Page 1

Data Sheet No.PD60231 revB

IR3621 & ( PbF)

2-PHASE / DUAL SYNCHRONOUS PWM CONTROLLER WITH

OSCILLA TOR SYNCHRONIZA TION AND PRE-BIAS ST ARTUP

FEATURES

Dual Synchronous Controller with 180

Out of Phase Operation

Configurable to 2-Independent Outputs or

Current Share Single Output

Voltage Mode Control

Current Sharing Using Inductor's DCR

Selectable Hiccup or Latched Current

Limit using MOSFET's R

DS(on)

sensing

Latched Over-Voltage Protection

Pre-Bias Start Up

Programmable Switching Frequency up to 500KHz

Two Independent Soft-Starts/Shutdowns

Precision Reference Voltage 0.8V

Power Good Output

External Frequency Synchronization

Thermal Protection

APPLICATIONS

Embedded Networking & Telecom Systems

Distributed Point-of-Load Power Architectures

2-Phase Power Supply

Graphics Card

DDR Memory Applications

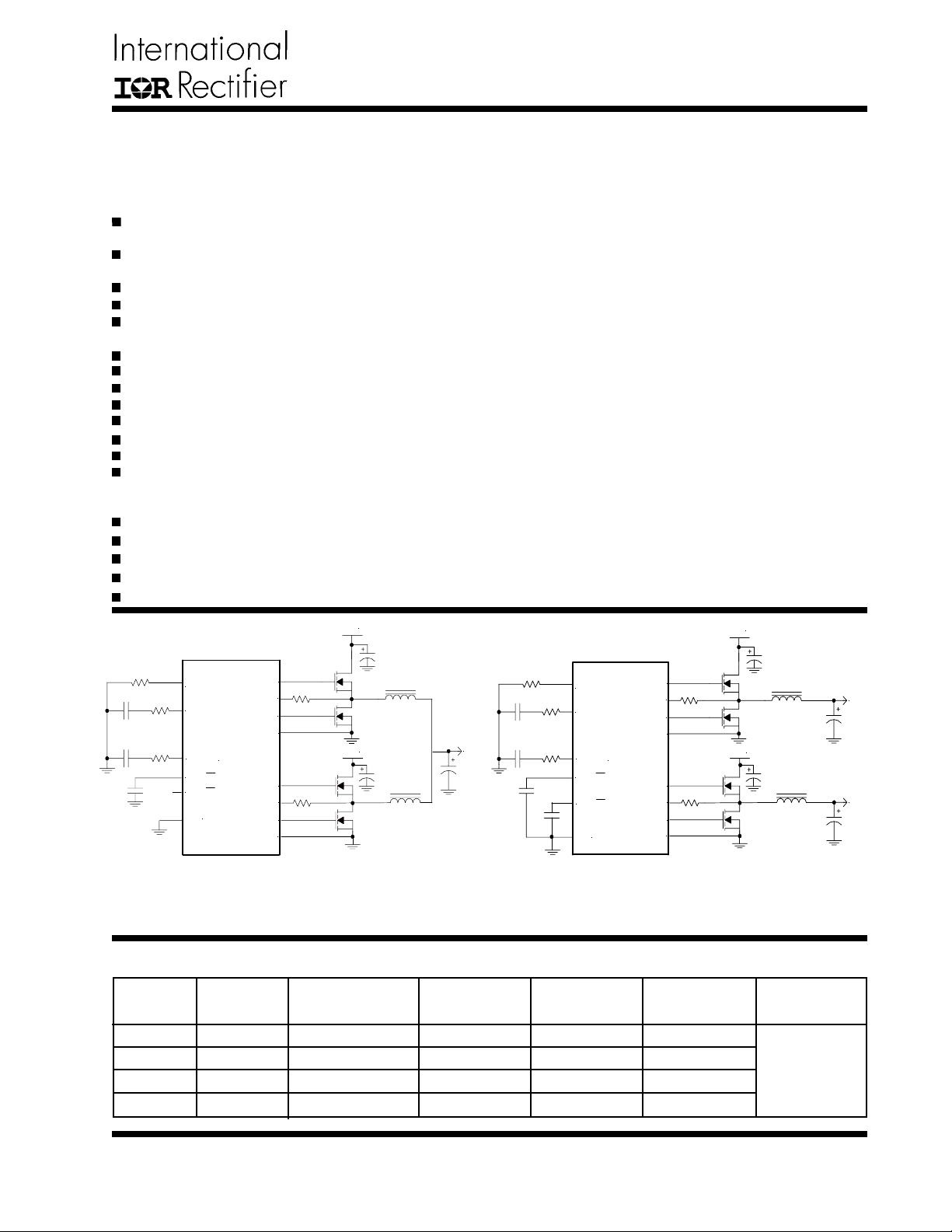

Vin

DESCRIPTION

The IR3621 IC combines a dual synchronous buck controller and drivers, providing a cost-effective, high performance

and flexible solution. The IR3621 operates in 2-Phase mode

to produce either 2-independent output voltages or current

share single output for high current application. The 180

out-of-phase operation allows the reduction of input and

output capacitance.

Other key features include two independently programmable

soft-start functions to allow system level sequencing of output voltages in various configurations. The pre-bias protection feature prevents the discharge of the output voltage and

possible damage to the load during start-up when a preexisting voltage is present at the output. Programmable

switching frequency up to 500KHz per phase allows flexibility to tune the operation of the IC to meet system level requirements, and synchronization allows the simplification

of system level filter design. Protection features such as

selectable hiccup or latched current limit, and under voltage

lock-out are provided to give required system level security

in the event of a fault condition.

Vin

IR3621

HDrv1

OCSet1

LDrv1

PGnd1

HDrv2

OCSet2

LDrv2

PGnd2

IR3621

HDrv1

OCSet1

LDrv1

PGnd1

HDrv2

OCSet2

LDrv2

PGnd2

Vout1

Vin

Vout2

Rt

Comp1

Vin

Vout

Comp2

SS1 / SD

SS2 / SD

Gnd

Rt

Comp1

Comp2

SS1 / SD

SS2 / SD

Gnd

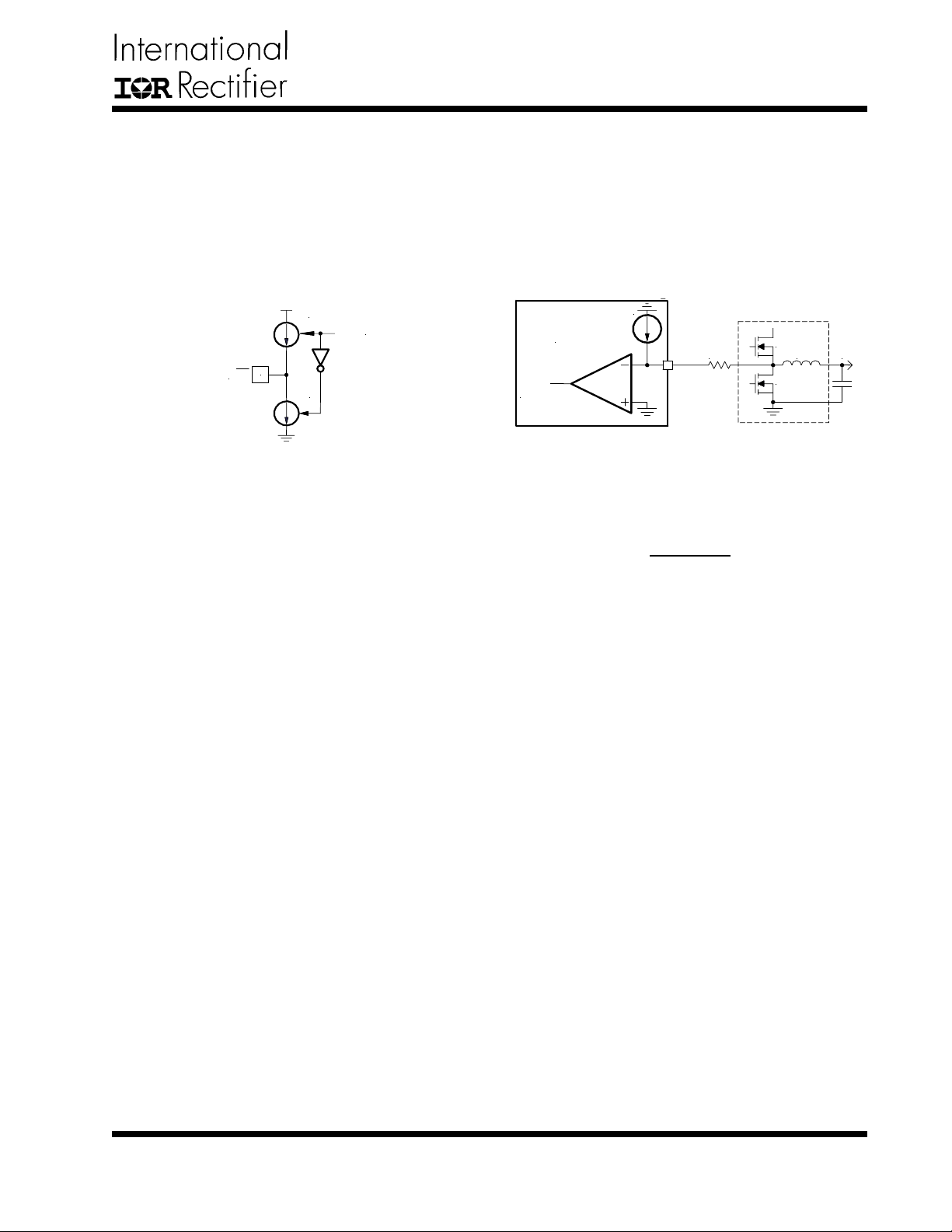

Current share, single output configuration 2-independent output voltage configuration

Figure 1 - Typical application of IR3621 in current share single output and 2-independent output voltage configuration

ORDERING INFORMATION

PKG

DESIG

M

M

F

F

PAR T LEADFREE

NUMBER P ART NUMBER

IR3621M IR3621MPbF

IR3621MTR IR3621MTRPbF

IR3621F IR3621FPbF

IR3621FTR IR3621FTRPbF

PIN

COUNT

32

32

28

28

P ARTS

PER TUBE

73

-----50

------

P ARTS

PER REEL

------

6000

------

2500

T & R

Orientation

Fig A

www.irf.com

1

Page 2

IR3621 & ( PbF)

ABSOLUTE MAXIMUM RATINGS

Vcc, VCL Supply Voltage ........................................... -0.5V To 16V

VcH1 and VcH2 Supply Voltage ................................ -0.5V To 25V

PGOOD.................................................................... -0.5V To 16V

Storage Temperature Range ...................................... -55°C To 150°C

Junction Temperature Range ..................................... -40°C To 150°C

ESD Classification ................................................... JEDEC, JESD22-A114

Caution: Stresses above those listed in “Absolute Maximum Rating” may cause permanent damage to the device. These are stress

ratings only and function of the device at these or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to “Absolute Maximum Rating” conditions for extended periods may affect device reliability

RECOMMENDED OPERATING CONDITIONS

Parameter Definition Min Max Units

Vcc Supply Voltage 5.5 14.5 V

VcH1,2 Supply Voltage 10 20 V

Fs Operating Frequency 200 500 kHz

Tj Junction Temperature -40 125 °C

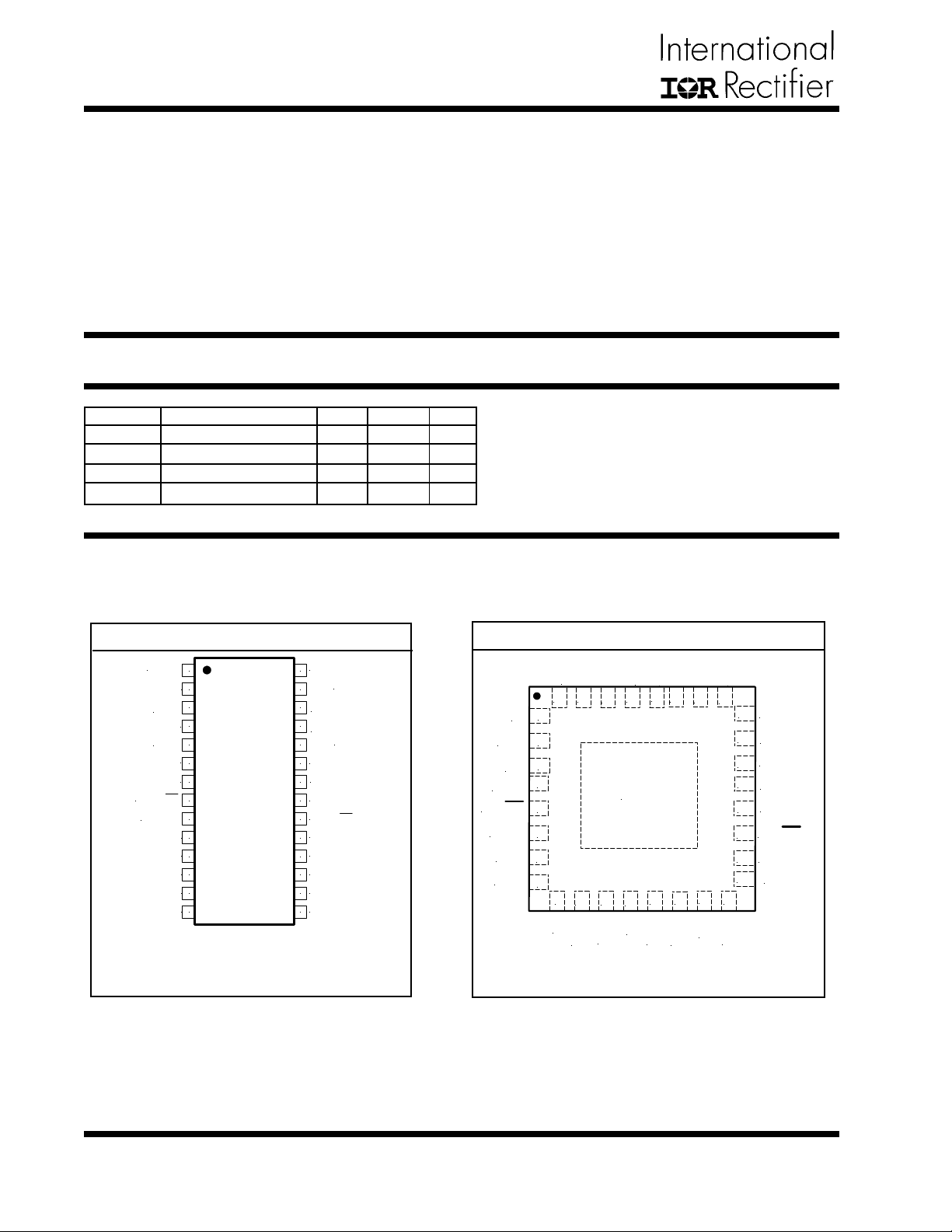

PACKAGE INFORMATION

IR3621F

28-PIN TSSOP (F)

1

PGood

2

CC

V

3

OUT3

V

4

Rt

5

SEN2

V

6

Fb2

7

Comp2

SS2 / SD

8 21

9 20

OCSet2

10 19

VcH2

11 18

HDrv2

12 17

PGnd2 HDrv1

13

LDrv2

14

CL

V

θJA = 75.5 °C/W

θJC =13.3 °C/W

28

Gnd

27

V

26

V

25

Hiccup

24

Sync

23

V

22

Fb1

Comp1

SS1 / SD

OCSet1

VcH1

16

PGnd1

15

LDrv1

REF

P2

SEN1

Rt

V

SEN2

Fb2

Comp2

SS2/SD2

OCSet2

VCH2

HDrv2

IR3621M & IR3621MPbF

32-Lead MLPQ 5mmx5mm (M)

OUT3

NC

V

Vcc

30

11

LDrv2

29

Pad

12

CL

V

3132

1

2

3

4

5

6

7

8

9

10

NC

PGnd2

PGood

13

LDrv1

REFVP2

Gnd

V

28

27

14

PGnd1

NC

26

25

15

16

NC

HDrv1

θJA = 36.0 °C/W

θJC = 1.0 °C/W

24

23

22

21

20

19

18

17

Hiccup

Sync

V

SEN1

Fb1

Comp1

SS1/SD1

OCSet1

VcH1

2

Exposed pad on underside is connected to a copper

pad through vias for 4-layer PCB board design.

www.irf.com

Page 3

IR3621 & ( PbF)

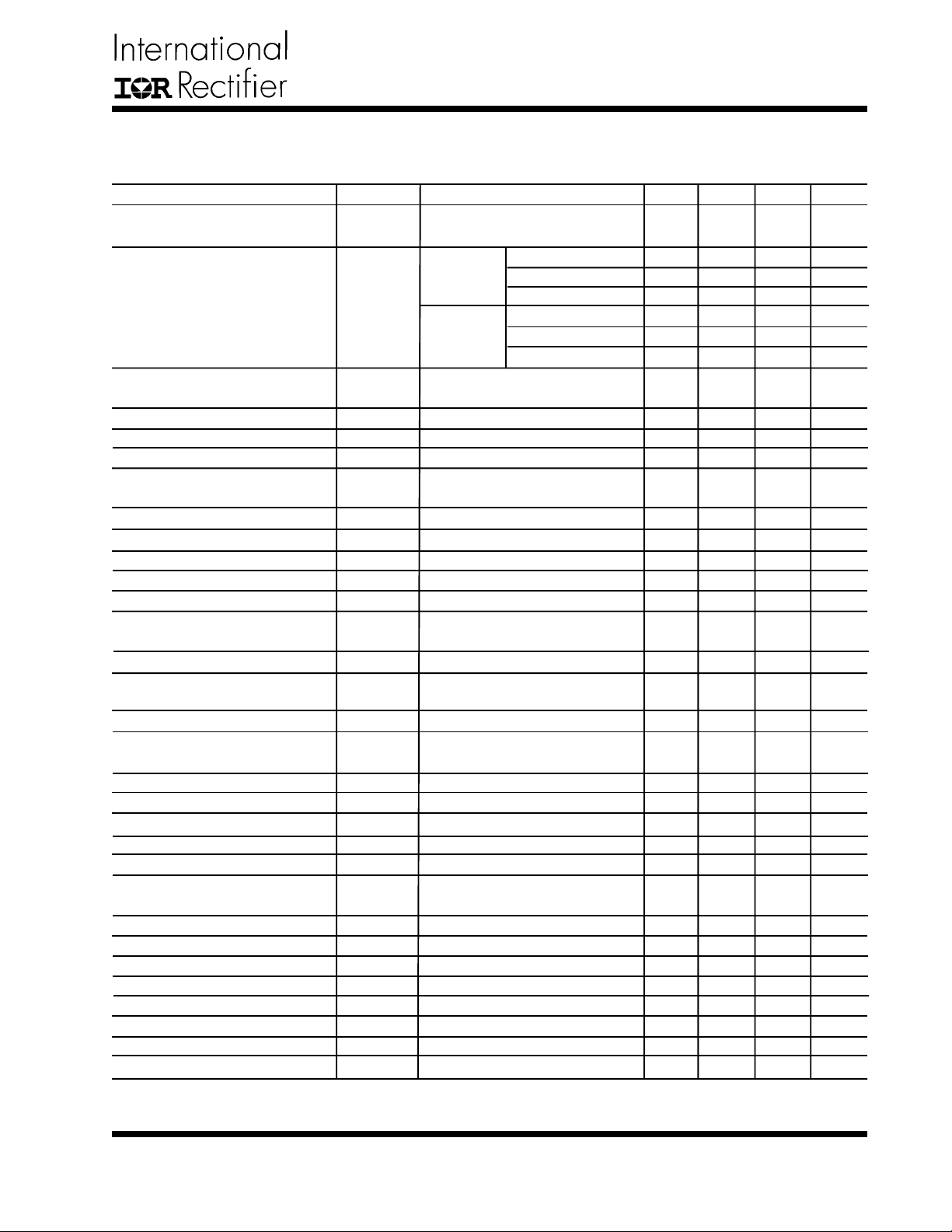

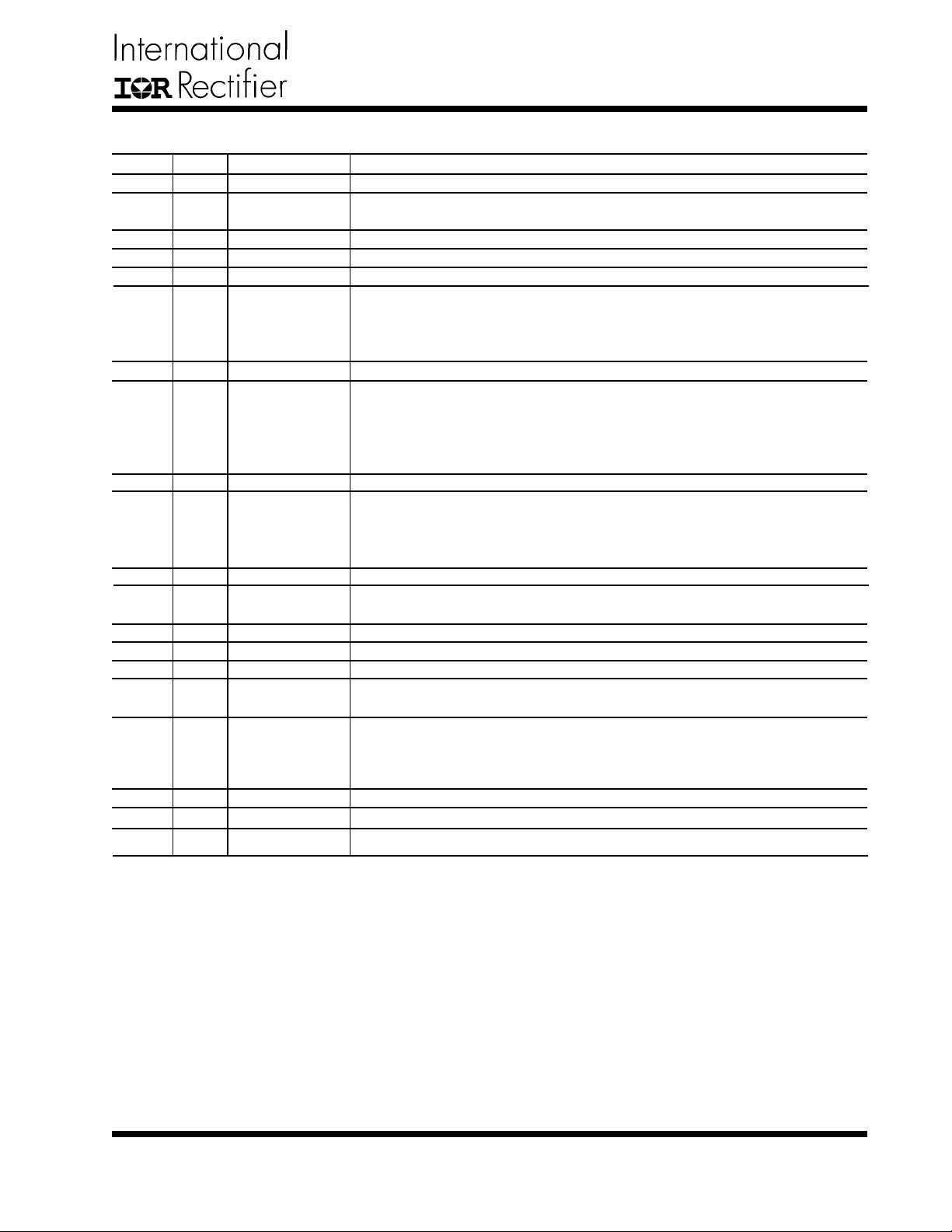

ELECTRICAL SPECIFICATIONS

Unless otherwise specified, these specifications apply over Vcc=12V , VcH1=VcH2=VCL=12V and 0°C<Tj<125°C.

PARAMETER SYMBOL TEST CONDITION MIN TYP MAX UNITS

Output V oltage Accuracy

2

0.80

1

0.75

10

15

15

10

6

6

28

0.9VREF

0.1

-0.1

100

0

1.25

300

+1

+1.35

+1.35

+1.35

+1.65

+1.65

5.3

4.0

15

25

25

15

10

10

35

0.25

0.95VREF

0.5

-0.5

2500

2500

140

+4

Vcc-2

345

0

1200

0.6

V

%

%

%

%

%

%

V

V

V

V

mA

mA

mA

mA

mA

mA

µA

V

V

V

µA

µmho

µmho

µA

mV

V

kHz

V

%

ns

%

kHz

ns

V

V

Feedback Voltage

Accuracy

UVLO Section

UVLO Threshold - Vcc

UVLO Hysteresis - Vcc

UVLO Threshold - VcH1,2

UVLO Hysteresis - VcH1,2

Supply Current Section

Vcc Dynamic Supply Current

VcH1 & VcH2 Dynamic Current

VCL Dynamic Supply Current

Vcc Static Supply Current

VcH1/VcH2 Static Current

VCL Static Supply Current

Soft-Start / SD Section

Charge Current

Shutdown Threshold

Power Good Section

VSENS1,2 Lower Trip Point

PGood Output Low Voltage

Error Amp Section

Fb Voltage Input Bias Current

Transconductance 1

Transconductance 2

Error Amp Source/Sink Current

Input Offset V oltage for E/A1,2

VP2 Voltage Range

Oscillator Section

Frequency

Ramp Amplitude

Min Duty Cycle

Min Pulse Width

Max Duty Cycle

Synch Frequency Range

Synch Pulse Duration

Synch High Level Threshold

Synch Low Level Threshold

Note1: Cold temperature performance is guaranteed via correlation using statistical quality control. Not 100% tested in production.

VFb1 , VFb2

UVLOVCC

UVLOVCH1,2

Dyn ICC

Dyn ICH

Dyn ICL

ICCQ

ICHQ

ICLQ

SSIB

SD

PGFB1,2L

PG(Voltage)

IFB1,2

gm1

gm2

I(E/A)1,2

VOS(ERR)

VP2

Freq

VRAMP

Dmin

Puls(ctrl)

Dmax

Sync(Fs)

Sync(puls)

Sync(H)

Sync(L)

Tj=25°C

MLPQ

TSSOP

Supply Ramping Up

Supply Ramp Up and Down

Supply Ramping Up

Supply Ramp Up and Down

Freq=300kHz, CL=1500pF

Freq=300kHz, CL=1500pF

Freq=300kHz, CL=1500pF

SS=0V

SS=0V

SS=0V

SS=0V

VSENS1,2 Ramping Down

ISINK=2mA

SS=3V

Fb1,2 to VREF

Note2

Rt(SET) to 30.9K

Note2

Fb=1V

FSW=300kHz, Note2

Fb=0.6V , FSW=200kHz

20% above free running freq

0°C <T

-40°C <T

Tj=25°C

0°C <Tj< 125°C

-40°C <Tj< 125°C

j< 125°C

j< 125°C

-1

-1.35

-2.5

-1.35

-1.65

-3.0

4.7

3.5

22

0.8VREF

1400

1400

60

-4

0.4

255

150

86.5

200

www.irf.com

3

Page 4

IR3621 & ( PbF)

PARAMETER SYMBOL TEST CONDITION MIN TYP MAX UNITS

OUT3 Internal Regulator

V

Output Voltage

Output Current

Protection Section

OVP Trip Threshold

OVP Fault Prop Delay

OCSET Current

Hiccup Duty Cycle

Hiccup High Level Threshold

Hiccup Low Level Threshold

Thermal Shutdown Trip Point

Thermal Shutdown Hysteresis

Output Drivers Section

LO Drive Rise Time

HI Drive Rise Time

LO Drive Fall Time

Hi Drive Fall Time

Dead Band Time

OVP

OVP(delay)

IOCSet

Tr(LO)

Tr(HI)

Tf(LO)

Tf(HI)

TDB

Output forced to 1.25VREF

Note2

Hiccup pin pulled high, Note2

Note2

Note2

Note2

Note2

CL=1500pF ,Figure 2

CL=1500pF , Figure 2

CL=1500pF ,Figure 2

CL=1500pF ,Figure 2

See Figure 2

5.8

44

1.1VREF

16

2

6.25

1.15

140

20

20

18

18

25

25

50

5

VREF

1.2

6.7

VREF

5

24

0.8

50

50

50

50

100

V

mA

V

µs

µA

%

V

V

C

C

ns

ns

ns

ns

ns

Note 2: Guaranteed by design but not tested for production.

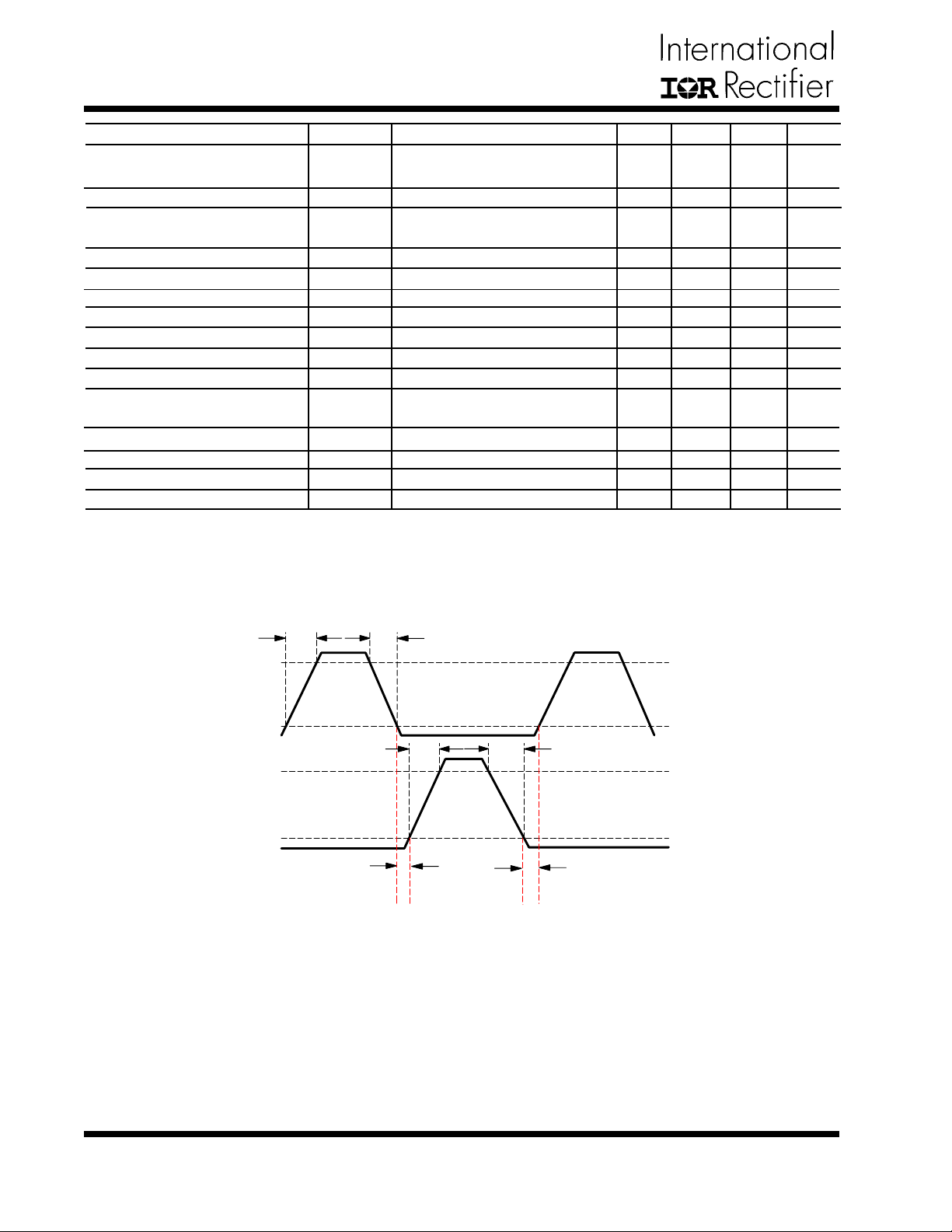

Tr

9V

High Side Driver

(HDrv )

2V

9V

Low Side Driver

(LDrv)

2V

Deadband

H_to_L

Tf

Tr

Tf

Deadband

L_to_H

4

Figure 2 - Rise Time, Fall Time and Deadband for Driver Section

www.irf.com

Page 5

PIN DESCRIPTIONS

TSSOP MLPQ PIN SYMBOL PIN DESCRIPTION

1

2

3

4

5,23

6,22

7,21

8

20

9,19

10,18

1 1,17

12,16

13,15

14

24

25

26

27

28

29

30

31

1

2,22

3,21

4,20

5

19

6,18

7,17

8,16

10,14

1 1,13

12

23

24

26

27

28

9,15,25.32

PGood

Vcc

VOUT3

Rt

VSEN2, VSEN1

Fb2,Fb1

Comp2, Comp1

SS2 / SD

SS1 / SD

OCSet2,OCSet1

VcH2, VcH1

HDrv2, HDrv1

PGnd2, PGnd1

LDrv2, LDrv1

V

CL

Sync

Hiccup

VP2

VREF

Gnd

N/C

Power Good pin. Low when any of the outputs fall 10% below the set voltages.

Supply voltage for the internal blocks of the IC. The Vcc slew rate should be

<0.1V/us.

Output of the internal LDO. Connect a 1.0uF capacitor from this pin to ground.

Connecting a resistor from this pin to ground sets the oscillator frequency .

Sense pins for OVP and PGood. For current share tie these pins together.

Inverting inputs to the error amplifiers. In current sharing mode, Fb1 is connected to a resistor divider to set the output voltage and Fb2 is connected to

programming resistor to achieve current sharing. In independent 2-channel mode,

these pins work as feedback inputs for each channel.

Compensation pins for the error amplifiers.

These pins provide user programmable soft-start function for each outputs.

Connect external capacitors from these pins to ground to set the start up time

for each output. These outputs can be shutdown independently by pulling the

respective pins below 0.3V . During shutdown both MOSFET s will be turned of f.

For current share mode SS2 must be floating.

A resistor from these pins to switching point will set current limit threshold.

Supply voltage for the high side output drivers. These are connected to voltages

that must be typically 6V higher than their bus voltages. A 0.1µF high frequency capacitor must be connected from these pins to PGND to provide peak

drive current capability .

Output drivers for the high side power MOSFET s. Note3

These pins serve as the separate grounds for MOSFET drivers and should be

connected to the system’s ground plane.

Output drivers for the synchronous power MOSFET s.

Supply voltage for the low side output drivers.

The internal oscillator can be synchronized to an external clock via this pin.

When pulled High, it puts the device current limit into a hiccup mode. When

pulled Low, the output latches of f, after an overcurrent event.

Non-inverting input to the second error amplifier. In the current sharing mode, it

is connected to the programming resistor to achieve current sharing. In independent 2-channel mode it is connected to V

the resistor divider to set the output voltage.

Reference Voltage. The drive capability of this pin is about 2µA.

Analog ground for internal reference and control circuitry .

No Connect

IR3621 & ( PbF)

REF pin when Fb2 is connected to

Note3: The negative voltage at these pins may cause instability for the gate drive circuits. To prevent this, a low

forward voltage drop diode (Schottky) is required between these pins and power ground.

www.irf.com

5

Page 6

IR3621 & ( PbF)

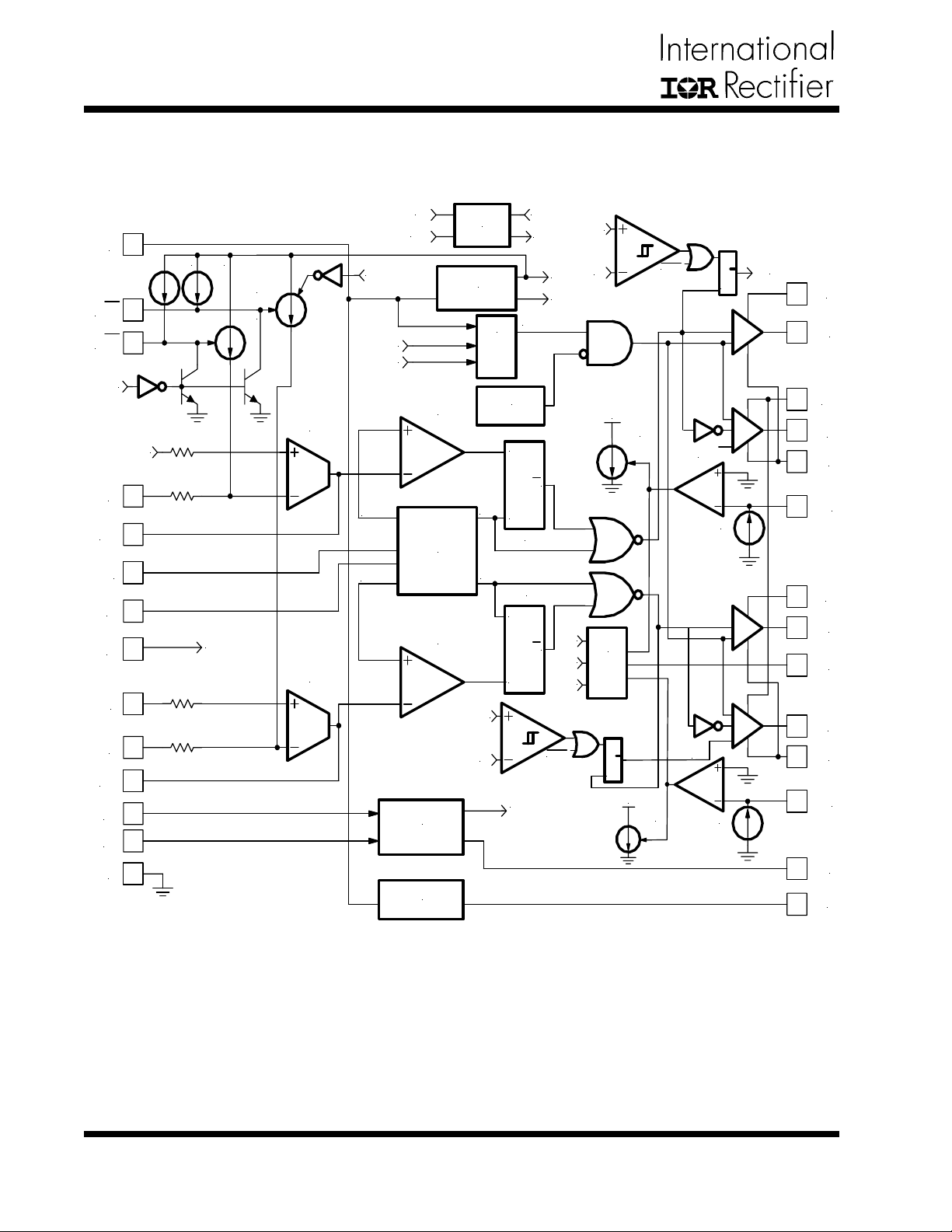

BLOCK DIAGRAM

Vcc

28uA

28uA

SS2 / SD

SS1 / SD

POR

Fb1

Comp1

Rt

Sync

V

REF

V

P2

Fb2

Comp2

V

SEN1

V

SEN2

0.8V

64uA

0.8V

64uA

Max

Error Amp1

Error Amp2

Mode

VcH1

VcH2

Ramp1

Ramp2

2

SS

0.8V

PWM Comp1

Two Phase

Osc illator

PWM Comp2

PGood / O V P

Mode

Control

Bias

Generator

UVLO

Set1

Set2

0.3V

SS2

POR

Mode

3V

0.8V

POR

Thermal

Shutdown

R

Q

S

Reset Dom

Reset Dom

S

Q

R

POR

OVP

HDrv OFF / LDrv ON

SS1

SS2

Mode

0.3V

SS1

Hiccup

Control

SS1

S

R

Q

SS2

3uA

3uA

POR

PBias1

PBias2

20uA

20uA

S

Q

PBias1

R

VcH1

HDrv1

V

CL

LDrv1

PGnd1

OCSet1

VcH2

HDrv2

Hiccup

LDrv2

PGnd2

OCSet2

6

Gnd

Regulator

Figure 3 - IR3621Block Diagram

www.irf.com

PGood

V

OUT3

Page 7

FUNCTIONAL DESCRIPTION

Introduction

The IR3621 is a versatile device for high performance

buck converters. It consists of two synchronous buck

controllers which can be operated either in two independent mode or in current share mode.

The timing of the IC is provided by an internal oscillator

circuit which generates two out-of-phase clock that can

be programmed up to 500kHz per phase.

Supply Voltage

Vcc is the supply voltage for internal controller. The operating range is from 5.5V to 14.5V . It also is fed to the

internal LDO. When Vcc is below under-voltage threshold, all MOSFET drivers will be turned off.

Internal Regulator

The regulator powers directly from Vcc and generates a

regulated voltage (Typ. 6.2V@40mA). The output is protected for short circuit. This voltage can be used for charge

pump circuitry as shown in Figure12.

IR3621 & ( PbF)

In this mode, one control loop acts as a master and sets

the output voltage as a regular Voltage Mode Buck controller and the other control loop acts as a slave and

monitors the current information for current sharing. The

voltage drops across the current sense resistors (or DCR

of inductors) are measured and their difference is amplified by the slave error amplifier and compared with the

ramp signal to generate the PWM pulses to match the

output current. In this mode the SS2 pin should be floating.

IR3621

PWM Comp1

PWM Comp2

Master E/A

Comp

0.8V

Fb1

VP2

V

L1

R1

C1

OUT

R

L1

Input Supplies UnderV oltage LockOut

The IR3621 UVLO block monitors three input voltages

(Vcc, VcH1 and VcH2) to ensure reliable start up. The

MOSFET driver output turn off when any of the supply

voltages drops below set thresholds. Normal operation

resumes once the supply voltages rise above the set

values.

Mode Selection

The SS2 pin is used for mode selection. In current share

mode this pin should be floating and in dual output mode

a soft start capacitor must be connected from this pin to

ground to program the start time for the second output.

Independent Mode

In this mode the IR3621 provides control to two independent output power supplies with either common or different input voltages. The output voltage of each individual

channel is set and controlled by the output of the error

amplifier, which is the amplified error signal from the

sensed output voltage and the reference voltage. The

error amplifier output voltage is compared to the ramp

signal thus generating fixed frequency pulses of variable

duty-cycle, which are applied to the FET drivers, Figure19 shows a typical schematic for such application.

FB2

Slave E/A

L2

L2

R

R2

C2

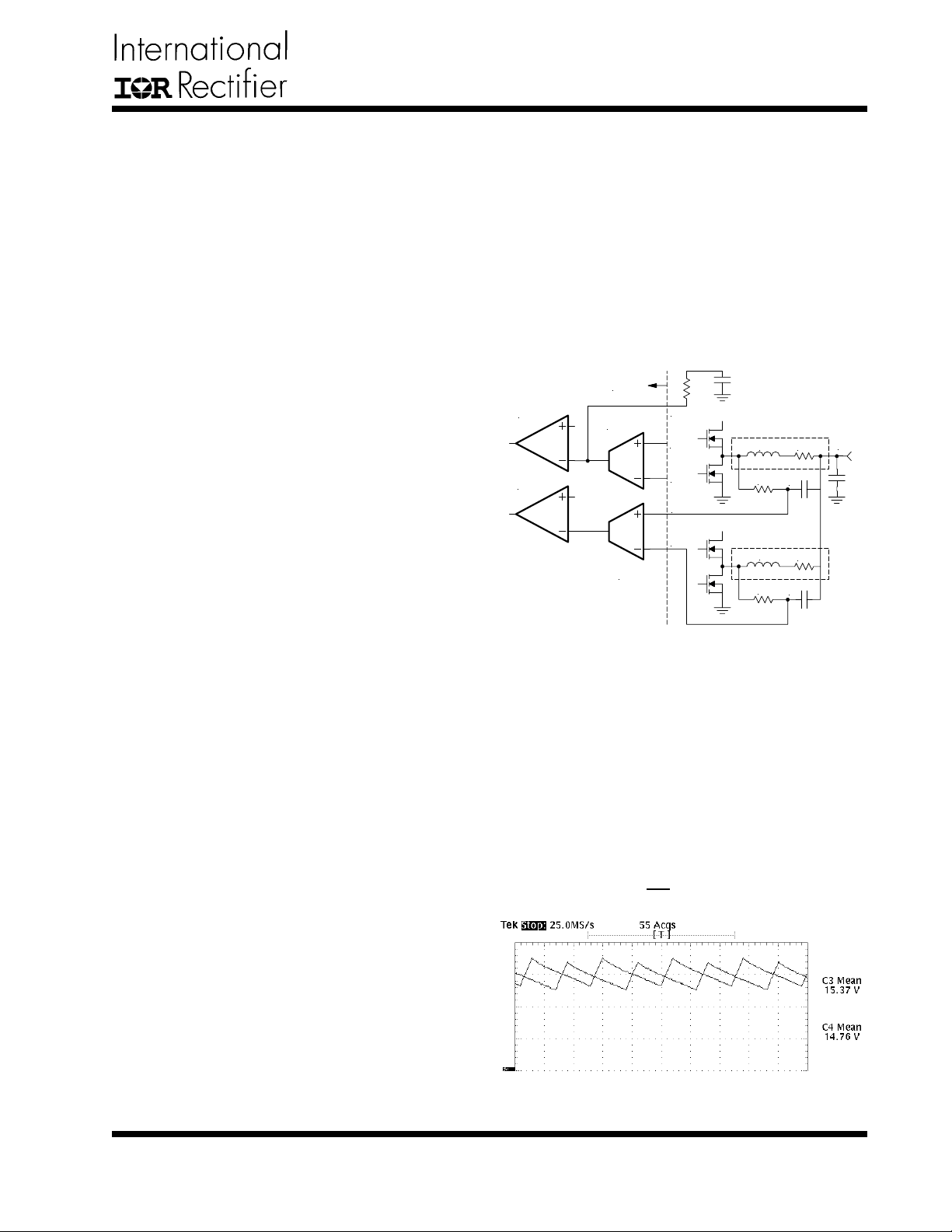

Figure 4 - Loss-less inductive current sensing

and current sharing.

In the diagram, L1 and L2 are the output inductors. RL1

and RL2 are inherent inductor resistances. The resistor

R1 and capacitor C1 are used to sense the average inductor current. The voltage across the capacitors C1

and C2 represent the average current flowing into resistance RL1 and RL2. The time constant of the RC network

should be equal or at most three times larger than the

time constant L1/RL1.

R1×C1=(1~3)× ---(1)

L1

RL1

Currnt Share Mode

This feature allows to connect both outputs together to

increase current handling capability of the converter to

support a common load. The current sharing can be done

either using external resistors or sensing the DCR of

inductors (see Figure 4).

www.irf.com

Figure 5 - 30A Current Sharing using Inductor sensing

(5A/Div)

7

Page 8

IR3621 & ( PbF)

Dual Soft-Start

The IR3621 has programmable soft-start to control the

output voltage rise and limit the inrush current during

start-up. It provides a separate Soft-Start function for each

outputs. This will enable to sequence the outputs by

controlling the rise time of each output through selection

of different value soft-start capacitors. The soft-start pins

will be connected together for applications where, both

outputs are required to ramp-up at the same time.

To ensure correct start-up, the soft-start sequence initiates when the Vcc, VcH1 and VcH2 rise above their

threshold and generate the Power On Reset (POR) signal. Soft-start function operates by sourcing an internal

current to charge an external capacitor to about 3V . Initially, the soft-start function clamps the E/A’s output of

the PWM converter. During power up, the converter output starts at zero and thus the voltage at Fb is about 0V .

A current (64µA) injects into the Fb pin and generates a

voltage about 1.6V (64µA×25K) across the negative

input of E/A and (see Figure6).

The magnitude of this current is inversely proportional to

the voltage at soft-start pin. The 28µA current source

starts to charge up the external capacitor. In the mean

time, the soft-start voltage ramps up, the current flowing

into Fb pin starts to decrease linearly and so does the

voltage at negative input of E/A.

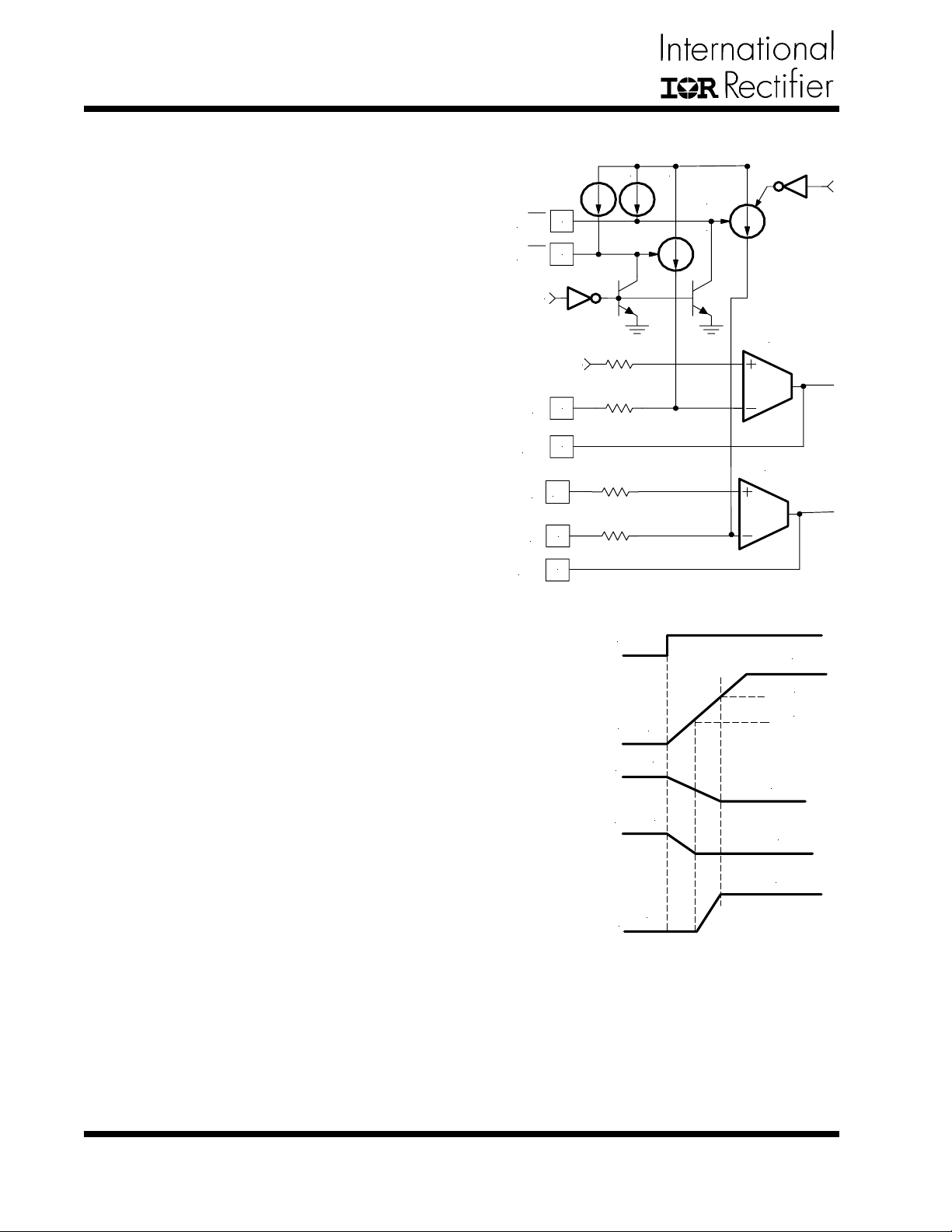

SS2 / SD

SS1 / SD

POR

Fb1

Comp1

V

P2

Fb2

Comp2

28uA

28uA

64uA

8

20

0.8V

22

21

26

6

7

Max

64uA

Error Amp1

Error Amp2

Figure 6 -Soft-start circuit for IR3621

Output of POR

3V

When the soft-start capacitor is around 1V , the current

flowing into the Fb pin is approximately 32µA. The voltage at the positive input of the E/A is approximately:

32µA×25K = 0.8V

The E/A will start to operate and the output voltage starts

to increase. As the soft-start capacitor voltage continues to go up, the current flowing into the Fb pin will keep

decreasing. Because the voltage at pin of E/A is regulated to reference voltage 0.8V , the voltage at the Fb is:

VFB = 0.8-(25K×Injected Current)

The feedback voltage increases linearly as the injecting

current goes down. The injecting current drops to zero

when soft-start voltage is around 1.8V and the output

voltage goes into steady state. Figure 7 shows the theoretical operational waveforms during soft-start.

Low Temperature Start-Up

The controller is capable of starting at -40C ambient

temperature.

≅

1.8V

≅

Soft-Start

Voltage

Current flowing

into Fb pin

Voltage at negative input

of Error Am p

Voltage at Fb pin

0V

64uA

≅

1.6V

0V

1V

0uA

0.8V

0.8V

Figure 7 - Theoretical operational waveforms

during soft-start.

The output start-up time is the time period when softstart capacitor voltage increases from 1V to 1.8V. The

start-up time will be dependent on the size of the external soft-start capacitor. The start-up time can be estimated by:

28µA×TSTART/CSS = 1.8V-1V

8

www.irf.com

Page 9

IR3621 & ( PbF)

For a given start up time, the soft-start capacitor can be

calculated by:

SS ≅ 28µA×TSTART/0.8V

C

The soft-start is part of the Over Current Protection

scheme, during the overload or short circuit condition

the external soft start capacitors will be charged and

discharged in certain slope rate to achieve the hiccup

mode function.

SS1 / SD

28uA

Hiccup

20

3uA

Figure 8 - 3uA current source for discharging soft

start-capacitor during Hiccup mode

Out-of-Phase Operation

The IR3621 drives its two output stages 180 out-of-phase.

In 2-phase configuration, the two inductor ripple currents

cancel each other and result in a reduction of the output

current ripple and yield a smaller output capacitor for the

same ripple voltage requirement.

In single input voltage applications, the input ripple current

reduces. This results in much smaller input capacitor's

RMS current and reduces the input capacitor quantity .

Over-Current Protection

The IR3621 can provide two different schemes for OverCurrent Protection (OCP). When the Hiccup pin is pulled

high, the OCP will operate in hiccup mode. In this mode,

during overload or short circuit, the outputs enter hiccup

mode and stay in that mode until the overload or short

circuit is removed. The converter will automatically recover.

When the Hiccup pin is pulled low, the OCP scheme

will be changed to the latch up type, in this mode the

converter will be turned off during Overcurrent or short

circuit. The power needs to be recycled for normal

operation.

Each phase has its own independent OCP circuitry.

The OCP is performed by sensing current through the

R

DS(ON) of low side MOSFET. As shown in Figure 9, an

external resistor (RSET) is connected between OCSet pin

and the drain of low side MOSFET (Q2) which sets the

current limit set point.

If using one soft start capacitor in dual configuration for a

precise power up the OCP needs to be set to latch mode.

The internal current source develops a voltage across

RSET. When the low side switch is turned on, the inductor current flows through the Q2 and results a voltage

which is given by:

OCSET = IOCSET×RSET-RDS(ON)×iL ---(2)

V

I

OCSET

Hiccup

Control

IR3621

OCSet

R

SET

Q1

Q2

V

L1

OUT

Figure 9 - Diagram of the over current sensing.

The critical inductor current can be calculated by setting:

V

OCSET = IOCSET×RSET - RDS(ON)×IL = 0

RSET×IOCSET

ISET = IL(CRITICAL)= ---(3)

RDS(ON)

The value of RSET should be checked in an actual

circuit to ensure that the Over Current Protection

circuit activates as expected. The IR3621 current limit

is designed primarily as disaster preventing, "no blow

up" circuit, and is not useful as a precision current

regulator.

In two independent mode, the output of each channel

is protected independently which means if one output

is under overload or short circuit condition, the other

output will remain functional. The OCP set limit can be

programmed to different levels by using the external

resistors. This is valid for both hiccup mode and latch

up mode.

In 2-phase configuration, the OCP's output depends on

any one channel, which means as soon as one

channel goes to overload or short circuit condition the

output will enter either hiccup or latch-up, dependes on

status of Hiccup pin.

Pre-bias Startup

The IR3621 allows pre-bias startup without discharging

the output capacitors. The output starts in asynchronous fashion and keeps the synchronous MOSFET off

until the first gate signal for control MOSFET is generated.

www.irf.com

9

Page 10

IR3621 & ( PbF)

Frequency Synchronization

The IR3621 is capable of accepting an external digital

synchronization signal. Synchronization will be enabled

by the rising edge at an external clock. Per-channel switching frequency is set by external resistor (Rt). The free

running oscillator frequency is twice the per-channel frequency . During synchronization, Rt is selected such that

the free running frequency is 20% below the sync frequency . Synchronization capability is provided for both 2output and 2-phase configurations. When unused, the

Sync pin will remain floating and is noise immune.

Thermal Shutdown

T emperature sensing is provided inside IR3621. The trip

threshold is typically set to 140C. When trip threshold is

exceeded, thermal shutdown turns off both MOSFETs.

Thermal shutdown is not latched and automatic restart is

initiated when the sensed temperature drops to normal

range. There is a 20C hysteresis in the shutdown threshold.

Power Good

The IR3621 provides a power good signal. The power good

signal should be available after both outputs have reached

regulation. This pin needs to be externally pulled high.

High state indicates that outputs are in regulation.

Power good will be low if either one of the output voltages

is 10% below the set value. There is only one power good

for both outputs.

Operation Frequency Selection

The optimum operating frequency range for the IR3621

is 300kHz per phase, theoretically the IR3621 can be

operated at higher switching frequency (e.g. 500kHz).

However the power dissipation for IC, which is function

of applied voltage, gate drivers load and switching frequency , will result in higher junction temperature of device. It may exceed absolute maximum rating of junction temperature, figure 18 (page 17) shows case temperature versus switching frequency with different capacitive loads for TSSOP package.

This should be considered when using IR3621 for such

application. The below equation shows the relationship

between the IC's maximum power dissipation and Junction temperature:

Where:

Pd =

ΤJ-ΤA

θJA

Tj: Maximum Operating Junction T emperature

T A: Ambient T emperature

θ

JA = Thermal Impedance of package

The switching frequency is determined by an external

resistor (Rt). The switching frequency is approximately

inversely proportioned to resistance (see Fig 10).

Per Ch a n n el Switching F requ en c y vs. RT

700

Over-V oltage Protection OVP

Over-voltage is sensed through separate V

OUT sense pins

VSEN1 and VSEN2. A separate OVP circuit is provided for

each output. Upon over-voltage condition of either one of

the outputs, the OVP forces a latched shutdown on both

outputs. In this mode, the upper FET drivers turn off and

the lower FET drivers turn on, thus crowbaring the outputs. Reset is performed by recycling Vcc.

Error Amplifier

The IR3621 is a voltage mode controller. The error amplifiers are of transconductance type. In independent mode,

each amplifier closes the loop around its own output voltage. In current sharing mode, amplifier 1 becomes the

master which regulates the common output voltage. Amplifier 2 performs the current sharing function. Both amplifiers are capable of operating with Type III compensation control scheme.

600

500

400

300

200

Switching Frequency (kHz)

100

0

0 10203040506070

RT (kohm)

Figure 10- Switching Frequency versus External Resistor.

Shutdown

The outputs can be shutdown independently by pulling

the respective soft-start pins below 0.3V. This can be

easily done by using an external small signal transistor. During shutdown both MOSFETs will be turned off.

During this mode the LDO will stay on. Normal operation will resume by cycling soft start pins.

10

www.irf.com

Page 11

IR3621 & ( PbF)

APPLICATION INFORMATION

Design Example:

The following example is a typical application for the

IR3621, the schematic is Figure19 on page18.

IN = 12V

V

VOUT(2.5V) = 2.5V @ 10A

VOUT(1.8V) = 1.8V @ 10A

∆VOUT = Output voltage ripple ≅ 3% of VOUT

FS = 400kHz

Output Voltage Programming

Output voltage is programmed by the reference voltage

and an external voltage divider. The Fb1 pin is the inverting input of the error amplifier, which is referenced to the

voltage on the non-inverting pin of error amplifier. For this

application, this pin (V

voltage (VREF). The output voltage is defined by using the

following equation:

VOUT = VP2 × 1 +

VP2 = VREF = 0.8V

When an external resistor divider is connected to the

output as shown in Figure 1 1.

V

V

Figure 1 1 - Typical application of the IR3621 for pro-

gramming the output voltage.

Equation (4) can be rewritten as:

R6 = R5 ×

Will result to:

VOUT(2.5V) = 2.5V

VREF = 0.8V

R9= 2.15K, R5= 1K

If the high value feedback resistors are used, the input

bias current of the Fb pin could cause a slight increase

in output voltage. The output voltage can be set more

accurately by using low value, precision resistors.

P2) is connected to the reference

R6

---(4)

R5

( )

IR3621

REF

P2

Fb

VOUT

- 1

( )

VP

VOUT(1.8V) = 1.8V

VREF = 0.8

R7= 1.24K, R8 = 1K

V

OUT

6

R

5

R

Soft-Start Programming

The soft-start timing can be programmed by selecting

the soft-start capacitance value. The start-up time of

the converter can be calculated by using:

Css ≅ 28×tSTART (µF) ---(5)

Where tSTART is the desired start-up time (ms)

For a start-up time of 4ms for both output, the soft-start

capacitor will be 0.1µF. Connect two 0.1µFceramic

capacitors from SS1 pin and SS2 pin to GND.

Supply VcH1 and VcH2

T o drive the high side MOSFET, it is necessary to supply a gate voltage at least 4V greater than the bus voltage. This is achieved by using a charge pump configuration as shown in Figure 12. This method is simple

and inexpensive. The operation of the circuit is as follows: when the lower MOSFET is turned on, the capacitor (C1) charges up to VOUT3, through the diode

(D1). The bus voltage will be added to this voltage when

upper MOSFET turns on in next cycle, and providing

supply voltage (VcH1) through diode (D2). VcH1 is approximately:

VCH1 ≅ VOUT3 + VBUS - (VD1 + VD2)

Capacitor in the range of 0.1µF is generally adequate

for most applications. The diode must be a fast recovery device to minimize the amount of charge fed back

from the charge pump capacitor into VOUT3. The diodes

need to be able to block the full power rail voltage, which

is seen when the high side MOSFET is switched on.

For low voltage application, Schottky diodes can be

used to minimize forward drop across the diodes at

start up.

D1

Regulator

IR3621

V

OUT3

Figure 12 - Charge pump circuit.

VcH1

C3

HDrv

C2

D2

C1

BUS

V

Q1

L2

Q2

www.irf.com

11

Page 12

IR3621 & ( PbF)

Input Capacitor Selection

The 1800 out of phase will reduce the RMS value of the

ripple current seen by input capacitors. This reduces

numbers of input capacitors. The input capacitors must

be selected that can handle both the maximum ripple

RMS at highest ambient temperature as well as the

maximum input voltage. The RMS value of current ripple

for duty cycles under 50% is expressed by:

= (I

2

D1(1-D1)+I

1

I

RMS

2

D2(1-D2)-2I1I2D1D2) --- (6)

2

Where:

is the RMS value of the input capacitor current

I

RMS

D1 and D2 are the duty cycle for each output

I1 and I2 are the current for each output

For this application the I

RMS

=4.8A

For higher efficiency, low ESR capacitors are recommended.

Choose two Poscap from Sanyo 16TPB47M (16V , 47µF,

70mΩ ) with a maximum allowable ripple current of 1.4A

for inputs of each channel.

Inductor Selection

The inductor is selected based on operating frequency ,

transient performance and allowable output voltage ripple.

Low inductor values result in faster response to step

load (high ∆i/∆t) and smaller size but will cause larger

output ripple due to increased inductor ripple current. As

a rule of thumb, select an inductor that produces a ripple

current of 10-40% of full load DC.

For the buck converter, the inductor value for desired

operating ripple current can be determined using the following relation:

VIN - VOUT = L× ; ∆t = D× ; D =

L = (VIN - VOUT)× ---(7)

∆i

∆t

VOUT

VIN×∆i×fS

1

fS

VOUT

VIN

Where:

VIN = Maximum Input V oltage

VOUT = Output Voltage

∆i = Inductor Ripple Current

fS = Switching Frequency

∆t = Turn On Time

D = Duty Cycle

For ∆i(2.5V) = 45%(IO(2.5V) ), then the output inductor will

be:

L4 = 1.1µH

For ∆i(1.8V) = 35%(IO(1.8V) ), then the output inductor will

be:

L3 = 1.1µH

Panasonic provides a range of inductors in different values and low profile for large currents.

Choose ETQP6F1R1BFA (1.1µH, 16A, 2.2mΩ) both for

L3 and L4.

For 2-phase application, equation (7) can be used for

calculating the inductors value. In such case the inductor ripple current is usually chosen to be between 1040% of maximum phase current.

Output Capacitor Selection

The criteria to select the output capacitor is normally

based on the value of the Effective Series Resistance

(ESR). In general, the output capacitor must have low

enough ESR to meet output ripple and load transient

requirements, yet have high enough ESR to satisfy stability requirements. The ESR of the output capacitor is

calculated by the following relationship:

(ESL, Equivalent Series Inductance is neglected)

ESR ≤ ---(8)

∆VO

∆IO

Where:

∆VO = Output Voltage Ripple

∆i = Inductor Ripple Current

∆VO = 3% of VO will result to ESR(2.5V) =16.6mΩ and

ESR(1.8V) =16mΩ

The Sanyo TPC series, Poscap capacitor is a good choice.

The 6TPC330M, 330µF, 6.3V has an ESR 40mΩ. Se-

lecting three of these capacitors in parallel for 2.5V output, results to an ESR of ≅ 13.3mΩ which achieves our

low ESR goal. And selecting three of these capacitors in

parallel for 1.8V output, results in an ESR of ≅ 13.3mΩ

which achieves our low ESR goal.

The capacitors value must be high enough to absorb the

inductor's ripple current.

Power MOSFET Selection

The IR3621 uses four N-Channel MOSFET s. The selection criteria to meet power transfer requirements is based

on maximum drain-source voltage (VDSS), gate-source

drive voltage (VGS), maximum output current, On-resistance RDS(ON) and thermal management.

The both control and synchronous MOSFET s must have

a maximum operating voltage (VDSS) that exceeds the

maximum input voltage (VIN).

12

www.irf.com

Page 13

IR3621 & ( PbF)

The gate drive requirement is almost the same for both

MOSFET s. Logic-level transistors can be used and caution should be taken with devices at very low V

GS to pre-

vent undesired turn-on of the complementary MOSFET ,

which results in a shoot-through.

The total power dissipation for MOSFET s includes conduction and switching losses. For the Buck converter,

the average inductor current is equal to the DC

load current. The conduction loss is defined as:

PCOND(Upper Switch) = ILOAD×RDS(on)×D×ϑ

PCOND(Lower Switch) = ILOAD×RDS(on)×(1 - D)×ϑ

2

2

ϑ = RDS(on) T emperature Dependency

The R

DS(ON) temperature dependency should be consid-

ered for the worst case operation. This is typically given

in the MOSFET data sheet. Ensure that the conduction

losses and switching losses do not exceed the package

ratings or violate the overall thermal budget.

Choose IRF7821 for control MOSFET s and IRF81 13 for

synchronous MOSFET s. These devices provide low onresistance in a compact SOIC 8-Pin package.

VDS(OFF)

P

SW = ILOAD ---(9)

2

×

tr + tf

T

×

Where:

VDS(OFF) = Drain to Source Voltage at of f time

tr = Rise Time

tf = Fall Time

T = Switching Period

LOAD = Load Current

I

V

DS

90%

10%

V

GS

t

d

t

d

(ON)

(OFF )

t

r

t

Figure 13 - Switching time waveforms.

From IRF7821 data sheet we obtain:

IRF7821

tr = 2.7ns

tf = 7.3ns

f

The MOSFET s have the following data:

IRF7821

VDSS = 30V

RDS(on) = 9mΩ

IRF81 13

VDSS = 30V

RDS(on) = 6mΩ

The total conduction losses for each output will be:

PCON(TOTAL, 2.5V) = PCON(UPPER) + PCON(LOWER)

PCON(TOTAL, 2.5V) = 1.0W

PCON(TOTAL, 1.8V) = PCON(UPPER) + PCON(LOWER)

PCON(TOTAL, 1.8V) = 1.0W

The switching loss is more difficult to calculate, even

though the switching transition is well understood. The

reason is the effect of the parasitic components and

switching times during the switching procedures such

as turn-on / turnoff delays and rise and fall times. The

control MOSFET contributes to the majority of the switching losses in a synchronous Buck converter. The synchronous MOSFET turns on under zero voltage conditions, therefore, the switching losses for synchronous

MOSFET can be neglected. With a linear approximation, the total switching loss can be expressed as:

These values are taken under a certain condition test.

For more details please refer to the IRF7821 data sheet.

By using equation (9), we can calculate the total switching losses.

PSW(TOTAL,2.5V) = 0.18W

PSW(TOTAL,1.8V) = 0.18W

Programming the Over-Current Limit

The over-current threshold can be set by connecting a

resistor (RSET) from drain of low side MOSFET to the

OCSet pin. The resistor can be calculated by using equation (3).

The RDS(on) has a positive temperature coefficient and it

should be considered for the worse case operation.

RDS(on) = 6mΩ×1.5 = 9mΩ

ISET ≅ IO(LIM) = 10A×1.5 = 15A

(50% over nominal output current)

This results to:

RSET = R1=R6=6.75KΩ

This resistor must be placed close to the IC, place a

small ceramic capacitor from this pin to ground for noise

rejection purposes.

www.irf.com

13

Page 14

IR3621 & ( PbF)

Feedback Compensation

The IR3621 is a voltage mode controller; the control loop

is a single voltage feedback path including error amplifier and error comparator. To achieve fast transient response and accurate output regulation, a compensation

circuit is necessary . The goal of the compensation network is to provide a closed loop transfer function with

the highest 0dB crossing frequency and adequate phase

margin (greater than 45).

The output LC filter introduces a double pole, –40dB/

decade gain slope above its corner resonant frequency ,

and a total phase lag of 180 (see Figure 14). The Resonant frequency of the LC filter is expressed as follows:

FLC = ---(10)

Where: Lo is the output inductor

For 2-phase application, the effective output

inductance should be used

Co is the total output capacitor

Figure 14 shows gain and phase of the LC filter. Since

we already have 180 phase shift just from the output

filter, the system risks being unstable.

1

2π× LO×CO

The ESR zero of the output capacitor is expressed as

follows:

FESR = ---(10A)

V

1

2π×ESR×Co

OUT

9

R

Fb

Comp

R

5

Vp=V

E/A

REF

Gain(dB)

Ve

C

9

C

R

4

POLE

H(s) dB

Frequency

F

Z

Figure 15 - Compensation network without local

feedback and its asymptotic gain plot.

The transfer function (Ve / V

OUT) is given by:

0dB

Gain

-40dB/decade

LC

F

Frequency

-180

Phase

0

LC

F

Frequency

Figure14 - Gain and phase of LC filter

The IR3621’s error amplifier is a differential-input transconductance amplifier. The output is available for DC gain

control or AC phase compensation.

The E/A can be compensated with or without the use of

local feedback. When operated without local feedback,

the transconductance properties of the E/A become evident and can be used to cancel one of the output filter

poles. This will be accomplished with a series RC circuit

from Comp pin to ground as shown in Figure 15.

Note that this method requires the output capacitor to

have enough ESR to satisfy stability requirements. In

general, the output capacitor’s ESR generates a zero

typically at 5kHz to 50kHz which is essential for an acceptable phase margin.

H(s) = gm× × ---(11)

( )

R5

R9 + R5

1 + sR4C9

sC9

The (s) indicates that the transfer function varies as a

function of frequency . This configuration introduces a gain

and zero, expressed by:

|H(s=j×2π×FO)| = gm× ×R4 ---(12)

FZ = ---(13)

1

2π×R4×C9

R5

R9+R5

|H(s)| is the gain at zero cross frequency .

First select the desired zero-crossover frequency (FO1):

FO1 > FESR and FO1 ≤ (1/5 ~ 1/10)×fS

14

www.irf.com

Page 15

IR3621 & ( PbF)

1

gm

VIN

FO1×FESR

2

FLC

R5 + R9

R5

VOSC

R4 = × × × ---(14)

Where:

VIN = Maximum Input Voltage

VOSC = Oscillator Ramp Voltage

FO1 = Crossover Frequency

FESR = Zero Frequency of the Output Capacitor

FLC = Resonant Frequency of the Output Filter

R5 and R9 = Resistor Dividers for Output Voltage

Programming

g

m = Error Amplifier Transconductance

For V2.5V:

VIN = 12V

VOSC = 1.25V

FO1 = 40KHz

FESR = 13.3kHz

FLC = 5.06kHz

R5 = 1K

R9 = 2.14K

gm = 1400µmho

This results to R4=4.8K

Choose R4=5K

To cancel one of the LC filter poles, place the zero before the LC filter resonant frequency pole:

FZ ≅ 75%FLC

FZ ≅ 0.75×

1

---(15)

2π LO × CO

For:

Lo = 1.1µH

Co = 990µF

FZ = 3.61kHz

R4 = 5K

Using equations (13) and (15) to calculate C9, we get:

C9 ≅ 8.3nF; Choose C9 =8.2nF

Same calcuation For V1.8V will result to: R3 = 4.2K and

C8 = 10nF

One more capacitor is sometimes added in parallel with

C9 and R4. This introduces one more pole which is mainly

used to suppress the switching noise. The additional

pole is given by:

FP =

2π×R4×

1

C9×CPOLE

C9 + CPOLE

The pole sets to one half of switching frequency which

results in the capacitor CPOLE:

CPOLE = ≅

π×R4×fS -

for FP <<

1

1

C9

fS

2

1

π×R4×fS

For a general solution for unconditional stability for ceramic output capacitor with very low ESR or any type of

output capacitors, in a wide range of ESR values we

should implement local feedback with a compensation

network. The typically used compensation network for a

voltage-mode controller is shown in Figure 16.

V

Z

IN

Gain(dB)

OUT

C

10

R

8

R

6

Fb

R

5

VP2=V

REF

R

7

E/A

C

12

C

11

Z

f

Comp

Ve

H(s) dB

F

Z

1

F

P

F

Z

2

2

Frequency

F

P

3

Figure 16- Compensation network with local

feedback and its asymptotic gain plot.

In such configuration, the transfer function is given by:

Ve

VOUT

1 - gmZf

=

1 + gmZIN

The error amplifier gain is independent of the transconductance under the following condition:

gmZf >> 1 and gmZIN >>1 ---(16)

By replacing ZIN and Zf according to Figure 16, the transformer function can be expressed as:

H(s) =

1

sR6(C12+C11)

(1+sR7C11)×[1+sC10(R6+R8)]

×

1+sR7

[ ( )]

C12C11

×(1+sR8C10)

C12+C11

As known, transconductance amplifier has high impedance (current source) output, therefore, consider should

be taken when loading the E/A output. It may exceed its

source/sink output current capability , so that the amplifier will not be able to swing its output voltage over the

necessary range.

The compensation network has three poles and two zeros and they are expressed as follows:

www.irf.com

15

Page 16

IR3621 & ( PbF)

FP1 = 0

FP2 =

FP3 = ≅

FZ1 =

FZ2 = ≅

Cross Over Frequency:

O = R7×C10× ×

F

Where:

VIN = Maximum Input V oltage

VOSC = Oscillator Ramp Voltage

Lo = Output Inductor

Co = T otal Output Capacitors

The stability requirement will be satisfied by placing the

poles and zeros of the compensation network according

to following design rules. The consideration has been

taken to satisfy condition (16) regarding transconductance error amplifier.

These design rules will give a crossover frequency approximately one-tenth of the switching frequency. The

higher the band width, the potentially faster the load transient response. The DC gain will be large enough to provide high DC-regulation accuracy (typically -5dB to -12dB).

The phase margin should be greater than 45 for overall

stability.

Based on the frequency of the zero generated by ESR

versus crossover frequency , the compensation type can

be different. The table below shows the compensation

type and location of crossover frequency .

Compensator

Type

Type II (PI)

Type III (PID)

Method A

Type III (PID)

Method B

T able - The compensation type and location of zero

Details are dicussed in application Note AN-1043 which

can be downloaded from the IR Web-Site.

1

2π×R8×C10

1

2π×R7×

2π×R

2π×C

Crossover Frequency

FLC < FESR < FO < fS/2

FLC < FO < FESR < fS/2

FLC < FO < fS/2 < FZO

crossover frequency .

C12×C11

( )

C12+C11

1

7×C11

1

10×(R6 + R8)

VIN

VOSC12π×Lo×Co

Location of Zero

(FO)

1

2π×R7×C12

1

2π×C10×R6

---(17)

Typical

Output

Capacitor

Electrolytic,

Tantalum

Tantalum,

Ceramic

Ceramic

Compensation for Slave Error Amplfier for 2-Phase

Configuration

The slave error amplifier is a differential-input transconductance amplifier, in 2-phase configuration the main goal

for the slave feed back loop is to control the inductor

current to match the master's inductor current as well

provides highest bandwidth and adequate phase margin

for overall stability . The following analysis is valid for both

using external current sense resistor and using DCR of

inductors.

The transfer function of power stage is expressed by:

G(s) = = ---(18)

Where:

VIN = Input Voltage

L2 = Output Inductor

VOSC = Oscillator Peak Voltage

As shown the transfer function is a function of inductor

current.

The transfer function for the compensation network is

given by equation (19), when using a series RC circuit

as shown in Figure 17:

D(s) = =

The loop gain function is:

H(s)=[G(s) × D(s) × RS2]

H(s)=RS2×

IL2(s)

Ve(s)

Ve(s)

RS2 × IL2(s)

R

S2

R

S1

Figure 17 - The PI compensation network

gm×

VIN

sL2 × VOSC

RS1

gm×

( )

RS2

I

L2

L

2

Fb2

E/A2

Vp2

L

1

I

L1

for slave channel.

RS1

RS2

×

( )( )

1+sR2C2

sC2

1 + sC2R2

×

( )

sC2

Comp2

R

2

C

2

×

( )

sL2×VOSC

---(19)

Ve

VIN

16

www.irf.com

Page 17

IR3621 & ( PbF)

)

Select a zero crossover frequency for control loop (FO2)

1.25 times larger than zero crossover frequency for voltage loop (FO1):

Fo2 ≅ 1.25%xF01

H(Fo) = gm×RS1×R2× =1 ---(20)

2π×Fo×L2×VOSC

VIN

From (20), R2 can be express as:

R2 = ×

1

gm × RS1

2π × F

O2 × L2 × VOSC

VIN

---(21)

The power stage of current loop has a dominant pole (Fp)

at frequency expressed by:

Req

F

p =

2π×L2

Where Req is the total resistance of the power stage

which includes the Rds(on) of the FET switches, the DCR

of inductor and shunt resistance (if it used).

Req=RDS(on)+RL+Rs

Set the zero of compensator at 10 times the dominant

pole frequency Fp, the compensator capacitor, C2 can

be calculated as:

Fz = 10 x Fp

C2 =

1

2πxR2xFz

All design should be tested for stability to verify the calculated values.

Layout Consideration

The layout is very important when designing high frequency switching converters. Layout will affect noise

pickup and can cause a good design to perform with

less than expected results.

Start by placing the power components. Make all the

connections in the top layer with wide, copper filled areas. The inductor, output capacitor and the MOSFET

should be as close to each other as possible. This helps

to reduce the EMI radiated by the power traces due to

the high switching. Place input capacitor near to the

drain of the high-side MOSFET .

The layout of driver section should be designed for a low

resistance (a wide, short trace) and low inductance (a

wide trace with ground return path directly beneath it),

this directly affects the driver's performance.

T o reduce the ESR, replace the one input capacitor with

two parallel ones. The feedback part of the system should

be kept away from the inductor and other noise sources

and must be placed close to the IC. In multilayer PCBs,

use one layer as power ground plane and have a separate control circuit ground (analog ground), to which all

signals are referenced. The goal is to localize the high

current paths to a separate loops that does not interfere

with the more sensitive analog control function. These

two grounds must be connected together on the PC board

layout at a single point.

Switching Frequency v s. Case Temp

90

80

70

60

50

Case temp (oC

40

30

200 300 400 500 600 700

Freq (kHz)

100pF

1000pF

1800pF

3300pF

Figure18- Case Temperature (TSSOP package) versus Switching Frequency at

Room T emperature

Test Condition: Vin=VcL=VcH1=VcH2=12V, Capacitors used as loads for output

drivers.

www.irf.com

17

Page 18

IR3621 & ( PbF)

TYPICAL APPLICATION

D1

C12

12V

C1

PGood

C10

C3

C8

C9

R2

C15

C5

C4

R3

R4

VcH2

V

CL

VcH2 VcH1

Vcc

Hiccup

V

P2

V

REF

Rt

U1

IR3621

Comp1

Comp2

PGood

SS1 / SD

SS2 / SD

V

OUT3

HDrv1

OCSet1

LDrv1

PGnd1

Sync

V

SEN1

V

SEN2

Fb1

Fb2

HDrv2

OCSet2

LDrv2

PGnd2

Gnd

V

V

SEN2

SEN1

R1

R6

C13

VcH2

Q2

Q3

Q4

Q5

D2

C17

V

C14

SEN2

C20

V

SEN1

L4

R22

R23

C11

L3

R20

R21

1.8V @ 10 A

C16

R7

R8

R5

R9

2.5V @ 10 A

C18

18

Figure 19 - Typical application of IR3621.

12V input and two independent outputs using type 2 compensation.

www.irf.com

Page 19

TYPICAL APPLICATION

IR3621 & ( PbF)

D1

C12

12V

PGood

C11

V

SEN1

SEN2

Fb1

Fb2

C13

R1

P2

V

SEN1

R6

Q2

Q3

Q4

Q5

C14

C17

R5

R9

L3

C15

C18

L4

R7

R8

C10

C3

C9

C8

R2

C5

C4

R3

R4

V

CL

VcH1 VcH2

Vcc

Hiccup

Sync

REF

V

U1

Rt

IR3621

Comp1

Comp2

PGood

SS1 / SD

SS2 / SD

V

OUT3

HDrv1

OCSet1

LDrv1

PGnd1

V

V

HDrv2

OCSet2

LDrv2

PGnd2

Gnd

Figure 20 - 2-phase operation with inductor current sensing using type 2 compensation.

12V to 1.8V @ 30A output

1.8V @ 30A

C16

R7

R8

www.irf.com

19

Page 20

IR3621 & ( PbF)

TYPICAL OPERATING CHARACTERISTICS

Vfb1 vs. Temperature

0.8060

0.8040

0.8020

0.8000

Vfb1 [V]

0.7980

0.7960

0.7940

-50 0 50 100 150

Temperature [C]

VOUT3 vs. Temperature

6.24

6.22

6.2

6.18

6.16

VOUT3 (V)

6.14

6.12

6.1

-50 -25 0 25 50 75 100 125

Temperature (C)

Vfb2 vs. Temperature

0.8060

0.8040

0.8020

0.8000

Vfb2 [V]

0.7980

0.7960

0.7940

-50 0 50 100 150

Temperature [C]

Frequency vs. Temperature

(Rt=30.9kohm)

350

300

250

200

150

100

Frequency (kHz)

50

0

-50 -25 0 25 50 75 100 125

Temperature (C)

20

SS Charge Current vs. Temperature

31

29

27

25

23

21

19

17

SS Charge Current (uA)

15

-50 -25 0 25 50 75 100 125

Temperature (C)

SS1

SS2

www.irf.com

Transconductance vs. Temperature

2500

2000

1500

1000

Transconductance 1

Transconductance 2

Transconductance (umho)

500

-50 -25 0 25 50 75 100 125

Temperature (C)

Page 21

TYPICAL OPERATING CHARACTERISTICS

e

IR3621 & ( PbF)

Static Supply Current v s. Temperature

30

25

20

15

10

5

Static Supply Current (uA)

0

-50 -25 0 25 50 75 100 125

25

24

23

22

21

20

19

IOCSet (uA)

18

17

16

15

-50 -25 0 25 50 75 100 125

ICC ICH 1+ICH2 ICL

Temperature (C)

IOCSet vs. Temperature

IOCSet1

IOCSet2

Temperature (C)

Dy namic Supply Cur rent vs. Temperature

30

25

20

15

10

5

Dynamic Supply Current (uA)

0

-50 -25 0 25 50 75 100 125

(300kHz , 1500pF)

ICC ICH1+ICH2 ICL

Temperature (C)

Deadband Time vs. Temperatur e

100

90

80

70

60

50

40

30

Deadband time (ns)

20

10

H_to_L_1 H_to_L_2

L_to_H_1 L_to_H_2

0

-50 -25 0 25 50 75 100 125

Temperature (C)

HI Drive Rise/Fall Time vs. Temperature

35

30

25

20

15

Rise/Fall time (ns)

10

5

-50 -25 0 25 50 75 100 125

HI Dr1 Rise HI Dr2 Ris

HI Dr1 Fall HI Dr2 Fall

Temperat ure (C)

Rise/Fal l time (ns)

www.irf.com

35

30

25

20

15

10

LO Drive Rise/Fall Time vs. Temperature

LO Dr1 Rise LO Dr2 Rise

LO Dr1 Fall LO Dr2 Fall

5

-50-250255075100125

Temperature (C)

21

Page 22

IR3621 & ( PbF)

TYPICAL OPERATING WAVEFORMS

T est Conditions:

VIN=12V , VOUT1=2.5V, IOUT1=0-10A, VOUT2=1.8V , IOUT2=0-10A, Fs=400kHz, TA=Room Temp, No Air Flow

Unless otherwise specified.

Figure 21 - Start up waveforms for 2.5V output

Ch1: Vin, Ch2: V out3, Ch3: SS1, Ch4:V o1 (2.5V)

Figure 23 - Start up waveforms

Ch1: Vin, Ch2: V out3, Ch3: V ref

Figure 22 - Start up waveforms for 1.8V output

Ch1: Vin, Ch2: V out3, Ch3: SS2, Ch4:Vo2 (1.8V)

Figure 24 - Vo1, V o2 and PGood

Ch1: Vin, Ch2: V o1, Ch3: V o2, Ch4: PGood

22

www.irf.com

Page 23

IR3621 & ( PbF)

TYPICAL OPERATING WAVEFORMS

T est Conditions:

VIN=12V, VOUT1=2.5V , I OUT1=0-10A, VOUT2=1.8V, IOUT2=0-10A, Fs=400kHz, Ta=Room Temp, No Air Flow

Unless otherwise specified.

Figure 25 - 2.5V output

Ch1: Vin, Ch2: SS1, Ch3: V o1, Ch4: PGood

Figure 27 - Gate waveforms with 180

out of phase

Ch1: Hdrv1, Ch2: Hdrv2

o

Figure 26 - 1.8V output

Ch1: Vin, Ch2: SS2, Ch3: V o2, Ch4: PGood

Figure 28 - 2.5V Waveforms

Ch1: Hdrv1, Ch2: Ldrv1, Ch3: Lx1, Ch4: Inductor Current

www.irf.com

23

Page 24

IR3621 & ( PbF)

TYPICAL OPERATING WAVEFORMS

T est Conditions:

VIN=12V, VOUT1=2.5V , I OUT1=0-10A, VOUT2=1.8V, IOUT2=0-10A, Fs=400kHz, Ta=Room Temp, No Air Flow

Unless otherwise specified.

Figure 29 - 2.5V Waveforms

Ch1: Hdrv2, Ch2: Ldrv2, Ch3: Lx2, Ch4: Inductor Current

Figure 31 - 2.5V output shorted

Ch1: Vo2, Ch2: SS1, Ch3: Inductor Current

Figure 30 - 1.8V output shorted

Ch1: Vo1, Ch2: SS2, Ch3: Inductor Current

Figure 32 - Prebias Start up

Ch1: SS1, Ch2: Vo1, Ch3: SS2, Ch4:V o2

24

www.irf.com

Page 25

IR3621 & ( PbF)

TYPICAL OPERATING WAVEFORMS

T est Conditions:

VIN=12V, VOUT1=2.5V , I OUT1=0-10A, VOUT2=1.8V, IOUT2=0-10A, Fs=400kHz, Ta=Room Temp, No Air Flow

Unless otherwise specified.

Figure 33 - SS1 pin shorted to Gnd

Ch1: SS1, Ch2: Hdrv1, Ch3: Ldrv1, Ch4:Vo2

Figure 34 - SS2 pin shorted to Gnd

Ch1: SS2, Ch2: Hdrv2, Ch3: Ldrv2, Ch4:Vo1

Figure 35 - External Synchronization

Ch1: External Clock, Ch2: Hdrv1, Ch3: Hdrv2

www.irf.com

25

Page 26

IR3621 & ( PbF)

TYPICAL OPERATING WAVEFORMS

T est Conditions:

VIN=12V, VOUT1=2.5V , I OUT1=0-10A, VOUT2=1.8V, IOUT2=0-10A, Fs=400kHz, Ta=Room Temp, No Air Flow

Unless otherwise specified.

Figure 36 - Load Transient Respons for V o1

(Io=0 to 10A)

Ch1: Vo1, Ch4:Io1

Figure 38 - Load Transient Respons for V o2

(Io=0 to 10A)

Ch1: Vo2, Ch4: Io2

Figure 37 - Load Transient Respons for V o1

(Io=10 to 0A)

Ch1: Vo1, Ch4: Io1

Figure 39 - Load Transient Respons for V o2

(Io=10 to 0A)

Ch1: Vo2, Ch4: Io2

26

www.irf.com

Page 27

IR3621 & ( PbF)

TYPICAL PERFORMANCE CURVES

T est Conditions:

VIN=12V, VOUT1=2.5V , I OUT1=0-10A, VOUT2=1.8V, IOUT2=0-10A, Fs=400kHz, Ta=Room Temp, No Air Flow

Unless otherwise specified.

12V to 2.5V and 1.8V

90

85

80

75

70

65

Efficiency (% )

60

55

50

45

0 2 4 6 8 10 12 14 16

Io(A)

Figure 40 - Efficiency for 2.5V and 1.8V outputs at room temperature and no air flow .

Efficiency was measured when the other output was operating at no load.

2.5V

1.8V

www.irf.com

27

Page 28

IR3621 & ( PbF)

(IR3621M & IR3621MPbF) MLPQ 5x5 Package

PIN 1 MARK AREA

(See Note1)

TOP VIEW

SIDE VIEW

D

32-Pin

D/2 D2

E/2

E

R

e

BOTTOM VIEW

Note 1: Details of pin #1 are optional, but

A

A3

A1

must be located within the zone indicated.

The identifier may be molded, or marked

features.

B

EXPOSED PAD

PIN NUMBER 1

E2

L

SYMBOL

DESIG

A

A1

A3

B

D

D2

E

E2

e

L

R

32-PIN 5x5

MIN

0.80

0.00

0.18

3.30

3.30

0.30

0.09

NOM

0.90

0.02

0.20 REF

0.23

5.00 BSC

3.45

5.00 BSC

3.45

0.50 BSC

0.40

---

NOTE: ALL MEASUREMENTS

ARE IN MILLIMETERS.

MAX

1.00

0.05

0.30

3.55

3.55

0.50

---

28

www.irf.com

Page 29

1.0 DIA

(IR3621F) TSSOP Package

A

28-Pin

B

C

IR3621 & ( PbF)

L

Q

R1

R

E

PIN NUMBER 1

F

SYMBOL

DESIG

A

B

C

D

E

F

G

H

J

K

L

M

N

O

P

Q

R

R1

MIN

4.30

0.19

9.60

---

0.85

0.05

0

0.50

0.09

0.09

G

28-PIN

NOM

0.65 BSC

4.40

6.40 BSC

---

1.00

1.00

9.70

---

0.90

--12 REF

12 REF

---

1.00 REF

0.60

0.20

---

---

MAX

4.50

0.30

9.80

1.10

0.95

0.15

8

0.75

---

---

D

J

H

K

TAPE & REEL ORIENTATION

Figure A : Feed Direction

M

1 11

P

O

DETAIL A

N

DETAIL A

NOTE: ALL MEASUREMENTS ARE IN MILLIMETERS.

IR WORLD HEADQUARTERS: 233 Kansas St., El Segundo, California 90245, USA T el: (310) 252-7105

This product has been designed and qualified for the Industrial market.

TAC Fax: (310) 252-7903

Visit us at www.irf.com for sales contact information

Data and specifications subject to change without notice. 11/29/2007

www.irf.com

29

Loading...

Loading...