Page 1

IRPT2056A

PD 6.099

PRELIMINARY

Power Module for 3 hp Motor Drives

· 3 hp (2.2 kW) power output

Industrial rating at 150% overload for 1 minute

· 180-240V AC input, 50/60 Hz

· 3-phase rectifier bridge

· 3-phase, short circuit rated, ultrafast IGBT inverter

· HEXFRED ultrafast soft recovery-freewheeling diodes

· Brake IGBT and diode

· Low inductance (current sense) shunts in positive

and negative DC rail

· NTC temperature sensor

· Pin-to-baseplate isolation 2500V rms

· Easy-to-mount two-screw package

· Case temperature range -25°C to 125°C operational

IRPT2056A

™

Figure 1. IRPT2056A Power Module

IRPT2056C

PWM

180-240V

3-phase input

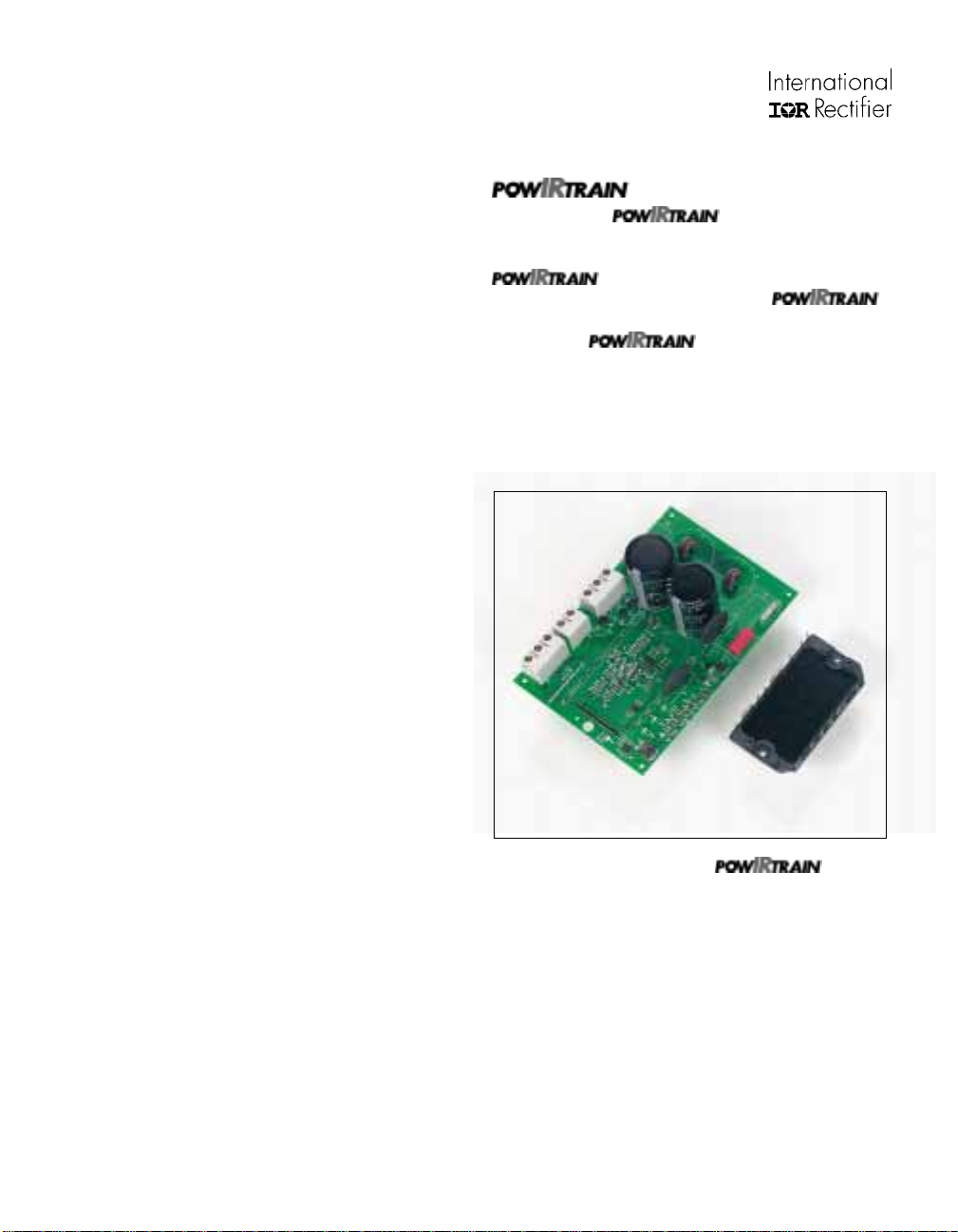

Figure 2. The power module and within a

IRPT 2056A

Power

Module

IRPT 2056D

Driver-

Plus

Board

PWM

generator

motor control system

variable

frequency

output

feedback

(non-isolated)

page 1

Page 2

IRPT2056A

System Description

Power Module

The IRPT2056A Power Module, shown in figure 1, is a chip

and wire epoxy encapsulated module. It houses input rectifiers,

output inverter, current sense shunts and NTC thermistor. The 3phase input bridge rectifiers are rated at 800V. The brake circuit

uses 600V IGBT and freewheeling diode. The inverter section

employs 600V, short circuit rated, ultrafast IGBT's and ultrafast

freewheeling diodes. Current sensing is achieved through 25

mΩ low inductance shunts provided in the positive and negative

DC bus rail. The NTC thermistors provide temperature sensing

capability. The lead spacing on the power module meets UL840

pollution level 3 requirements.

The power circuit and layout within the module are carefully

designed to minimize inductance in the power path, to reduce

noise during inverter operation and to improve the inverter

efficiency. The Driver-Plus Board required to run the inverter

can be soldered to the power module pins, thus minimizing

assembly and alignment. The power module is designed to be

mounted to a heat sink with two screw mount positions, in order

to insure good thermal contact between the module substrate and

the heat sink.

and Design Kit

The IRPT2056C (Figure 3) provides the

complete power conversion function for a 3 hp (2.2 kW) variable

voltage, variable frequency AC motor controller. The

combines the Power Module (IRPT2056A)

with a Driver-Plus Board (IRPT2056D). The

Design Kit, IRPT2056E includes the following:

• Complete integrated power stage

• Specification and operating instructions

• Bill of materials

• Electrical schematic

• Mechanical layout of the Driver-Plus Board

• Software transferrable file for easy design integration

• Application information and layout considerations

page 2

Figure 3. IRPT2056C

Page 3

IRPT2056A

Specifications

PARAMETERS VALUES CONDITIONS

Input Power

Voltage 220V AC, -15%, +10%, 3-phase

Frequency 50/60 Hz

Current 15.4A rms @ nominal output TA = 40°C, R

I

FSM

400A 10ms half-cycle, non-repetitive surge

Output Power

Voltage 0-230V rms defined by external PWM control

Nominal motor hp (kW) 3 hp (2.2 kW) nominal full load power Vin = 230V AC, f

Nominal motor current 11A nominal full load power T

150% overload for 1 minute fo = 60 Hz,

= 40°C, R

16.5A 150% overload for 1 minute

A

DC Link

DC link voltage 400V maximum

Brake

Current 20A

Sensor

Temp. sense resistance 50 kOhms ±5% @ T

3.1kOhms ±10% @ T

Current sense 25mOhms ±5% @ T

Protection

IGBT short circuit time 10 µs DC bus = 400V, VGE = 15V,

line to line short

Recommended short circuit- 70A peak

shutdown current

Gate Drive

Q

G

Recommended gate driver IR2133 (see Figure 10)

120 nC (typical) @ VGE = 15V, refer figure 5b

Module

Isolation voltage 2500V rms pin-to-baseplate, 60 Hz, 1 minute

Operating case temperature -25°C to 125°C 95% RH max. (non-condensing)

Mounting torque 1 Nm M4 screw type

Storage temperature range -40°C to 125°C

Soldering temperature for 10 sec. 260°C maximum at the pins (.06" from case)

thSA

thSA

NTC

NTC

SHUNT

= 25°C

= 100°C

= 25°C

= 0.42°C/W

= 4kHz,

pwm

= 0.42°C/W

page 3

Page 4

IRPT2056A

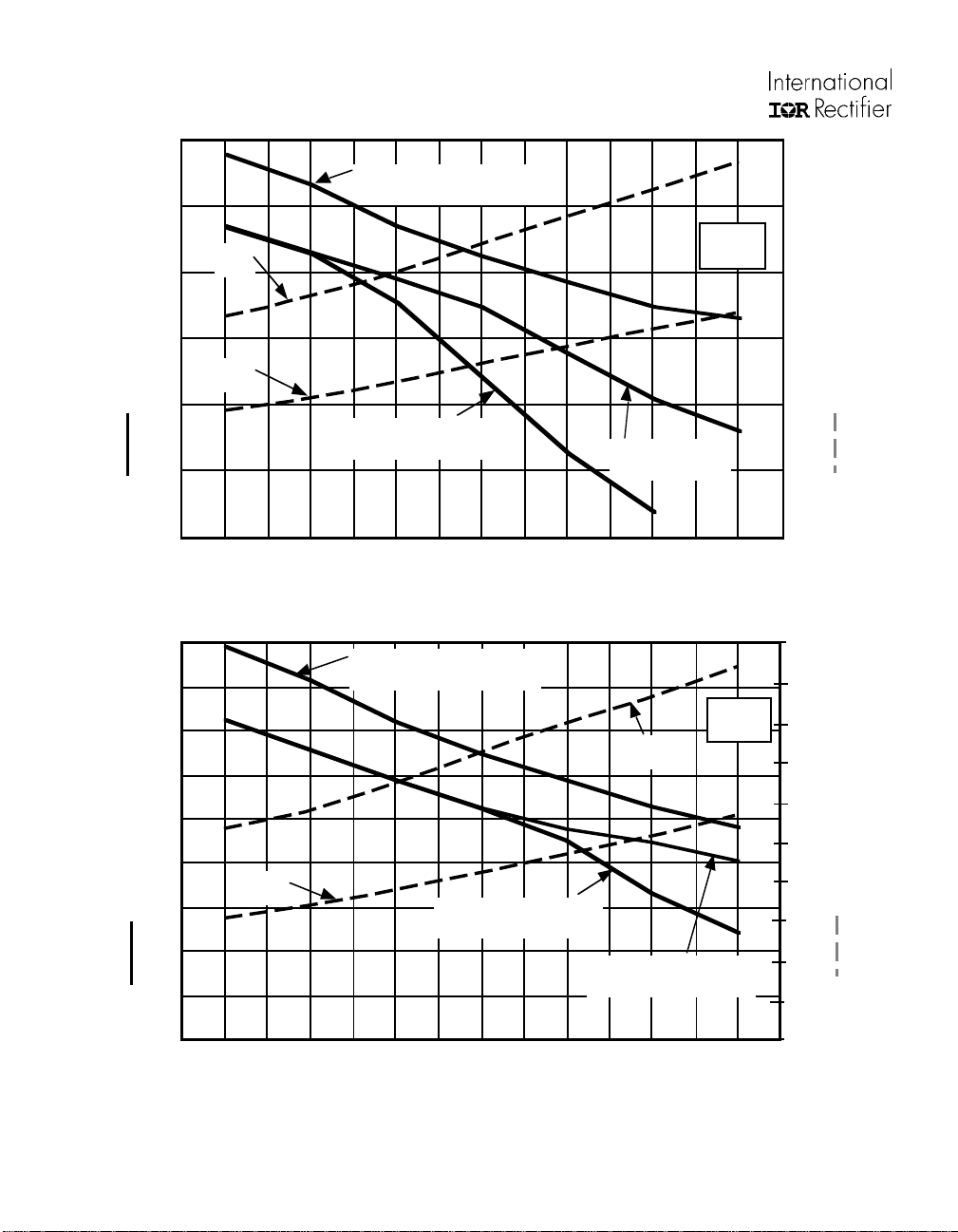

0.6

0.5

°C/W)

thSA

0.4

0.3

Power

150%

R

100% Load Continuous

thSA

10-60 Hz

3 hp

(2.2 kW)

300

250

200

150

Power

100%

Thermal Resistance (R

0.2

0.1

R

150% Load (1 min.)

thSA

Down to 3 Hz

0

1 4 8 12 20

R

150% Load

thSA

1 min.)10-60 Hz

16 24

100

50

0

PWM Frequency (kHz) – (Induction Motor Load)

Figure 4a. 3hp/11A output Heat Sink Thermal Resistance and Power Dissipation vs. PWM Frequency

0.9

0.8

0.7

°C/W)

thSA

0.6

R

100% Load Continuous

thSA

10-60 Hz

Power

150%

2 hp

(1.5 kW)

200

180

160

140

120

0.5

100

0.4

0.3

Thermal Resistance (R

0.2

0.1

Power

100%

R

150% Load (1 min.)

thSA

Down to 3 Hz

R

150% Load (1 min.)

thSA

10-60 Hz

80

60

40

20

Total Power Dissipation (Watts)

Total Power Dissipation (Watts)

0

1 4 8 12 16 20 24

PWM Frequency (kHz) – (Induction Motor Load)

Figure 4b. 2hp/8A output Heat Sink Thermal Resistance and Power Dissipation vs. PWM Frequency

NOTE: For Figures 4a and 4b: Operating Conditions: Vin = 230V

during 1 minute overload to 10°C

page 4

, MI =1.15, PF = 0.8, TA = 40°C, Tj < 145°C, Ts < 95°C, Z

rms

0

thSA

limits ∆T

c

Page 5

IRPT2056A

(

3000

=

0V,

2500

2000

1500

1000

V

GE

C

=

ies ge gc , ce

C

=

res

C

=

oes ce gc

C

C

C

C

ies

+ C

gc

+ C

f = 1MHz

C SHORTED

C, Capacitance (pF)

C

500

0

1 10 100

100

oes

C

res

V , Collector-to-Emitter Voltage

CE

Figure 5a. Typical Capacitance vs

Collector-to-Emitter Voltage

20

CC

V = 400V

C

I = 25A

16

12

8

4

GE

V , Gate-to-Emitter Voltage (V)

0

0 20406080100120140

Q , Total Gate Charge (nC)

G

Figure 5b. Typical Gate Charge vs

Gate-to-Emitter Voltage

T = 150°C

J

T = 25°C

10

C

I , Collector-to-Emitter Current (A)

1

5 7911

V , Gate-to-Emitter Voltage (V)

GE

Figure 5c. Typical Transfer Characteristics Figure 6. Nominal R-T Characteristics of the

J

V = 50V

CC

5µs PULSE WIDTH•

A

NTC␣ Thermistor

page 5

Page 6

IRPT2056A

0

0

0

0

0

0

0

0

0

0

Mounting, Hookup and Application Instructions

Mounting

1. Connect the driver board and the IRPT2056A module.

2. Remove all particles and grit from the heat sink and power

substrate.

3. Spread a .004" to .005" layer of silicone grease on the heat

sink, covering the entire area that the power substrate will

occupy. Recommended heat sink flatness in .001 inch/inch and

Total Indicator Readout (TIR) of .003 inch below substrate.

4. Place the power substrate onto the heat sink with the

mounting holes aligned and press it firmly into the silicone

grease.

5. Place the 2 M4 mounting screws through the PCB and

power module and into the heat sink and tighten the screws to

1 Nm torque.

2345678901234567890123456789

2345678901234567890123456789

2345678901234567890123456789

2345678901234567890123456789

2345678901234567890123456789

2345678901234567890123456789

2345678901234567890123456789

1 2

2345678901234567890123456789

2345678901234567890123456789

2345678901234567890123456789

Figure 7. Power Module Mounting Screw Sequence

Power Connections

The power module pin designation, function and other details

can be obtained from the package outline (figure 8) and circuit

diagram (figure 9). 3-phase input connections are made to pins

R, S and T and inverter output connections are made to pins U,

V and W. Positive DC bus and brake IGBT collector

connections are brought out to pins P and BR, respectively.

Positive rectifier output and positive inverter bus are brought out

to pins RP and P, respectively, in order to provide DC bus

capacitor soft charging implementation option. The current

shunt terminals are connected to pins IS1, IS2 and IS3, IS4 on

the positive and negative DC rails, respectively.

page 6

Page 7

IRPT2056A Mechanical Specifications

NOTE: Dimensions are in inches (millimeters)

IRPT2056A

2.105

[53.47]

1.662

[42.21]

3.854

[97.89]

3.215

[81.66]

R

N

T

S

P

E1

G1

RP

IS2

IS1

E2

G2

IS3

IS4

G7

BR

E5

E3

G5

G3

E4

G4

V

U

N/C

RT2

RT1

N/C

W

E6

G6

Figure 8a. Package Outline and Mechanical Specifications

HATCHED SURFACE

.032 [0.81]

31X

.020 [0.51]

THICKNESS

2.040 [51.82]

HATCHED SURFACE

F

.650

[16.51]

.307

[7.80]

.507

[12.87]

E

page 7

Page 8

IRPT2056A

IRPT2056A Mechanical Specifications

NOTE: Dimensions are in inches (millimeters)

ALL PIN COORDINATE DIMENSIONS ARE BASIC

3.420 [86.87]

2X .104

MINUS DRAFT X .400

.002

±

Ø

±

[2.64 0.05]

.010 A B-C

S

Ø

G

.800 [20.32]

.400 [10.16]

4X .260 [6.60]

Ø

HATCHED SURFACE

.050 [ 1.27]

.450 [11.43]

.350 [ 8.89]

.550 [13.97]

C

31X ( .026 - .024)

31X .050 [1.27]

F

.650 [16.51]

1.250 [31.75]

1.550 [39.37]

.950 [24.13]

1.450 [36.83]

1.750 [44.45]

.050 [ 1.27]

.000 [ 0.00]

.250 [ 6.35]

.150 [ 3.81]

.350 [ 8.89]

.450 [11.43]

.250 [ 6.35]

.550 [13.97]

.850 [21.59]

.750 [19.05]

1.050 [26.67]

.950 [24.13]

Figure 8b. Package Outline and Mechanical Specifications

1.350 [34.29]

1.450 [36.83]

1.550 [39.37]

1.020 [25.91]

PIN CENTER

.187 [4.75]

2X

.175 [4.45]

.000 [ 0.00]

2X R .250 [6.35]

PIN CENTER

1.020 [25.91]

PIN DIAGONAL

.037 - .034

[.940 - .864]

1.250 [31.75]

1.150 [29.21]

31X

M

.019 E-F G B-C

Ø

.010 E-FM

Ø

E

HATCHED SURFACE

MOUNTING SURFACE IN CLAMPED CONDITION

A

B

page 8

Page 9

IRPT2056A

RP P

D7 D9 D11 D13

R

S

T

D8 D10 D12

N BR G7 IS4 1S3 G2 E2 G4 E4 G6 E6

IS1 IS2 E1G1

RS1

Q7

RS2

E3 G3 E5 G5 RT1 RT2

Q1

D1

Q2

D2

Figure 9. Power Module Circuit Diagram

Q3

Q4

Q5

Q6

D5

RT

U

V

W

D6

D3

D4

Figure 10. Recommended Gate Drive Circuit

page 9

Page 10

IRPT2056A

Functional Information

Heat Sink Requirements

Figures 4a through 4b show the thermal resistance of the heat

sink required for various output power levels and pulse-widthmodulated (PWM) switching frequencies. Maximum total losses

of the unit are also shown. This data is based on the following

key operating conditions:

• The maximum continuous combined losses of the rectifier

and inverter occur at full pulse-width-modulation. These

losses set the maximum continuous operating temperature

of the heat sink.

• The maximum combined losses of the rectifier and inverter

at full pulse-width modulation under overload set the

incremental temperature rise of the heat sink during

overload.

• The minimum output frequency at which full load current

is to be delivered sets the peak IGBT junction temperature.

• At low frequency, IGBT junction temperature tends to

follow the instantaneous fluctuations of the output current.

Thus, peak junction temperature rise increases as output

frequency decreases.

Over-Temperature Protection

Over-temperature can be detected using the NTC thermistor

included in the power module for thermal sensing. A protection

circuit that initiates a shutdown if the temperature of the IMS

exceeds a set level can be implemented. The nominal resistance

vs. temperature characteristic of the thermistor is given in

figure 6.

Voltage Rise During Braking

The motor will feed energy back to the DC link during

regenerative braking, forcing the bus voltage to rise above the

level defined by the input voltage. Deceleration of the motor

must be controlled by appropriate PWM control to keep the DC

bus voltage within the rated maximum value. For high inertial

loads, or for very fast deceleration rates, this can be achieved by

connecting an external braking resistor across P and BR and

controlling the brake IGBT switching when the bus voltage

exceeds the allowable limit.

page 10

Page 11

IRPT2056A

Part Number Identification and Ordering Instructions

IRPT2056A Power Module

Chip and wire epoxy encapsulated module with 800V input

rectifiers, 600V brake IGBT and freewheeling diode, 600V

short-circuit rated, ultra-fast IGBT inverter with ultra-fast

freewheeling diodes, NTC temperature sensing thermistor and

current sensing low-inductance shunts.

IRPT2056C Complete

IRPT2056A Power Module and IRPT2056D Driver-Plus

Board pre-assembled and tested to meet all system

specifications.

IRPT2056D Driver-

Printed circuit board assembled with DC link capacitors.

NTC in-rush limiting thermistors, high-power terminal blocks,

surge suppression MOVs, IGBT gate drivers, protection circuitry

and low power supply. The PCB is functionally tested with

standard power module to meet all system specifications.

Plus

Board

IRPT2056E Design Kit

Complete (IRPT2056C) with full set of

design documentation including detailed schematic diagram, bill

of material, mechanical layout, schematic file, Gerber files and

design tips.

page 11

Page 12

IRPT2056A

WORLD HEADQUARTERS: 233 Kansas St., El Segundo, California 90245, Tel: (310) 322 3331

EUROPEAN HEADQUARTERS: Hurst Green, Oxted, Surrey RH8 9BB, UK Tel: ++ 44 1883 732020

IR CANADA: 7321 Victoria Park Ave., Suite 201, Markham, Ontario L3R 2Z8, Tel: (905) 475 1897

IR GERMANY: Saalburgstrasse 157, 61350 Bad Homburg Tel: ++ 49 6172 96590

IR FAR EAST: 171 (K&H Bldg.), 3-30-4 Nishi-ikebukuro 3-Chome, Toshima-ku, Tokyo Japan Tel: 81 3 3983 0086

IR SOUTHEAST ASIA: 315 Outram Road, #10-02 Tan Boon Liat Building, Singapore 0316 Tel: 65 221 8371

page 12

http://www.irf.com/ Data and specifications subject to change without notice. 5/97

IR ITALY: Via Liguria 49, 10071 Borgaro, Torino Tel: ++ 39 11 451 0111

Loading...

Loading...