

is the secondary winding inductance, and IO is the output

s

N

P

is the voltage across the current sense resistor,

CS

1D–()VOf⋅⋅

⎛⎞

--------------------------------------------

I

+

⎜⎟

O

⎝⎠

2L

sw

s

current at current limit. Equation 13 assumes the voltage

drop across the output rectifier is negligible.

Since the peak current limit threshold is 1.00V, the total

current feedback signal plus the external ramp voltage must

sum to this value when the output load is at the current limit

threshold.

+ 1=

V

eVCS

(EQ. 14)

Substituting Equations 12 and 13 into Equation 14 and

solving for R

---------------------------------------------------------------------------------------------------------------------------------------------------- -

R

=

CS

Df

-------------------------------

yields

CS

⋅⋅

swVIN

L

p

1

1

-- -

0.5+

⎛⎞

π

⎜⎟

----------------- -

⋅

⎜⎟

1D–

⎝⎠

N

s

-------

1–

N

p

1D–()VOf

⎛⎞

I

+

⋅+

⎜⎟

O

⎝⎠

⋅⋅

2L

sw

s

(EQ. 15)

--------------------------------------------

Adding slope compensation is accomplished in the

ISL884xA using an external buffer transistor and the RTCT

signal. A typical application sums the buffered RTCT signal

with the current sense feedback and applies the result to the

CS pin as shown in Figure 6.

VREF

R9

R6

C4

FIGURE 6. SLOPE COMPENSATION

ISL8843

CS

RTCT

Assuming the designer has selected values for the RC filter

(R

and C4) placed on the CS pin, the value of R9 required

6

to add the appropriate external ramp can be found by

superposition.

2.05D R6⋅

----------------------------

V

= V

e

R

6R9

+

(EQ. 16)

The factor of 2.05 in Equation 16 arises from the peak

amplitude of the sawtooth waveform on RTCT minus a

base-emitter junction drop. That voltage multiplied by the

maximum duty cycle is the voltage source for the slope

compensation. Rearranging to solve for R

2.05D Ve–()R6⋅

----------------------------------------------

R

= Ω

9

V

e

yields:

9

(EQ. 17)

The value of RCS determined in Equation 15 must be

rescaled so that the current sense signal presented at the

CS pin is that predicted by Equation 13. The divider created

by R

and R9 makes this necessary.

6

R6R9+

CS

---------------------

R

9

⋅=

R

CS

(EQ. 18)

R′

12

FN6320.3

April 18, 2007

ISL8840A, ISL8841A, ISL8842A, ISL8843A, ISL8844A, ISL8845A

www.BDTIC.com/Intersil

Example:

VIN = 12V

VO = 48V

Ls = 800μH

Ns/Np = 10

Lp = 8.0μH

IO = 200mA

Switching Frequency, fsw = 200kHz

Duty Cycle, D = 28.6%

R6 = 499Ω

Solve for the current sense resistor, RCS, using Equation 15.

RCS = 295mΩ

Determine the amount of voltage, Ve, that must be added to

the current feedback signal using Equation 12.

Ve = 92.4mV

Using Equation 17, solve for the summing resistor, R

CT to CS.

, from

9

Fault Conditions

A Fault condition occurs if VREF falls below 4.65V. When a

Fault is detected OUT is disabled. When VREF exceeds

4.80V, the Fault condition clears, and OUT is enabled.

Ground Plane Requirements

Careful layout is essential for satisfactory operation of the

device. A good ground plane must be employed. A unique

section of the ground plane must be designated for high di/dt

currents associated with the output stage. V

bypassed directly to GND with good high frequency

capacitors.

should be

DD

References

[1] Ridley , R., “A New Continuous-T ime Model for Current

Mode Control”, IEEE Transactions on Power

Electronics, Vol. 6, No. 2, April 1991.

R

= 2.67kΩ

9

Determine the new value of R

R’CS = 350mΩ

Additional slope compensation may be considered for

design margin. The above discussion determines the

minimum external ramp that is required. The buffer transistor

used to create the external ramp from RTCT should have a

sufficiently high gain (>200) so as to minimize the required

base current. Whatever base current is required reduces the

charging current into RTCT and will reduce the oscillator

frequency.

(R’CS) using Equation 18.

CS

13

FN6320.3

April 18, 2007

ISL8840A, ISL8841A, ISL8842A, ISL8843A, ISL8844A, ISL8845A

www.BDTIC.com/Intersil

Small Outline Plastic Packages (SOIC)

N

INDEX

AREA

123

-A-

E

-B-

SEATING PLANE

D

A

-C-

0.25(0.010) BM M

H

L

h x 45°

α

e

B

0.25(0.010) C AM BS

NOTES:

1. Symbols are defined in the “MO Series Symbol List” in Section 2.2 of

Publication Number 95.

2. Dimensioning and tolerancing per ANSI Y14.5M-1982.

3. Dimension “D” does not include mold flash, protrusions or gate burrs.

Mold flash, protrusion and gate burrs shall not exceed 0.15mm (0.006

inch) per side.

4. Dimension “E” does not include interlead flash or protrusions. Interlead flash and protrusions shall not exceed 0.25mm (0.010 inch) per

side.

5. The chamfer on the body is optional. If it is not present, a visual index

feature must be located within the crosshatched area.

6. “L” is the length of terminal for soldering to a substrate.

7. “N” is the number of terminal positions.

8. Terminal numbers are shown for reference only.

9. The lead width “B”, as measured 0.36mm (0.014 inch) or greater

above the seating plane, shall not exceed a maximum value of

0.61mm (0.024 inch).

10. Controlling dimension: MILLIMETER. Converted inch dimensions

are not necessarily exact.

M

A1

C

0.10(0.004)

M8.15 (JEDEC MS-012-AA ISSUE C)

8 LEAD NARROW BODY SMALL OUTLINE PLASTIC PACKAGE

INCHES MILLIMETERS

SYMBOL

A 0.0532 0.0688 1.35 1.75 -

A1 0.0040 0.0098 0.10 0.25 -

B 0.013 0.020 0.33 0.51 9

C 0.0075 0.0098 0.19 0.25 -

D 0.1890 0.1968 4.80 5.00 3

E 0.1497 0.1574 3.80 4.00 4

e 0.050 BSC 1.27 BSC -

H 0.2284 0.2440 5.80 6.20 -

h 0.0099 0.0196 0.25 0.50 5

L 0.016 0.050 0.40 1.27 6

N8 87

α

0° 8° 0° 8° -

NOTESMIN MAX MIN MAX

Rev. 1 6/05

14

FN6320.3

April 18, 2007

ISL8840A, ISL8841A, ISL8842A, ISL8843A, ISL8844A, ISL8845A

www.BDTIC.com/Intersil

Mini Small Outline Plastic Packages (MSOP)

N

EE1

INDEX

AREA

AA1A2

-H-

SIDE VIEW

12

TOP VIEW

b

e

D

NOTES:

1. These package dimensions are within allowable dimensions of

JEDEC MO-187BA.

2. Dimensioning and tolerancing per ANSI Y14.5M-1994.

3. Dimension “D” does not include mold flash, protrusions or gate

burrs and are measured at Datum Plane. Mold flash, protrusion

and gate burrs shall not exceed 0.15mm (0.006 inch) per side.

4. Dimension “E1” does not include interlead flash or protrusions

and are measured at Datum Plane. Interlead flash and

protrusions shall not exceed 0.15mm (0.006 inch) per side.

5. Formed leads shall be planar with respect to one another within

0.10mm (0.004) at seating Plane.

6. “L” is the length of terminal for soldering to a substrate.

7. “N” is the number of terminal positions.

8. Terminal numbers are shown for reference only.

9. Dimension “b” does not include dambar protrusion. Allowable

dambar protrusion shall be 0.08mm (0.003 inch) total in excess

of “b” dimension at maximum material condition. Minimum space

between protrusion and adjacent lead is 0.07mm (0.0027 inch).

- H -

-A -

.

10. Datums and to be determined at Datum plane

11. Controlling dimension: MILLIMETER. Converted inch dimensions are for reference only.

-B-

0.20 (0.008) A

GAUGE

PLANE

SEATING

PLANE

0.10 (0.004) C

-A-

0.20 (0.008) C

- B -

0.25

(0.010)

-C-

SEATING

PLANE

a

0.20 (0.008) C

- H -

B

4X θ

C

D

4X θ

L1

C

C

L

E

1

END VIEW

R1

R

L

-B-

M8.118 (JEDEC MO-187AA)

8 LEAD MINI SMALL OUTLINE PLASTIC PACKAGE

INCHES MILLIMETERS

SYMBOL

A 0.037 0.043 0.94 1.10 A1 0.002 0.006 0.05 0.15 A2 0.030 0.037 0.75 0.95 -

b 0.010 0.014 0.25 0.36 9

c 0.004 0.008 0.09 0.20 -

D 0.116 0.120 2.95 3.05 3

E1 0.116 0.120 2.95 3.05 4

e 0.026 BSC 0.65 BSC -

E 0.187 0.199 4.75 5.05 -

L 0.016 0.028 0.40 0.70 6

L1 0.037 REF 0.95 REF -

N8 87

R 0.003 - 0.07 - R1 0.003 - 0.07 - -

0 5

α

o

o

0

15

o

o

6

o

5

o

0

15

o

o

6

Rev. 2 01/03

NOTESMIN MAX MIN MAX

-

-

All Intersil U.S. products are manufactured, assembled and tested utilizing ISO9000 quality systems.

Intersil Corporation’s quality certifications can be viewed at www.intersil.com/design/quality

Intersil products are sold by description only. Intersil Corporation reserves the right to make changes in circuit design, software and/or specifications at any time without

notice. Accordingly, the reader is cautioned to verify that data sheets are current before placing orders. Information furnished by Intersil is believed to be accurate and

reliable. However, no responsibility is assumed by Intersil or its subsidiaries for its use; nor for any infringements of patents or other rights of third parties which may result

from its use. No license is granted by implic atio n or other wise u nde r any p a tent or patent rights of Intersil or its subsidiaries.

For information regarding Intersil Corporation and its products, see www.intersil.com

15

FN6320.3

April 18, 2007

Loading...

Loading...