Page 1

查询IRF1503供应商

PD-94526A

AUTOMOTIVE MOSFET

Typical Applications

● 14V Automotive Electrical Systems

● 14V Electronic Power Steering

HEXFET® Power MOSFET

D

IRF1503

V

= 30V

DSS

Features

● Advanced Process Technology

● Ultra Low On-Resistance

● 175°C Operating Temperature

● Fast Switching

● Repetitive Avalanche Allowed up to Tjmax

G

S

R

DS(on)

= 3.3mΩ

ID = 75A

Description

Specifically designed for Automotive applications, this

design of HEXFET

processing techniques to achieve extremely low onresistance per silicon area. Additional features of this

HEXFET power MOSFET are a 175°C junction operating

temperature, fast switching speed and improved repetitive

avalanche rating. These combine to make this design an

extremely efficient and reliable device for use in Automotive

applications and a wide variety of other applications.

®

Power MOSFETs utilizes the lastest

TO-220AB

Absolute Maximum Ratings

Parameter Max. Units

ID @ TC = 25°C Continuous Drain Current, VGS @ 10V (Silicon limited) 240

ID @ TC = 100°C Continuous Drain Current, VGS @ 10V (See Fig.9) 170 A

ID @ TC = 25°C Continuous Drain Current, VGS @ 10V (Package limited) 75

I

DM

PD @TC = 25°C Power Dissipation 330 W

V

GS

E

AS

E

(tested) Single Pulse Avalanche Energy Tested Value 980

AS

I

AR

E

AR

T

J

T

STG

Pulsed Drain Current 960

Linear Derating Factor 2.2 W/°C

Gate-to-Source Voltage ± 20 V

Single Pulse Avalanche Energy 510 mJ

Avalanche Current See Fig.12a, 12b, 15, 16 A

Repetitive Avalanche Energy mJ

Operating Junction and -55 to + 175

Storage Temperature Range

Soldering Temperature, for 10 seconds 300 (1.6mm from case )

°C

Thermal Resistance

Parameter Typ. Max. Units

R

θJC

R

θCS

R

θJA

Junction-to-Case ––– 0.45

Case-to-Sink, Flat, Greased Surface 0.50 ––– °C/W

Junction-to-Ambient ––– 62

www.irf.com 1

12/11/02

Page 2

IRF1503

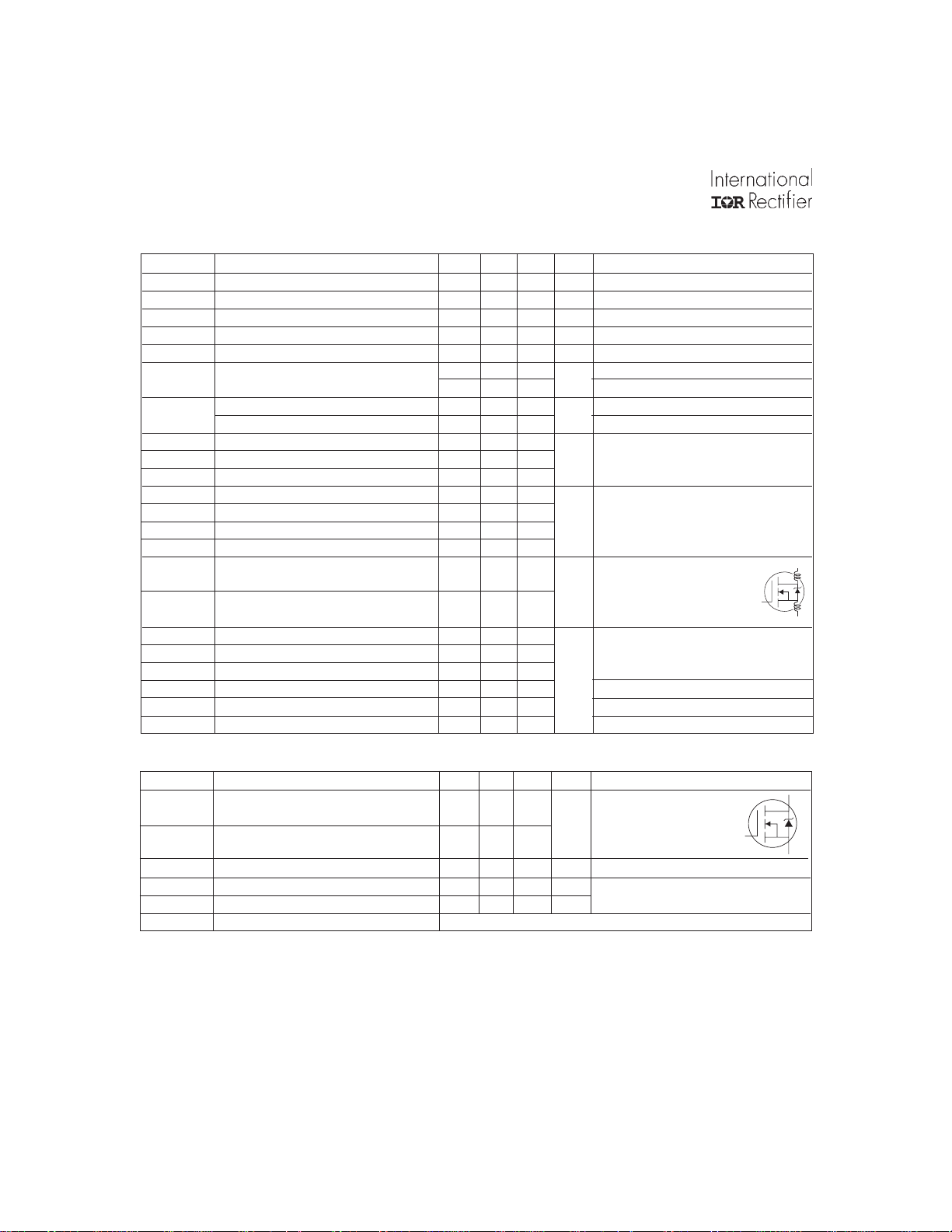

Electrical Characteristics @ TJ = 25°C (unless otherwise specified)

Parameter Min. Typ. Max. Units Conditions

V

(BR)DSS

∆V

(BR)DSS

R

DS(on)

V

GS(th)

g

fs

I

DSS

I

GSS

Q

g

Q

gs

Q

gd

t

d(on)

t

r

t

d(off)

t

f

L

D

L

S

C

iss

C

oss

C

rss

C

oss

C

oss

C

eff. Effective Output Capacitance ––– 3420 ––– VGS = 0V, VDS = 0V to 24V

oss

Drain-to-Source Breakdown Voltage 30 ––– ––– V VGS = 0V, ID = 250µA

/∆T

Breakdown Voltage Temp. Coefficient ––– 0.028 ––– V/°C Reference to 25°C, ID = 1mA

J

Static Drain-to-Source On-Resistance ––– 2.6 3.3 mΩ VGS = 10V, ID = 140A

Gate Threshold Voltage 2.0 ––– 4.0 V VDS = 10V, ID = 250µA

Forward Transconductance 75 ––– ––– S VDS = 25V, ID = 140A

Drain-to-Source Leakage Current

––– ––– 20

––– ––– 250 VDS = 30V, VGS = 0V, TJ = 125°C

Gate-to-Source Forward Leakage ––– ––– 200 V

Gate-to-Source Reverse Leakage ––– ––– -200

µA

nA

V

= 30V, VGS = 0V

DS

= 20V

GS

VGS = -20V

Total Gate Charge ––– 130 200 ID = 140A

Gate-to-Source Charge ––– 36 54 nC VDS = 24V

Gate-to-Drain ("Miller") Charge ––– 41 62 VGS = 10V

Turn-On Delay Time ––– 17 ––– VDD = 15V

Rise Time ––– 130 ––– ID = 140A

Turn-Off Delay Time ––– 59 ––– RG = 2.5Ω

ns

Fall Time ––– 48 ––– VGS = 10V

5.0

Internal Drain Inductance

Internal Source Inductance ––– –––

––– –––

13

Between lead,

6mm (0.25in.)

nH

from package

and center of die contact

Input Capacitance ––– 5730 ––– VGS = 0V

Output Capacitance ––– 2250 ––– pF VDS = 25V

Reverse Transfer Capacitance ––– 290 ––– ƒ = 1.0MHz, See Fig. 5

Output Capacitance ––– 7580 ––– VGS = 0V, VDS = 1.0V, ƒ = 1.0MHz

Output Capacitance ––– 2290 ––– VGS = 0V, VDS = 24V, ƒ = 1.0MHz

D

G

S

Source-Drain Ratings and Characteristics

Parameter Min. Typ. Max. Units Conditions

I

S

I

SM

V

SD

t

rr

Q

rr

t

on

Continuous Source Current MOSFET symbol

(Body Diode)

Pulsed Source Current integral reverse

(Body Diode)

––– –––

––– –––

240

960

showing the

A

p-n junction diode.

G

Diode Forward Voltage ––– ––– 1.3 V TJ = 25°C, IS = 140A, VGS = 0V

Reverse Recovery Time ––– 71 110 ns TJ = 25°C, IF = 140A, VDD = 15V

Reverse RecoveryCharge ––– 110 170 nC di/dt = 100A/µs

Forward Turn-On Time Intrinsic turn-on time is negligible (turn-on is dominated by LS+LD)

Notes:

Repetitive rating; pulse width limited by

max. junction temperature. (See fig. 11).

Starting T

RG = 25Ω, I

= 25°C, L = 0.049mH

J

= 140A. (See Figure 12).

AS

Pulse width ≤ 400µs; duty cycle ≤ 2%.

C

eff. is a fixed capacitance that gives the same charging time

oss

as C

Limited by T

oss

while V

is rising from 0 to 80% V

DS

, see Fig.12a, 12b, 15, 16 for typical repetitive

Jmax

DSS

.

avalanche performance.

This value determined from sample failure population. 100%

tested to this value in production.

2 www.irf.com

D

S

Page 3

IRF1503

1000

)

A

(

t

n

e

r

r

100

u

C

e

c

r

u

o

S

o

t

-

10

n

i

a

r

D

,

D

I

VGS

TOP 15 V

10 V

8.0V

7.0V

6.0V

5.5V

5.0V

BOTTOM 4.5V

4.5V

20µs PULSE WIDTH

Tj = 25° C

1

0. 1 1 10 100

VDS, Drain-to-Source Vol tage (V)

1000

TJ = 25°C

)

Α

(

t

n

e

r

r

u

C

e

c

r

100

u

o

S

o

t

n

i

a

r

D

,

D

I

10

4.0 5.0 6.0 7.0 8.0 9.0 10.0

V

= 25V

DS

20µs PULSE WIDTH

VGS, Gate-to-Source Voltage (V)

TJ = 175°C

1000

)

A

(

t

n

e

r

r

u

C

e

c

r

100

u

o

S

o

t

n

i

a

r

D

,

D

I

VGS

TOP 15 V

10V

8.0V

7.0V

6.0V

5.5V

5.0V

BOTTOM 4.5V

4.5V

20µs PULSE WIDTH

10

0. 1 1 10 100

Tj = 175°C

VDS, Drain-to-Source Voltage (V)

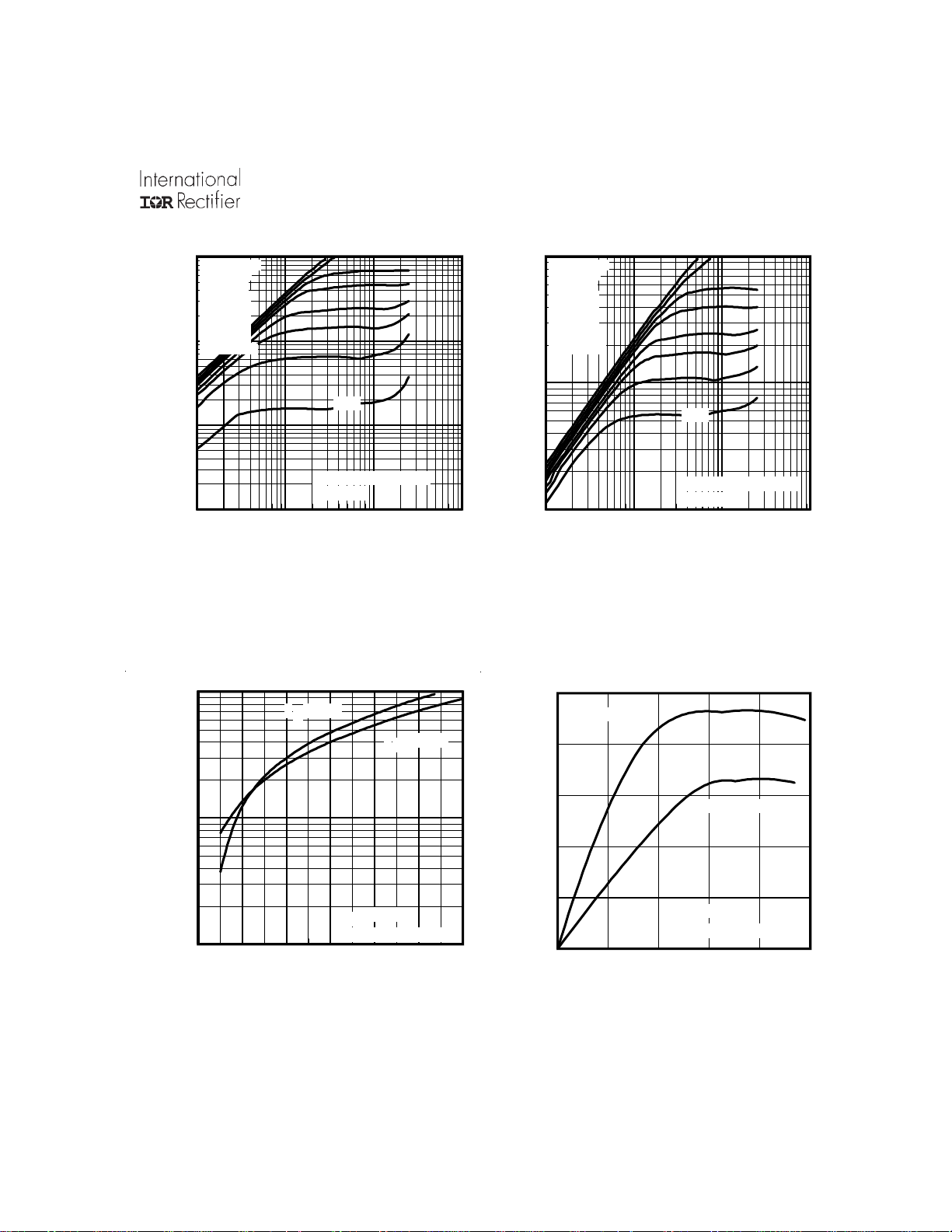

Fig 2. Typical Output CharacteristicsFig 1. Typical Output Characteristics

200

)

S

(

160

e

c

n

a

t

c

u

d

120

n

o

c

s

n

a

r

T

80

d

r

a

w

r

o

F

40

,

s

f

G

0

TJ = 175°C

TJ = 25°C

V

= 25V

DS

20µs PULSE WIDTH

0 40 80 120 160 200

ID, Drain-to-Source Current (A)

Fig 3. Typical Transfer Characteristics

Fig 4. Typical Forward Transconductance

Vs. Drain Current

www.irf.com 3

Page 4

IRF1503

)

F

p

(

e

c

n

a

t

i

c

a

p

a

C

,

C

10000

8000

6000

4000

2000

0

1 10 100

V

= 0V, f = 1 MHZ

GS

C

= C

is s

SHORTED

C

= C

rss

C

= C

oss

VDS, Drain-to-Source Voltage (V)

Fig 5. Typical Capacitance Vs.

Drain-to-Source Voltage

1000.0

)

A

(

t

100.0

n

e

r

r

u

C

n

i

a

r

10.0

D

e

s

r

e

v

e

R

,

D

S

I

TJ = 175°C

1.0

TJ = 25°C

0.1

0.0 0.4 0.8 1.2 1.6 2.0

VSD, Source-toDrain Voltage (V)

gd

ds

Cis s

Coss

Crss

+ Cgd, C

gs

+ C

gd

V

GS

ds

= 0V

20

ID= 140A

)

V

(

16

e

g

a

t

l

o

V

12

e

c

r

u

o

S

o

8

t

e

t

a

G

,

S

4

G

V

0

0 40 80 120 160 200

Q

VDS= 24V

Total Gate Charge (nC)

G

Fig 6. Typical Gate Charge Vs.

Gate-to-Source Voltage

10000

)

A

(

t

n

e

r

r

u

C

e

c

r

u

o

S

o

t

n

i

a

r

D

,

D

I

1000

100

10

Tc = 25°C

Tj = 175°C

Single Pulse

1

1 10 100

OPERATION IN THIS A REA

LIMITED BY RDS(on)

V

, Drain-toSource Voltage (V)

DS

100µsec

1msec

10msec

Fig 7. Typical Source-Drain Diode

Fig 8. Maximum Safe Operating Area

Forward Voltage

4 www.irf.com

Page 5

IRF1503

240

LIMITED BY PACKAGE

200

160

120

80

D

I , Drain Current (A)

40

0

25 50 75 100 125 150 175

T , Case Temperature ( C)

C

°

Fig 9. Maximum Drain Current Vs.

Case Temperature

1

2.0

240A

I =

D

1.5

1.0

(Normalized)

0.5

DS(on)

R , Drain-to-Source On Resistance

0.0

-60 -40 -20 0 20 40 60 80 100 120 140 160 180

T , Junction Temperature ( C)

J

Fig 10. Normalized On-Resistance

Vs. Temperature

V =

GS

°

10V

D = 0.50

thJC

0.20

0.1

0.10

0.05

0.02

0.01

0.01

Thermal Response (Z )

0.001

0.00001 0.0001 0.001 0.01 0.1

SINGLE PULSE

(THERMAL RESPONSE)

t , Rectangular Pulse Duration (sec)

1

P

DM

Not es:

1. Duty factor D = t / t

2. Peak T = P x Z + T

1 2

J DM thJC C

t

1

t

2

Fig 11. Maximum Effective Transient Thermal Impedance, Junction-to-Case

www.irf.com 5

Page 6

IRF1503

A

15V

DRIVER

+

-

V

DD

R

20V

V

V

DS

G

GS

L

D.U.T

I

AS

Ω

0.01

t

p

Fig 12a. Unclamped Inductive Test Circuit

V

(BR)DSS

t

p

I

AS

Fig 12b. Unclamped Inductive Waveforms

Q

G

10 V

Q

GS

Q

GD

1000

TOP

800

600

400

200

AS

E , Single Pulse Avalanche Energy (mJ)

0

25 50 75 100 125 150 175

Starting T , Junction Temperature ( C)

J

BOTTOM

Fig 12c. Maximum Avalanche Energy

Vs. Drain Current

4. 0

I

°

D

59A

100A

140A

)

V

G

Charge

Fig 13a. Basic Gate Charge Waveform

Current Regulator

Same Type as D.U.T.

50KΩ

.2µF

12V

V

GS

.3µF

D.U.T.

3mA

I

G

Current Sampling Resistors

+

V

DS

-

I

D

Fig 13b. Gate Charge Test Circuit

V

(

e

g

a

t

l

o

3. 0

V

d

l

o

h

s

e

r

h

t

e

t

a

2. 0

G

)

h

t

(

S

G

V

1. 0

-75 -50 -25 0 25 50 75 100 125 150 175 200

ID = 250µA

TJ , Temperature ( °C )

Fig 14. Threshold Voltage Vs. Temperature

6 www.irf.com

Page 7

IRF1503

10000

Duty Cycle = Single Pulse

1000

)

A

(

t

n

e

r

r

u

C

100

e

h

c

n

a

l

a

v

A

10

1

1.0E-07 1.0E-06 1.0E-05 1.0E-04 1.0E-03 1.0E-02 1.0E-01

0.01

0.05

0.10

tav (sec)

Fig 15. Typical Avalanche Current Vs.Pulsewidth

Allowed avalanche Current vs

avalanche pulsewidth, tav

assuming ∆Tj = 25°C due to

avalanche losses. Note: In no

case should Tj be allowed to

exceed Tjmax

600

TOP Single Pulse

500

)

J

m

(

y

g

400

r

e

n

E

e

300

h

c

n

a

l

a

v

200

A

,

R

A

E

100

BOTTOM 50% Duty Cycle

ID = 140A

Notes on Repetitive Avalanche Curves , Figures 15, 16:

(For further info, see AN-1005 at www.irf.com)

1. Avalanche failures assumption:

Purely a thermal phenomenon and failure occurs at a

temperature far in excess of T

every part type.

2. Safe operation in Avalanche is allowed as long asT

not exceeded.

. This is validated for

jmax

jmax

3. Equation below based on circuit and waveforms shown in

Figures 12a, 12b.

4. P

avalanche pulse.

= Average power dissipation per single

D (ave)

5. BV = Rated breakdown voltage (1.3 factor accounts for

voltage increase during avalanche).

6. I

= Allowable avalanche current.

av

7. ∆T = Allowable rise in junction temperature, not to exceed

T

(assumed as 25°C in Figure 15, 16).

0

25 50 75 100 125 150 175

Starting TJ , Junction Temperature (°C)

Fig 16. Maximum Avalanche Energy

Vs. Temperature

jmax

t

Average time in avalanche.

av =

D = Duty cycle in avalanche = t

Z

(D, tav) = Transient thermal resistance, see figure 11)

thJC

P

= 1/2 ( 1.3·BV·Iav) = DT/ Z

D (ave)

I

2DT/ [1.3·BV·Zth]

av =

E

= P

AS (AR)

·f

av

D (ave)·tav

thJC

www.irf.com 7

is

Page 8

IRF1503

+

-

+

-

Reverse

Recovery

Current

Driver Gate Drive

P.W.

D.U.T. ISDWaveform

D.U.T. VDSWaveform

D.U.T

+

-

+

Circuit Layout Considerations

• Low Stray Inductance

• Ground Plane

-

• Low Leakage Inductance

Current Transformer

-

+

V

DD

R

G

• dv/dt controlled by R

• Driver same type as D.U.T.

• ISD controlled by Duty Factor "D"

• D.U.T. - Device Under Test

G

Re-Applied

Voltage

Inductor Curent

* V

GS

Period

Body Diode Forward

Current

di/dt

Diode Recovery

dv/dt

Body Diode Forward Drop

Ripple ≤ 5%

= 5V for Logic Level Devices

D =

P. W .

Period

VGS=10V

V

DD

I

SD

*

Fig 17. Peak Diode Recovery dv/dt Test Circuit for N-Channel

HEXFET® Power MOSFETs

R

D.U.T.

D

V

DD

V

DS

V

GS

R

G

10V

Pulse Width ≤ 1 µs

Duty Factor ≤ 0.1 %

Fig 18a. Switching Time Test Circuit

V

DS

90%

10%

V

GS

t

d(on)tr

t

d(off)tf

Fig 18b. Switching Time Waveforms

8 www.irf.com

Page 9

Package Outline

A

TO-220AB

Dimensions are shown in millimeters (inches)

10.54 (.415)

2.87 (. 113)

2.62 (. 103)

15.24 (.600)

14.84 (.584)

14.09 (.555)

13.47 (.530)

10.29 (.405)

1 2 3

6.47 (. 255)

6.10 (. 240)

4

1.15 (. 045)

MIN

4.06 (. 160)

3.55 (. 140)

3.78 (.149)

3.54 (.139)

- A -

4.69 (.1 85)

4.20 (.1 65)

- B -

1.32 (. 052)

1.22 (. 048)

IRF1503

LEAD ASSIGNMENTS

1 - GATE

2 - DRAIN

3 - SOURCE

4 - DRAIN

0.93 (. 037)

3X

1.40 (.055)

3X

1.15 (.045)

2.54 (.1 00)

NOTES:

1 DIMENSION ING & TO LERAN CING PER AN SI Y14.5M, 19 82. 3 OUTLINE C ONFOR MS TO JEDEC OUTLIN E TO-220A B.

2 C ONTRO LLING DIMENSION : INCH 4 HEATSINK & LEAD MEASUREMENTS DO NOT INCLUDE BURRS.

2X

0.69 (. 027)

0.36 (.014) M B A M

2.92 ( .115)

2.64 ( .104)

Part Marking Information

TO-220AB

EXAMPLE : THIS IS AN IRF1010

WITH ASSEMBLY

LOT CODE 9B1M

TO-220AB package is not recommended for Surface Mount Application.

This product has been designed and qualified for Automotive [Q101] market.

INTERNATIONAL

RECTIFIER

LOGO

IRF1010

9246

9B 1M

ASSEMBLY

LOT CODE

Data and specifications subject to change without notice.

Qualification Standards can be found on IR’s Web site.

3X

0.55 (. 022)

0.46 (. 018)

PART NUMBER

DATE CODE

(YYWW)

YY = YEAR

WW = WEEK

IR WORLD HEADQUARTERS: 233 Kansas St., El Segundo, California 90245, USA Tel: (310) 252-7105

TAC Fax: (310) 252-7903

Visit us at www.irf.com for sales contact information. 12/02

www.irf.com 9

Loading...

Loading...